Spiral twisting belt embedded with reinforced framework shaft core

A spiral and skeleton technology, which is applied in the direction of rotating equipment cleaning, cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of complex structure of the end fixing device, scraping of the inner wall of the heat transfer tube, and short service life, so as to avoid the inside of the tube Fouling, reduced scratch wear, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

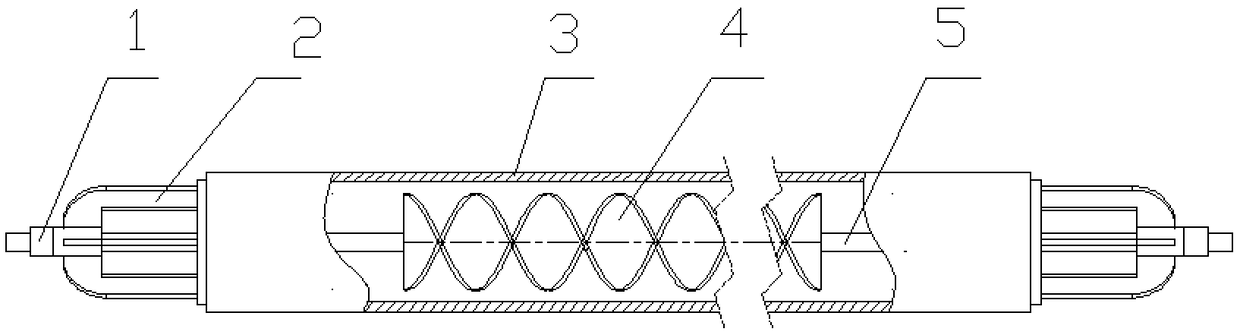

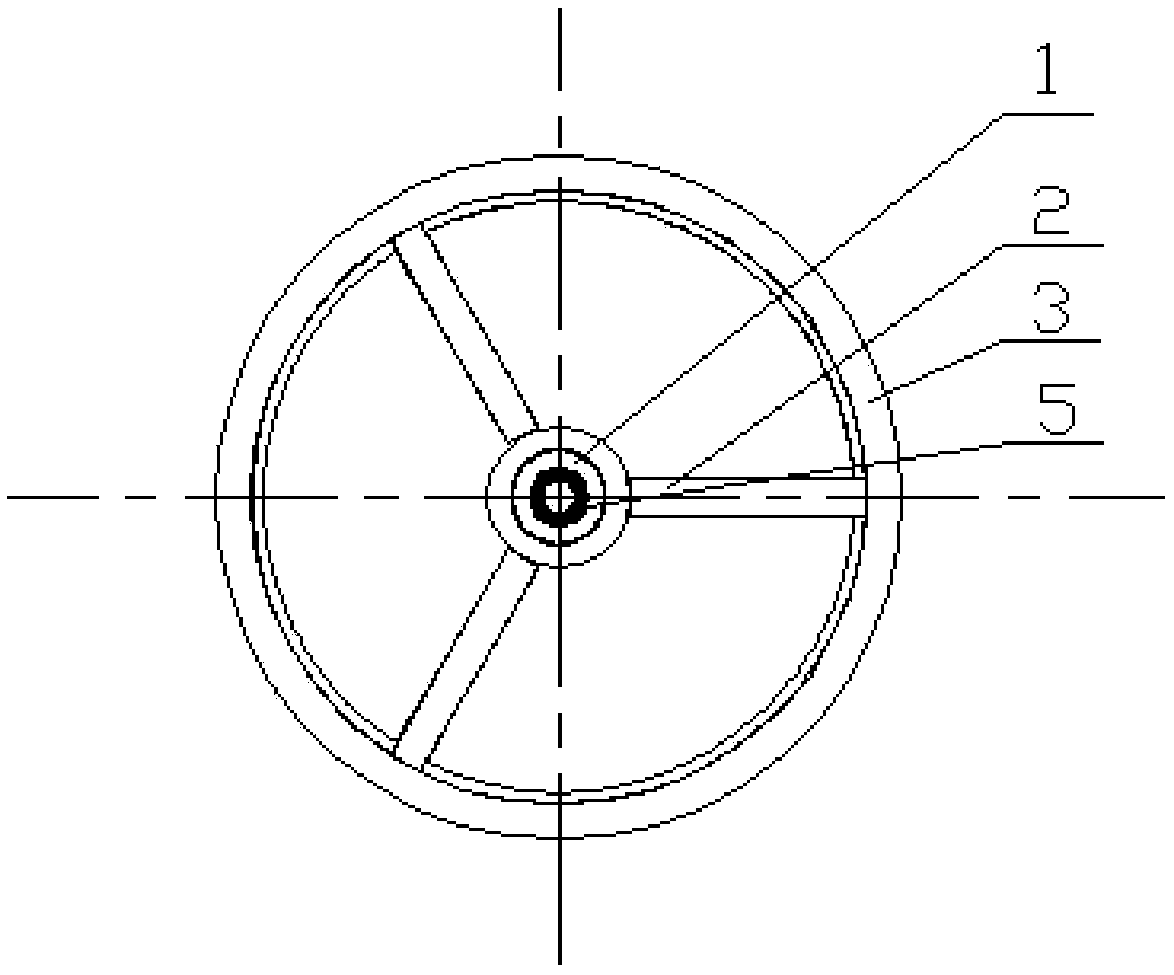

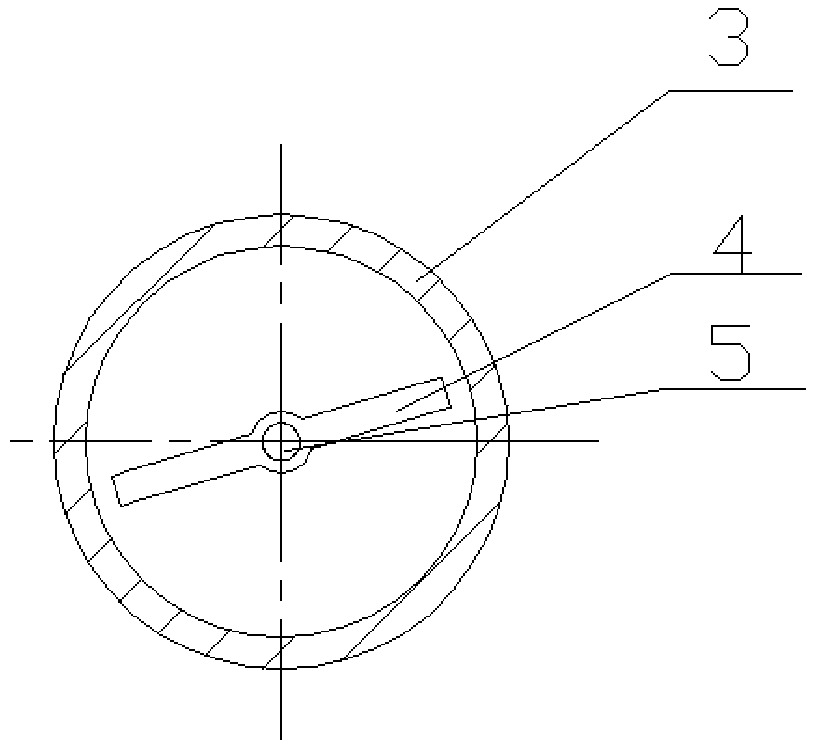

[0022] Such as Figure 1 to Figure 8 As shown, it includes a limit piece 1, a support frame 2, a heat transfer tube 3, a helical twisted belt 4, a reinforced skeleton core 5, and a bone spur 6; the helical twisted belt 4 and the flexible shaft 5 are continuously connected through the cable coating technology. Production and consolidation of the spiral twisted belt 4 and the reinforced skeleton shaft core 5, wherein the part of the reinforced skeleton shaft core protruding from the spiral twisted strip is used as the mandrel.

[0023] Such as figure 1 As shown in the installation schematic diagram, the support frame 2 is installed on both ends of the heat transfer tube 3 through interference fit, the mandrel passes through the inner hole of the support frame 2, and the limiter 1 is fixed on the mandrel on the outside of the support frame 2. For axial positioning, the fixing method of the limiting member 1 and the mandrel is riveting, bonding, adhesion or screw connection, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com