Novel method for preparing micro-nano multivalent silver by soft chemistry technology

A multivalent silver, micro-nano technology, applied in chemical instruments and methods, botanical equipment and methods, chemicals for biological control, etc., can solve problems such as waste, large water consumption, difficult industrial application, etc., and achieve distribution Uniform, well-exchanged, synthetically efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0022] Implementation Case 1: Synthesis of Micro-nano Multivalent Silver Oxide by Rheological Phase Method and Determination of Antibacterial Properties

[0023] 1. Weigh 2.4g oxidant sodium persulfate, 2.4g sodium hydroxide and 1.4g silver nitrate, put them into a mortar, grind them evenly, add 3ml deionized water, keep warm at 90°C for 20min, filter, and rinse with pure water for four times to remove potassium sulfate (sodium) and potassium nitrate (sodium) and other impurities. After drying, 0.8788 g of black powder (polyvalent silver oxide) was obtained.

[0024] 2. Take 0.2g of micro-nano multivalent silver oxide powder, add 2ml of 25% concentrated ammonia water, 8ml of distilled water, and stir at room temperature for 5-10min until it is completely dissolved.

[0025] 3. Take 2.5 μl of the above-mentioned 2% micro-nano multivalent silver oxide sample stock solution and add it to 100ml distilled water (the bacteria content is greater than 100,000cpu / cc, the test bacteria...

Embodiment example 2

[0027] Implementation Case 2: Synthesis of micro-nano polyvalent silver oxides by rheological phase method

[0028] 1. Weigh 2.4g of oxidant sodium persulfate and 2.4g of sodium hydroxide, put them into a mortar and grind them evenly.

[0029] 2. Weigh 1.4g of silver nitrate, completely dissolve it in 3ml of deionized water, mix it into the above solid powder, and quickly adjust it into a rheological state.

[0030] 3. Incubate at 90°C for 20 minutes, filter, and rinse with pure water four times to remove potassium sulfate (sodium) and potassium nitrate (sodium) and other impurities. After drying, 0.9503 g of black powder (polyvalent silver oxide) was obtained.

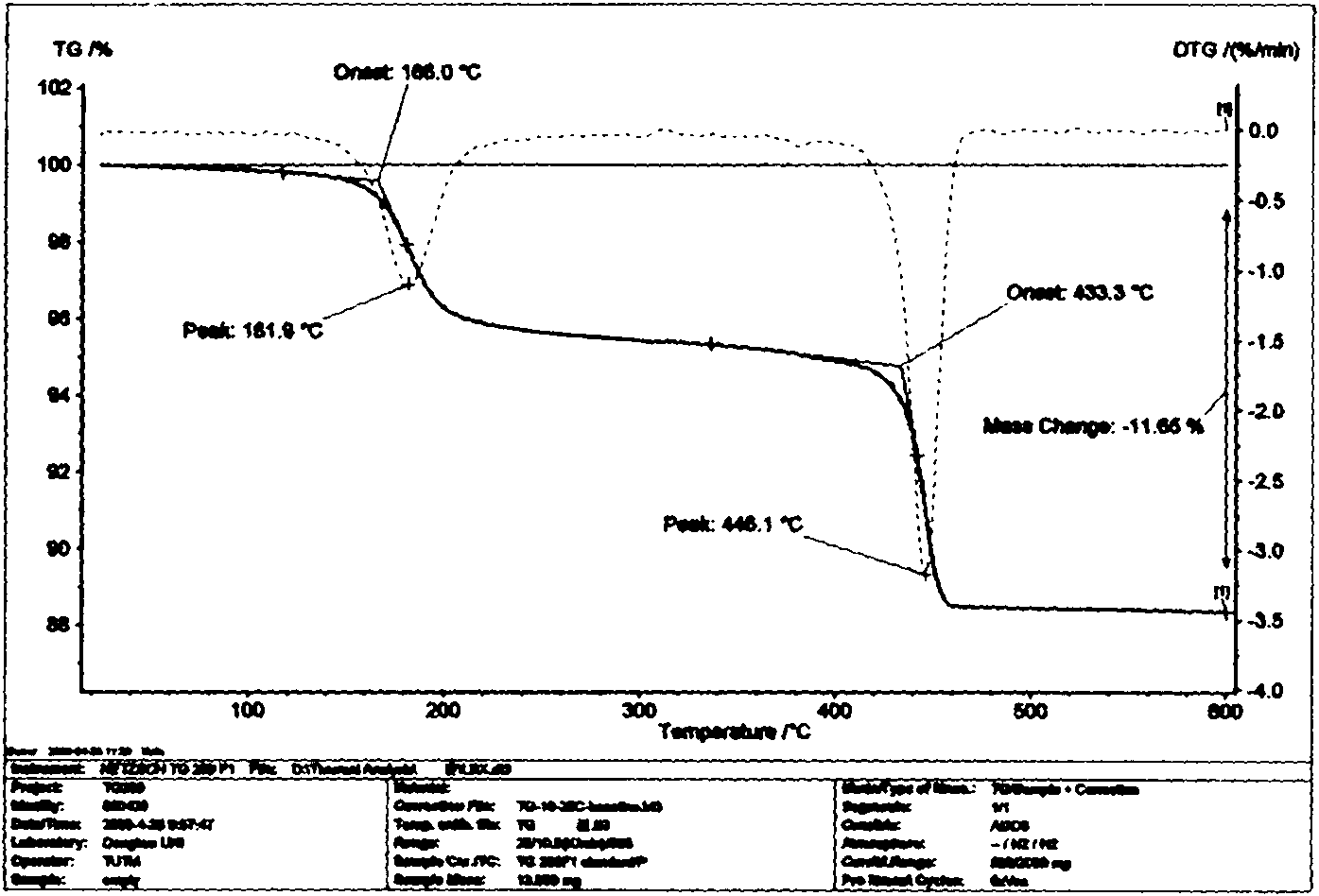

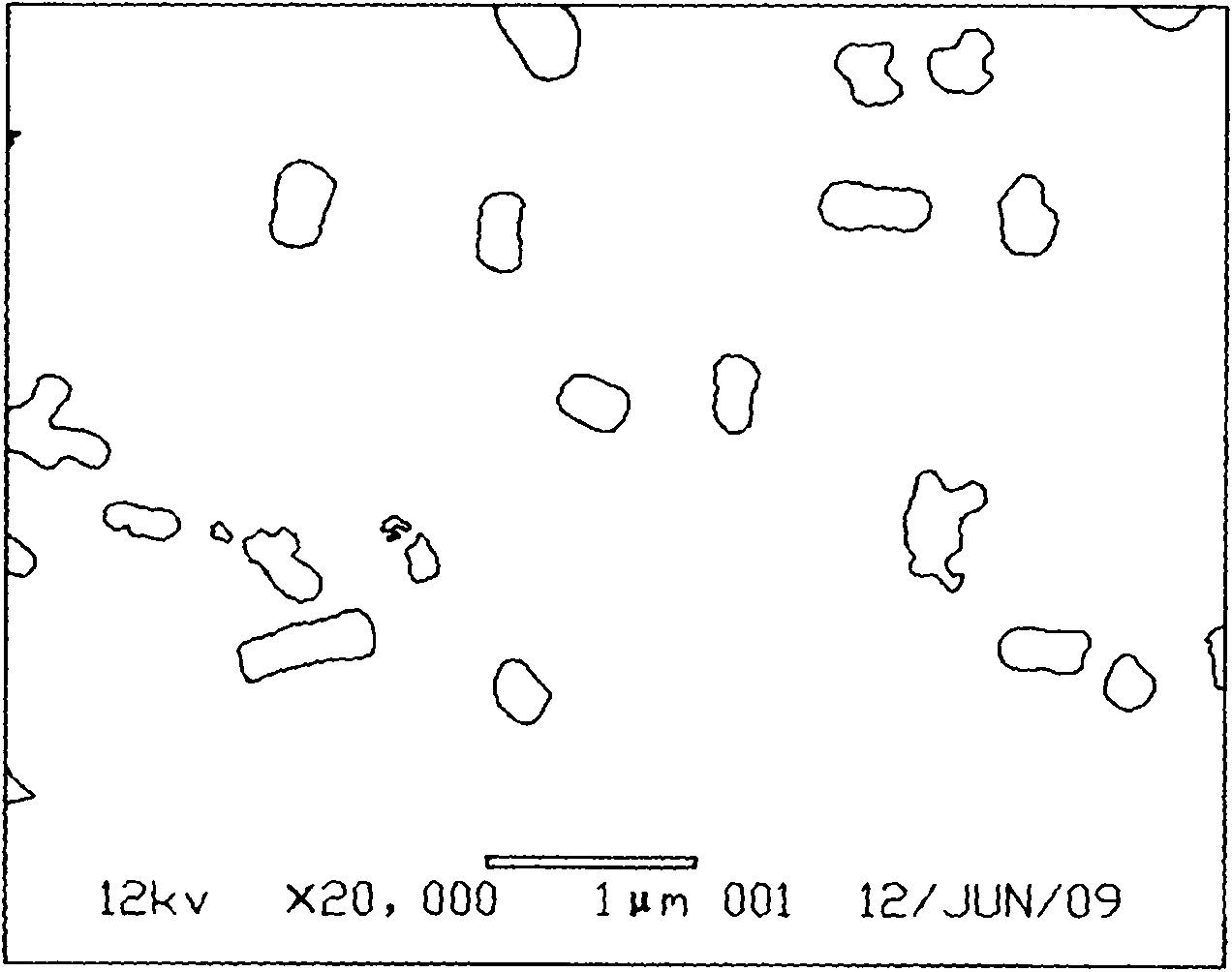

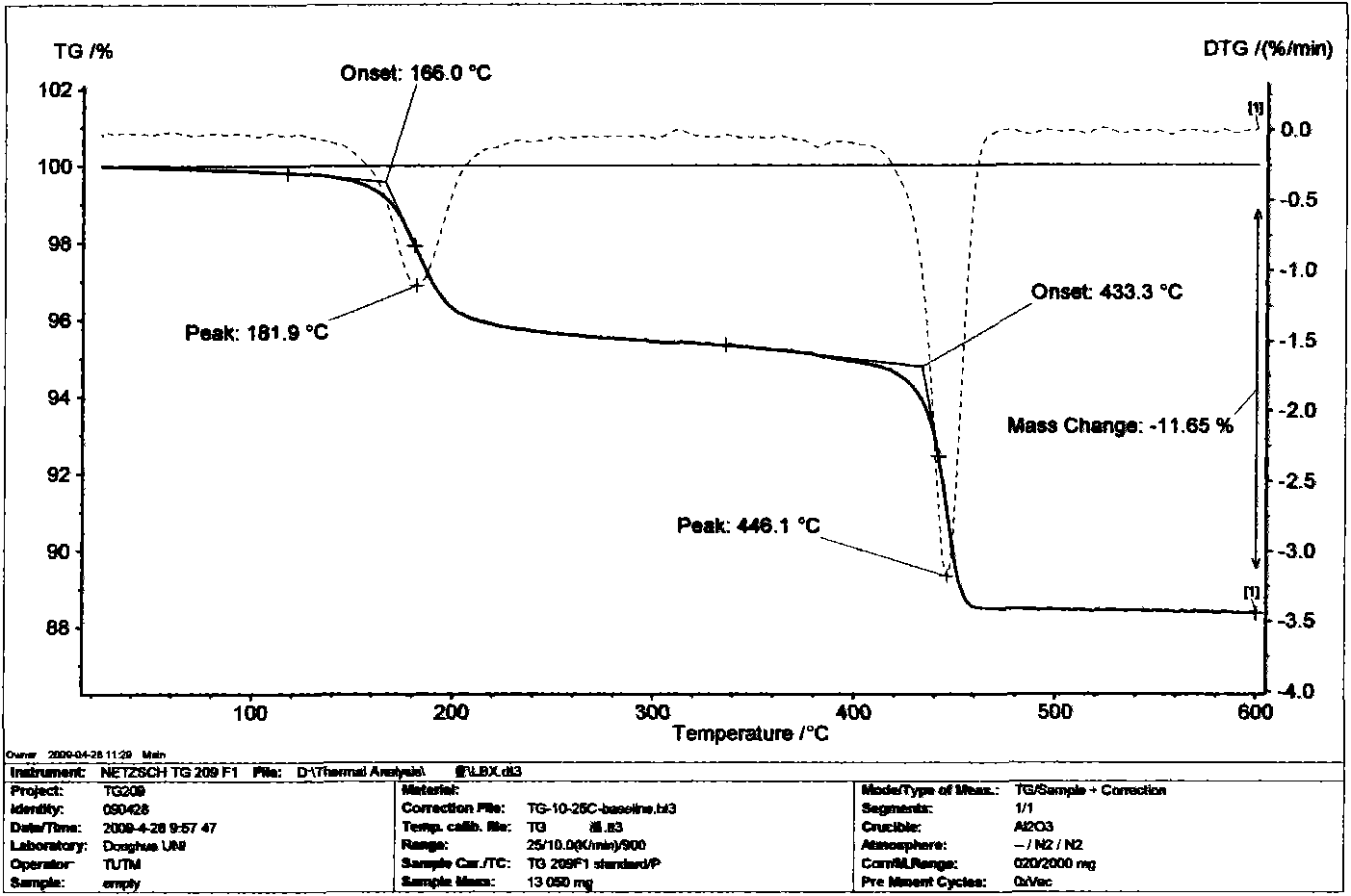

[0031] 4. Take an appropriate amount of the above-mentioned black powder for analysis, and the characterization of the product results is shown in the attached figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com