Enhanced heat-conductive louver sheets

A louver fin, heat transfer enhancement technology, applied in heat exchange equipment, lighting and heating equipment, tubular elements, etc., can solve problems such as increased air flow resistance, and achieve the effect of improving heat transfer performance and reducing heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

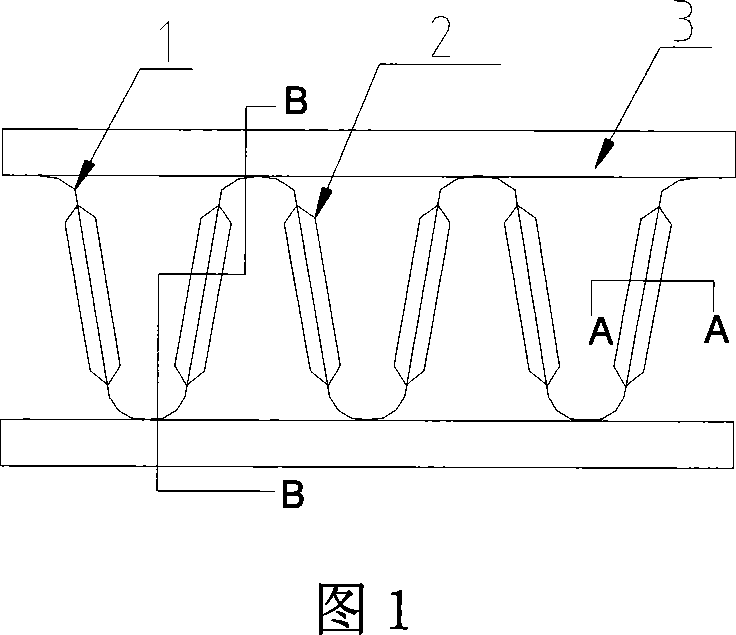

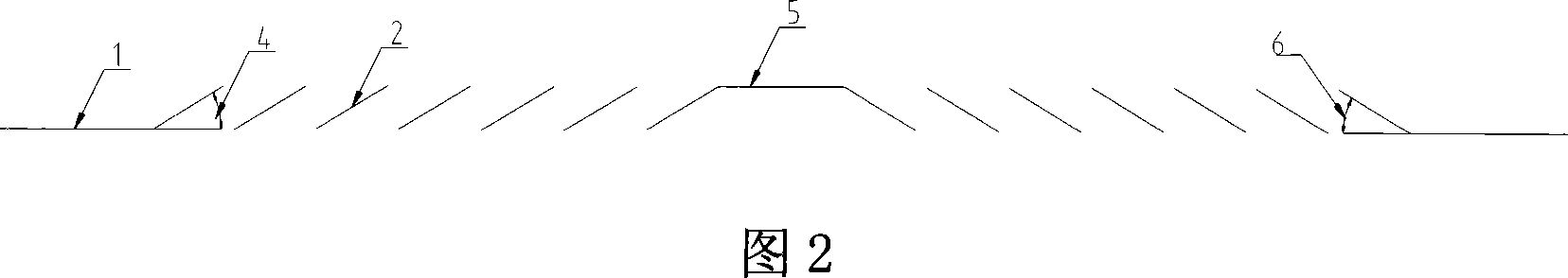

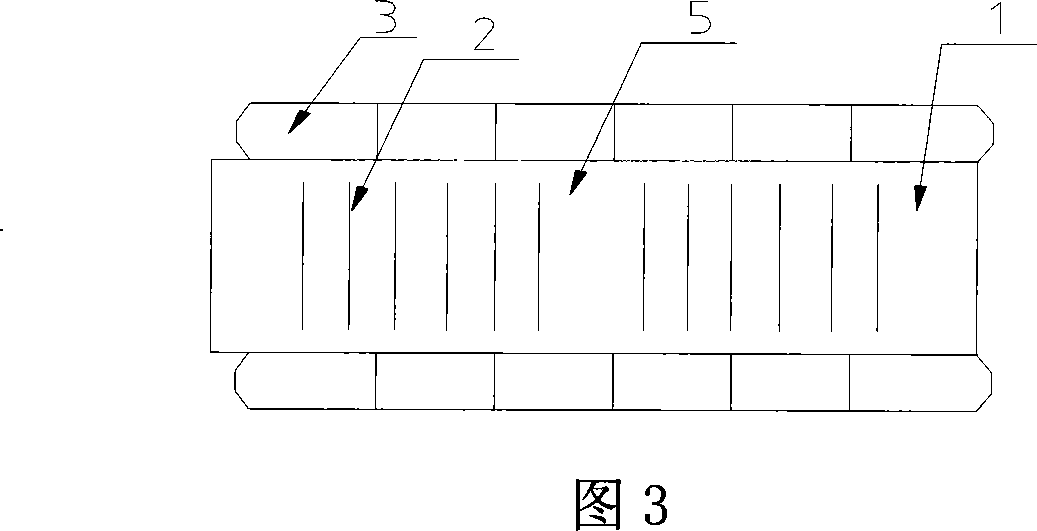

[0025] As shown in FIGS. 1 , 2 and 3 , this embodiment includes: a flat substrate 1 and a window fin 2 . The connection relationship is as follows: several groups of window fins 2 are provided on the straight substrate 1, and the flat substrate 1 is connected to the roots of the window fins 2, and forms a window opening angle with the window fins 2; between each group of window fins is the reversing area 5, and the window opening directions of the window fins 2 on both sides of the reversing area 5 are opposite; the window opening angles of the window fins 2 in each group of window...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com