Centrifugal swing type strengthened grinding machining device

A grinding and swinging technology, which is applied in the field of mechanical processing, can solve the problems of low mechanical and physical properties of the strengthening layer, low efficiency of strengthening processing, and low consistency of strengthening processing, so as to improve processing quality, improve grinding effect, and improve The effect of contact uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

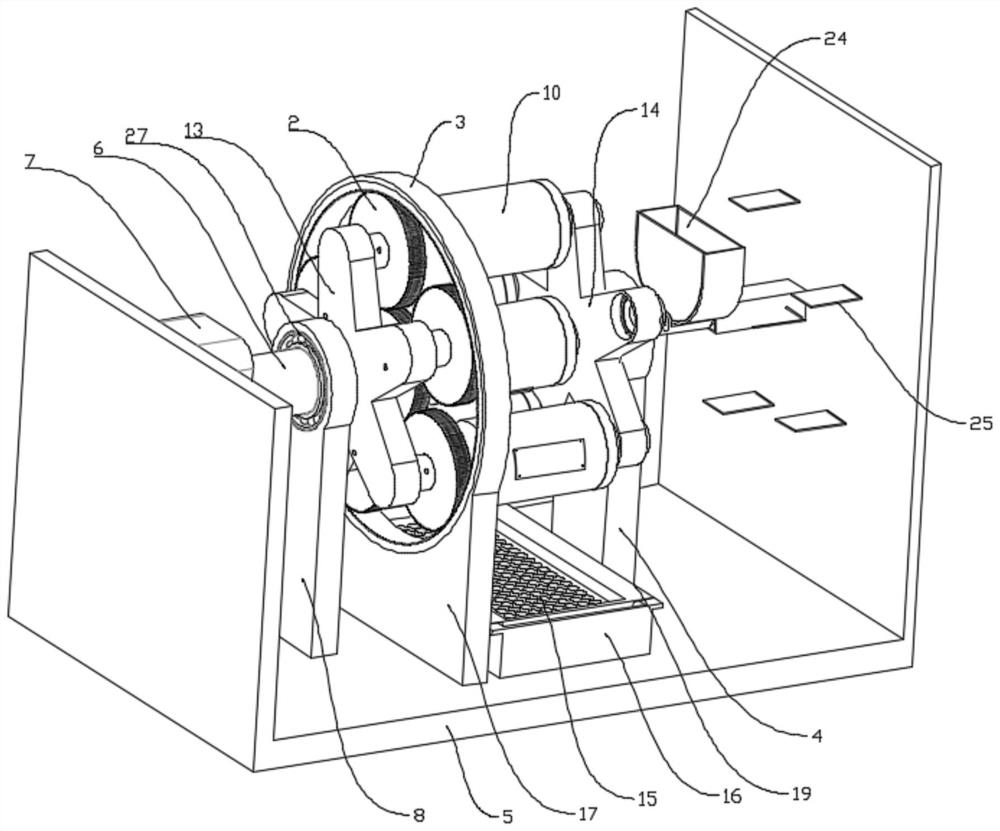

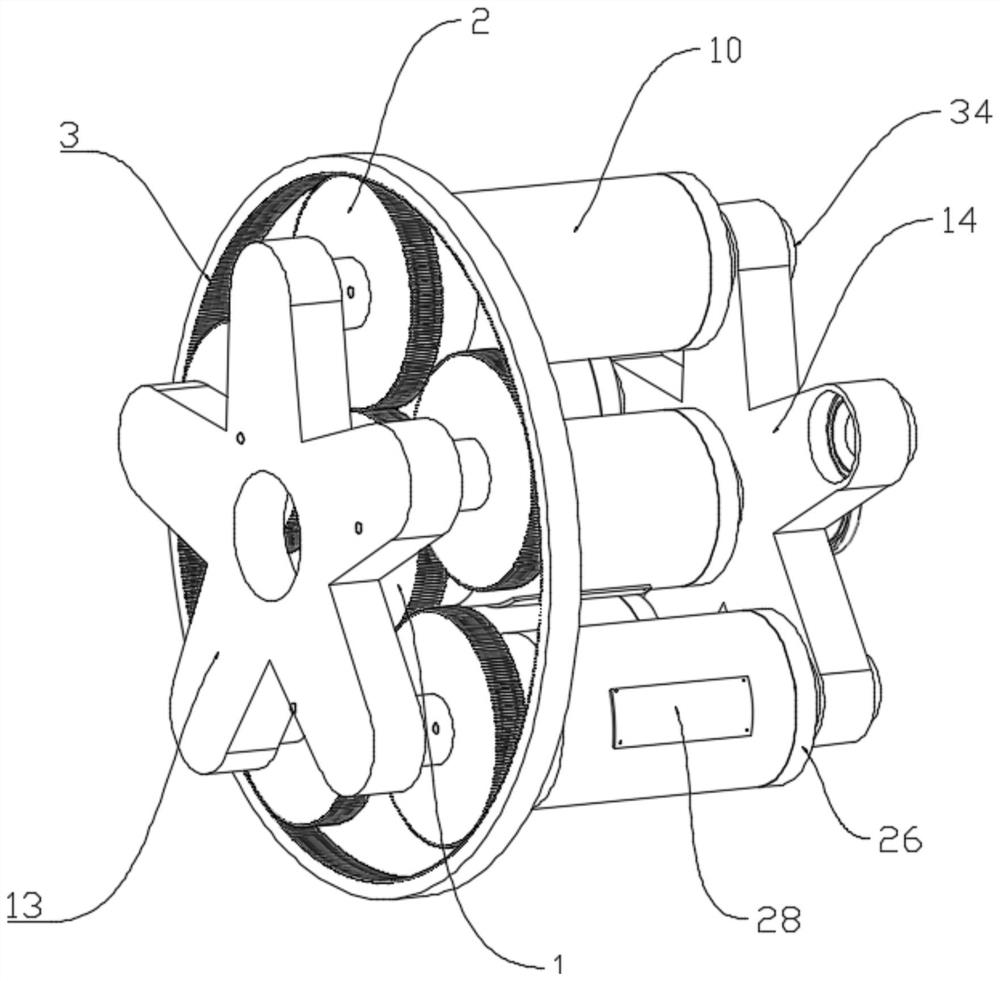

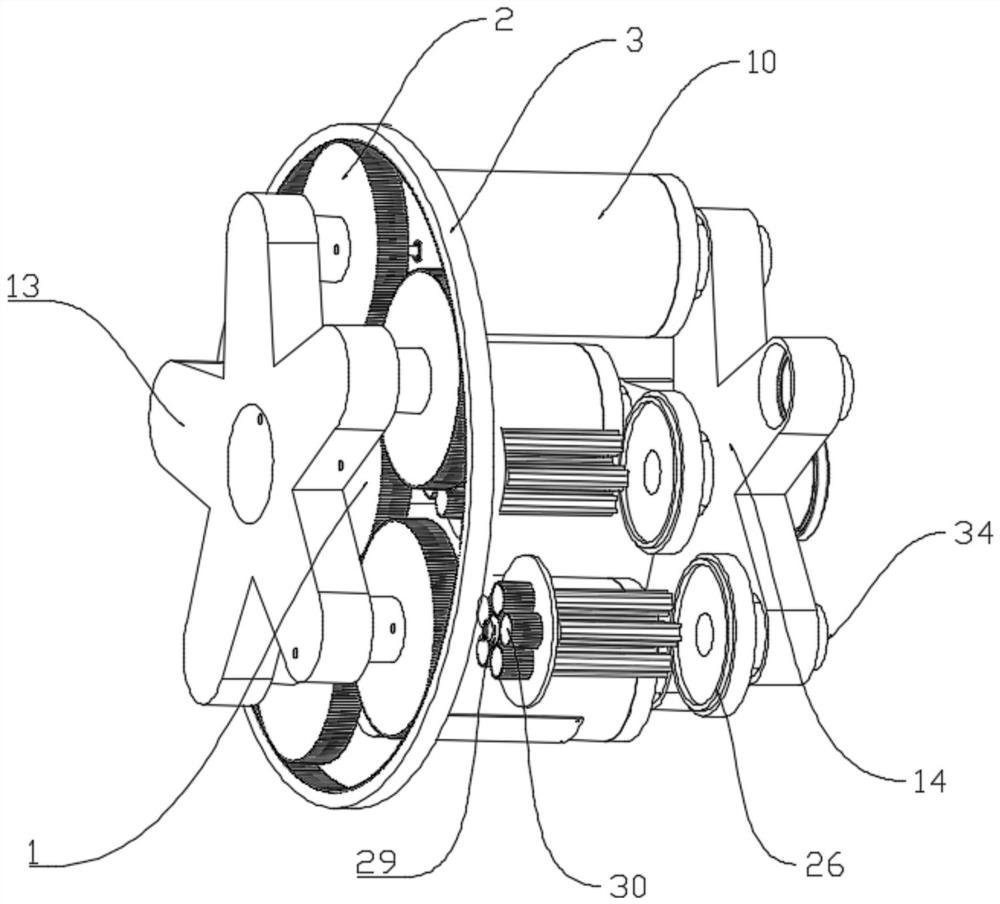

[0033] like Figure 1-Figure 7 as shown,

[0034] A centrifugal oscillating enhanced grinding device, comprising a planetary gear train mechanism, the planetary gear train mechanism includes a sun gear 1, a plurality of planetary gears 2 meshed with the outer periphery of the sun gear 1; in this embodiment, the outer periphery of the sun gear 1 meshes with There are five planetary gears 2 connected. It should be understood that the number of planetary gears 2 is not limited to five, and an appropriate number of planetary gears can also be selected according to actual conditions.

[0035] A gear sleeve 3 is provided on the outer side of a plurality of planetary gears 2, the gear sleeve 3 is in a circular structure, the gear sleeve 3 is fixed on the base 5 through the connecting plate 17, and the inner side of the gear sleeve 3 is provided with a ring of teeth, so that The outer teeth of the planetary gear 2 mesh with the sun gear on the one hand, and mesh with the teeth of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com