Magnesium-based composite material and composite cookware

A composite material and composite pot technology, applied in the direction of special materials for cooking utensils, etc., can solve problems such as unfavorable human health, poor heat transfer and corrosion resistance, and achieve good cooking effect, stable pot structure, and uniform heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The magnesium-based composite material of this embodiment includes the following components in mass percentage: Zn 1.0%, Zr 0.7%, Nd 8.0%, Gd 0.5%, Cu 0.1%, Ni 0.01%, particle reinforcement 10%, and the rest Quantities are magnesium and unavoidable impurities.

[0035] Wherein, the particle reinforcement material is SiC with a particle size of 30-100 μm; the mass percentage of impurities is 0.3%.

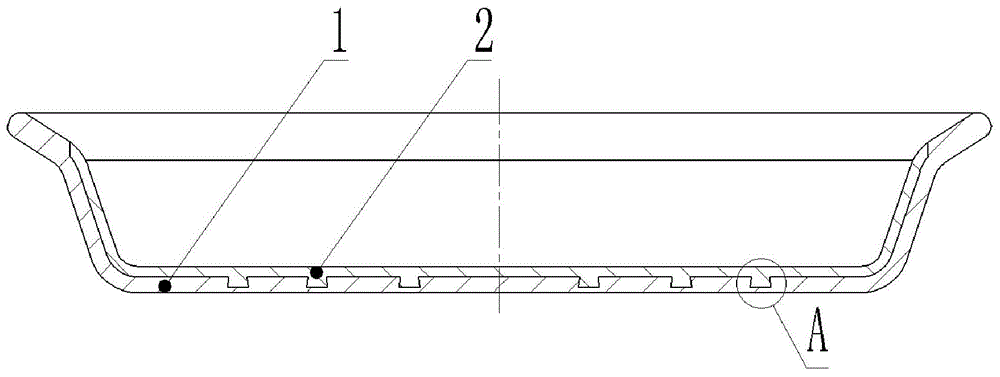

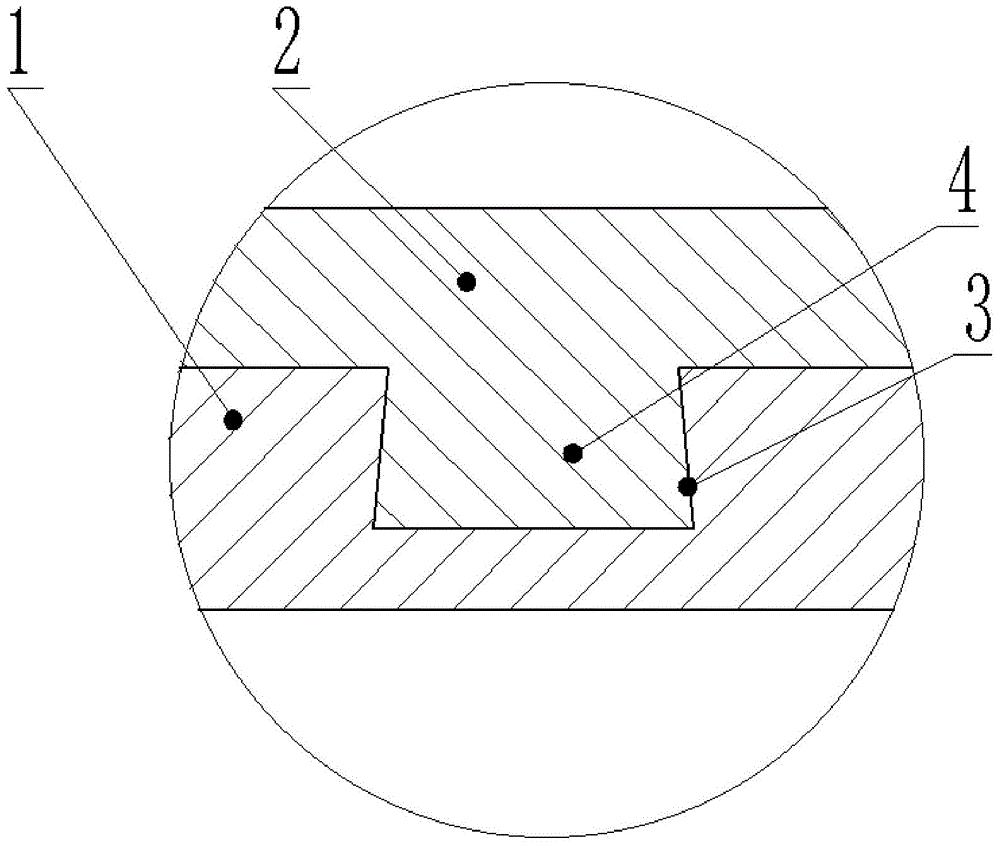

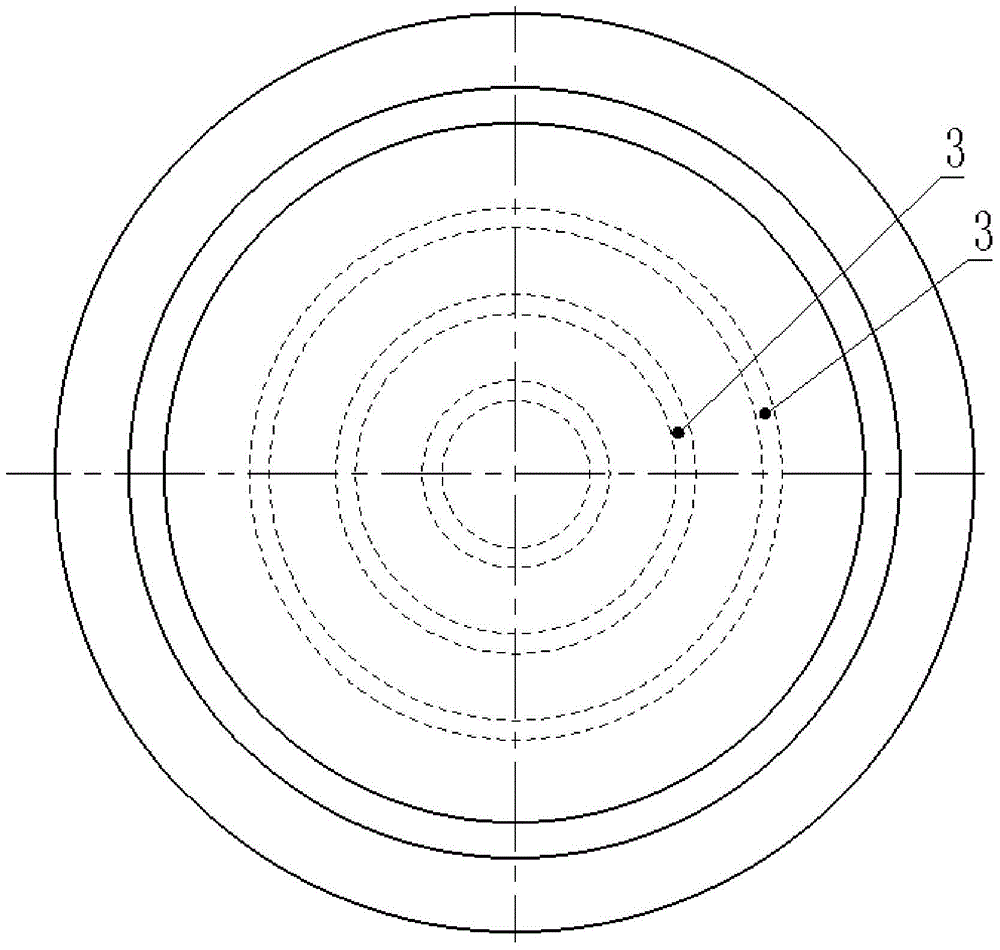

[0036] The composite pot of this embodiment includes a pot body, the pot body includes an inner layer pot body and an outer layer pot body, the material of the inner layer pot body is a magnesium-based composite material, and the magnesium-based composite material includes the following mass percent Component content: Zn 1.0%, Zr 0.7%, Nd 8.0%, Gd 0.5%, Cu 0.1%, Ni 0.01%, granular reinforcement 10%, the balance is magnesium and unavoidable impurities; the outer pot Body material is aluminum alloy ZL305.

[0037] The composite pan of the present embodiment has a specific str...

Embodiment 2

[0055] The magnesium-based composite material of this embodiment includes the following components in mass percentage: Zn 2.0%, Zr 1.0%, Nd 5.0%, Gd 1.0%, Cu 0.1%, Ni 0.01%, particle reinforcement 5%, and the rest Quantities are magnesium and unavoidable impurities.

[0056] Wherein, the particle reinforcement material is SiO 2 , the particle size is 30-100 μm; the mass percentage of impurities is 0.3%.

[0057] The composite pot of this embodiment includes a pot body, the pot body includes an inner layer pot body and an outer layer pot body, the material of the inner layer pot body is a magnesium-based composite material, and the magnesium-based composite material includes the following mass percent Component content: Zn 2.0%, Zr 1.0%, Nd 5.0%, Gd 1.0%, Cu 0.1%, Ni 0.01%, particle reinforcement 5%, the balance is magnesium and unavoidable impurities; the outer pot Body material is aluminum alloy ZL305.

[0058] The composite pan of this embodiment, such as Figure 10 , 1...

Embodiment 3

[0062] The magnesium-based composite material of this embodiment includes the following components in mass percentage: Zn 3.0%, Zr 0.5%, Nd 1.0%, Gd 1.8%, Cu 0.1%, Ni 0.01%, particle reinforcement 15%, and the rest Quantities are magnesium and unavoidable impurities.

[0063] Wherein, the particle reinforcement material is SiC with a particle size of 30-100 μm; the mass percentage of impurities is 0.3%.

[0064] The composite pot of this embodiment includes a pot body, the pot body includes an inner layer pot body and an outer layer pot body, the material of the inner layer pot body is a magnesium-based composite material, and the magnesium-based composite material includes the following mass percent Content components: Zn 3.0%, Zr 0.5%, Nd 1.0%, Gd 1.8%, Cu 0.1%, Ni 0.01%, granular reinforcement 15%, the balance is magnesium and unavoidable impurities; the outer pot Body material is aluminum alloy ZL305.

[0065] The composite cookware of this embodiment differs from that o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com