Hydrogen production system and method

A technology of hydrogen production system and hydrogen storage tank, which is applied in the field of hydrogen production, can solve the problems of poor stability and low efficiency, achieve stable heat transfer, high heat transfer efficiency, and improve efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

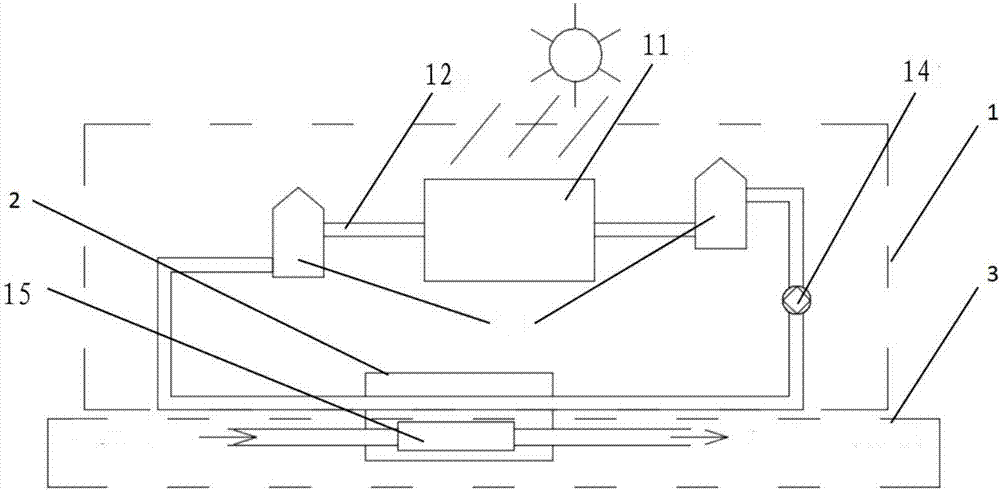

[0052] like figure 1 and Figure 4As shown, the present embodiment adopts the method that methane reacts with water to generate hydrogen. The heat collecting mechanism 1 also includes a liquid metal pump 15 and a liquid metal liquid storage tank 13, the liquid metal pump 15 and the liquid metal liquid storage tank 13 are both arranged on the liquid metal pipeline 12, and the hydrogen production mechanism 3 includes Reactor 17.

[0053] Working process: The heat collector collects the liquid metal that transfers heat to the liquid metal pipe, using the liquid metal as the heat transfer medium, the liquid metal is passed into the heat exchanger, and methane and water are passed into the reactor, and the second heat exchange tube Hydrogen and carbon monoxide are produced after heat exchange of liquid metal, and the hydrogen and carbon monoxide need to be separated later.

[0054] Among them, the use of trough, dish or tower heat collection systems can obtain temperatures as hi...

Embodiment 2

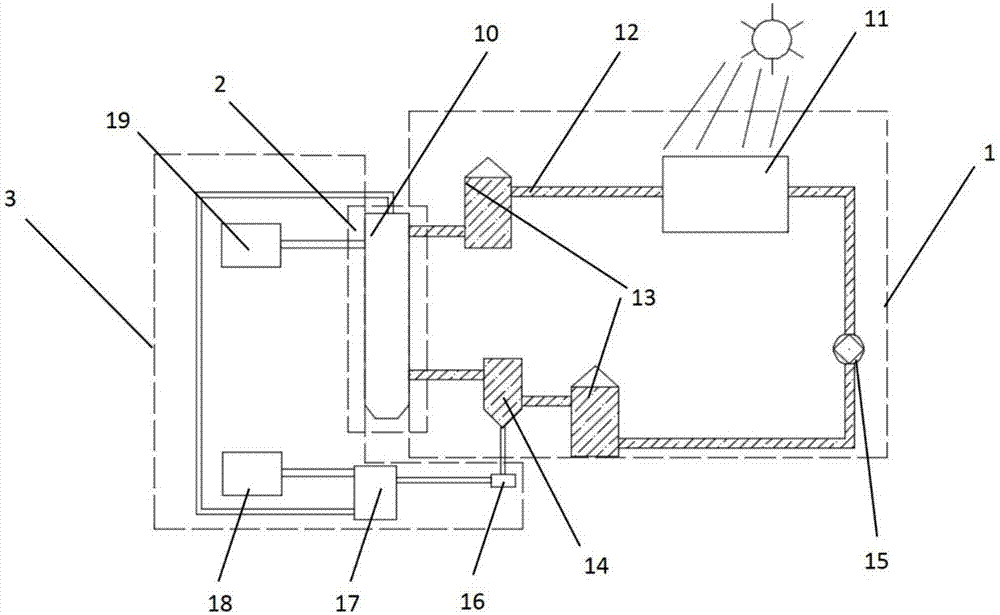

[0056] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

[0057] like figure 2 and Figure 5 As shown, this embodiment adopts the method that metal and water react to generate hydrogen. Its structure includes a gas storage tank 19, and the hydrogen production mechanism 3 also includes a metal storage tank 16 and a hydrogen storage tank 18. One end of the metal storage tank 16, the gas storage tank 19 and the reactor 17 are all connected to the heat exchanger. 2, the other end of the metal storage tank 16 is connected to the hydrogen storage tank 18 through the reactor 17, and the liquid metal pipeline 12 is connected to the second heat exchange tube of the heat exchanger 2. Heat pipe connection.

[0058] Working process: the heat collector collect...

Embodiment 3

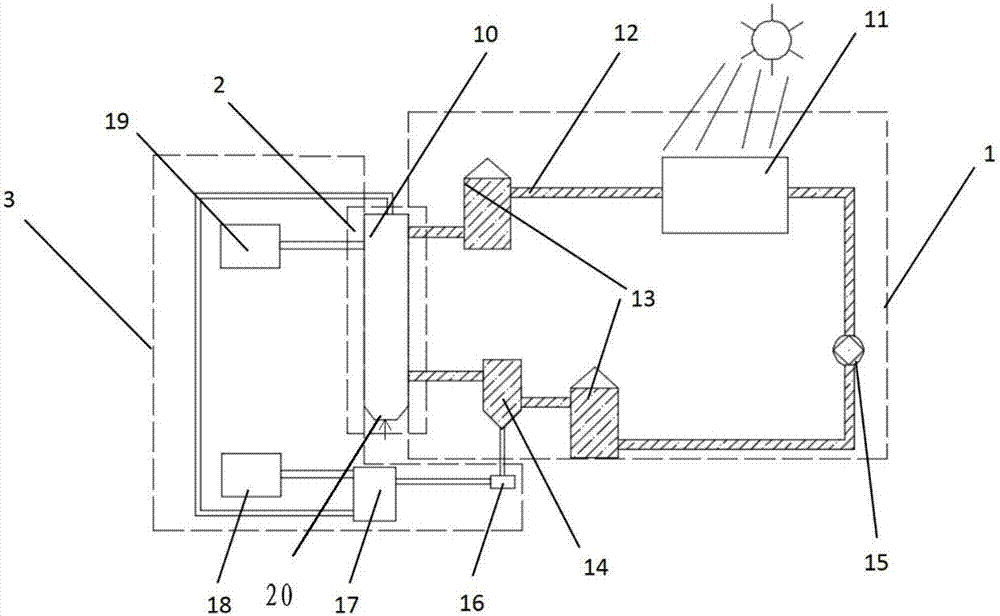

[0062] This embodiment is basically the same as Embodiment 2. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 2 will not be described, and only the differences between this embodiment and Embodiment 2 will be described:

[0063] like image 3 and Image 6 As shown, this embodiment adopts the method that methane reacts with metal oxides to generate metal and fuel gas, and the metal reacts with water to generate hydrogen. Its structure is that the heat exchanger 2 is also provided with a methane inlet 20 .

[0064] Working method: The heat collector collects the liquid metal that transfers heat to the liquid metal pipe, using the liquid metal as the heat transfer medium, the liquid metal is passed into the heat exchanger, the reactor is passed into water, and the first heat exchange tube is filled with metal oxides and methane, after exchanging heat with the liquid metal in the second heat exchange tube, metal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com