Cut stem drying method by using roller-air flow

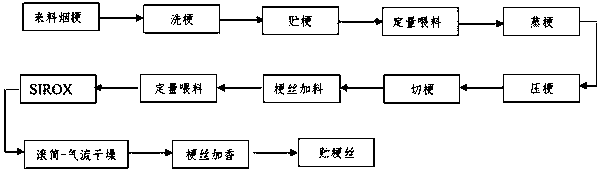

A drying method and drum technology, which is applied in the field of cigarette processing, can solve problems such as large dry ends, uneven moisture in cut stems, and large fluctuations in moisture at the outlet of cut stems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

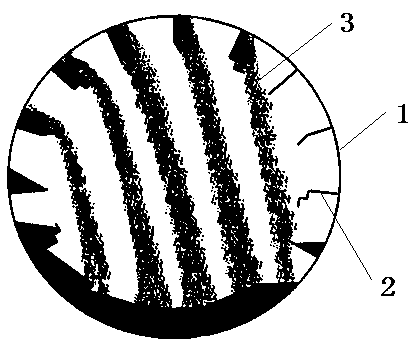

Image

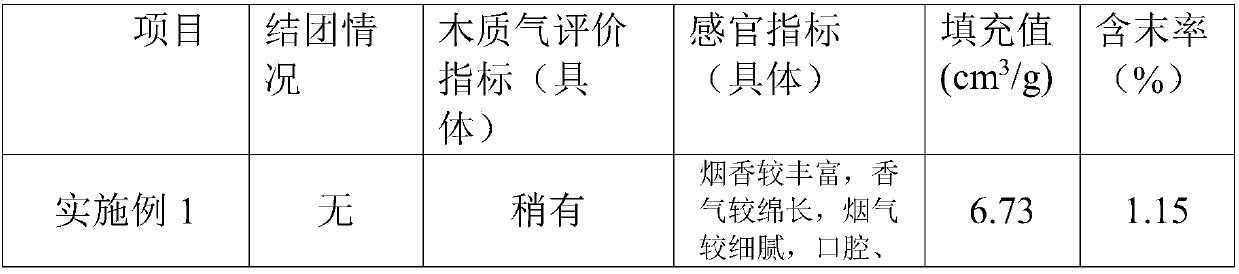

Examples

Embodiment 1

[0025] (1) Screening and stem washing: sieve the tobacco stems, remove the broken stems and wash the stems with 60°C stem washing water;

[0026] (2) Stem storage: send the washed tobacco stems into a storage cabinet for 22-66 hours;

[0027] (3) Stem steaming: After the stems are stored, the tobacco stems enter the steaming equipment through the feed air lock, and the discharge temperature is ≥75°C;

[0028] (4) Stem pressing: After steaming the stems, the tobacco stems are immediately sent to the pressing machine for pressing the stems, and the thickness of the stems is 0.65-0.75mm;

[0029] (5) stem cutting: the tobacco stem of step (4) is cut into shredded stems with a thickness of 0.09-0.15mm;

[0030] (6) cut stems feeding: quantitatively add the cut stems of step (5) into the cut stems feeder, so that the moisture content of the cut stems is controlled at 35.%-36.0%;

[0031] (7) Cut stem expansion: the cut stem is expanded in the SIROX expansion unit, and the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com