Superheated steam drying method for sludge and drying equipment

A technology of superheated steam and drying method, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc., which can solve the problems of complicated drying process and equipment, large heat loss of drying tail gas, and poor economic efficiency of the drying process, so as to shorten the drying time and reduce fuel consumption. The effect of high operating cost and reduced heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A sludge drying method using superheated steam as the drying medium, using a heat exchanger to recover the sensible heat and latent heat in the drying tail steam, making it exchange heat with water, and then heating it into superheated steam, then passing it into a closed direct In the type dryer, the superheated steam exchanges heat and mass with the wet sludge added to the dryer, and then the dried sludge and the dry tail steam are subjected to vapor-solid separation, and the dried sludge is collected, and the separated dry tail The steam is then sent to the heat exchanger for heat recovery so as to participate in the next drying cycle. The dry tail steam is condensed into a saturated steam-water mixture after heat exchange and discharged after sewage treatment. In the present invention, the above water is a liquid working Medium, the present invention can adopt Freon (model can be R12, R22 etc.), methanol, ethanol or ether and other liquid working media as equivalent ...

Embodiment 2

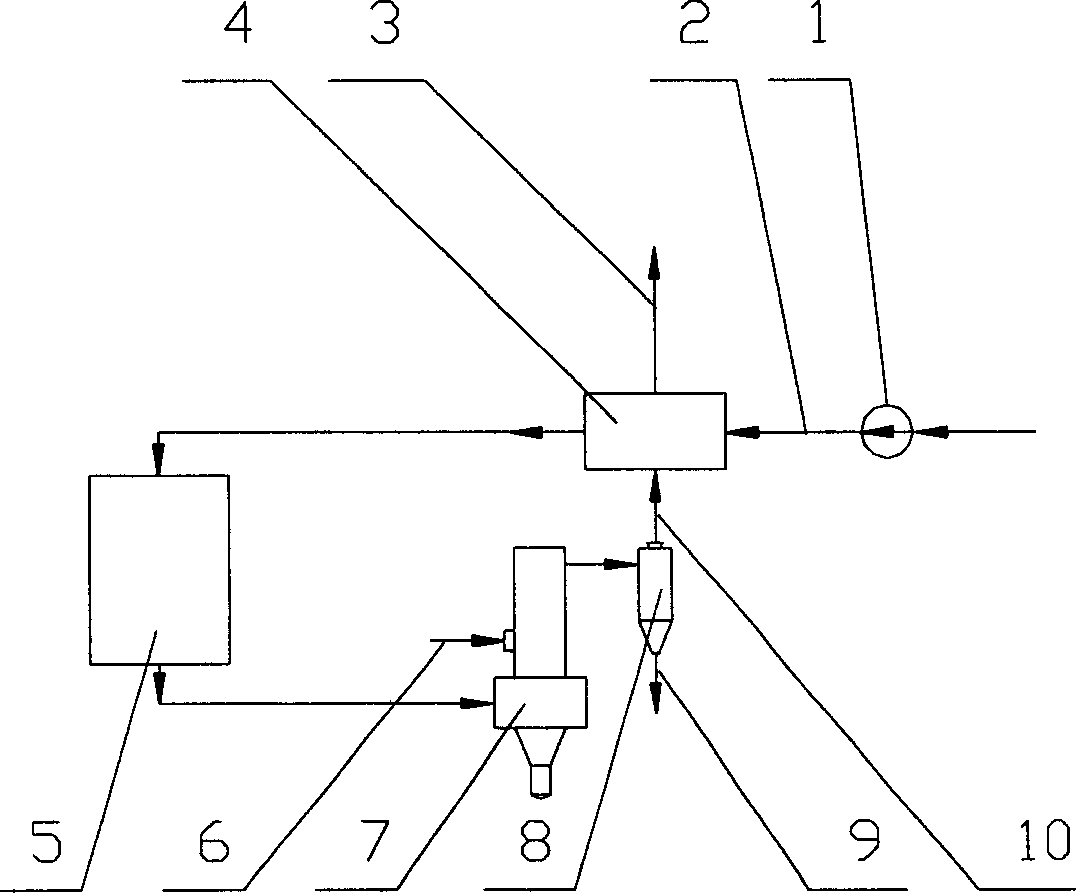

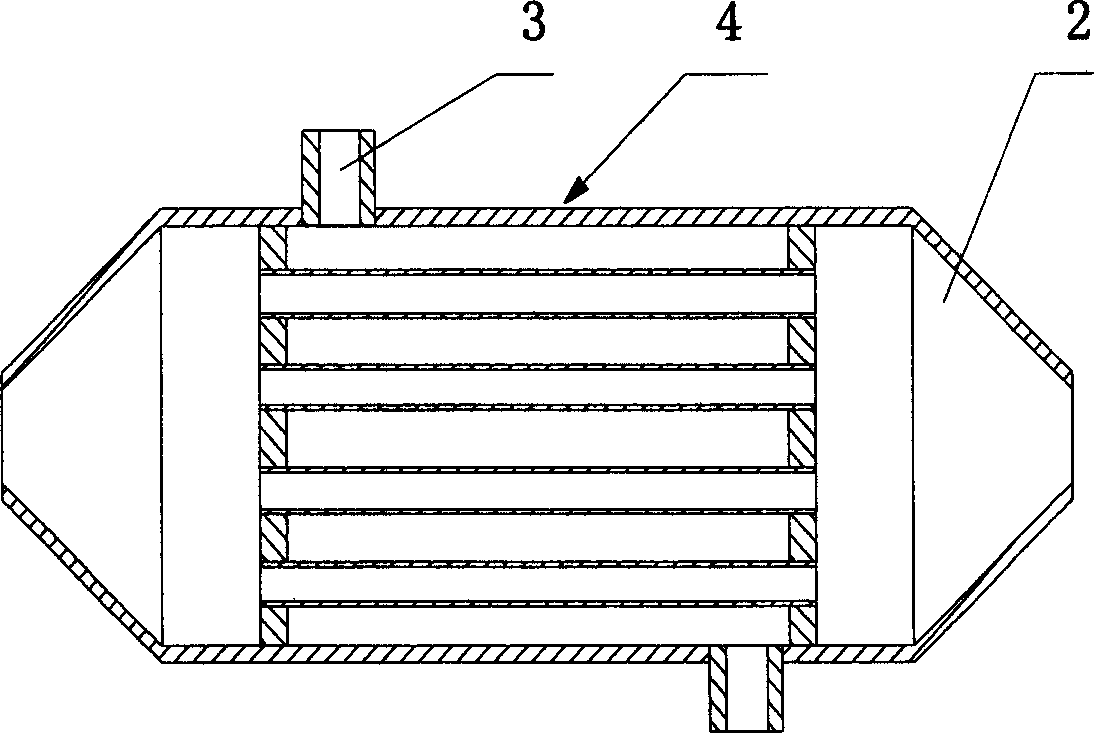

[0014] A drying device for implementing the above superheated steam drying method, consisting of a shell-and-tube heat exchanger 4, a heater 5, a closed direct dryer 7 and a vapor-solid separator 8, the tubes of the shell-and-tube heat exchanger 4 The channel inlet 2 is connected to the outlet of the water pump 1, and the tube side outlet is connected to the inlet of the heater 5, and the outlet of the heater 5 is connected to the inlet of the closed direct dryer 7, and the closed direct dryer 7 is equipped with wet sludge to add Port 6, the outlet of the closed direct dryer 7 is connected to the inlet of the vapor-solid separator 8 , and the dry tail gas outlet 10 of the vapor-solid separator 8 is connected to the shell side of the shell-and-tube heat exchanger 4 .

[0015] Working process of the present invention is as follows:

[0016] After the water is pressurized by the water pump 1, it enters the shell-and-tube heat exchanger 4 from the tube side inlet 2. After absorbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com