Air burning method in low oxygen and high temperature, and equipment

A technology of high-temperature air and combustion method, which is applied in the direction of combustion method, combustion equipment, indirect carbon dioxide emission reduction, etc., and can solve the problems of not paying attention to the importance of airflow organization, easy burning of four-way reversing valve, unstable combustion flame, etc. , to achieve the effect of reliable performance, stable pressure and stable heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

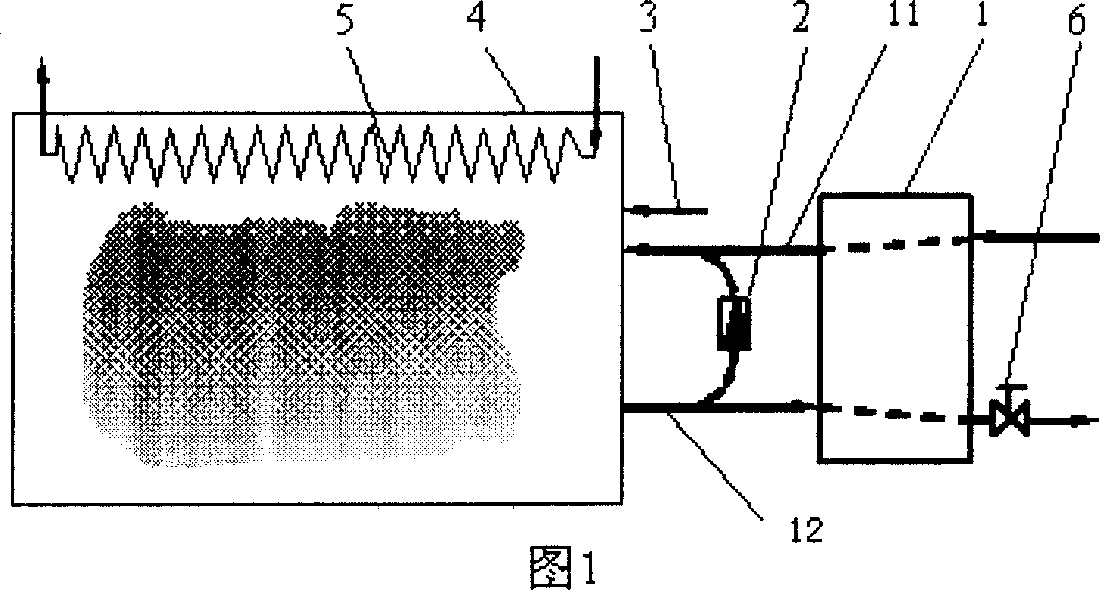

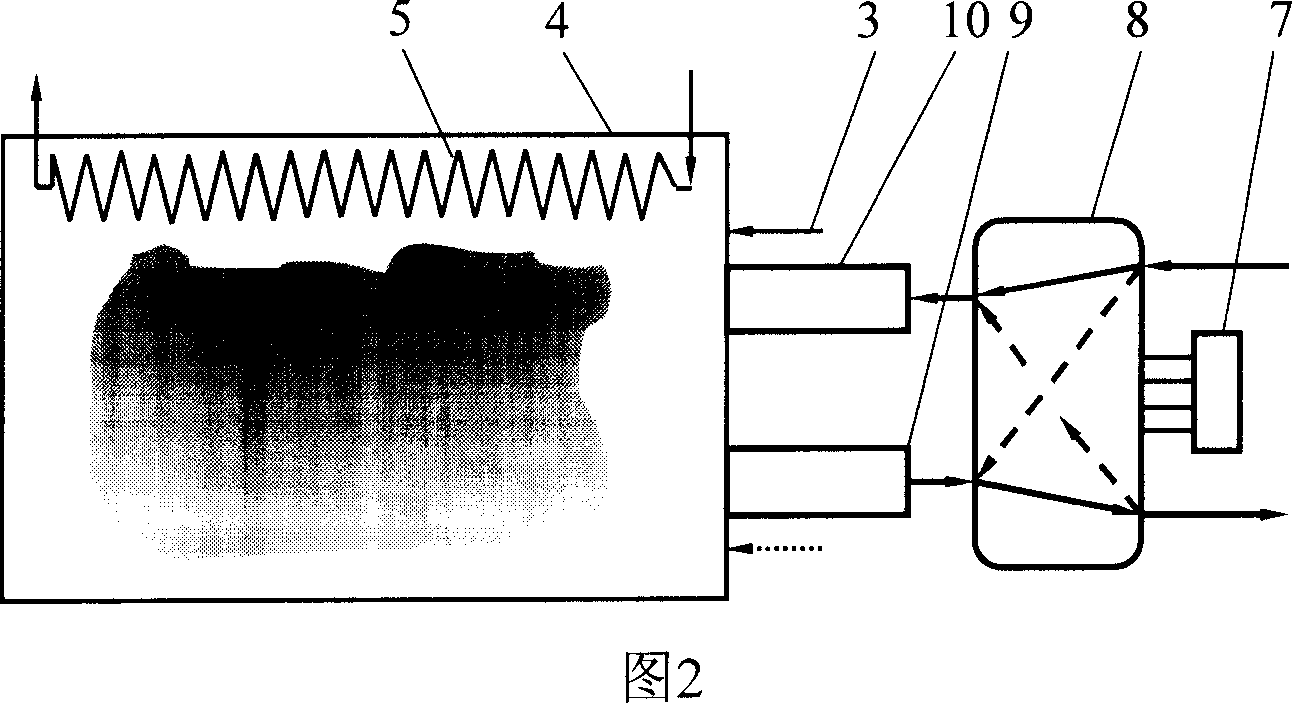

[0023] As shown in Figure 1, the invention is mainly composed of a high-efficiency partition wall heat exchanger 1, a ceramic check valve 2, a gas pipe 3, a furnace 4, a combustion air pipe 11, a flue gas discharge pipe 12, a cooling pipe 5 and a flue gas flow regulating valve 6 , the furnace 4 is provided with a cooling pipe 5, a gas pipe 3 and a flue gas discharge pipe 12, the combustion air pipe 11 communicates with the furnace 4 after passing through the high-efficiency partition heat exchanger 1, and the flue gas discharge pipe 12 of the furnace 4 passes through a high-efficiency The partition heat exchanger 1 is also provided with a flue gas flow regulating valve 6, and a flue gas discharge pipe 12 is provided between the combustion air pipe 11 and the flue gas discharge pipe 12 between the furnace 4 and the high-efficiency partition heat exchanger 1. Check valve 2 to combustion air line 11.

[0024]Referring to Figure 1, fresh air enters the high-efficiency partition wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com