Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "High heat and mass transfer coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superheated steam drying method for sludge and drying equipment

InactiveCN1686876AReduces the possibility of dry deflagrationReduce heat transfer areaSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

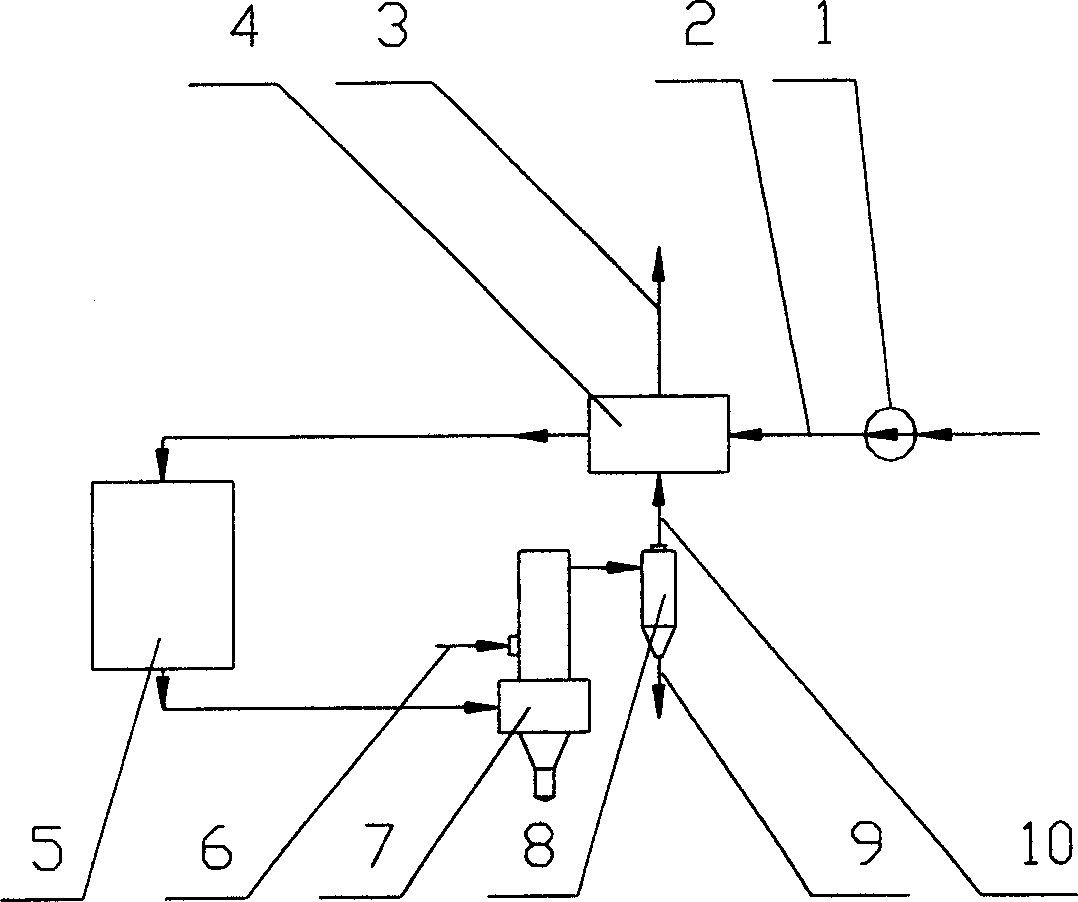

The present invention relates to a sludge drying method, said method utilizes the sensible heat and latent heat of dried tail gas recovered by heat exchanger, and makes it exchange with water and heats it to obtain superheated steam, then makes the superheated steam by fed into a closed direct drying machine to make heat exchange with wet sludge being in said drying machine to obtain the dried sludge. Then said method can make the dried sludge and dried tail gas implement gas-solid separation, so that the dried sludge can be collected. Said drying equipment includes pipe-shell type heat exchanger, heater, closed direct drying machine and gas-solid separator, etc.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD +1

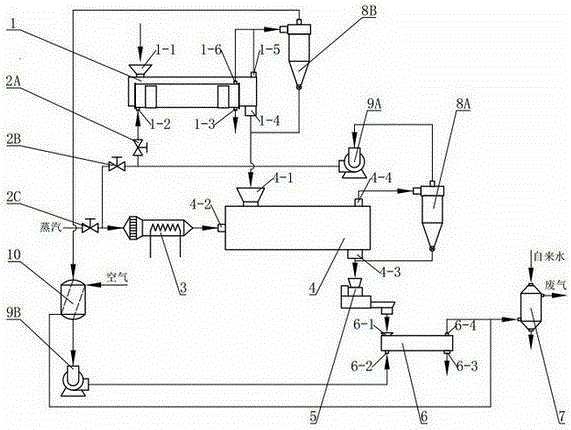

Tobacco material pneumatic drying process and equipment

ActiveCN101601500AShorten speedExtended drying timeTobacco preparationVolumetric Mass DensityEngineering

The invention provides a pneumatic drying method and equipment thereof for realizing large-flow tobacco material puffing drying treatment; the method comprises the following steps: puffed tobacco material is conveyed to a drying pipe for being dried by hot air flows, and then the tobacco material is separated from hot sir; the drying pipe is composed of a horizontal drying pipe and a vertical drying pipe of which the cross section is more than the cross section of the horizontal drying pipe; hot air with the temperature at 100-250 DEG C and air flow speed of10-50m / s of is sent in the horizontal drying pipe, wherein the air flow feeding direction is vertical to the material feeding direction; the material driven by hot air flows enters in the vertical drying pipe and is ascended in a suspension way, and the ascending speed of the material is reduced to 0.5-5m / s; meanwhile, sundries such as slivers with large density in the material can not be suspended and are separated pneumatically under the wind speed. By arranging the vertical drying pipe with large caliber, the speed of the material, moving upwards along the air flow direction, is reduced, on the premise of not increasing the drying route, the drying time of the material is prolonged, heat-transferring and mass transferring coefficient is improved, and the drying time of the material is improved.

Owner:ZHISI HLDG GRP

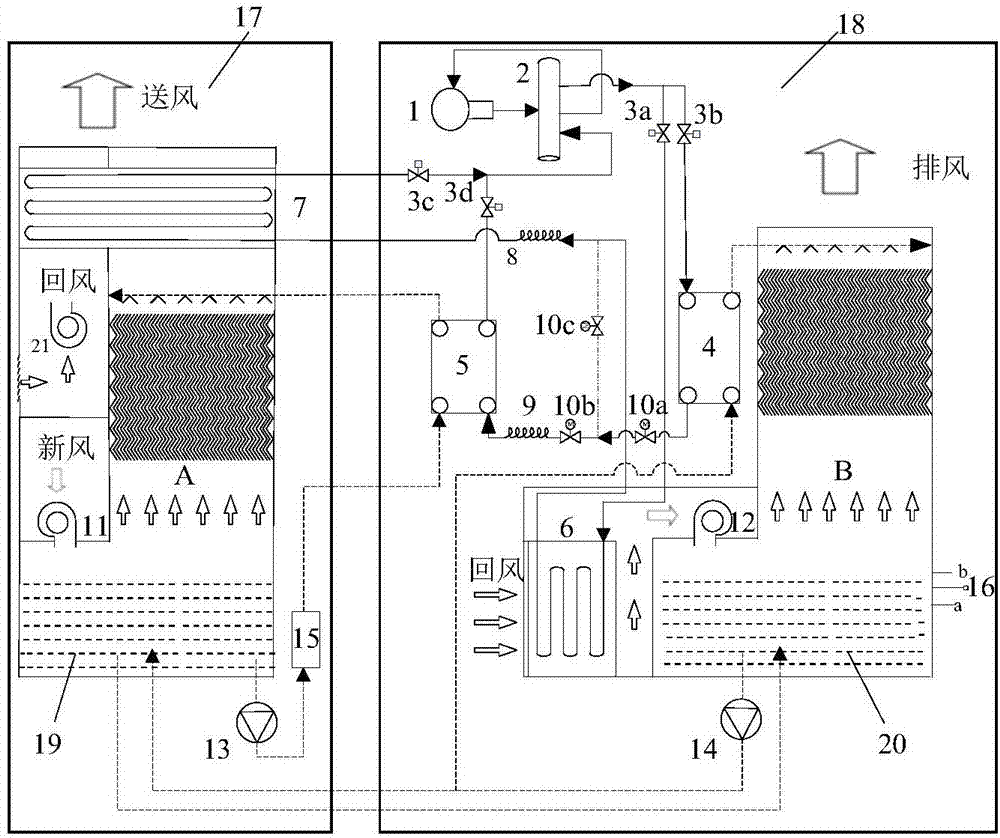

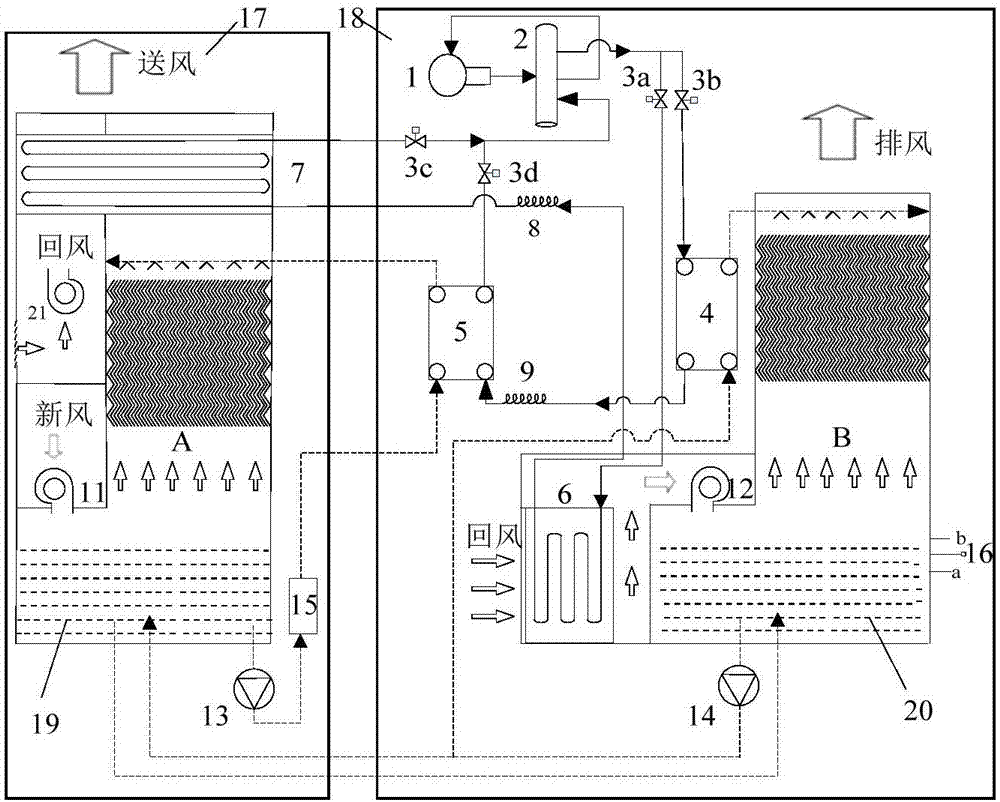

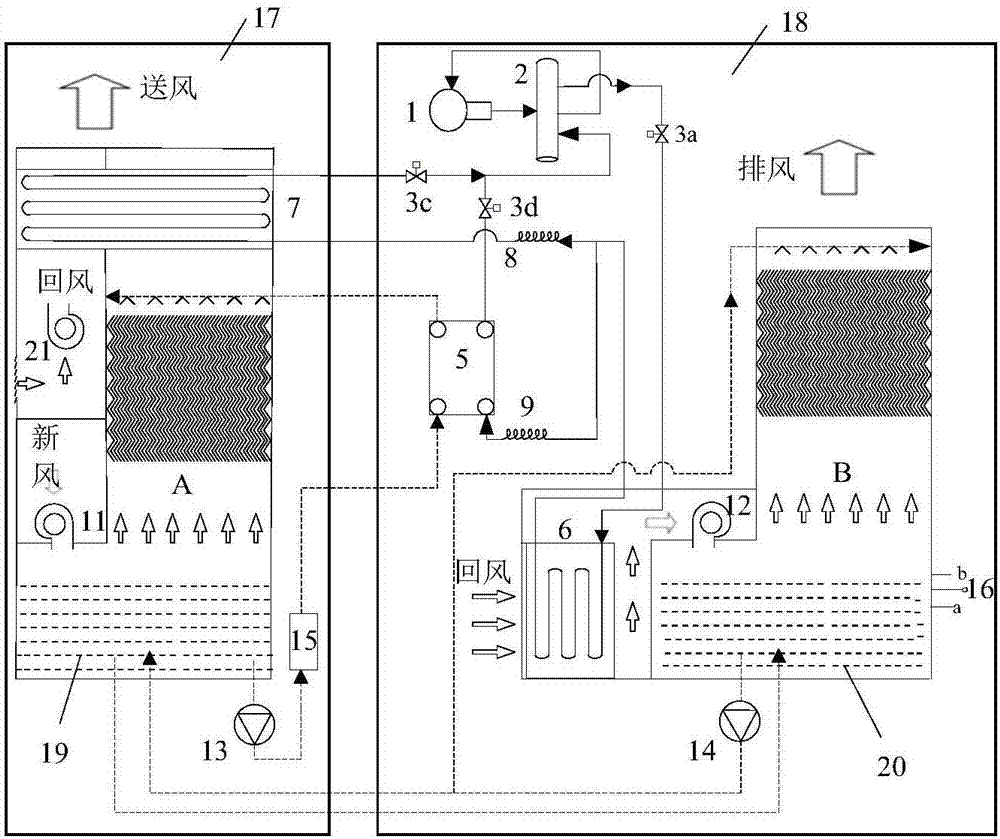

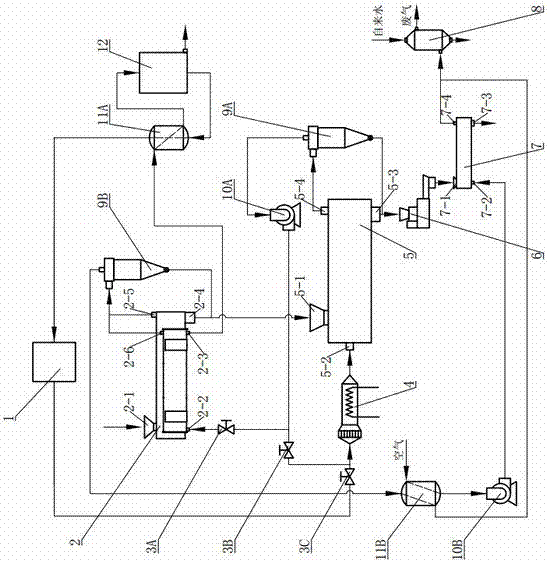

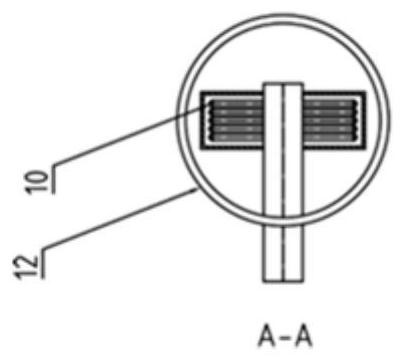

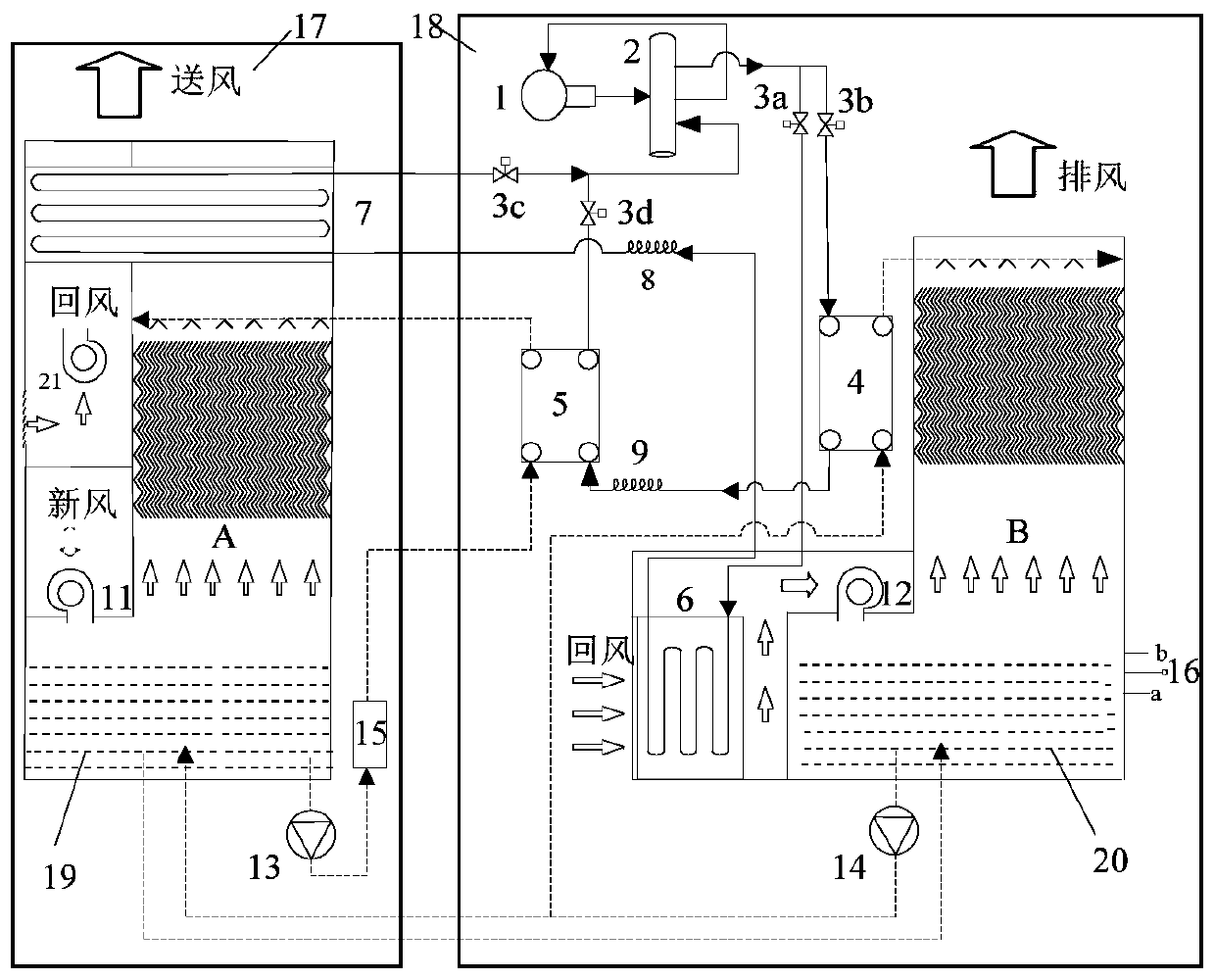

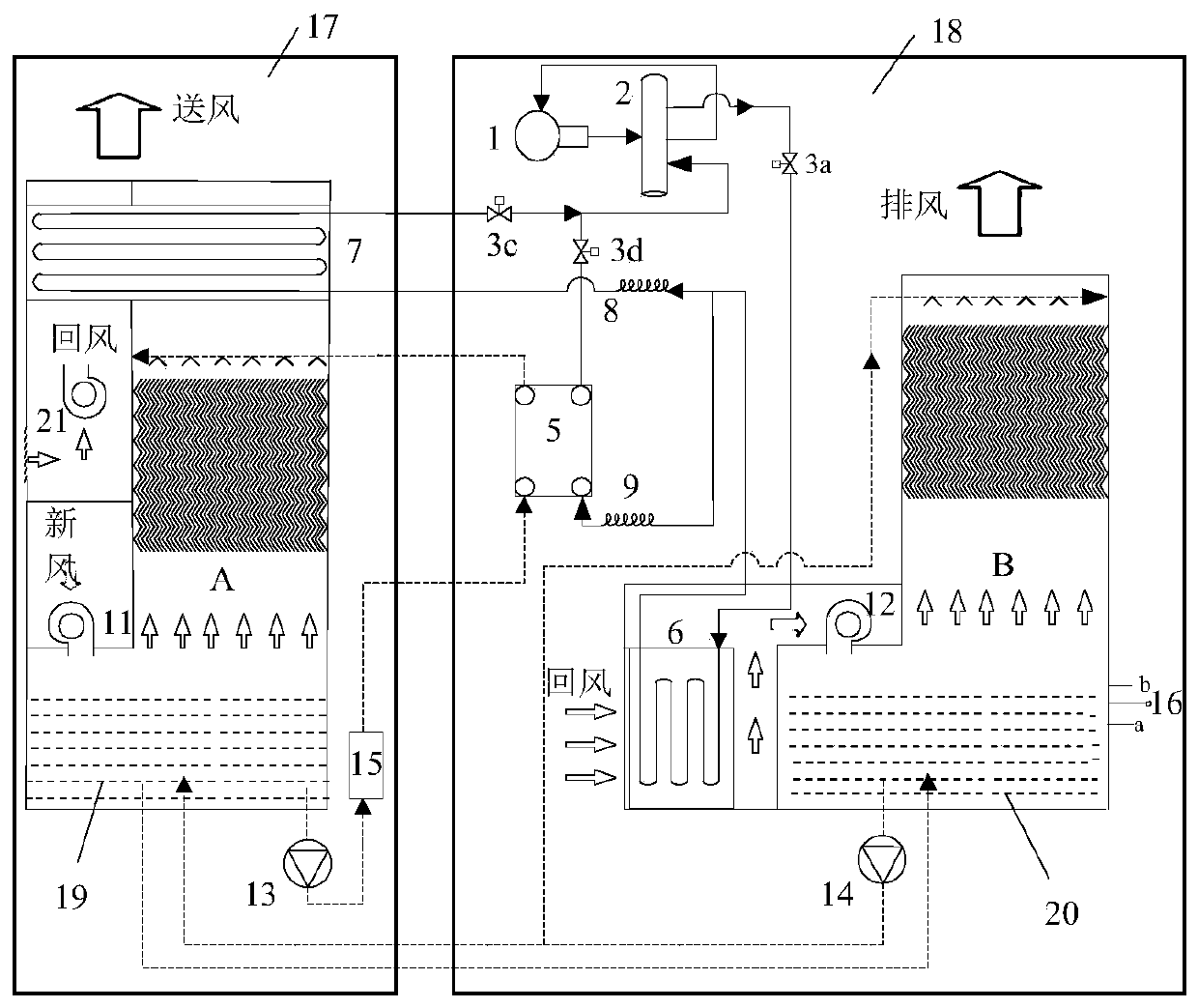

Household type air conditioner and operation method thereof

ActiveCN107255311APromotional useSmall sizeEnergy recovery in ventilation and heatingAir treatment detailsTemperature controlCoupling

The invention discloses a household type air conditioner and an operation method thereof, and belongs to the technical field of heating ventilation air conditioners. The household type air conditioner comprises a heat pump system, a solution humidifying system and a wind control system. The heat pump system comprises a compressor, heat exchangers, two-way expansion valves, a flow adjusting valve and an electric switch valve. The solution humidifying system comprises a solution pump, wet curtain packing and a liquid arrangement device, and meanwhile, the solution humidifying system comprises a solution filtering device and a return air energy recovery device. The wind control system mainly comprises a return air and new air blower, an air supply parameter inductor and a mechanical air exhausting system. The household type air conditioner with new air is designed by adopting a solution humidifying technology, through the air conditioner, temperature control and humidity control are conducted on the outdoor new air, temperature control is conducted on the indoor return air, then the outdoor new air and the indoor return air are sent to indoor, for the problem of lack of the new air of indoor air adjusting of a household type building in the prior art, the solution humidifying technology can be directly used for household air conditioner equipment, and the problem that water supplement is needed owing to too much heat brought by a heat pump coupling solution humidifying technology is solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

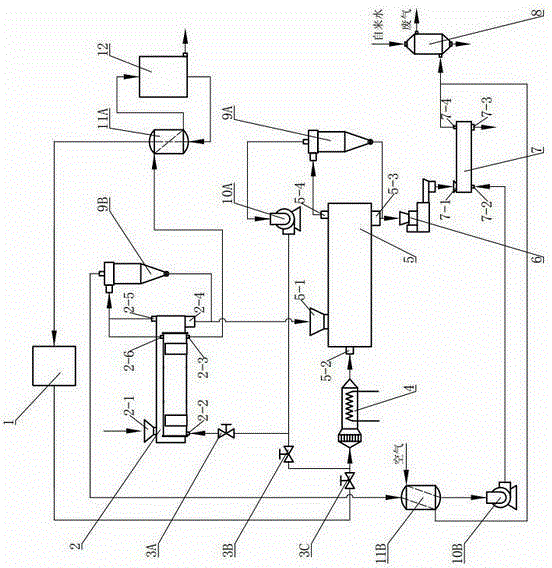

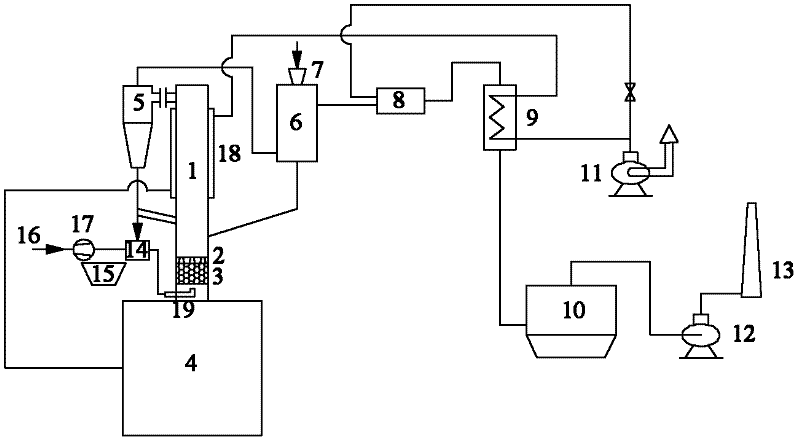

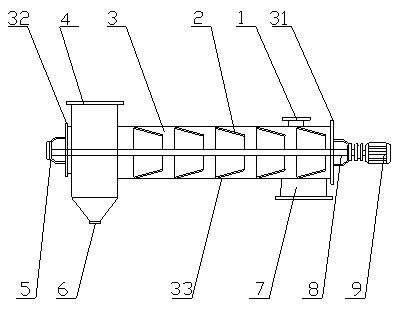

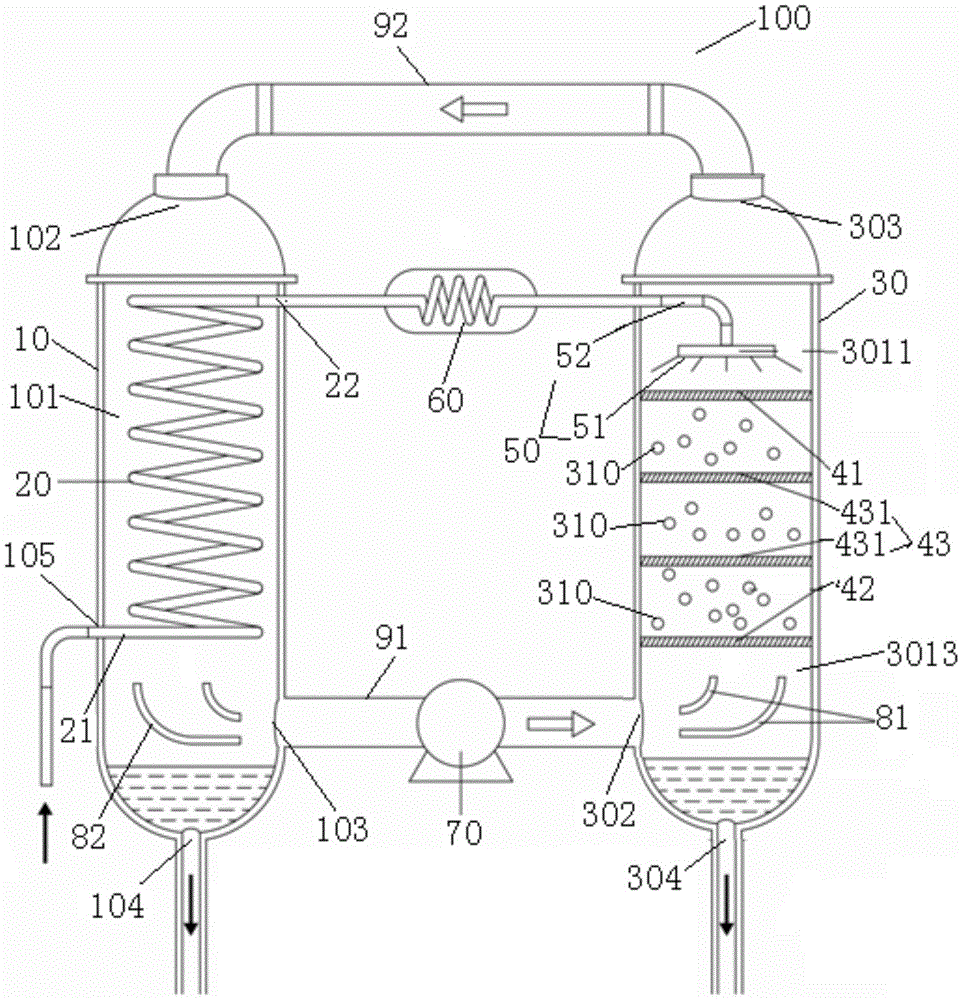

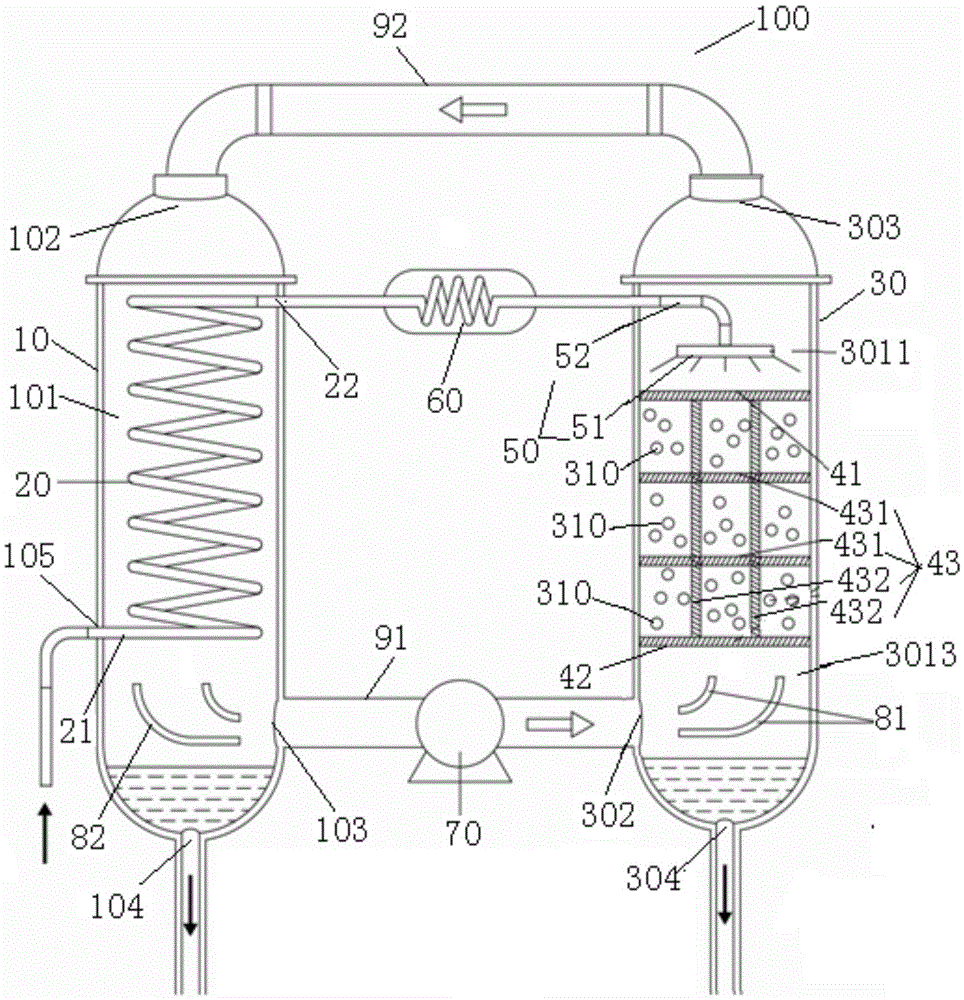

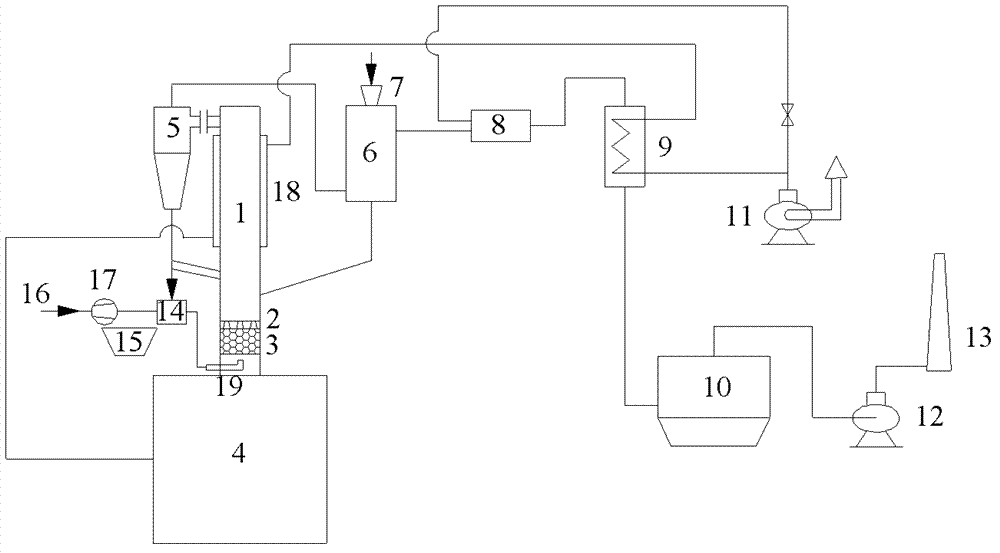

Triple utilization device and method for exhaust steam waste heat produced during superheat steam drying of sludge

ActiveCN105254147AHigh heat and mass transfer coefficientLarge specific heat capacitySludge treatment by de-watering/drying/thickeningSludgeCyclonic separation

Owner:NANCHANG HANGKONG UNIVERSITY

Rotary fluidized drying device and method

InactiveCN101798165AIsolation leakEnsure safetySludge treatment by de-watering/drying/thickeningSludgeEngineering

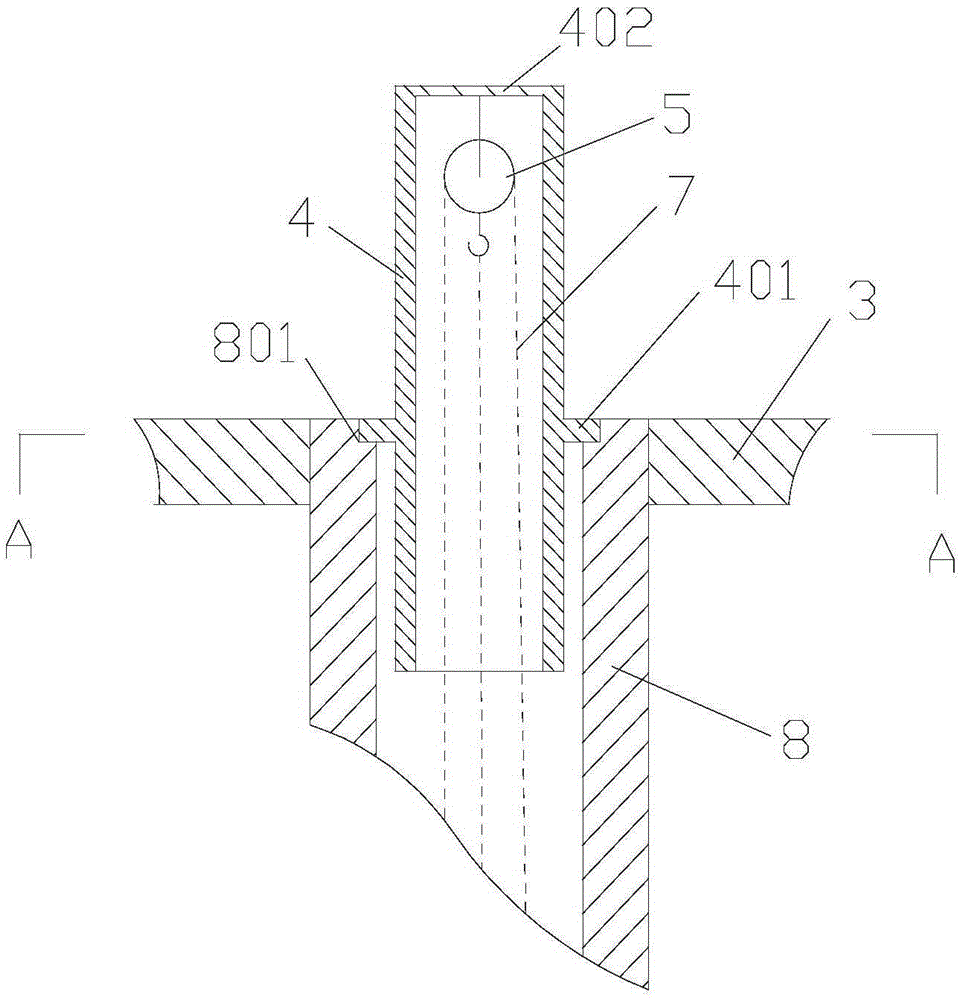

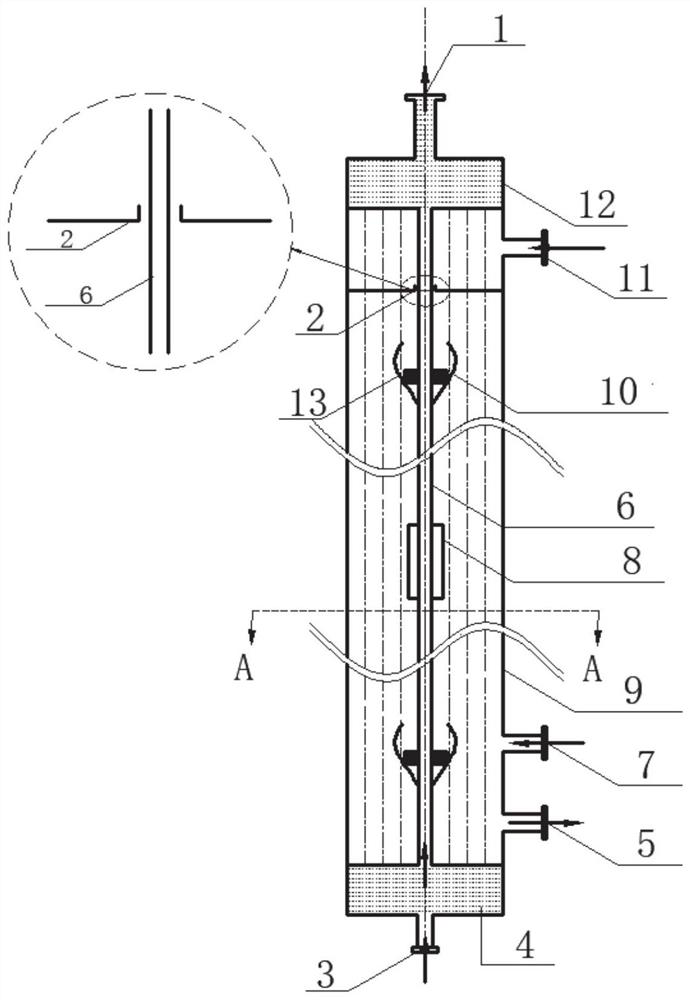

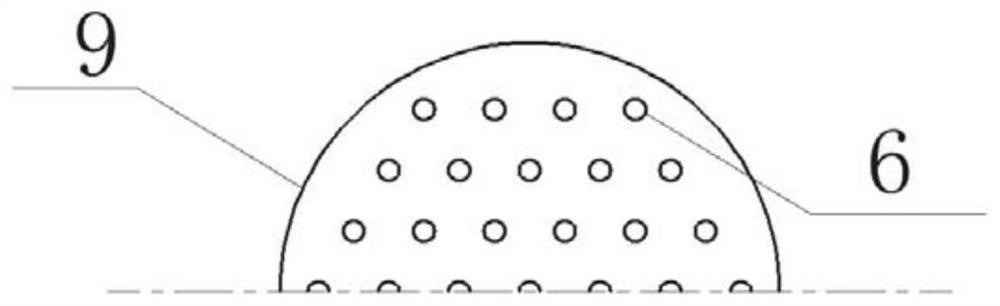

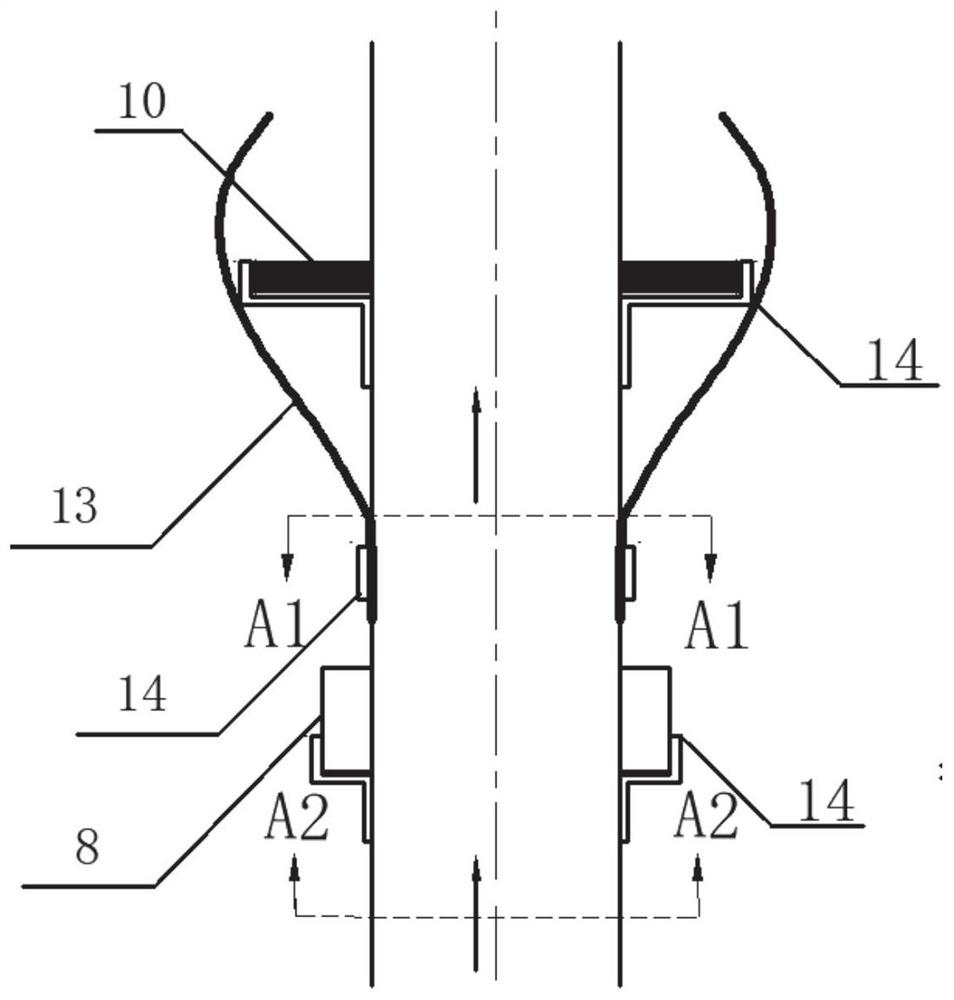

The invention discloses a rotary fluidized drying device and a rotary fluidized drying method and relates to a drying device and a drying method applied to sludge treatment. In the device, the two ends of a machine body (8) is provided with a front bearing pedestal (11) and a rear bearing pedestal (6) respectively; a rotating shaft (9) is positioned in the machine body (8); the two ends of the rotating shaft (9) are positioned in the front bearing pedestal (11) and the rear bearing pedestal (6); one end of the rotating shaft (9) is connected with a motor (12) through a speed changer; a crushing device (2), a propulsion device (3) and a scraper plate (4) are arranged on the rotating shaft (9) of the machine body (8) from the front bearing pedestal (11) to the rear bearing pedestal (6) sequentially; a wet sludge charge opening (1) is arranged on the upper side of the crushing device (2); a high-temperature smoke inlet (10) is arranged on the lower side of the crushing device (2); a low-temperature smoke outlet (5) is arranged on the upper side of the scraper plate (4) at one end of the rear bearing pedestal (6); and a dry sludge discharge opening (7) is arranged on the lower side of the scraper plate (4) at one end of the rear bearing pedestal (6). The device can realize the continuous operation of sludge drying and has the advantages of high production efficiency, low heat consumption and particularly low power consumption.

Owner:SOUTHEAST UNIV

Device and method for flue gas cyclone jet white removal coupling absorption heat pump waste heat recovery

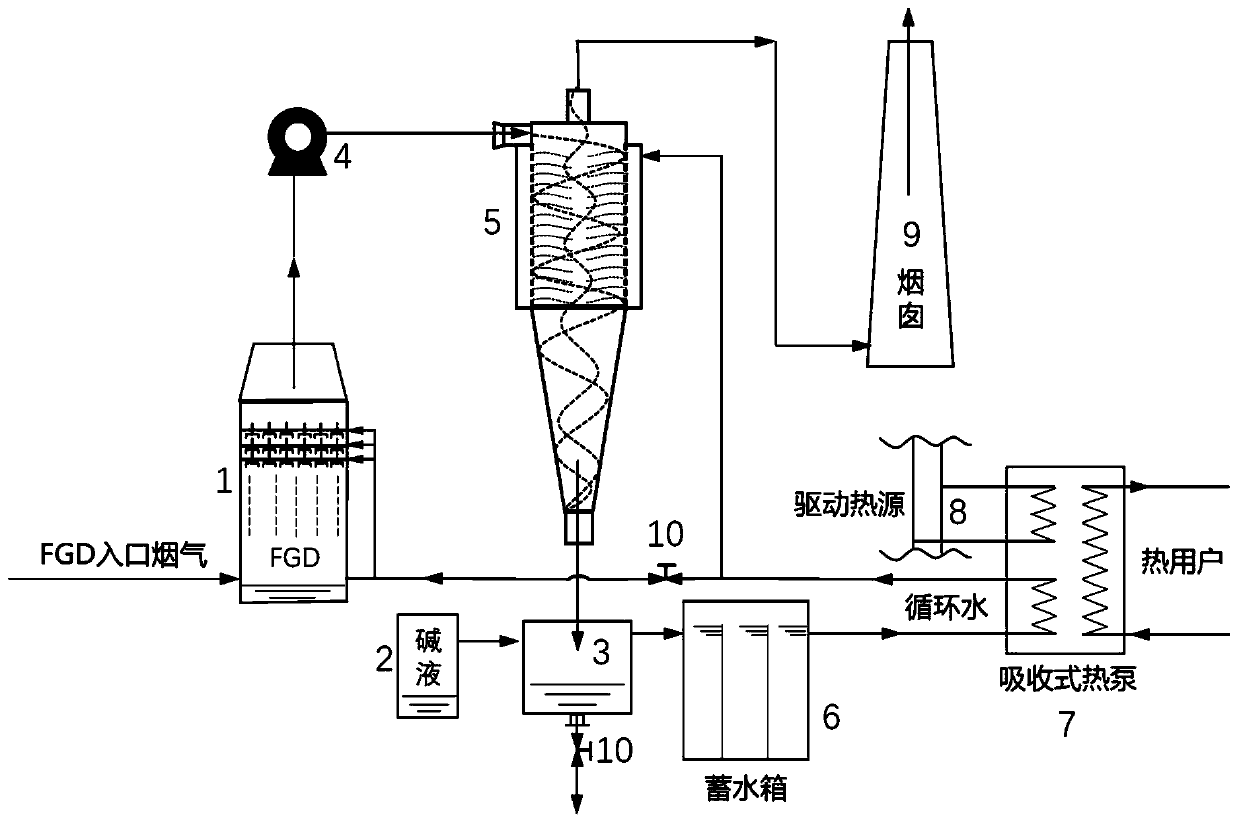

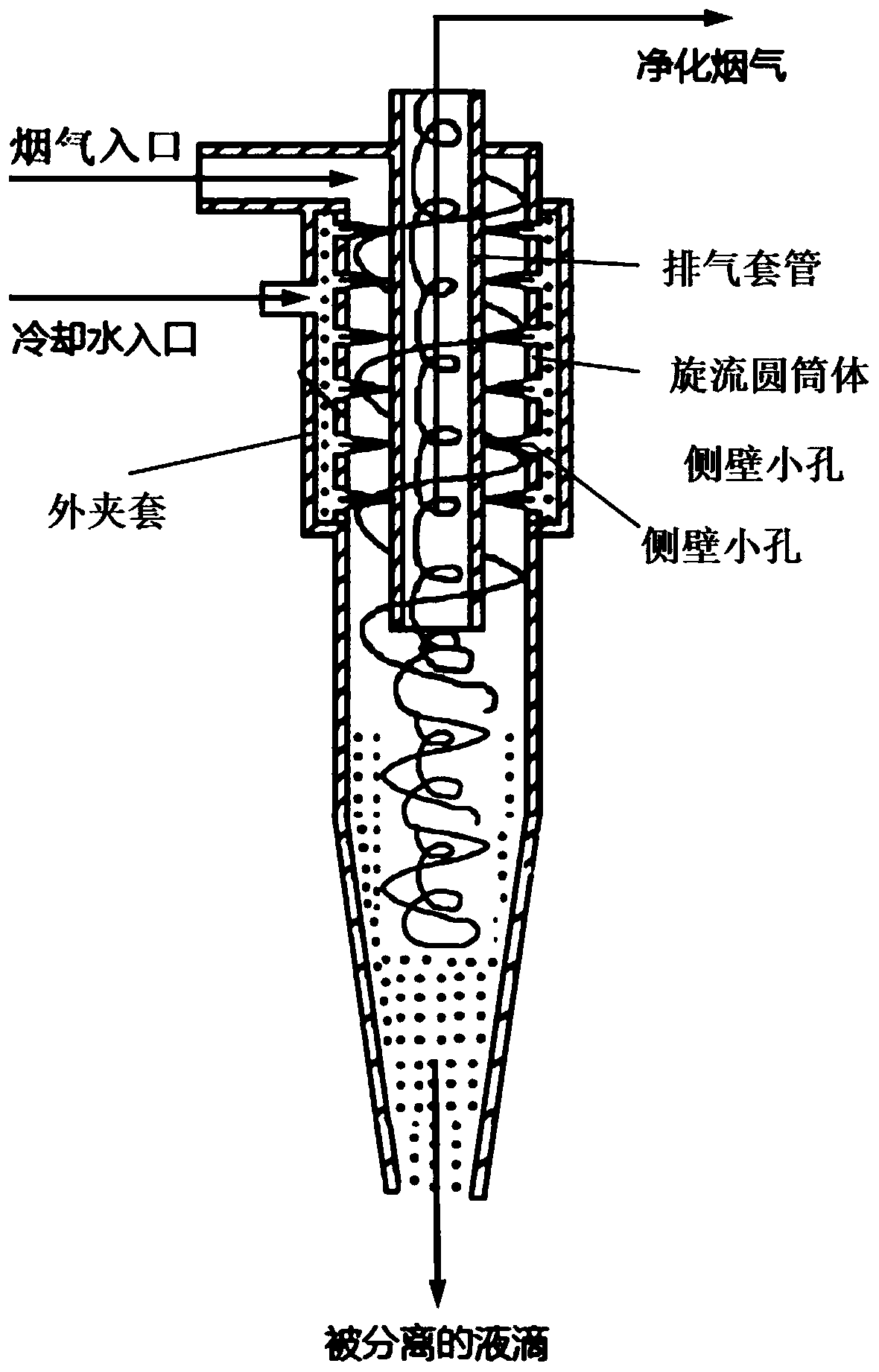

InactiveCN111457408AImprove corrosion resistanceHigh heat and mass transfer coefficientFluid heatersGas treatmentWater storage tankFlue gas

The invention belongs to the technical field of environmental protection, and particularly relates to a device and method for flue gas cyclone jet white removal coupling absorption heat pump waste heat recovery. The device comprises a desulfurization tower, a fan, a cyclone jet, an alkali liquor tank, a liquid collecting tank, a water storage tank, an absorption heat pump and a driving heat source. According to the device and method, flue gas white removal and low-temperature waste heat recovery are coupled, so that the exhaust gas temperature can be reduced, saturated water vapor and solublesalt are condensed and separated out, and the content of the water vapor and the soluble salt in the exhausted flue gas is reduced; the cyclone jet cuts and atomizes liquid into small liquid drops, sothat the heat transfer and mass transfer coefficients of the flue gas and the liquid drops are increased; the liquid drops absorb the heat of the flue gas to become low-temperature heat source water,the low-temperature heat source water flows into the absorption heat pump to release heat and be cooled to become cooling water, one part of the cooling water is used for supplementing water for desulfurization slurry, the other part of the cooling water enters the cyclone jet to be sprayed and atomized and then absorbs the heat of the flue gas, and the process is circulated. The device is smallin occupied area, low in investment cost, free of moving components, easy and convenient to maintain and suitable for existing unit transformation.

Owner:FUDAN UNIV

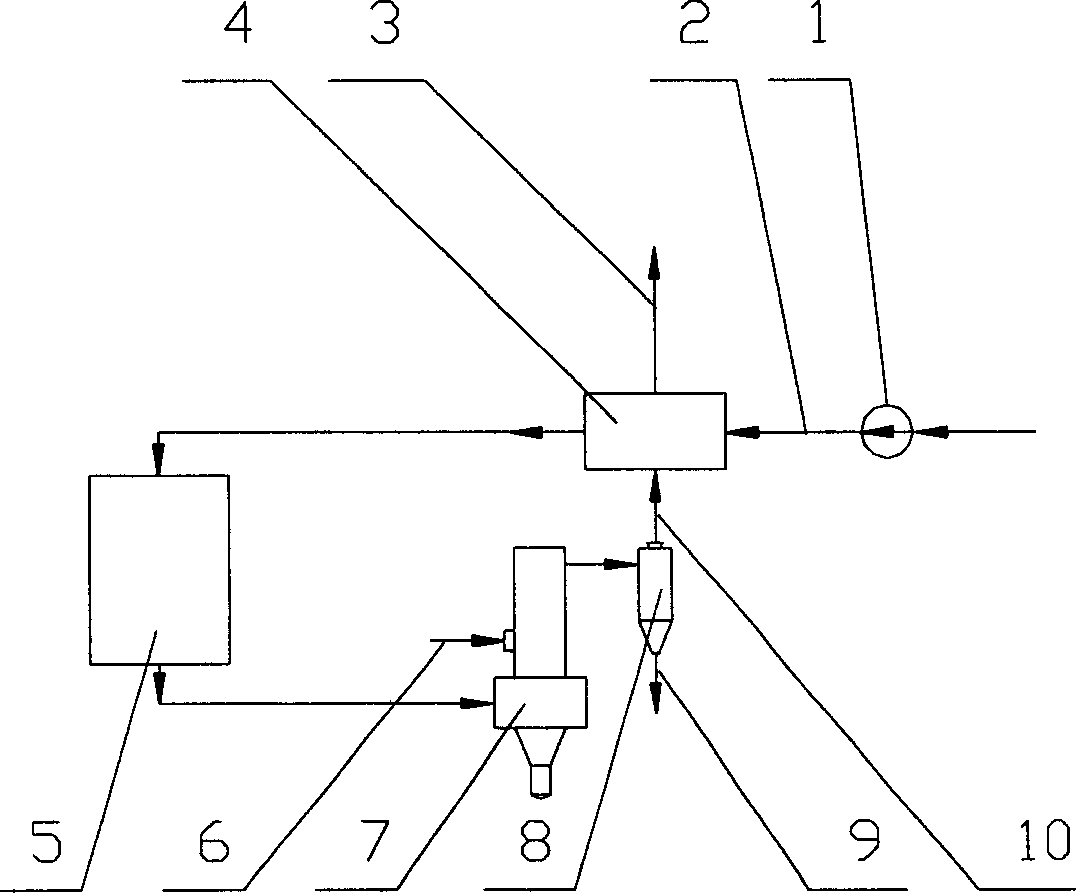

Refractory poor iron ore pulsating fluidized bed magnetizing roasting device and roasting method

The invention relates to a refractory poor iron ore pulsating fluidized bed magnetizing roasting device and a refractory poor iron ore pulsating fluidized bed magnetizing roasting method. Iron ore powder is magnetized and roasted by adopting a pulsating fluidized bed formed by direct coupling of Rick tube type pulsating combustion and a fluidized bed. The iron ore powder is preheated by an ore heater (6) in a bin (7) and then delivered to a roasting furnace (1), the roasting exhaust is cooled by the ore heater (6) and then delivered to a burner (8) and burnt, and the burnt exhaust is cooled by a gas-gas pre-heater (9), delivered to a bag-type dust remover (10) and then discharged to the atmosphere. Sensible heat of high-temperature iron ore concentrate is reclaimed by an ore cooler (14). The device has the advantages of simple system, compact structure, low energy consumption, reduced resistance, short roasting time and the like; and by using the device and the method, poor phenomena of channeling, dead zone, short circuit and the like of common fluidized bed magnetizing roasting and the problem of over wide residence time distribution of a reactor are effectively solved, and the roasting quality and the roasting efficiency are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

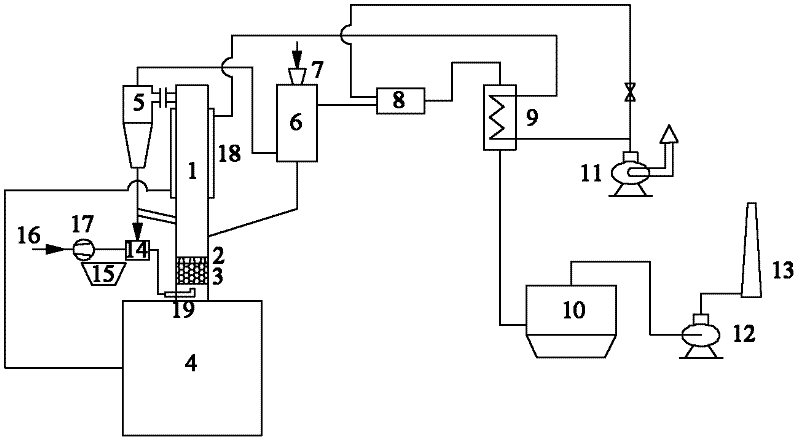

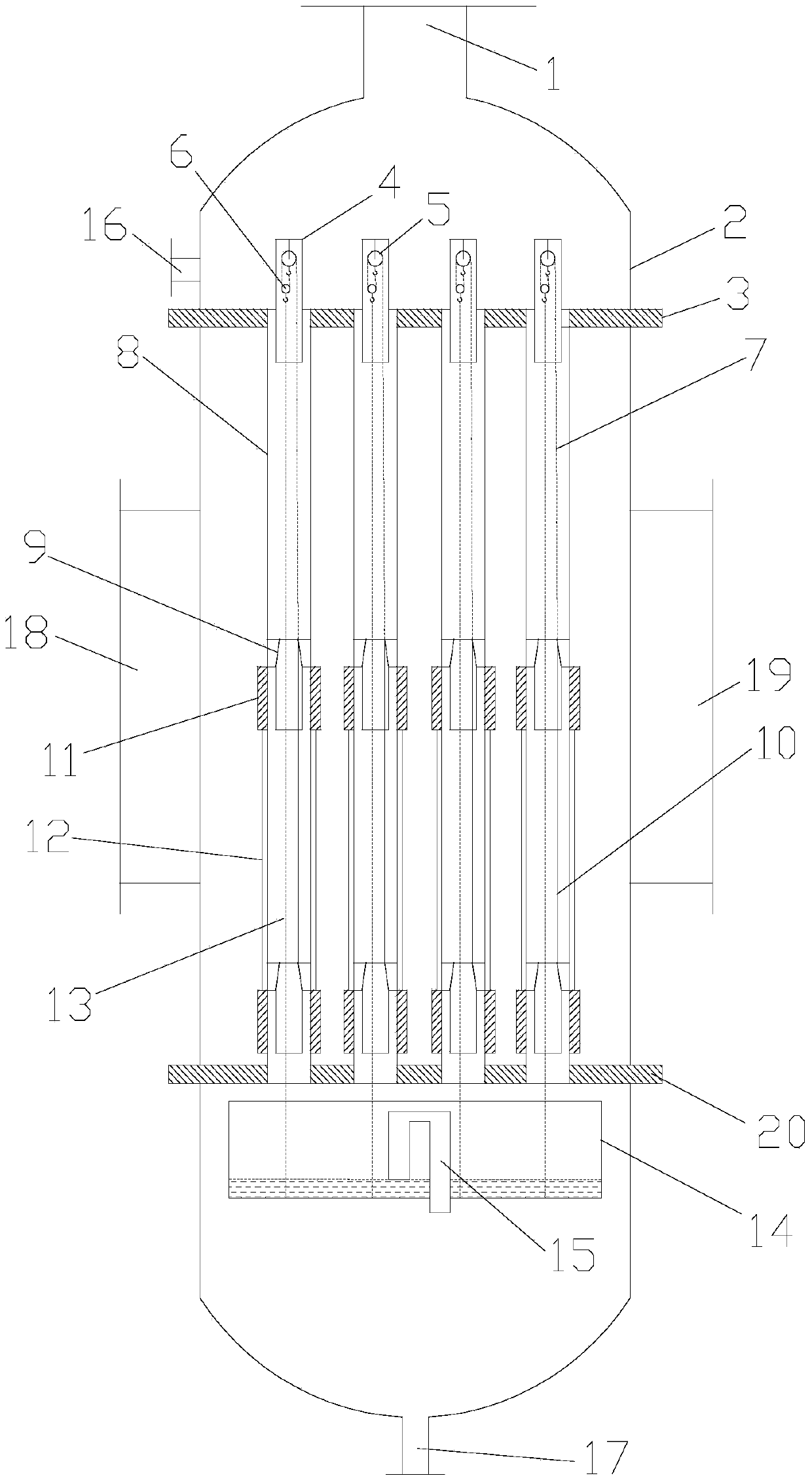

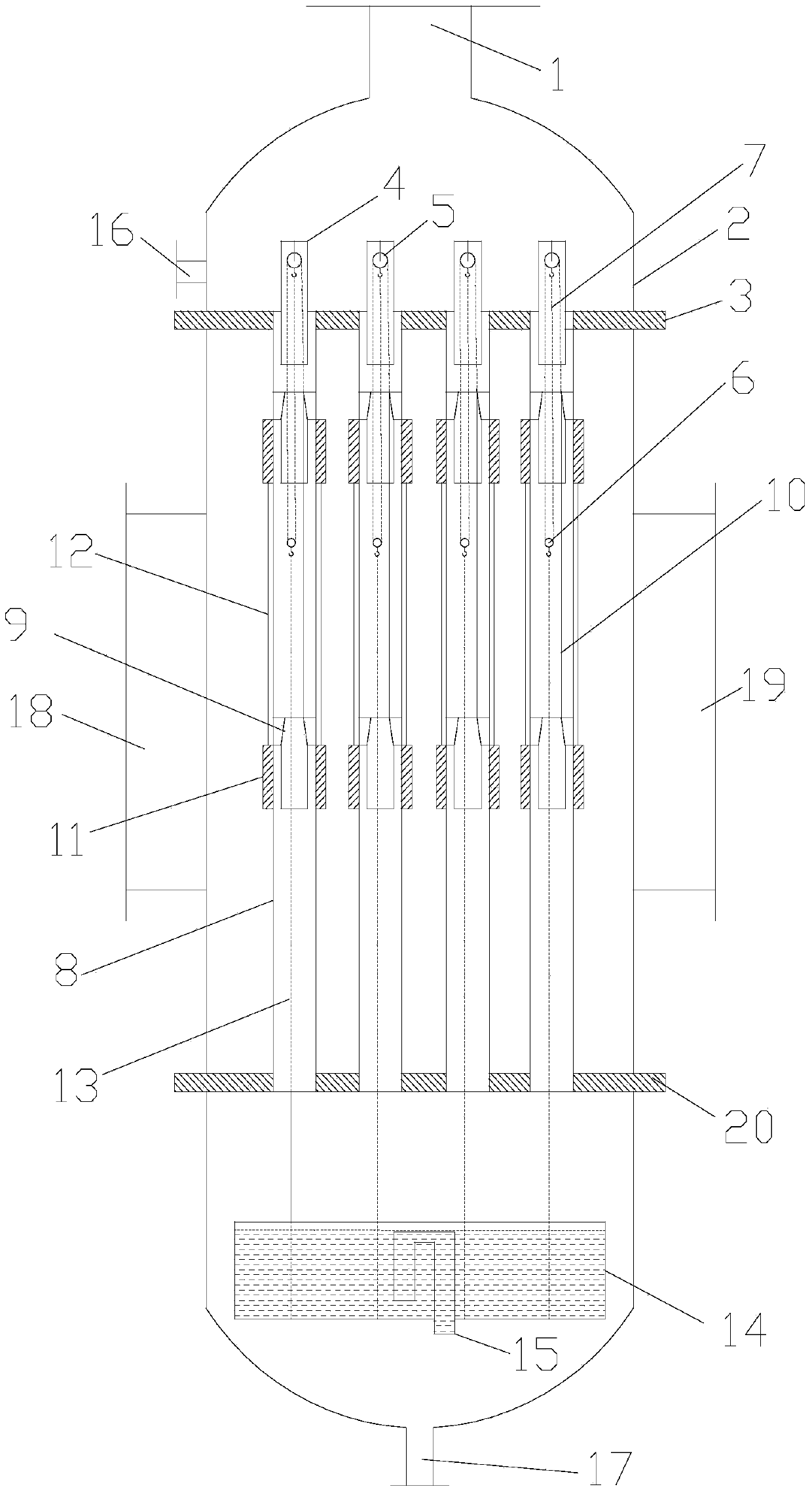

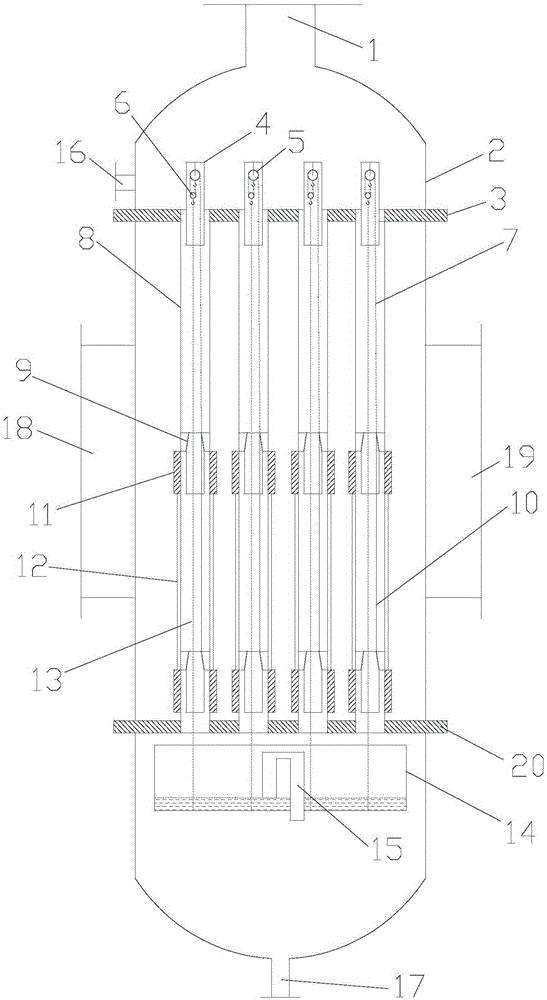

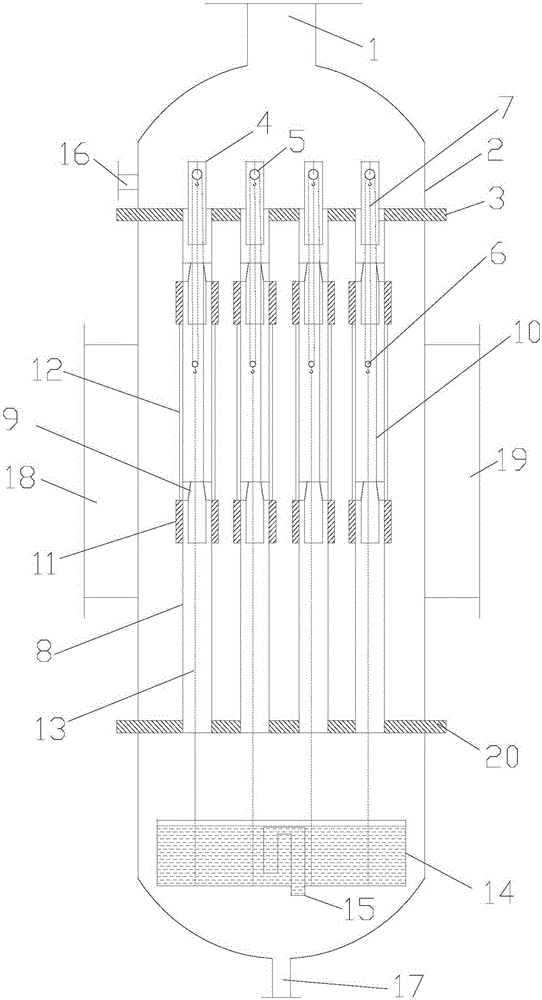

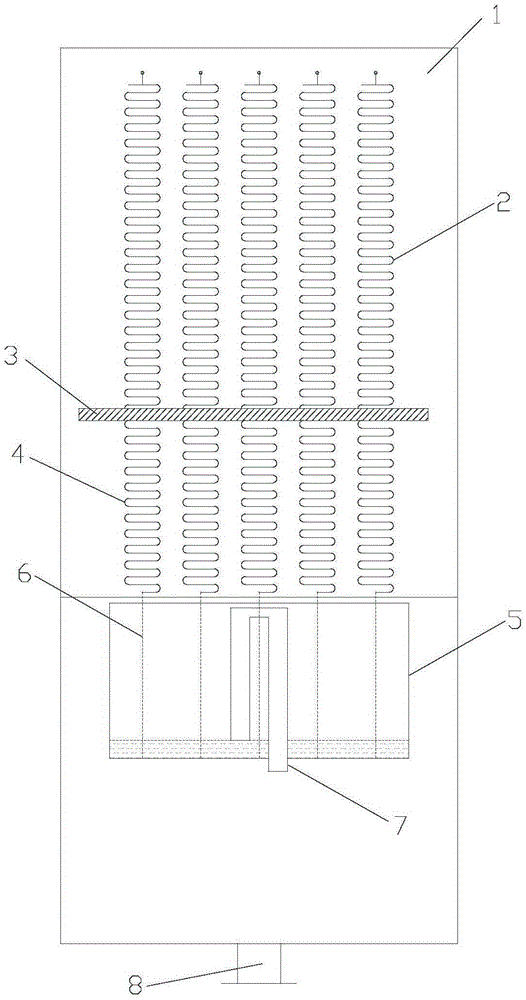

Dual utilization device and method for exhaust steam waste heat produced during superheat steam drying of sludge

ActiveCN105254148AHigh heat and mass transfer coefficientLarge specific heat capacitySludge treatment by de-watering/drying/thickeningCycloneSludge

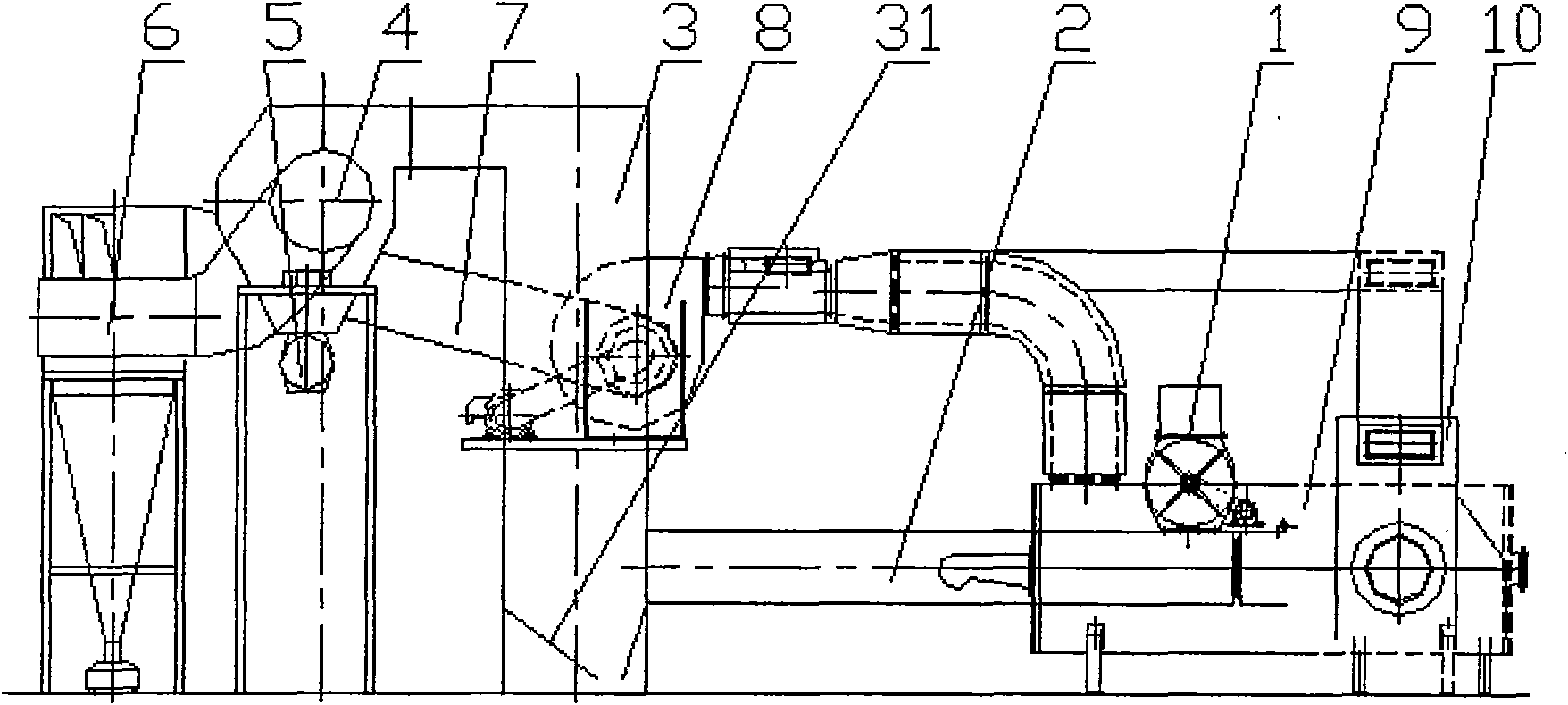

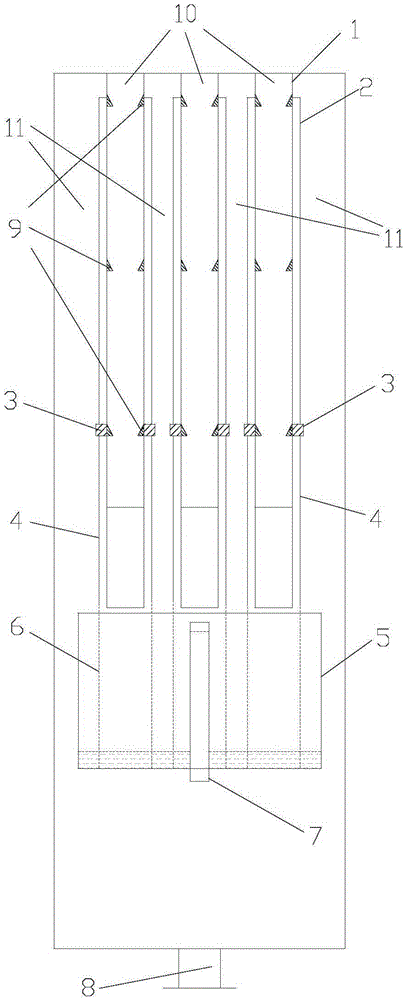

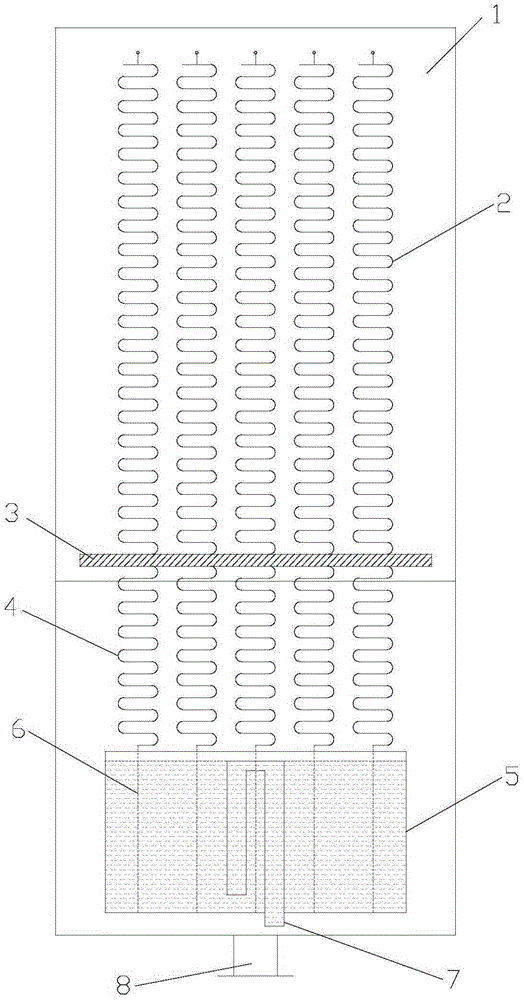

The invention relates to a dual utilization device and method for exhaust steam waste heat produced during superheat steam drying of sludge The device comprises a shaftless screw feeder, air valves, a heater, a double-shaft stirring dryer, a sludge particle forming machine, a net belt dryer, a tail gas washing tower, cyclone separators (A and B), fans (A and B) and a heat exchanger, wherein the shaftless screw feeder, the double-shaft stirring dryer, the sludge particle forming machine and the net belt dryer are sequentially connected, and a material channel is formed; the heater, the double-shaft stirring dryer, the cycle separator A, the fan A and the air valve B are sequentially connected to form an internal circulation air channel; the shaftless screw feeder, the cyclone separator B, the heat exchanger and the tail gas washing tower are sequentially connected to form an external air channel; the heat exchanger, the fans and the net belt dryer are combined for drying. The device and the method have the advantages that dual utilization of exhaust steam waste heat is realized, the device and the method are efficient and energy-saving, and condensation can be effectively prevented; zero-pollution discharge of waste water and waste gas is realized; formed sludge can be used for preparing fertilizers, and reutilization of the sludge is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

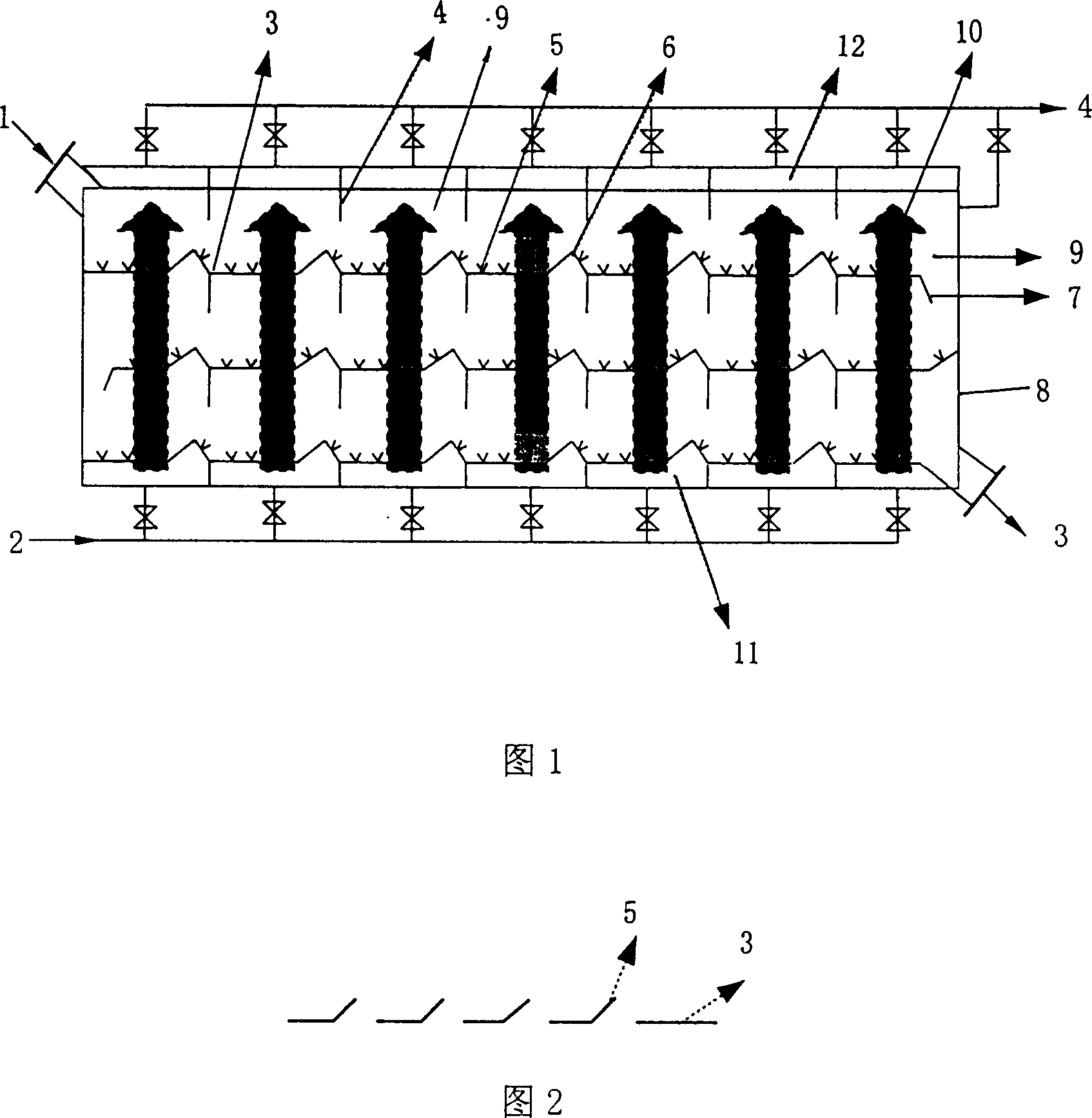

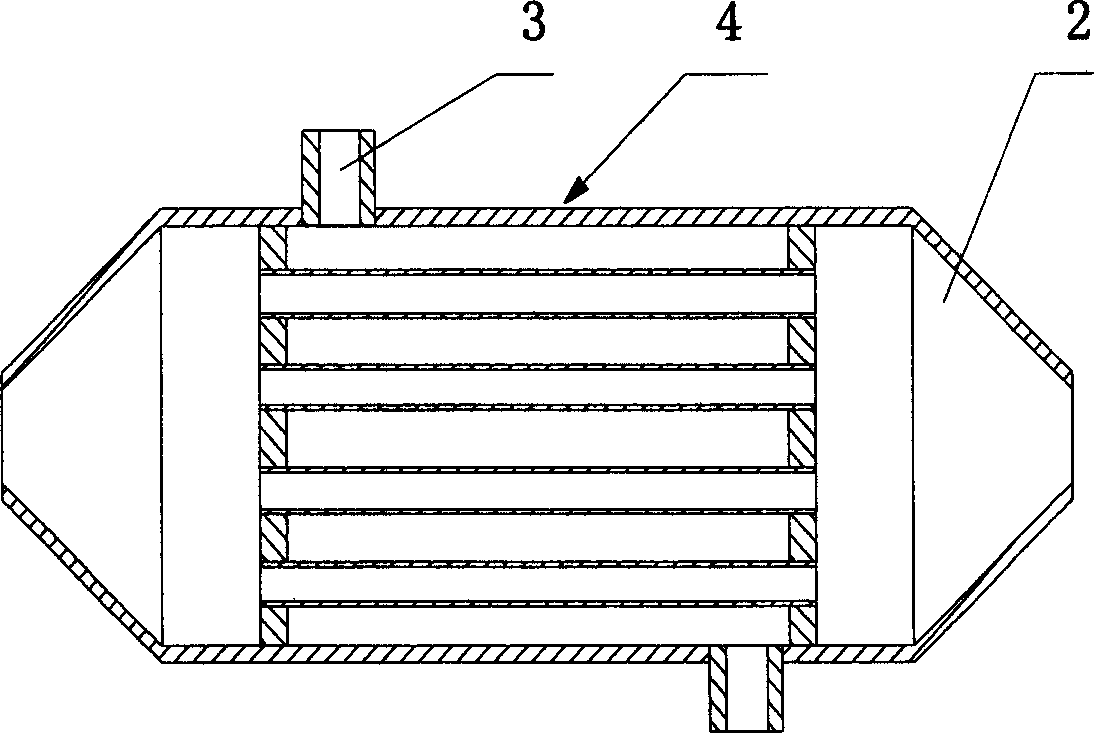

Horizontal polyester solid phase polycondensation reaction device

The invention discloses a horizontal polyester solid-phase polycondensation reaction device, which comprises the following parts: horizontal tank (8), several fluid bed boards (3), several fluid chambers (9) separated by baffle (4), fluid bed row (10) between adjacent fluid chambers (9), nitrogen chamber (11) on the bottom of each fluid bed row (10) with nitrogen exhaust chamber on the top (12), wherein the feed hole (1) is set on the tank (8); the fluid bed board (3) is set in the tank (8), which displays inclined shape.

Owner:SINOPEC YIZHENG CHEM FIBER

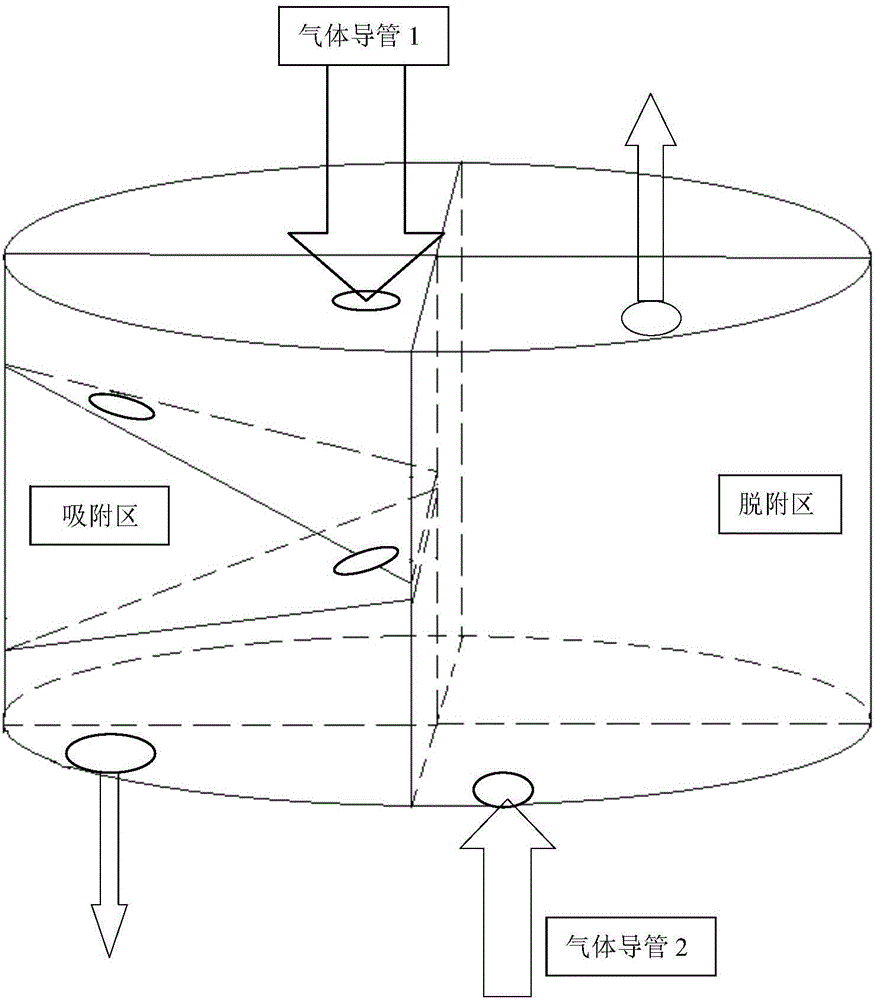

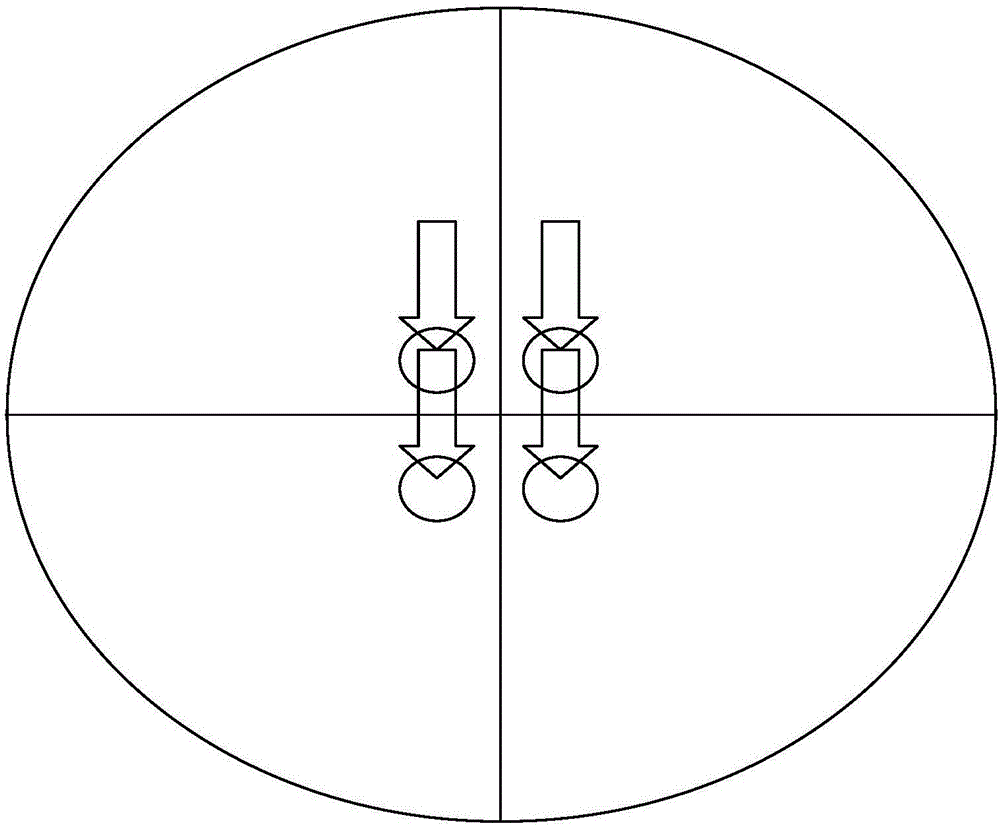

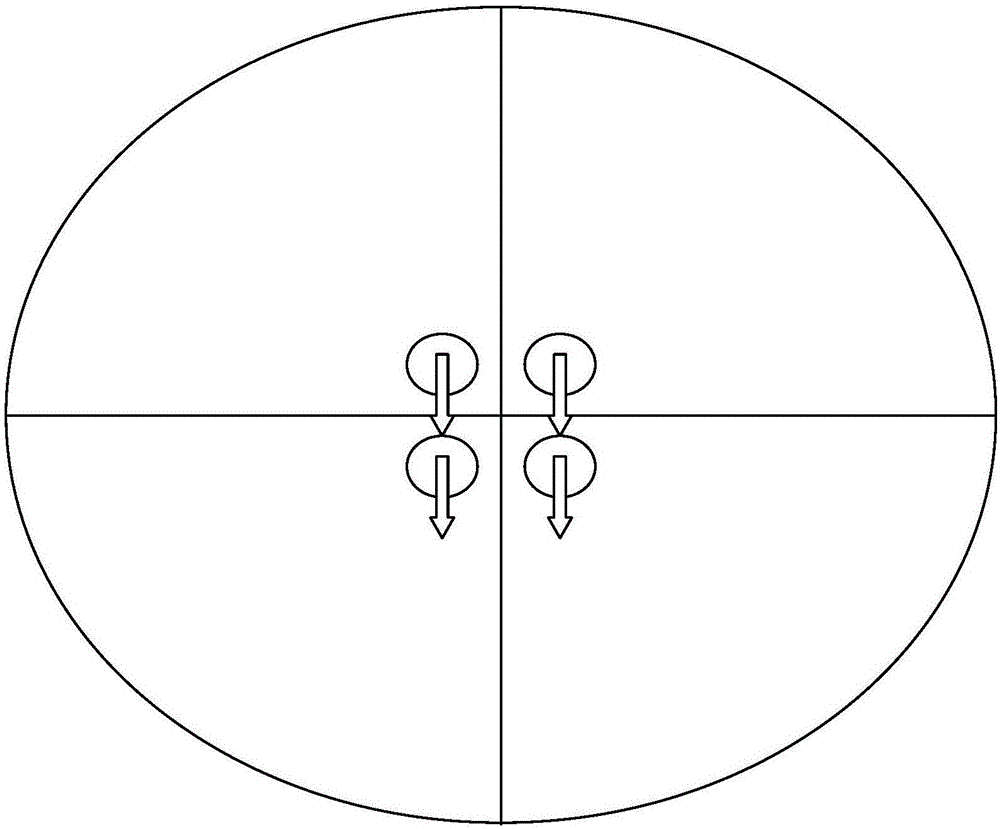

CO2 adsorption/desorption circulating treatment device and preparation method and treatment method thereof

InactiveCN106492589ATake advantage ofImprove adsorption efficiencyGas treatmentDispersed particle separationSorbentDesorption

The invention discloses a CO2 adsorption / desorption circulating treatment device and a preparation method and a treatment method thereof. The device comprises a power driving device, a turning wheel and a gas conduit, wherein the power driving device drives the turning wheel to rotate, a plurality of gas inlet and outlet holes are formed in the turning wheel, and each gas inlet and outlet hole is respectively connected with the gas conduit; the turning wheel internally comprises a plurality of adsorption areas and a plurality of desorption areas, and adjacent areas are sealed; and a plurality of splitting layers are arranged in each adsorption area, each splitting layer is filled with adsorbents, air holes for to-be-adsorbed gas or purified gas to flow through are formed in the left end and right end of each splitting layer, and the to-be-adsorbed gas or purified gas is discharged from the gas inlet and outlet holes after sequentially flowing through each splitting layer. By using MOF materials as the adsorbents, horizontal layering is achieved inside the turning wheel, and the layers are separated so as to ensure that the gas sufficiently flows through the adsorbents, so that the adsorbents can be fully utilized, and the adsorption efficiency of carbon dioxide can be greatly improved.

Owner:SUN YAT SEN UNIV

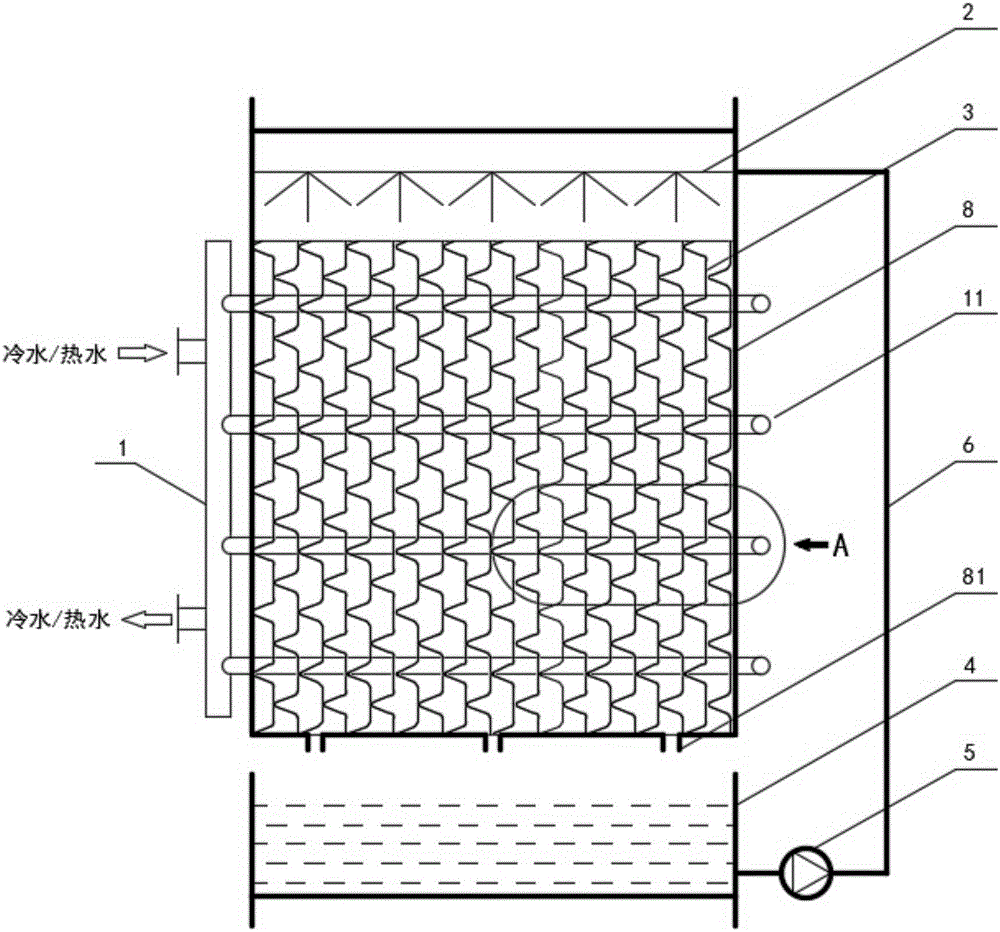

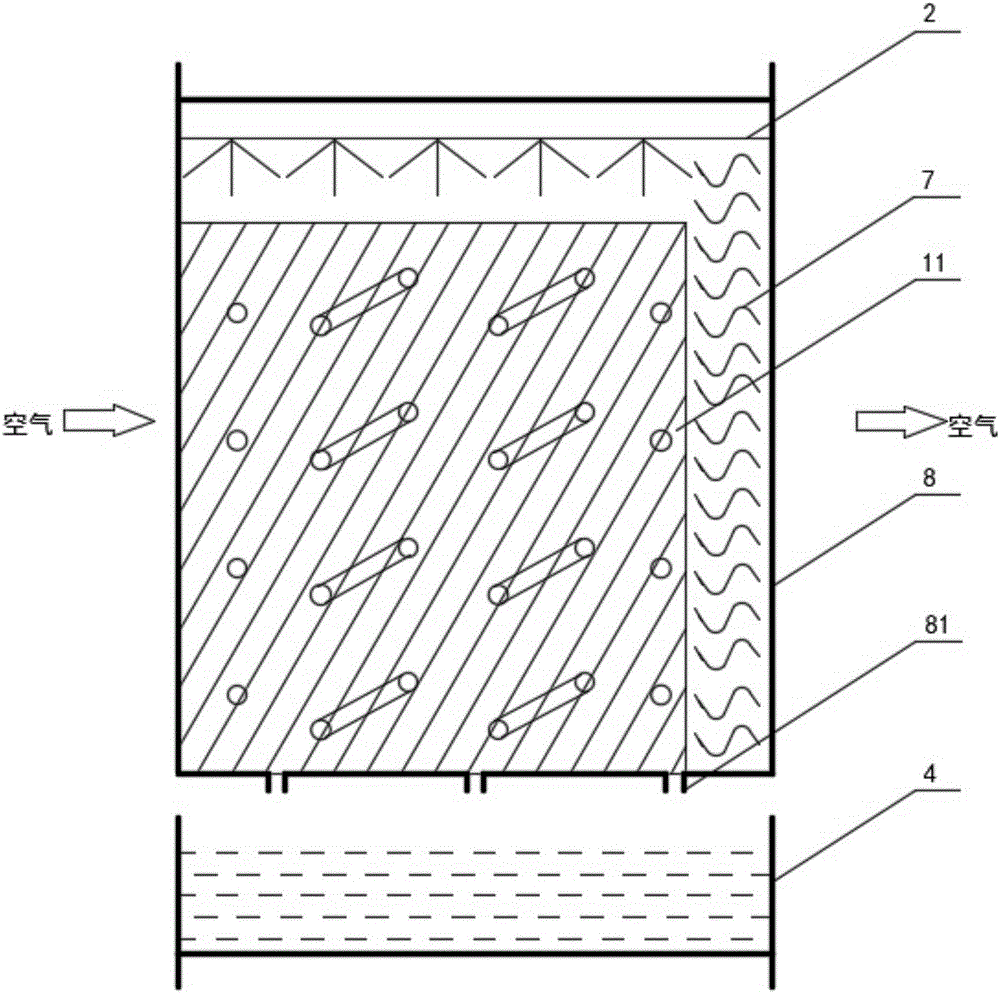

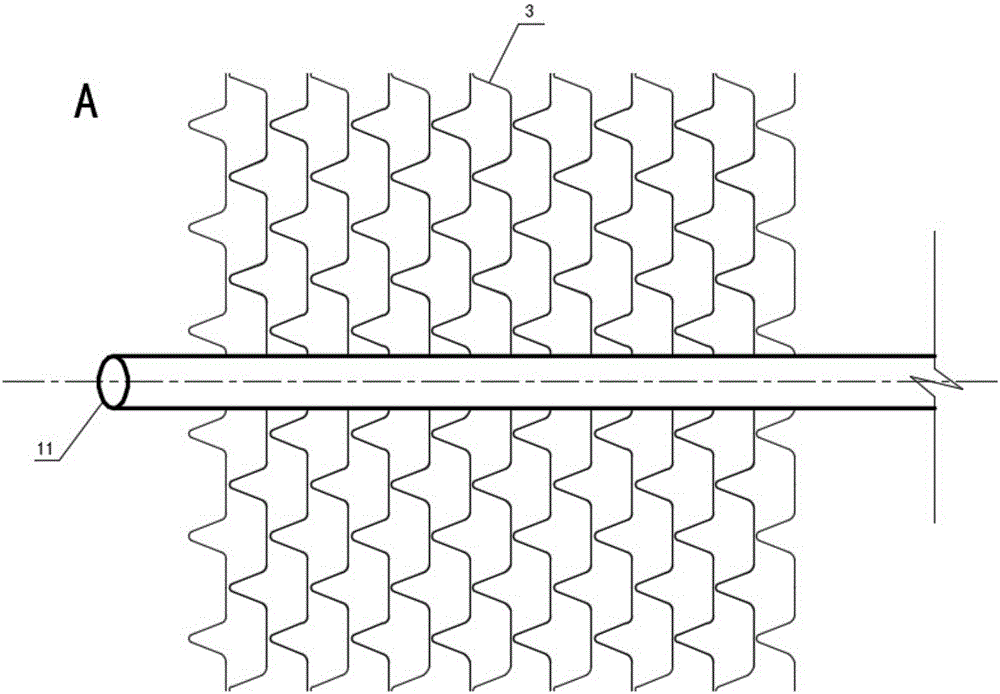

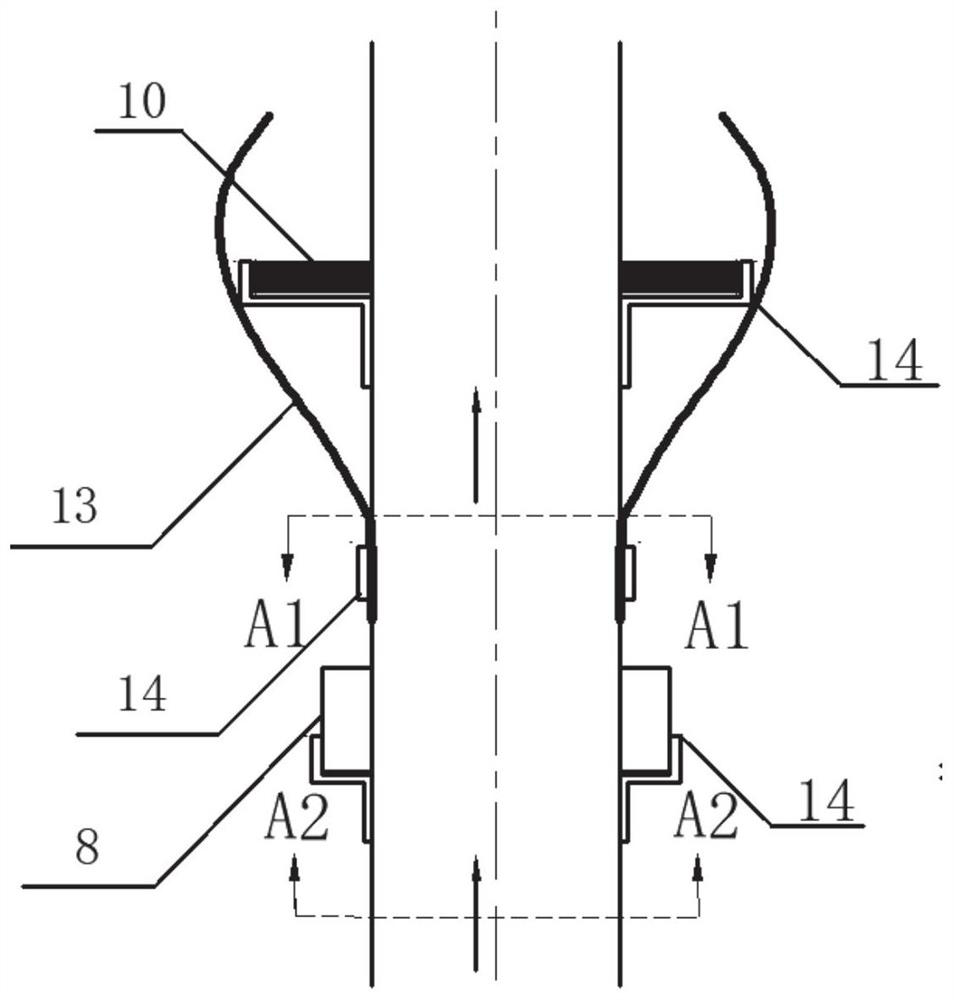

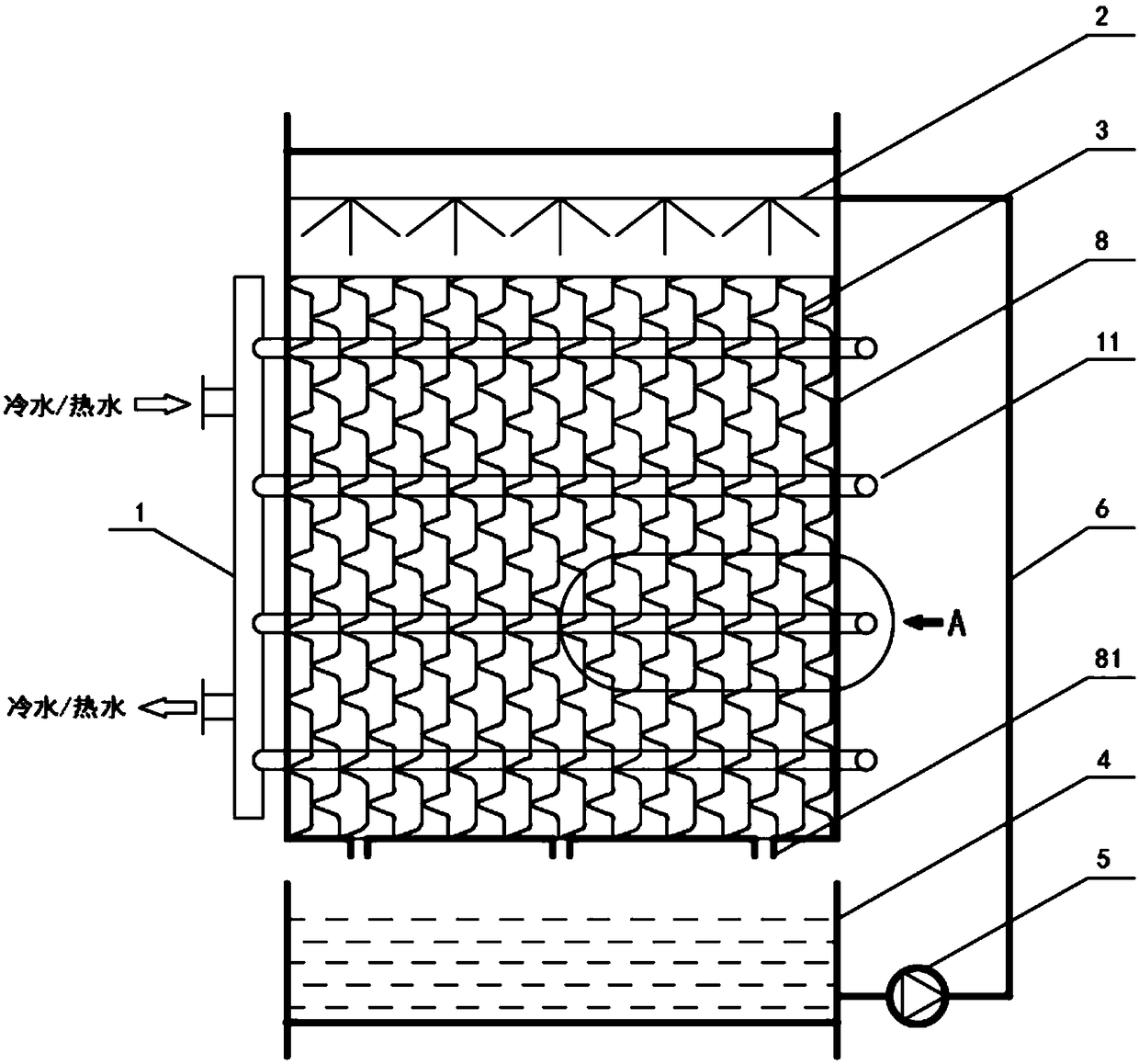

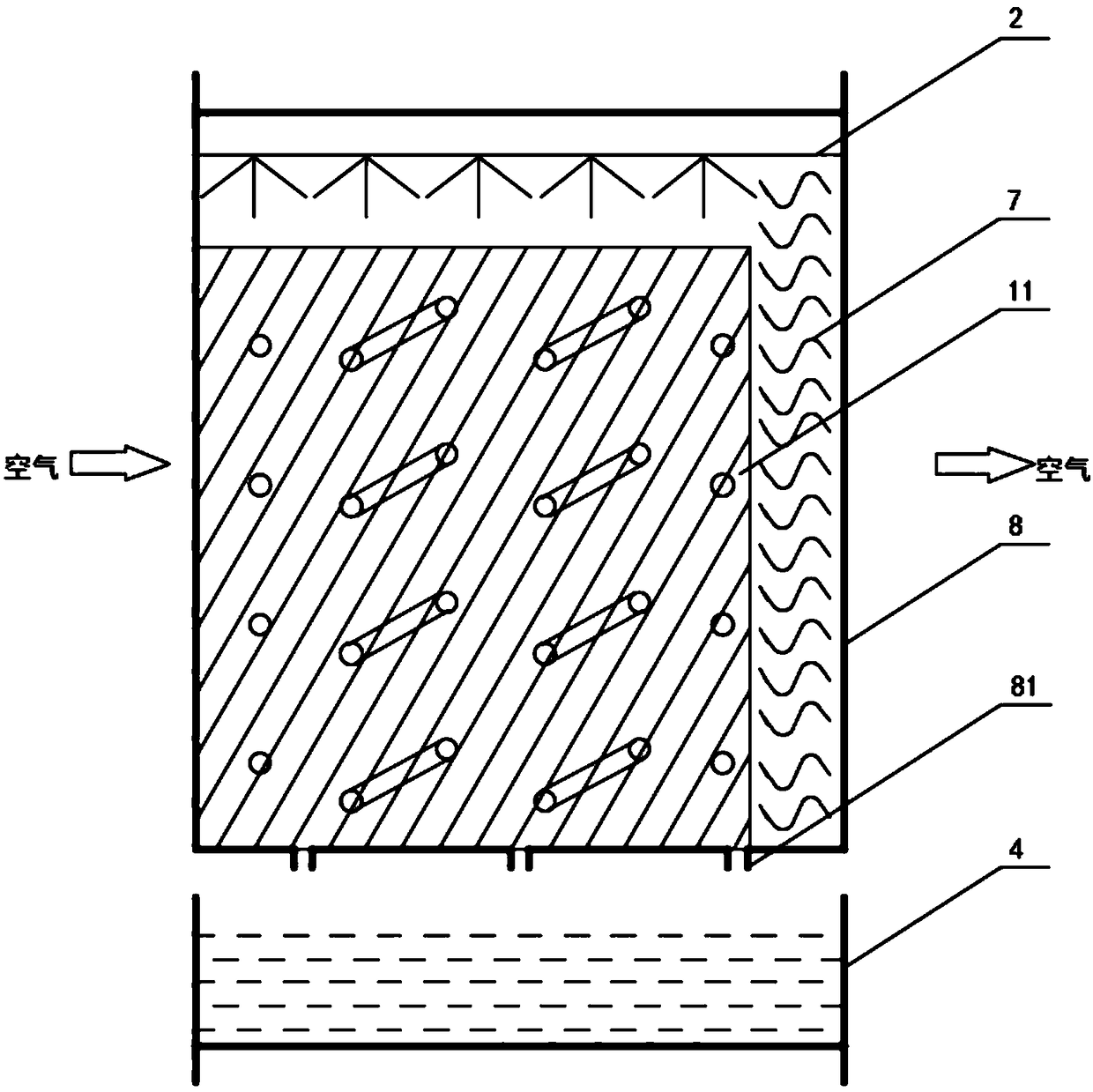

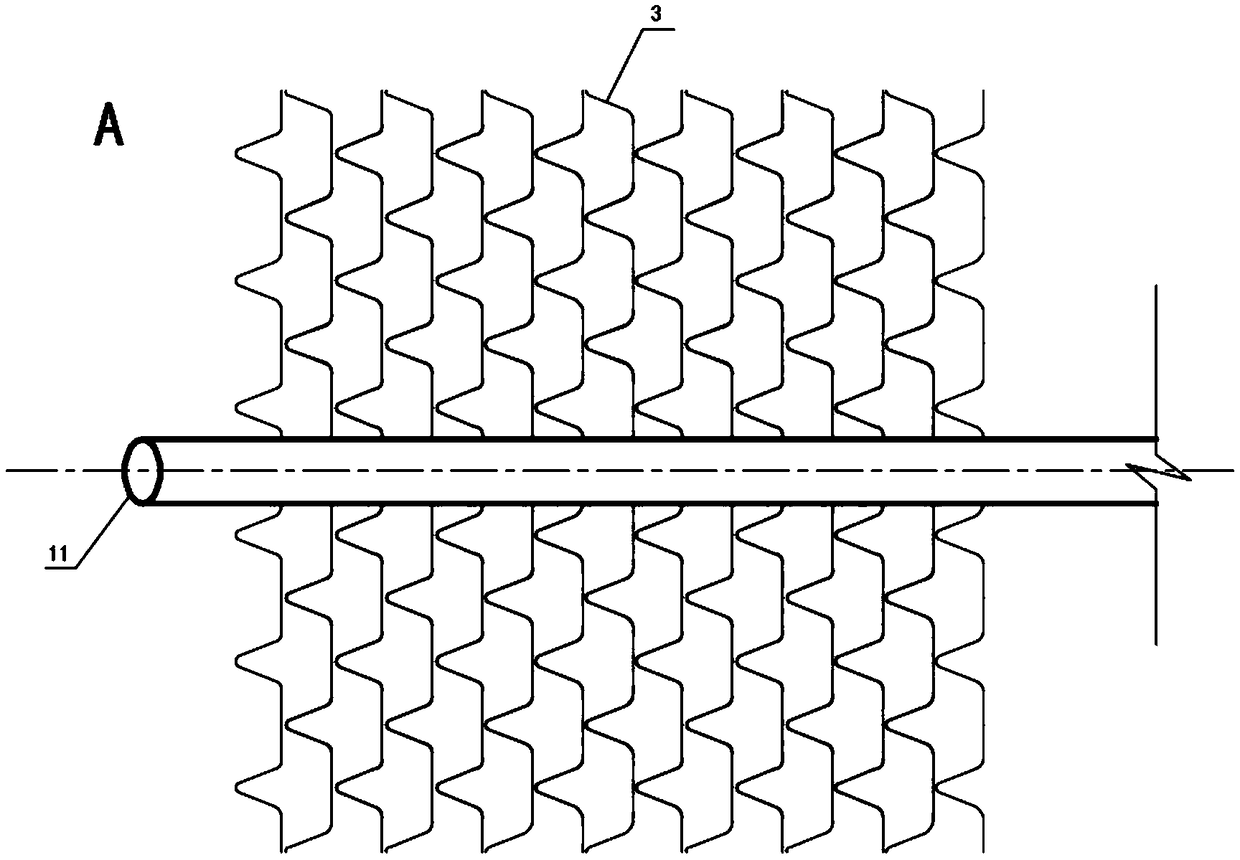

Gas-liquid whole-heat exchange device with built-in cold and heat source based on metal fiberfill

ActiveCN105890147AIncrease contact areaExtension of timeSpace heating and ventilation detailsTrickle coolersMetal fiberHeat mass transfer

The invention discloses a gas-liquid whole-heat exchange device with a built-in cold and heat source based on a metal fiberfill. The gas-liquid whole-heat exchange device comprises a heat exchange coil, a sprayer, a metal fiberfill, a solution tank, a solution pump, a solution circulating pipeline and a tank body, wherein the solution tank is located under the tank body; the sprayer is arranged above the metal fiberfill; the solution tank is communicated with the sprayer through the solution circulating pipeline; the solution pump is arranged on the solution circulating pipeline; the heat exchange coil and the metal fiberfill are arranged in the tank body; the metal fiberfill is formed by overlapping and assembling the inclined ripple metal fiber mats at two angles; the surfaces of the metal fiber mats are preferably treated through hydrophilic nano coating; the heat exchange coil comprises a metal heat exchange tube which penetrates through the metal fiber mats along the overlapped direction of the metal fiber mats; a solution flowing channel and an air-guide channel are formed between the two adjacent metal fiber mats. According to the device, can effectively increase the contact area between the solution and air can be effectively increased, the contact time of the solution and air can be effectively prolonged, the heat mass transfer coefficient can be increased and the device can be served as a dehumidifying or regenerating unit of a solution humidity-adjusting air-conditioning system.

Owner:BEIJING KANGFU TECH

Inter-pipe redistributed film generation device capable of automatically cleaning away smoke dirt outside pipe

ActiveCN103994606AImprove mass transfer coefficientImprove heat transfer coefficientBoilers/analysersEngineeringMechanical engineering

The invention discloses an inter-pipe redistributed film generation device capable of automatically cleaning away smoke dirt outside a pipe. The inter-pipe redistributed film generation device comprises a shell, an upper baffle, a lower baffle, a film distribution unit and a hoisting liquid receiving pot. A siphon pipe is arranged in the hoisting liquid receiving pot. Each film distribution unit comprises an initial film distribution device, a fixed pulley, a movable pulley, a pulley line, a falling film pipe, a film redistribution device, an ash scraping ring and a bearing rope, wherein the top end of the falling film pipe is connected to the upper baffle, the bottom end of the falling film pipe is connected to the lower baffle, the initial film distribution device is located in a through hole in the upper baffle, the fixed pulley is fixedly connected to the initial film distribution device, the two ends of the pulley line are connected to a pulley hook of the fixed pulley and the top end of the film redistribution device, the ash scraping ring is located outside the falling film pipe, magnetic force exists between the ash scraping ring and the film redistribution device, and the two ends of the bearing rope are connected with the movable pulley and the hoisting liquid receiving pot. In the inter-pipe distributed film generation device, the film redistribution devices can reciprocate in the pipe for film redistribution, occurrence of channeling or plume is effectively restrained, liquid film distribution is uniformized, and dust accumulated outside the pipe is removed through the ash scraping devices outside the pipe.

Owner:山东东岳能源交口肥美铝业有限责任公司

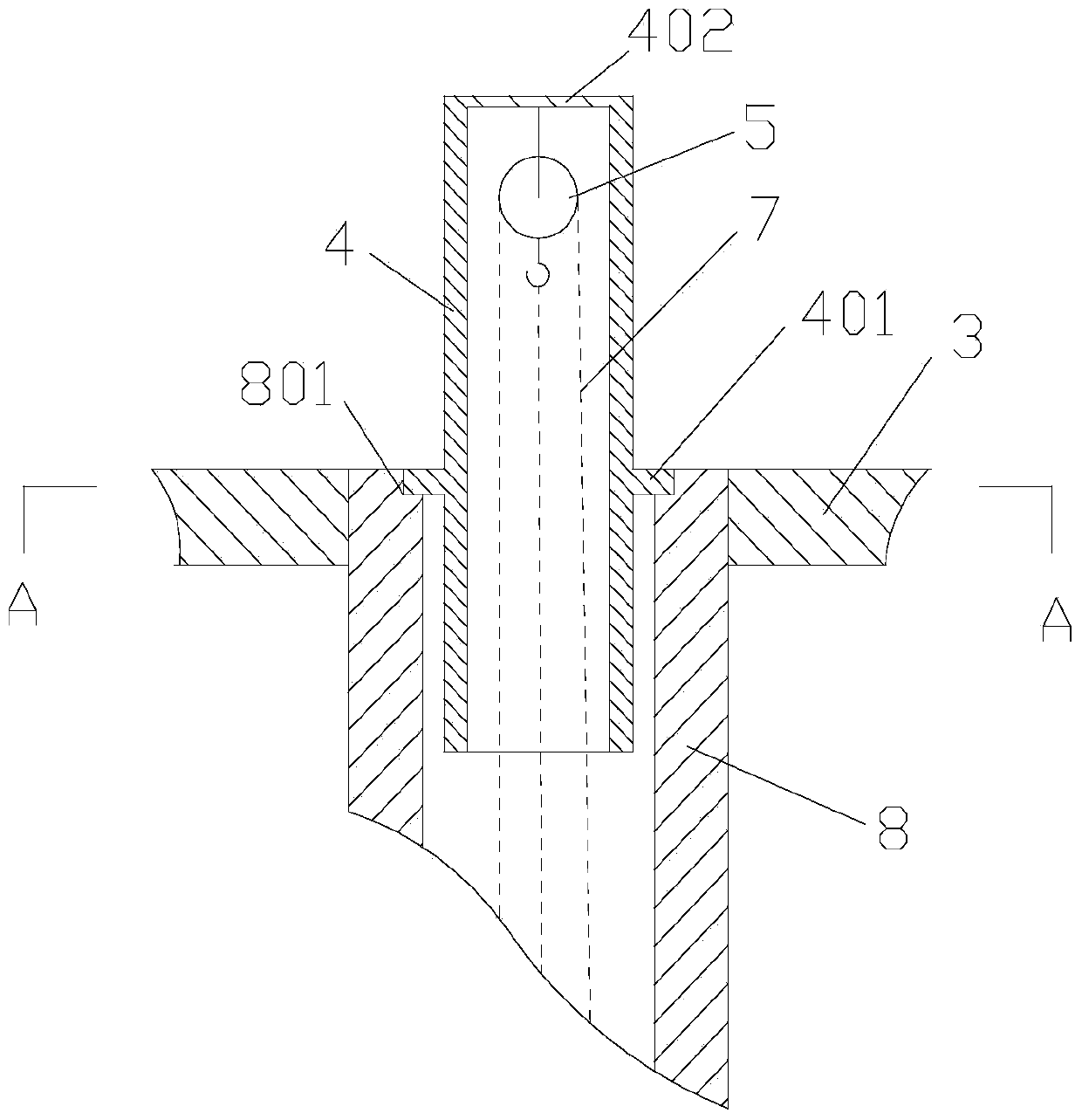

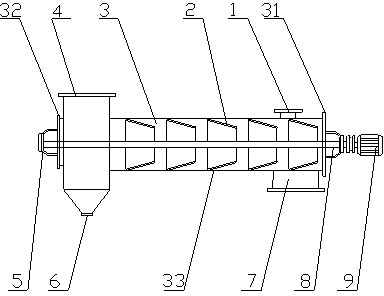

Screw type pneumatic drying machine and method

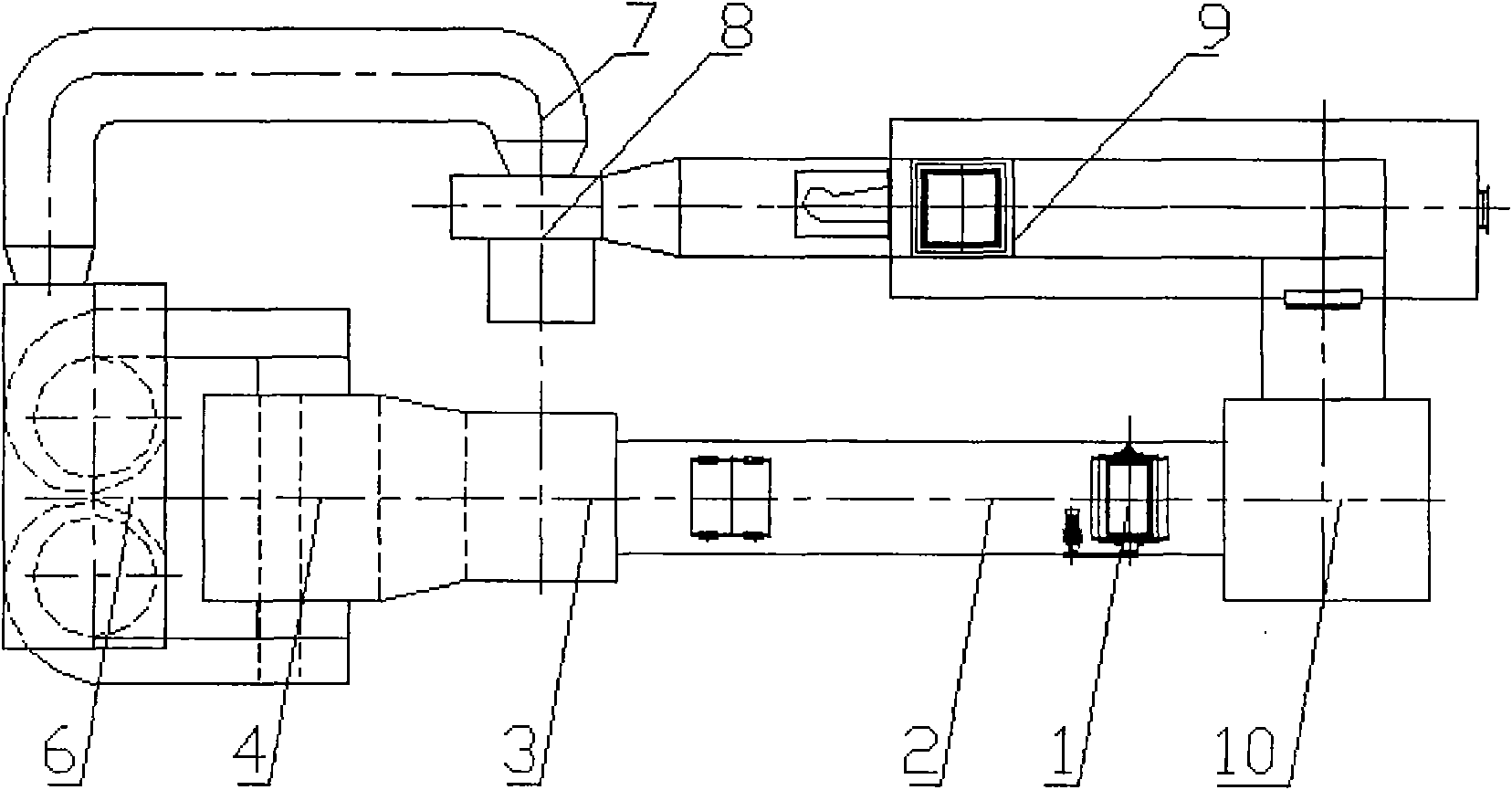

InactiveCN102092917AReduces the possibility of deflagrationAdaptableSludge treatment by de-watering/drying/thickeningSludgeEngineering

The invention relates to a screw type pneumatic drying machine and method. The screw type pneumatic drying machine comprises an airtight drying machine body (3), wherein the drying machine body (3) comprises a first end part (31), a second end part (32) and a shell (33); the first end part (31) and the second end part (32) are oppositely arranged, and the first end part (31); the first end part (31) and the second end part (32) are connected through the shell (33); and the second end part (32) and the shell (33) form an airtight working space. The drying machine also comprises a screw propulsion unit (2), a wet sludge feed port (1), high temperature smoke inlet (7) and a low temperature smoke outlet (4), wherein the screw propulsion unit (2) is installed in the working space; the wet sludge feed port (1) and the high temperature smoke inlet (7) are respectively arranged on the drying machine body (3); and the low temperature smoke outlet (4) is arranged on the drying machine body (3) and penetrates through the shell (33). The device and method are suitable for drying sludge, and have the advantages that the operation is continuous, the labor intensity is low, and the heat consumption is low.

Owner:SOUTHEAST UNIV

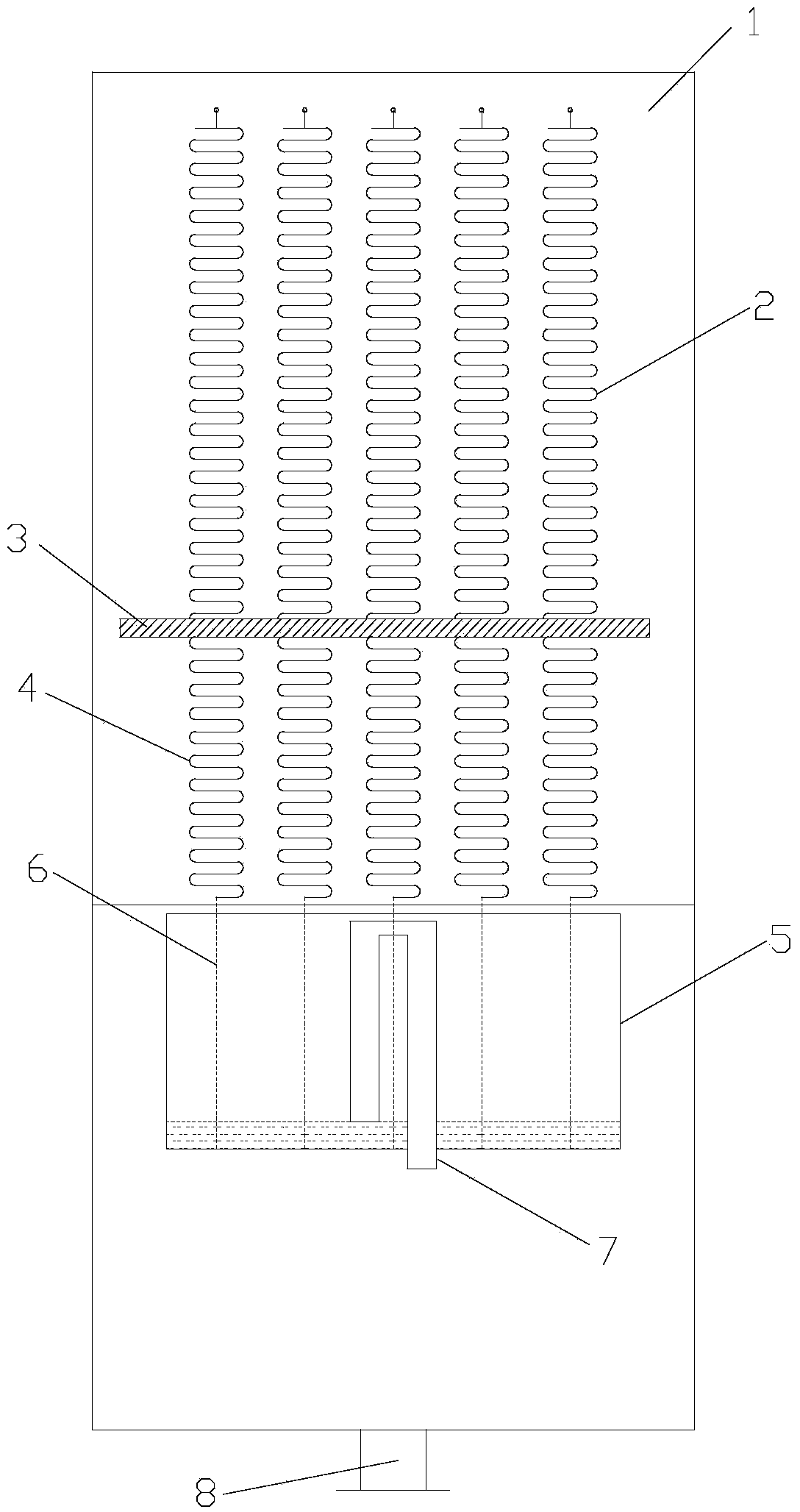

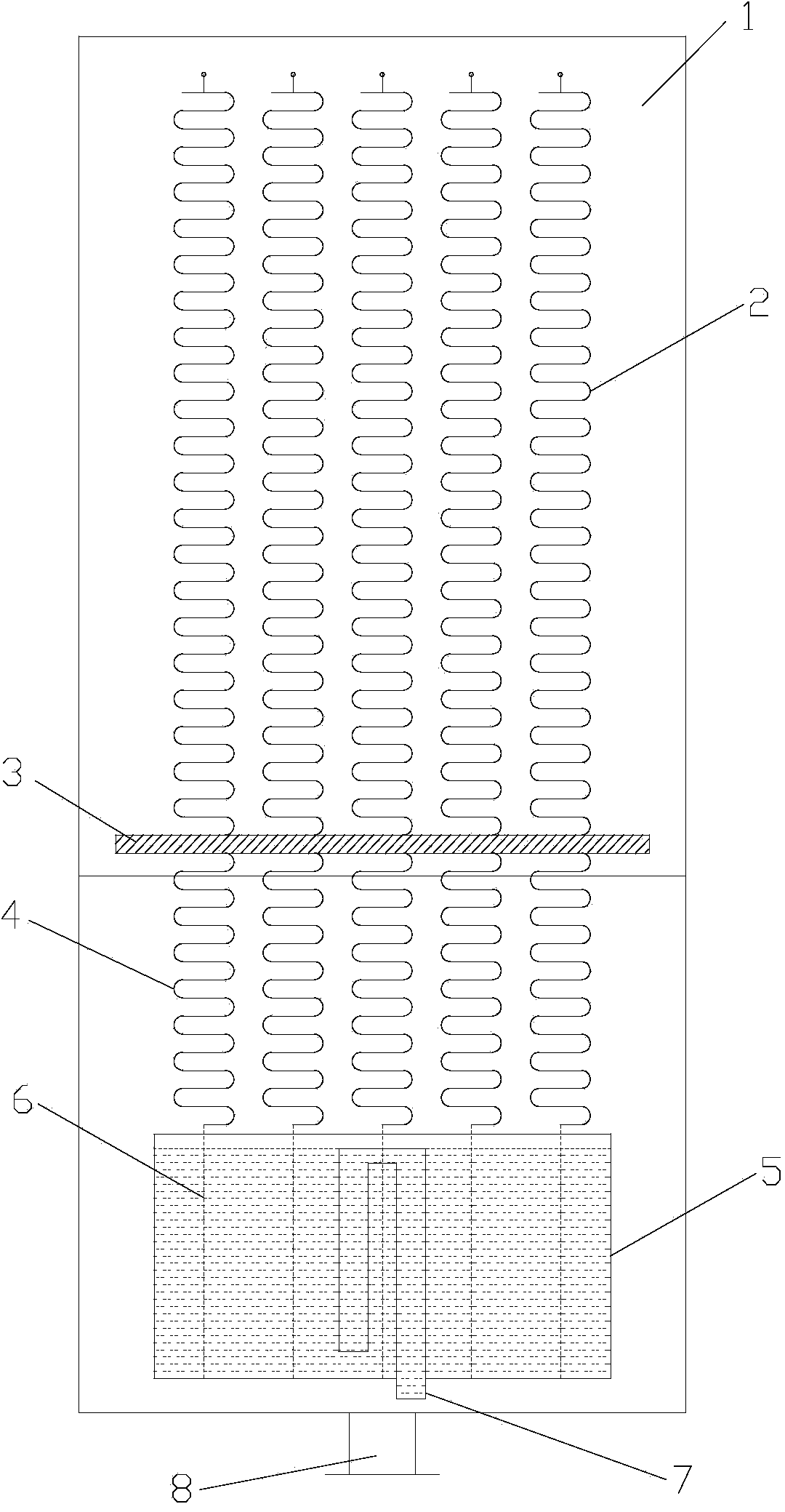

Humidification and dehumidification type water purification device for evaporation enhancement of fluidized bed

ActiveCN105621509AImprove purification efficiencyHigh heat and mass transfer coefficientSeawater treatmentEnergy based wastewater treatmentFluidized bedSewage

The invention discloses a humidification and dehumidification type water purification device for evaporation enhancement of a fluidized bed. The humidification and dehumidification type water purification device comprises a condensation chamber, a condenser, an evaporation chamber, an upper partition board, a lower partition board, a spraying device, a heating device and a drive device, wherein an evaporation cavity is limited in the evaporation chamber, a second gas inlet, a second gas outlet and a sewage outlet are formed in the evaporation chamber, and the second gas outlet is communicated with a first gas inlet; the upper partition board and the lower partition board are arranged in the evaporation cavity in a spaced mode so as to divide the evaporation cavity into an upper cavity, a middle cavity and a lower cavity, suspended solid particles are arranged in the middle cavity, the second gas inlet is communicated with the lower cavity, and the second gas outlet is communicated with the upper cavity. The spraying device is provided with a spraying nozzle in the upper cavity. The heating device is connected between the spraying device and a water outlet pipe. The drive device is connected between a first gas outlet and the second gas inlet. By means of the humidification and dehumidification type water purification device, water purification efficiency can be improved, the structure is simple, and cost is low.

Owner:TSINGHUA UNIV

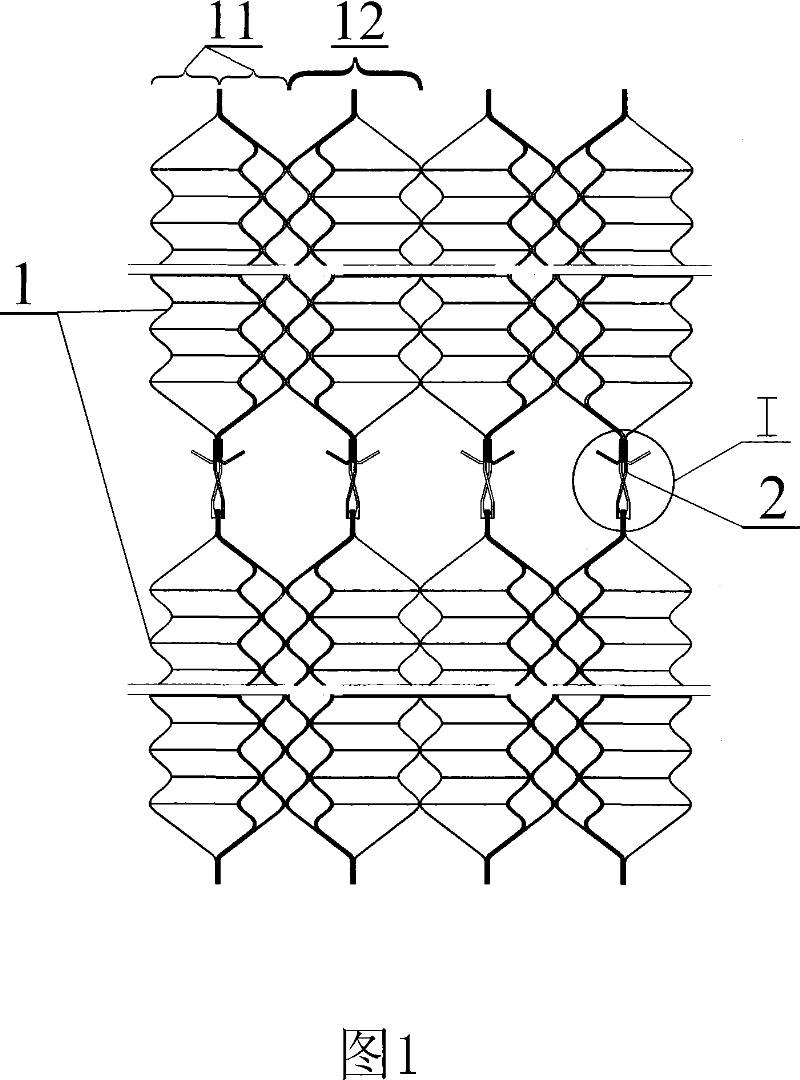

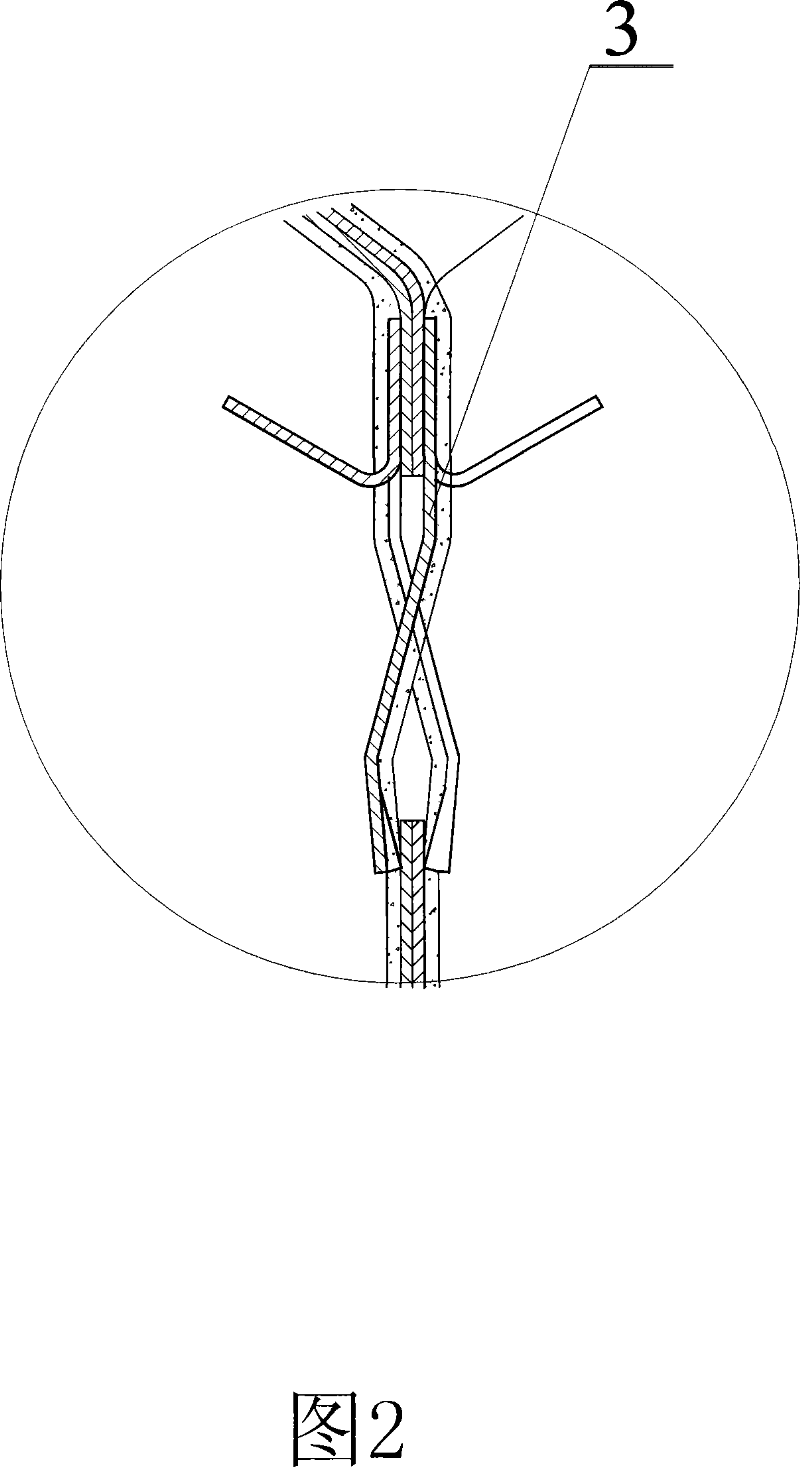

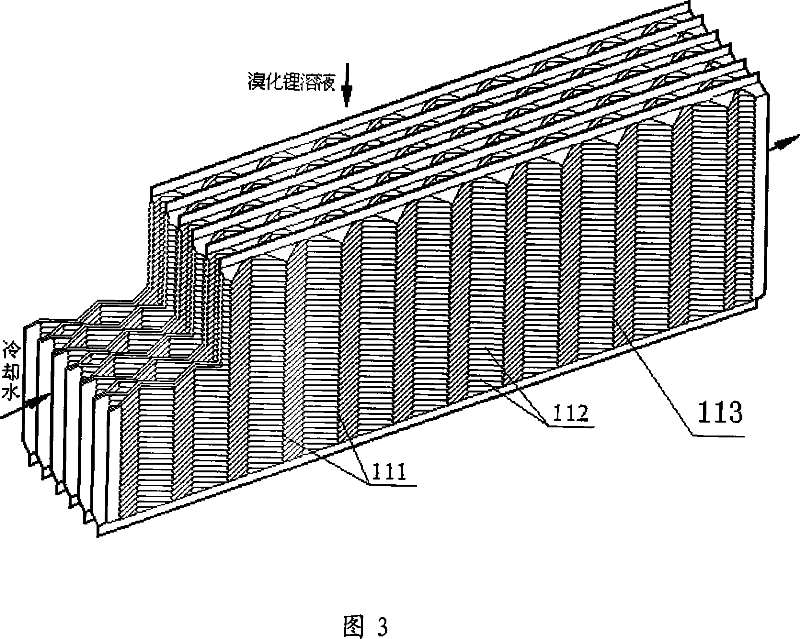

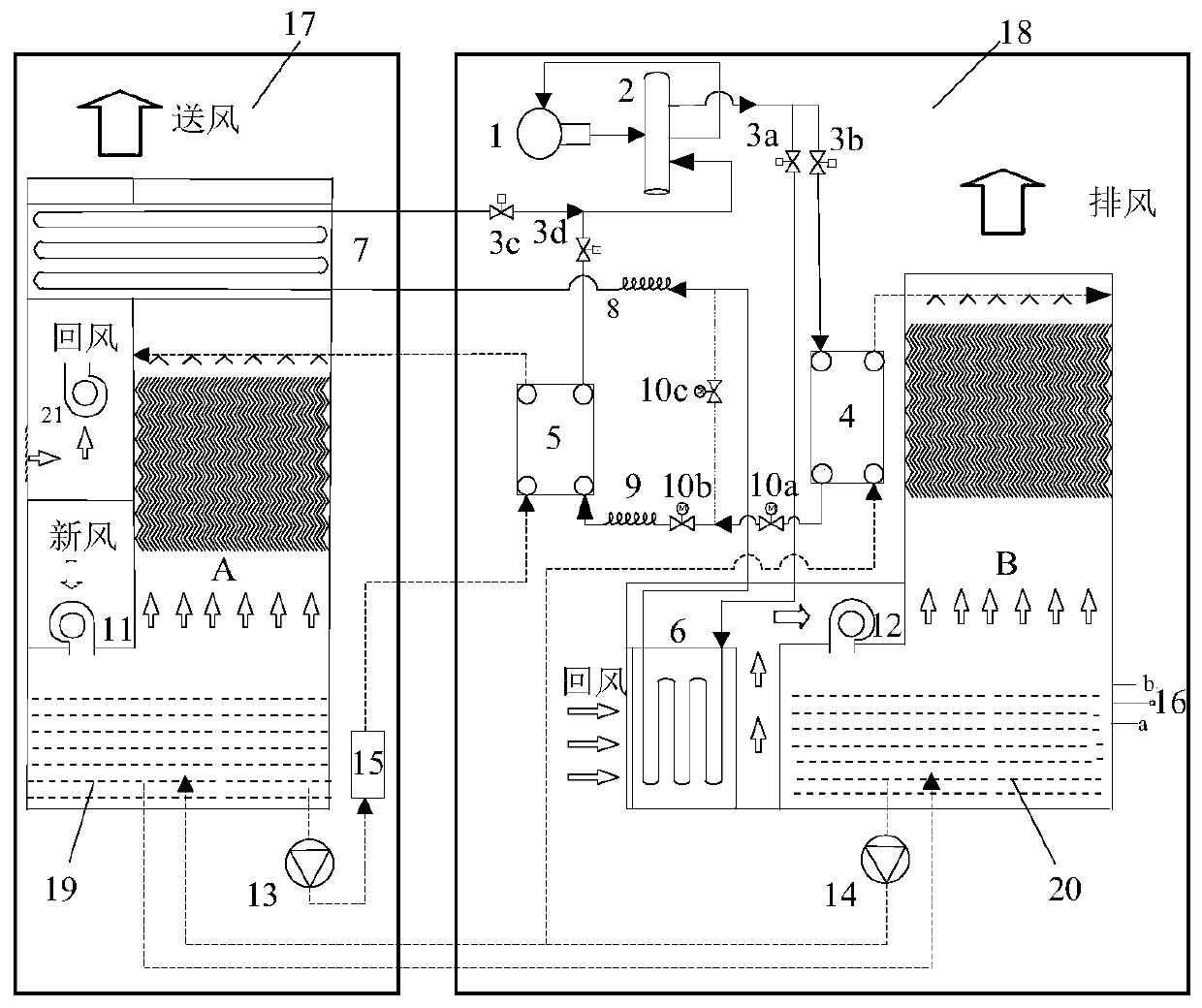

Two-sided liquid film reversal intercrossing double-dimension corrugated board absorber heat exchanging elements

InactiveCN101038136AIncrease the effective heat transfer areaHigh heat and mass transfer coefficientHeat transfer modificationLaminated elementsMass transferEngineering

The present invention discloses a double side liquid film reverse cross double scale ripple plate absorber heat exchanging element, which includes at least two groups double scale ripple plate heat conduction plate bundles (1) disposed vertically that has a double crossing harrow type guide devices (2) mounted between each corresponding pair of plates. The harrow type guide device (2) includes an upper edge (21), the lower surface of the upper edge (21) is disposed with a guide tongue (22), and the side surface of the upper edge (21) is disposed with a liquid blocking piece (23). The present invention can realize the reverse for the double side liquid film, and fully uses the heat conduction surface of the heat exchanging element, improves the absorb ability of the solution liquid film on the heat exchanging element, and has excellent strengthen heat conduction and mass transfer characteristics.

Owner:SOUTHEAST UNIV

Automatic dust removal board type falling film generation device utilizing waste heat of exhaust gas

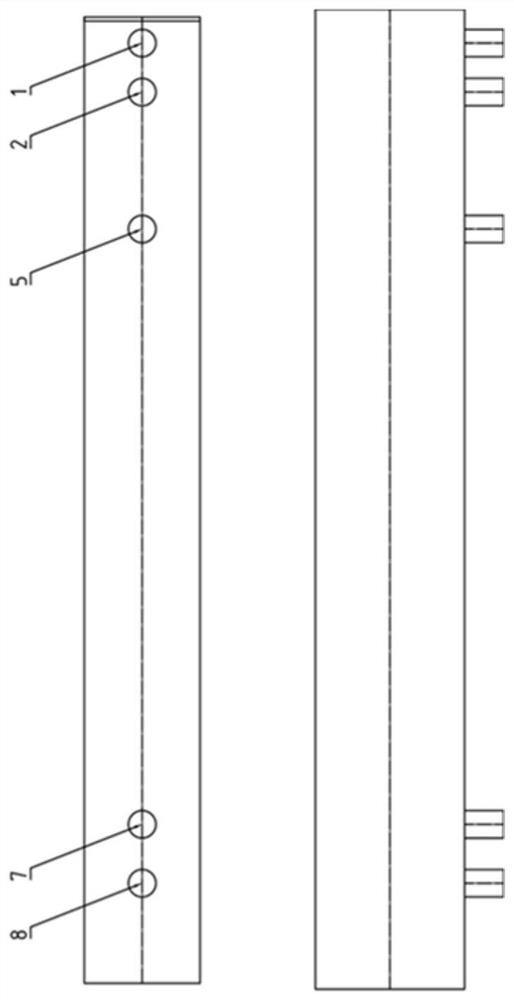

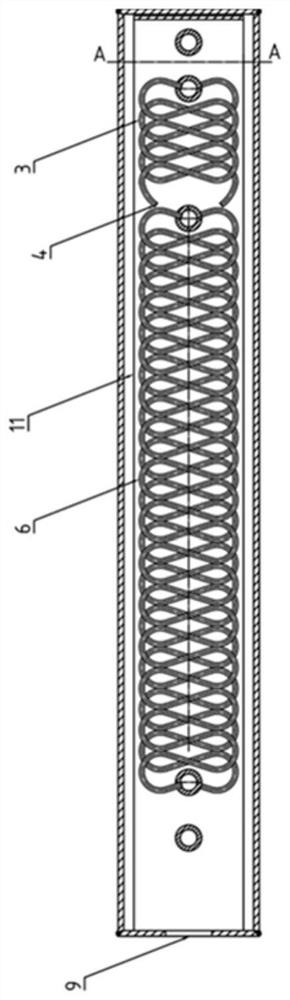

ActiveCN103994605AImprove heat transfer coefficientIncrease disturbanceBoilers/analysersSiphonProcess engineering

The invention discloses an automatic dust removal board type falling film generation device utilizing waste heat of exhaust gas. The automatic dust removal board type falling film generation device comprises a shell, n falling film units, a suspended liquid receiving tank, a suspension line and a siphon. A solution outlet is formed in the bottom end of the shell. Each falling film unit comprises a falling film board, an upper section S-shaped planer spring, a lower section S-shaped planer spring, a bar magnet and a dust scraping device, wherein the bar magnet and the dust scraping device are located on the two sides of the falling film board, the top end of the upper section S-shaped planer spring is connected with the wall face of the falling film board, the bottom end of the upper section S-shaped planer spring is connected with the top face of the bar magnet, the top end of the lower section S-shaped planer spring is connected with the bottom face of the bar magnet, and the bottom end of the lower section S-shaped planer spring is connected with the suspended liquid receiving tank. The siphon is located inside the suspended liquid receiving tank. According to the automatic dust removal board type falling film generation device, the siphon principle is utilized, by the arrangement of the S-shaped planer springs for automatic and reciprocating washing, springs on the falling film walls can move in an automatic and reciprocating mode, channeling or plumes can be effectively restrained from being generated, the liquid film distribution is uniformed, and the falling film generation device has the automatic scale removal function.

Owner:山东东岳能源交口肥美铝业有限责任公司

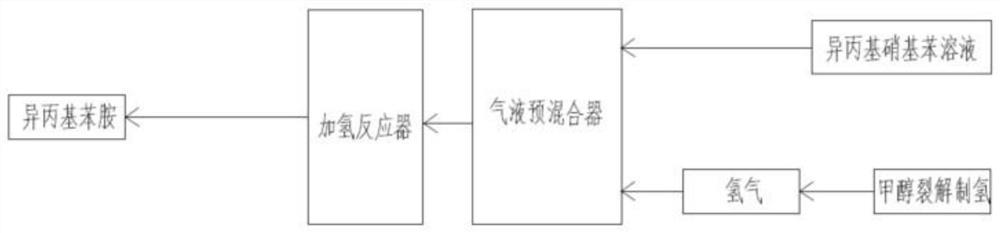

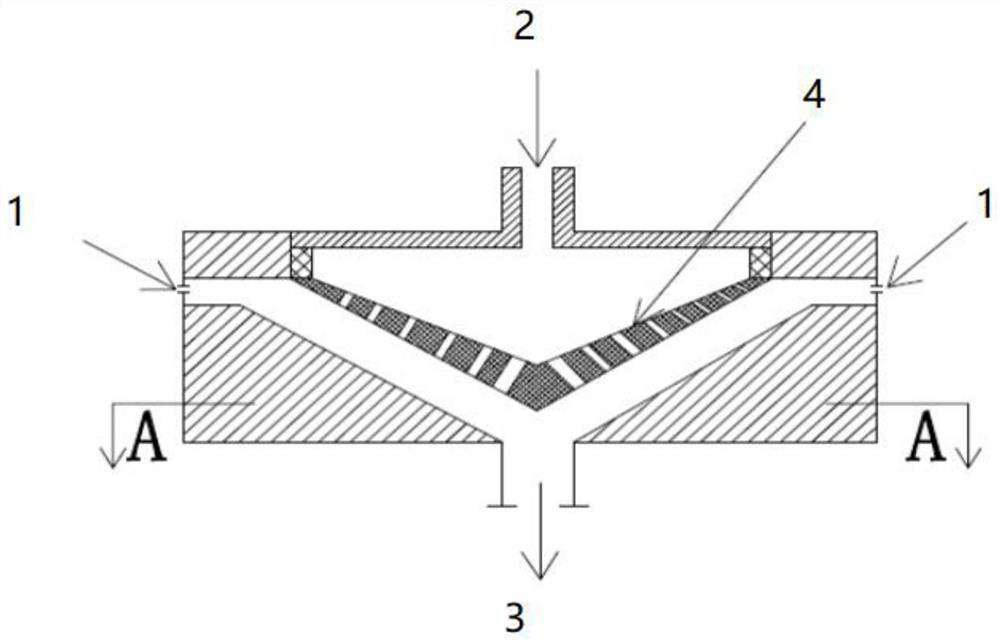

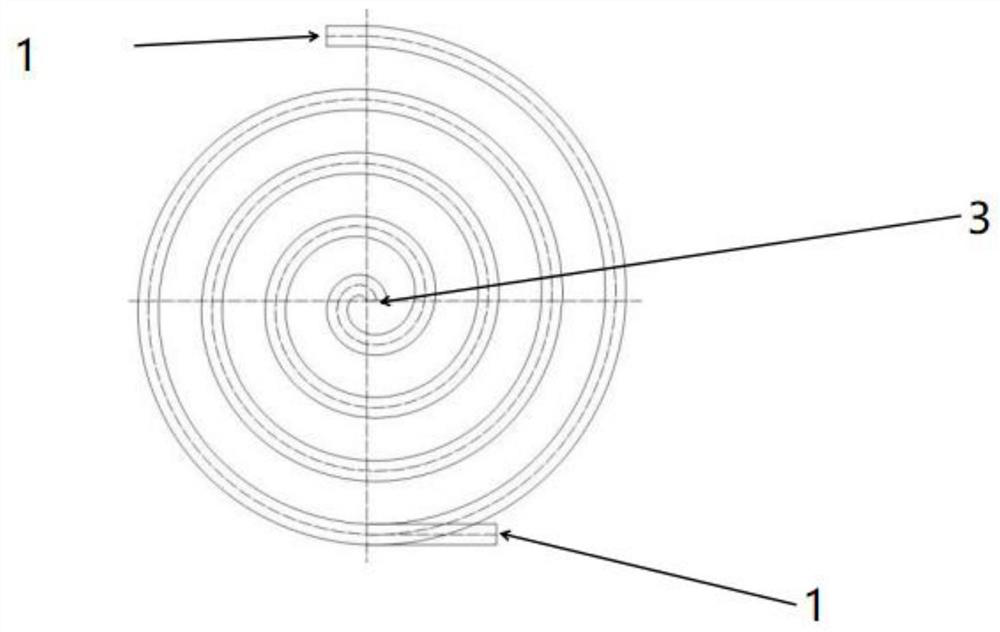

Method for preparing iso-propylaniline by novel hydrogenation technology

ActiveCN112430188AIncrease the concentration of the mixtureWell mixedOrganic compound preparationAmino compound preparationPtru catalystNitrobenzene

The invention provides a method for preparing iso-propylaniline by a novel hydrogenation technology. The method comprises the following steps of 1, sequentially putting isopropyl nitrobenzene and H2 conveyed through methanol cracking into a slit vortex gas-liquid mixer for mixing; 2, feeding a formed mixture into a millimeter hydrogenation reactor filled with a catalyst, and carrying out a hydrogenation reaction; and 3, putting the hydrogenated product into a gas-liquid separation tank, sending waste gas into a combustion furnace, and separating the iso-propylaniline mixture in a product rectifying tower to obtain the product iso-propylaniline. According to a millimeter tubular fixed bed hydrogenation reactor, a millimeter plate type hydrogenation reactor and a millimeter plate fin type hydrogenation reactor, due to the fact that the distance between tubes and plates is small, the heat and mass transfer boundary layer is smaller than 1 mm, the interphase heat and mass transfer area islarge, and the heat and mass transfer coefficient is high. According to the process, solvent-free hydrogenation is adopted, compared with an existing process, the steps of product desolvation and solvent circulation are omitted, energy consumption is reduced, and production cost is saved.

Owner:西安联众安科化工有限公司

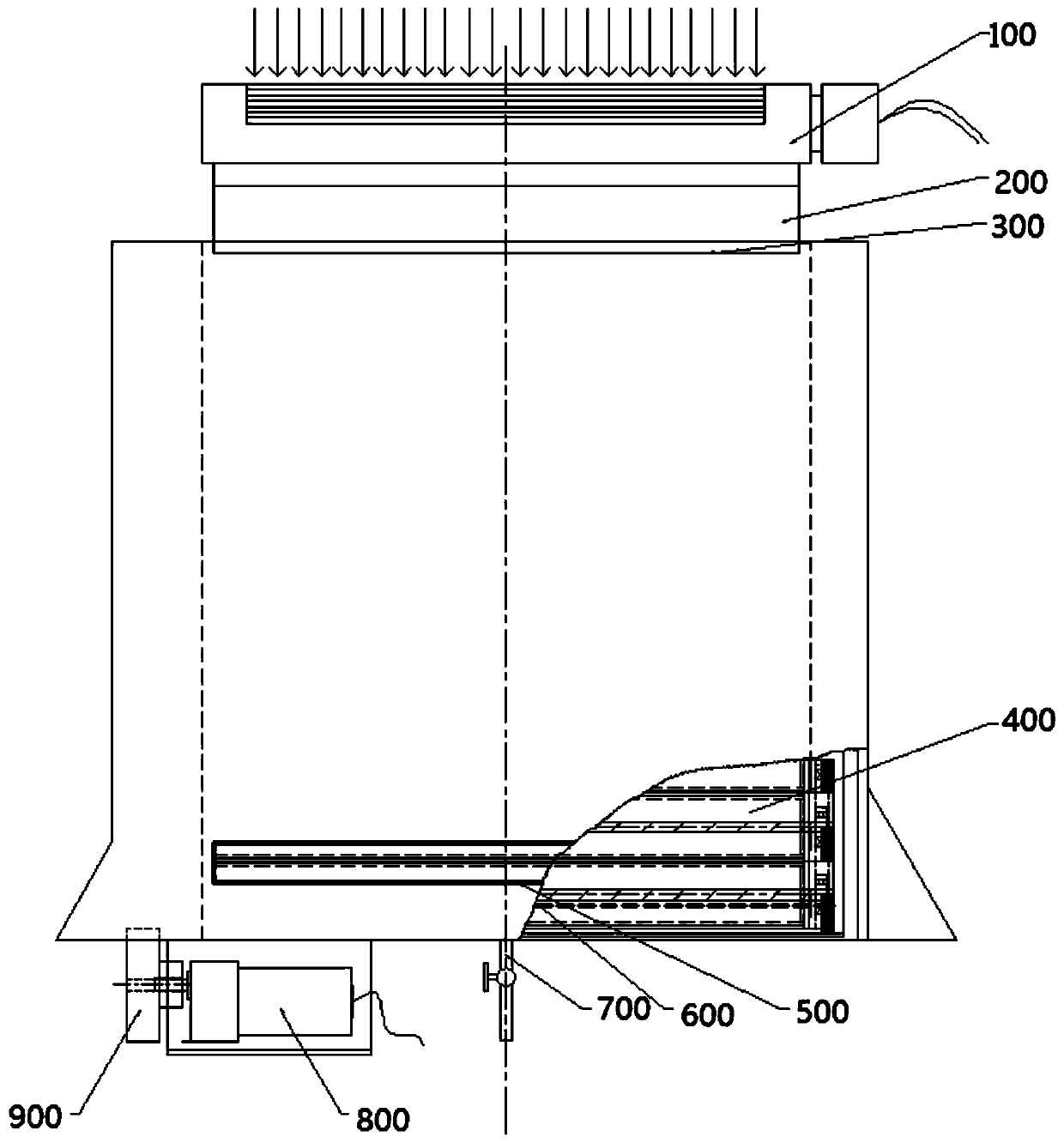

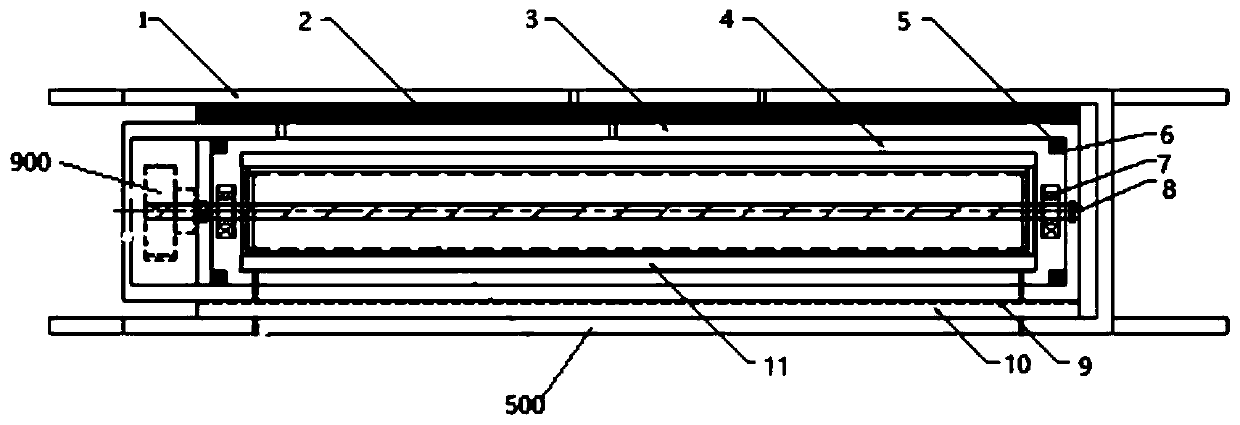

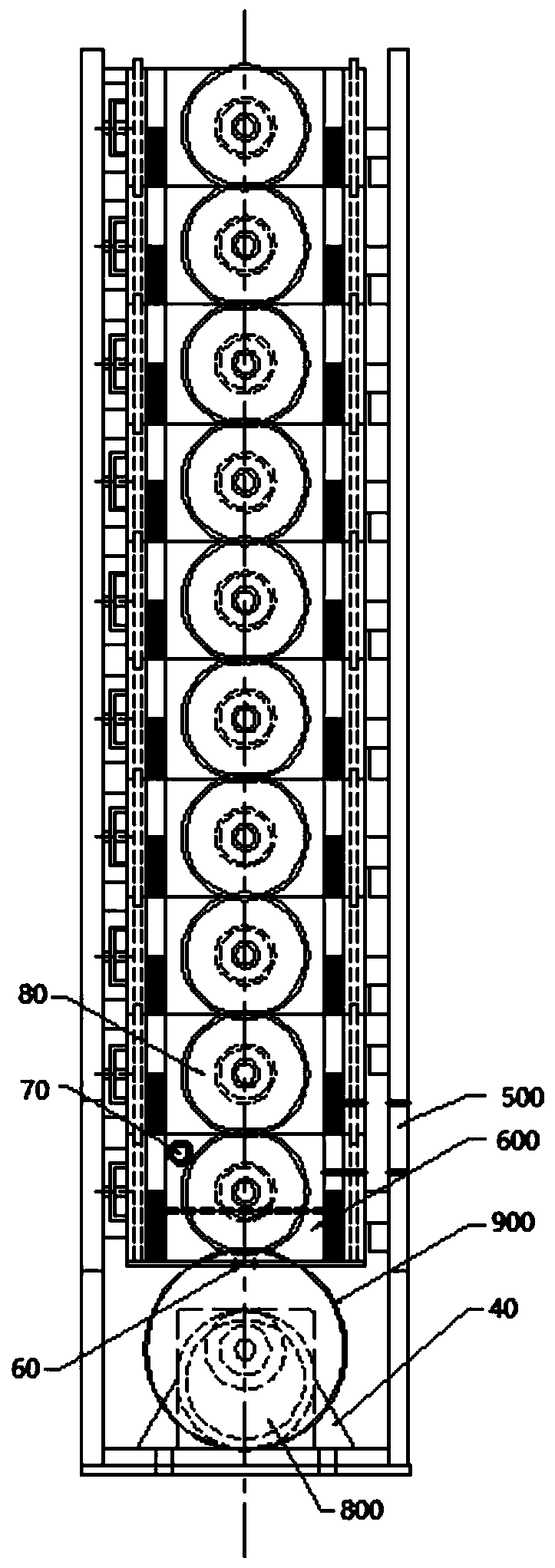

A device and method for triple utilization of exhaust steam waste heat of sludge superheated steam drying

ActiveCN105254147BHigh heat and mass transfer coefficientLarge specific heat capacitySludge treatment by de-watering/drying/thickeningCycloneCyclonic separation

The invention relates to a device and method for triple utilization of sludge superheated steam drying, exhaust steam and waste heat, including a shaftless screw feeder, a biaxial stirring dryer, a sludge particle forming machine and other components. Shaftless screw feeder, double-shaft stirring dryer, sludge granule forming machine, and mesh belt dryer are connected in sequence to form a logistics channel; heater, double-shaft stirring dryer, cyclone separator A, fan A, and air valve B are sequentially connected. The connection forms an internal circulation air flow channel; the shaftless screw feeder, cyclone separator B, heat exchanger B, and tail gas scrubber are connected in sequence to form an external air flow channel; the shaftless screw feeder, heat exchanger A, and sewage treatment system form a water cycle. Channel; heat exchanger, fan, mesh belt dryer form a combined drying. The invention has the beneficial effects of recovering the sensible heat and latent heat of exhausted steam at the same time, high efficiency and energy saving, and effective prevention of condensation; waste water recycling and zero-pollution discharge of waste gas; sludge is used to make fertilizer after forming, realizing sludge reuse.

Owner:NANCHANG HANGKONG UNIVERSITY

Superheated steam drying method for sludge and drying equipment

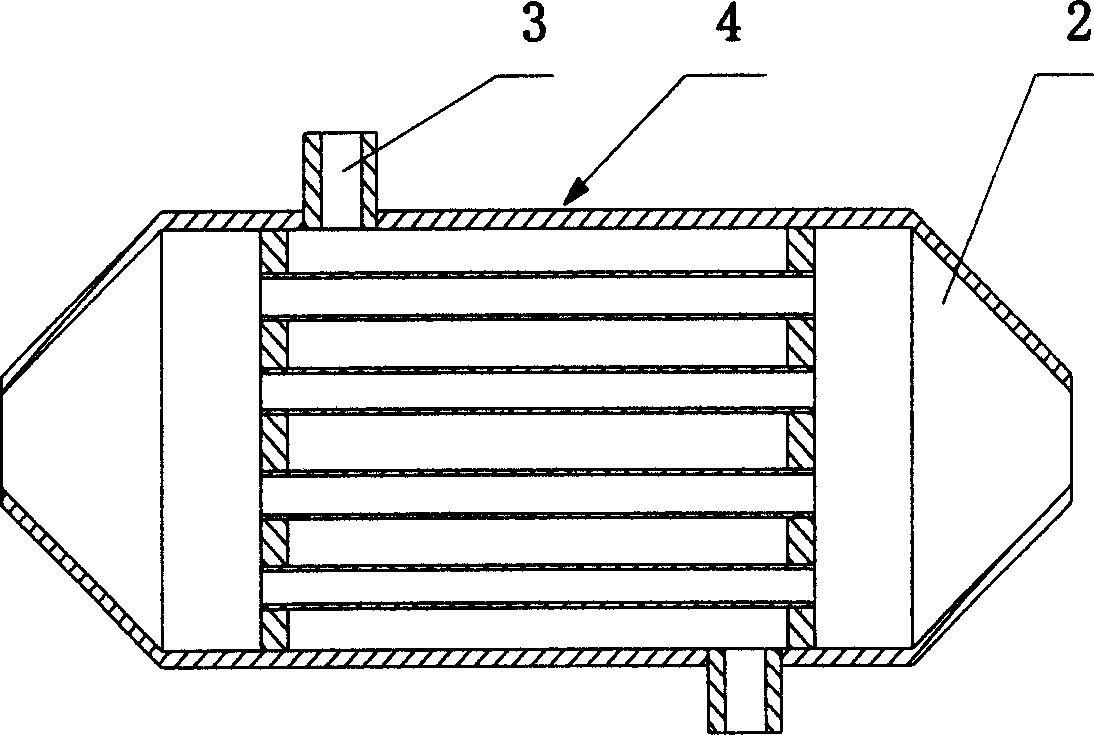

InactiveCN1280216CReduces the possibility of dry deflagrationReduce heat transfer areaSludge treatment by de-watering/drying/thickeningShell and tube heat exchangerSludge

The sludge drying method is to use a heat exchanger to recover the sensible heat and latent heat of the drying tail steam, exchange heat with water, and then heat it into superheated steam. The mud is exchanged for heat and mass, and the dried sludge and the dried tail steam are separated from the steam-solid to collect the dry sludge, and the separated dry tail steam is sent to the heat exchanger for heat recovery. The dried tail steam is exchanged After heating, it condenses into a saturated soda-water mixture, which is discharged after sewage treatment. The drying device consists of a shell-and-tube heat exchanger, a heater, a closed direct dryer and a vapor-solid separator. The tube side of the shell-and-tube heat exchanger leads to the liquid working medium, and its outlet is connected to the inlet of the heater to heat The outlet of the closed direct dryer is connected to the inlet of the closed direct dryer, the wet sludge inlet is provided in the closed direct dryer, the outlet of the closed direct dryer is connected to the inlet of the steam-solid separator, and the drying tail gas of the steam-solid separator The outlet is connected to the shell side of the shell and tube heat exchanger.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD +1

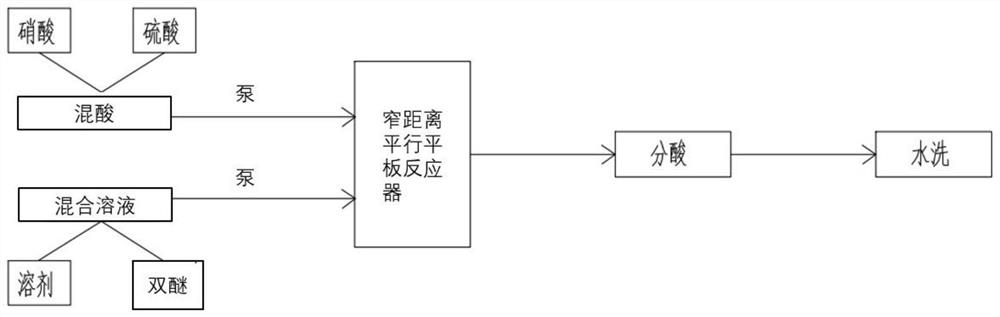

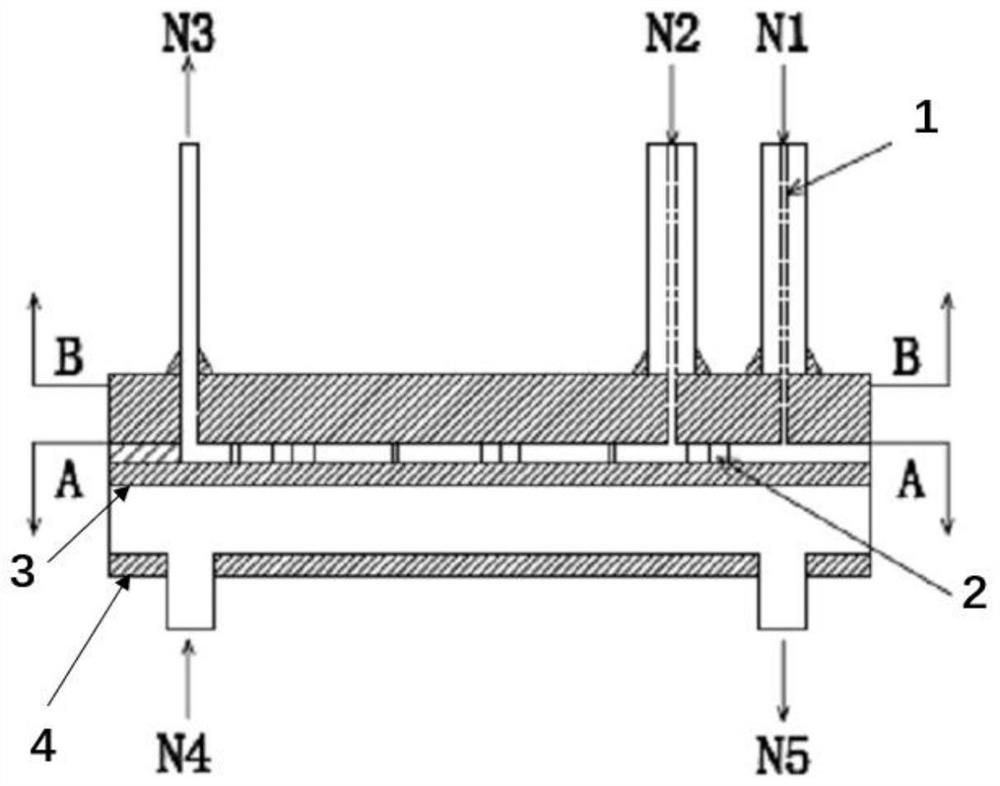

Process for synthesizing nitro diether by adopting narrow-distance parallel plate reactor

PendingCN112174826AEasy to removeShort reaction timeChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsMeth-Parallel plate

The invention belongs to the technical field of chemical engineering, and discloses a process for synthesizing an intermediate nitrodiether of oxyfluorfen by adopting a narrow-distance parallel platereactor, which comprises the following steps: by using 3, 4-dichlorobenzotrifluoride and resorcinol as raw materials, condensing to obtain 1, 3-bis[2-chloro-4-(trifluoromethyl)phenoxy]benzene, and carrying out a nitration reaction process on 1, 3-bis[2-chloro-4-(trifluoromethyl)phenoxy]benzene and a nitrating agent in a narrow-distance parallel plate reactor, so that nitro diether is prepared. Thecontinuous narrow-distance parallel plate reaction is adopted, so that huge heat generated by the reaction can be quickly removed, the reaction temperature can be controlled at 50-95 DEG C, the reaction time is greatly shortened, and the molar equivalent of reaction substances in the reaction process is extremely small, so that the reaction is intrinsically safe, the reaction risk is reduced, andthe process safety is improved.

Owner:西安本清化学技术有限公司

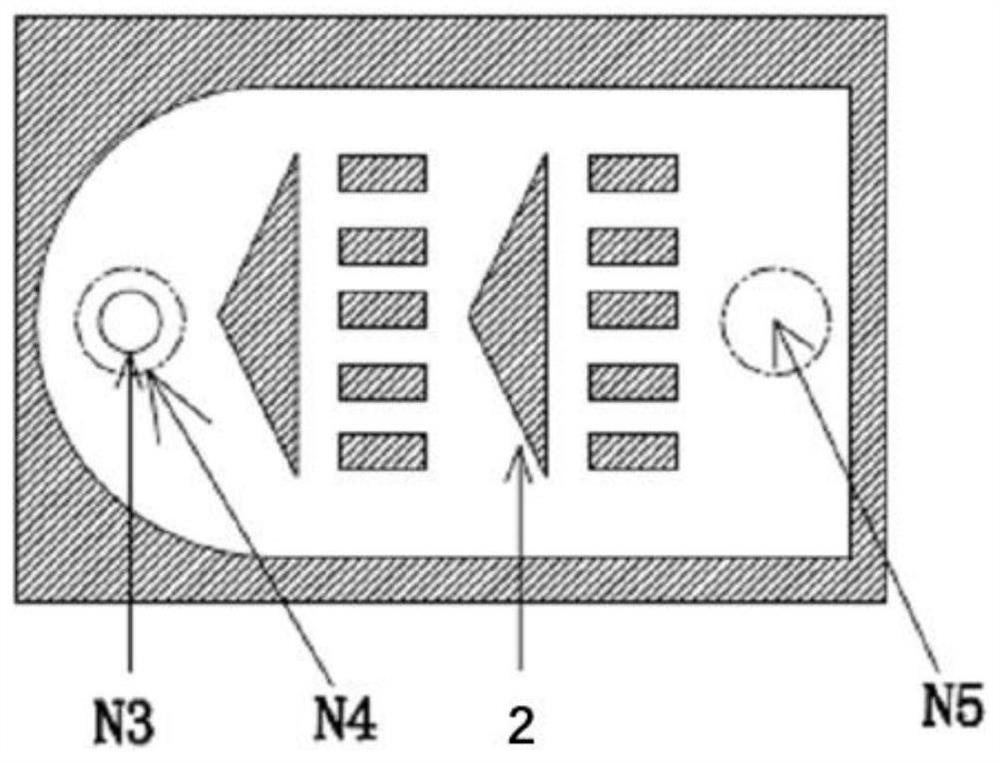

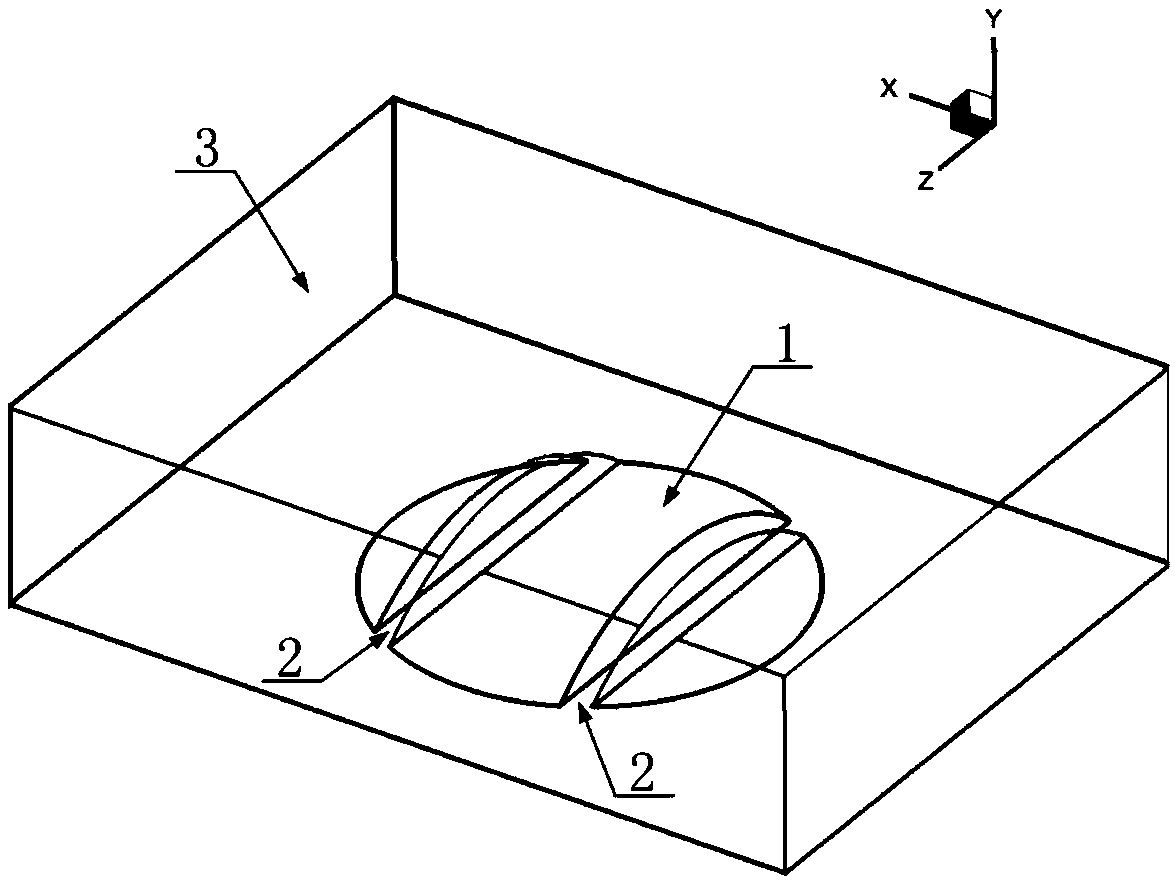

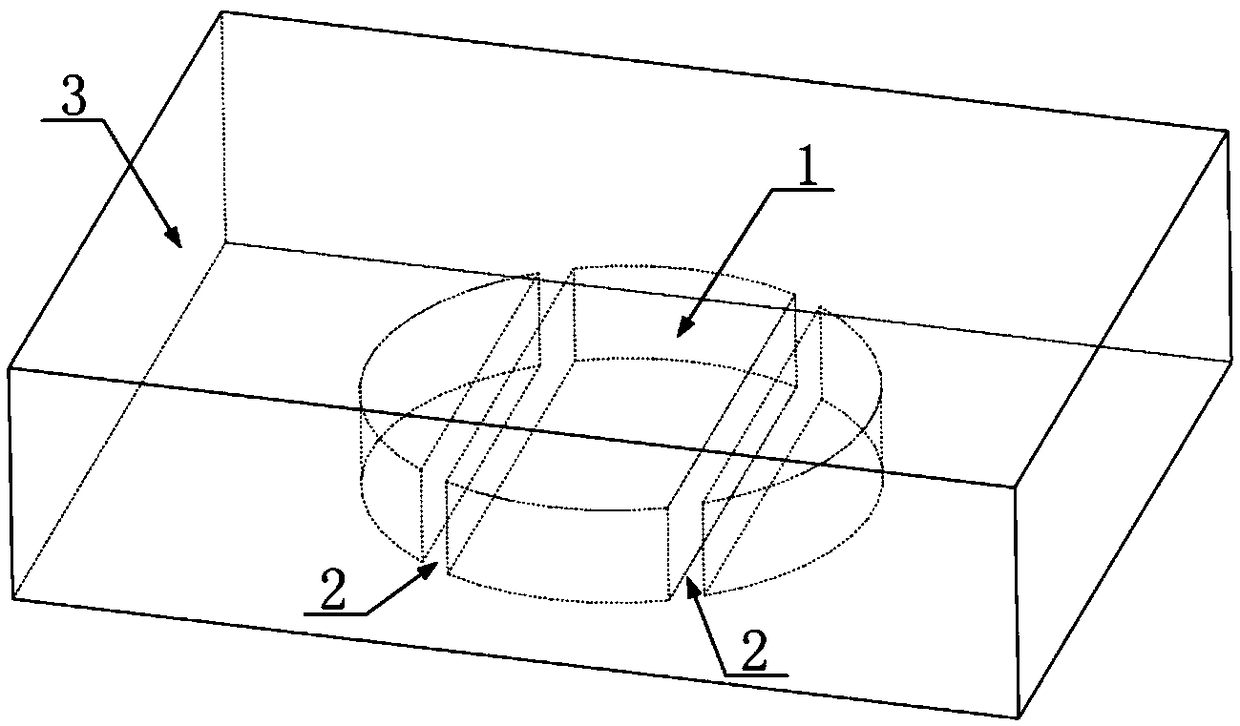

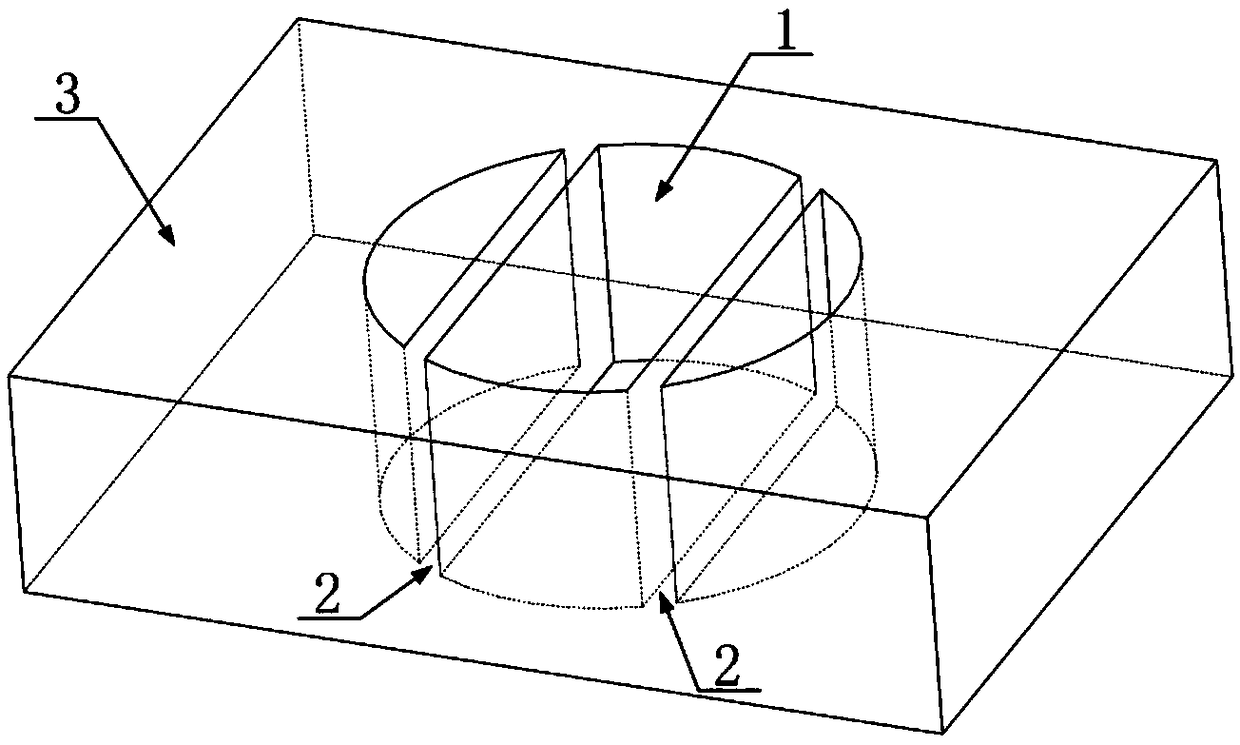

A heat and mass exchange enhanced structure and design method thereof

ActiveCN106323078BHigh heat and mass transfer coefficientIncrease fluid turbulenceHeat transfer modificationEngineeringDesign methods

The invention discloses a heat and mass transfer enhancement structure and a design method thereof. The heat and mass transfer enhancement structure comprises a flow control structure matrix, self-jet channels and a flow channel, wherein the flow control structure matrix adopts a bulged structure and is arranged on the inner or outer wall of the flow channel; the self-jet channels through which incoming main flow and an outlet position are connected are distributed in the flow control structure matrix in a penetrating manner; and the outlet position is the boundary of the core area of separating vortex or corner vortex and the flow control structure matrix or the boundary of the core area of wake and the flow control structure matrix. As a flow control structure with a self-jet function is adopted, the increase of flow resistance is smaller while the heat exchange performance is improved, further, the comprehensive heat and mass transfer efficiency of the channels can be greatly improved, accordingly, the equipment size is reduced and the economical efficiency and the safe reliability are improved.

Owner:XI AN JIAOTONG UNIV

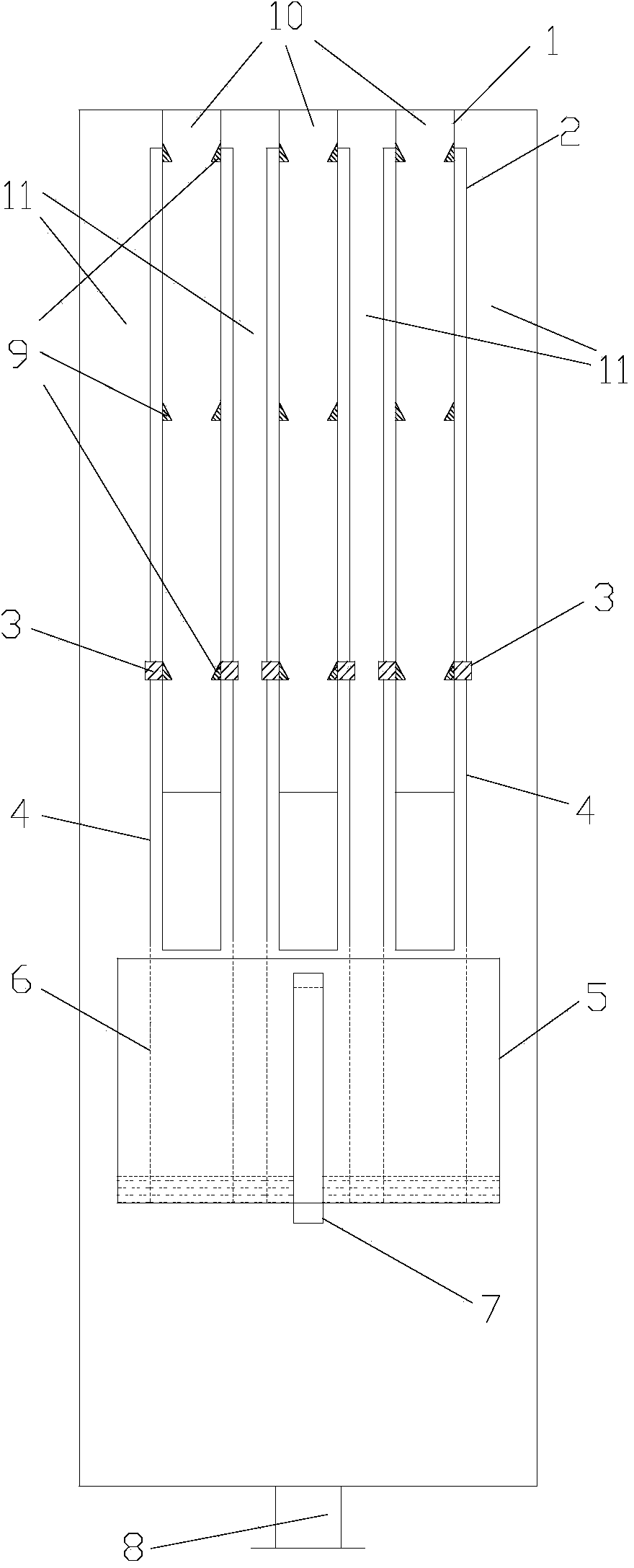

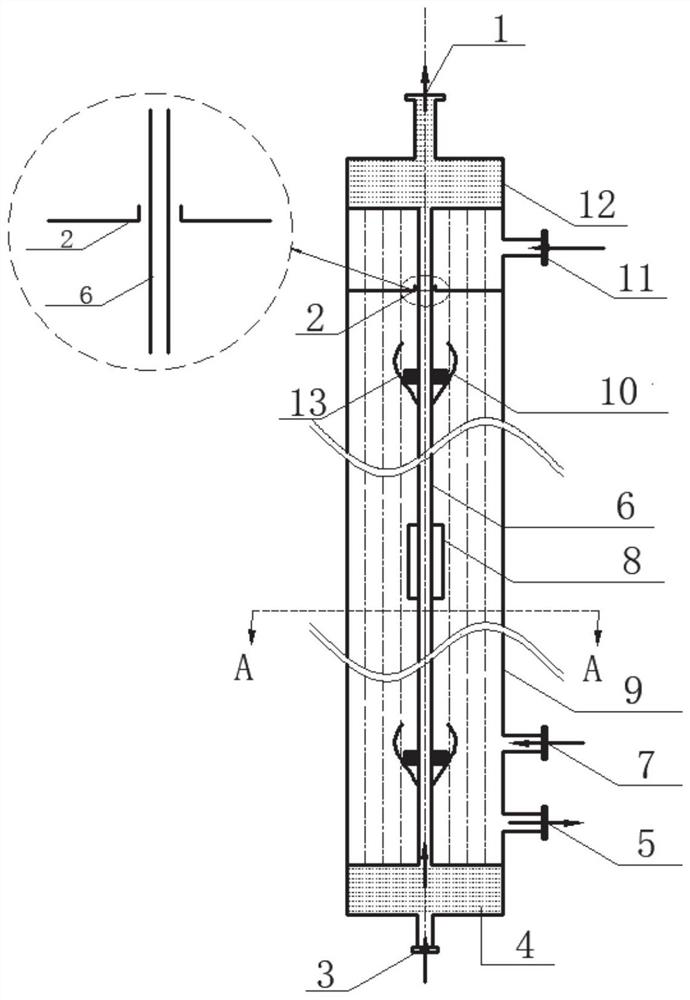

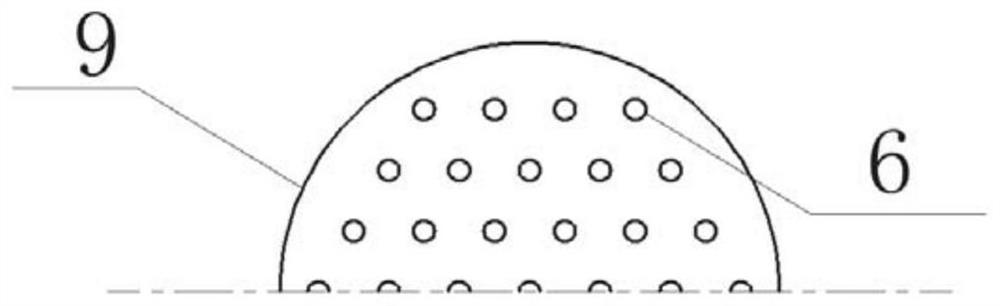

S-tube bundle falling film absorber

ActiveCN110813034BHas small-scale heat and mass transfer characteristicsHigh heat and mass transfer coefficientDispersed particle separationEngineeringMechanical engineering

The invention provides an S-shaped tube bundle falling film absorber, which includes a casing, a cylinder body, a liquid distribution device, a cooling device and a plurality of air holes, the cylinder body is arranged in the casing; the liquid distribution device and the cooling device are all arranged in the In the cylinder, the liquid distribution device is arranged above the cooling device; the air holes include a first air hole and a second air hole, and the first air hole and the second air hole are arranged on the side wall of the cylinder body; along the height direction, the liquid distribution device and the cooling device are both It is arranged between the first air hole and the second air hole; the bottom of the cylinder is also provided with an outlet. The invention adopts an "S-shaped" heat exchange tube bundle, which effectively improves the uniformity of liquid distribution of the solution outside the "S-shaped" heat exchange tube bundle. It has the advantages of large specific surface area, uniform liquid distribution, long time for the solution to reside on the heat exchange surface, and the induction of solution mixing to promote absorption, heat and mass transfer, etc., thereby significantly improving the absorption performance of falling film; when the characteristic size of the pipe diameter is small, it can realize small scale Heat and mass transfer.

Owner:SHANGHAI JIAO TONG UNIV

A household air conditioner and its operating method

ActiveCN107255311BPromotional useSmall sizeEnergy recovery in ventilation and heatingMechanical apparatusTemperature controlCoupling

The invention discloses a household type air conditioner and an operation method thereof, and belongs to the technical field of heating ventilation air conditioners. The household type air conditioner comprises a heat pump system, a solution humidifying system and a wind control system. The heat pump system comprises a compressor, heat exchangers, two-way expansion valves, a flow adjusting valve and an electric switch valve. The solution humidifying system comprises a solution pump, wet curtain packing and a liquid arrangement device, and meanwhile, the solution humidifying system comprises a solution filtering device and a return air energy recovery device. The wind control system mainly comprises a return air and new air blower, an air supply parameter inductor and a mechanical air exhausting system. The household type air conditioner with new air is designed by adopting a solution humidifying technology, through the air conditioner, temperature control and humidity control are conducted on the outdoor new air, temperature control is conducted on the indoor return air, then the outdoor new air and the indoor return air are sent to indoor, for the problem of lack of the new air of indoor air adjusting of a household type building in the prior art, the solution humidifying technology can be directly used for household air conditioner equipment, and the problem that water supplement is needed owing to too much heat brought by a heat pump coupling solution humidifying technology is solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

An in-pipe redistribution film generating device for automatically cleaning smoke and dirt outside the pipe

ActiveCN103994606BImprove mass transfer coefficientImprove heat transfer coefficientBoilers/analysersSiphonAgricultural engineering

The invention discloses an inter-pipe redistributed film generation device capable of automatically cleaning away smoke dirt outside a pipe. The inter-pipe redistributed film generation device comprises a shell, an upper baffle, a lower baffle, a film distribution unit and a hoisting liquid receiving pot. A siphon pipe is arranged in the hoisting liquid receiving pot. Each film distribution unit comprises an initial film distribution device, a fixed pulley, a movable pulley, a pulley line, a falling film pipe, a film redistribution device, an ash scraping ring and a bearing rope, wherein the top end of the falling film pipe is connected to the upper baffle, the bottom end of the falling film pipe is connected to the lower baffle, the initial film distribution device is located in a through hole in the upper baffle, the fixed pulley is fixedly connected to the initial film distribution device, the two ends of the pulley line are connected to a pulley hook of the fixed pulley and the top end of the film redistribution device, the ash scraping ring is located outside the falling film pipe, magnetic force exists between the ash scraping ring and the film redistribution device, and the two ends of the bearing rope are connected with the movable pulley and the hoisting liquid receiving pot. In the inter-pipe distributed film generation device, the film redistribution devices can reciprocate in the pipe for film redistribution, occurrence of channeling or plume is effectively restrained, liquid film distribution is uniformized, and dust accumulated outside the pipe is removed through the ash scraping devices outside the pipe.

Owner:山东东岳能源交口肥美铝业有限责任公司

Ammonia water absorption refrigerator absorber for improving ammonia water falling film type absorption performance

ActiveCN112539570AIncrease contact areaImprove cooling effectAbsorbers/adsorbersLiquid spraying apparatusAmmonia gasMaterials science

The invention provides an ammonia water absorption refrigerator absorber for improving ammonia water falling film type absorption performance. The ammonia water absorption refrigerator absorber comprises a shell, a plurality of falling film tubes are arranged in the shell, a passages where absorption liquid and ammonia gas reverse flow are formed outside the falling film tubes, cooling water passages are formed inside the falling film tubes, and cooling water and absorption liquid flow reversely; a plurality of groups of ultrasonic atomizers are arranged on the outer wall of each falling filmtube at intervals along the flowing direction of the absorption liquid, and the ultrasonic atomizers generate high-frequency oscillation to atomize a solution flowing through the outer walls of the falling film tubes into fine liquid drops and diffuse the fine liquid drops into a cavity formed by each falling film tube and the shell to absorb ammonia gas; and at least one group of ultrasonic oscillators are arranged on the outer wall of each falling film tube in the absorption liquid flowing direction. The absorption effect of the absorber is remarkably improved, an absorption solution with higher concentration is obtained, the area of the falling film tubes needed by the absorber is reduced, the circulation ratio of an absorption refrigeration system is reduced, and therefore the overallperformance of the system is improved.

Owner:SOUTHEAST UNIV

Multi-stage roller linked evaporative cooling system

PendingCN110345588AEven and sufficient water film on the wet surfaceImprove cooling efficiencyLighting and heating apparatusSpace heating and ventilation detailsEvaporative coolerChiller

The invention provides an evaporative cooling system which comprises a fan, an evaporation device, a water drainage device and a drive device. The evaporation device comprises a multi-stage linked roller set and a water storage box, and the water storage box is arranged at the bottom of the multi-stage linked roller set. The fan is arranged at the top of the evaporation device. The water drainagedevice is arranged at the bottom of the water storage box. The drive device is connected with the evaporation device and used for driving the evaporation device to run. A ventilation cooling system comprises a building wall and the evaporative cooling system, and the evaporative cooling system is arranged in the building wall. Compared with a traditional roller type evaporative cooler, the wet superficial area of multi-stage rollers is increased by more than three times, the heat and mass transfer area of air and water is larger, and the heat and humidity transfer effect is better.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

An automatic ash-removing plate-type falling film generating device utilizing the waste heat of flue gas

ActiveCN103994605BImprove heat transfer coefficientIncrease disturbanceBoilers/analysersSiphonFlue gas

The invention discloses an automatic ash-removing plate-type falling film generating device utilizing the residual heat of flue gas, which comprises a housing, n falling film units, a suspended liquid receiving box, a suspension wire and a siphon tube, and a solution outlet is provided at the bottom of the housing ; Each falling film unit includes a falling film plate, an upper S-shaped planar spring, a lower S-shaped planar spring, a bar magnet and ash scraping device; in each falling film unit, the bar magnet and ash scraping device are located on the falling film plate Both sides; the top of the upper S-shaped planar spring is connected to the wall of the falling film plate, and the bottom is connected to the top surface of the bar magnet; the top of the lower S-shaped planar spring is connected to the bottom of the bar magnet, and the bottom is connected to the suspension On the hanging liquid tank; the siphon is located in the hanging liquid tank. The falling film generating device uses the principle of siphon, and by setting an S-shaped planar spring for automatic reciprocating cleaning, the spring on the wall of the falling film can automatically reciprocate, effectively inhibiting the generation of channel flow or stream flow, homogenizing the distribution of the liquid film, and having automatic cleaning. dirt function.

Owner:山东东岳能源交口肥美铝业有限责任公司

Absorber for Ammonia Water Absorption Refrigerator with Enhanced Ammonia Water Falling Film Absorption Performance

ActiveCN112539570BIncrease contact areaImprove cooling effectAbsorbers/adsorbersLiquid spraying apparatusHigh concentrationUltrasonic oscillation

The invention provides an absorber for an ammonia water absorption refrigerating machine that improves the falling film absorption performance of ammonia water. It includes a shell, in which a plurality of falling film tubes are arranged, and the outside of the falling film tubes forms a passage for the reverse flow of the absorption liquid and the ammonia gas. A cooling water passage is formed inside the falling film tube, and the cooling water and the absorption liquid flow in reverse; multiple sets of ultrasonic atomizers are arranged at intervals along the flow direction of the absorption liquid on the outer wall of each falling film tube. The solution passing through the outer wall of the falling film tube is atomized into fine droplets and diffuses into the cavity formed by each falling film tube and the shell to absorb ammonia gas; on the outer wall of each falling film tube is set at least one set of ultrasonic vibration along the flow direction of the absorption liquid device. The invention significantly improves the absorption effect of the absorber, obtains a higher-concentration end-of-absorption solution, reduces the area of the falling film tube required by the absorber, and reduces the cycle rate of the absorption refrigeration system, thereby improving the overall performance of the system.

Owner:SOUTHEAST UNIV

A gas-liquid total heat exchange device with built-in cold and heat source based on metal fiber filler

ActiveCN105890147BIncrease contact areaExtension of timeSpace heating and ventilation detailsTrickle coolersContact timeHeat mass transfer

Owner:BEIJING KANGFU TECH

Refractory poor iron ore pulsating fluidized bed magnetizing roasting device and roasting method

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com