Patents

Literature

71results about How to "Stable heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

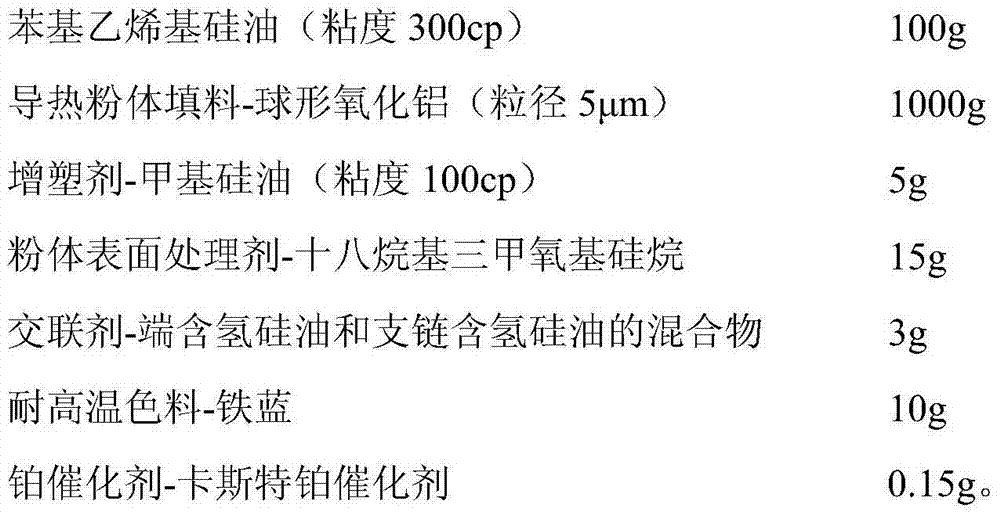

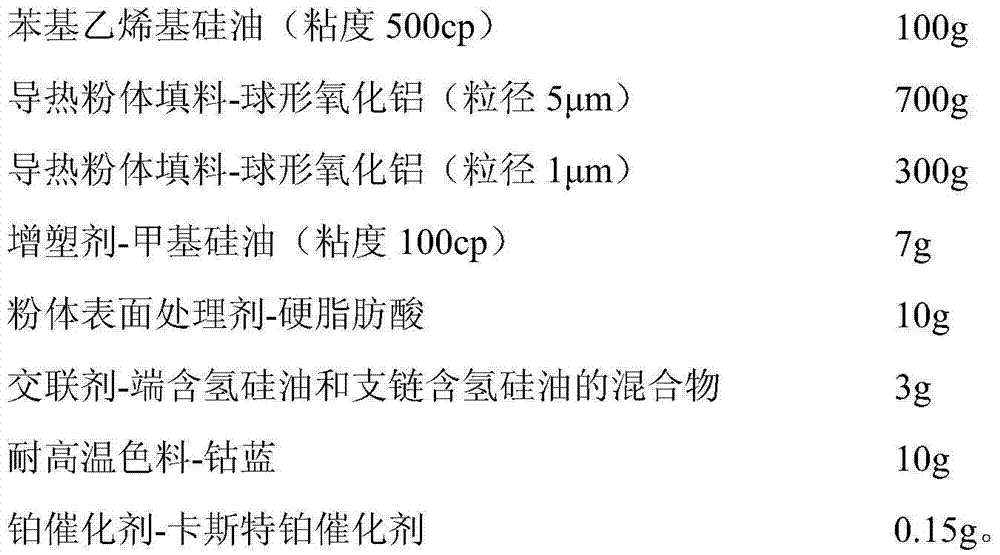

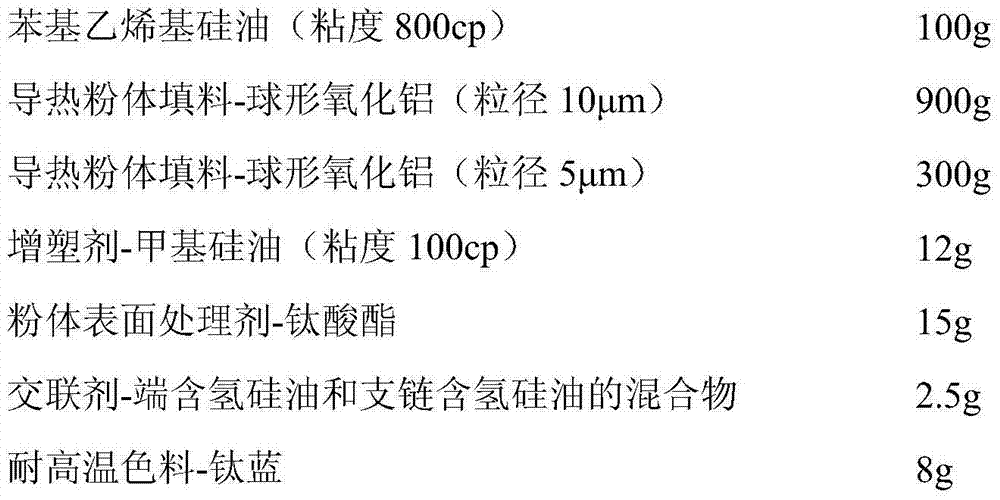

High-thermal-conductivity organosilicone mud and preparation method thereof

ActiveCN104497575AIncrease filling volumeReduce molecular forcesHeat-exchange elementsHeat conductingTemperature resistance

The invention discloses a high-thermal-conductivity organosilicone mud. The high-thermal-conductivity organosilicone mud is prepared from the following raw materials: 100 parts of silicone oil and 1000-1200 parts of heat-conducting powder filler in parts by weight, 0.5-1wt% of plasticizer and 1-3wt% of powder surface treating agent in terms of the heat-conducting powder filler, and 1-3wt% of cross-linking agent, 5-10wt% of high temperature resistant pigment and 0.01-0.015wt% of platinum catalyst in terms of the silicone oil. Besides, the invention also discloses a preparation method of the high-thermal-conductivity organosilicone mud. The high-thermal-conductivity organosilicone mud product has the advantages of high thermal conductivity, stable heat transfer property, excellent high temperature resistance, plasticity just as plasticine and the like; the preparation method of the high-thermal-conductivity organosilicone mud is simple; a better thermal-conductivity solution way can be provided for electronic heating components and radiating or other cooling devices.

Owner:GUANGZHOU BAIYUN CHEM IND

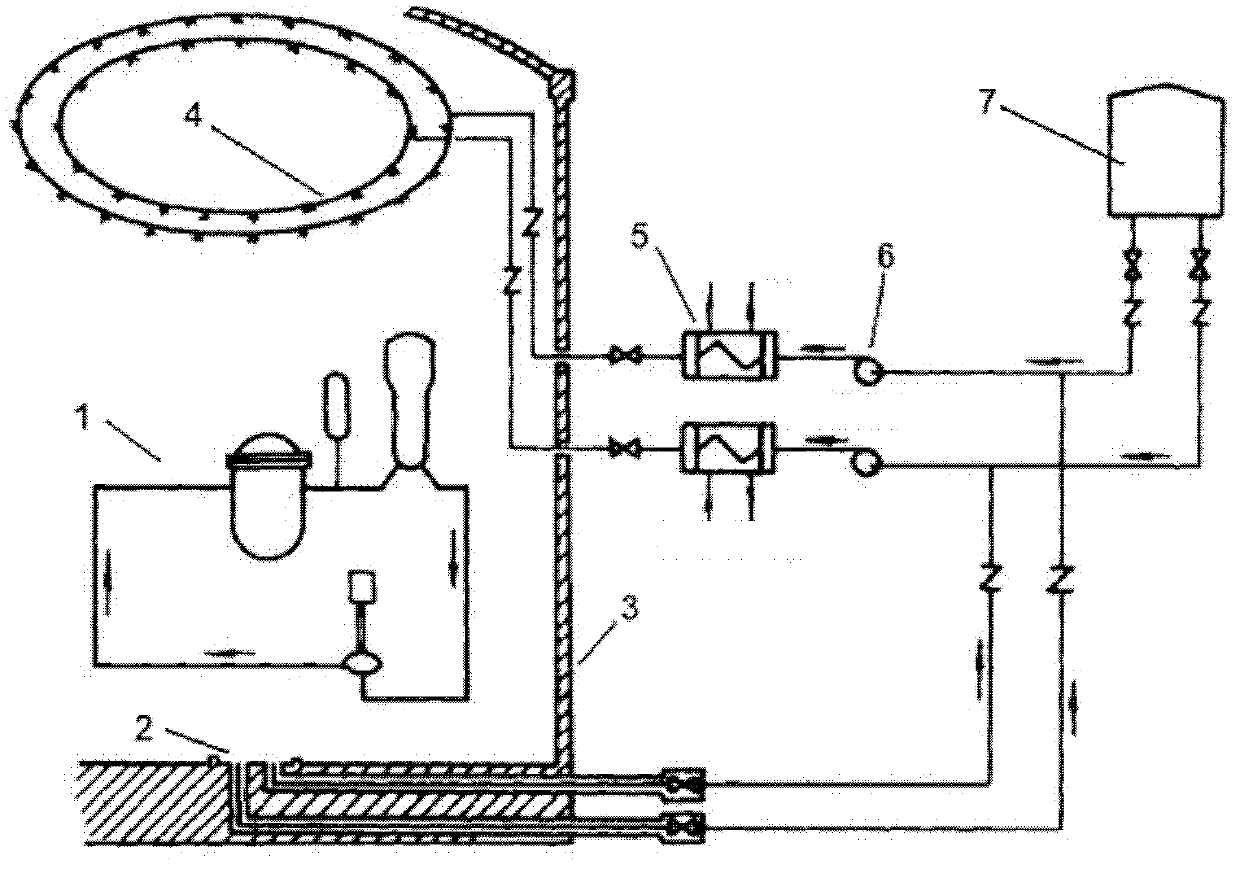

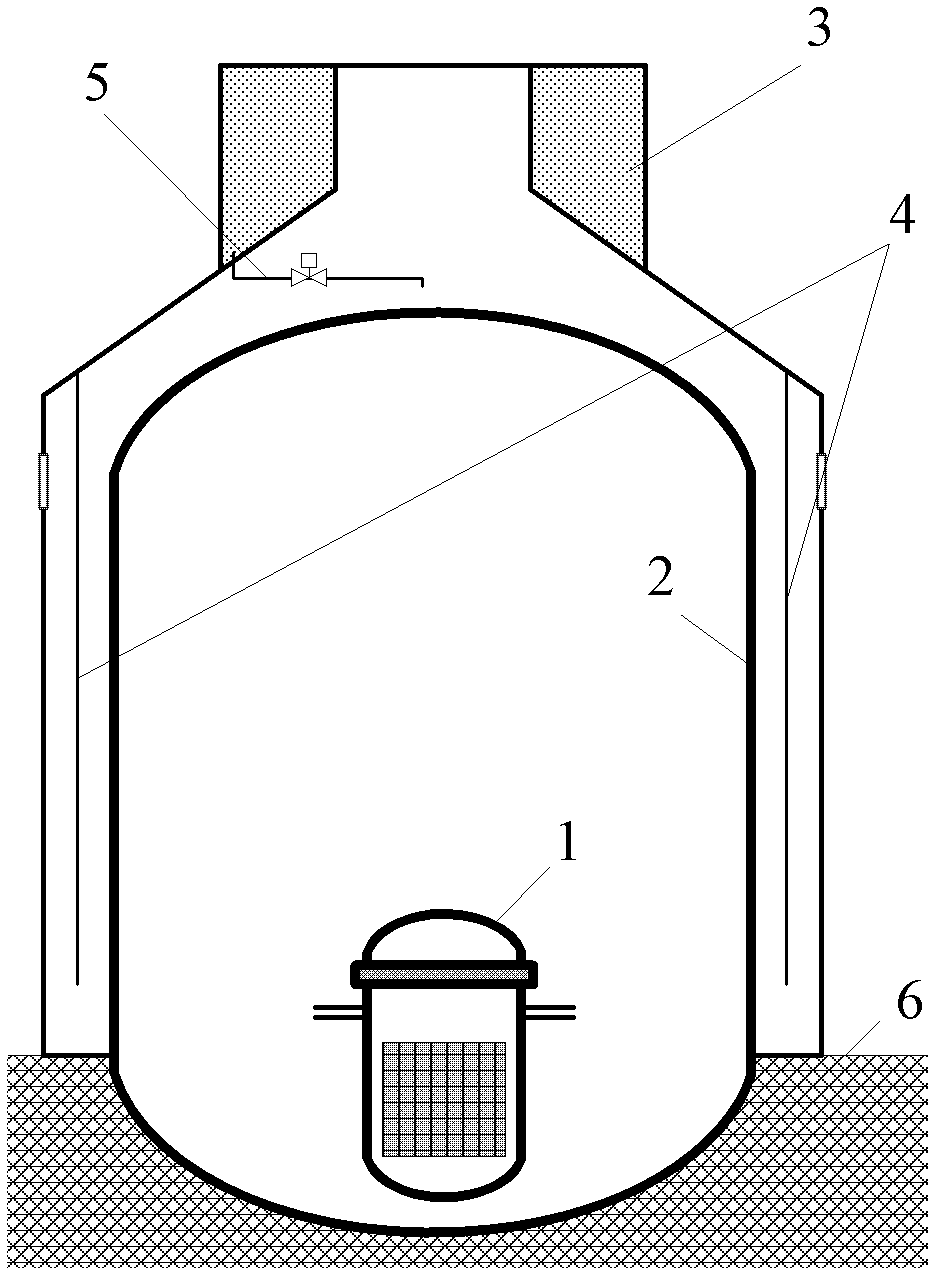

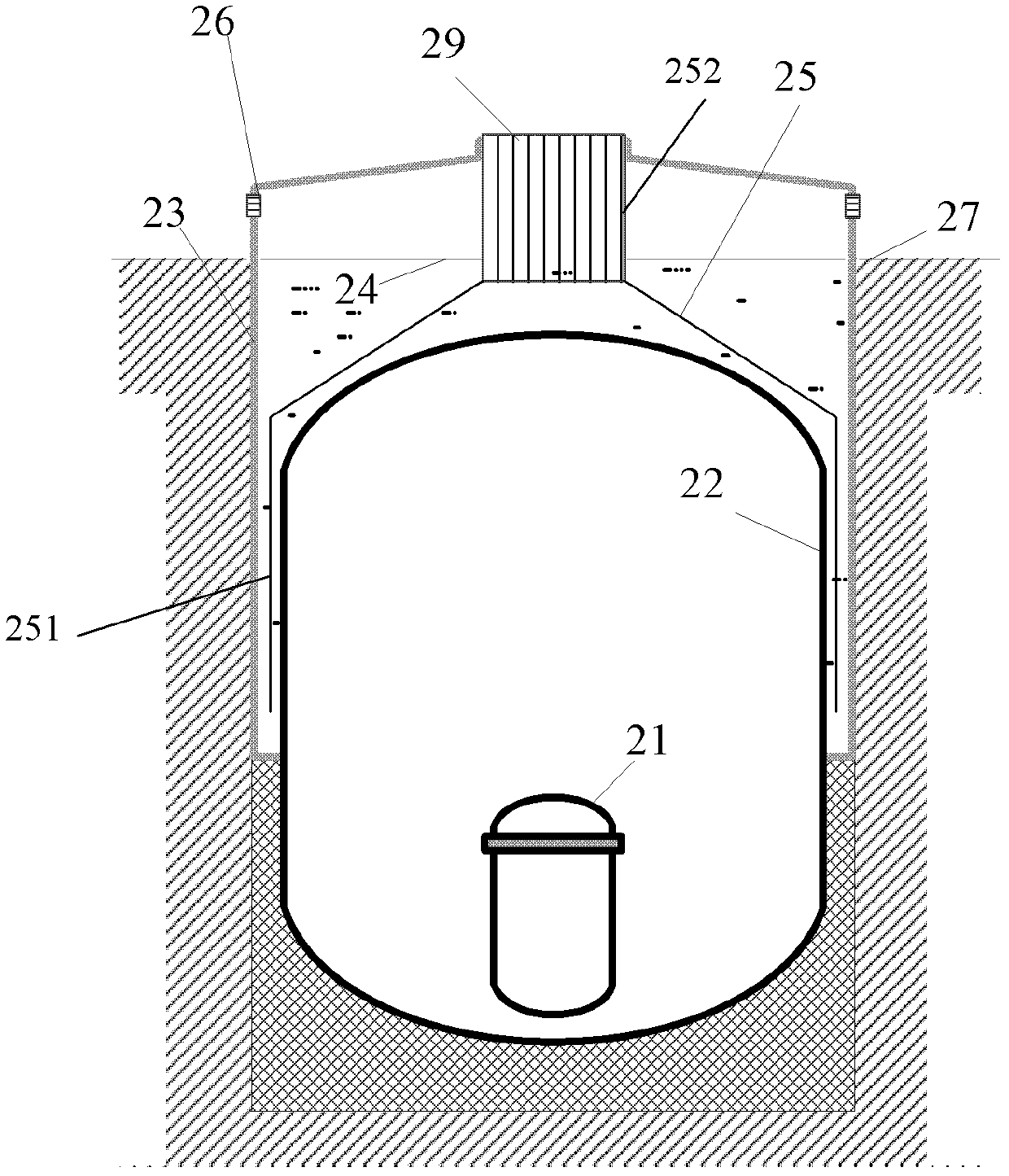

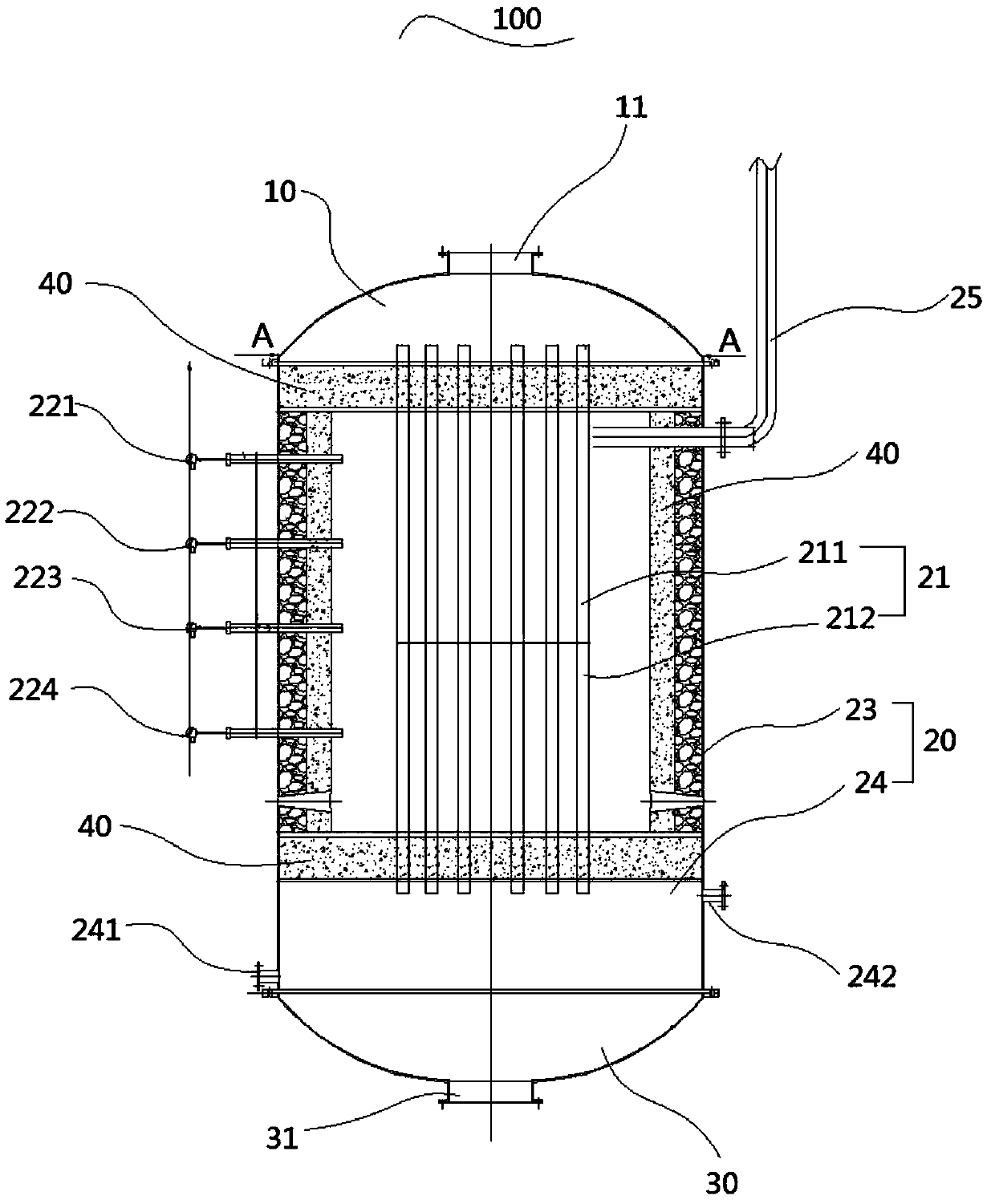

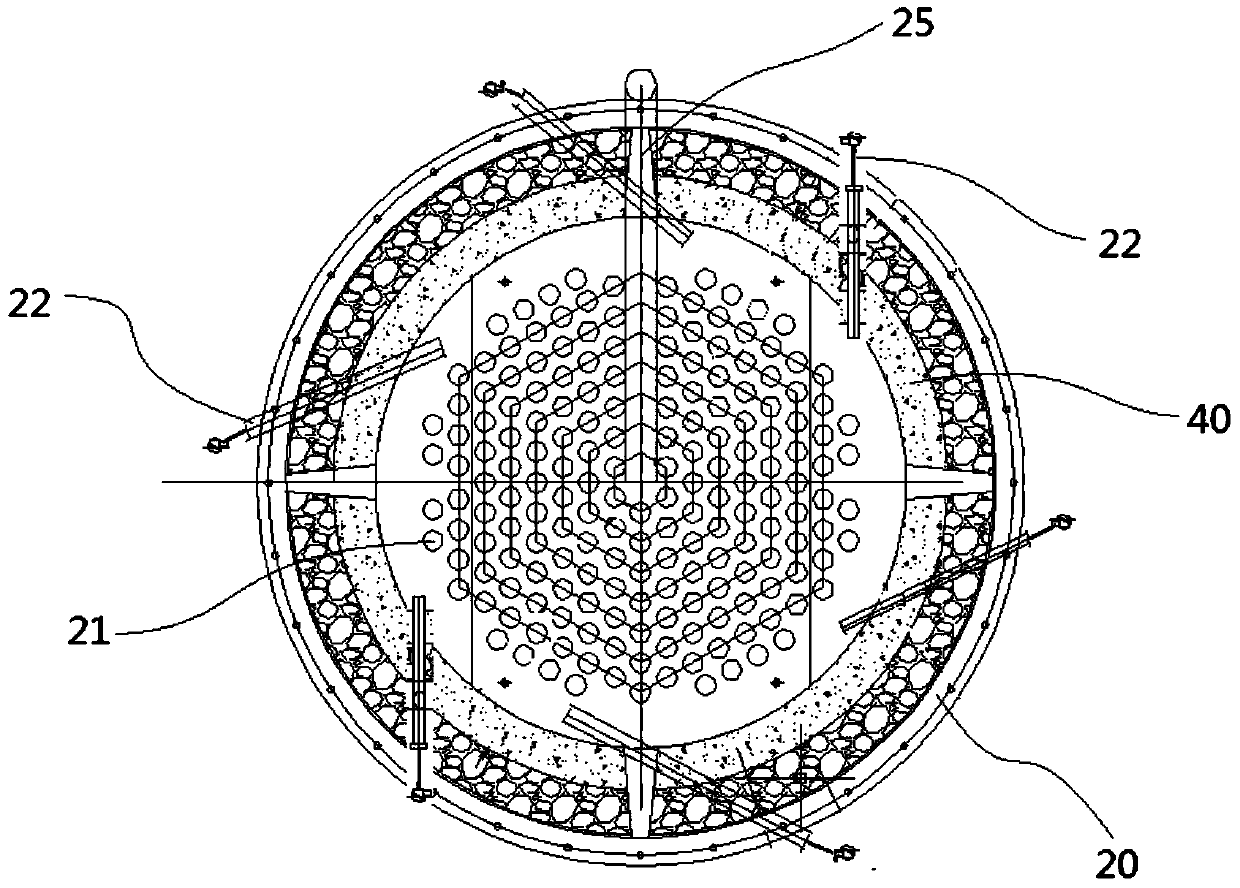

Water logging and air cooling combined passive containment cooling system and method

InactiveCN103295655ARealize self-startStable heat transferNuclear energy generationCooling arrangementWell loggingEngineering

The invention provides a water logging and air cooling combined passive containment cooling system and method. The system is completely self-started, free of intermediate control procedure and high in reliability. The is characterized by comprising a cooling pool and an air flow guide cover, wherein the cooling pool can submerge a containment, the air flow guide cover is arranged at the outside of the containment in the cooling pool, the air flow guide cover is provided with a surrounding part surrounding the containment, and a flow guide part located above the top part of the containment and extending to the atmosphere, the surrounding part and the flow guide part are connected into an entirety, the cooling pool is provided with an air inlet, and the air inlet of the cooling pool, the surrounding part of the air flow guide cover and the flow guide part form an air flow passage with a chimney effect.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

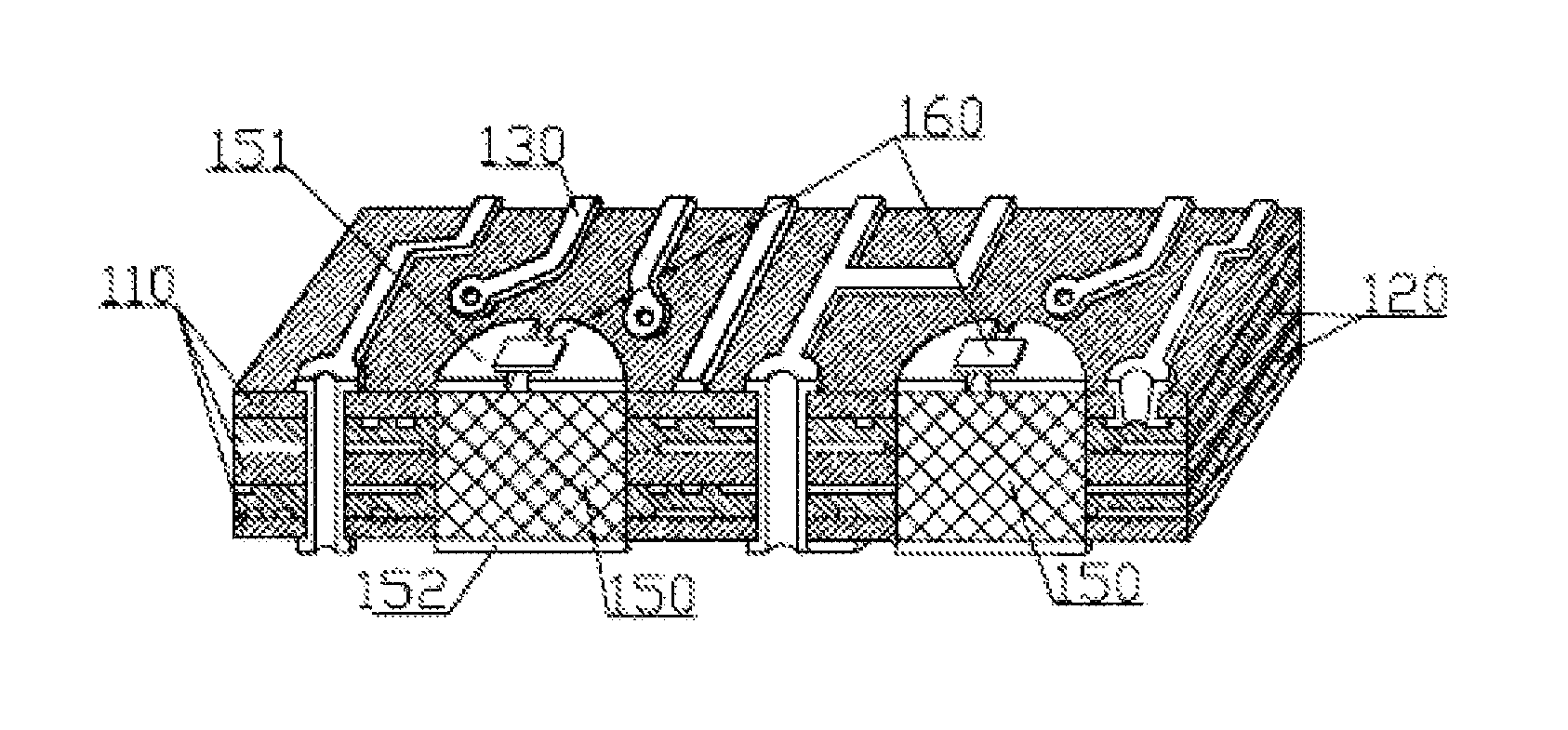

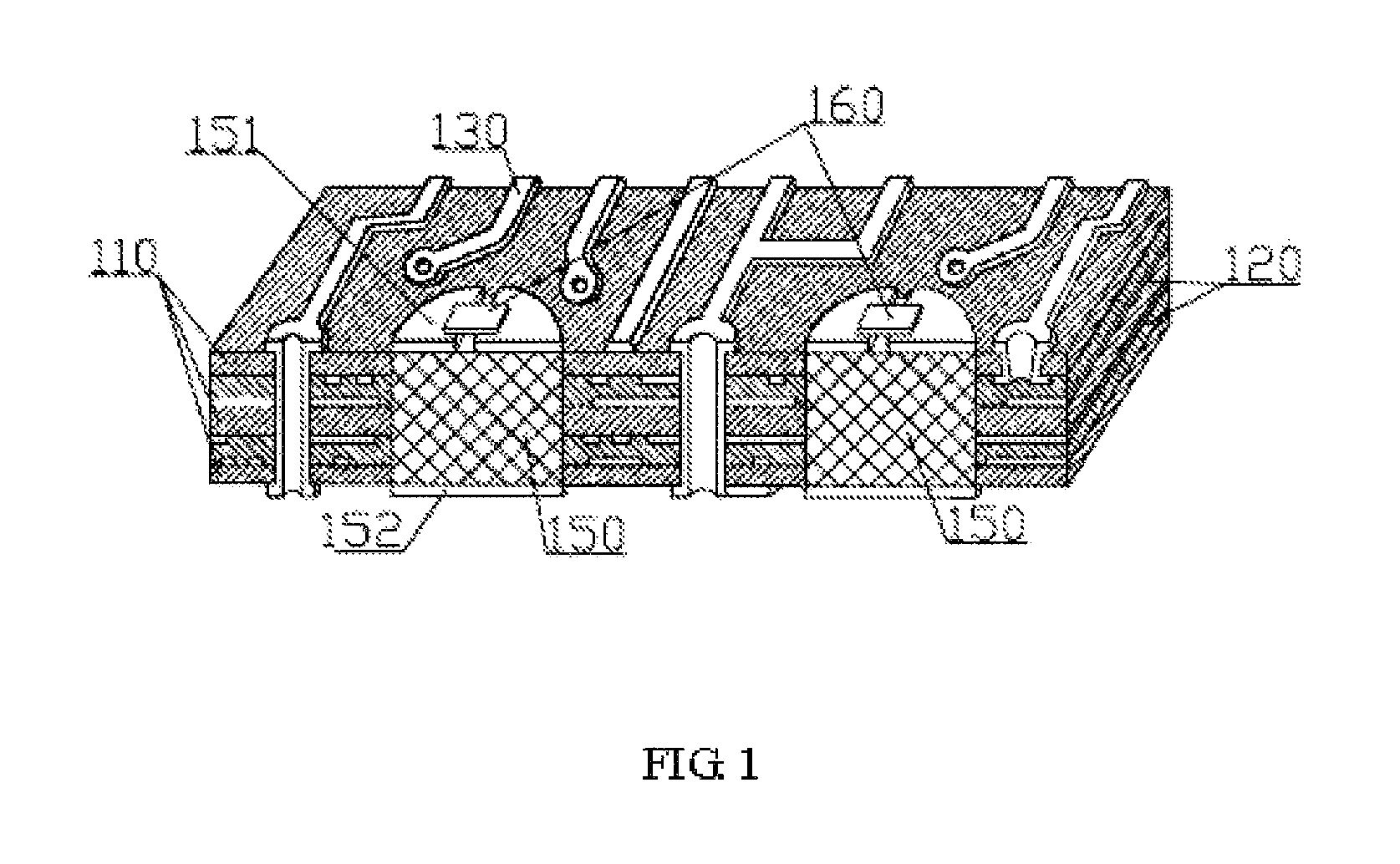

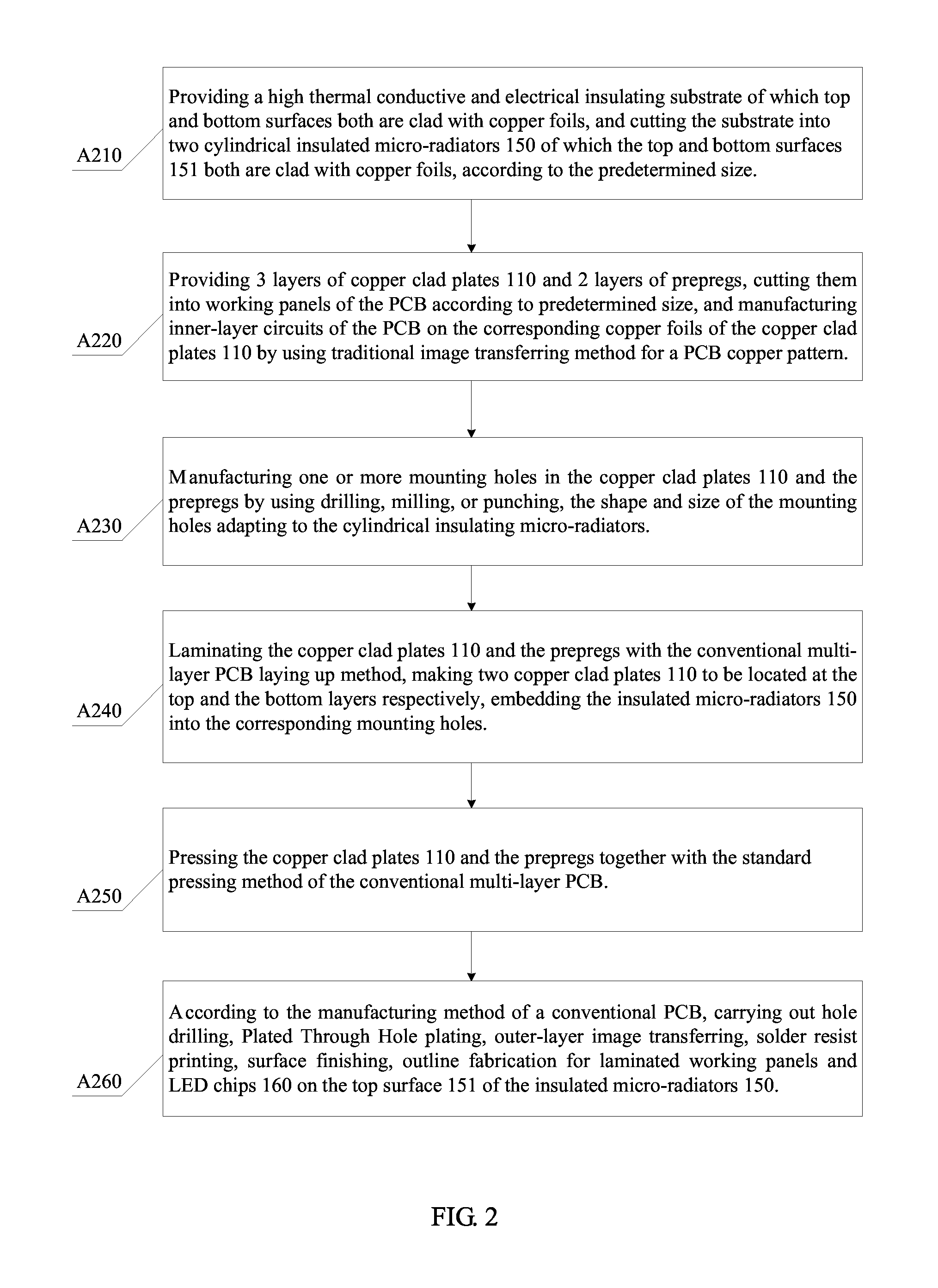

Manufacturing method of printing circuit board with micro-radiators

ActiveUS9185791B2PracticalImprove thermal conductivityPrinted circuit aspectsSolid-state devicesElectricityElectrical connection

The present invention relates to a manufacturing method of a printing circuit board. The manufacturing method mainly includes: forming one or more cylindrical micro-radiators by cutting a high conductive and electrical insulating substrate according to predetermined size; manufacturing one or more mounting holes in copper clad plates and prepregs; embedding the cylindrical micro-radiators into the mounting holes. The present invention combines the micro-radiator with high thermal conductivity and traditional stiffness printing circuit board. The printing circuit board with micro-radiators has the advantages of high thermal conductivity and stable heat transfer, and also has the advantages of routing flexibility and reliable electrical connections.

Owner:RAYBEN TECH ZHUHAI

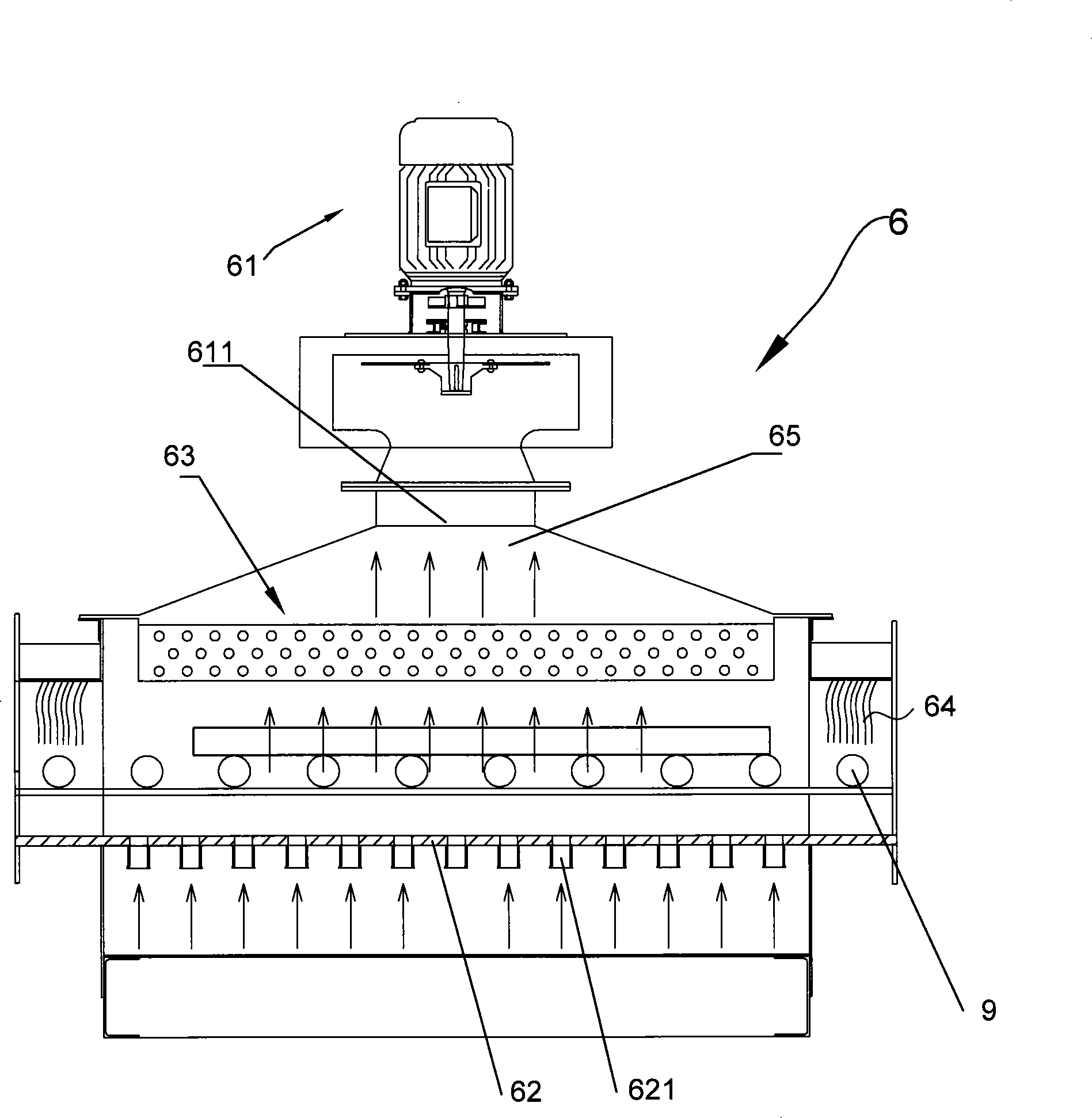

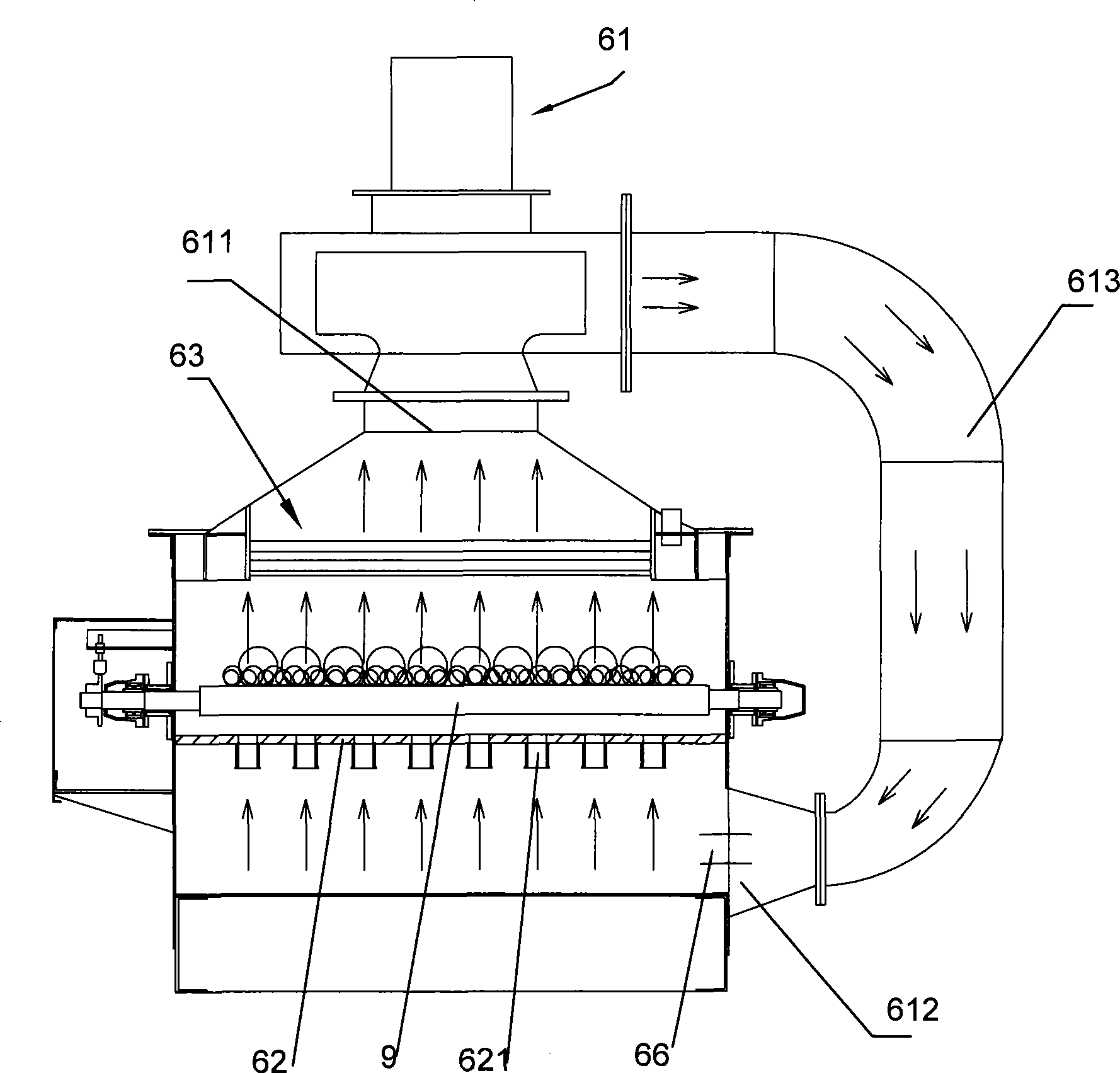

Low stove pressure convection continuous roller bottom type annealing furnace and annealing technique

The invention relates to a low furnace pressure convective continuous roller hearth type annealing furnace, which comprises a charging magazine, a heating chamber, a strong cooling chamber and a roller way driving system, wherein an internal circulation draught fan and a plurality of heating elements are arranged in the heating chamber, both an air inlet and an air outlet of the internal circulation draught fan are located in a furnace body of the heating chamber, the air inlet is vertical to the plane of a roller way, the air outlet is parallel to the plane of the roller way, an external circulation draught fan, a heat exchanger and a baffle plate are arranged in the strong cooling chamber, the baffle plate is located in the middle portion of the furnace body of the strong cooling chamber, the roller way is located between the heat exchanger and the baffle plate, an upper opening and a lower opening are respectively opened on the top and the bottom of the furnace body of the strong cooling chamber, the air inlet of the external circulation draught fan is communicated with the upper opening, the air outlet of the external circulation draught fan is connected with the lower opening through a connecting pipe which is arranged outside the strong cooling chamber, the complex number of nozzles are evenly distributed on the baffle plate, and the upper portion and the lower portion of the furnace body of the strong cooling chamber are communicated only through a complex number of nozzles. The annealing furnace of the invention has the advantages of even heating, rapid cooling, high efficiency and the like.

Owner:SUZHOU ZHONGMENZI IND FURNACE TECH CO LTD

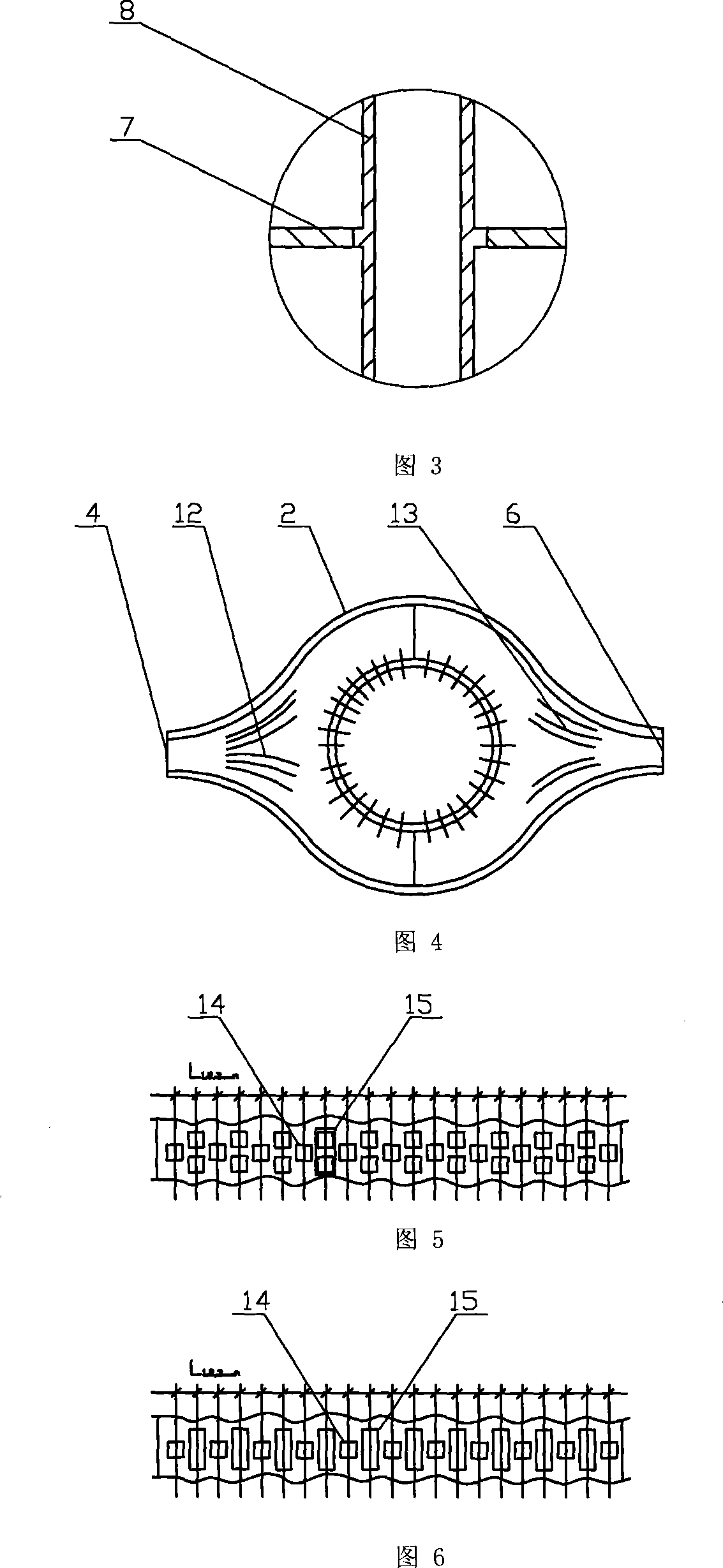

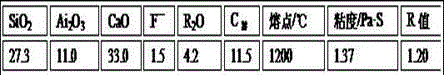

Casting powder for continuous casting crystallizer and preparation method of casting powder

The invention discloses casting powder for a continuous casting crystallizer. The casting powder comprises raw materials in parts by weight as follows: 3.5-15 parts of fluorite, 35-55 parts of aedelforsite, 5-15 parts of alkali, 0-2 parts of lithium carbonate, 0-10 parts of diaspore, 0-6 parts of a cement clinker, 1-5 parts of magnesia powder, 2-5 parts of pyrolusite, 0-8 parts of sodium fluoride, 0-5 parts of barium carbonate, 0-5 parts of bentonite, 1-4 parts of coke, 0-8 parts of a carburant, 1-3 parts of carbon black and 1-2 parts of a binder. According to the casting powder, the preparation cost is low; the recovery rate of the casting powder is larger than or equal to 98.5%; the color of the casting powder is uniform; the granularity is uniform; the granulation rate is high; dust is reduced; the melting point of the casting powder is low; the viscosity is low; after the casting powder is added into the crystallizer, the casting powder is melted uniformly and shows excellent spreadability, heat retaining property and adsorptive property; heat is transferred uniformly all around the crystallizer, and the lubrication is excellent; and defects such as concave pits, impurities and the like don't exist on the surface of a casting blank, the internal quality is excellent, and the qualified rate of the casting blank is equal to or larger than 99.8%.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

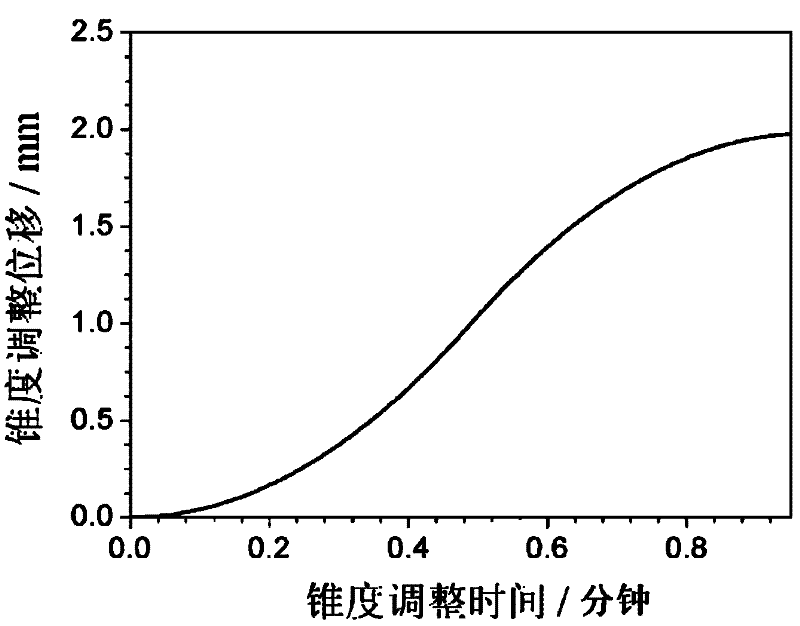

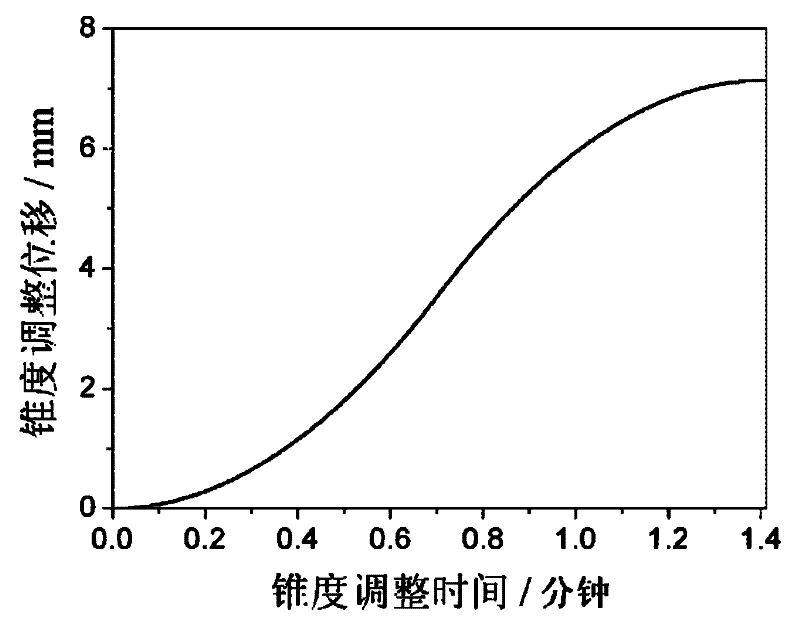

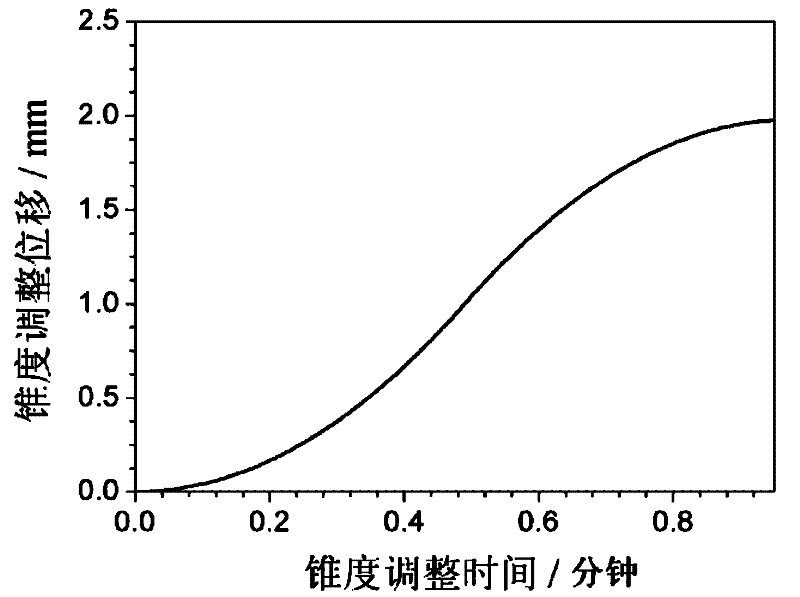

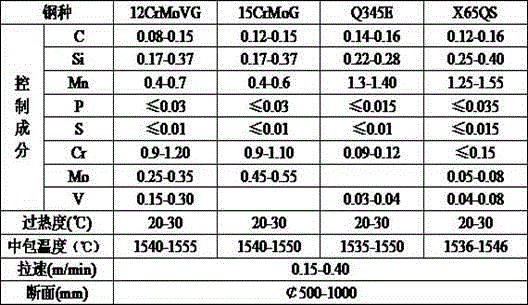

On-line adjustment method of taper change when continuous casting mold width reduction process is hindered

ActiveCN102266920AStable solidification heat transfer processReduce wearCasting moldMaterials science

The invention relates to a method for changing a conical degree at the moment of obstructing a process of on-line width reduction of a continuous casting crystallizer. The method comprises the following steps: taking solidifying contraction of a blank shell as a starting point, and then introducing a process obstructing condition in the process of reducing the width of the continuous casting crystallizer into the process of on-line width reduction at real time, so as to confirm a control parameter which contains an accelerated speed and a resetting time for adjusting a conical degree in the conical degree changing process of a casting machine, thereby reliably ensuring the safety continuous production of the casting machine. The method provided by the invention has significance on lowering the production cost, promoting the production quality, promoting the metal yield and promoting the market competitiveness of products.

Owner:中国冶金科工股份有限公司

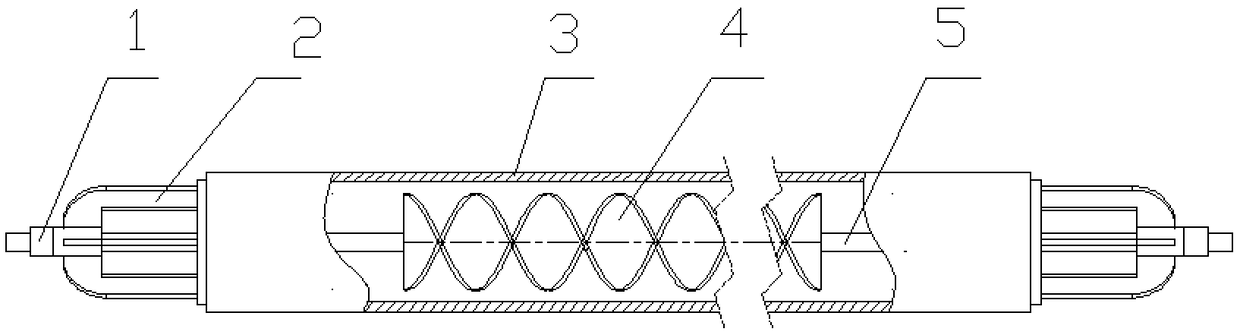

Spiral twisting belt embedded with reinforced framework shaft core

PendingCN108759548AReduce deflectionReduce Scratch WearHeat transfer modificationRotary device cleaningFriction lossEngineering

The invention relates to a spiral twisting belt embedded with a reinforced framework shaft core. The spiral twisting belt comprises a spiral twisting belt body, the reinforced framework shaft core andan axial positioning device, wherein the axial positioning device comprises a supporting rod and a limiting part; the spiral twisting belt and the reinforced framework shaft core are fixedly connected into an integer; the part, extending out of the spiral twisting belt, of the reinforced framework shaft core is taken as a mandrel; supporting frames are mounted at the two ends of a heat transmitting tube through interference fit; and the mandrel passes through inner holes of the supporting frames for fixing the limiting part on the mandrel at the outer sides of the supporting frames for axially positioning the limiting part. The spiral twisting belt body is embedded with the reinforced framework shaft core, so that strength and rigidity of the spiral twisting belt are enhanced, deflectionof the twisting belt is reduced, and severe scratch and abrasion, on the tube wall, of the spiral twisting belt is reduced; besides, the contact surfaces between the limiting part and the supporting frames are small, so that friction loss is small; and disturbance of liquid is increased as spiral flow is generated by liquid in a runner of the spiral twisting belt body, so that turbulence degree ofthe liquid in the tube is further increased, and therefore, heat exchange efficiency is improved.

Owner:BEIJING UNIV OF CHEM TECH

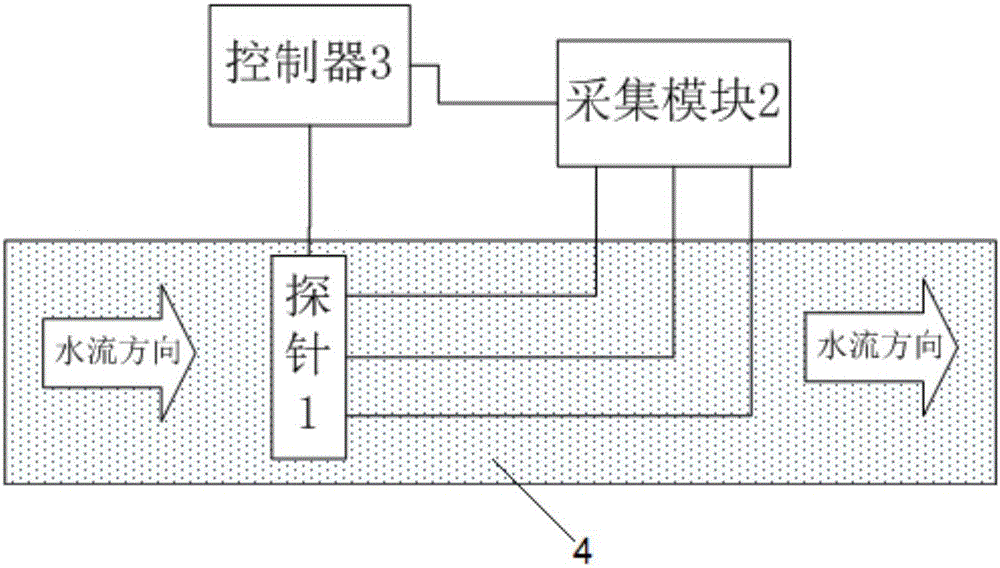

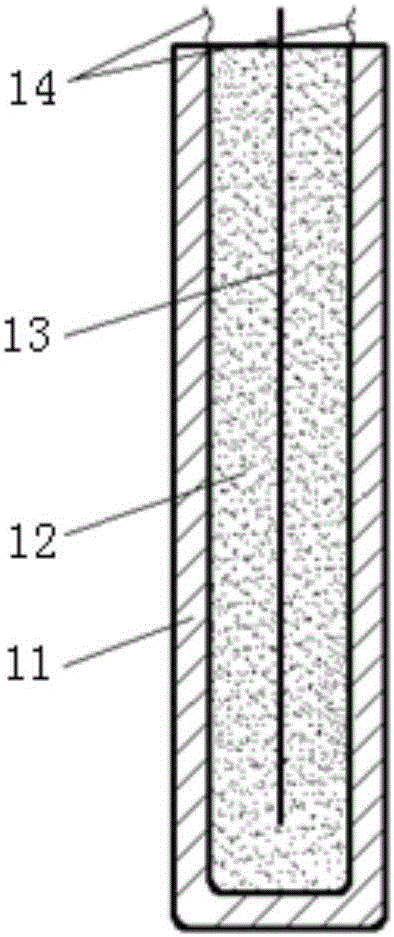

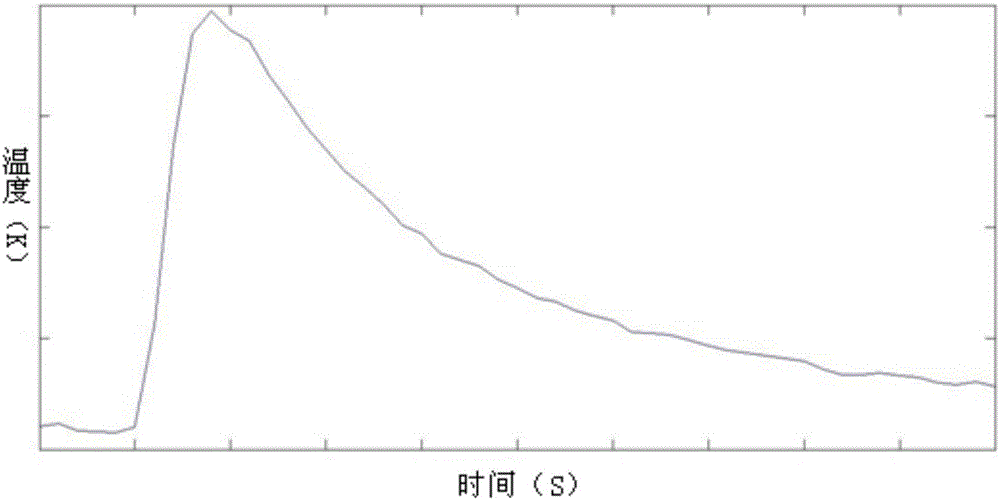

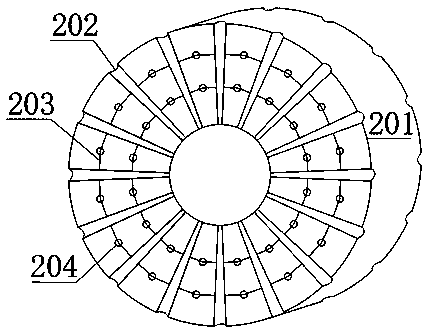

Device and method for measuring soil water flow velocity on basis of thermal pulse method

ActiveCN106199061ANo bendingMeet assembly needsFluid speed measurement using thermal variablesElectrical resistance and conductanceHeating time

The invention relates to a device and method for measuring the soil water flow velocity on the basis of a thermal pulse method. The device comprises a probe, a collection module and a controller; the probe is perpendicularly inserted into soil completely, closely makes contact with the soil and comprises a thermal conducting metal steel shell, a heating resistance wire and thermocouple bare wires, a through hole is formed in the center of the top of the thermal conducting metal steel shell, the heating resistance wire penetrates through the through hole to be fixedly inserted into the probe, the thermocouple bare wires for measuring surface temperature signals of the thermal conducting metal steel shell are uniformly distributed at the periphery of the heating resistance wire, the output ends of the thermocouple bare wires are connected with an input port of the collection module through signal transmission lines separately, and the controller is connected with the heating resistance wire and the collection module separately and used for controlling the heating time of the heating resistance wire to enable heat to be capable of being transmitted into the soil in the mode of an instantaneous pulse and controlling the collection module to conduct data collection. The device and method are precise in measurement and stable in thermal transmission and can be widely applied to soil water flow velocity measurement.

Owner:CHINA AGRI UNIV

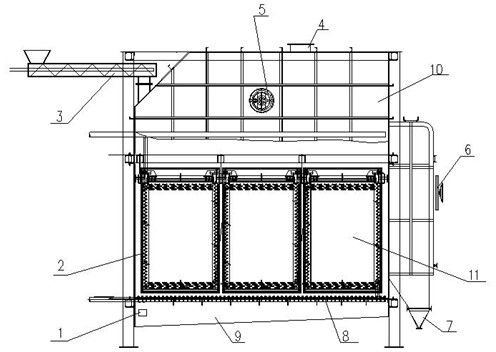

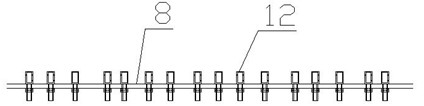

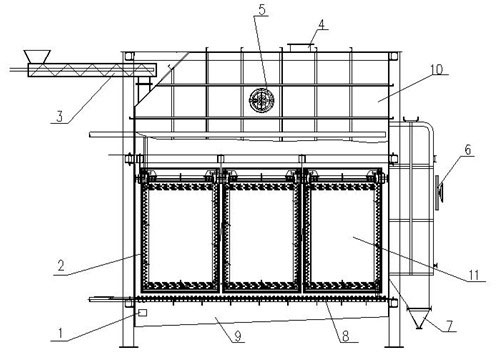

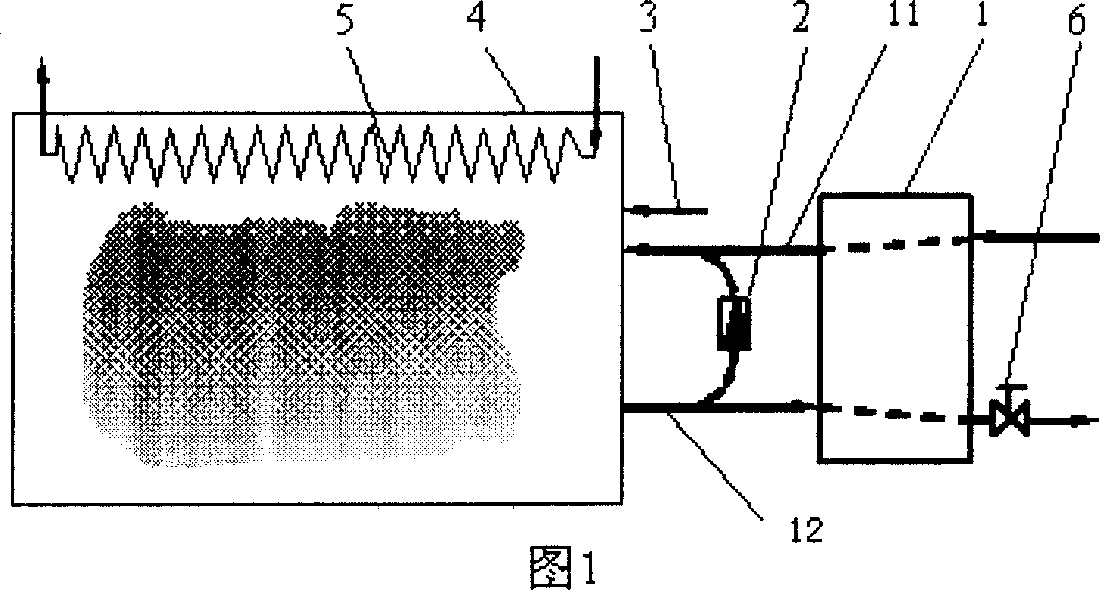

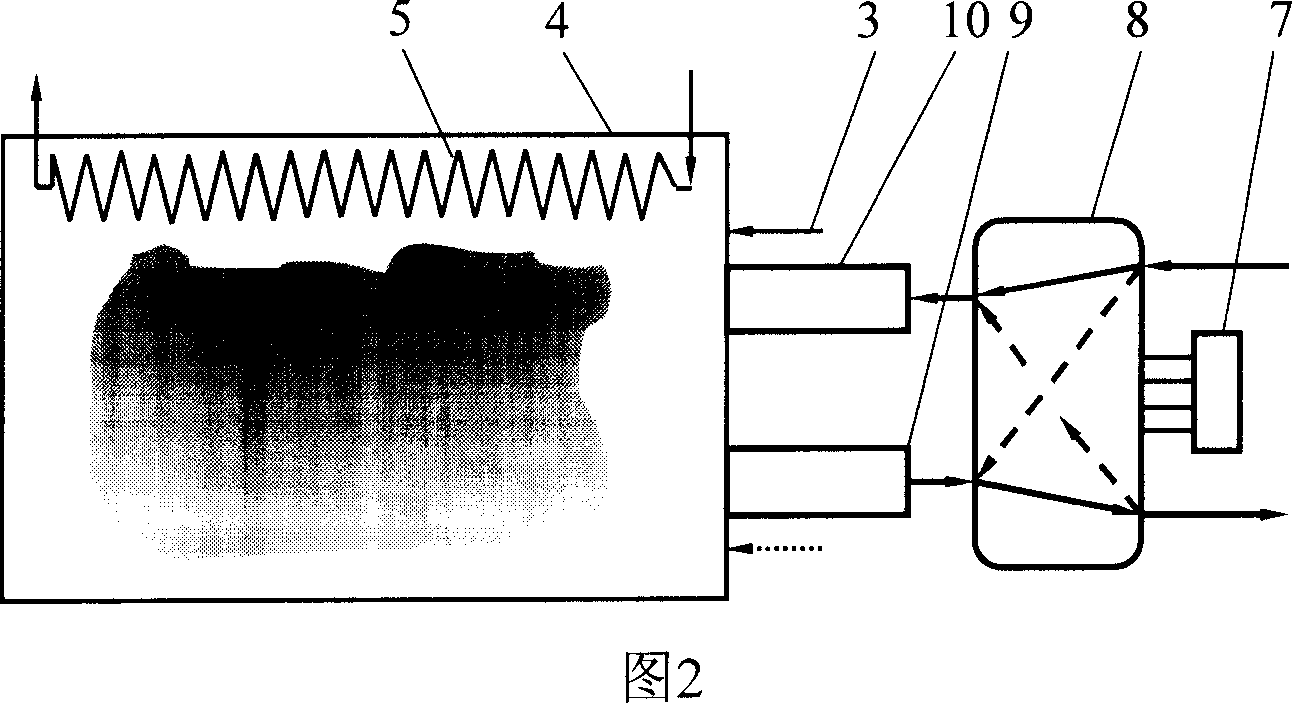

Internal heating type dryer for in-furnace coking coal dehumidification

InactiveCN102533302AImprove heat transfer efficiencyExpand the adjustment rangeDrying solid materials with heatCoke ovensFluidized bed dryingComputer module

The invention discloses an internal heating type dryer for in-furnace coking coal dehumidification, which comprises a dryer outer frame, a drying area on the upper portion in the dryer outer frame, a fluidized bed drying heating area under the drying area and an air distribution area on the lower portion in the dryer outer frame. The drying area is provided with an exhaust space (10) and a heat exchange face, a coil heat exchanger (11) is arranged in the fluidized bed drying heating area, a fluidized air chamber (9), an air distribution plate (8) and a hood (12) are arranged in the air distribution area, and the air distribution plate (8) and the hood (12) form a module structure connected with the fluidized air chamber (9). The internal heating type dryer is simple in structure, good in exchangeability, convenient to overhaul, reliable in operation and reliable and flexible in dehumidification control adjustment, saves energy, is simple in system adjustment and responses quickly to heat adjustment of the heat exchanger. A large drying system can be formed by a plurality of dryers according to the production requirement, and only one backup module is needed to ensure normal production of a humidifying system, so that scale of spare equipment of the existing humidifying system is reduced.

Owner:WUXI YIEN TECH

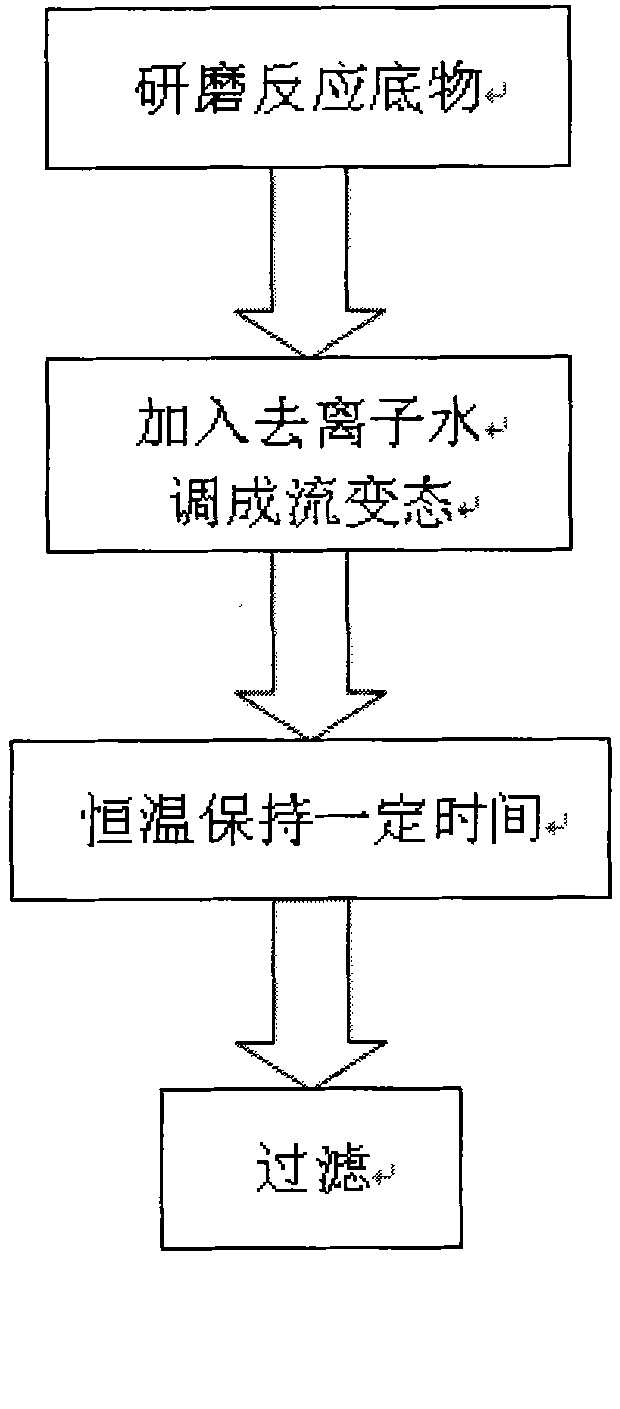

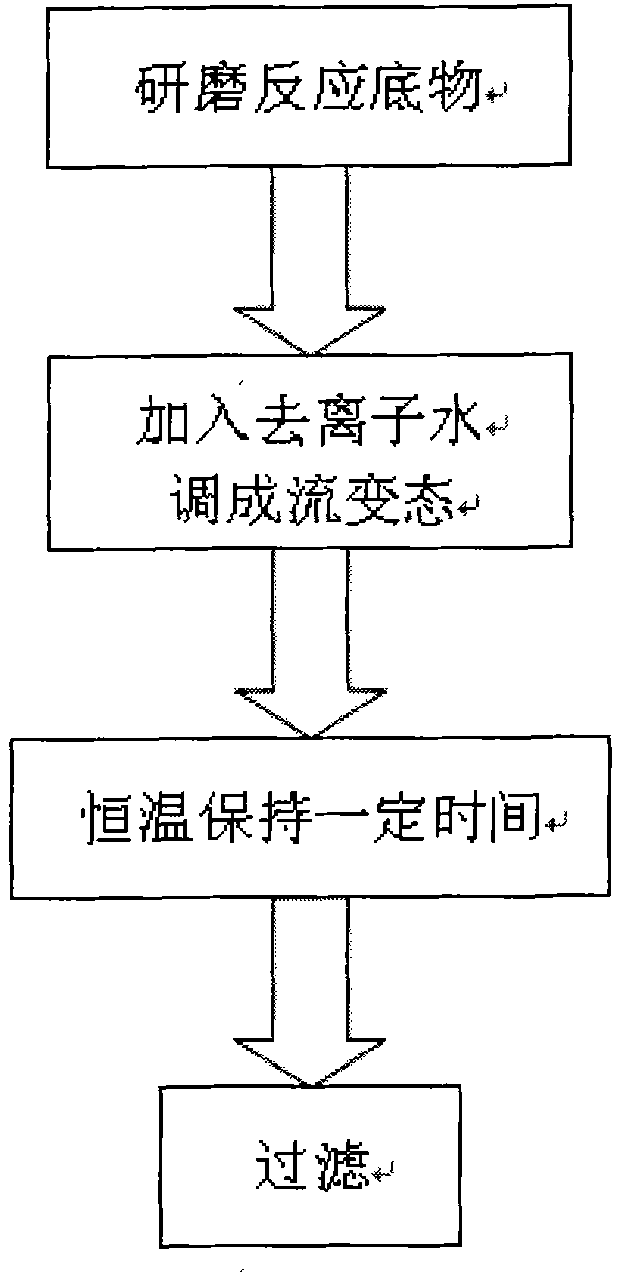

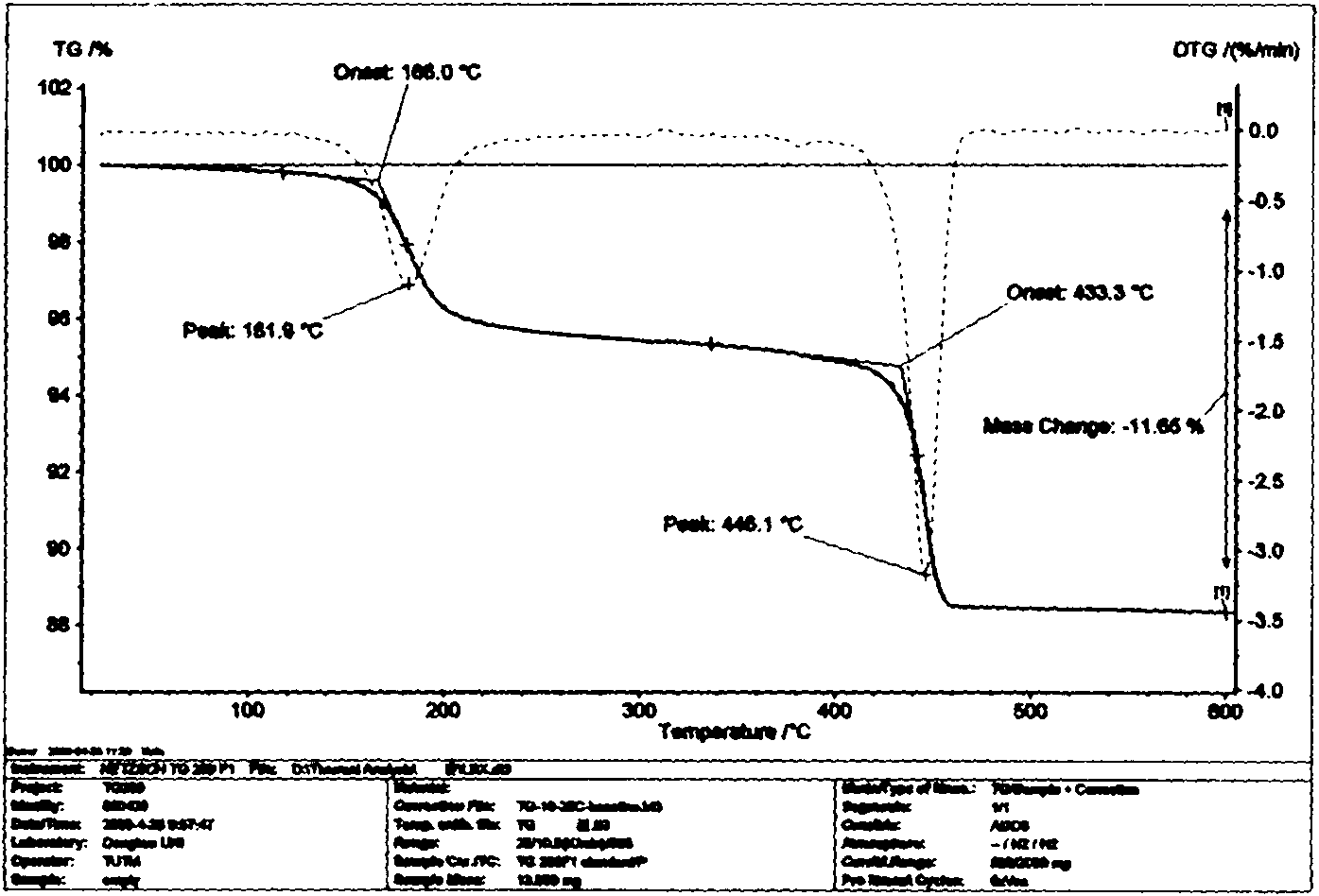

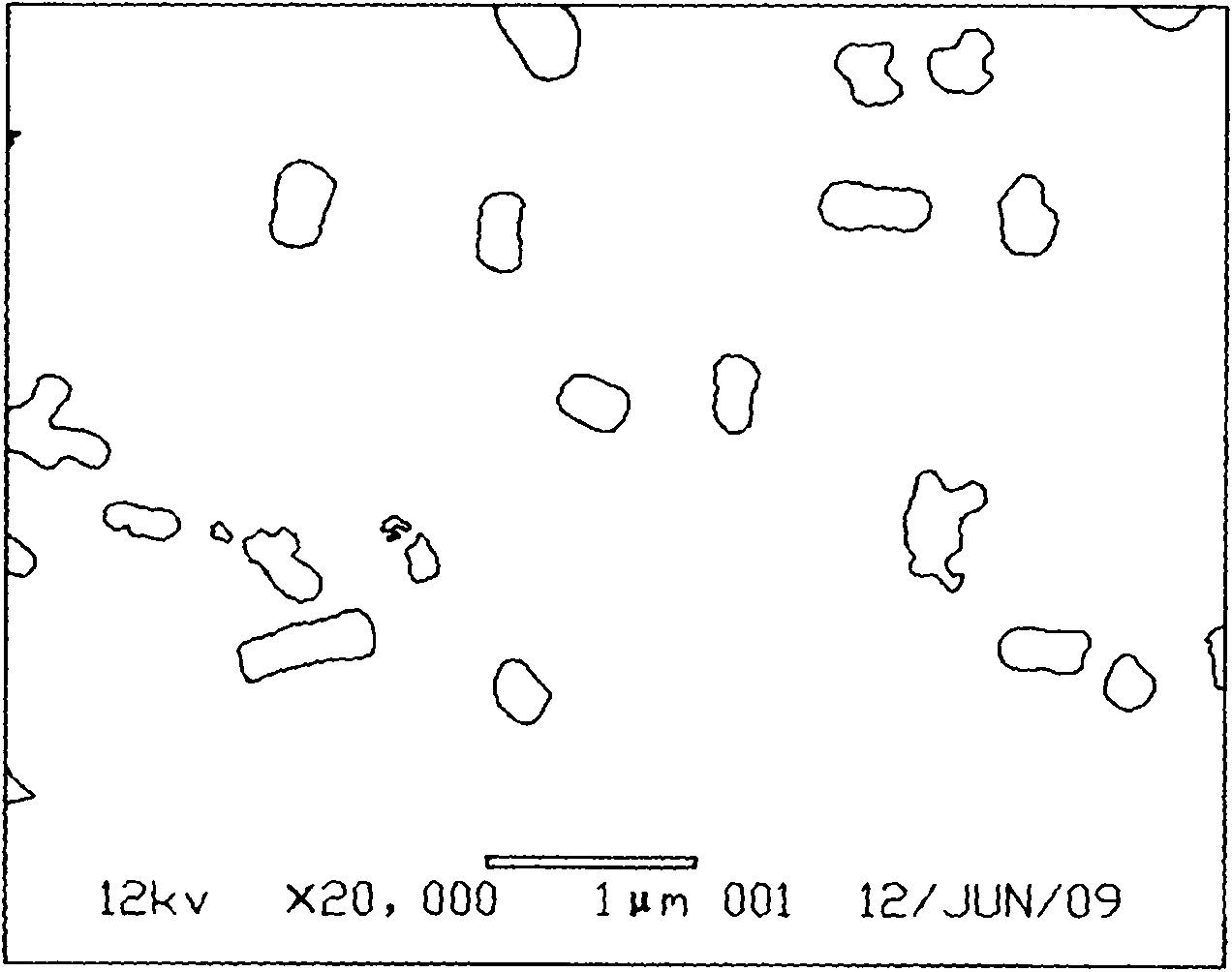

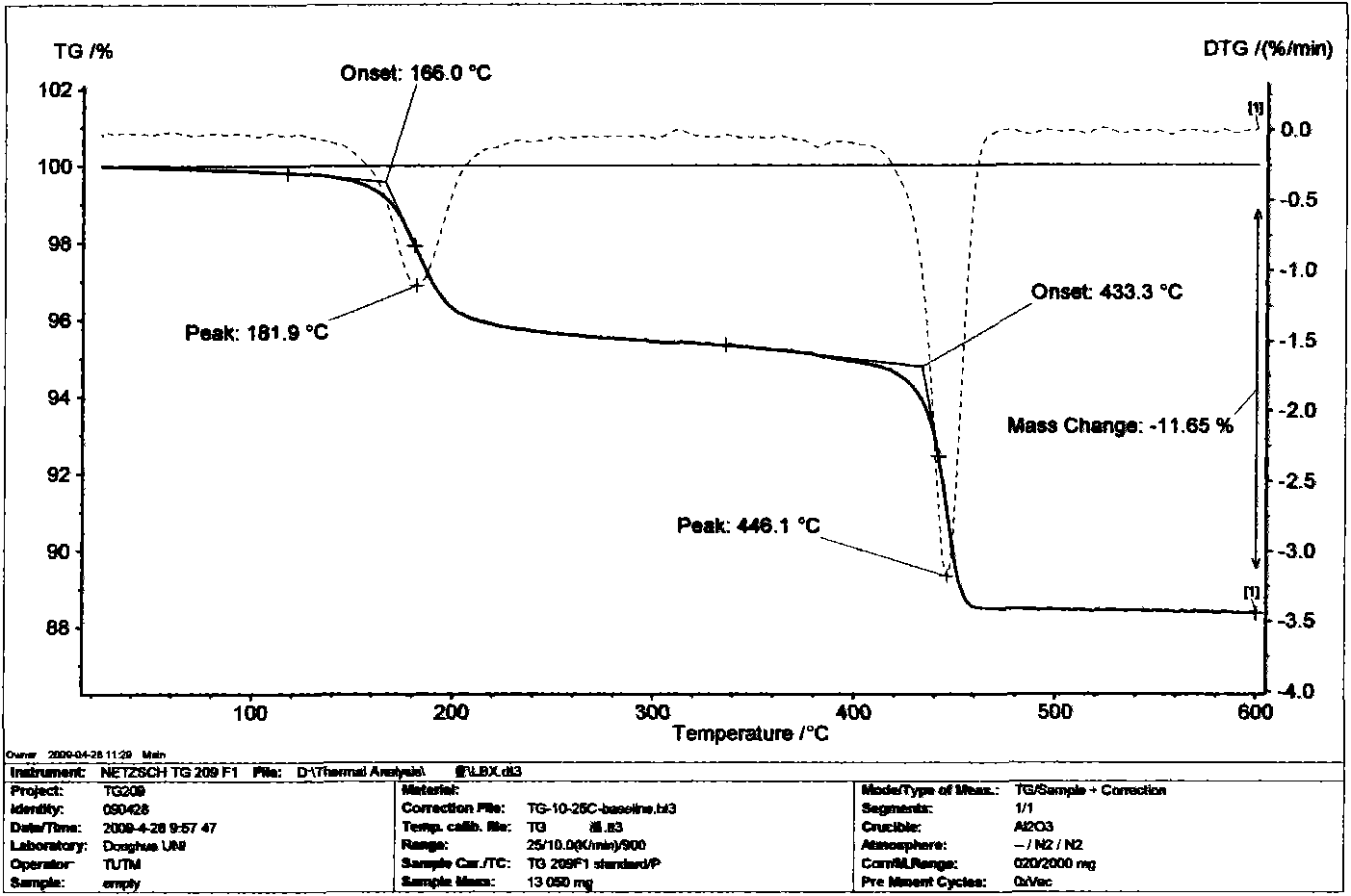

Novel micro/nano trivalent silver iron compound synthesizing method

InactiveCN101857262AEvenly distributedHigh recovery rateBiocideNanostructure manufactureMetallurgyMicroparticle

The invention relates to a novel micro / nano trivalent silver iron compound synthesizing method, which comprises the following steps of: (1) weighing silver-containing reactants according to a ratio, fully grinding the silver-containing reactants and uniformly mixing the grinded materials; (2) adding de-ionized water into the mixed material to stir the mixed material into a flowing deformation state; (3) keeping the mixture constant for a certain time; and (4) filtering the mixture, washing the obtained product clean with pure water and washing away un-reacted materials to obtain a novel micro / nano trivalent silver iron compound. In a flowing deformation phase system, solid particles are uniformly distributed in fluid and tightly contact one another, and the surfaces of the solid particles can be effectively used, so the reaction is more complete, the product recovery rate is high and the synthesis efficiency is high; the ratio of the product to the reactor volume is very high, the mass production of wastes is avoided, and thus, the method is favorable for environment protection and is a green production process with the advantages of high efficiency, energy conservation, cost conservation and environmental friendliness; and all parts in the fluid have high exchangeability and stable heat transmission and mass transfer, the partial overheat can be avoided and the temperature is easy to control, so homogeneous granular micro / nano materials can be obtained.

Owner:苏州泰利三佳纳米科技有限公司

Air burning method in low oxygen and high temperature, and equipment

InactiveCN1959206AReduce oxygen concentrationStable combustion flameIndirect carbon-dioxide mitigationCombustion apparatusSolid fuelEngineering

A method for burning low oxygen and high temperature air includes entering air into recuperative heat exchanger to be preheated, mixing it with high temperature smoke sent from ceramic check valve to form it to be low oxygen high temperature air being sent into firepot, carrying out volume-form combustion being able to be controlled at firepot, exhausting partial smoke out to ambient through smoke flow rate regulation valve after sensible heat of smoke is released at heat exchanger.

Owner:CENT SOUTH UNIV

Novel method for preparing micro-nano multivalent silver by soft chemistry technology

InactiveCN101926360AEvenly distributedHigh recovery rateBiocideDisinfectantsPotassium persulfateMicro nano

The invention discloses a novel method for preparing micro-nano multivalent silver oxides by soft chemistry synthesis. The micro-nano multivalent silver oxides are chemical substances which have excellent killing effect on microorganisms and tumor cells. The method for preparing micro-nano disinfectants comprises the following steps of: uniformly mixing an oxidant potassium persulfate or sodium persulfate, sodium hydroxide and silver nitrate according to a ratio of 2.4-9:4.8-6:5-20, putting into a reactor, adding a proper amount of distilled water, adjusting into a rheologic state, reacting at the temperature of between 80 and 100 DEG C for 10 to 30 minutes, filtering, and washing with purified water for four times to obtain micro-nano multivalent silver particles. The product synthesized by the method has the advantages of uniform size, simple production process, high efficiency, remarkable killing effect on various microorganisms, and safety to the environment and human.

Owner:DONGHUA UNIV +3

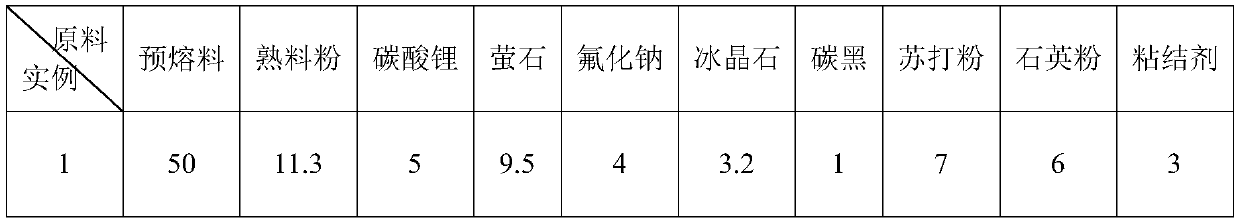

High-speed wide and thick slab continuous casting mold flux

The invention provides a high-speed wide and thick slab continuous casting mold flux, and belongs to the technical field of continuous casting mold fluxes. The high-speed wide and thick slab continuous casting mold flux comprises the following raw materials: pre-melting materials, soda ash, lithium carbonate, fluorspar, limestone, wollastonite, albite, carbonate manganese, amorphous graphite, carbon black and a dispersant, and is obtained by grinding, mixing, granulation and other processing steps. According to the invention, the high-speed wide and thick slab continuous casting mold flux is uniform in size, bright black and uniform in color, high in strength, difficult to be crushed, excellent in all performances responded in the casting mold, stable and uniform in conducted heat, adaptive to the requirements of continuous change of the speed, and good in lubrication; the problem of uneven inflow is solved; the sticking breakout is avoided; the slab surface has no cracks, dents, bulges, surface-included slag, sticking slag and other phenomena.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Bubble pump and application of bubble pump

InactiveCN103277283AHigh promotion rateTemperature rises fastPositive displacement pump componentsPumpsHeat transmissionLithium bromide

The invention relates to a bubble pump which is composed of a vertical lifting pipe, a high-level liquid storing device, a low-level liquid storing device and a heating device. The heating device is a flat-board type heater or a combination of the flat-board type heater and a fin device for strengthening heat exchange. The flat-board type heater is horizontally arranged in the low-level liquid storing device and adjacent to the bottom of the low-level liquid storing device. The fin device for strengthening heat exchange is installed vertical to the flat-board type heater. The surface of the bottom of the fin device for strengthening heat exchange is tightly connected with the upper surface of the flat-board type heater in a welding mode. The bubble pump is simple and compact in structure, high in heat transmission efficiency, capable of shortening time cost in starting the bubble pump and even and stable in generated bubbles, improves a production rate of the bubbles, reduces heat loss and improves a heat energy utilization rate by enlarging heat transmission area. The bubble pump can be applied to a lithium bromide absorbing type refrigerating device to improve refrigerating capacity of the lithium bromide absorbing type refrigerating device.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

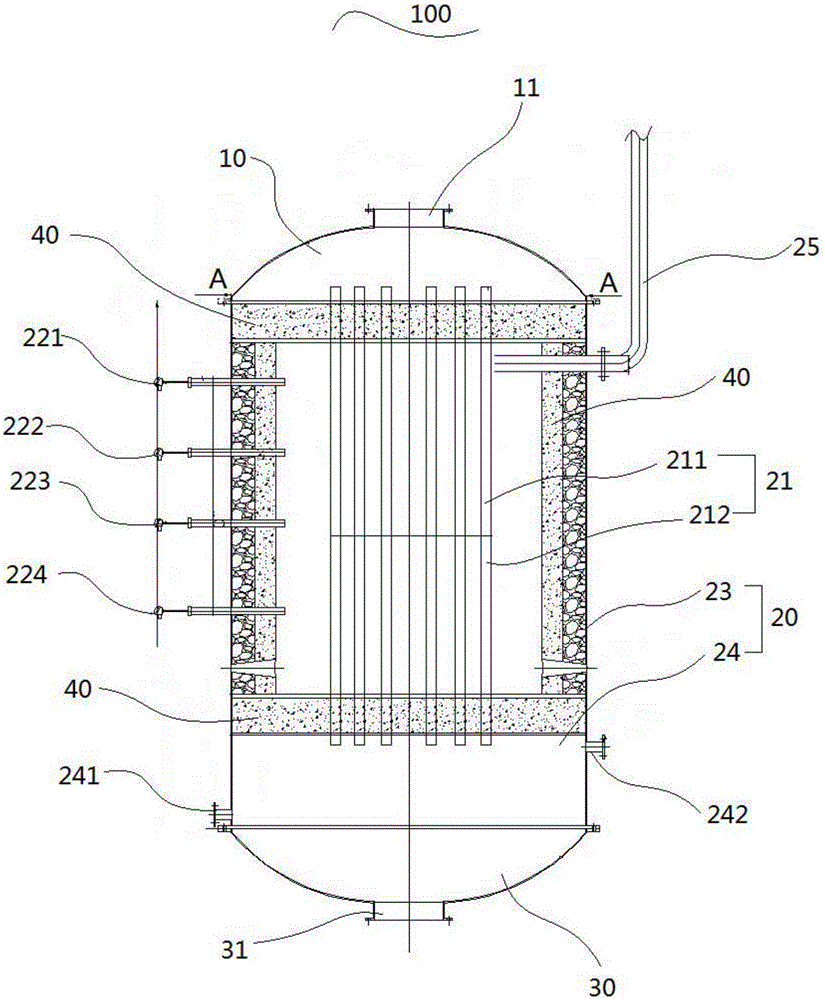

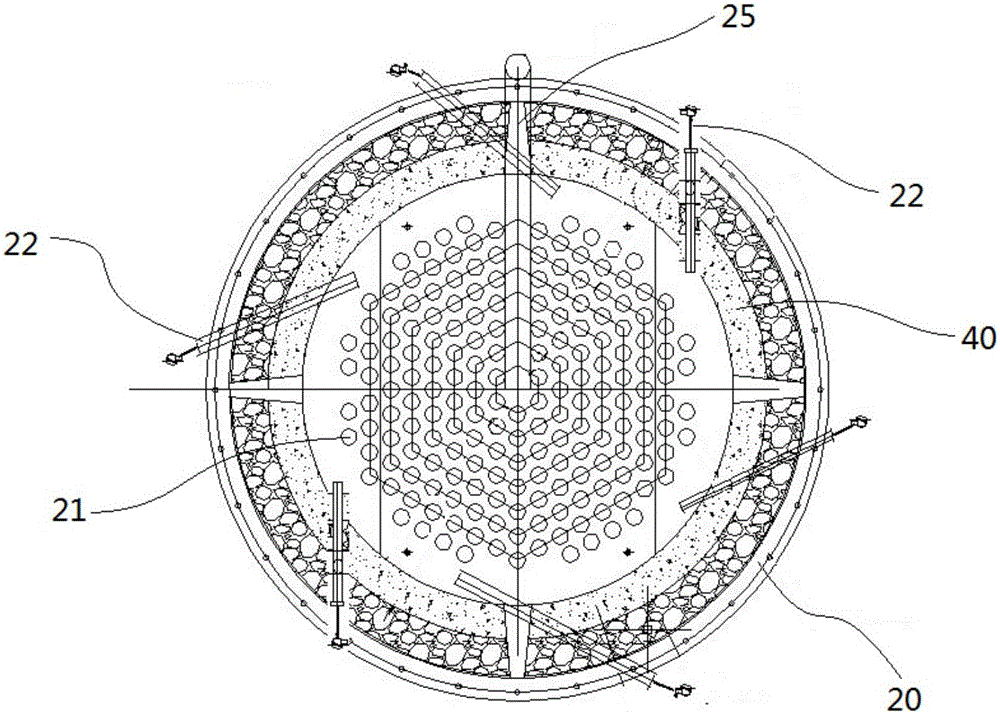

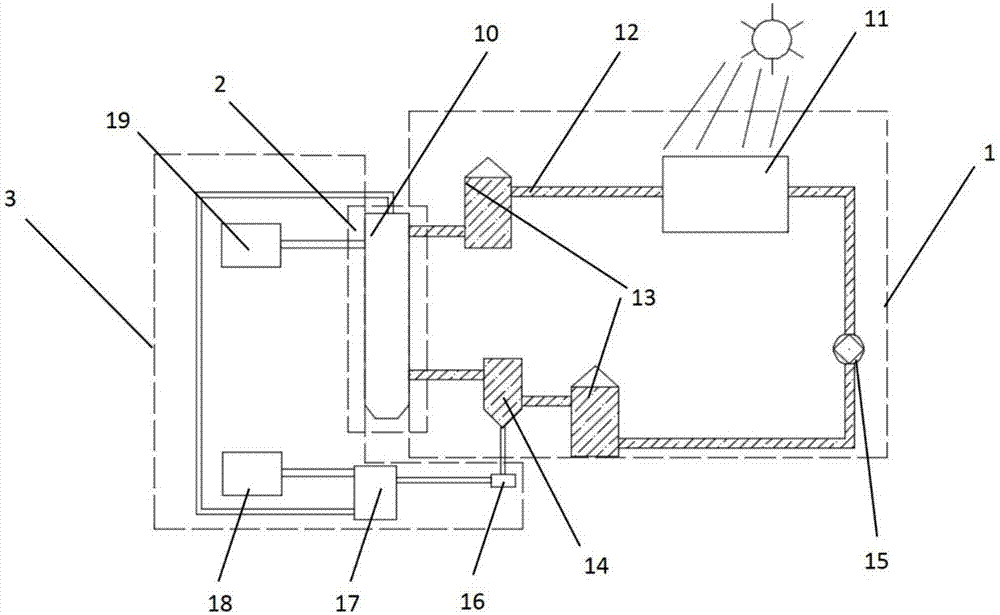

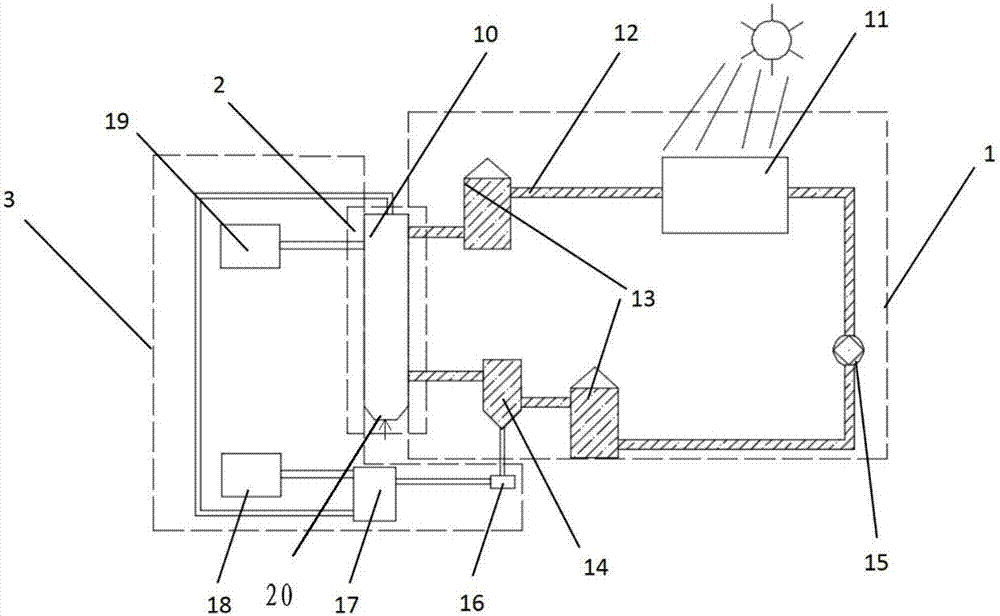

Reaction device for preparing synthesis gas through catalytic reforming of methane and carbon dioxide

ActiveCN105861055ASolve sinteringSolve problems such as easy carbon depositionHydrogenCarburetting gasesTemperature controlCatalytic reforming

The invention discloses a reaction device for preparing synthesis gas through catalytic reforming of methane and carbon dioxide, and belongs to the technical field of energy utilization. The reaction device comprises a gas distributor, a shell-pass shell and a gas collector which are connected in sequence, multiple gas reaction tubes are contained in an inner cavity of the shell-pass shell and are arrayed in a regular hexagon shape, one ends of the gas reaction tubes are arranged in the gas distributor, the other ends of the gas reaction tubes are arranged in the shell-pass shell, at least two layers of flame nozzles are connected to the outer surface of the shell-pass shell, and at least one layer of flame nozzles are matched with the corresponding gas reaction tubes and are arranged annularly. According to the reaction device for preparing synthesis gas through catalytic reforming of methane and carbon dioxide, the flame nozzles of the shell-pass shell are uniformly distributed along the side boundary of the hexagon array of the gas reaction tubes in the same direction, and the effects of stable and uniform heat transfer and easy temperature control are achieved.

Owner:TAIYUAN UNIV OF TECH

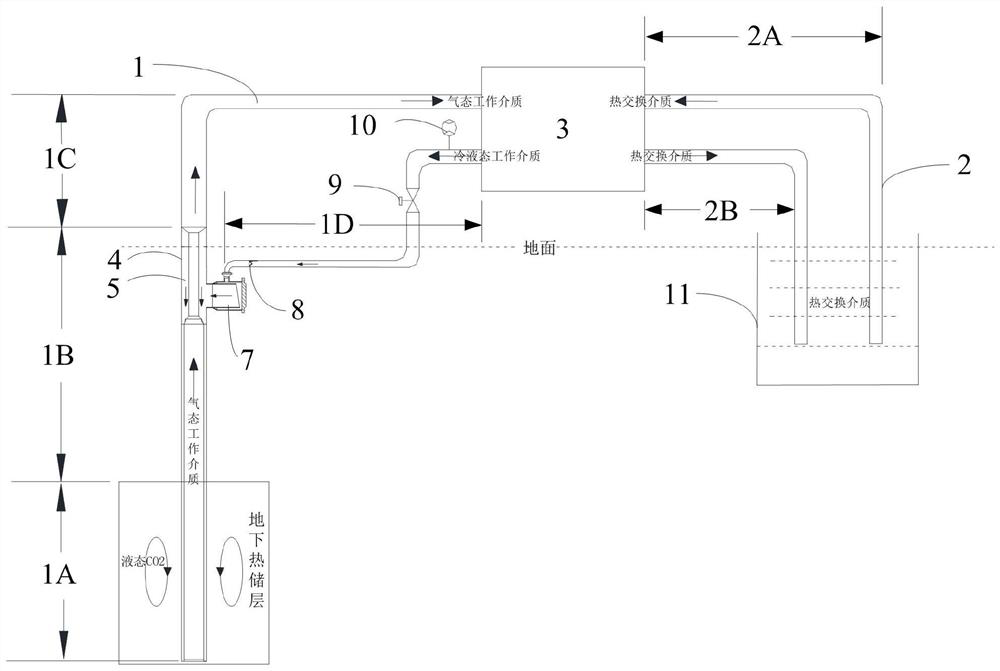

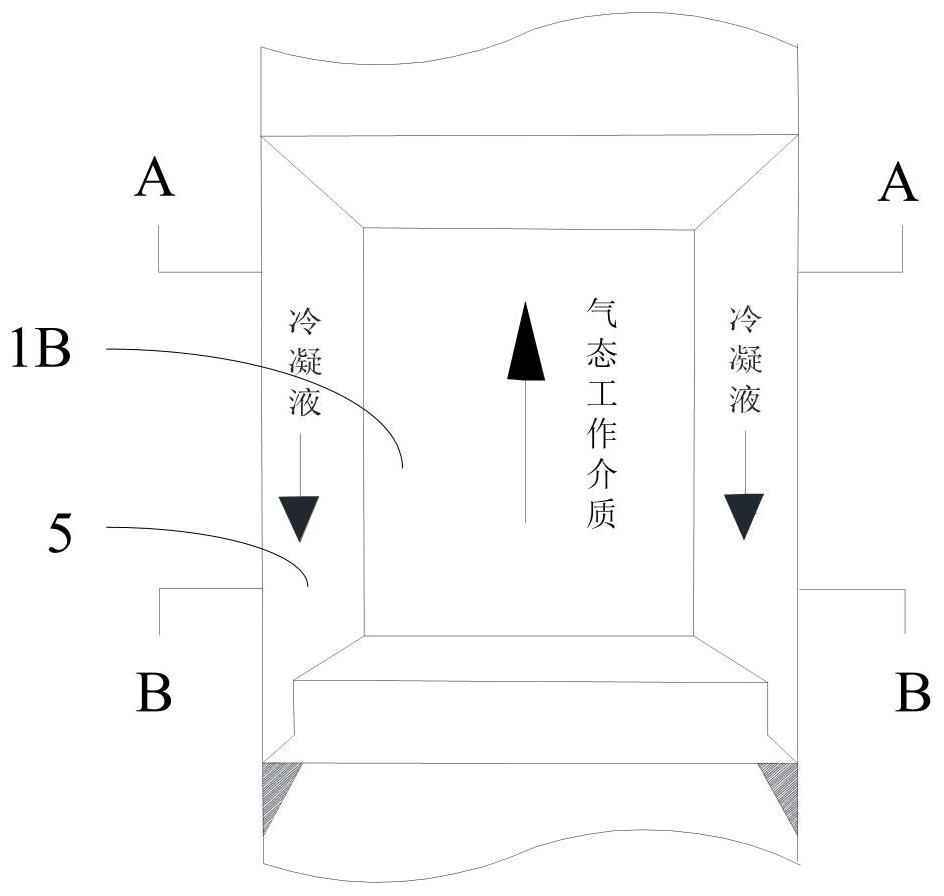

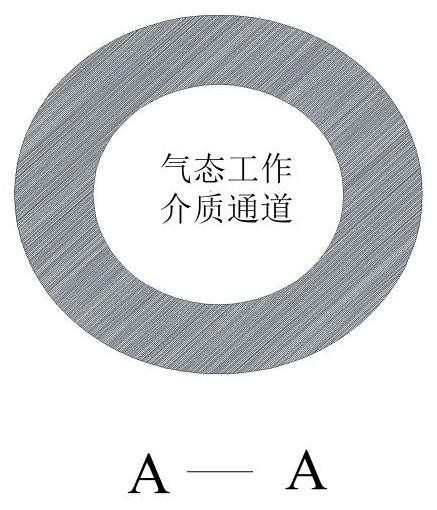

Geothermal energy extraction device and method

PendingCN112268474ASupercriticalPrevent drynessGeothermal energy generationStationary plate conduit assembliesPlate heat exchangerEngineering

The invention discloses a geothermal energy extraction device and method. A gravity heat pipe of the device comprises an evaporation section, an adiabatic section, a condensation section and a backflow section, wherein the end, away from the adiabatic section, of the evaporation section is sealed; the evaporation section, the adiabatic section, the condensation section, a plate heat exchanger, thebackflow section and a gas-liquid separator are in butt joint end to end in sequence; the gas-liquid separator is arranged on one section of pipe wall of the adiabatic section in a sleeved mode; thegas-liquid separator is fixed to the section of pipe wall of the adiabatic section in a seamless welding mode; an independent space is formed between the interior of the gas-liquid separator and the section of pipe wall of the adiabatic section; the liquid outlet end of the space is a diversion hole arranged in the section of pipe wall; and a heat transfer pipe comprises a liquid inlet section anda liquid outlet section, wherein the liquid outlet end of the liquid inlet section and the liquid inlet end of the liquid outlet section are communicated with the interior of the plate heat exchangerrespectively. The method is realized through the operation of the device. The device and the method are environment-friendly and economical, pump work does not need to be consumed, meanwhile, the heat pipe is high in heat transfer speed and stable in heat transfer, and the heat energy exploitation efficiency can be improved.

Owner:NANJING UNIV OF TECH

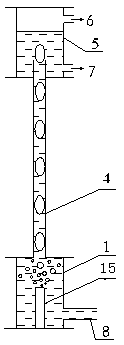

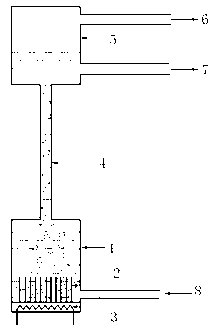

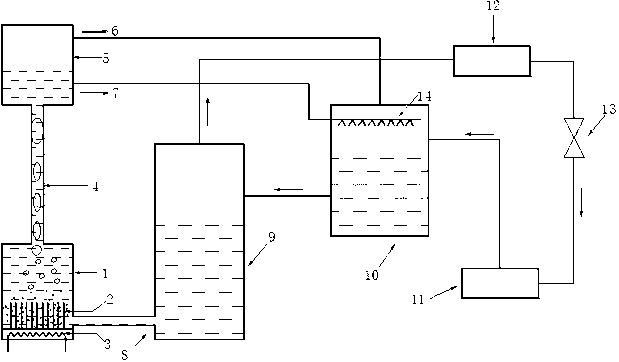

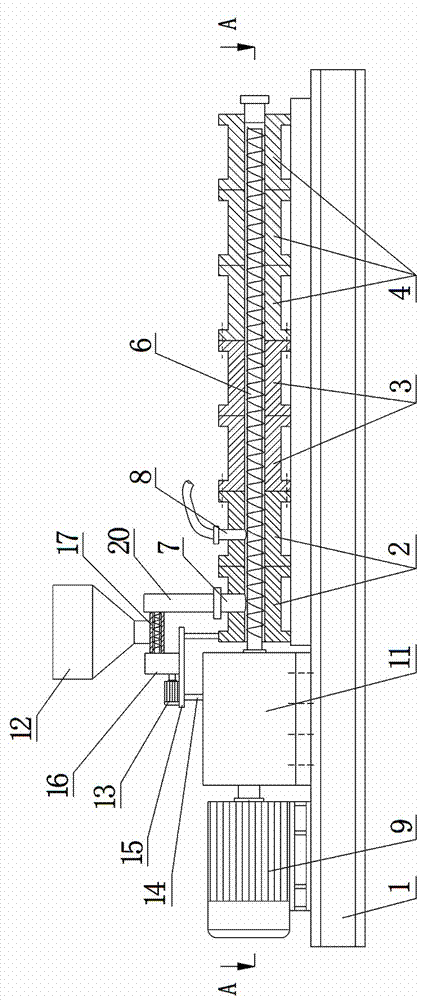

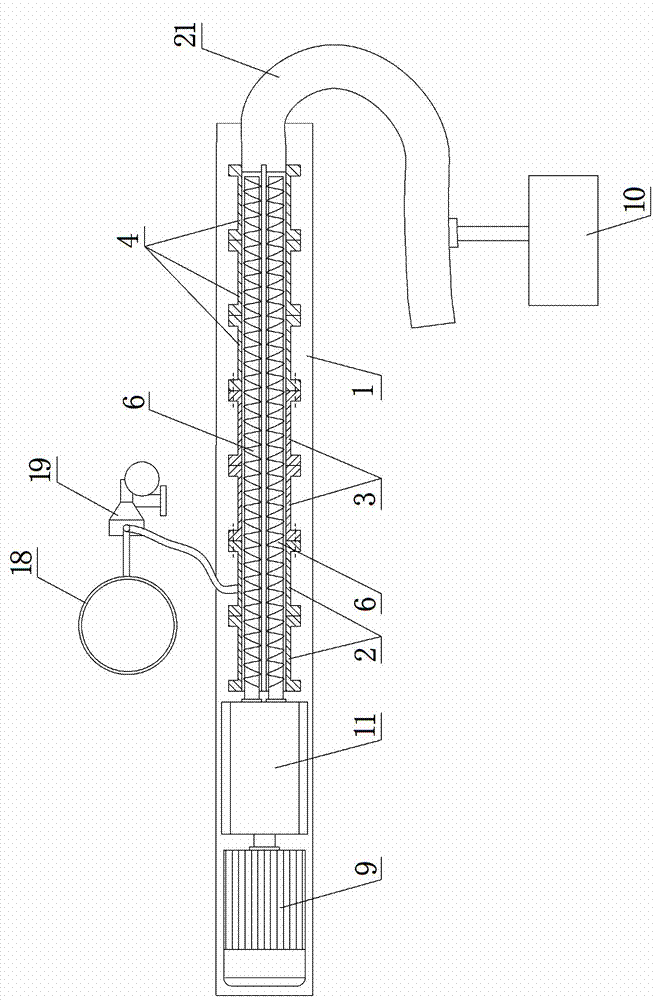

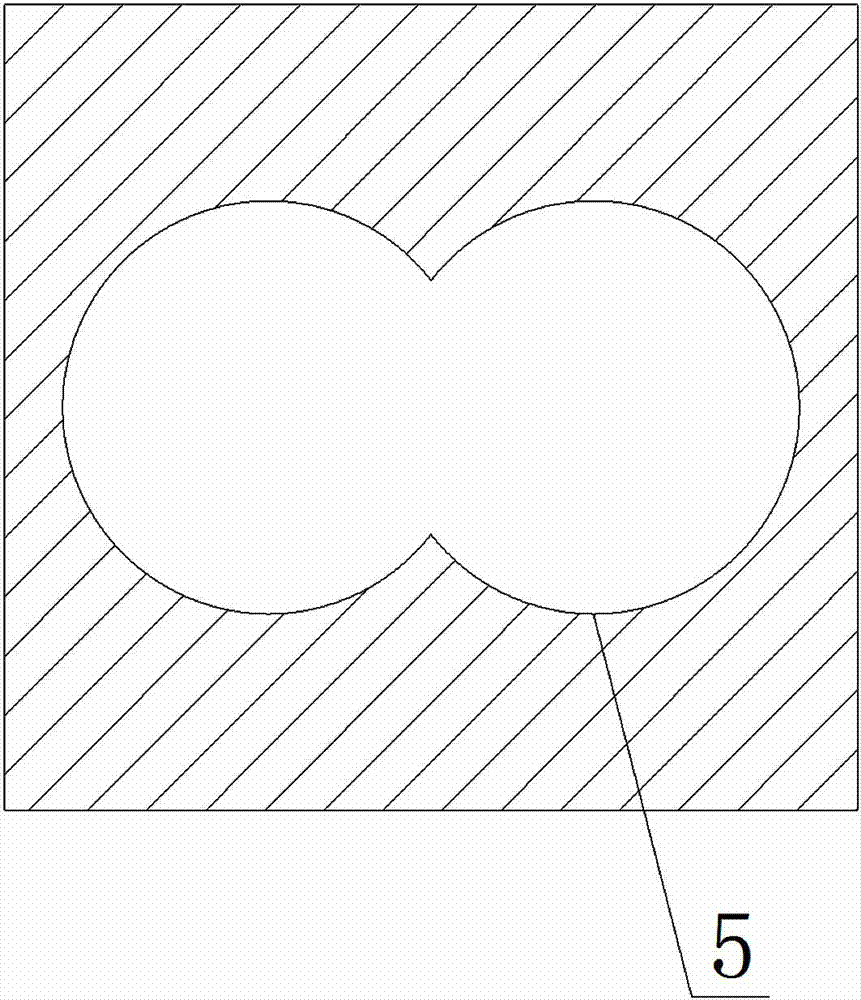

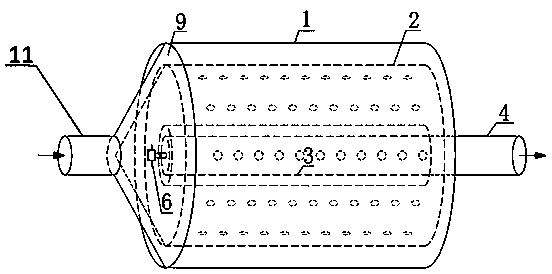

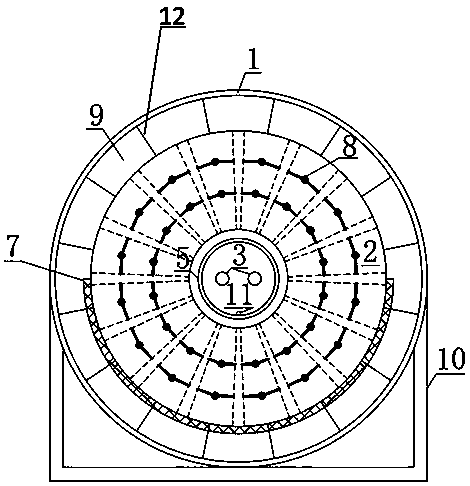

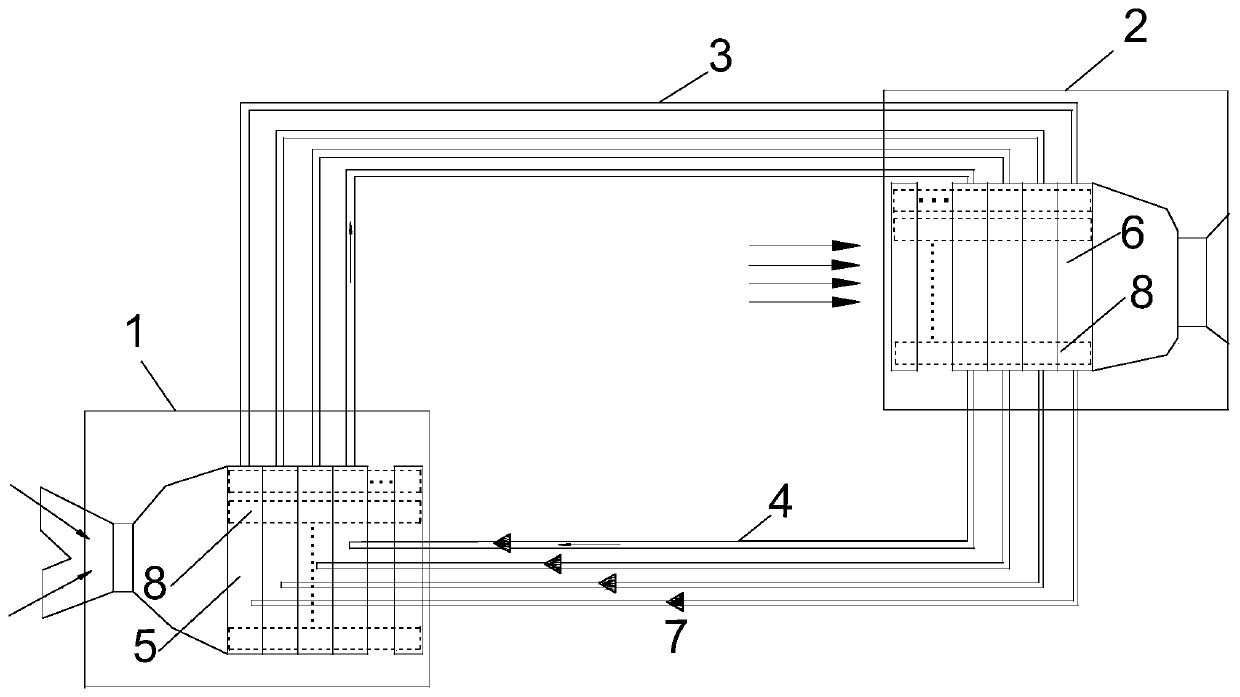

Device and method for preparing foam resin microspheres for physical sensitization of emulsified explosives

The invention discloses a device for preparing foam resin microspheres for physical sensitization of emulsified explosives. The device comprises a frame (1) and a conveying channel cylinder, wherein the conveying channel cylinder is composed of a charging cylinder section (2), a mixing cylinder section (3) and a foaming cylinder section (4) for foaming resin microspheres; the three sections are orderly connected by use of flanges, and a feeding hole A (7) and a feeding hole B (8) both communicated with a conveying channel (5) are formed in the top of the charging cylinder section (2); the device further comprises a charging system, a liquid adding system, a motor I (9), a nitrogen cooling device (10) and a reduction gearbox I (11) with two output ends, wherein the motor I (9), the reduction gearbox I (11) and the conveying channel cylinder are orderly arranged on the frame (1). The invention also discloses a method for preparing the foam resin microspheres. The device for preparing the foam resin microspheres for physical sensitization of the emulsified explosives has the beneficial effects that the production efficiency is high, the dust generated after the foaming of the foam resin microspheres for physical sensitization of the emulsified explosives is effectively reduced, and sticking of the foam resin microspheres for physical sensitization of the emulsified explosives at high temperatures is effectively prevented.

Owner:雅化集团三台化工有限公司

Efficient energy-saving nested heat storage device

PendingCN111473398AImprove distributionReduce resistanceHeat storage plantsElectric heating systemEngineeringHeat conservation

The invention discloses an efficient energy-saving nested heat storage device. The efficient energy-saving nested heat storage device comprises a heat insulation shell, and a columnar hollow heat storage module is arranged in the heat insulation shell. An adjusting sleeve assembly for adjusting the heat exchange mode is arranged in the heat storage module, and a heat exchange disc is arranged in the adjusting sleeve assembly. The heat insulation shell comprises a columnar cavity for containing the columnar heat storage module and a conical cavity for containing a flow diffusing structure. According to the efficient energy-saving nested heat storage device, a cylindrical heat storage form is adopted, a heat exchange hole in a heat storage body is perpendicular to the axis of the heat storage module, heat energy distribution in the heat storage body is optimized, quick and stable temperature rising can be achieved, and quick heat transferring is achieved; the heat exchange disc is arranged in the heat storage module, a radiation heat exchange and convectional heat exchange-radiation heat exchange mode is achieved, and when the work temperature of the heat storage module changes, adjustment can be carried out in time; and therefore power consumption waste is avoided, the resistance of an air system is reduced, the service life of a fan is prolonged, the heat exchange efficiency isenhanced, the use time of the fan is shortened, and the system operation cost is reduced.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

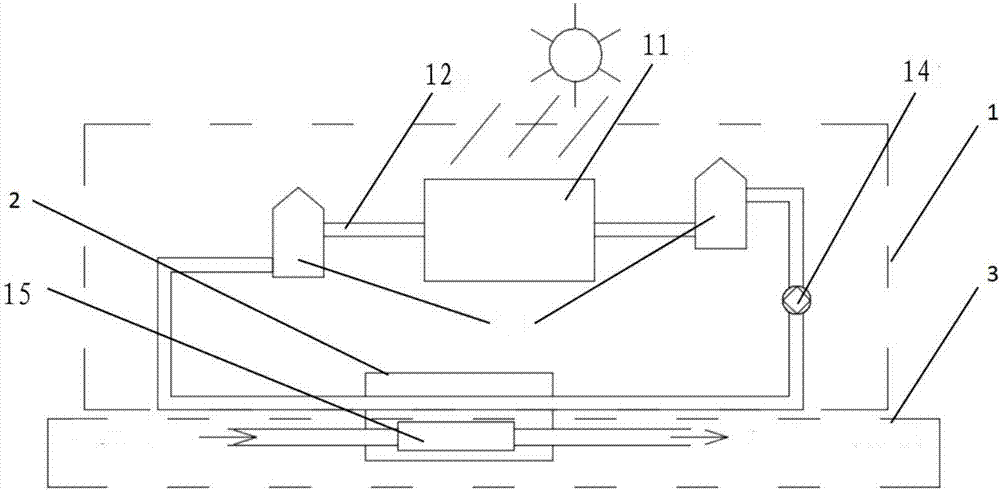

Hydrogen production system and method

PendingCN107285276AImprove efficiencyImprove stabilityChemical industryHydrogen productionLiquid metalHydrogen production

The invention relates to the field of hydrogen production, and discloses a hydrogen production system. The hydrogen production system comprises a heat collection mechanism, a hydrogen production mechanism and a heat exchanger, wherein the heat collection mechanism comprises a heat collector and a liquid metal pipeline, the liquid metal pipeline is connected with a heat collector, the heat collector is used for absorbing heat, and the liquid metal pipeline is filled with liquid metal; and the heat exchanger is respectively connected with the hydrogen production mechanism and the liquid metal pipeline. The invention also discloses a hydrogen production method. The hydrogen production method comprises the following steps: the heat collector collects heat and transfers the heat to liquid metal of the liquid metal pipeline; and the liquid metal is introduced into the heat exchanger to provide heat for the reaction of the hydrogen production mechanism. The liquid metal is used for replacing molten salt as a heat transfer medium, has lower melting point and higher boiling point, can be kept at a liquid state in a large temperature range, does not have phase change and is stable in heat transfer; the liquid metal has the heat conductivity which is far higher than that of nonmetal cooling agents such as air and water and is high in heat transfer efficiency; the mobility is good; and the efficiency and the stability of the hydrogen production system can be improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

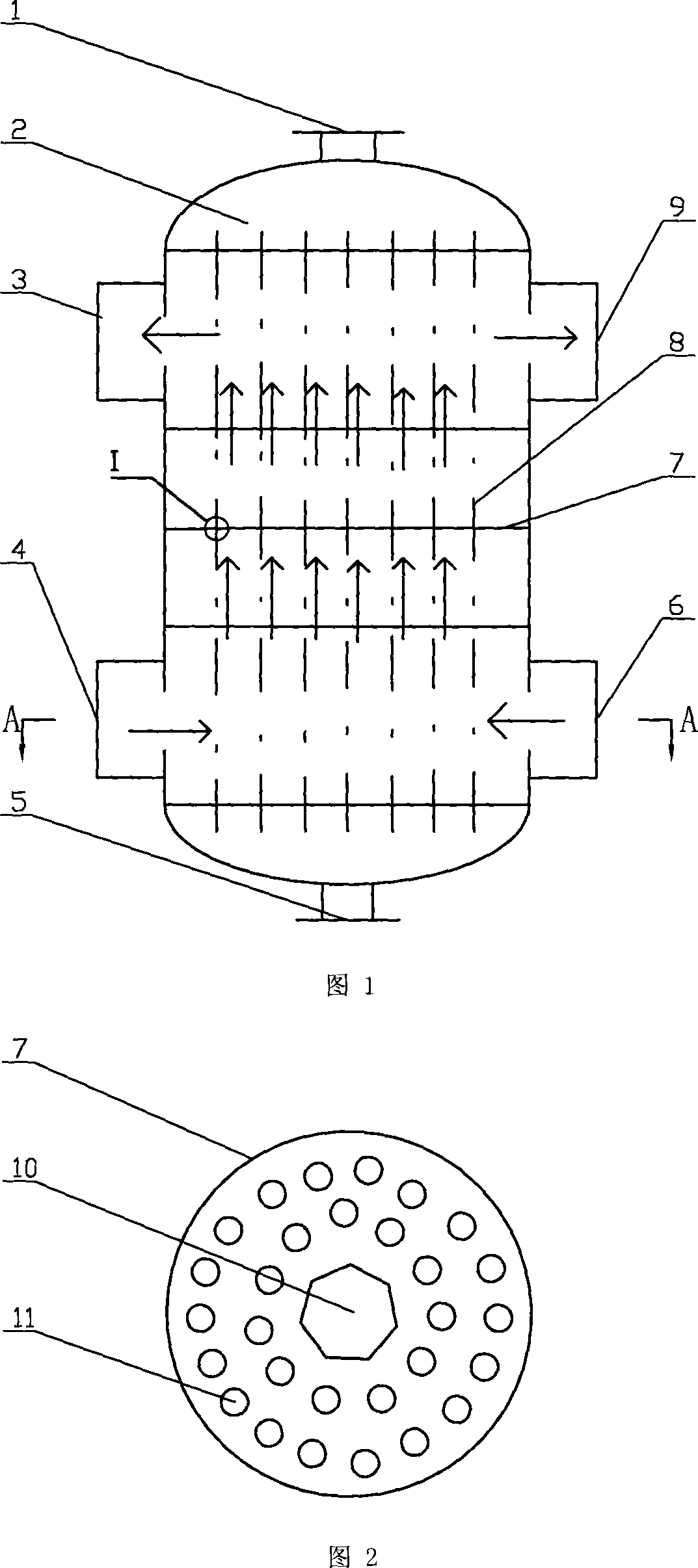

Phthalic anhydride reactor

The present invention belongs to the field of phthalic anhydride producing apparatus, and is especially one kind of phthalic anhydride reactor. The phthalic anhydride reactor includes one cylindrical shell with gas inlet, gas outlet, molten salt inlet and molten salt outlet; one molten salt passage inside the shell; one tube array and one baffle plate with holes matching the tube array. It features the belled molten salt inlet and molten salt outlet, the molten salt passage with crossed small holes and large holes, and the circular baffle plate matching the inner side of the shell. The present invention has the advantages of low cost, stable operation and high yield.

Owner:山东宏信化工股份有限公司

Ultralow-alkalinity high-vitrification covering slag for bloom medium-high carbon steel and preparation method thereof

The invention discloses ultralow-alkalinity high-vitrification covering slag for bloom medium-high carbon steel and a preparation method thereof, and belongs to the technical field of steelmaking metallurgy auxiliary materials. The ultralow-alkalinity high-vitrification covering slag for the bloom medium-high carbon steel is prepared from the following raw materials of, by weight, 15-35 parts of wollastonite, 15-30 parts of power plant molten coal cinder waste, 2-13 parts of quartz, 6-13 parts of albite, 2-8 parts of sodium fluoride, 1-5 parts of sodium carbonate, 6-10 parts of fluorite, 2-5 parts of magnesia powder, 1-6 parts of 390 medium-carbon graphite, 2-6 parts of high-carbon amorphous graphite, 1.5-3 parts of semi-reinforcing natural gas carbon black and 5-8 parts of sodium silicate. The ultra-low alkalinity is adopted, the vitrification rate in the slag solidification process is controlled to be high, and then the blank shell thickness and the lubricating effect in the medium-high carbon continuous casting process are guaranteed; the high viscosity is adopted, under the condition that a casting blank has certain shrinkage, molten slag is evenly guided in, solid slag film is uniform, and it is guaranteed that the surface of the casting blank is smooth; slightly high melting point and viscosity are adopted, so that the use amount of flux is reduced, the slag surface tension is improved, and the slag entrapment probability is reduced; and compound carbon blending is adopted, and then the problem of accidental carbon pickup of the casting blank is relieved by adjusting the carbon blending.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Function protective material of extra-large round billet peritectic steel continuous casting crystallizer

ActiveCN104624998AImprove the lubrication effectImprove lubrication functionGraphite carbonLiquid slag

The invention provides a function protective material of an extra-large round billet peritectic steel continuous casting crystallizer. The function protective material comprises the following components in percentage by weight: 55-60 parts of premelting material, 3-7 parts of calcite, 2-4 parts of sodium carbonate, 12-18 parts of fluorite, 2-4 parts of high alumina, 3-5 parts of cryolite, 2-3 parts of lithium carbonate, 1.8-2.5 parts of carbon black and 6-10 parts of graphite carbon. The function protective material not only is uniform in melting in the crystallizer and less in slag rim, but also the liquid slag has the thickness of 8-10mm in normal pull speed; the steel consumption amount of each ton is 0.1-0.35Kg; longitudinal pits and cracks are not generated in the weak pats of a billet shell, and the non-cleaned rate of the surface of a casting blank reaches above 98%.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP +1

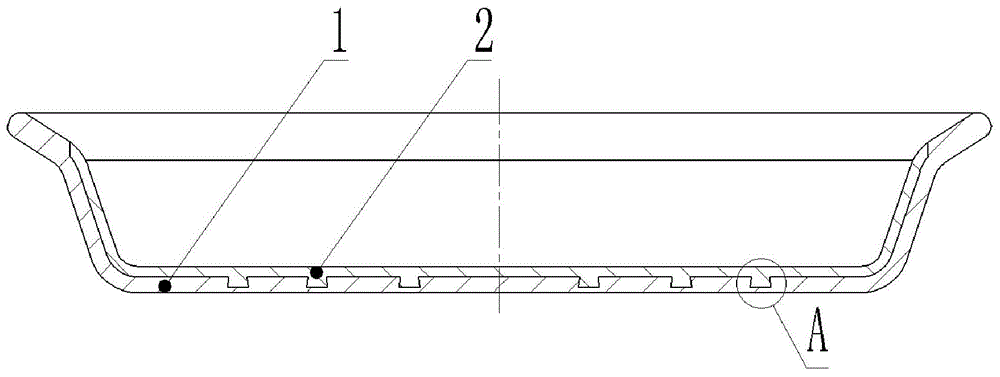

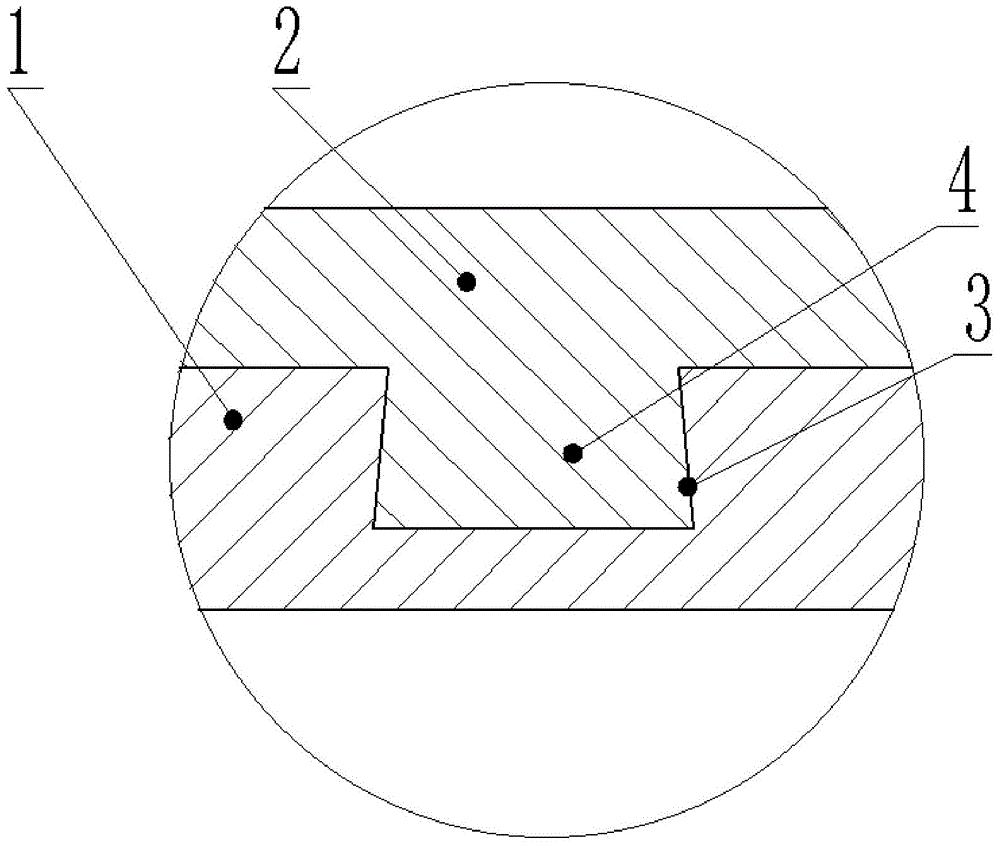

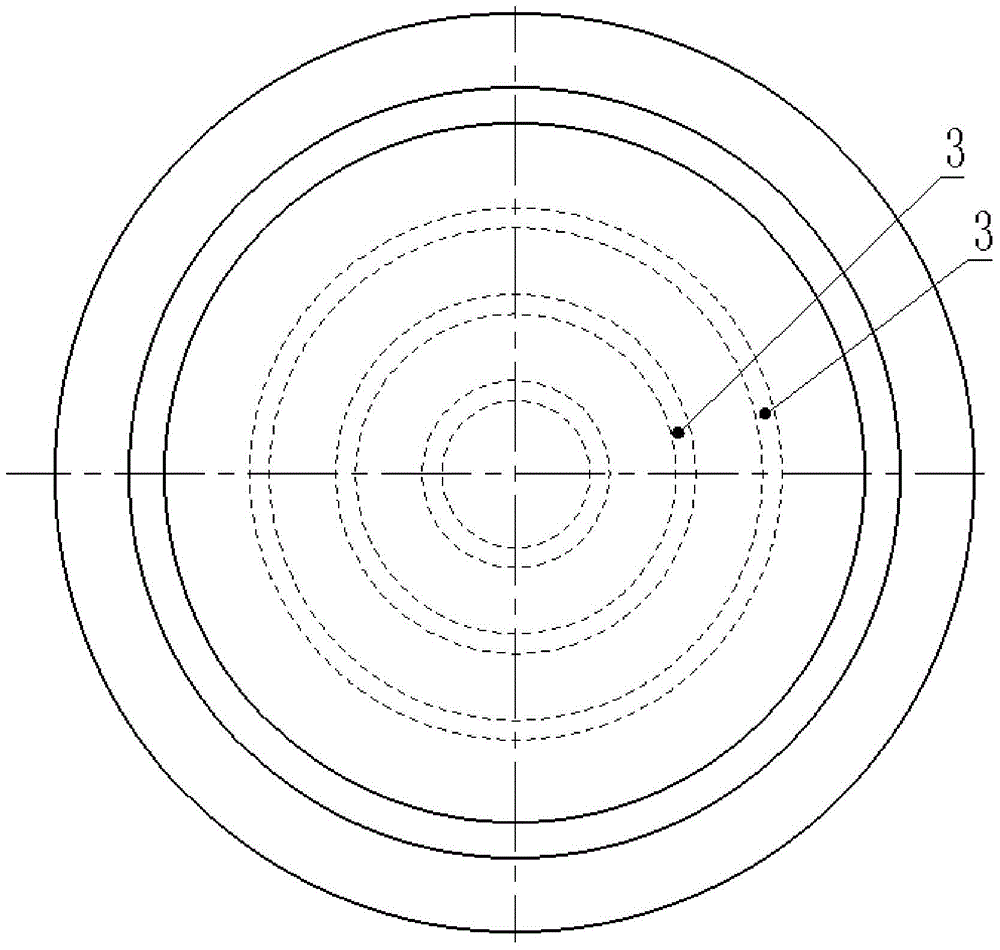

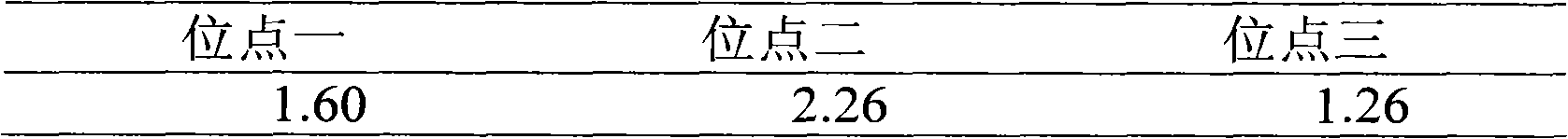

Magnesium-based composite material and composite cookware

ActiveCN104630588AStable structureGood for healthCooking-vessel materialsMagnesium matrix compositeHuman health

The invention discloses a magnesium-based composite material and composite cookware. The magnesium-based composite material comprises the following components in percentage by mass: 1.0-3.0 percent of Zn, 0.5-1.0 percent of Zr, 1.0-8.0 percent of Nd, 0.5-1.8 percent of Gd, 0.1 percent of Cu, 0.01 percent of Ni, 5-15 percent of particle reinforced materials and the balance of magnesium and inevitable impurities. According to the magnesium-based composite material disclosed by the invention, magnesium is taken as a main component, the material also comprises Zn, Zr, Nd, Gd, Cu, Ni and particle reinforced materials, the various components are matched with one another and are coordinated, the obtained magnesium-based composite material has high heat-conducting property and corrosion resistance, is very favorable for the human health and is used for manufacturing the liner (the inner pot body) of the cookware. Moreover, according to magnesium separated out in the using process, the intake of magnesium in the human body can be effectively supplemented, and the magnesium deficiency symptom of the human body is effectively relieved.

Owner:洛阳天久科技有限公司

Process for preparing novel silver loaded active carbon by rheological phase reaction method

InactiveCN102091594AEvenly distributedHigh recovery rateOther chemical processesPotassium persulfateMass ratio

The invention relates to a process for preparing novel silver loaded active carbon by a rheological phase reaction method, comprising the following steps of: evenly mixing finely ground tetrasilver tetroxide and active carbon according to mass ratio of 1:800-12000, adding water into the mixed material to stir the mixed material into a flowing deformation state, wherein each part of the active carbon is added with 1-2 parts of water; vacuum drying for 10-40min under 60-150 DEG C; adding potassium persulfate or sodium persulfate, sodium hydroxide or potassium hydroxide into the mixed material for finely grinding; adding distilled water in the material to stir into the flowing deformation state, wherein the contents of the added potassium persulfate or sodium persulfate, sodium hydroxide or potassium hydroxide are 1-3 times of that of each part of tetrasilver tetroxide; finally vacuum drying for 10-30min under 80-110 DEG C, filtering, and washing for 2-4 times by pure water. The invention is featured with simple technology for preparing adhesion trivalent silver active carbon, high synthetic efficiency and low energy consumption; the silver ions are evenly distributed on the active carbon, fixedly adhered and difficult for falling off. The product has obvious action to various microorganisms, and is safe to environment and human.

Owner:苏州泰利三佳纳米科技有限公司

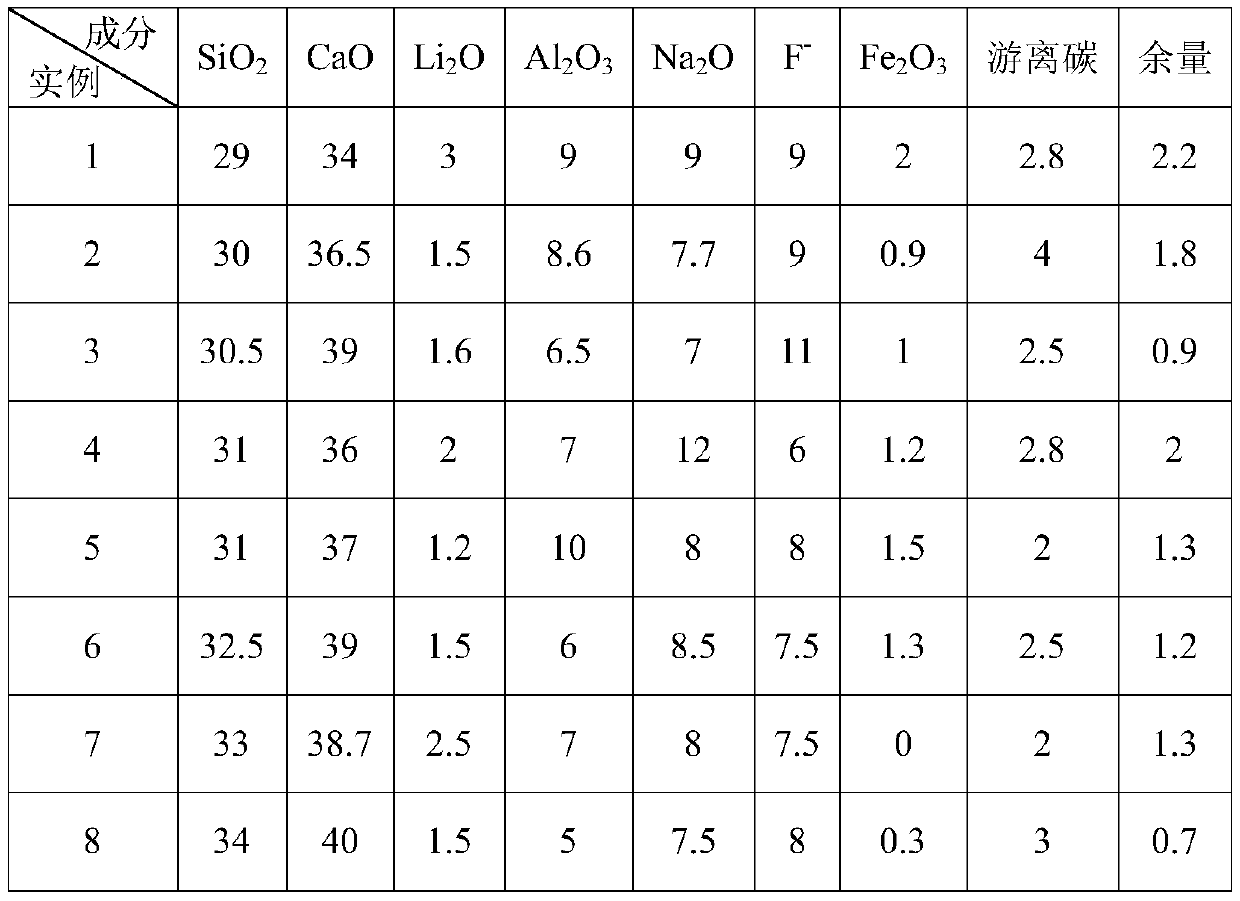

Continuous casting crystallizer casting powder for 310S stainless steel

InactiveCN109954852AImprove heat transfer uniformityImprove performanceChemical compositionTrace element

The invention discloses continuous casting crystallizer casting powder for 310S stainless steel. The continuous casting crystallizer casting powder is prepared from the chemical components in percentage by weight: 29%-34% of SiO2, 34%-40% of CaO, 1.2%-3% of Li2O, 5%-10% of Al2O3, 7%-12% of Na2O, 7.5%-11% of F<->, 0-2% of Fe2O3, 2%-4% of free carbon and the balance of trace elements. The casting powder is high in heat transfer uniformity, good in lubrication effect, stable in slag layer and uniform in melting, the non-clearing rate of the surfaces of cast 310S stainless steel casting blanks is99% or above, and the subsurface and interior quality of the casting blanks is good.

Owner:西峡县西保冶金材料有限公司

Reactor for preparing synthesis gas by catalytic reforming of methane and carbon dioxide

ActiveCN105861055BReduce wasteIncrease profitHydrogenCarburetting gasesCatalytic reformingTemperature control

The invention discloses a reaction device for preparing synthesis gas through catalytic reforming of methane and carbon dioxide, and belongs to the technical field of energy utilization. The reaction device comprises a gas distributor, a shell-pass shell and a gas collector which are connected in sequence, multiple gas reaction tubes are contained in an inner cavity of the shell-pass shell and are arrayed in a regular hexagon shape, one ends of the gas reaction tubes are arranged in the gas distributor, the other ends of the gas reaction tubes are arranged in the shell-pass shell, at least two layers of flame nozzles are connected to the outer surface of the shell-pass shell, and at least one layer of flame nozzles are matched with the corresponding gas reaction tubes and are arranged annularly. According to the reaction device for preparing synthesis gas through catalytic reforming of methane and carbon dioxide, the flame nozzles of the shell-pass shell are uniformly distributed along the side boundary of the hexagon array of the gas reaction tubes in the same direction, and the effects of stable and uniform heat transfer and easy temperature control are achieved.

Owner:TAIYUAN UNIV OF TECH

Long-distance separation type heat tube heat exchange system

InactiveCN110822958AStable heat transferEasy to manageIndirect heat exchangersThermodynamicsEngineering

The invention relates to a long-distance separation type heat tube heat exchange system. The heat exchange system is divided into a heat absorption module and a heat release module according to functions, wherein the whole heat exchange system is divided into multiple units which are independent from one another, and each independent unit consists of a heat absorption sub module, a heat release sub module as well as a steam tube and a liquid recycling tube for connecting the heat absorption sub module to the heat release sub module; an arrangement sequence of unit sub modules in the two modules is set, and an air flowing channel is arranged, so that air quantity in each channel is basically consistent, and sufficient heat exchange between a heat exchange module and air fluid is facilitated; in order to ensure normal efficient operation of the heat exchange system, a liquid return pump is mounted on a liquid return tube; the heat exchange system is suitable for practical application oflong-distance separation type heat exchange tube heat exchange; and moreover, the arrangement way is simple and easy.

Owner:SHANDONG UNIV OF SCI & TECH

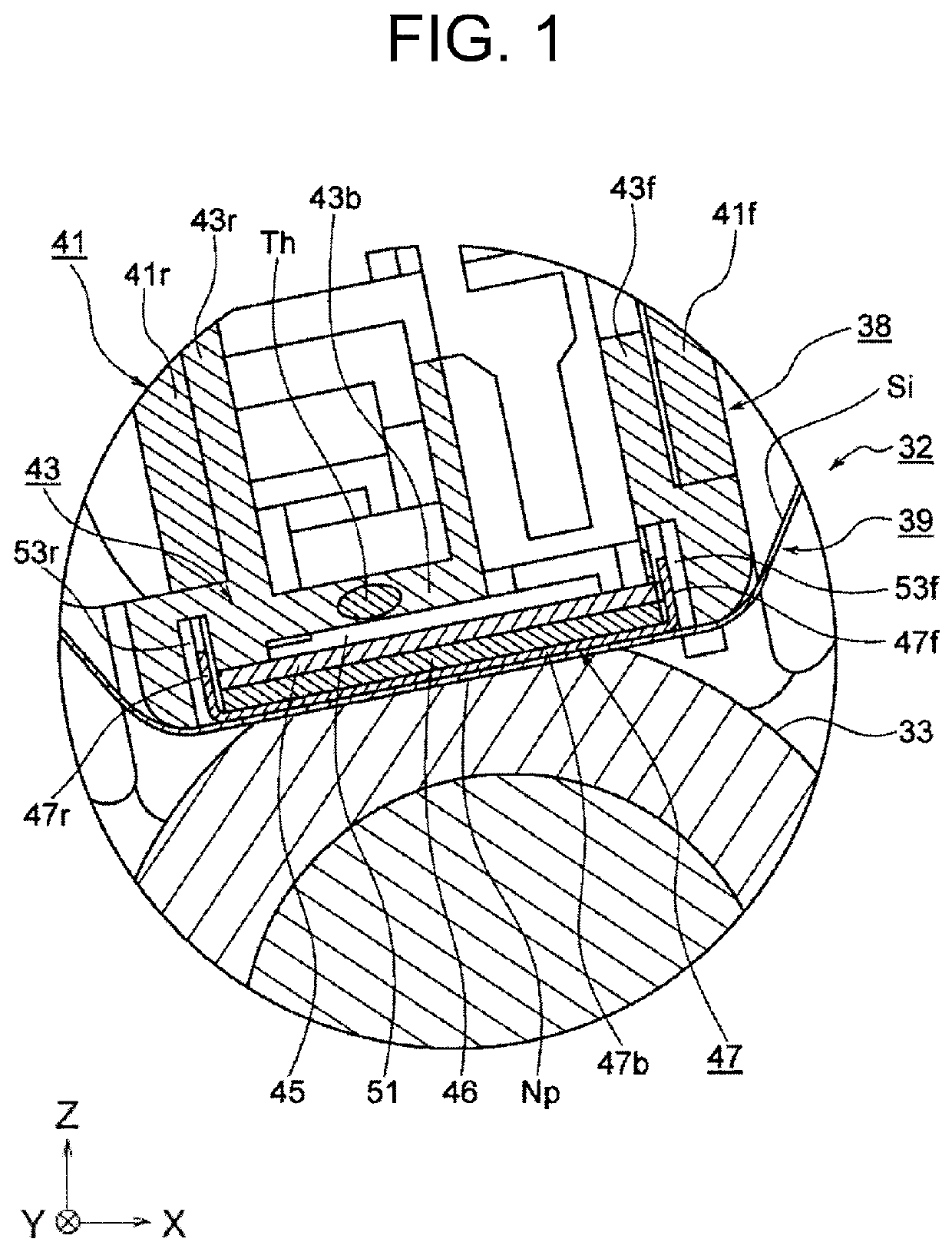

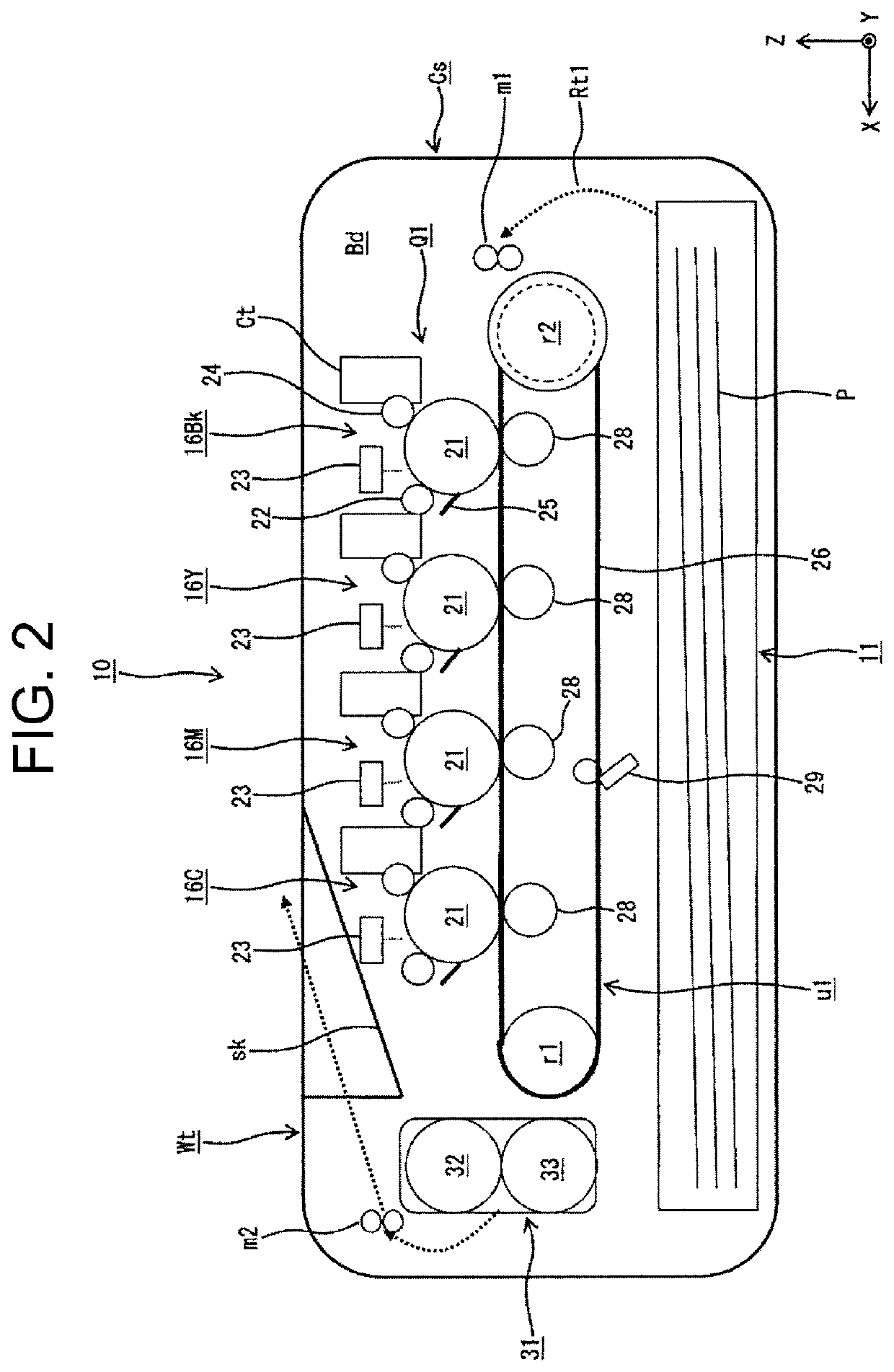

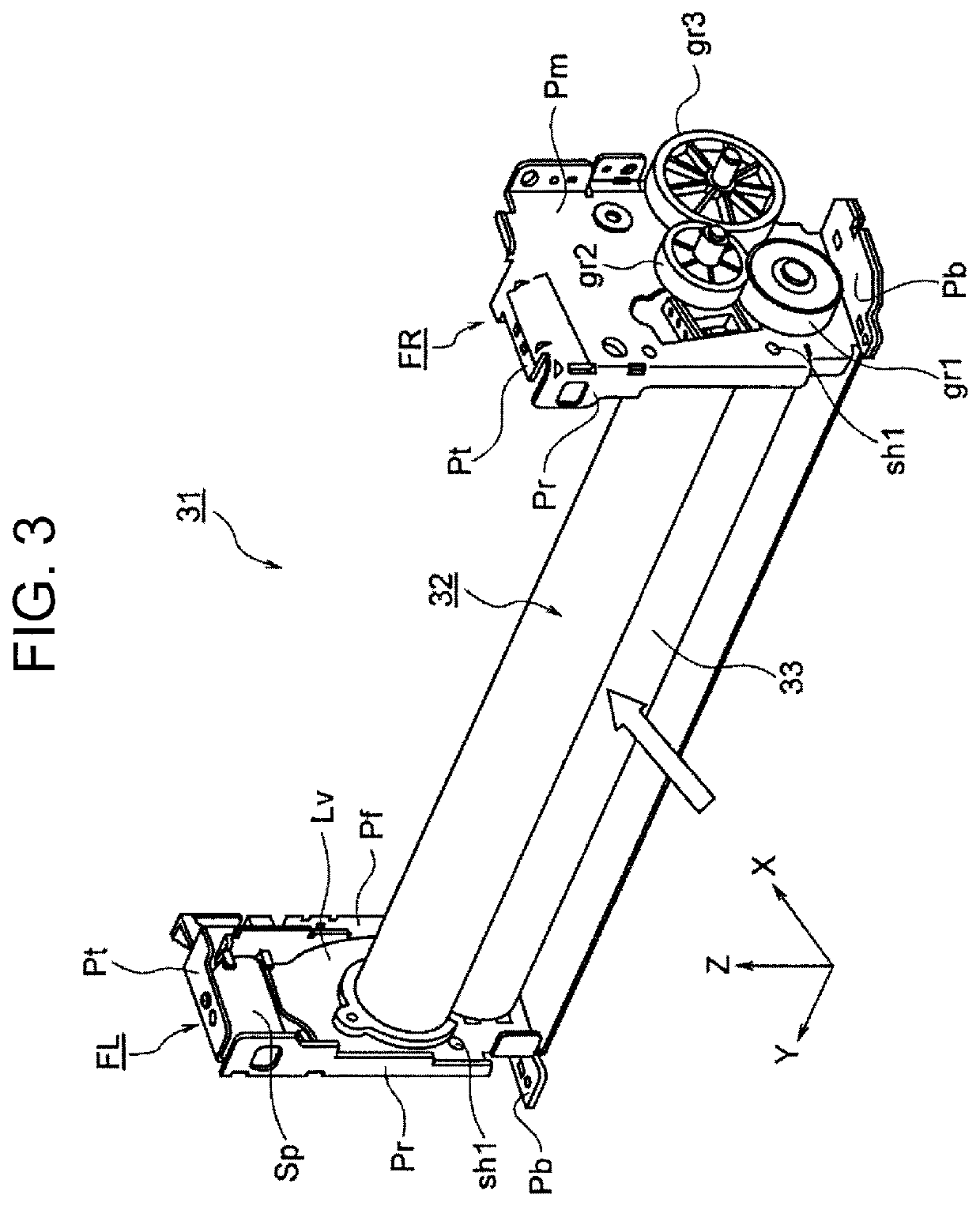

Fixing device and image forming apparatus

PendingUS20220236676A1Stable heat transferImprove image qualityElectrographic process apparatusThermal diffusivityEngineering

A fixing device includes an annular belt, a heating member disposed to face an inner circumferential surface of the annular belt; and a heat storage member disposed to face a surface of the heating member on a side opposite to the annular belt. A thermal diffusivity of the heat storage member is lower than a thermal diffusivity of the annular belt.

Owner:OKI ELECTRIC IND CO LTD

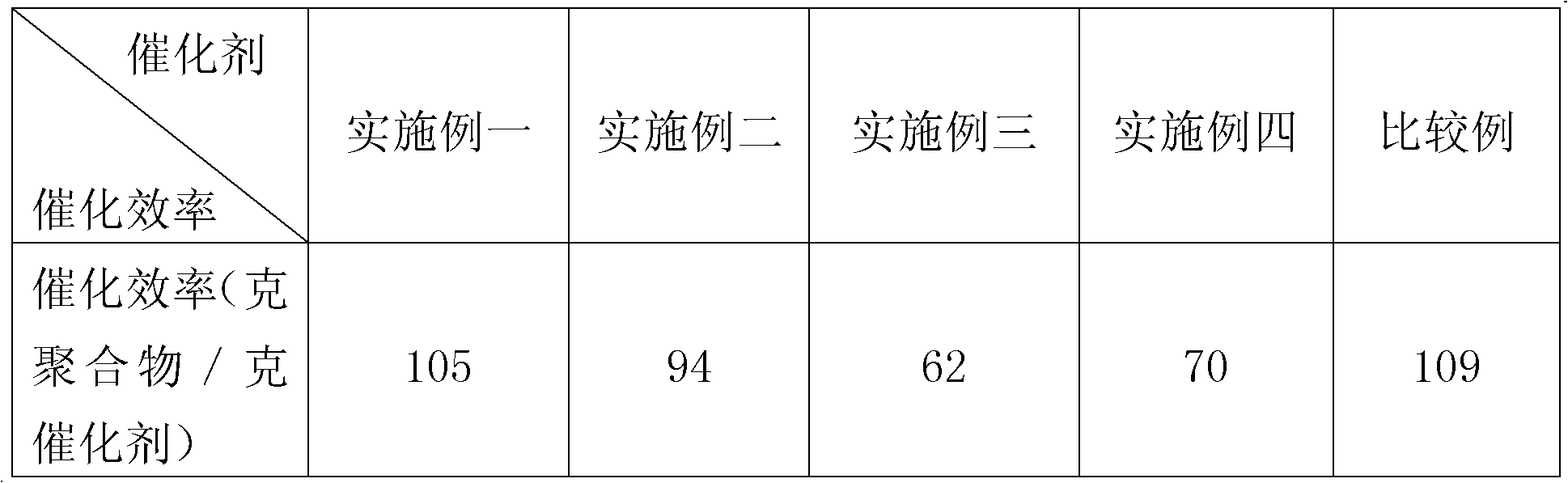

Method for preparing dicarboxylic acid zinc catalyst with rheological phase reaction method

InactiveCN102911351AEvenly distributedStable heat transferCarboxylic acid salt preparationSolid particleChemistry

The invention relates to a method for preparing a dicarboxylic acid zinc catalyst used in carbon dioxide and alkyleneoxide copolymerization reaction. The method comprises the steps of mixing zinc oxide, dicarboxylic acid and an organic solvent or water in an airtight reactor into a rheological phase state, keeping certain time at constant temperature, then filtering, washing with acetone, vacuumizing for 24 hours at 100 DEG C, and finally obtaining the dicarboxylic acid zinc catalyst. The method for preparing the dicarboxylic acid zinc catalyst has high efficiency and energy saving and is suitable for industrial production. In the rheological phase system, solid particles are uniformly distributed and closely contacted in fluid, the heat transfer and the mass transfer are stable, the temperature is uniform and is easily controlled, the reaction is more fully conducted, and the yield is high. The reaction does not need a large number of scattered medium and does not need stirring, the process is greatly simplified, and the production cost can be greatly reduced.

Owner:ZHANJIANG NORMAL UNIV

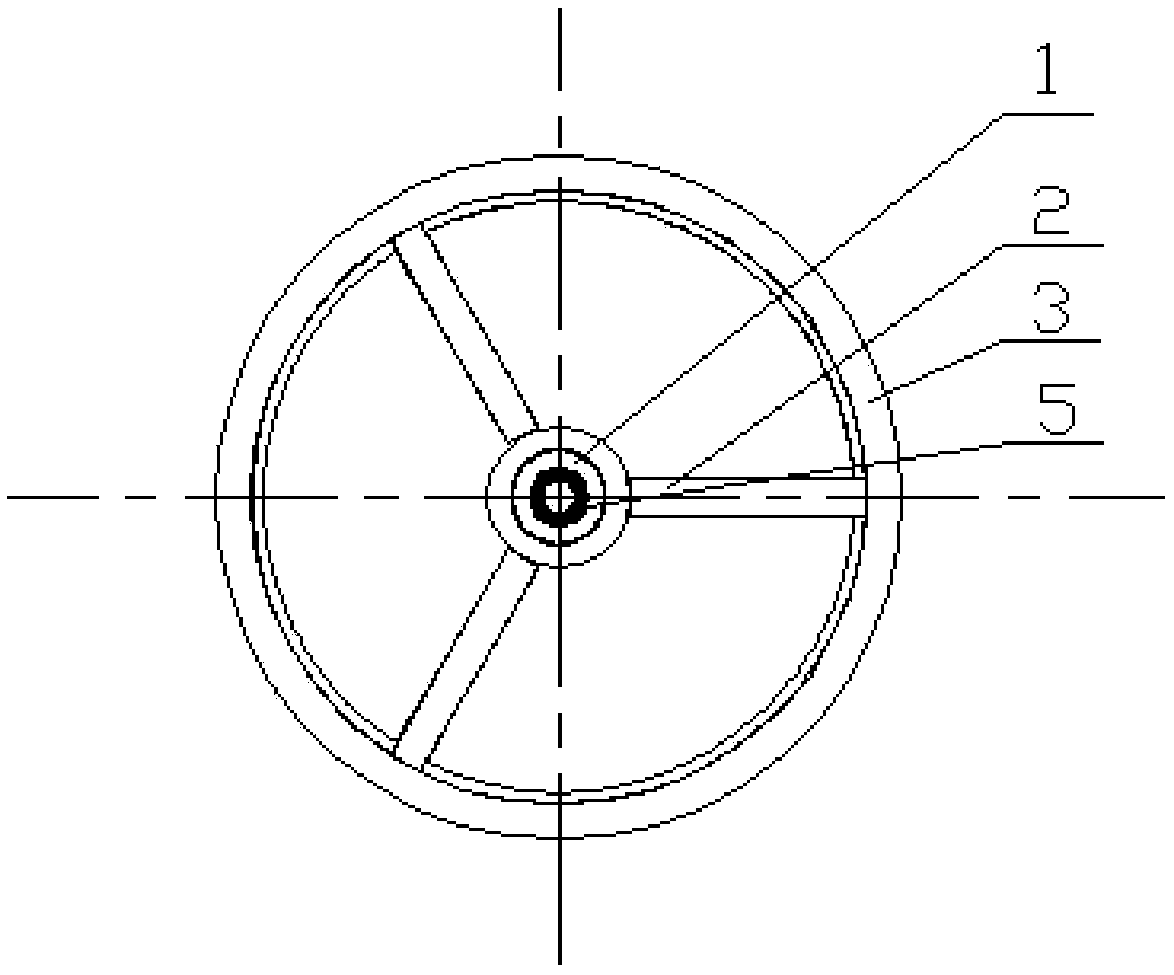

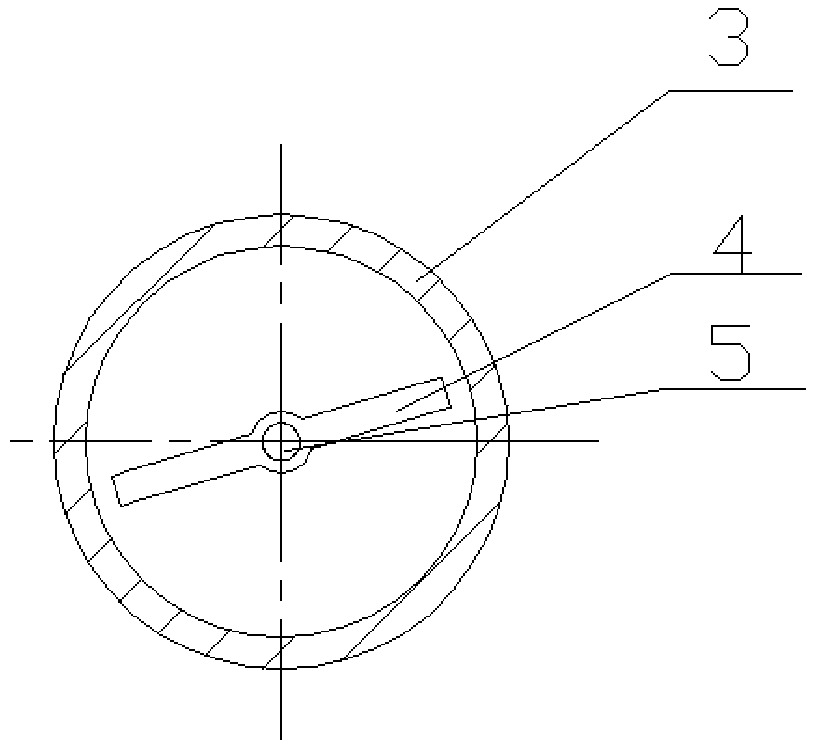

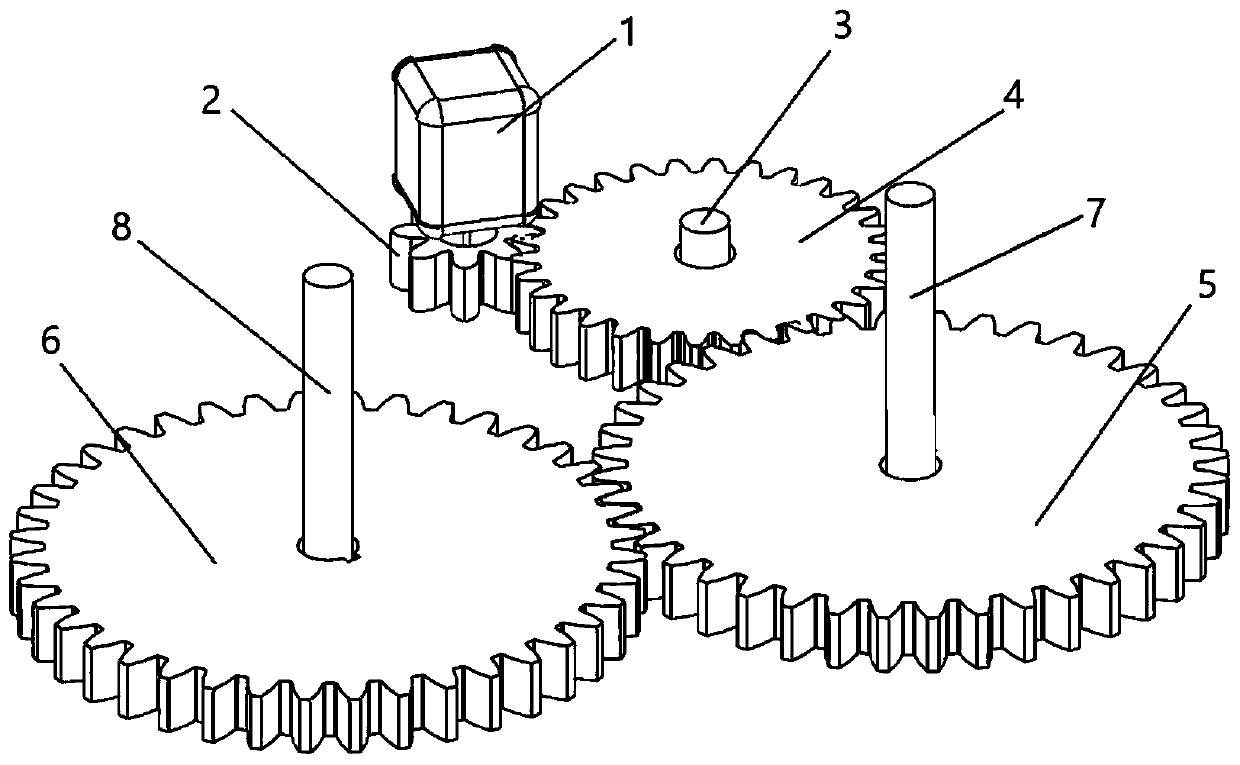

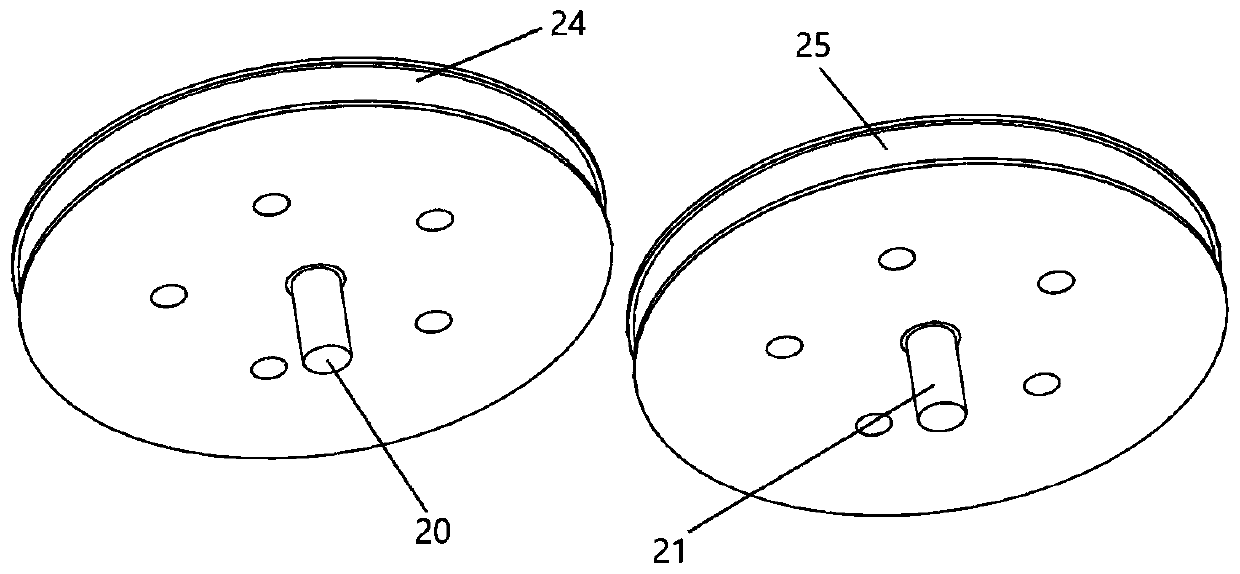

Wheel disc traction type optical fiber tapering machine and method

ActiveCN111538121AGuaranteed traction protectionAchieving taperOptical fibre/cable installationCoupling light guidesGear wheelElectric machinery

The invention provides a wheel disc traction type optical fiber tapering machine. The wheel disc traction type optical fiber tapering machine comprises a control processing device, a power transmission device, a guide control device, a wheel disc traction device, a heating and displacement control device, an optical fiber rotating device, an optical power monitoring device and a working platform,wherein the control processing device, the power transmission device, the guide control device, the wheel disc traction device, the heating and displacement control device and the optical fiber rotating device are all fixed on the working platform, and the optical power monitoring device is used for assisting in evaluating the real-time process of operation by monitoring the optical power transmitted by an optical fiber in the optical fiber tapering process. According to the invention, the two opposite wheel discs with adjustable positions are used for clamping and fixing the operation opticalfiber; the two wheel discs rotate reversely at the same speed during work, controlled rotation of the motor is converted into controlled traction and stretching of optical fiber tapering by means ofmeshing rotation between system gears, and the tapering process can be accurately controlled by means of the speed reduction effect of the transmission gear set. The resistance heating device is stable in heat transfer and high in controllability.

Owner:SHENZHEN GOLIGHT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com