Long-distance separation type heat tube heat exchange system

A separate heat pipe and heat exchange system technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of poor heat transfer efficiency in long-distance heat transfer, and achieve sufficient heat exchange and high heat transfer efficiency , is conducive to the effect of stable heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

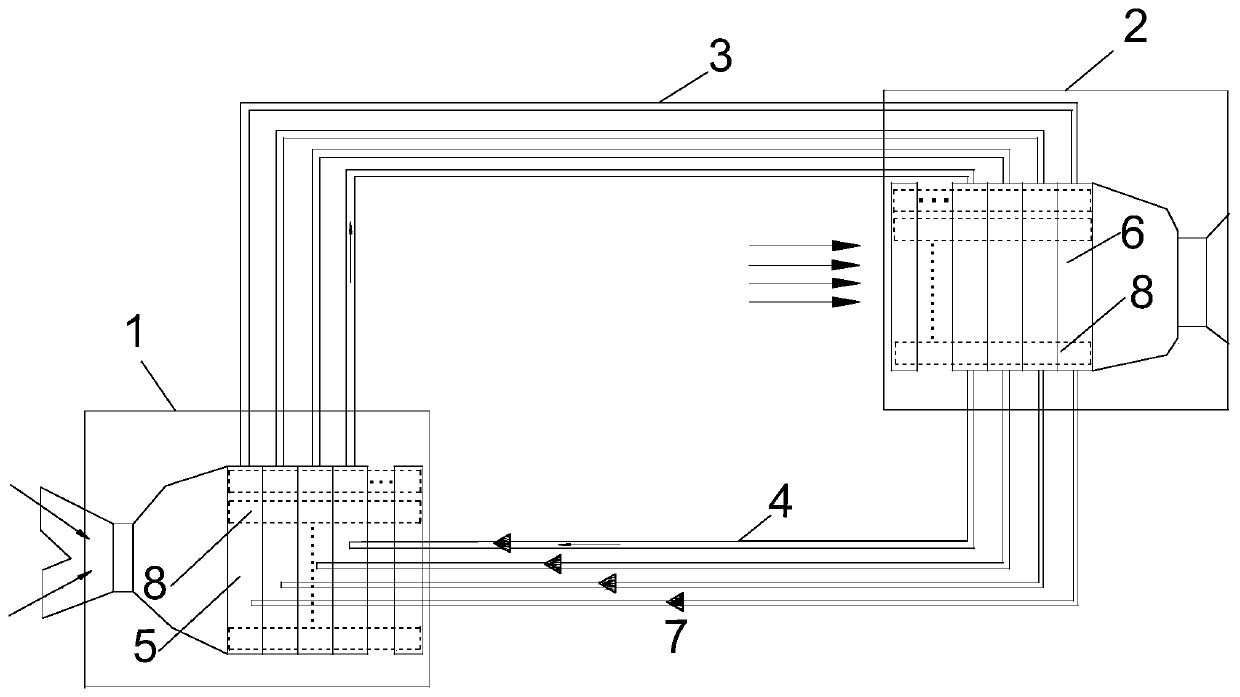

[0017] The following is combined with specific examples and attached figure 1 The present invention is described in detail, and the description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0018] In the specific implementation, the heat exchange part can be regarded as two modules according to the functional area, which are the heat absorption module 1 and the heat release module 2. The heat absorption module 1 transfers the heat absorbed from the thermal fluid to the heat release module 2. in the cold fluid. The whole heat exchange system is composed of a plurality of mutually independent units, and each independent unit is composed of a heat-absorbing sub-module 5, a heat-releasing sub-module 6, and a steam pipe 3 and a liquid return pipe 4 connecting the two sub-modules. Each unit completes the heat transfer process independently. The temperature of the hot fluid decreases gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com