Gas-liquid whole-heat exchange device with built-in cold and heat source based on metal fiberfill

A technology of metal fiber and total heat exchange, which is applied in household heating, household heating, heating methods, etc., can solve the problem of insufficient heat transfer coefficient of gas-liquid effective contact area, constrained internal cooling (heat) type dehumidification (regeneration) device Development and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings. In the following description, more details are set forth in order to fully understand the present invention, but the present invention can obviously be implemented in a variety of other ways different from this description, Those skilled in the art can make similar promotions and deductions based on actual applications without violating the connotation of the present invention, so the content of this specific embodiment should not limit the protection scope of the present invention.

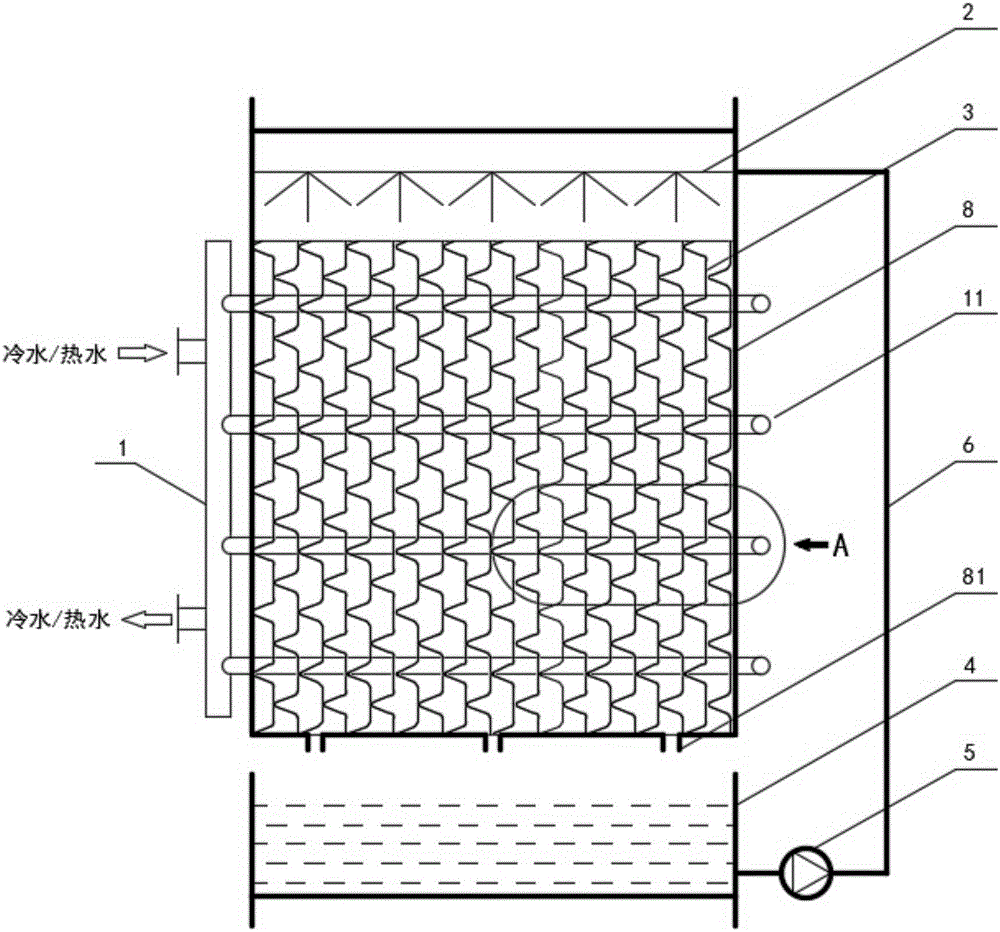

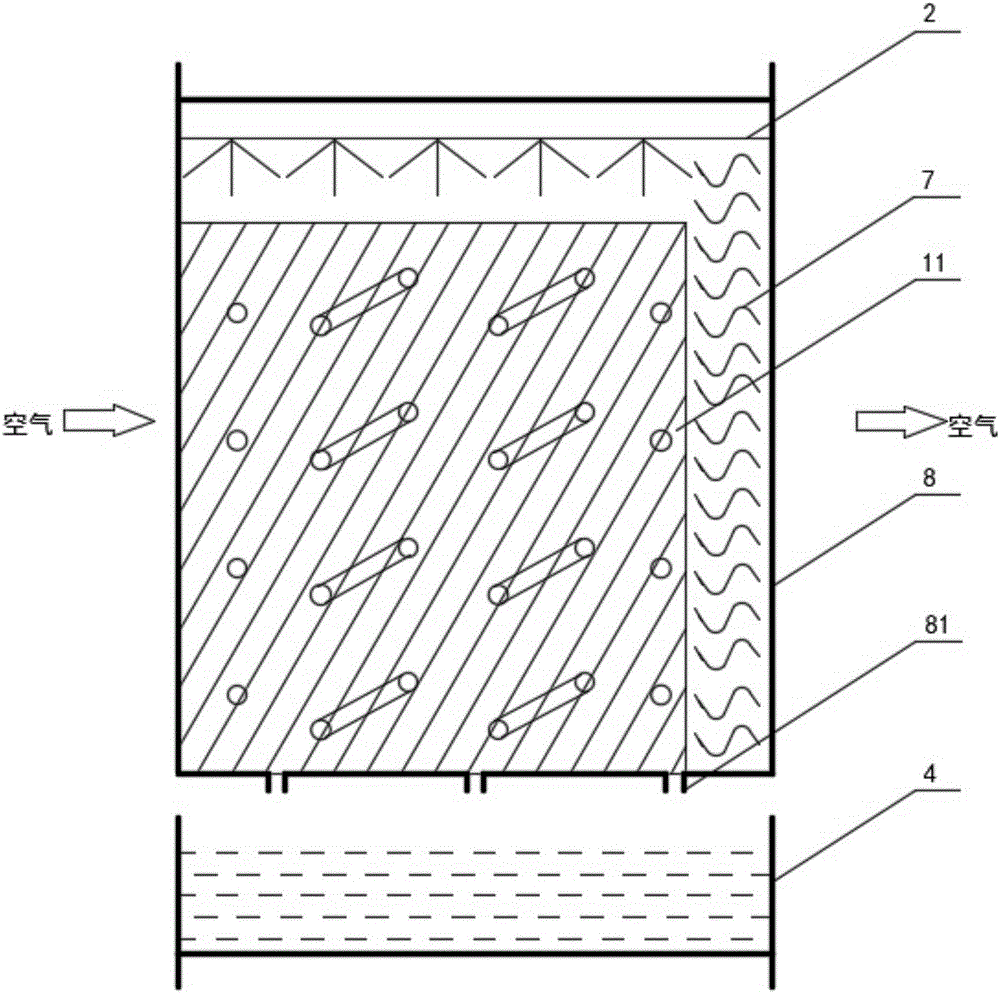

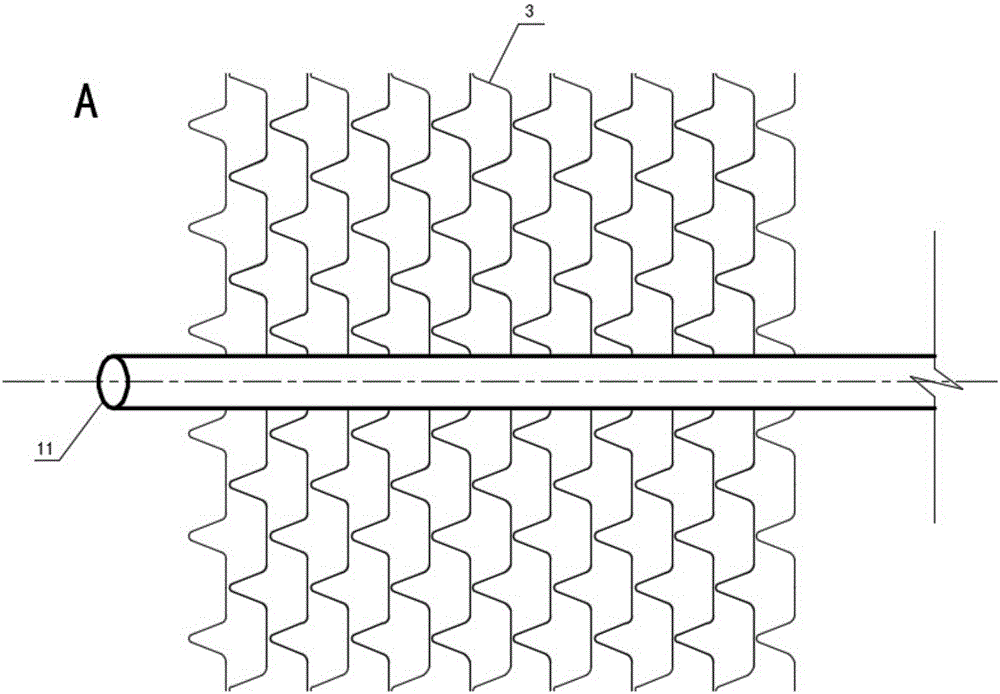

[0027] figure 1 and figure 2 It is a structural diagram of a gas-liquid total heat exchange device with a built-in cold and heat source based on metal fiber filler. The device mainly includes: heat exchange coil 1, sprayer 2, metal fiber filler 3, solution tank 4, solution pump 5, solution The circulation pipeline 6, the air outlet liquid shield 7 and the box bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com