Method for preparing dicarboxylic acid zinc catalyst with rheological phase reaction method

A technology of zinc dicarboxylic acid and dicarboxylic acid is applied in the field of preparing zinc dicarboxylic acid catalyst by applying rheological phase reaction method, and can solve the problems of high preparation cost, high energy consumption, increased equipment investment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

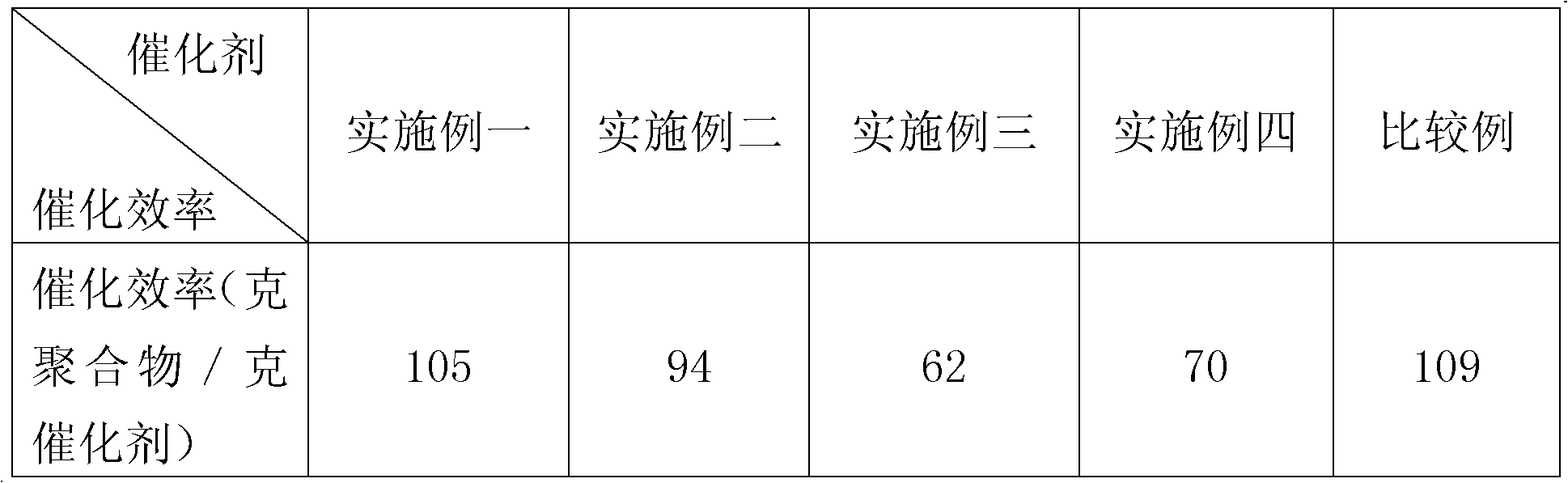

Examples

Embodiment 1

[0027] Preparation of zinc glutarate.

[0028] Mix and grind 6.3 grams of zinc oxide and 10 grams of glutaric acid in a mortar, transfer to a 20mL stainless steel reaction kettle, add 5.4 grams of toluene, stir evenly, seal the reaction kettle, keep warm at 60°C for 10 hours, filter under reduced pressure, After washing with acetone for 3 times, vacuum drying at 100° C. for 24 hours, a white powdery zinc glutarate catalyst was obtained, and the conversion rate of glutaric acid was 99.7%.

Embodiment 2

[0030] Preparation of zinc glutarate.

[0031] Raw material and consumption are with embodiment one, just change toluene into dehydrated alcohol. The conversion rate of glutaric acid was 96.3%.

Embodiment 3

[0033] Preparation of zinc glutarate.

[0034] The raw materials and consumption are the same as in Example 1, except that toluene is replaced by water, and the obtained catalyst particles are thicker. The conversion rate of glutaric acid was 95.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com