Water logging and air cooling combined passive containment cooling system and method

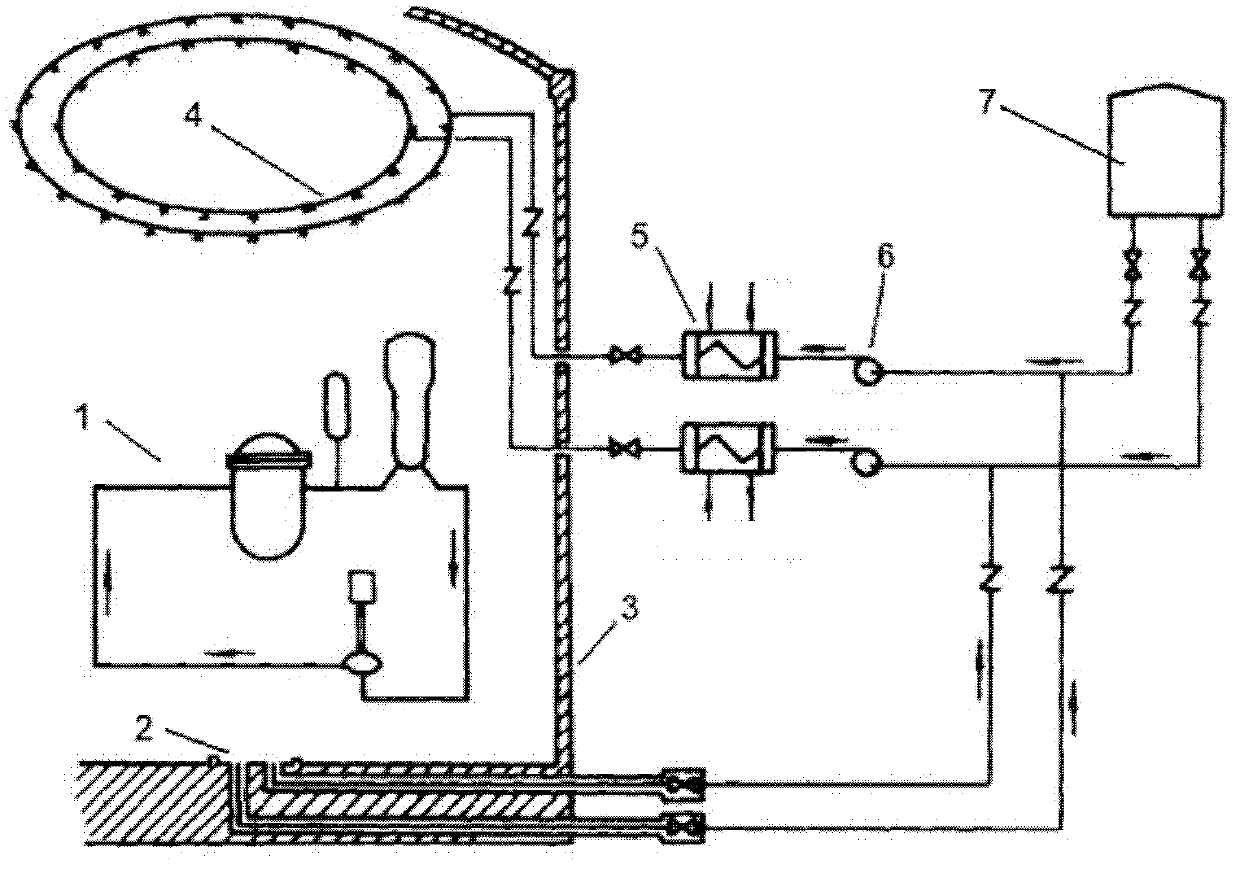

A passive containment and cooling system technology, applied in the field of containment cooling systems, can solve problems such as potential safety hazards and system inability to perform functions, and achieve the effects of speeding up switching, facilitating heat transfer, and small water storage cross-sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

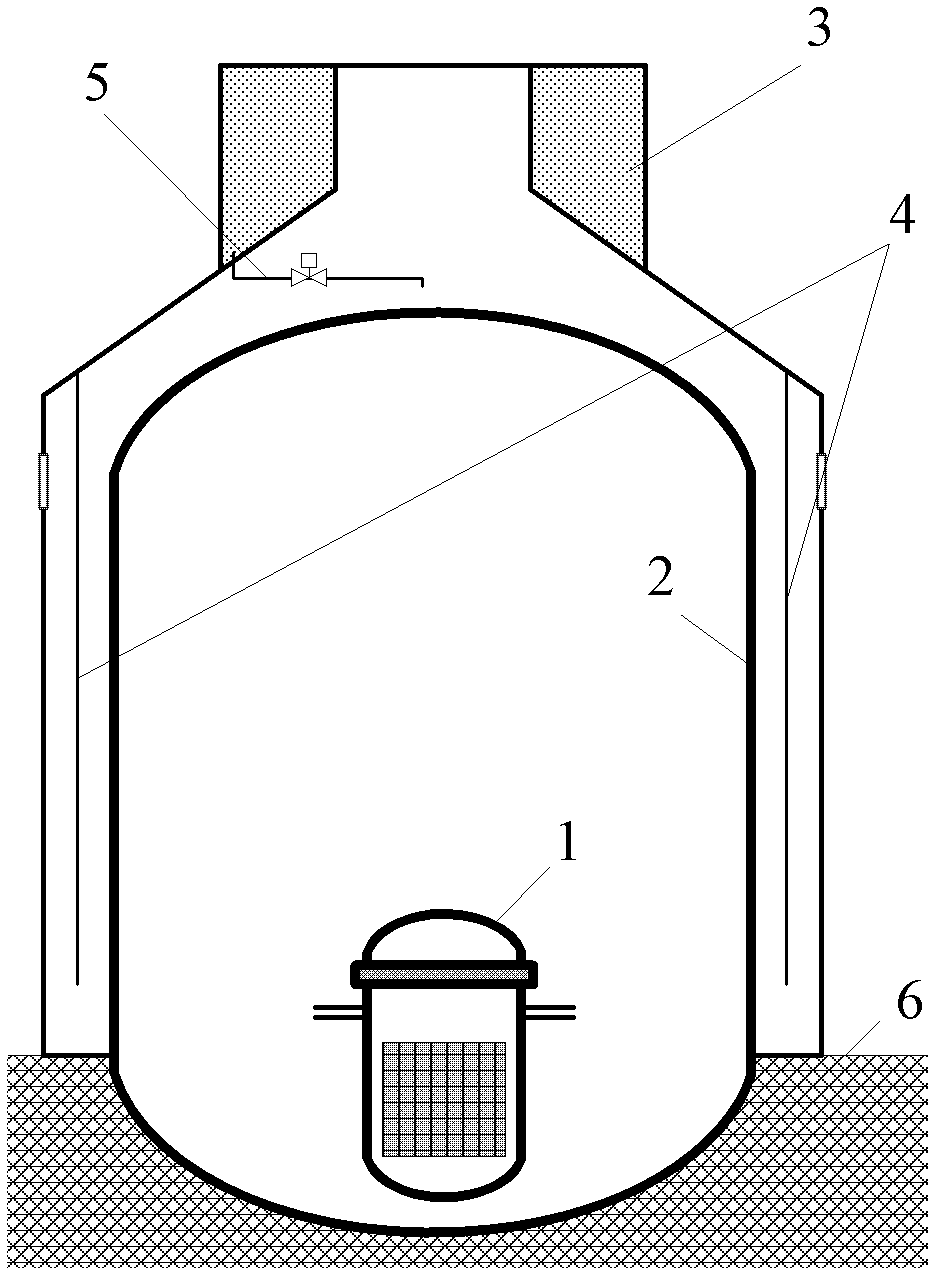

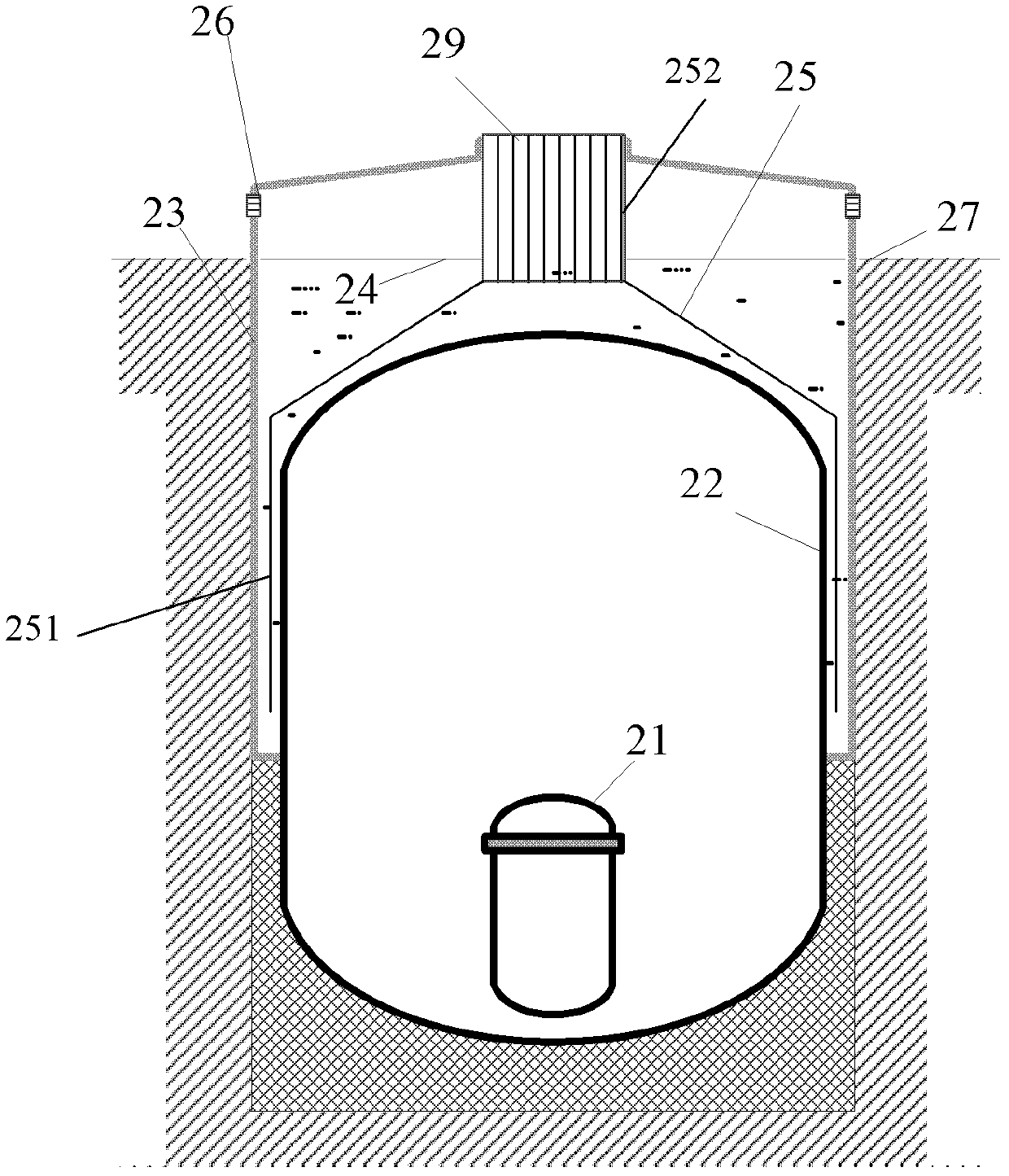

[0025] Such as image 3 As shown, in an embodiment of the present invention, the passive containment cooling system includes a steel containment container 22 , a cooling water pool 23 and an air shroud 25 . The steel containment vessel (ie containment vessel) 22 is completely submerged in an external cooling water pool 23 in normal standby condition, and the water pool 23 is a decay heat sink for the containment vessel in case of an accident. An air guide 25 is arranged inside the pool 23 and outside the steel containment container 22, the air guide 25 has a surrounding portion 251 surrounding the containment 22 and a guide portion 252 with an air outlet 29 above the top of the containment 22, The surrounding part 251 and the guide part 252 are connected as a whole, and the cooling water pool 23 has an air inlet 26. From the air inlet 26 of the cooling water pool, to the bottom of the surrounding part 251 of the air guide cover 25, and then to the guide part 252, a chimney is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com