Patents

Literature

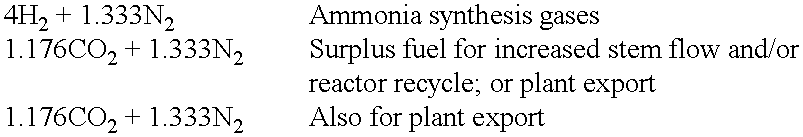

109results about "Carburetting gases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

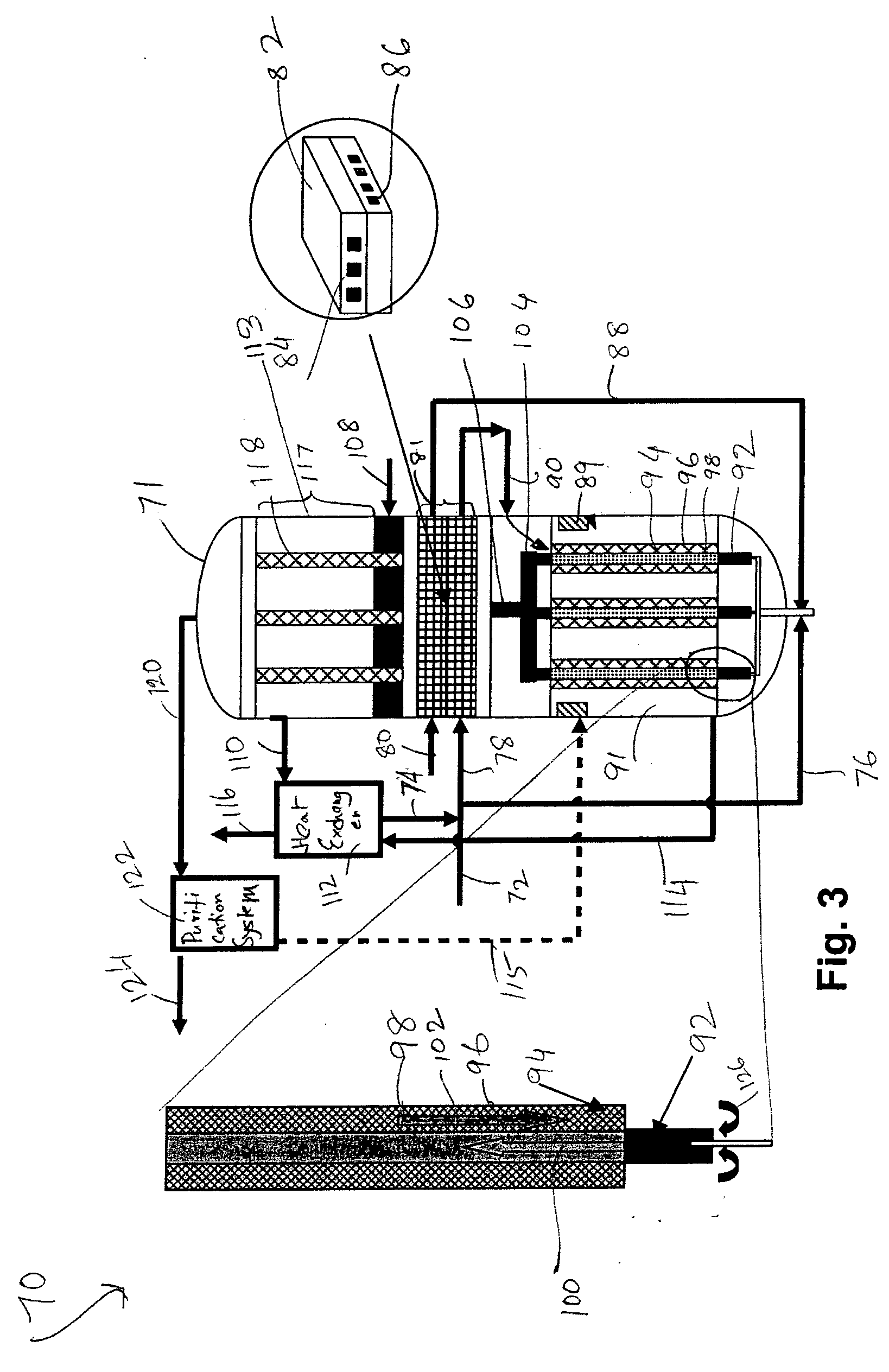

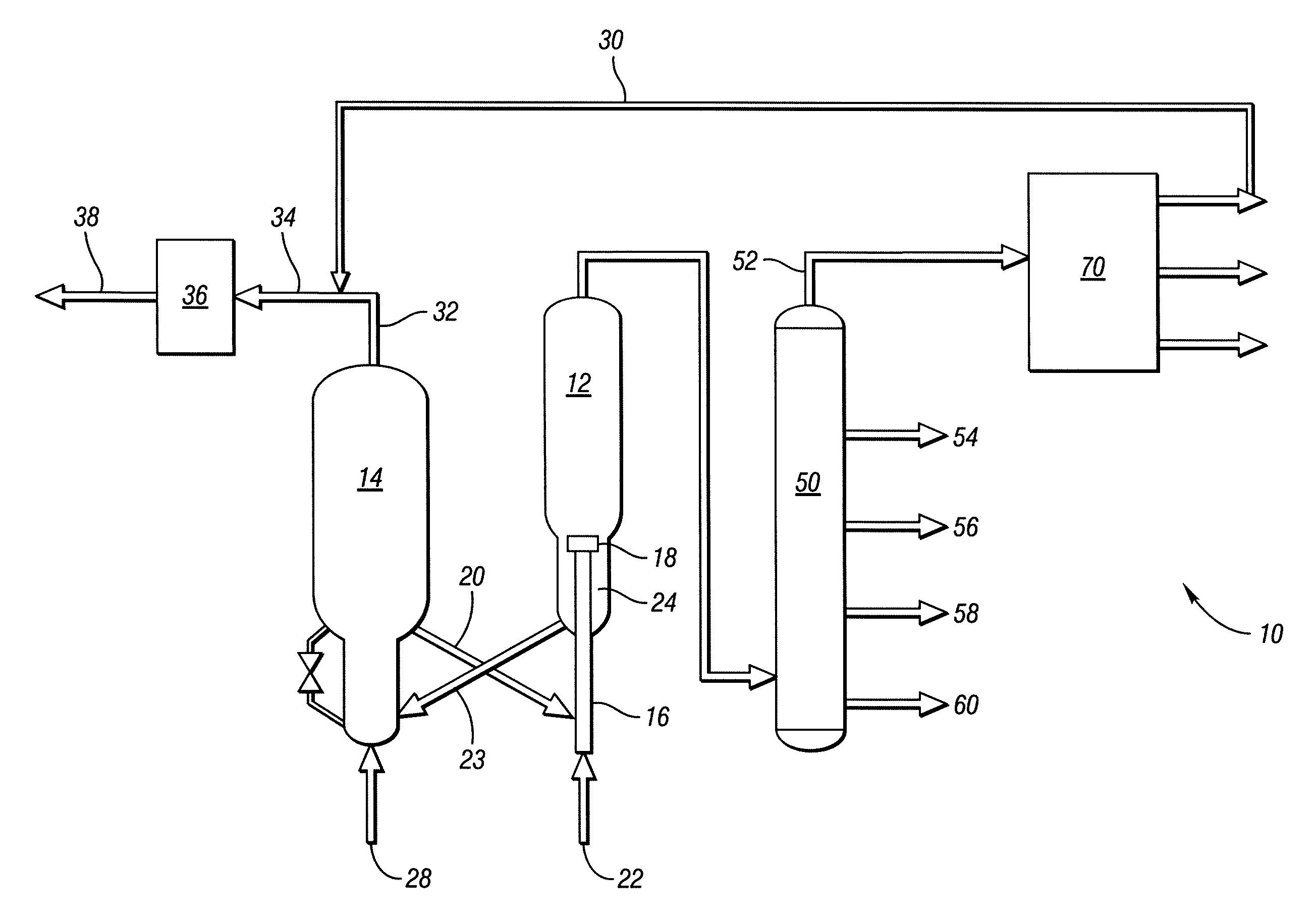

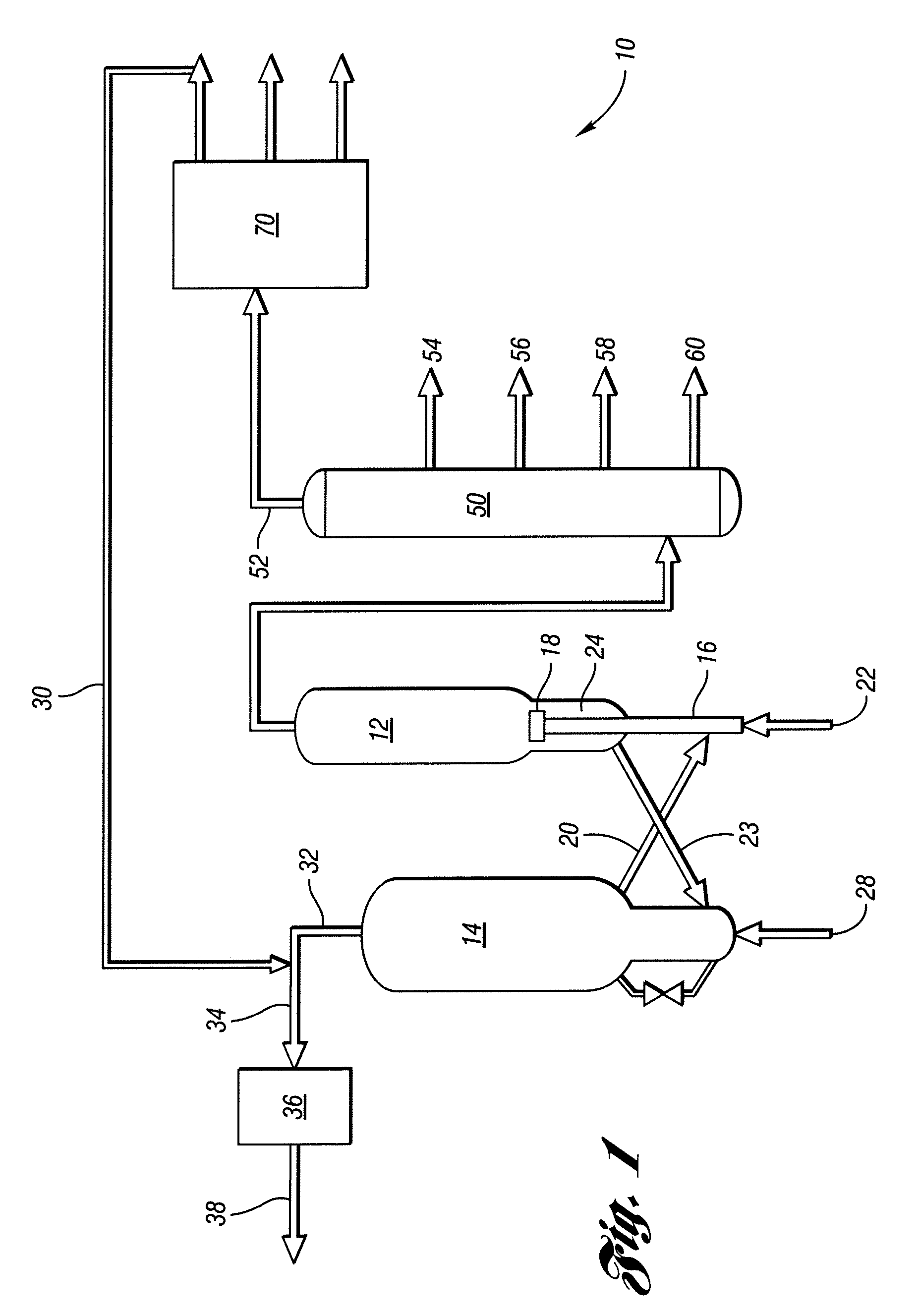

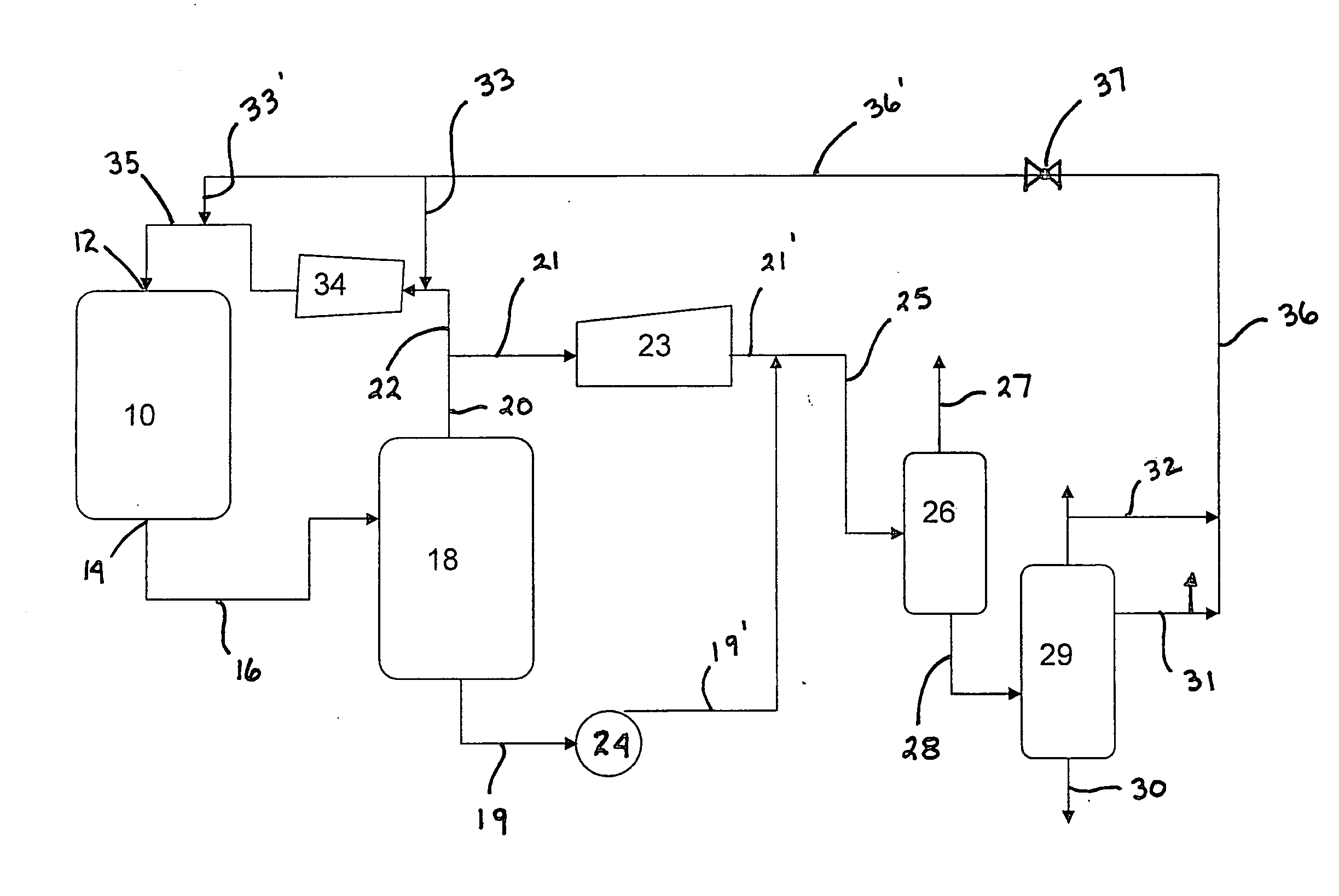

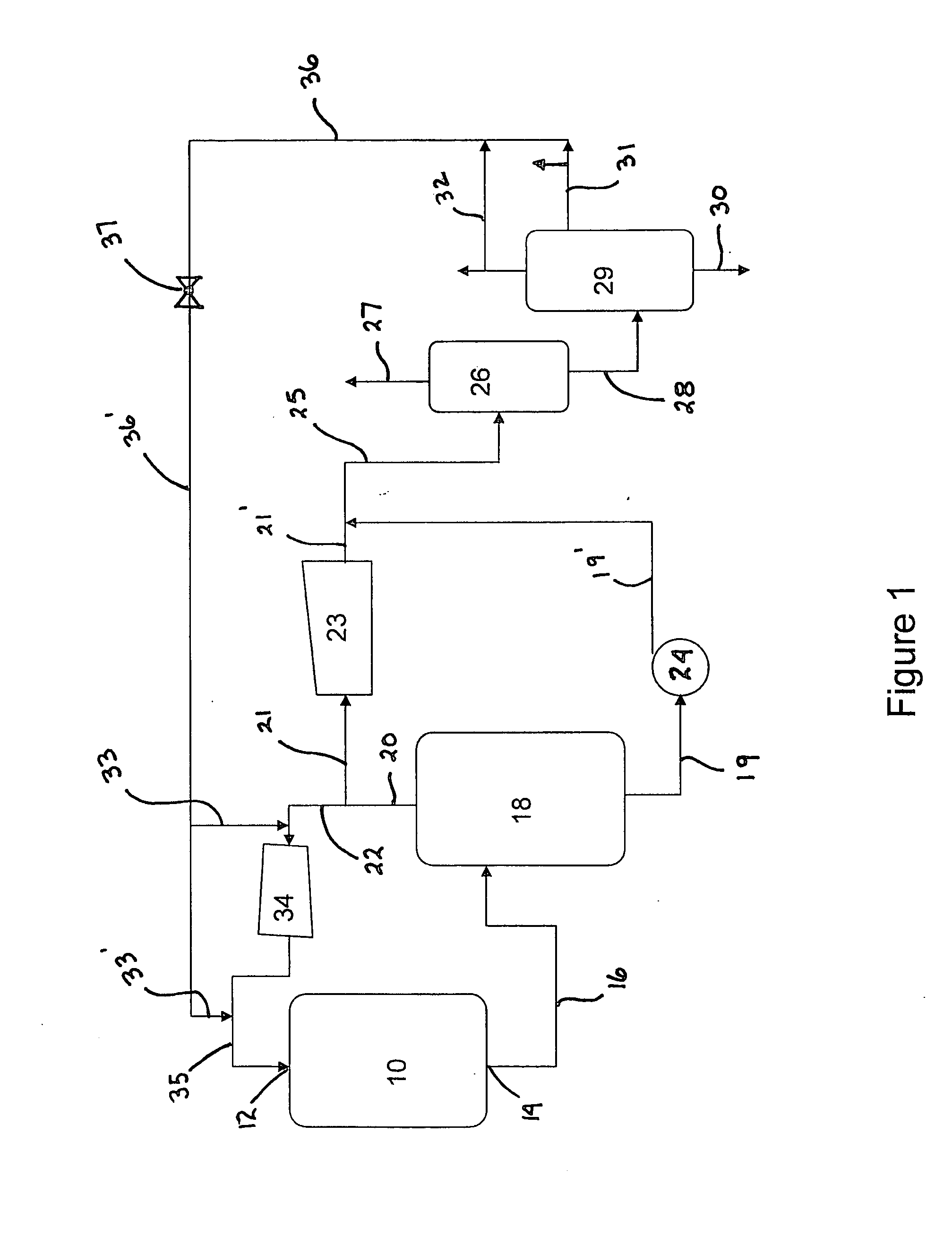

Catalytic Partial Oxidation Reforming for Syngas Processing and Products Made Therefrom

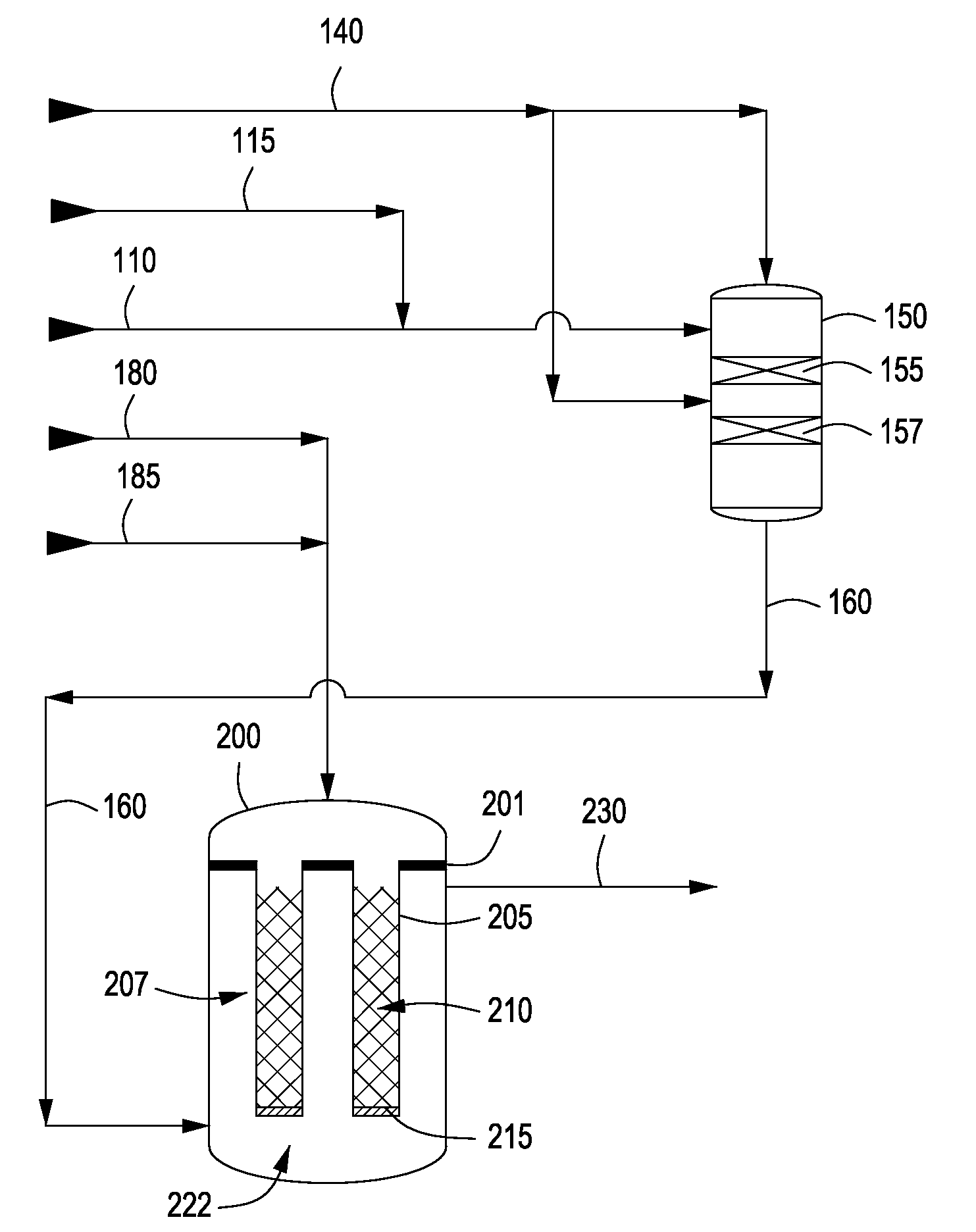

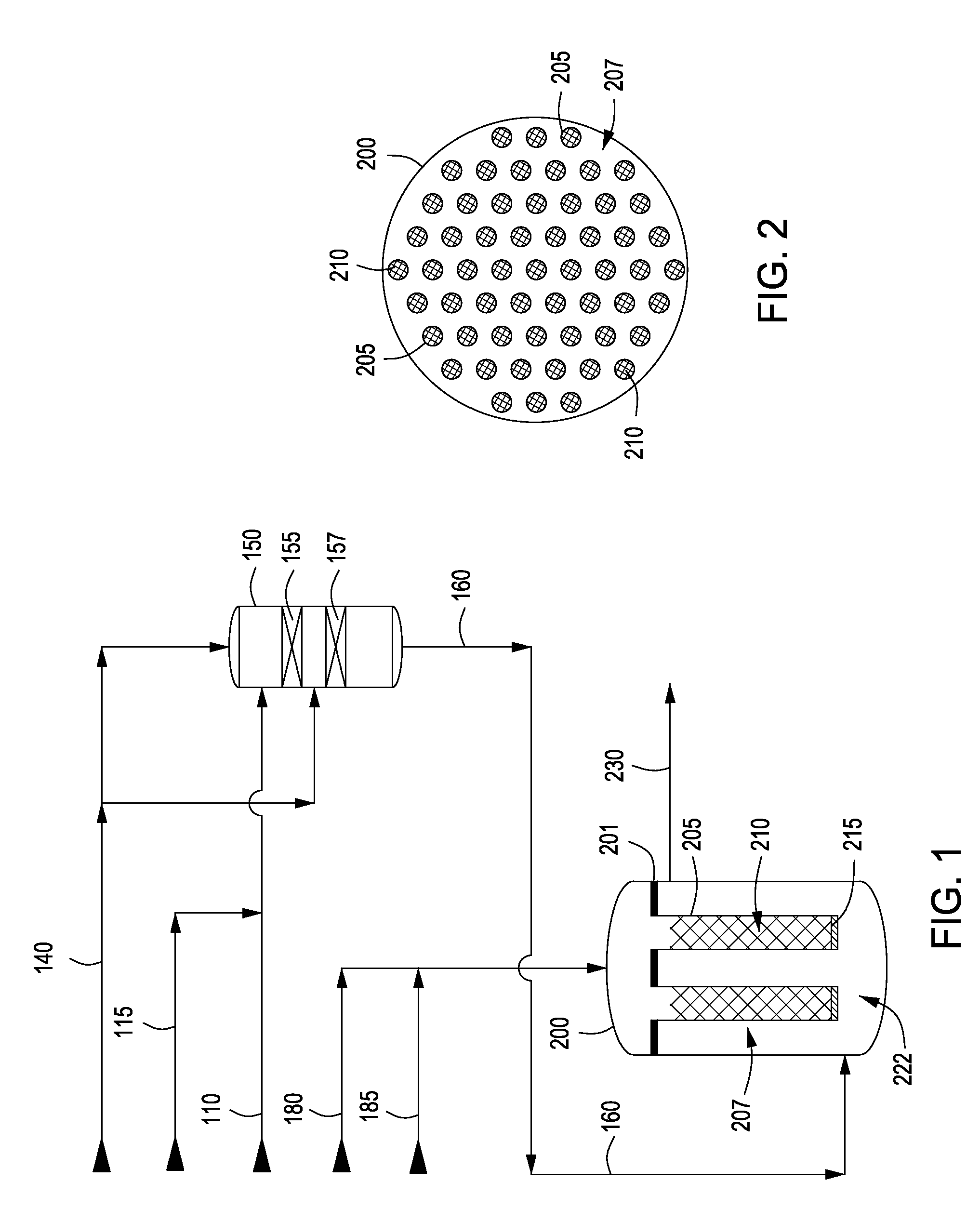

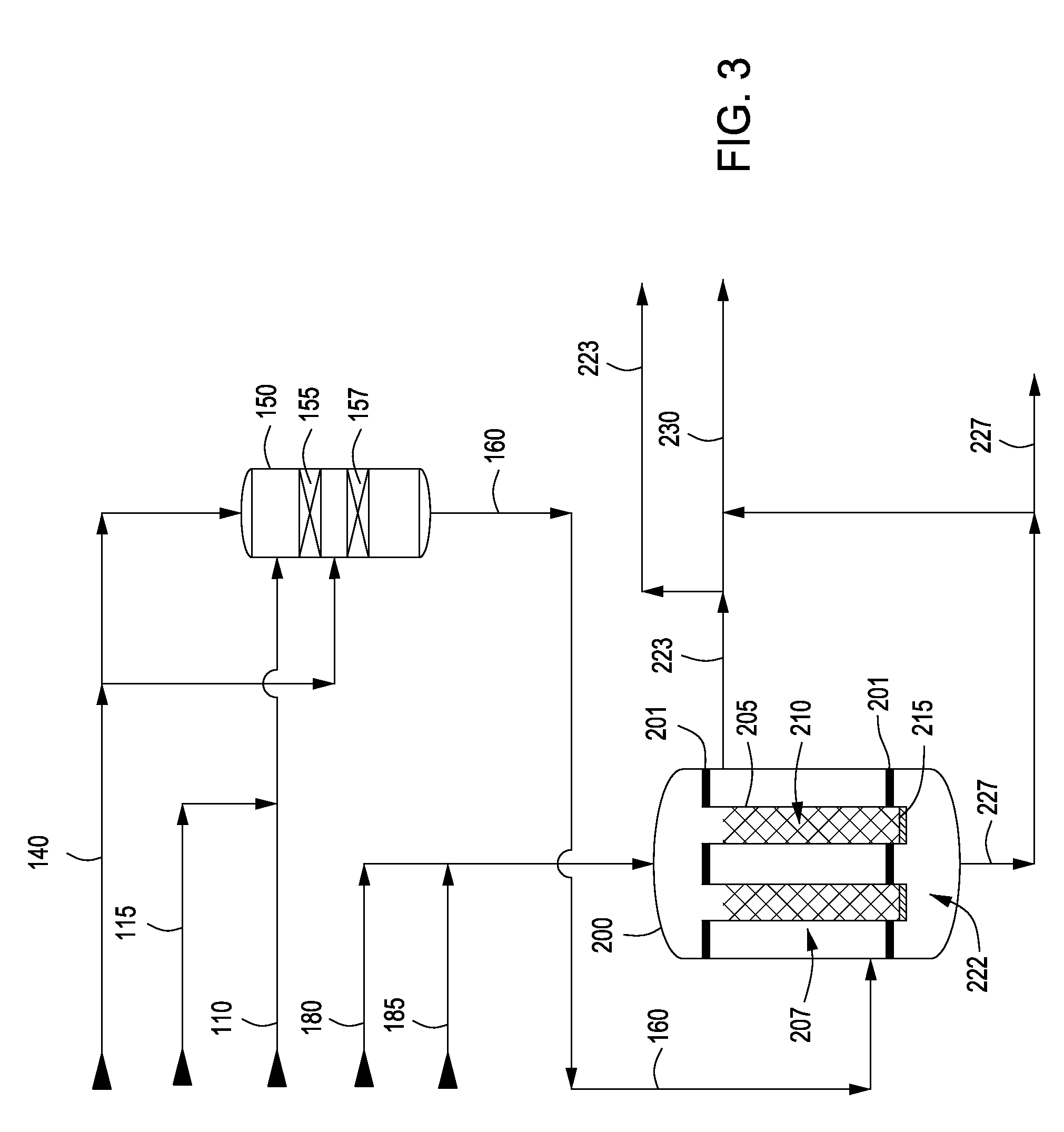

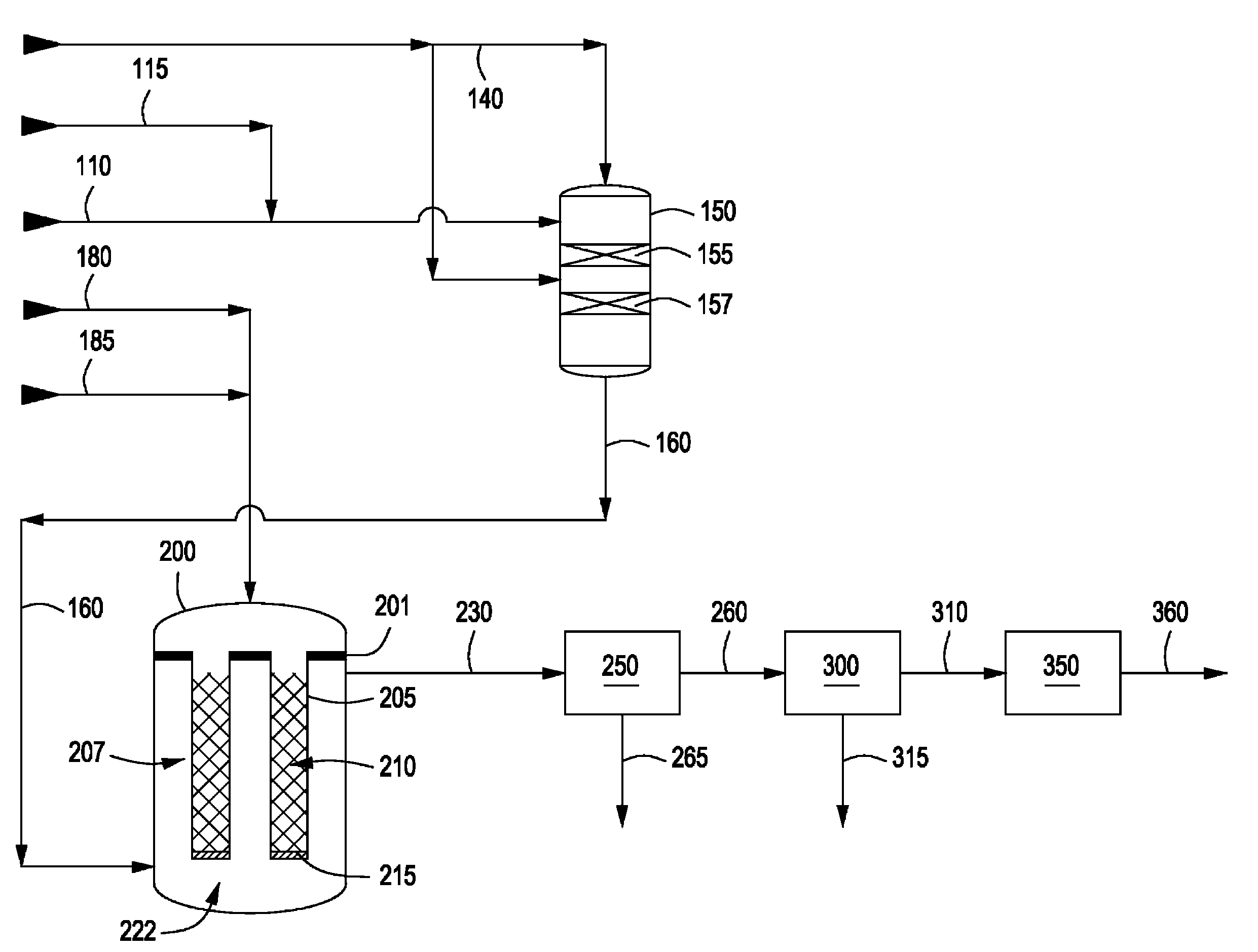

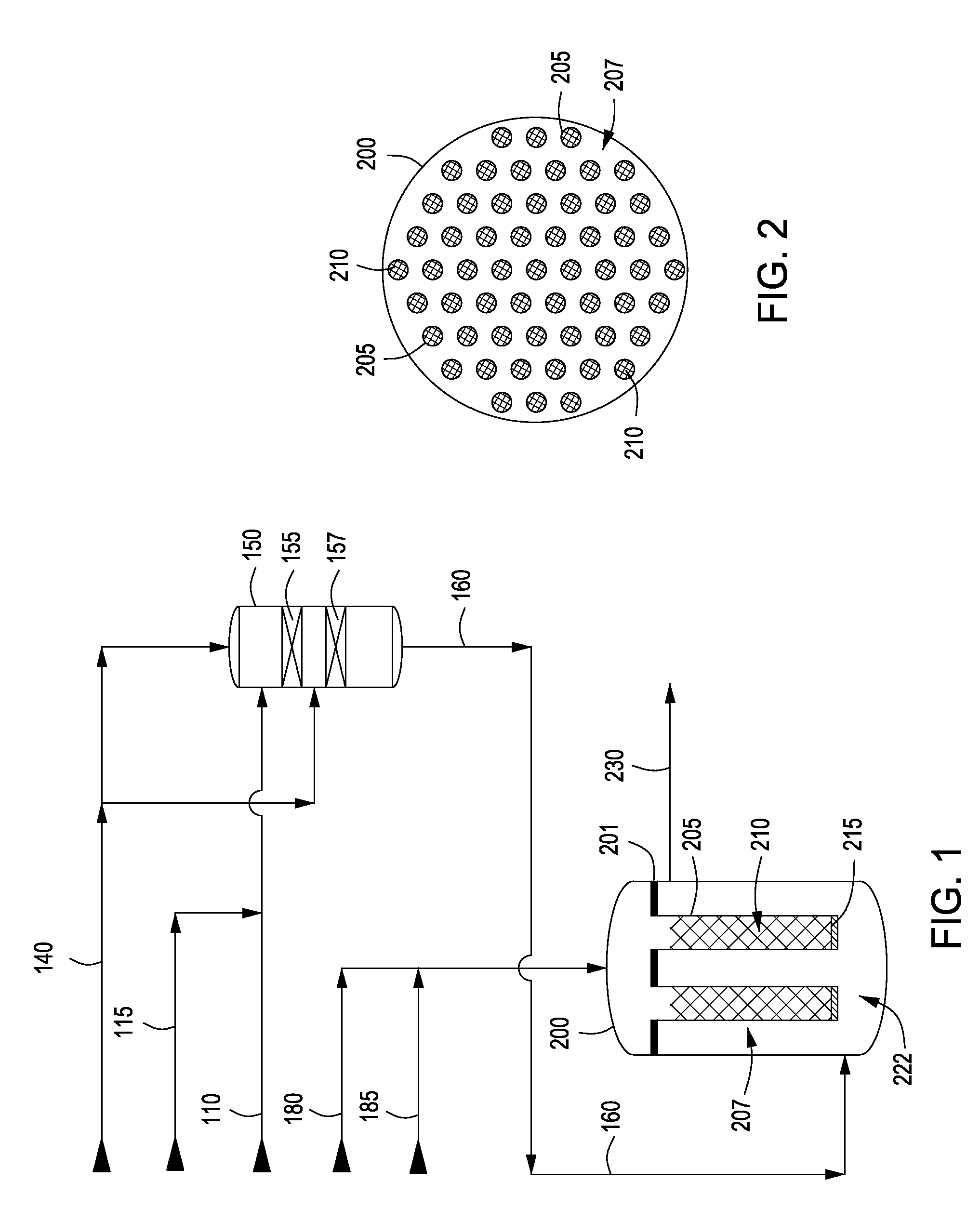

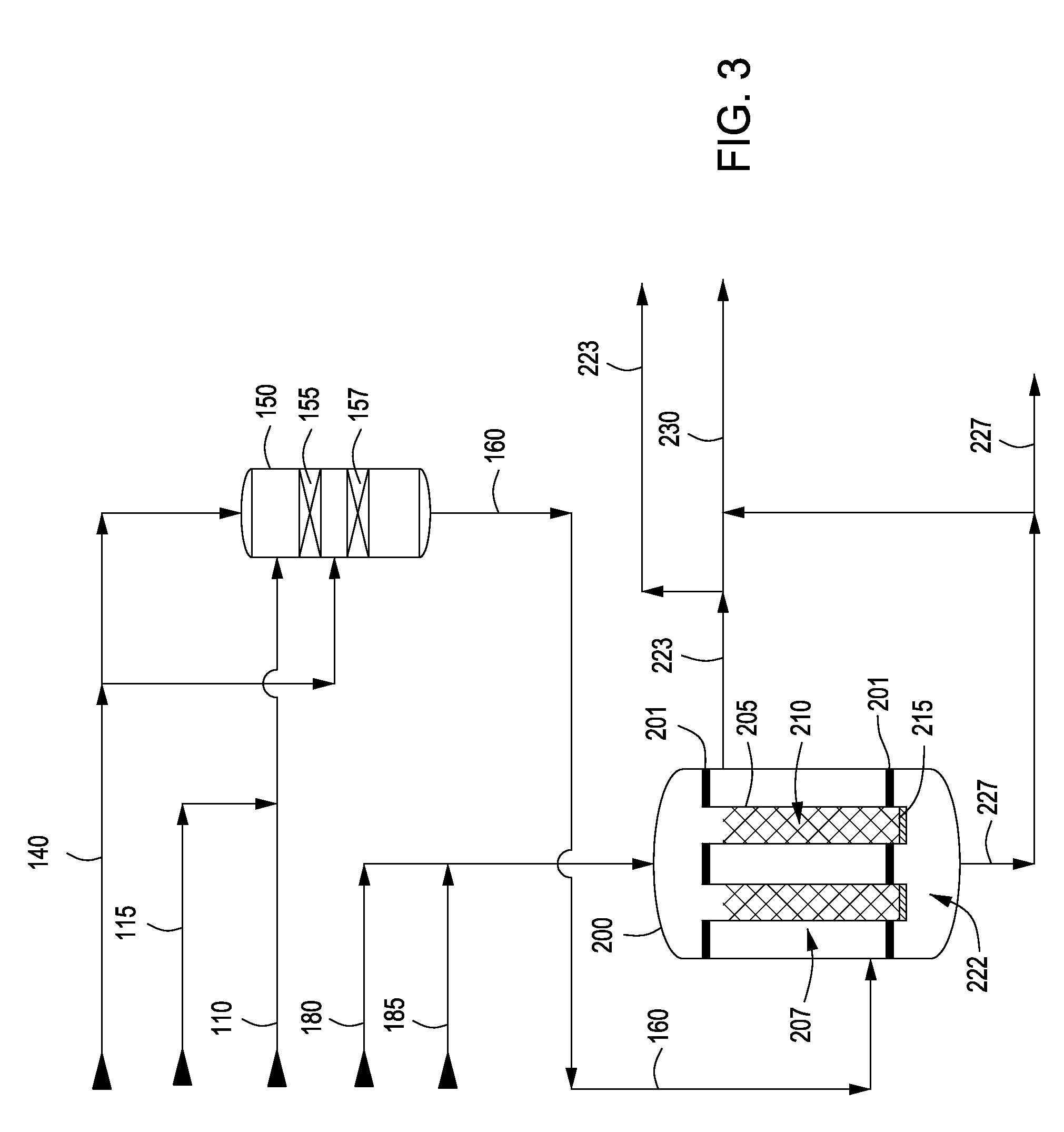

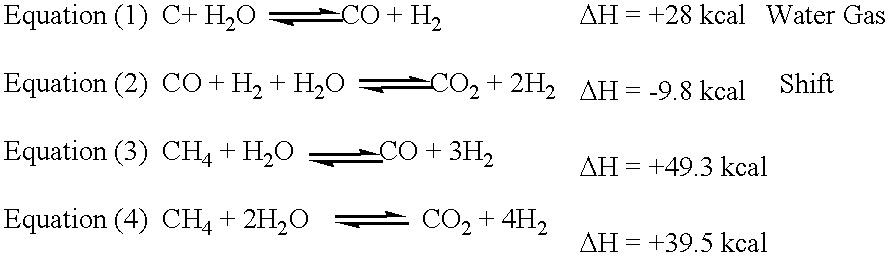

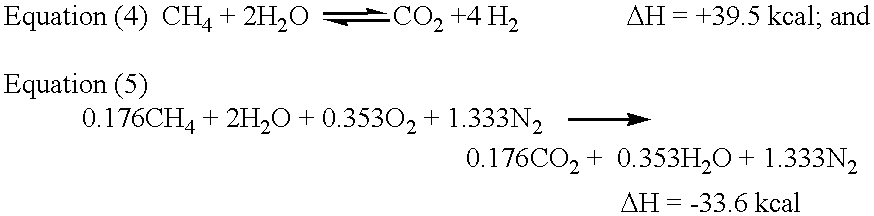

Systems and methods for producing syngas are provided. A first hydrocarbon can be partially oxidized in the presence of an oxidant and one or more first catalysts at conditions sufficient to partially combust a portion of the first hydrocarbon to provide carbon dioxide, non-combusted first hydrocarbon, and heat. The non-combusted first hydrocarbon can be reformed in the presence of the heat generated in the partial oxidation step and the one or more first catalysts to provide a first syngas. Heat can be indirectly exchanged from the first syngas to a second hydrocarbon to reform at least a portion of the second hydrocarbon in the presence of steam and one or more second catalysts to provide a second syngas. A syngas, which can include the at least a portion of the first syngas, at least a portion of the second syngas, or a mixture thereof can be converted to provide one or more Fischer-Tropsch products, methanol, derivatives thereof, or combinations thereof.

Owner:KELLOGG BROWN & ROOT LLC

Catalytic partial oxidation reforming for syngas processing and products made therefrom

Systems and methods for producing syngas are provided. A first hydrocarbon can be partially oxidized in the presence of an oxidant and one or more first catalysts at conditions sufficient to partially combust a portion of the first hydrocarbon to provide carbon dioxide, non-combusted first hydrocarbon, and heat. The non-combusted first hydrocarbon can be reformed in the presence of the heat generated in the partial oxidation step and the one or more first catalysts to provide a first syngas. Heat can be indirectly exchanged from the first syngas to a second hydrocarbon to reform at least a portion of the second hydrocarbon in the presence of steam and one or more second catalysts to provide a second syngas. A syngas, which can include the at least a portion of the first syngas, at least a portion of the second syngas, or a mixture thereof can be converted to provide one or more Fischer-Tropsch products, methanol, derivatives thereof, or combinations thereof.

Owner:KELLOGG BROWN & ROOT LLC

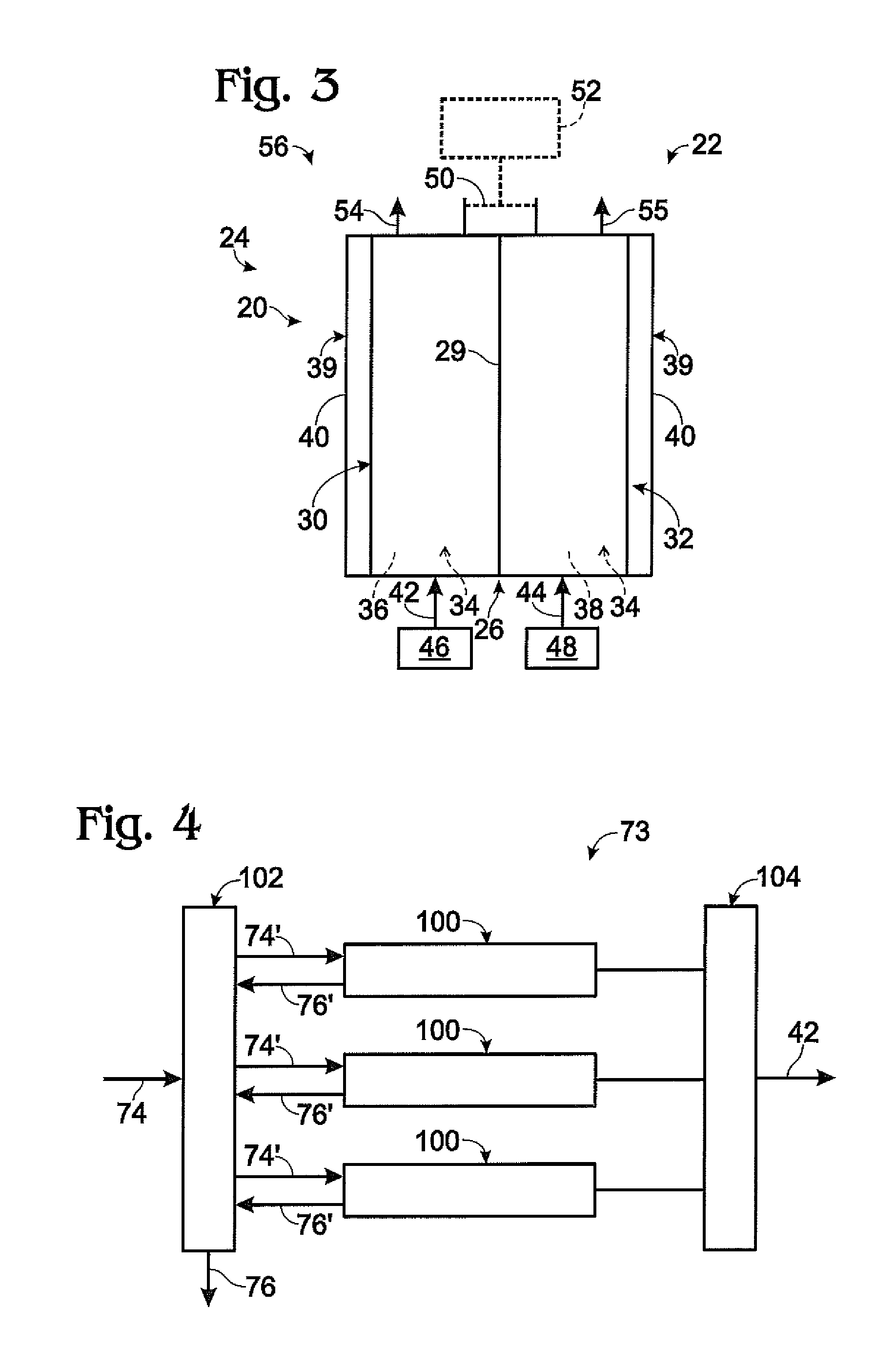

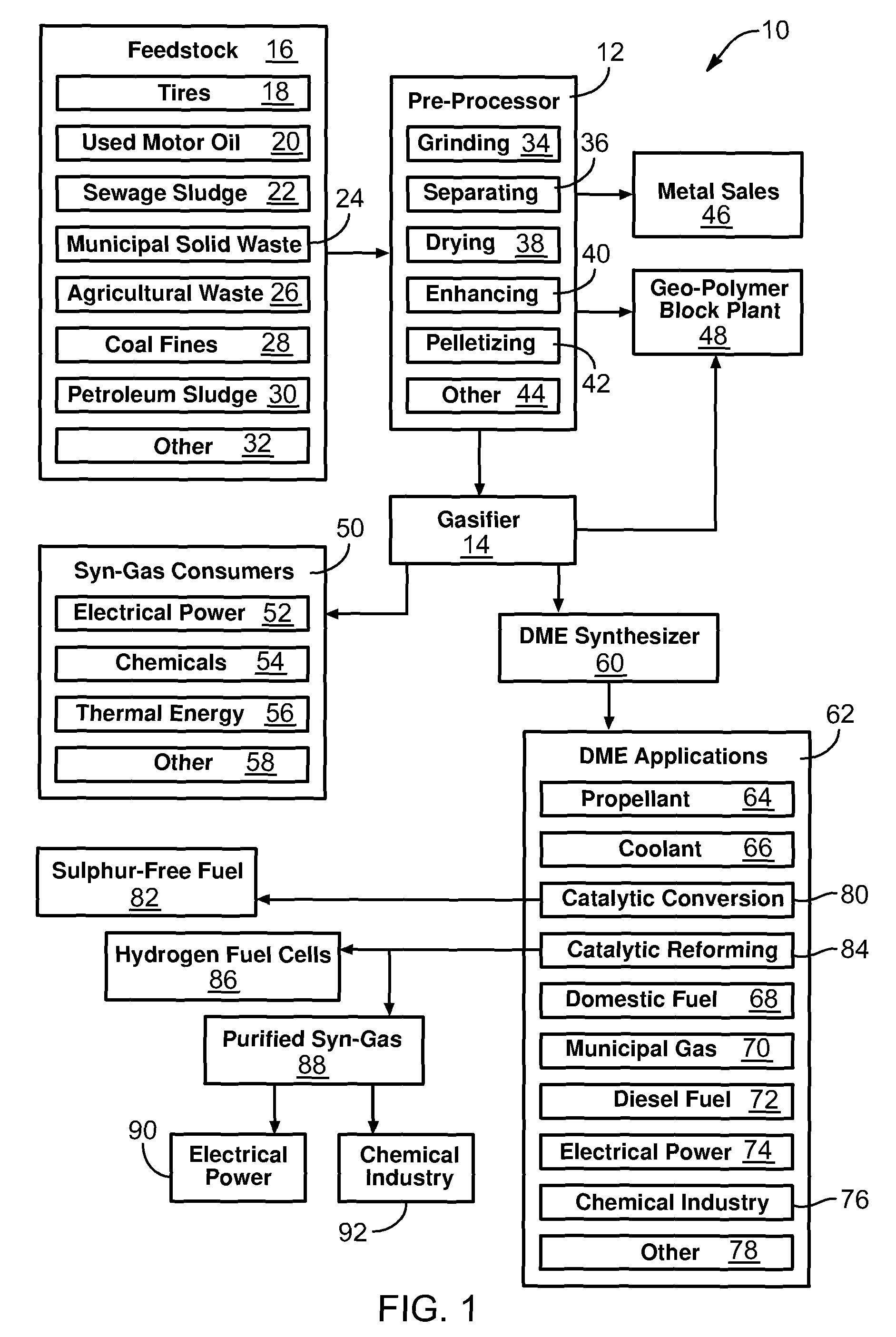

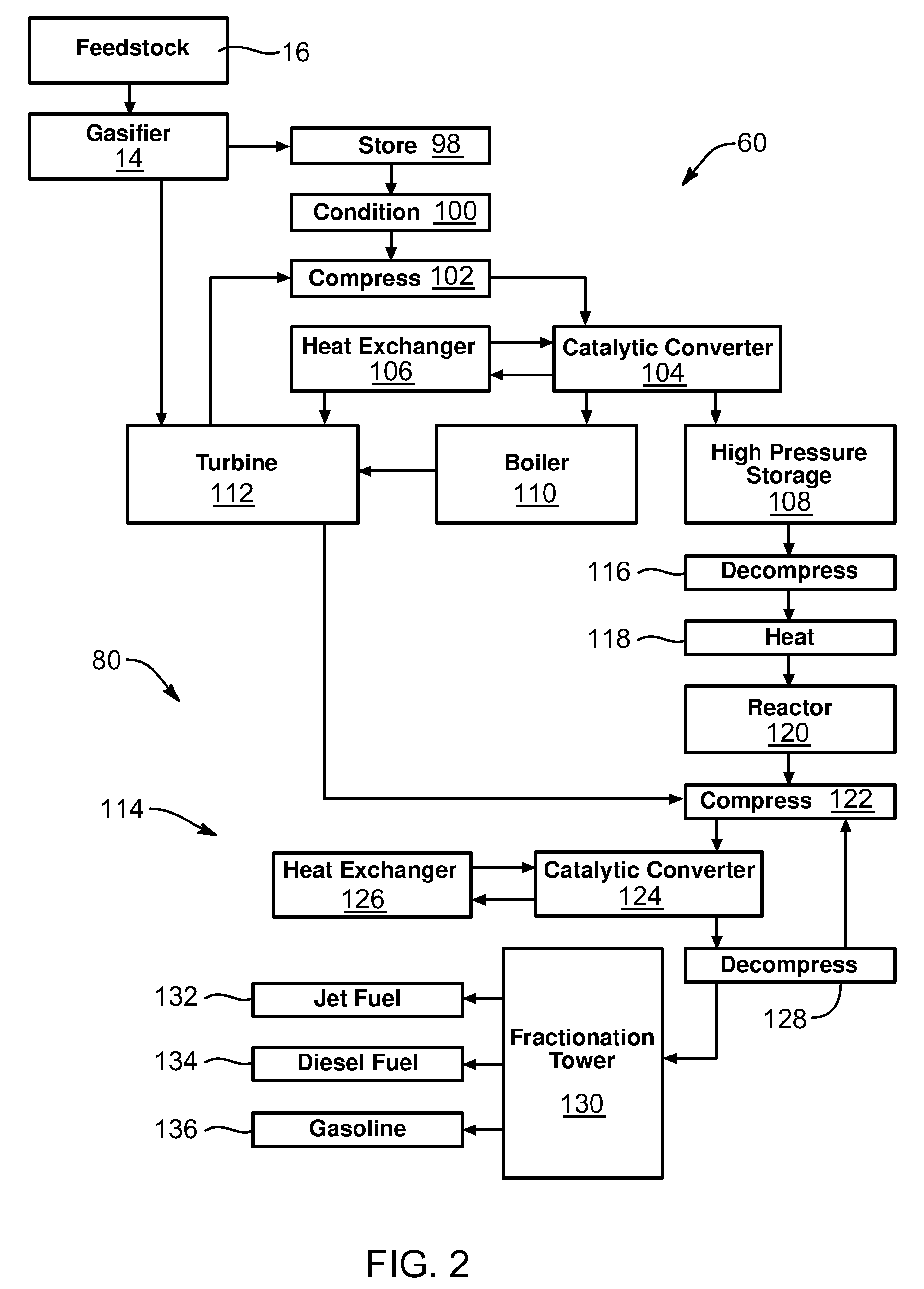

Method and apparatus for total energy fuel conversion systems

InactiveUS6350394B1Thermal non-catalytic crackingInternal combustion piston enginesPeak loadElectric power

An independent and conserved source of fuel and / or power comprises a top stage rocket engine firing up to 5000 F. at very high pressures, delivering jet flows up to transonic velocities into a near adiabatic tunnel for mixing in general and / or for transforming reactants introduced to suit specific objectives. The related compression is supplied by an independent prime mover which compresses its exhaust and other recoverable fluids. Low grade flows, thereby upgraded in temperature and pressure, are adiabatically contained, are further upgraded in the tunnel to become part of the prescribed fuel for export at the tunnel ends; or fuel to be fired in a prime mover for electric or other power, or hydrogen for chemical use. Expansion turbines for this purpose are relieved of the load used to compress the excess air in standard gas turbines thus increasing export power. A portion of the expansion turbine's exhaust becomes part of recoverable fluids. When oxygen is used instead of air, the gases through turbines are nitrogen-free with more heat capacity reducing turbine inlet temperatures for the same power. When reactant transformation is specified, the larger water vapor content in the cycle enhances the water gas / shift autothermally for ammonia and / or power and alternatively for pyrolysis cracking for olefins and diolefins. Further, staging rocket engine reactors increases efficiency in boilers and steam turbines; and staging can produce sponge iron and / or iron carbide as well as expansion turbine power and fuel cells for peak and off-peak loads.

Owner:EGT ENTERPRISES

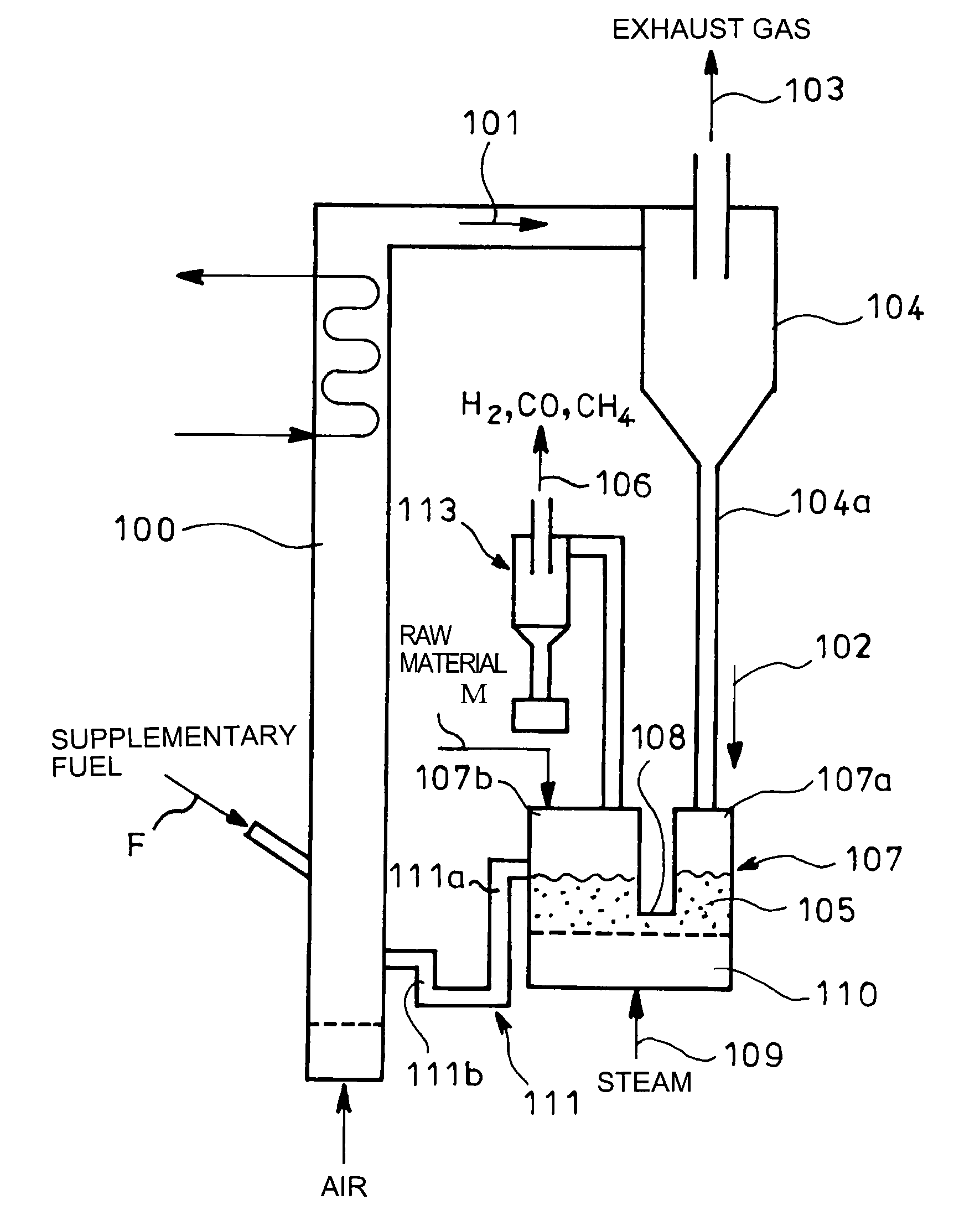

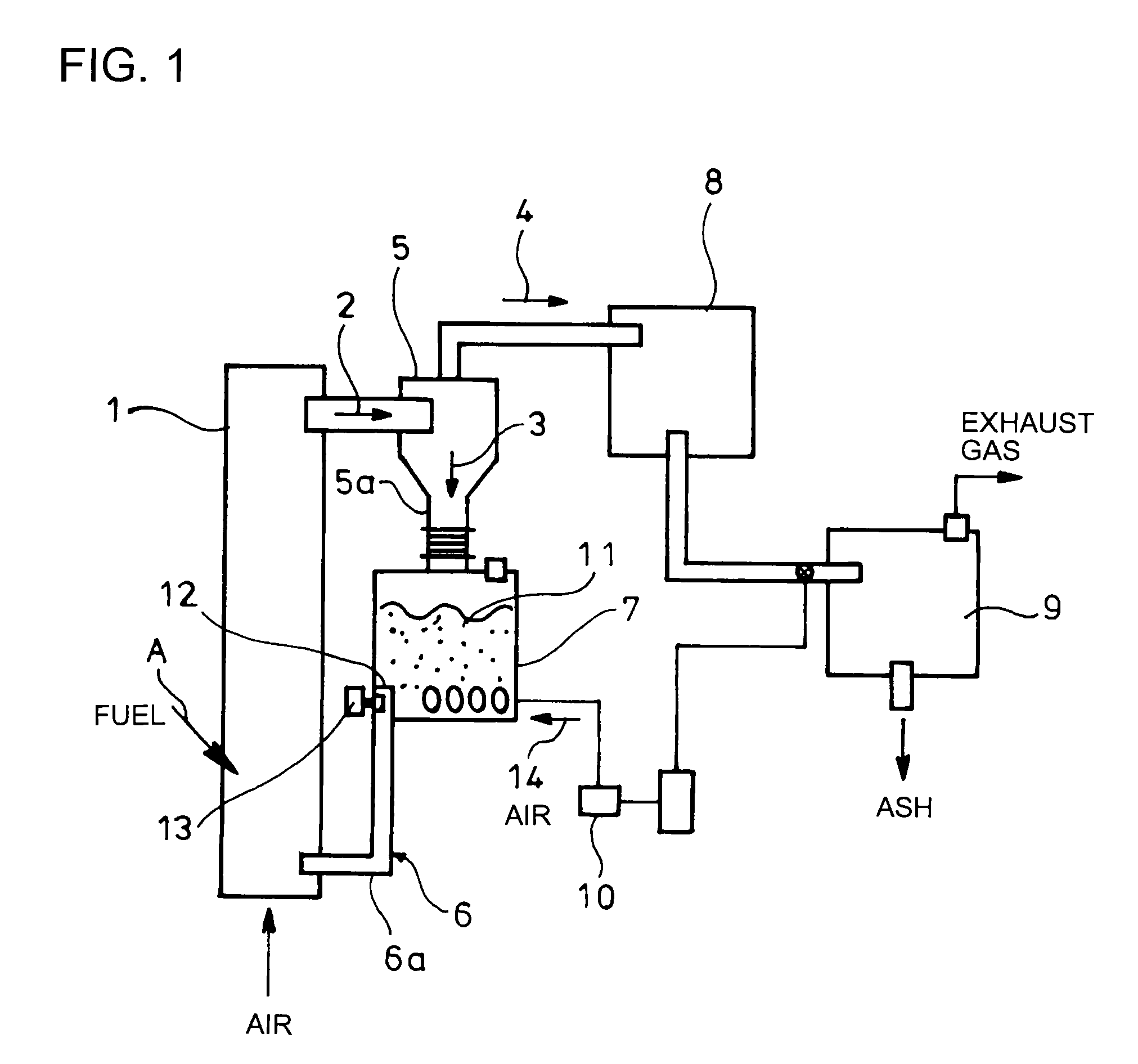

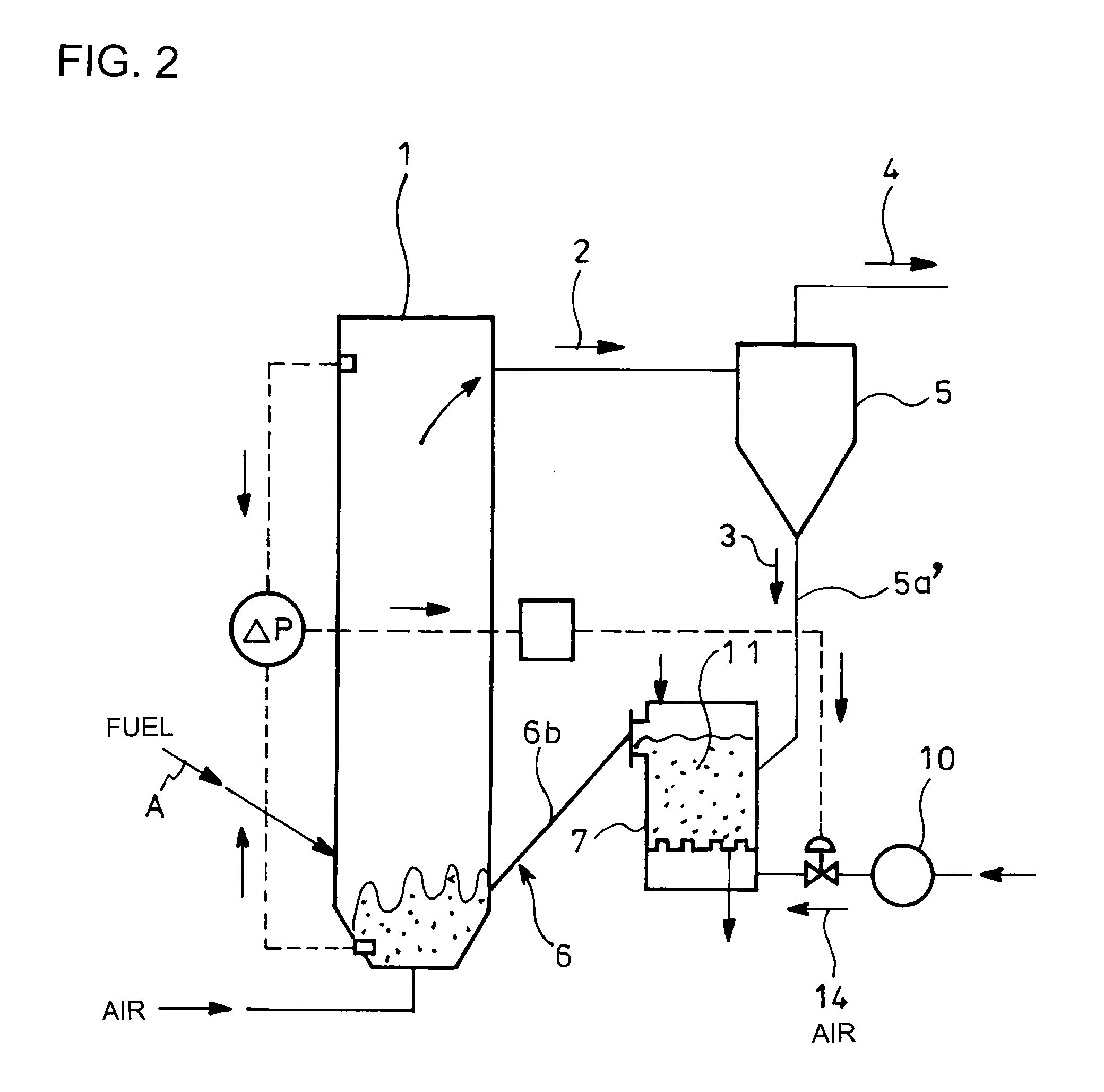

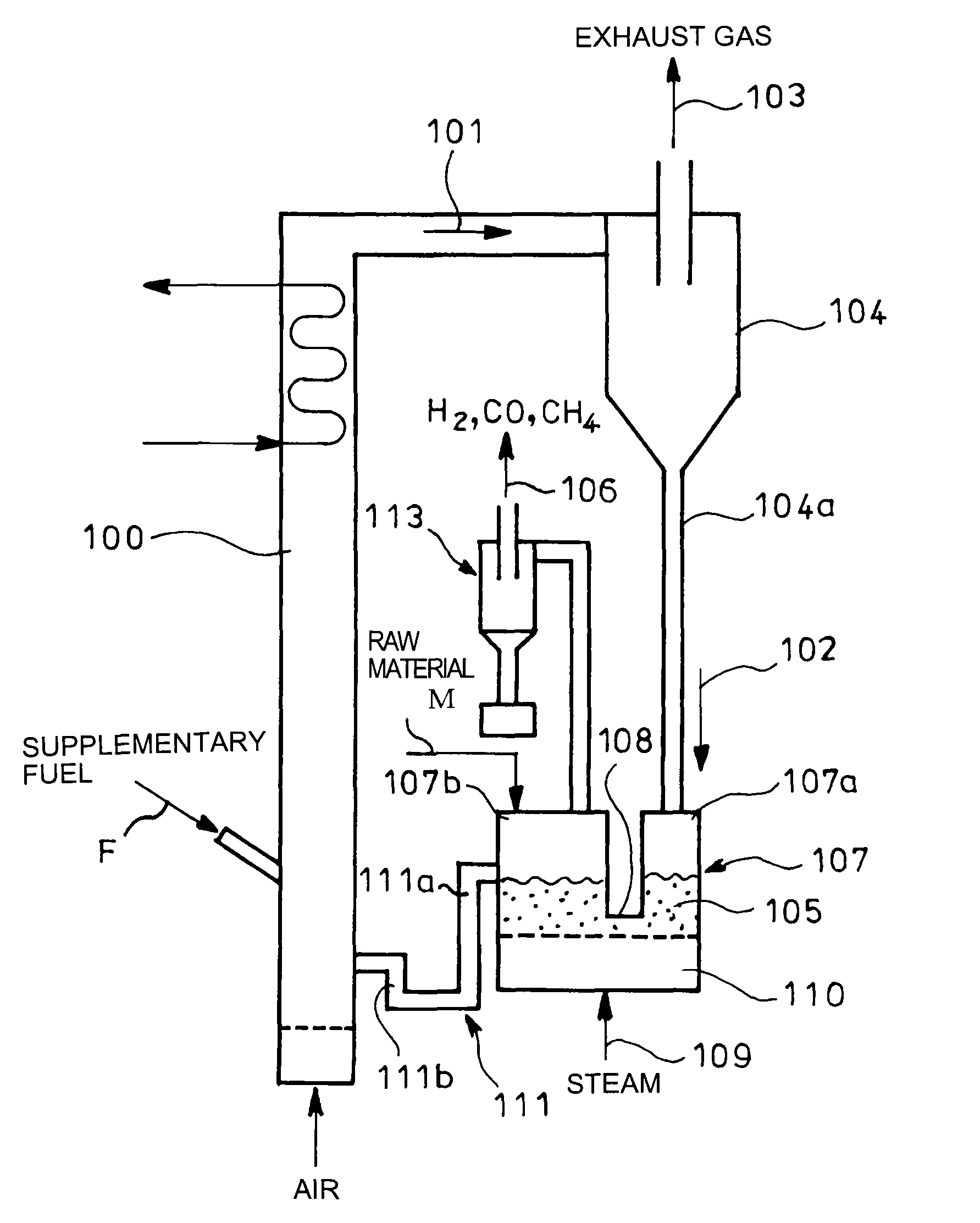

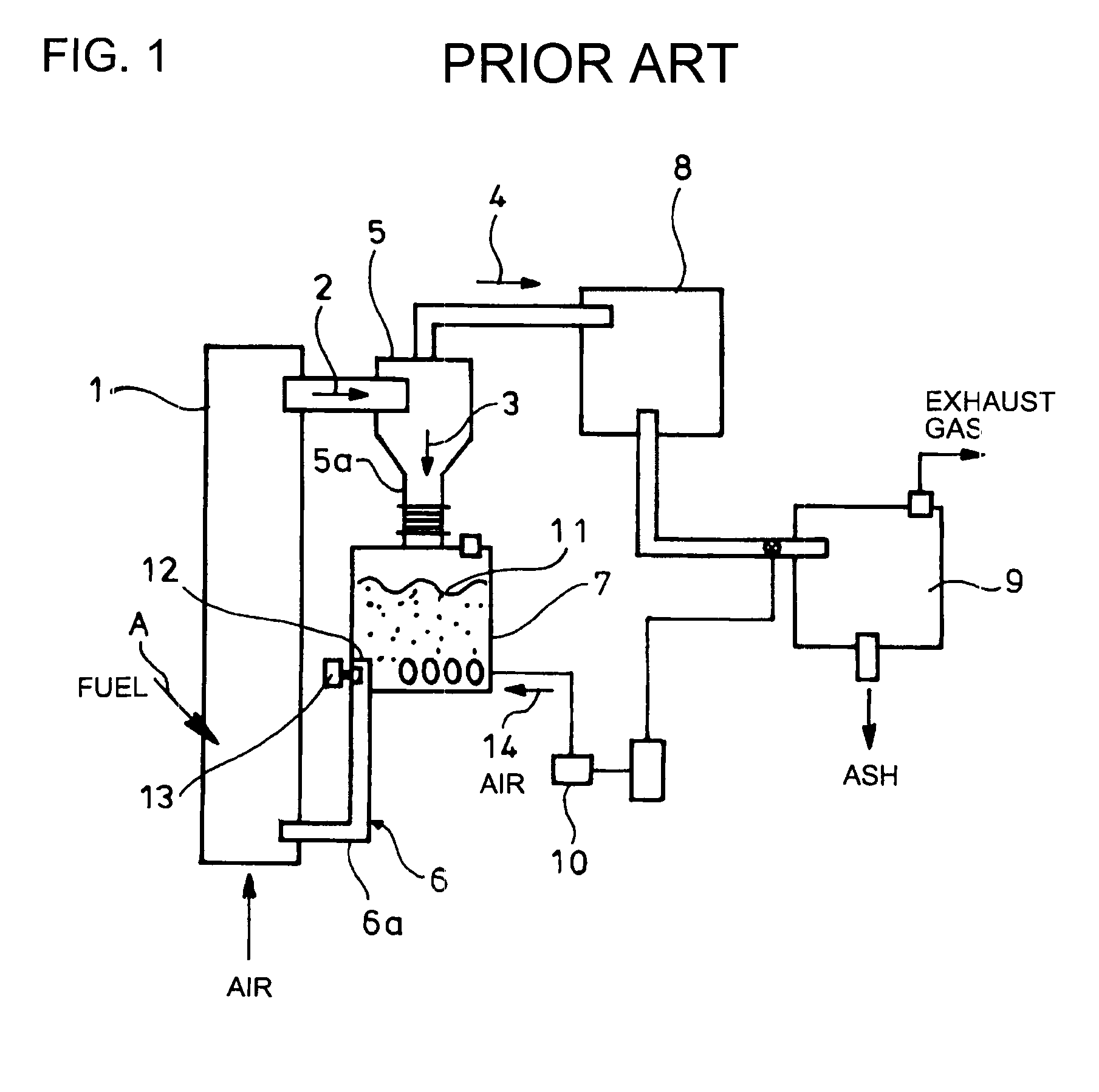

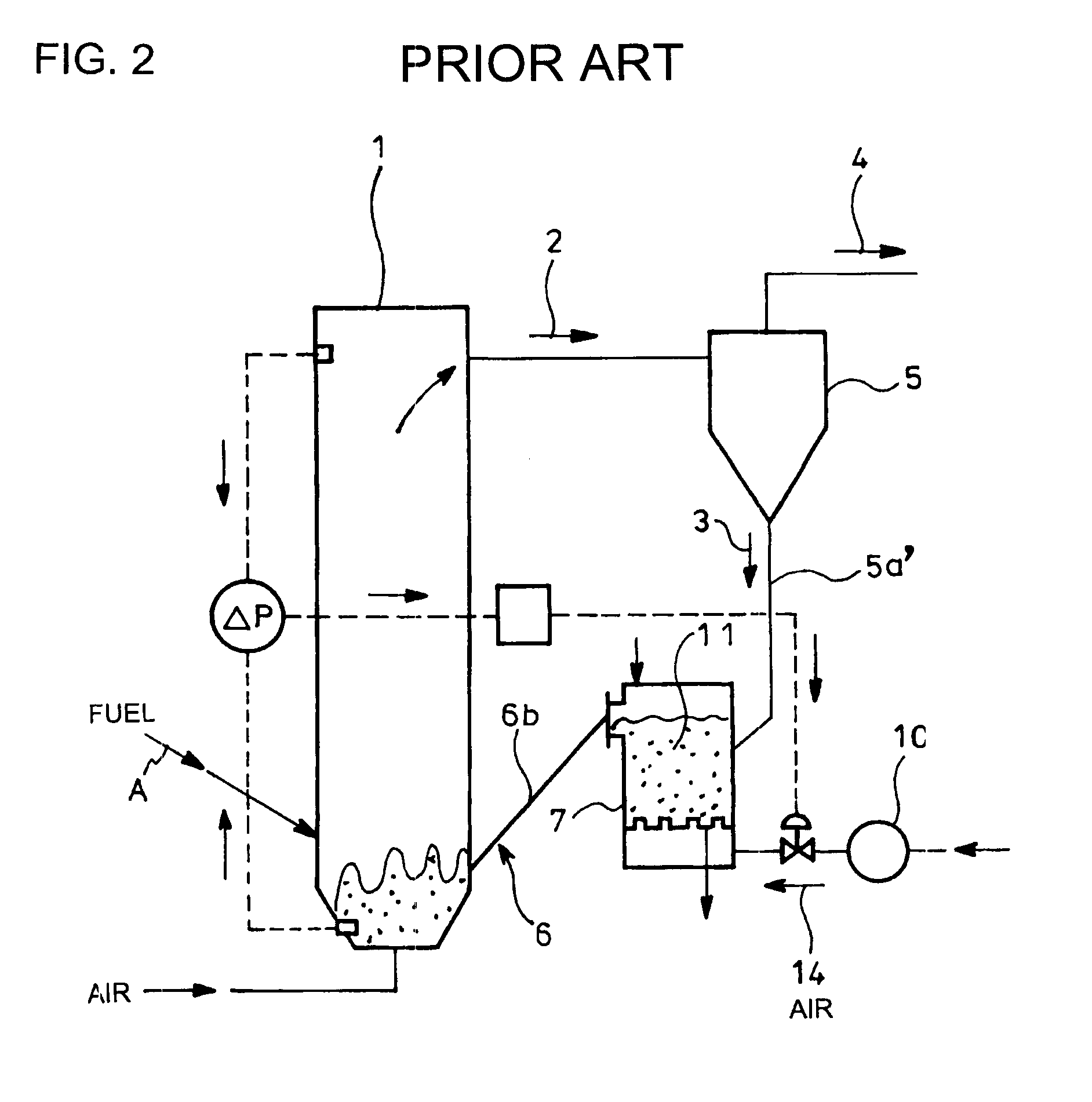

System for controlling circulatory amount of particles in circulating fluidized bed furnace

ActiveUS20100024297A1Improve gasification efficiencyFluidized bed combustionLevel controlFluidized bed gasifierDifferential pressure

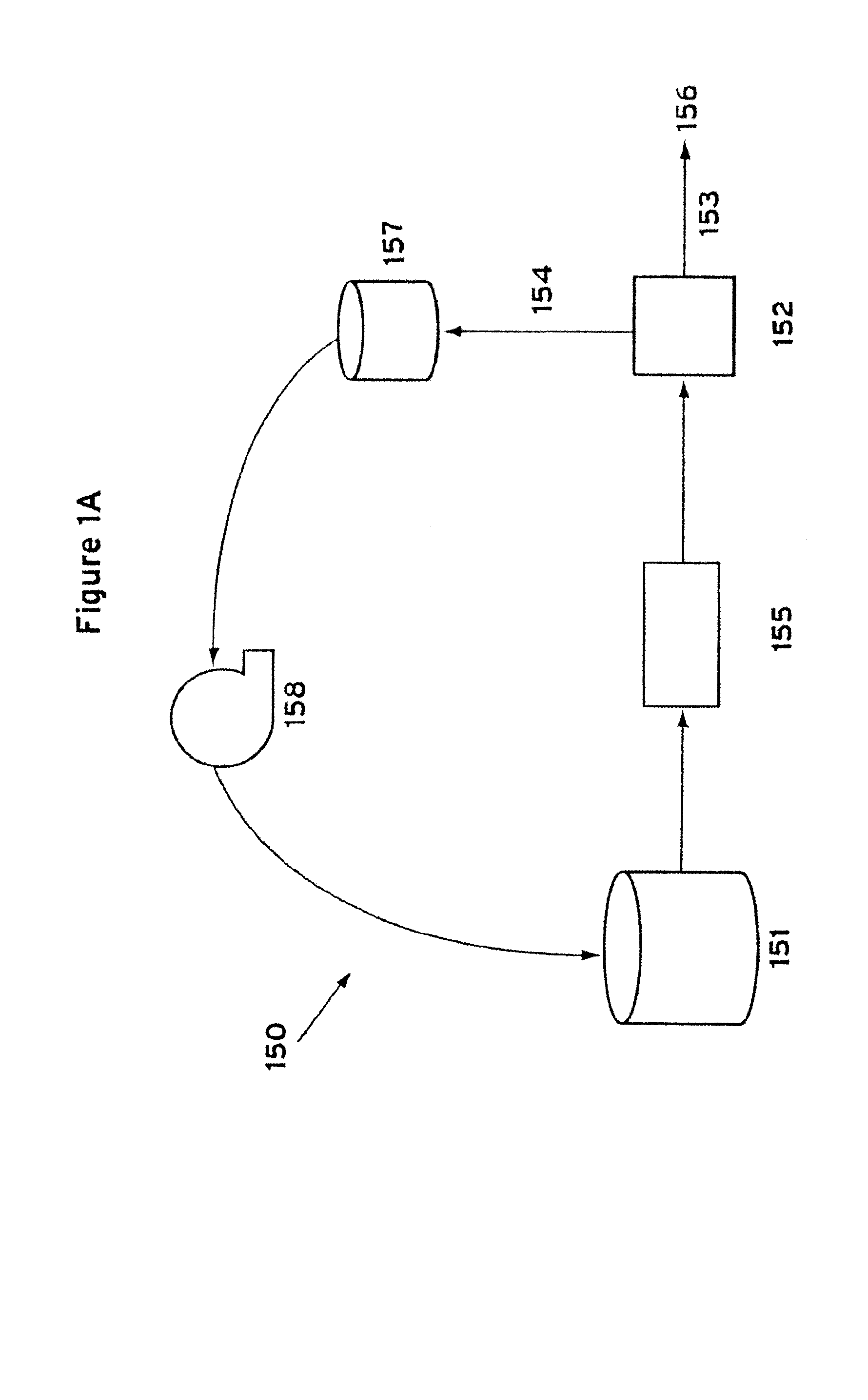

The invention has its object to arbitrarily adjust an amount of particles to be circulated without changing a flow rate of a gasification agent to thereby enhance gasification efficiency in a fluidized bed gasification furnace.The fluidized bed gasification furnace 107 comprises first and second chambers 113 and 114 in communication with each other in a fluidized bed 105. The hot particles 102 separated in the separator 104 and raw material M are introduced into the first chamber 113. The particles 102 introduced from the first chamber 113 through interior in the fluidized bed 105 to the second chamber 114 are supplied in an overflow manner to the fluidized bed combustion furnace 100. A first pressure controller 121 is provided to control the resultant gas induction means 116 such that the pressure in the first chamber 113 is kept to preset pressure 120; and a second pressure controller 124 is provided to control the exhaust gas induction means 118 such that difference between pressure in the first and second chambers 113 and 114 is equal to the preset differential pressure 123, so that the fluidized bed 105 in the first chamber 113 is controlled in height to control an amount of particles 102 to be circulated.

Owner:IHI CORP

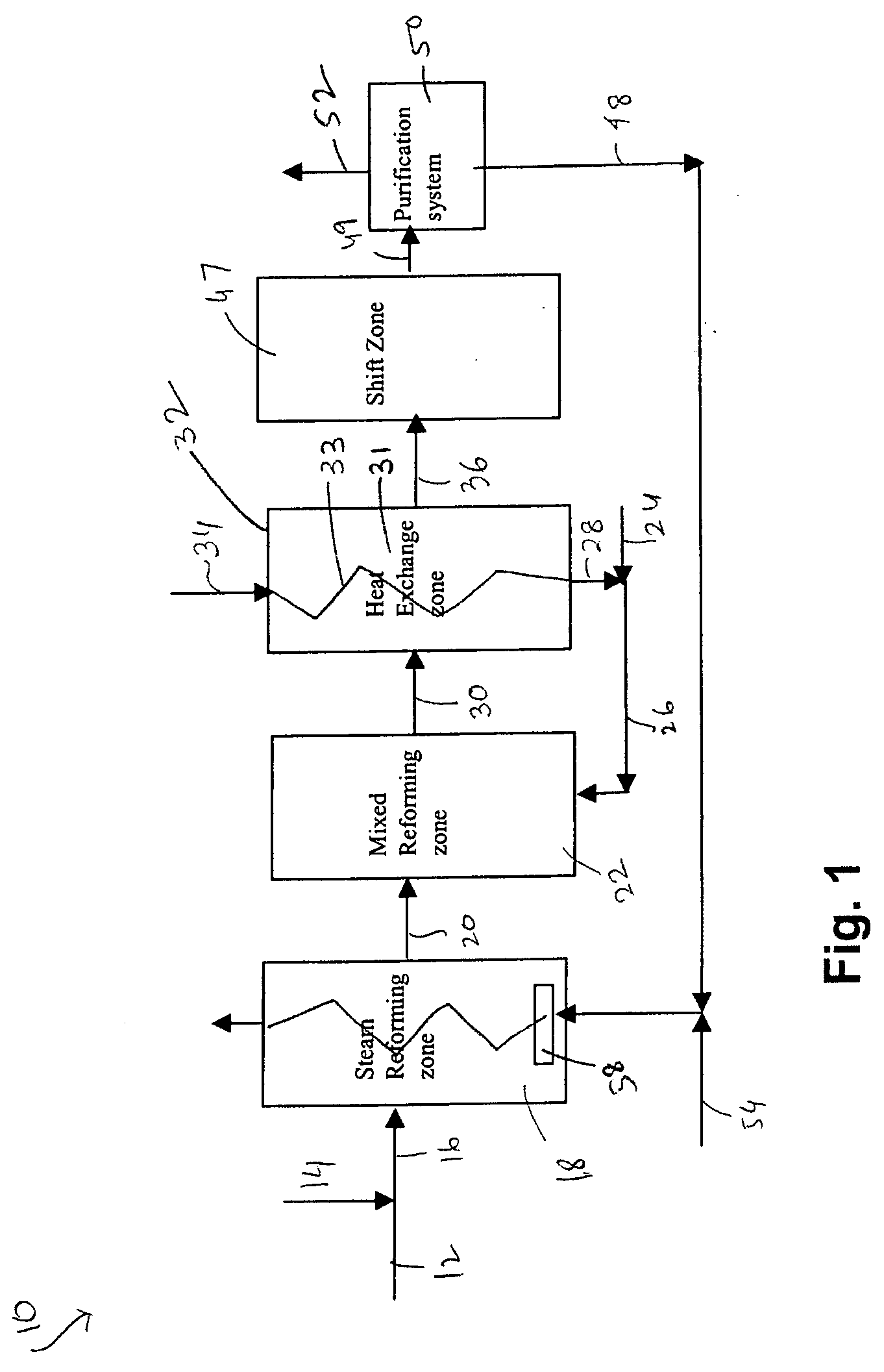

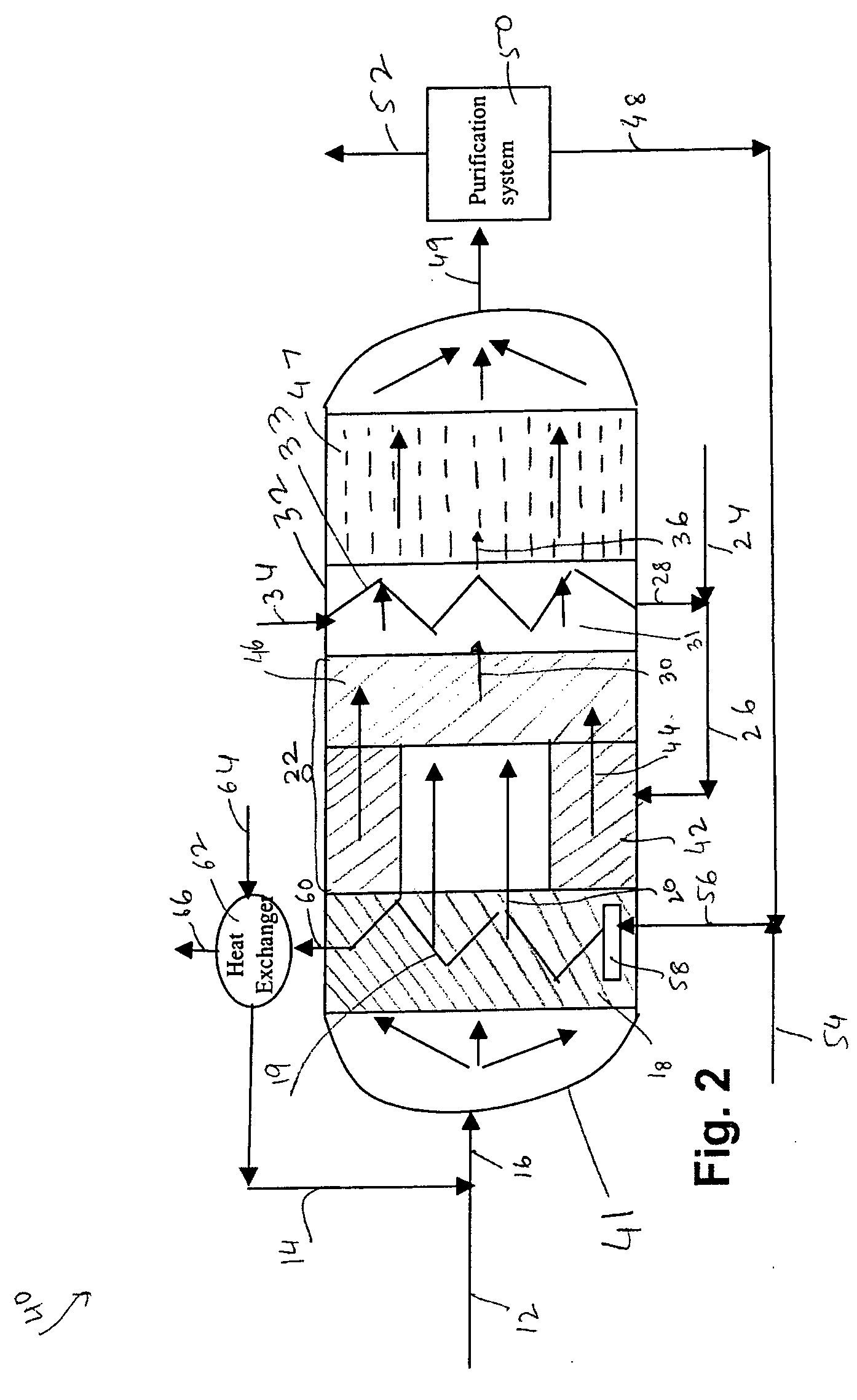

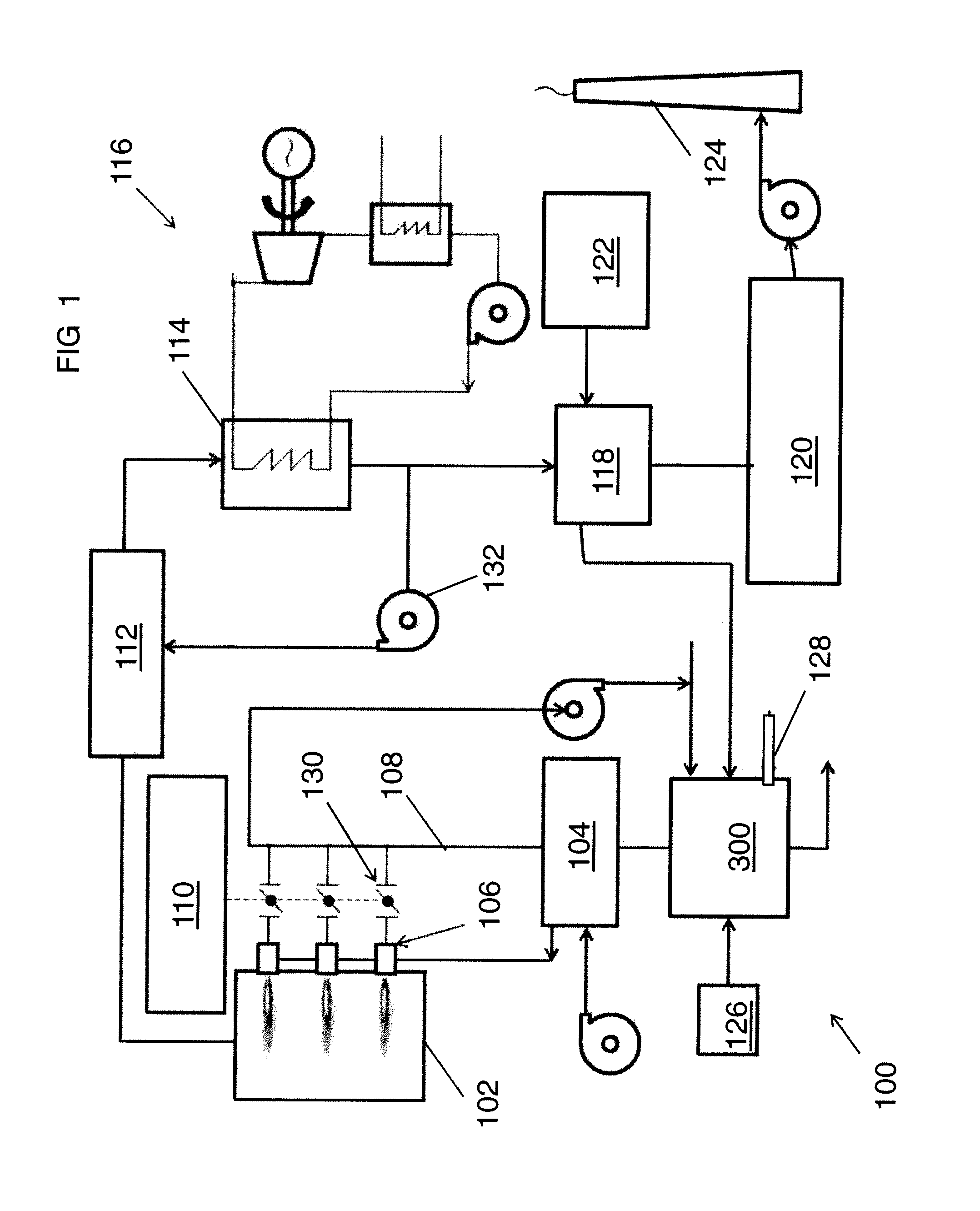

System and method for hydrogen production

A system for production of hydrogen comprises at least one steam reforming zone configured to receive a first fuel and steam to produce a first reformate gas stream comprising hydrogen using a steam reforming process. The system further comprises a mixed reforming zone configured to receive an oxidant to produce a second reformate gas stream comprising hydrogen, wherein the first reformate gas stream is sent to the mixed reforming zone to complete the reforming process.

Owner:GENERAL ELECTRIC CO

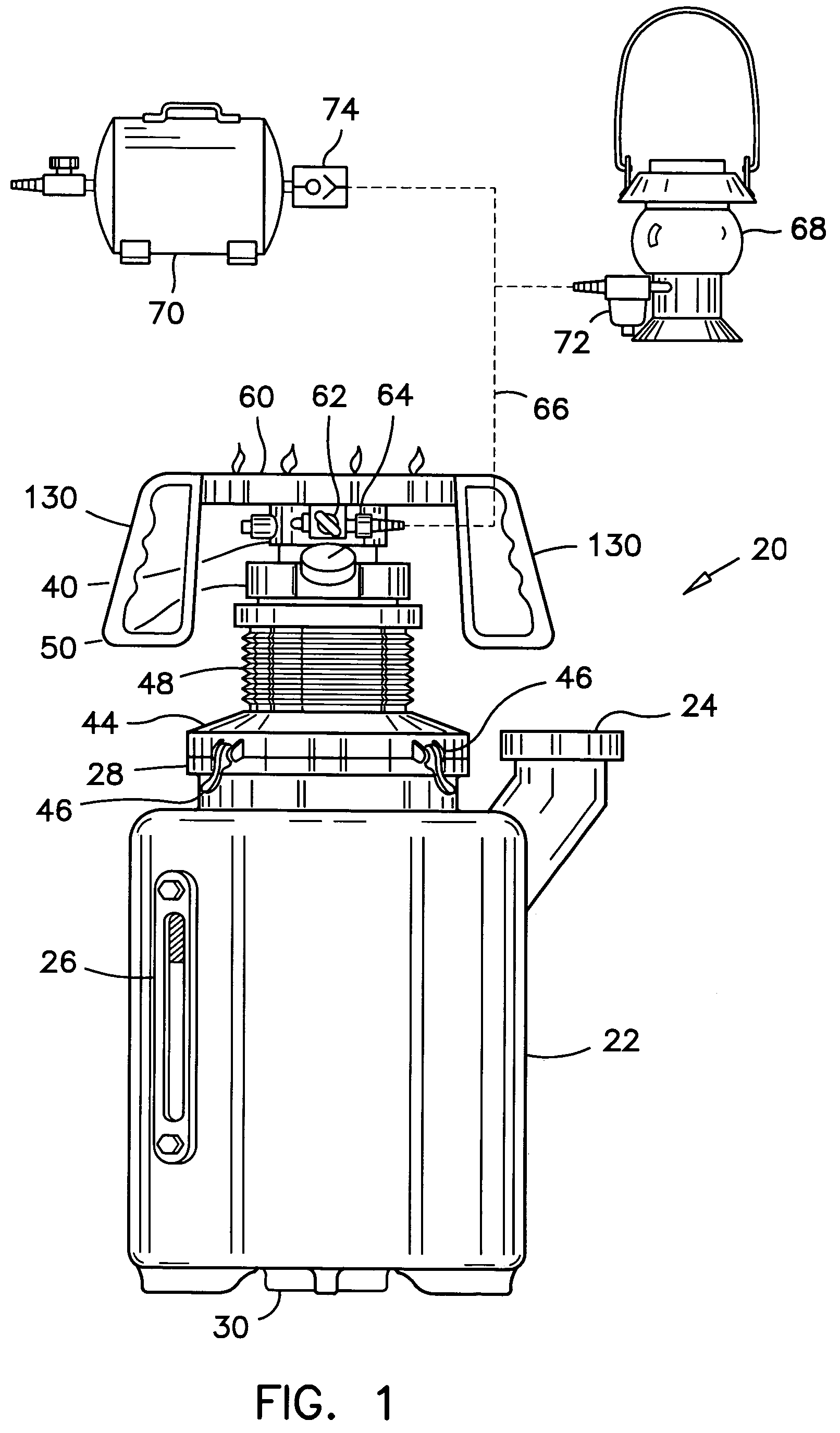

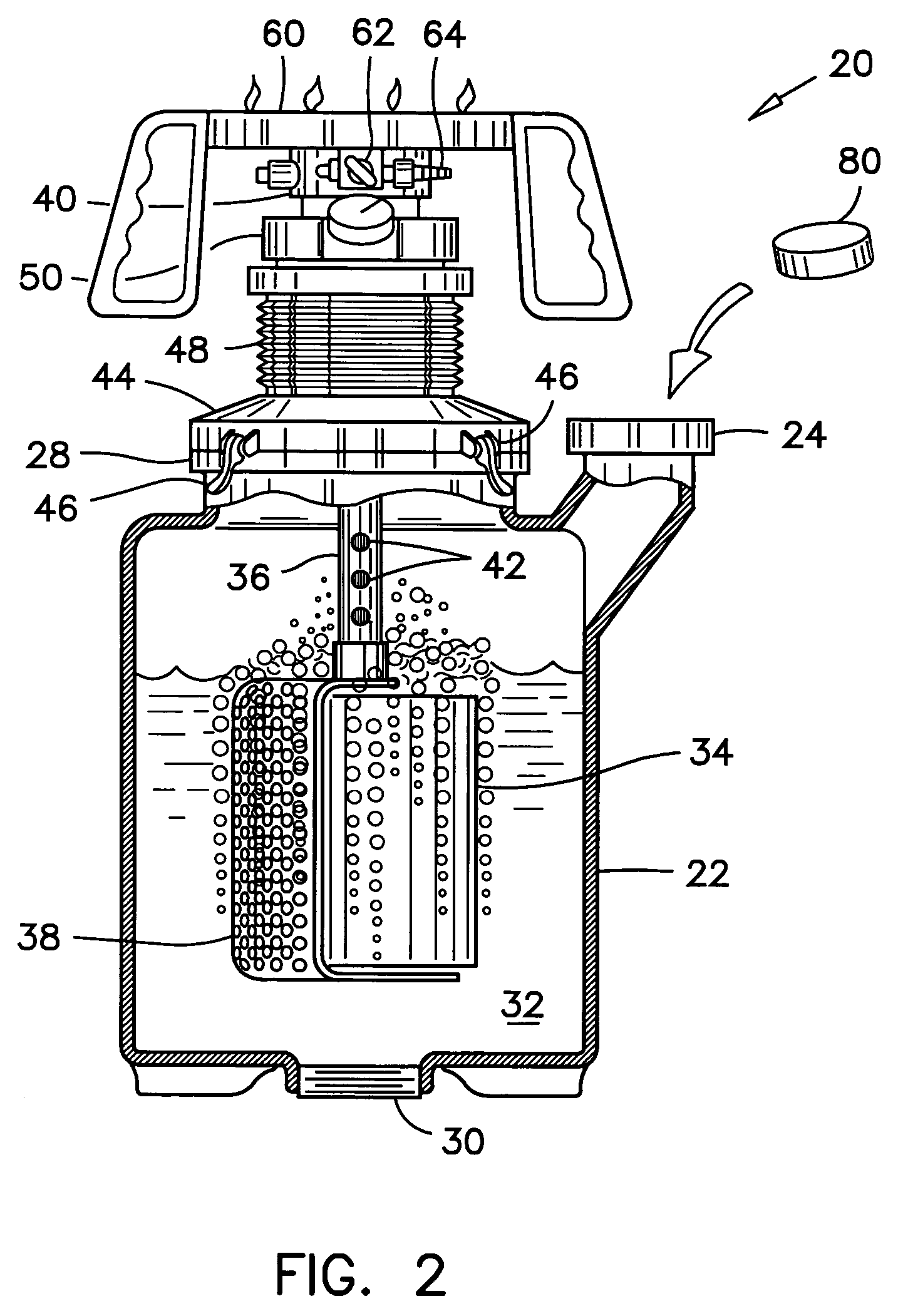

Method and apparatus for hydrogenating hydrocarbon fuels

InactiveUS7326263B2High purityFirmly connectedAluminium compoundsHydrogen productionHydrogenAqueous solution

In the present invention, there is provided a process and an apparatus for hydrogenating hydrocarbon fuels. A receptacle is partly filled an aqueous solution containing sodium hydroxide. A hydrocarbon fuel is then introduced inside the receptacle atop the aqueous solution. Aluminum is introduced in the aqueous solution, thereby producing hydrogen gas. The hydrogen gas is bubbled through the hydrocarbon fuel for hydrogenating the fuel.

Owner:ANDERSEN ERLING REIDAR

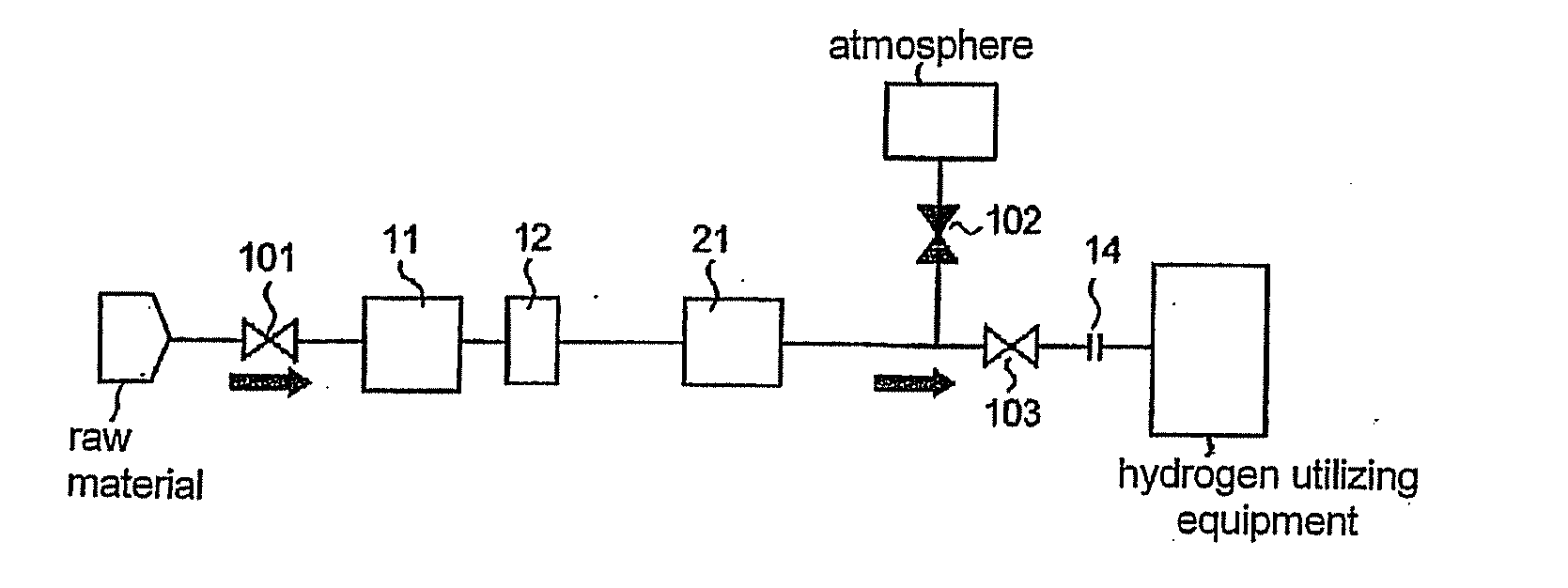

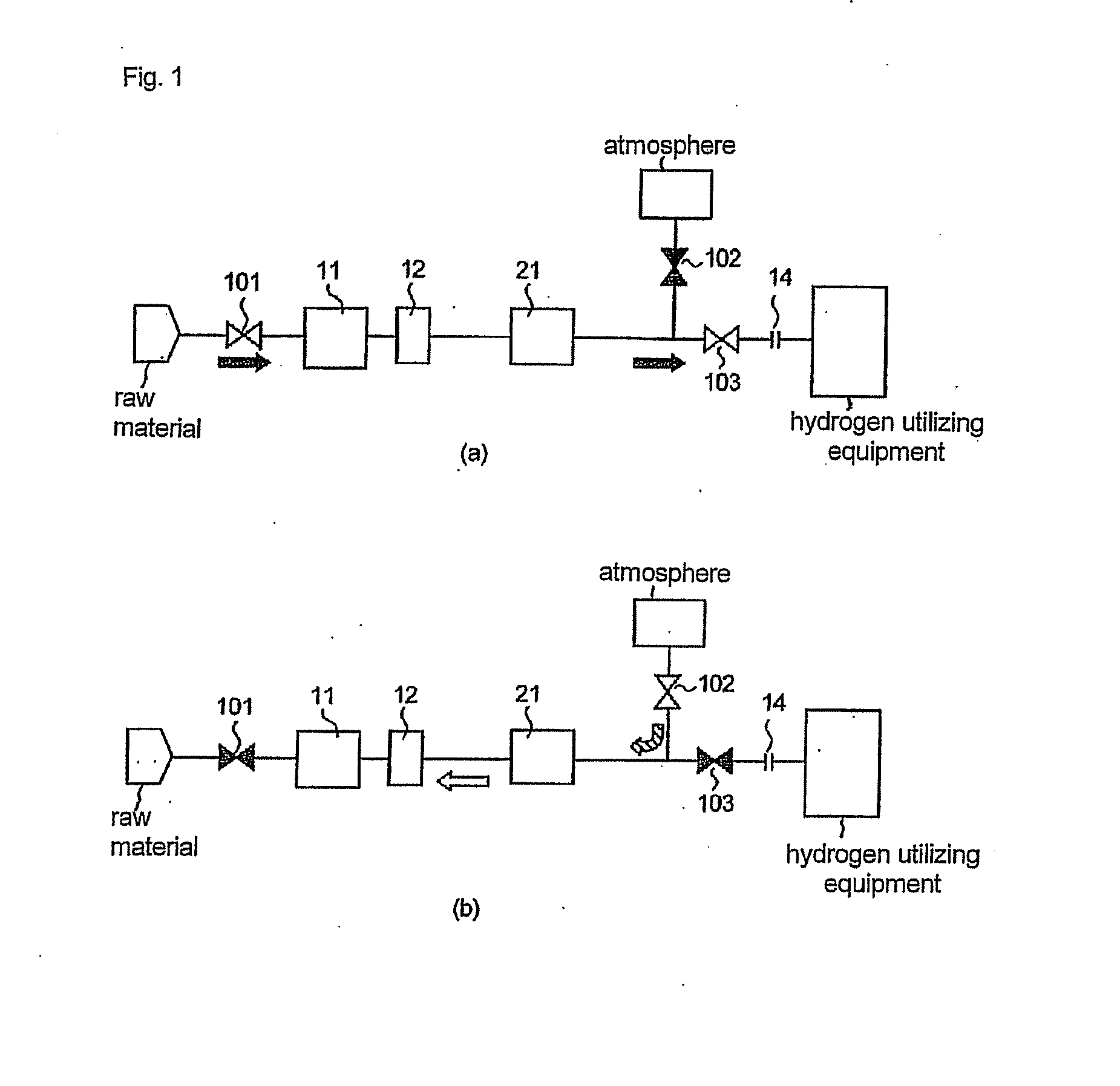

Hydrogen Production Apparatus, Fuel Cell System and Operation Method Thereof

InactiveUS20090011298A1Reliable suppressionReliably suppress catalyst degradationHydrogenOxygen/ozone/oxide/hydroxideFuel cellsAtmospheric air

There are provided a hydrogen production apparatus, a fuel cell system and operation method thereof, which can more reliably suppress degradation due to oxidation of a catalyst in a hydrogen production apparatus even when start-ups and shutdowns are repeated without a purge operation during the shutdowns. The hydrogen production apparatus includes a reforming part, a shift reaction part, and a selective oxidation reaction part having a selective oxidation catalyst bed packed with a selective oxidation catalyst, wherein the hydrogen production apparatus has an oxygen absorbent bed packed with an oxygen absorbent capable of absorbing oxygen and capable of being regenerated by a reducing gas, and the oxygen absorbent bed and the selective oxidation catalyst bed are stacked with the oxygen absorbent bed on the downstream side, and the hydrogen production apparatus has means for opening the downstream of the oxygen absorbent bed to the atmosphere. The fuel cell system has this hydrogen production apparatus. The operation method of this fuel cell system includes opening the downstream of the oxygen absorbent bed to the atmosphere upon shutdown of the fuel cell system, and regenerating the oxygen absorbent using a hydrogen-containing gas during hydrogen production by the hydrogen production apparatus.

Owner:JX NIPPON OIL & ENERGY CORP

System and method of increasing synthesis gas yield in a fluid catalytic cracking unit

ActiveUS20090158662A1Reduce carbon dioxide emissionsIncrease productionCombination devicesCatalytic crackingHydrogenUnit system

Systems and methods of reducing refinery carbon dioxide emissions by improving the overall synthesis gas yield in a fluid catalytic cracking unit having a reactor and a regenerator are discussed. In one example, a method comprises introducing spent catalyst and a feed gas comprising oxygen to the regenerator at gasification conditions. The method further comprises heating the spent catalyst to burn coke therefrom to produce a synthesis gas. The method further comprises combining the synthesis gas with a dry gas comprising hydrogen, creating the overall synthesis gas and thereby increasing the yield of the overall synthesis gas produced in the FCC unit.

Owner:UOP LLC +1

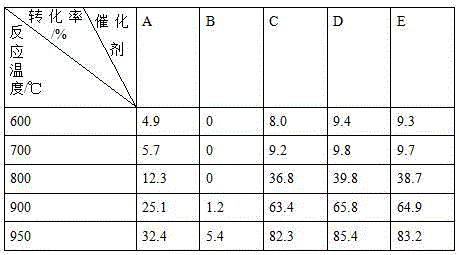

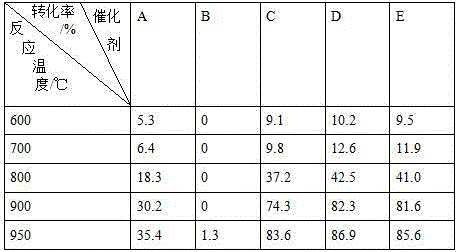

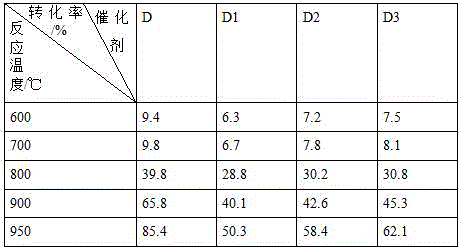

Method for preparing synthesis gas through catalytic reforming of methane and carbon dioxide

ActiveCN106281464AImprove conversion rateGuaranteed uptimeHydrogenCarburetting gasesCatalytic reformingIridium

The invention discloses a method for preparing synthesis gas through catalytic reforming of methane and carbon dioxide and belongs to the technical field of catalytic reactions. According to the method, a supported uranium-based multi-metal catalyst is taken as a catalyst for a reforming reaction of methane and carbon dioxide. The catalyst is prepared from a primary reactive metal component, namely, uranium, secondary reactive metal components and a carrier, wherein the content of uranium in the catalyst is 0.05%-30% by mass, the secondary reactive metal components comprise one or more of thorium, nickel, cobalt, molybdenum, palladium, platinum, ruthenium, rhodium and iridium, and the content of the secondary reactive metal components in the catalyst is 0.01%-20% by mass; the carrier is one of a carbon carrier, inorganic oxide and molecular sieves or a mixed carrier of more of the carbon carrier, inorganic oxide and the molecular sieves. The pressure for the reforming reaction of methane and carbon dioxide is 50 atm lower than the normal pressure, and the reaction temperature is 450-950 DEG C. The method for preparing the synthesis gas through catalytic reforming of methane and carbon dioxide has the advantages of wide reaction temperature range, high catalyst activity, good stability, carbon deposition resistance and the like.

Owner:TSINGHUA UNIV

Method for Gasification and A Gasifier

InactiveUS20120023823A1Reduce and eliminate operational shutdownReducing wall refractory erosionFluidized bed combustionIncinerator apparatusEngineering

Owner:AIR PROD & CHEM INC

Apparatus and method for providing hydrogen at a high pressure

An apparatus and method for providing a hydrogen rich gas stream at a high pressure for use by hydrogen vehicles or other devices requiring hydrogen rich feed streams are disclosed in the present invention. As the pressure of gaseous hydrogen is increased, the temperature of the gaseous hydrogen also increases due to the heat of compression. The apparatus and method of the present invention utilize localized cooling via a vortex tube to cool the gaseous hydrogen caused by the increase in pressure.

Owner:TEXACO INC

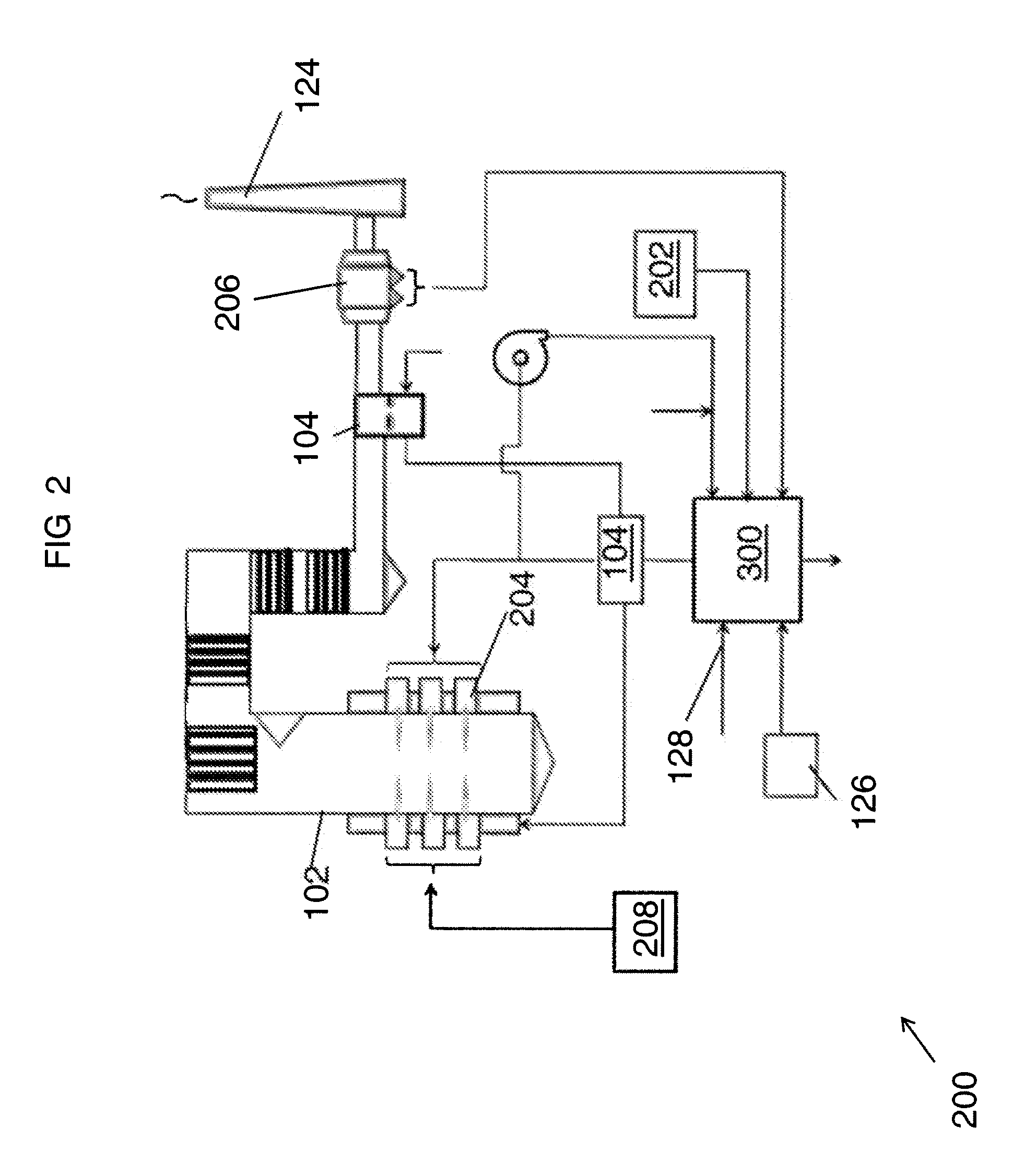

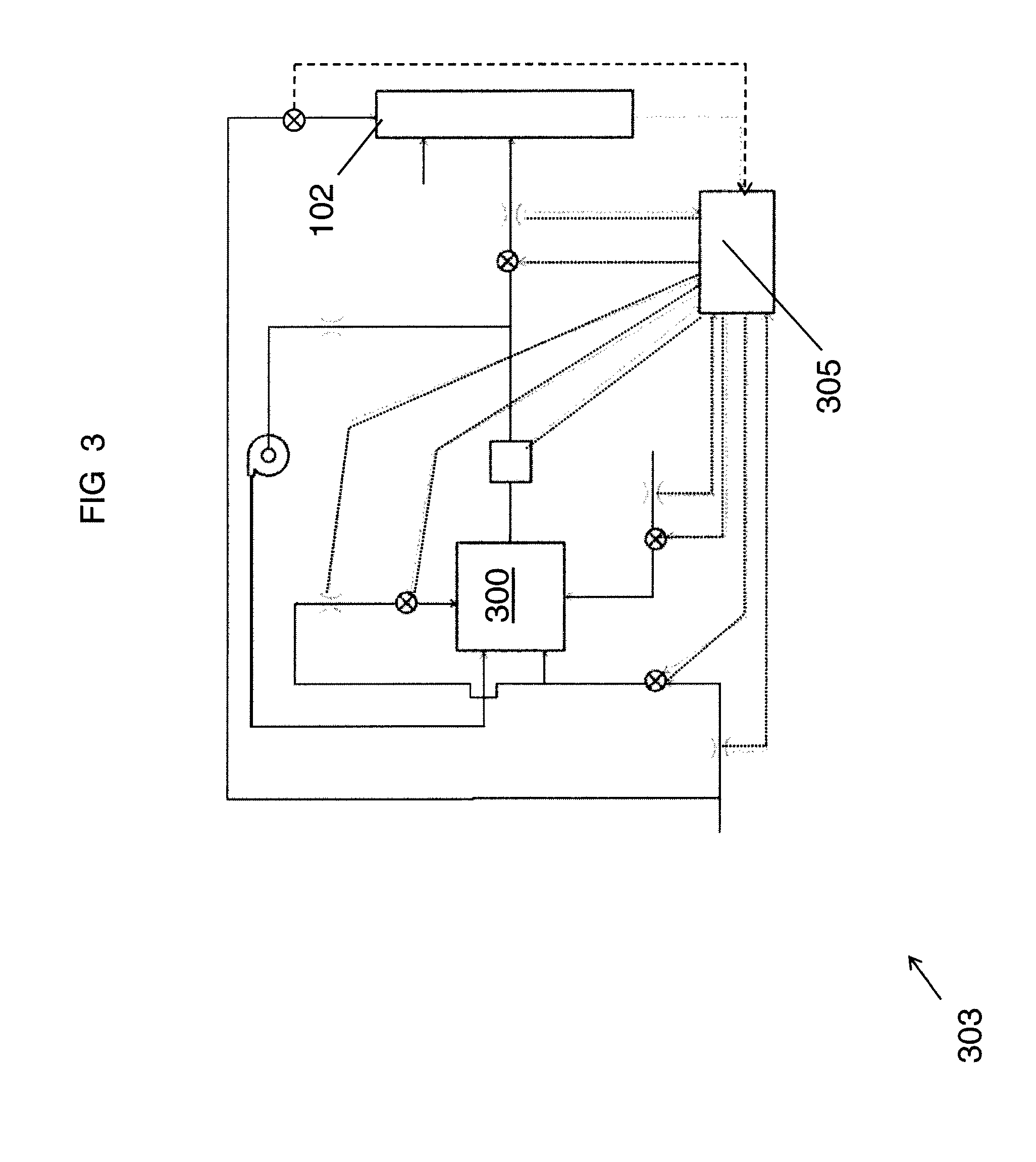

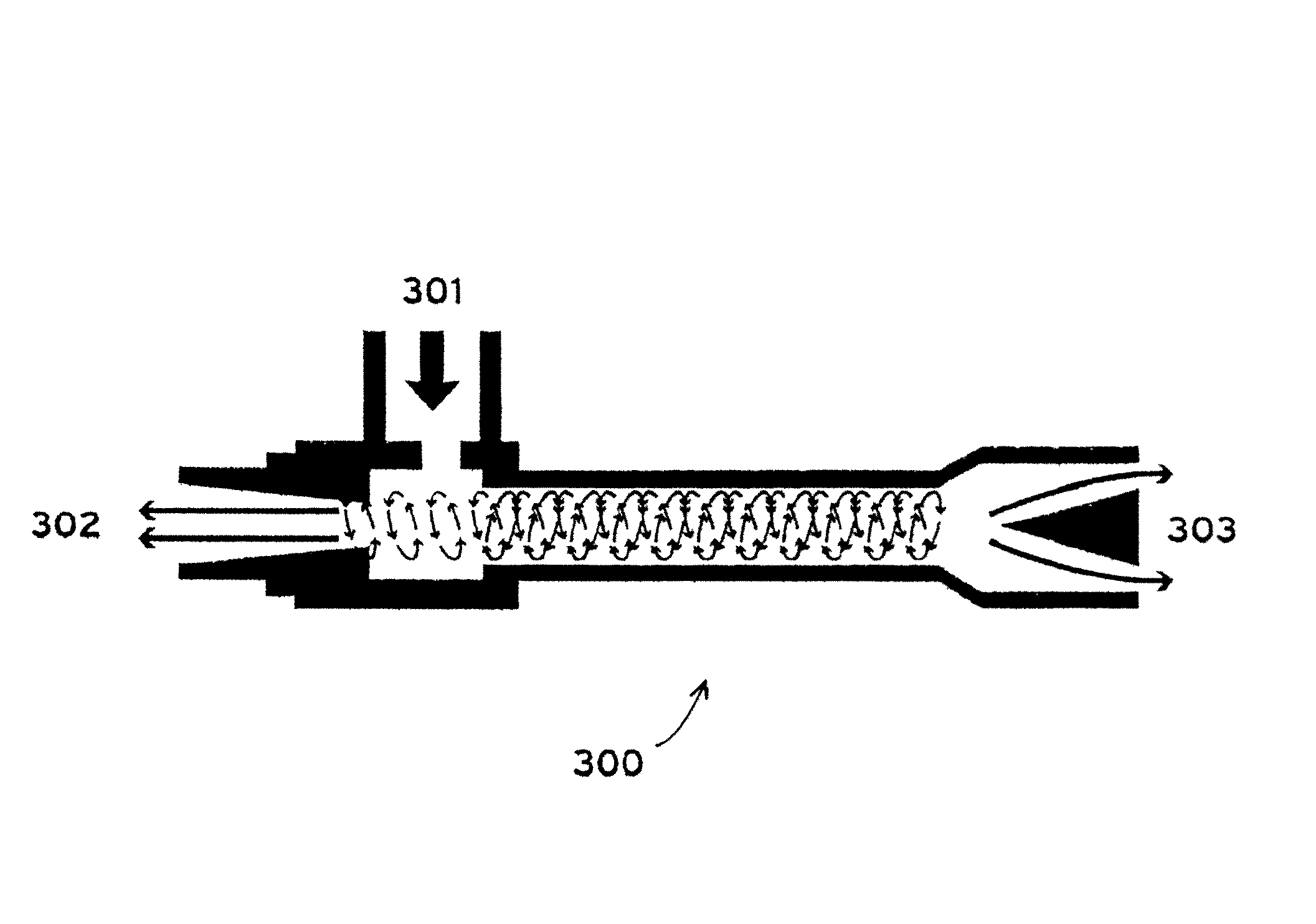

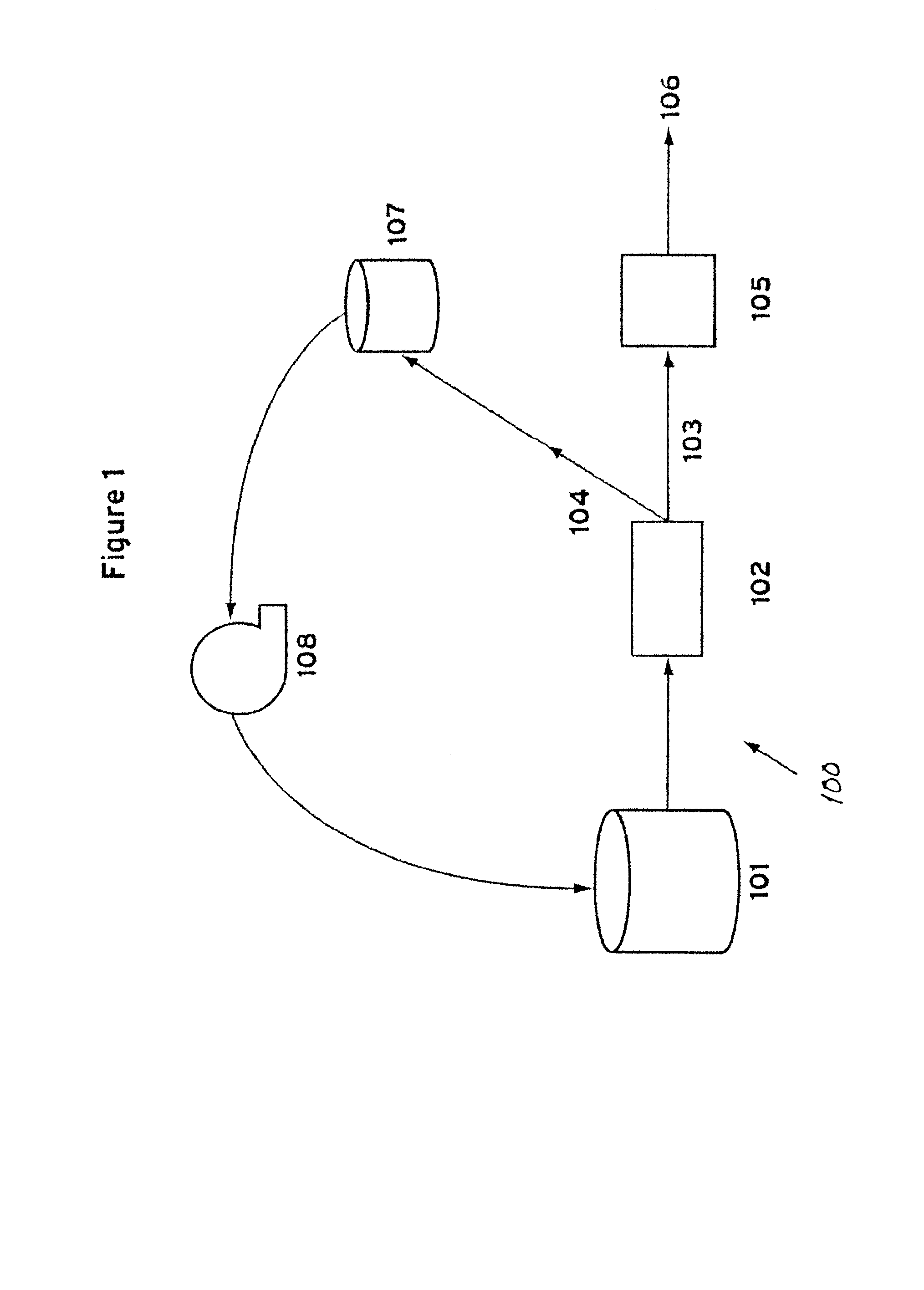

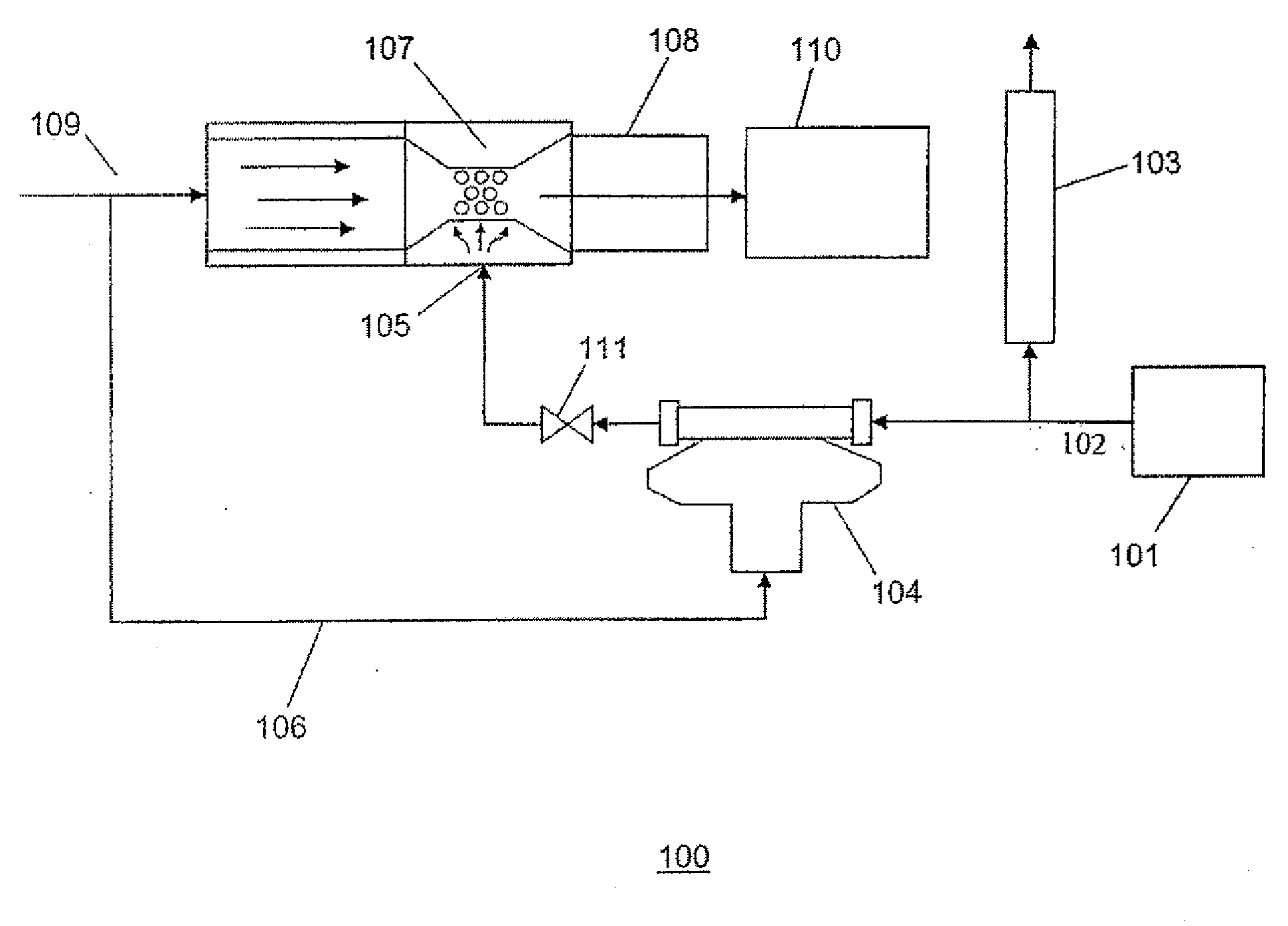

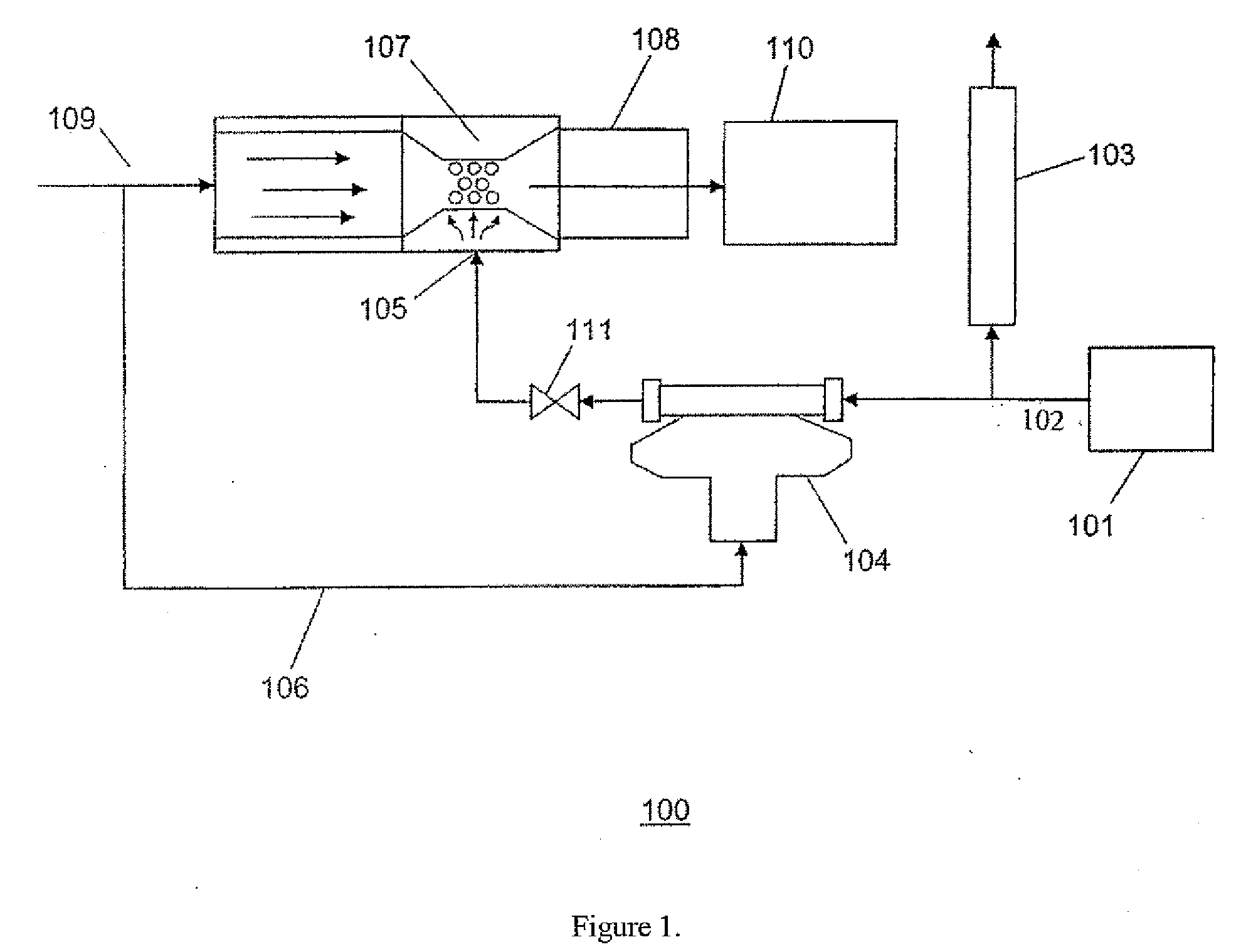

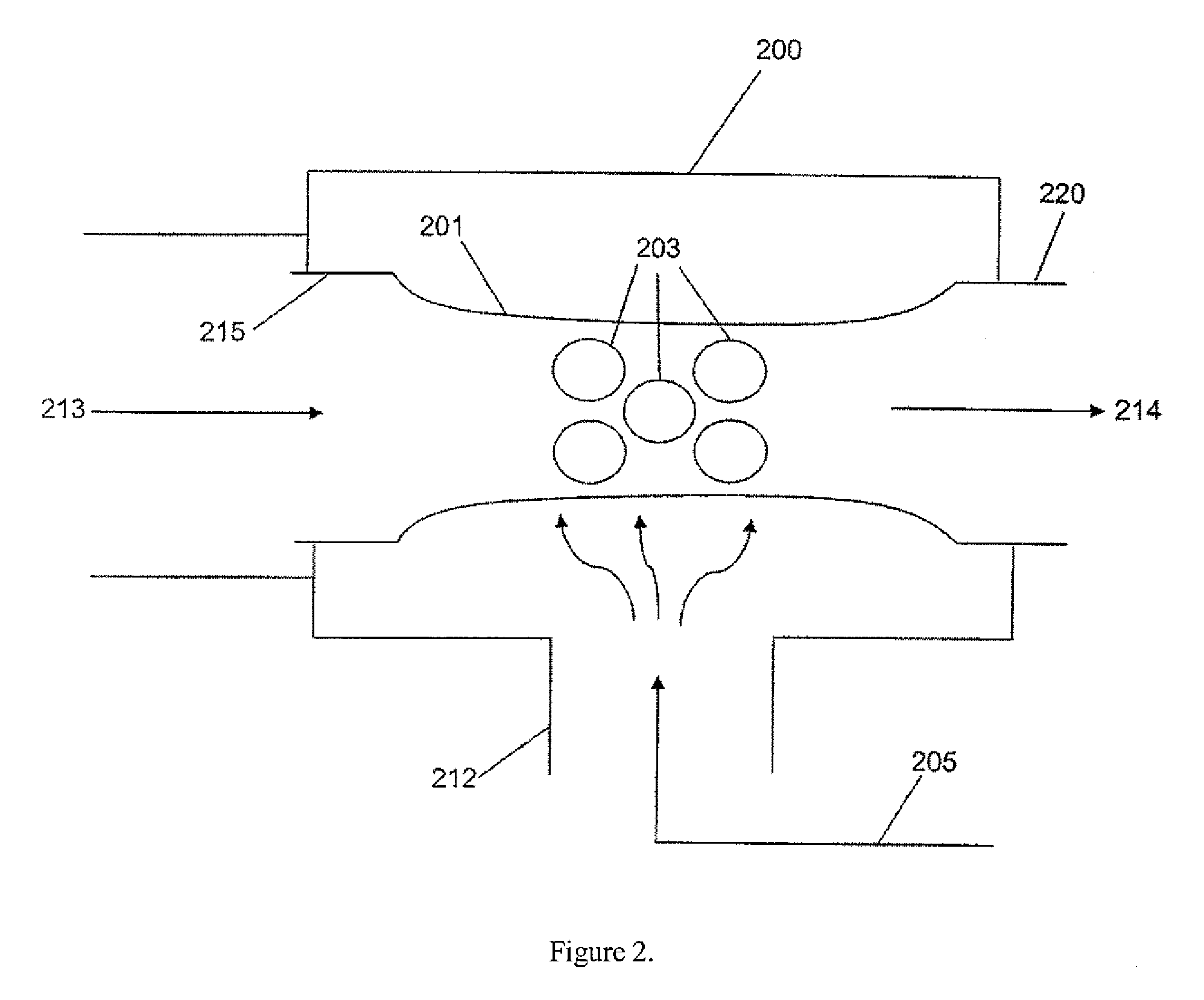

Method and apparatus for supply of low-btu gas to an engine generator

InactiveUS20070209642A1Thermal non-catalytic crackingCarburetting gasesProcess engineeringCarburetor

A carburetion system and method for adapting a low-Btu gas source with a low-Btu gas consumer. Pressure-based air-gas mixers geometrically appropriate for the carburetion system and method. The carburetion system comprises a low-Btu gas inlet, a gas outlet, a zero-pressure regulator, and at least one pressure-based air-gas mixer capable of maintaining a volumetric air to low-Btu gas ratio of no more than about 2:1. The method comprises diverting a low-Btu gas to a gas outlet when the gas consumer is off. The method further comprises, during operation of the consumer, diverting low-Btu gas to a zero-pressure regulator in order to balance low-Btu gas pressure with air pressure, passing low-Btu gas to at least one pressure-based air-gas mixer capable of maintaining a volumetric air to low-Btu gas ratio of no more than about 2:1, mixing the low-Btu gas with air in the at least one pressure-based air-gas mixer to form an air-gas mixture, and sending the air-gas mixture to the consumer. A venturi air-gas mixer comprising at least one venturi gas intake and at least one venturi air intake wherein the at least one venturi gas intake has a cross-sectional area at least equal to the cross-sectional area of the at least one venturi air intake whereby the venturi air-gas mixer is capable of maintaining a volumetric air-to-gas ratio of no more than about 1:1.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

Process and catalyst system for the production of high quality syngas from light hydrocarbons and carbon dioxide

ActiveUS20150031922A1Improve thermal stabilityImprove the immunityHydrocarbon distillationHydroxy compound preparationSyngasCarbon dioxide production

The present invention describes a process and catalysts for the conversion of a light hydrocarbon and carbon dioxide input stream into high quality syngas with the subsequent conversion of the syngas into fuels or chemicals. In one aspect, the present invention provides an efficient, solid solution catalyst for the production of a carbon containing gas from carbon dioxide and light hydrocarbons. The catalyst comprises a single transition metal, and the transition metal is nickel.

Owner:INFINIUM TECH LLC

System for controlling circulatory amount of particles in circulating fluidized bed furnace

ActiveUS8292977B2Improve gasification efficiencyFluidized bed combustionLevel controlFluidized bed gasifierDifferential pressure

The invention has its object to arbitrarily adjust an amount of particles to be circulated without changing a flow rate of a gasification agent to thereby enhance gasification efficiency in a fluidized bed gasification furnace.The fluidized bed gasification furnace 107 comprises first and second chambers 113 and 114 in communication with each other in a fluidized bed 105. The hot particles 102 separated in the separator 104 and raw material M are introduced into the first chamber 113. The particles 102 introduced from the first chamber 113 through interior in the fluidized bed 105 to the second chamber 114 are supplied in an overflow manner to the fluidized bed combustion furnace 100. A first pressure controller 121 is provided to control the resultant gas induction means 116 such that the pressure in the first chamber 113 is kept to preset pressure 120; and a second pressure controller 124 is provided to control the exhaust gas induction means 118 such that difference between pressure in the first and second chambers 113 and 114 is equal to the preset differential pressure 123, so that the fluidized bed 105 in the first chamber 113 is controlled in height to control an amount of particles 102 to be circulated.

Owner:IHI CORP

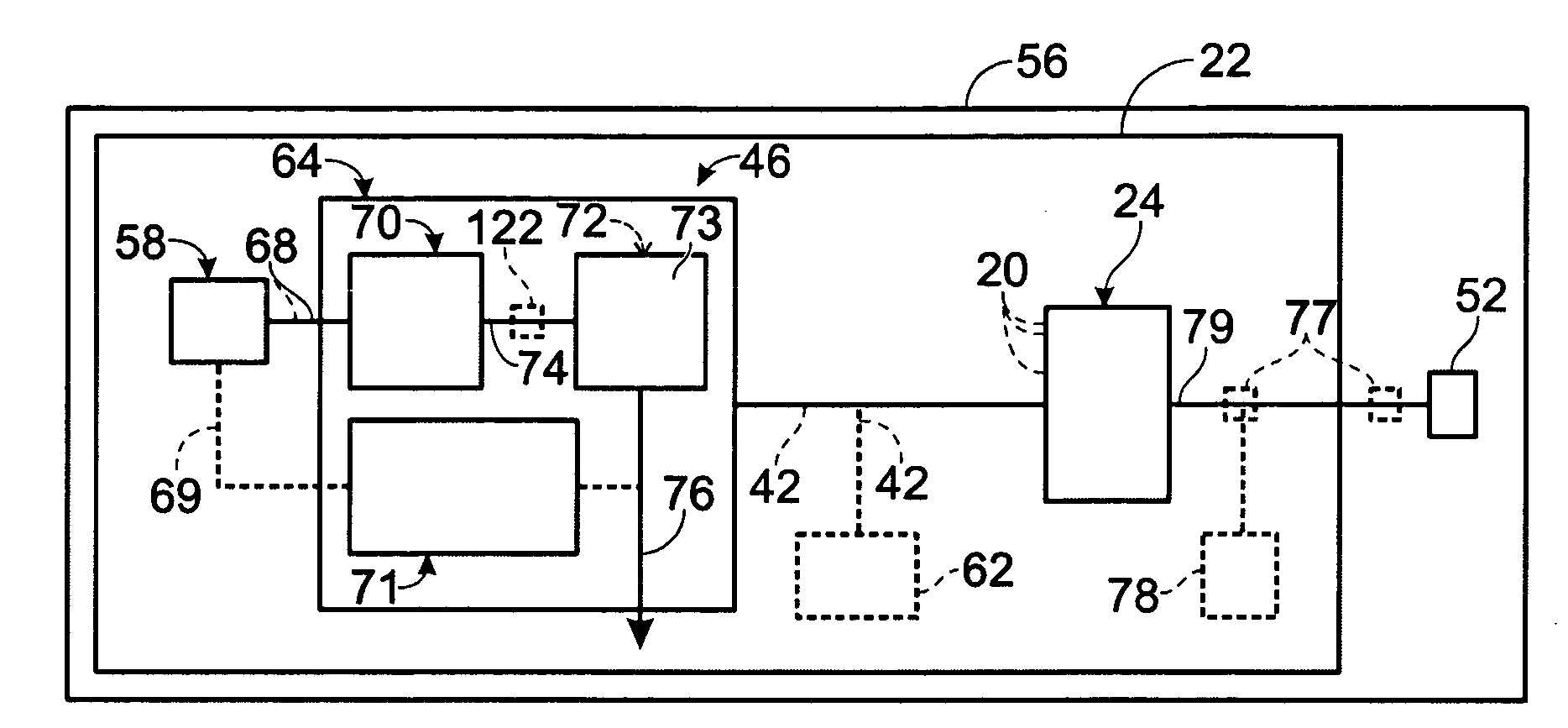

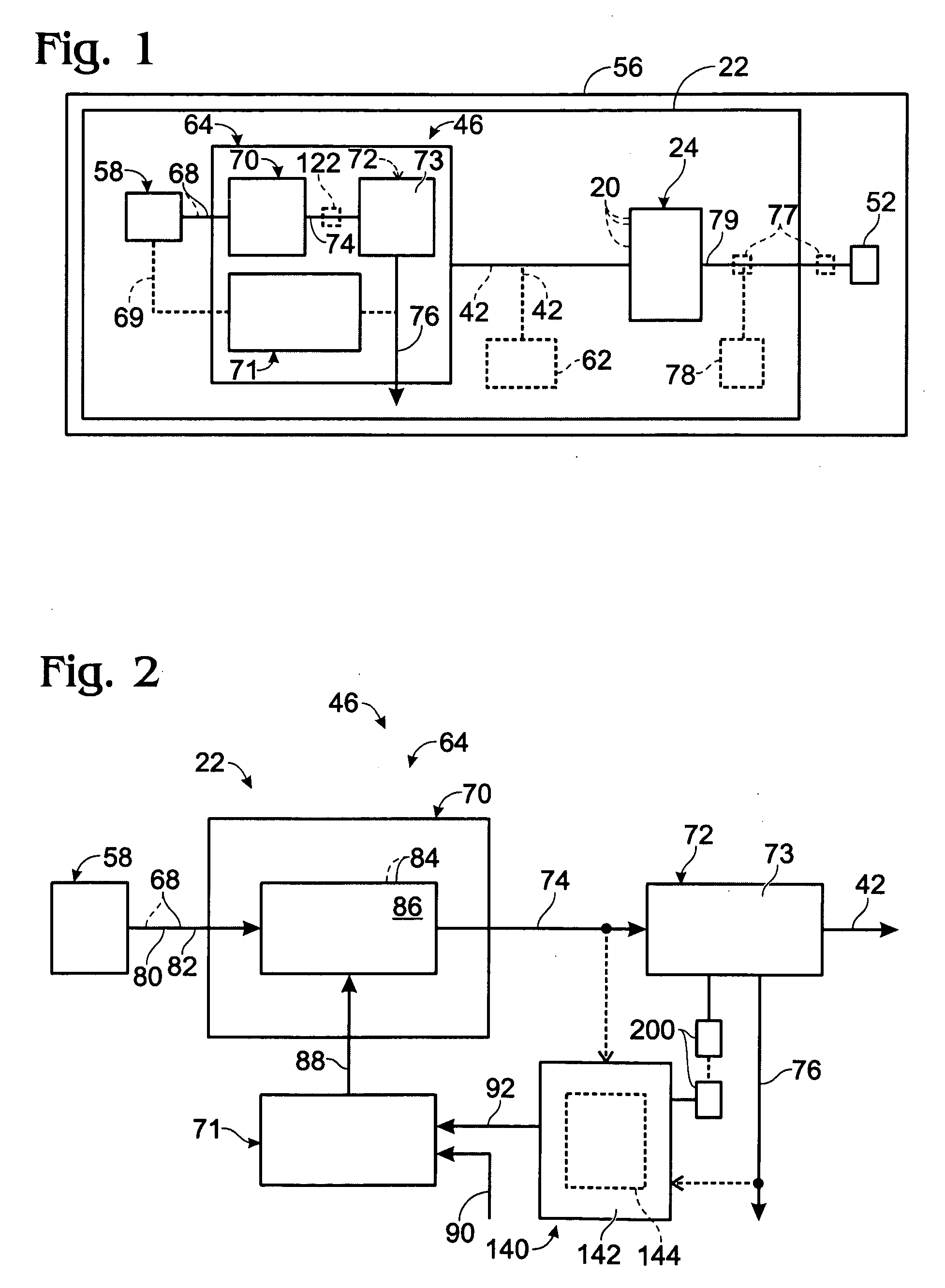

Systems and methods for supplying auxiliary fuel streams during intermittent byproduct discharge from pressure swing adsorption assemblies

Pressure swing adsorption (PSA) assemblies and hydrogen-producing fuel processing assemblies and / or fuel cell systems including the same. The PSA assemblies include, or are utilized with, combustion fuel stream supply systems that are adapted to regulate the flow of a byproduct stream from the PSA assembly for delivery to a heating assembly for use as a combustible fuel stream, such as to maintain at least a hydrogen-producing region of the fuel processing system at a hydrogen-producing temperature or range of temperatures. In some embodiments, the combustion fuel stream supply system is configured to ensure that the supply of combustible fuel from the PSA assembly to the heating assembly contains at least a sufficient fuel value, such as to maintain at least the hydrogen-producing region at or within a predetermined hydrogen-producing temperature or range of temperatures.

Owner:DCNS SA

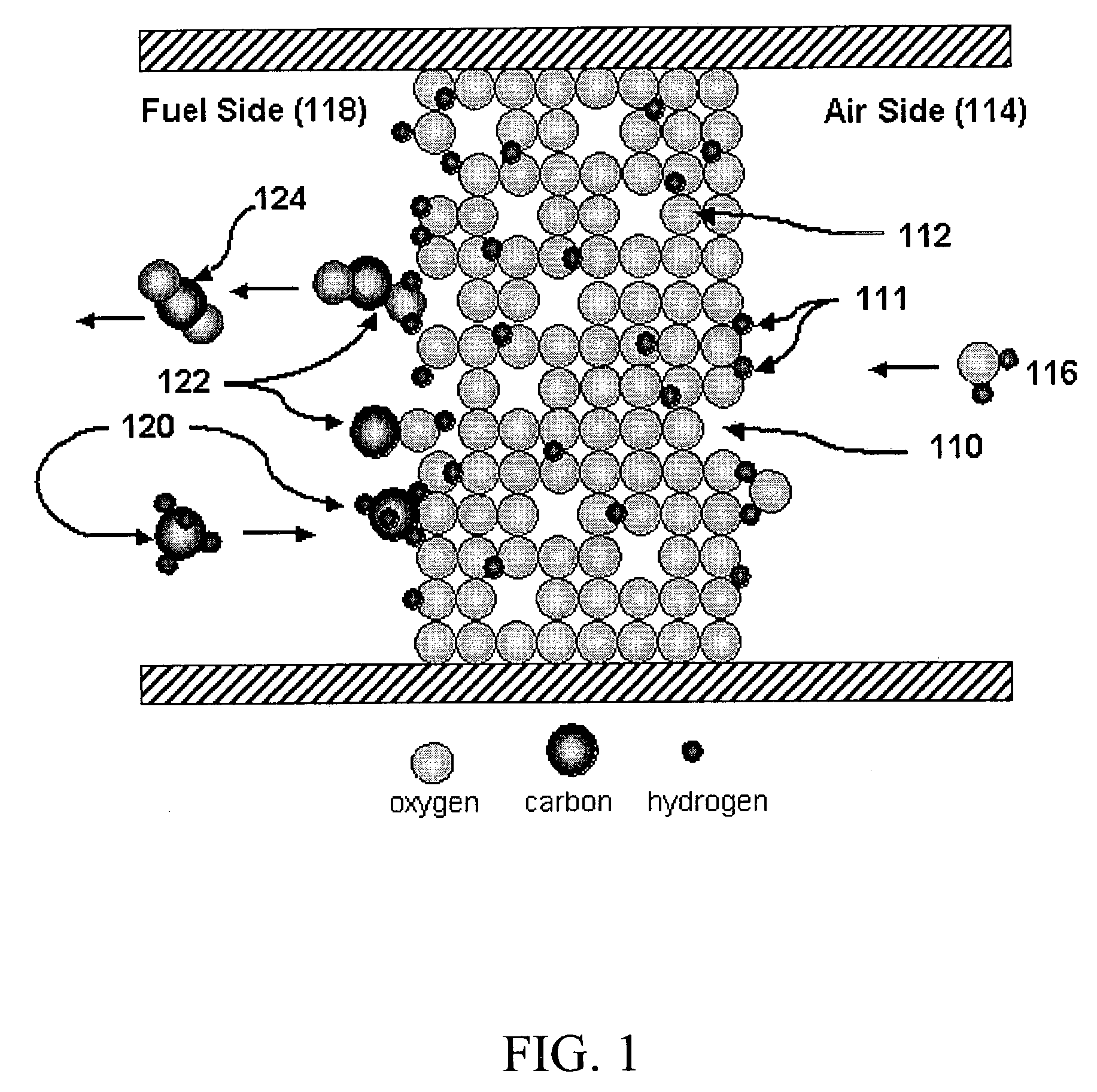

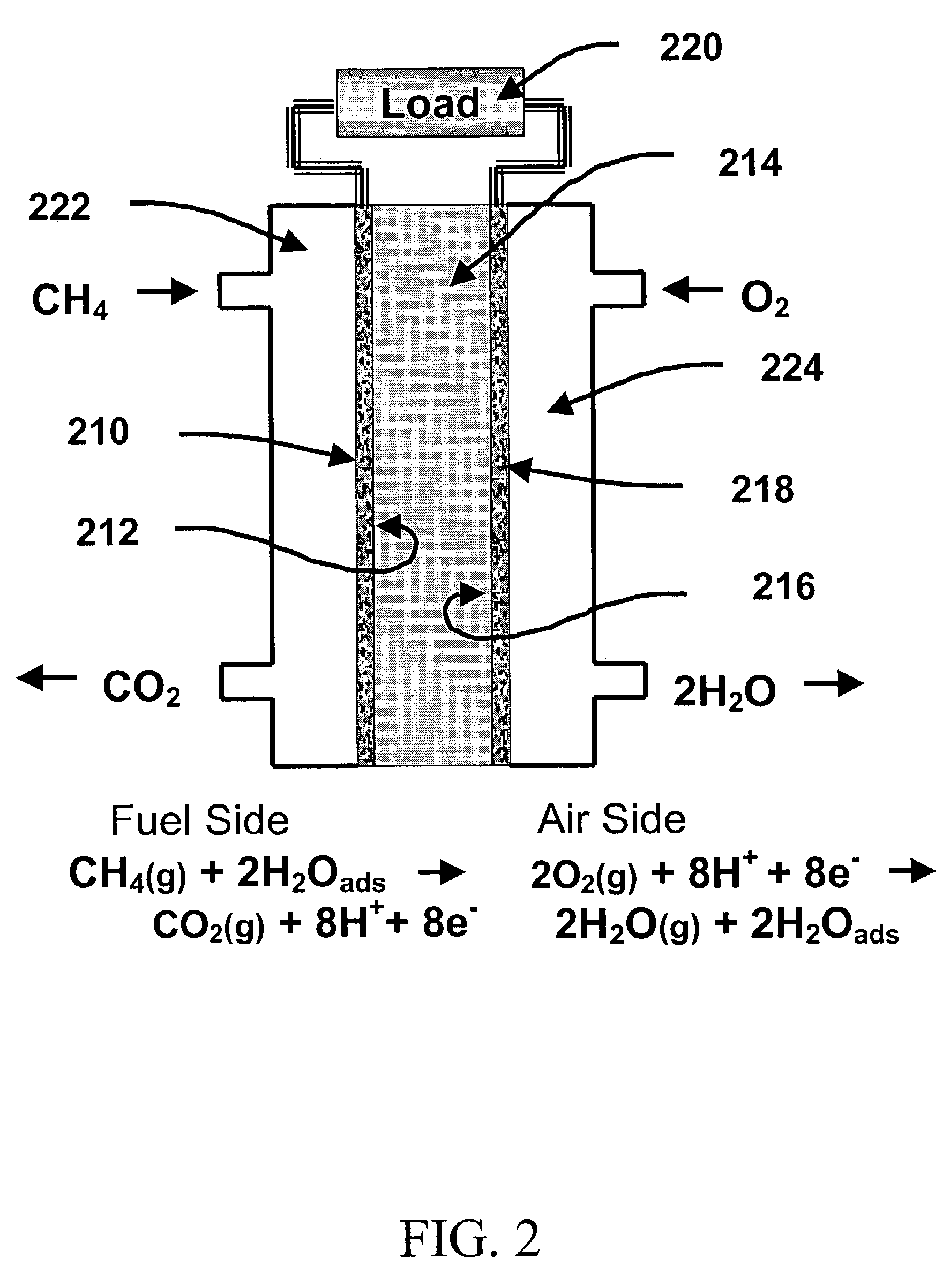

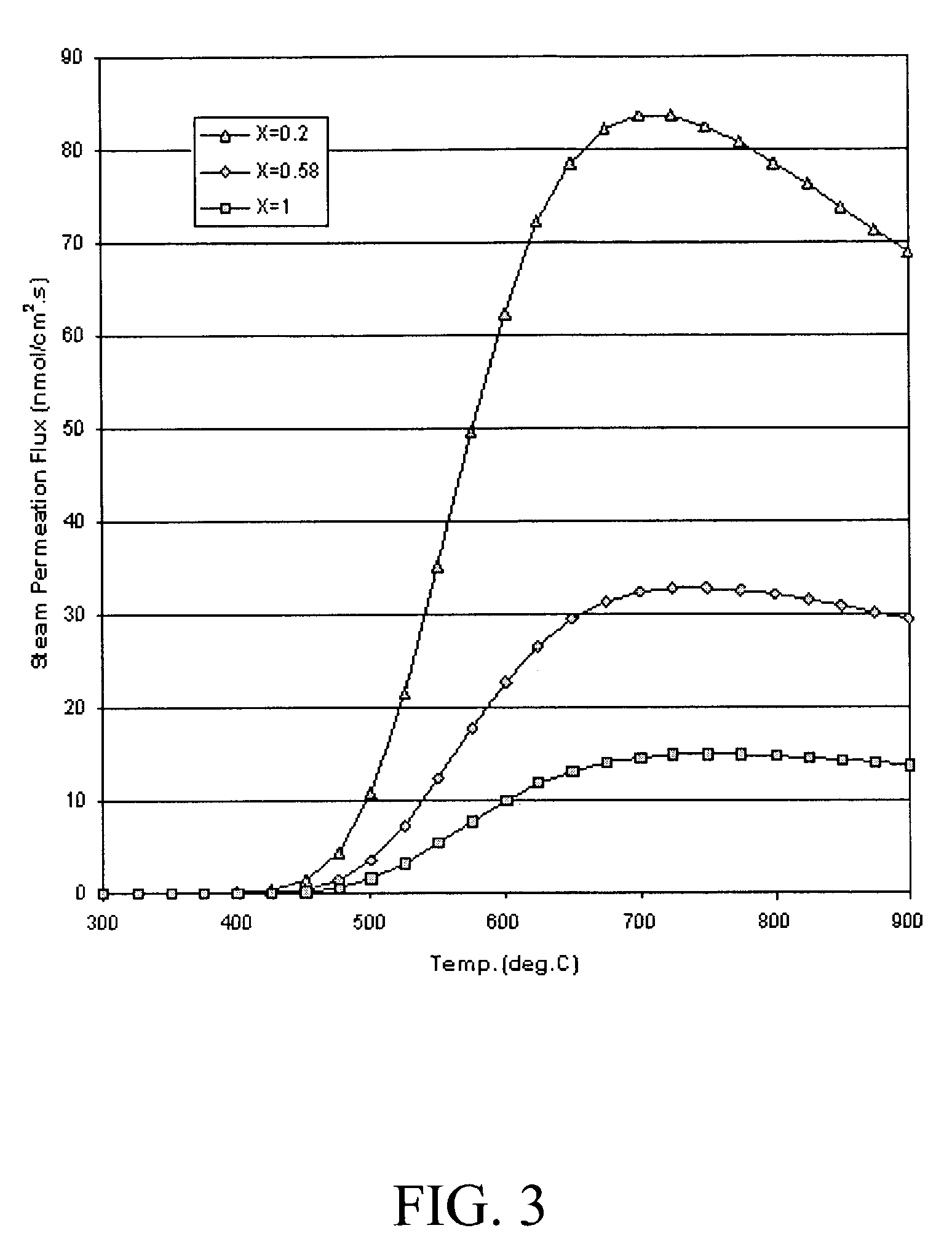

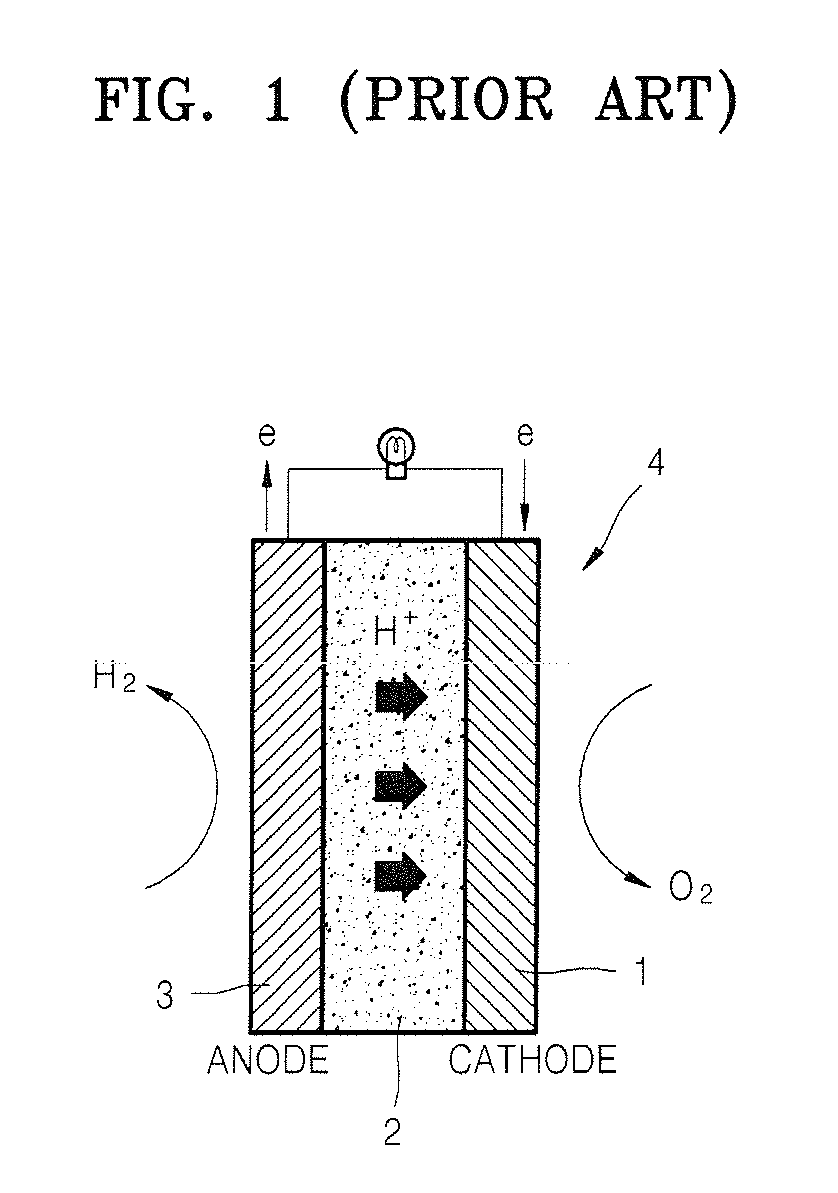

Direct hydrocarbon reforming in protonic ceramic fuel cells by electrolyte steam permeation

InactiveUS7045231B2Reduces and eliminates propensityReduce fluxHydrogenCarburetting gasesWater vaporConcentration gradient

A process for converting hydrocarbons and water vapor into hydrogen, carbon monoxide, and carbon dioxide; a fuel cell device; and a process of utilizing the fuel cell to convert chemical energy to electrical energy is described. The fuel cell comprises a metallic and / or mixed conducting anode, a metallic and / or mixed conducting cathode, a proton-conducting ceramic electrolyte between the anode and the cathode, and an external load connecting the anode and the cathode. The fuel cell also includes systems for bringing gaseous hydrocarbon fuels into contact with the anode and for bringing oxygen and water vapor into contact with the cathode. Water vapor in the fuel cell passes through the ceramic electrolyte membrane from the cathode side to the anode side by ambipolar diffusion, called “steam permeation” without conducting current, under the influence of a water vapor concentration gradient.

Owner:PROTONETICS INT

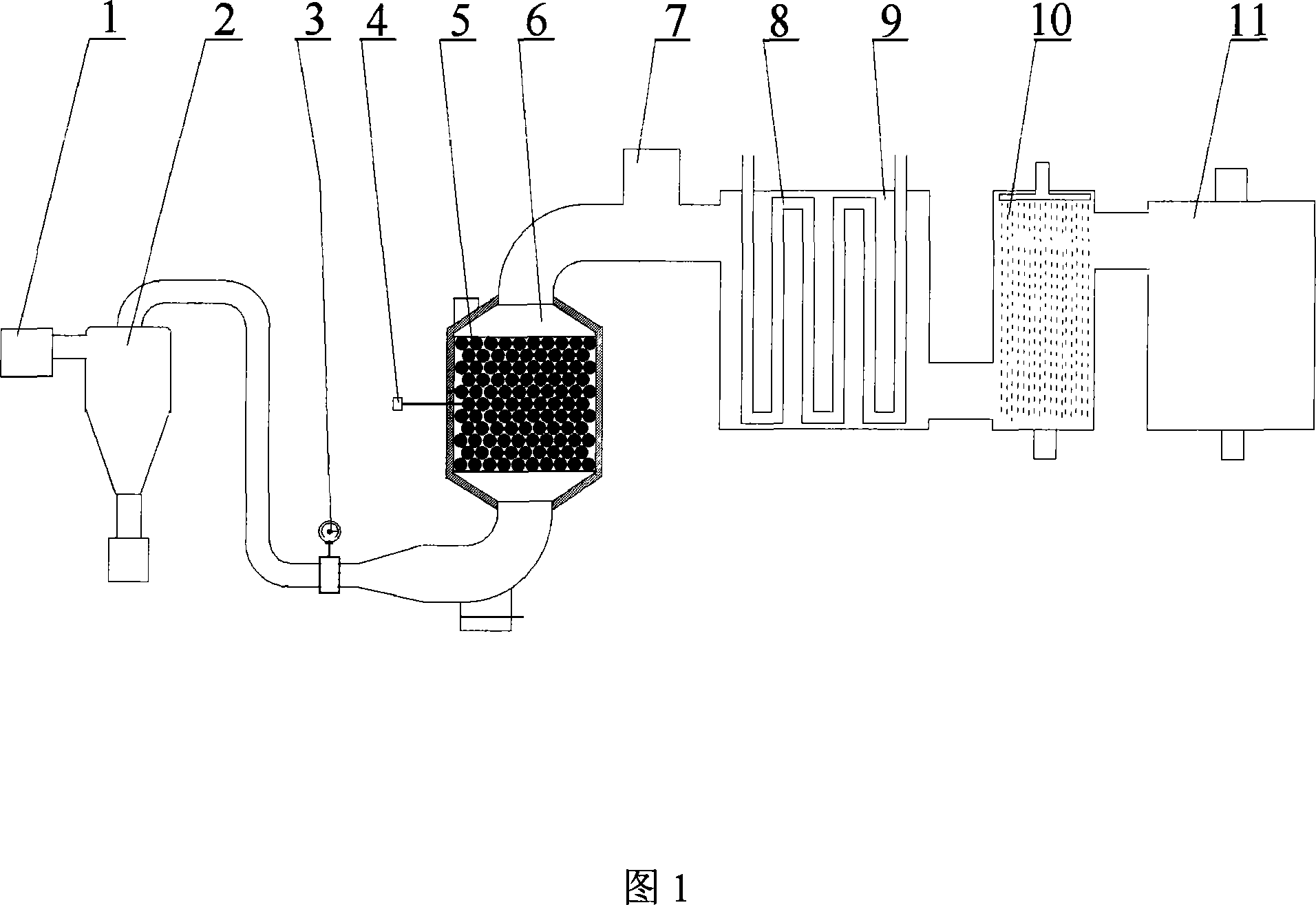

Method for directly preparing coal gas from industrial high temperature CO2 waste gas

InactiveCN101144035AReduce pollutionSave energyCarburetting gasesEnergy inputThermal energyExhaust fumes

The invention relates to a method directly using industrial waste heat and industrial high temperature CO2 waste gas to directly prepare coal gas, which uses carbon as raw material, and uses waste heat from industrial high temperature CO2 waste gas to heat the carbon reaction bed, so as to directly convert the high temperature CO2 waste gas passing through the carbon reaction bed into coal gas CO. Because of using the heat energy form high temperature CO2 waste gas, the large number of energy consumption is saved, and the purity of produced CO is high, and the production cost is low, and the purpose of decreasing CO2 discharge in industrial production is achieved.

Owner:张成顺

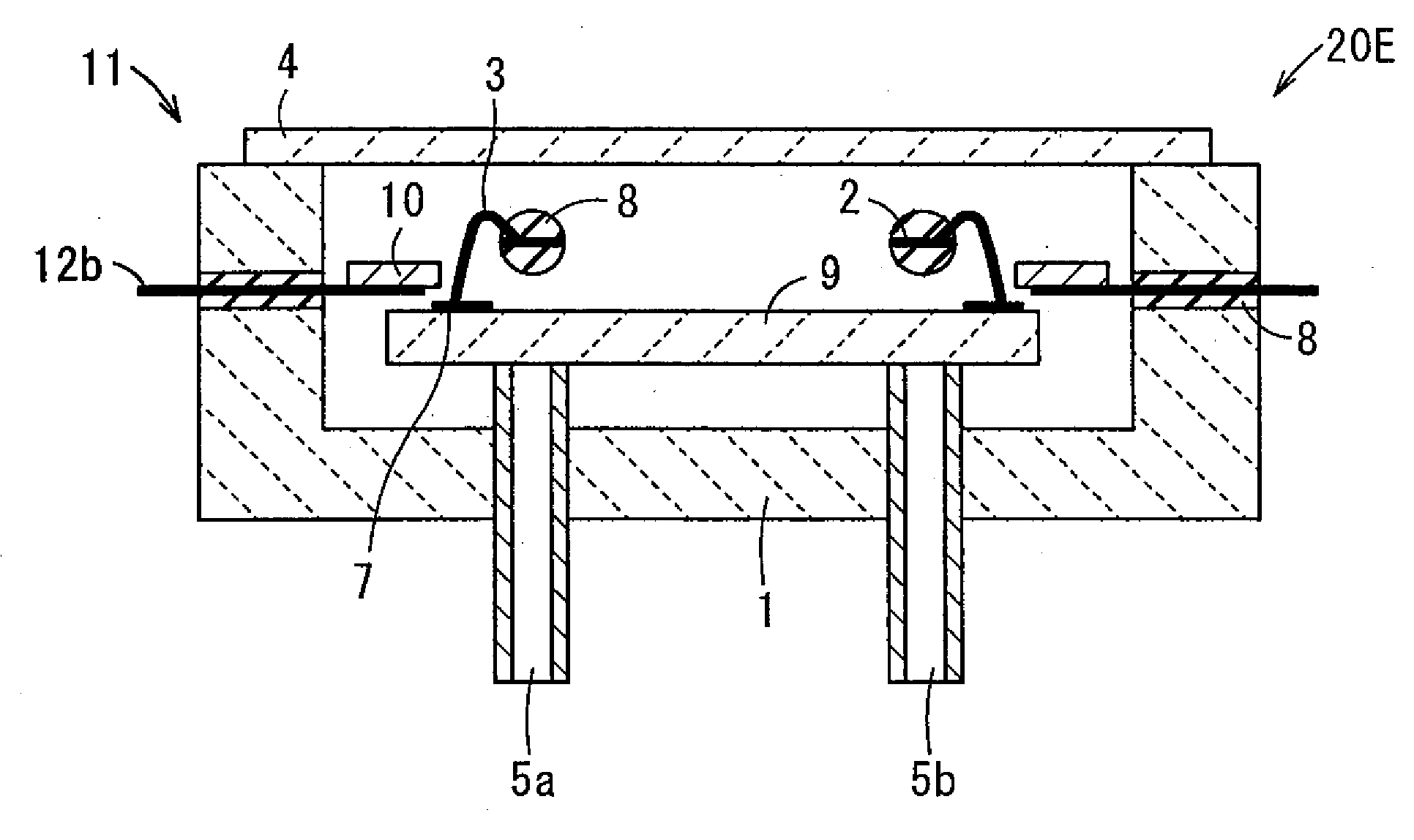

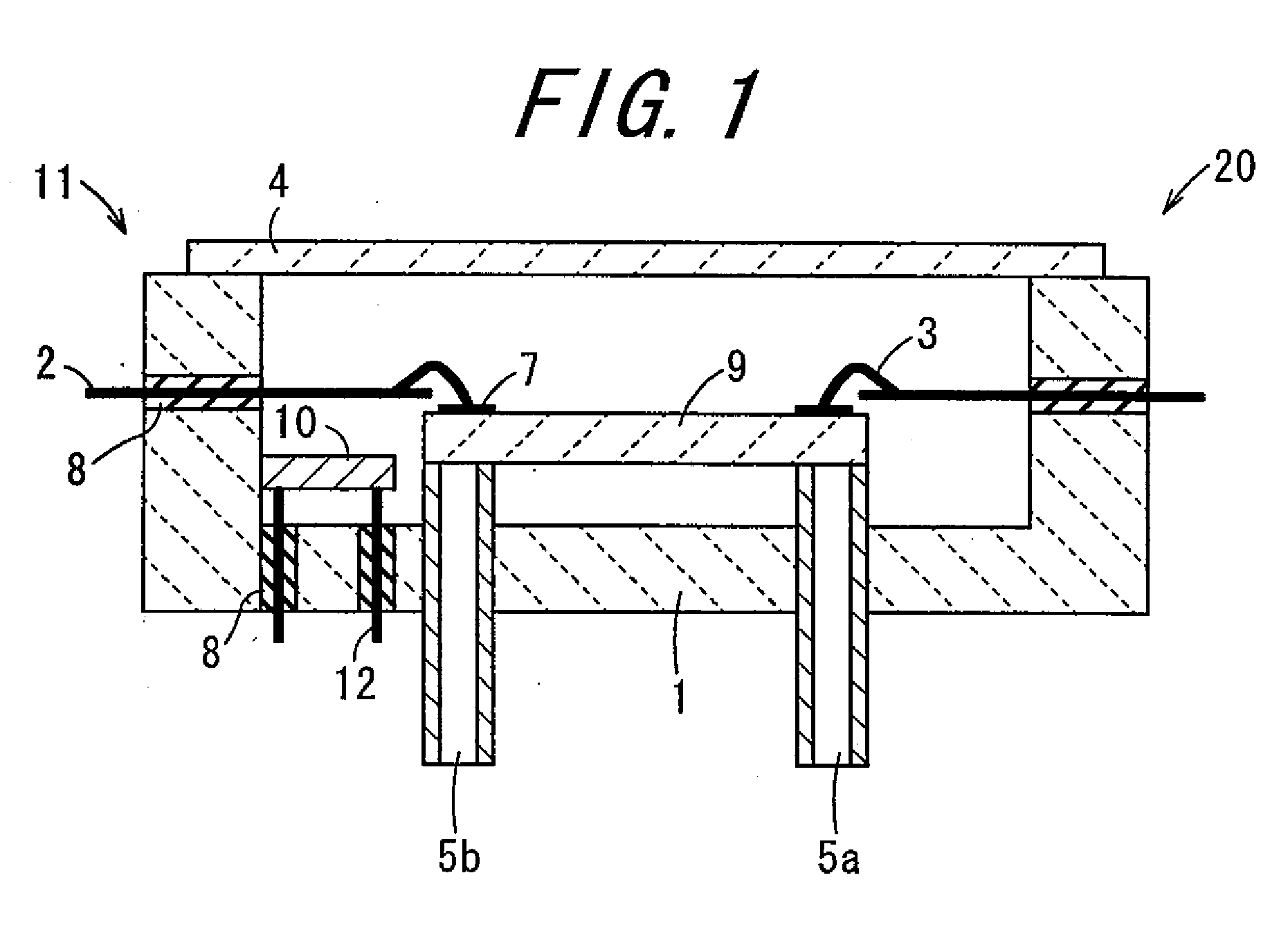

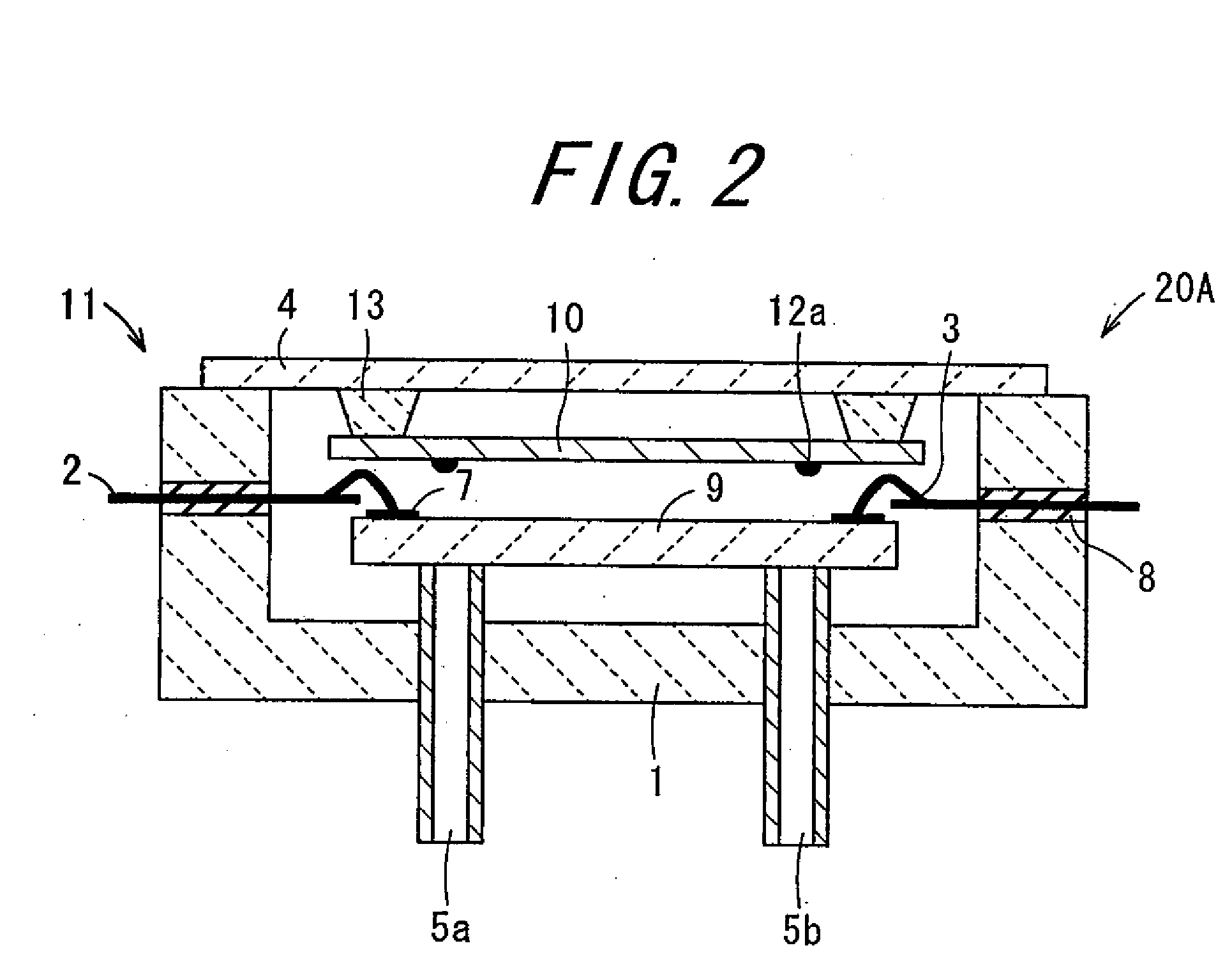

Fuel reformer housing container and fuel reforming apparatus

InactiveUS20090229181A1Less power generation lossEasy maintenanceDomestic cooling apparatusLighting and heating apparatusHydrogenGeneration loss

An object of the invention is to provide a fuel reformer housing container and a fuel reforming apparatus, which are capable of maintaining a level of vacuum inside the fuel reformer housing container favorably and which have less power generation loss. A fuel reformer housing container (11) includes a base (1) having a concave portion for housing a fuel reformer (9) in which reformed gas containing hydrogen gas is generated from fuel, a discharge pipe (5b) for communicating inside of the concave portion with outside thereof to discharge the reformed gas from the fuel reformer, a supply pipe (5a) for communicating inside of the concave portion with outside thereof to supply the fuel to the fuel reformer (9), and a gas adsorbent (10) housed in the concave portion, for adsorbing gas in the concave portion.

Owner:KYOCERA CORP

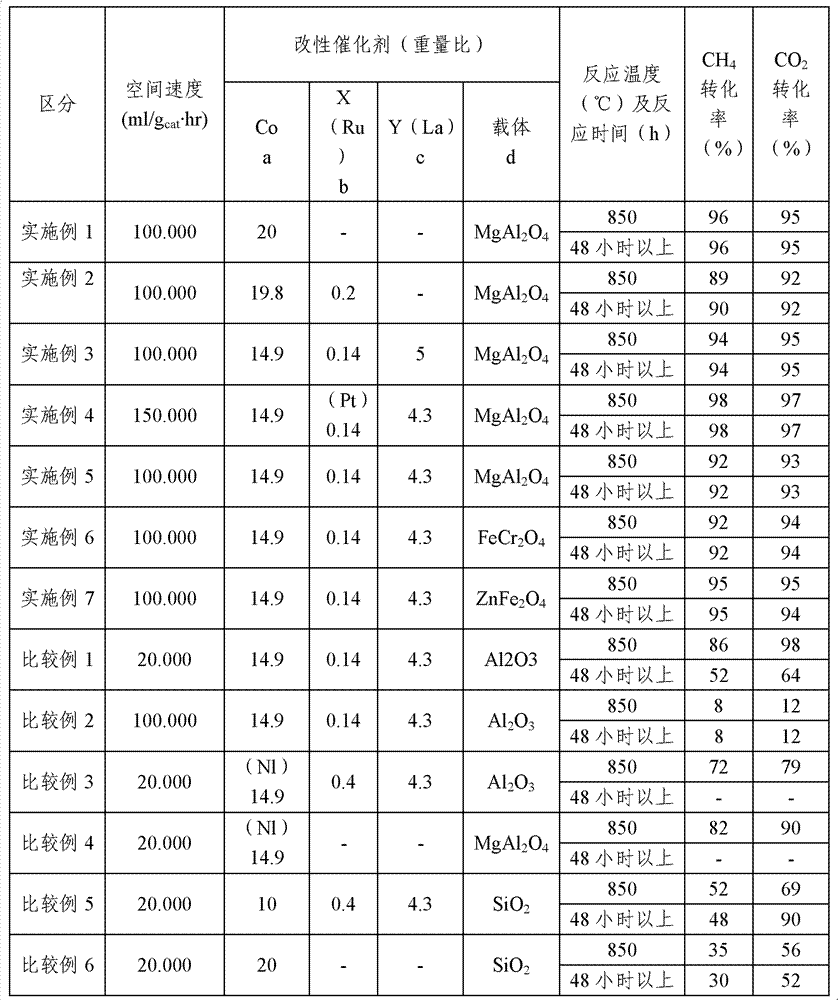

Methane carbon dioxide reforming catalyst and preparation method and using method thereof

ActiveCN106391020ALow reaction temperatureExtend your lifeHydrogenCarburetting gasesReaction temperatureCobalt

The invention discloses a methane carbon dioxide reforming catalyst and a preparation method and a using method thereof. The methane carbon dioxide reforming catalyst is prepared by loading active metals onto a carbon material as a carrier, wherein in terms of percent by weight, the carbon material accounts for 80-98wt%, a cobalt active component accounts for 1-12wt%, and an iron active component accounts for 1-8wt%; the carbon material is generated after a resultant H2 of a subcritical H2O-CO reaction modifies lignite. The preparation method comprises the following steps: crushing the lignite into granules below 100-mesh first and then uniformly mixing the coal granules with a cobalt-based metal mixture and H2O; then, inflating CO to adjust the reaction temperature and the like to form a subcritical reaction system, and modifying the lignite through subcritical H2O-CO to prepare a methane carbon dioxide reforming catalyst carrier. Through the preparation method, the reaction can be performed at relatively low temperature, so that the temperature of the reaction system is reduced, and thus compared with other methods, the preparation method has the advantage of energy conservation.

Owner:TAIYUAN UNIV OF TECH

Process and reactor for the preparation of hydrogen and carbon monoxide rich gas

InactiveUS6908571B2Avoid problemsImprove ignition performanceHydrogenHydrocarbon from carbon oxidesSteam reformingHydrogen

Soot formation is suppressed in the preparation of hydrogen and / or carbon monoxide rich gas by arranging on at least a surface of an upper portion of a reactor a catalytic material which is active in steam reforming hydrocarbons, introducing a hydrocarbon feedstock and an oxygen-containing atmosphere into the upper portion of the reactor, partially oxidising the feedstock with oxygen in the upper portion of the reactor, and contacting a part of the partially oxidized feedstock with the reforming catalyst in the reactor upper portion.

Owner:HALDOR TOPSOE AS

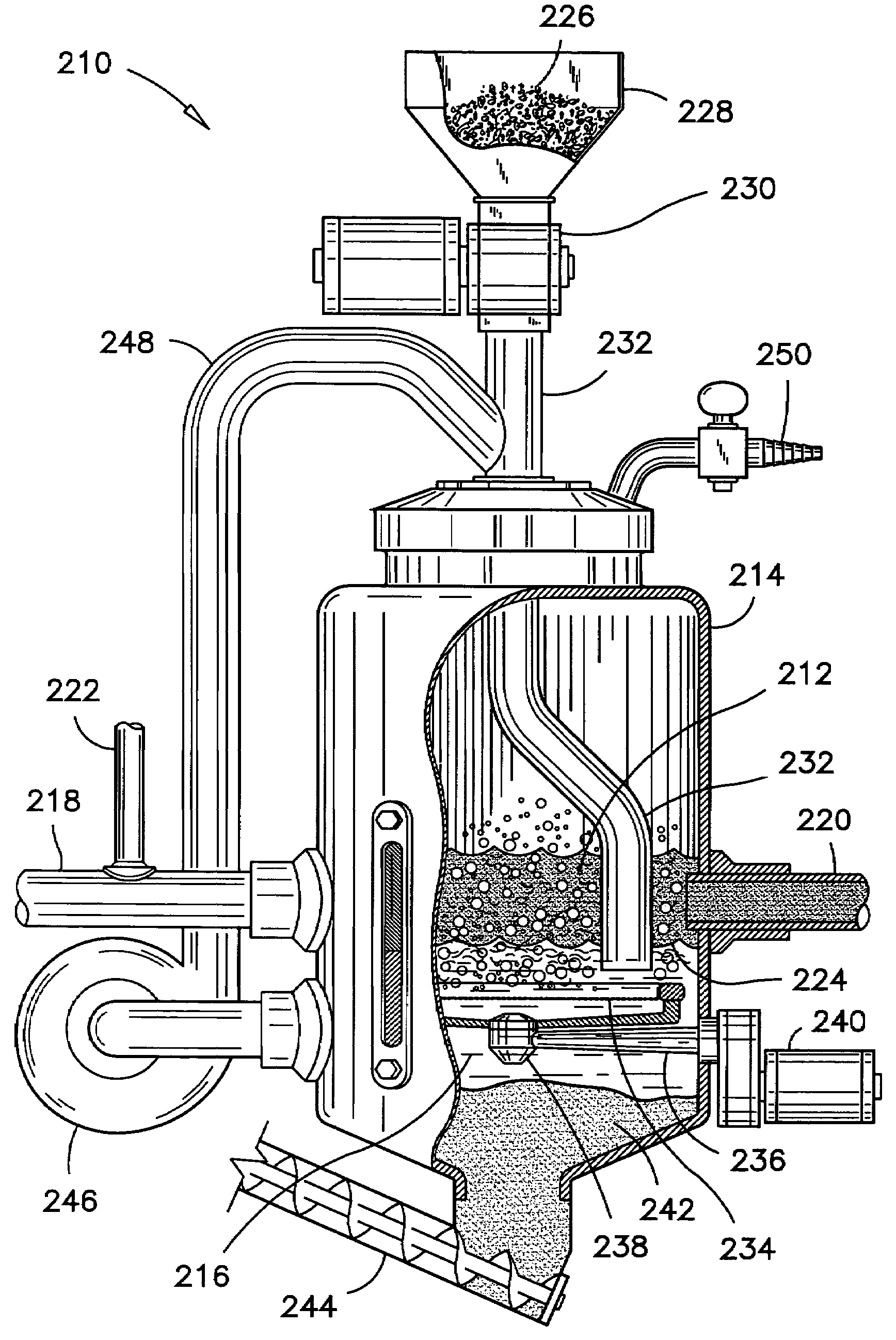

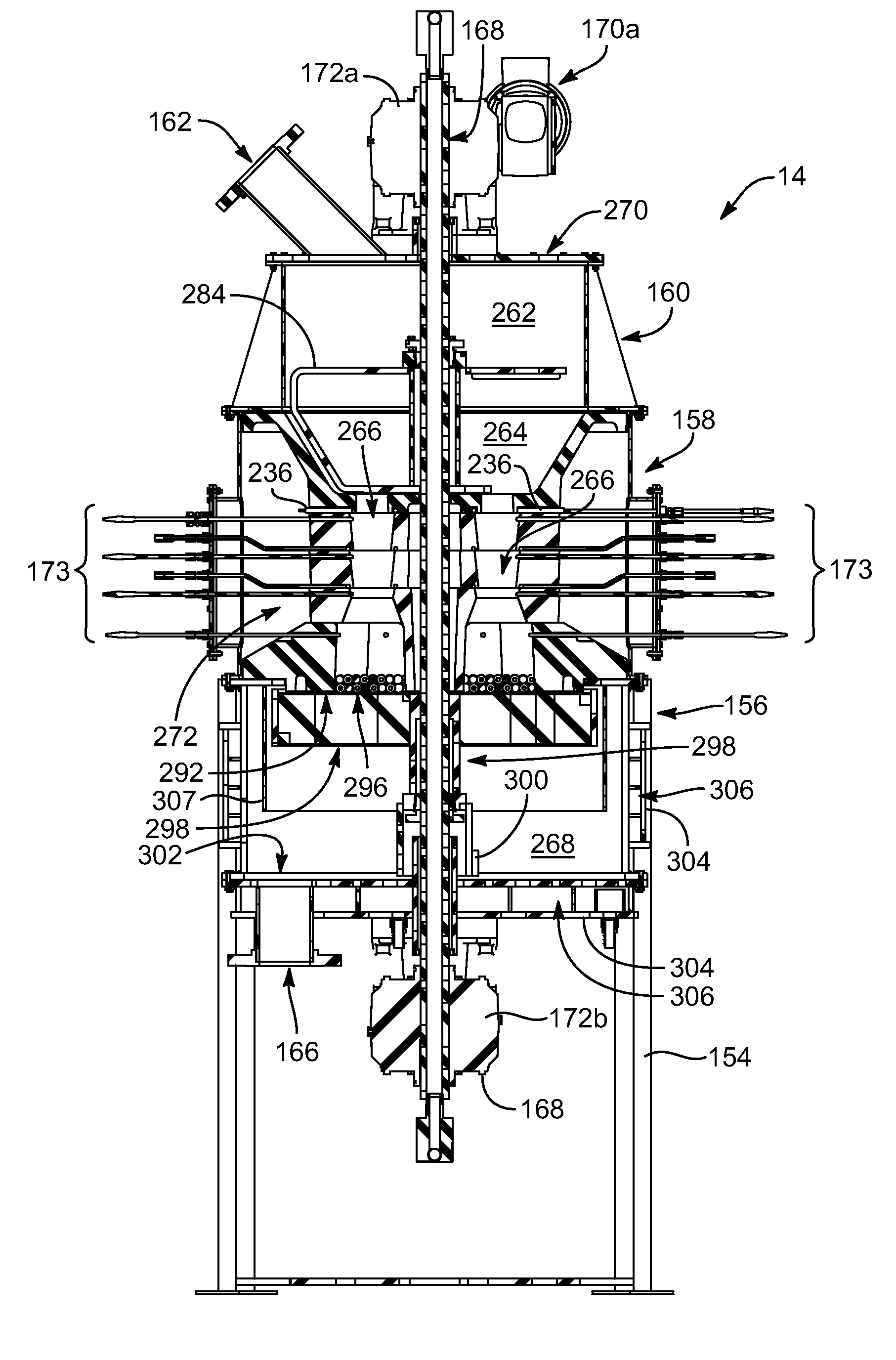

Parallel path, downdraft gasifier apparatus and method

ActiveUS8105401B2Effectively stopCompound undesirableGasifier mechanical detailsGas modification by gas mixingOxidation zoneOxygen

A method for using a downdraft gasifier comprising a housing and a refractory stack contained within the housing. The refractory stack may comprise various sections. Apertures in the sections may be aligned to form multiple columnar cavities. Each columnar cavity may comprise an individual oxidation zone. The method of use may include the steps of placing a feedstock into an upper portion of the refractory stack, measuring the temperature of each columnar cavity, and adjusting the flow of oxygen to a particular columnar cavity to maintain the temperature of the particular columnar cavity within a particular range.

Owner:STRATEAN

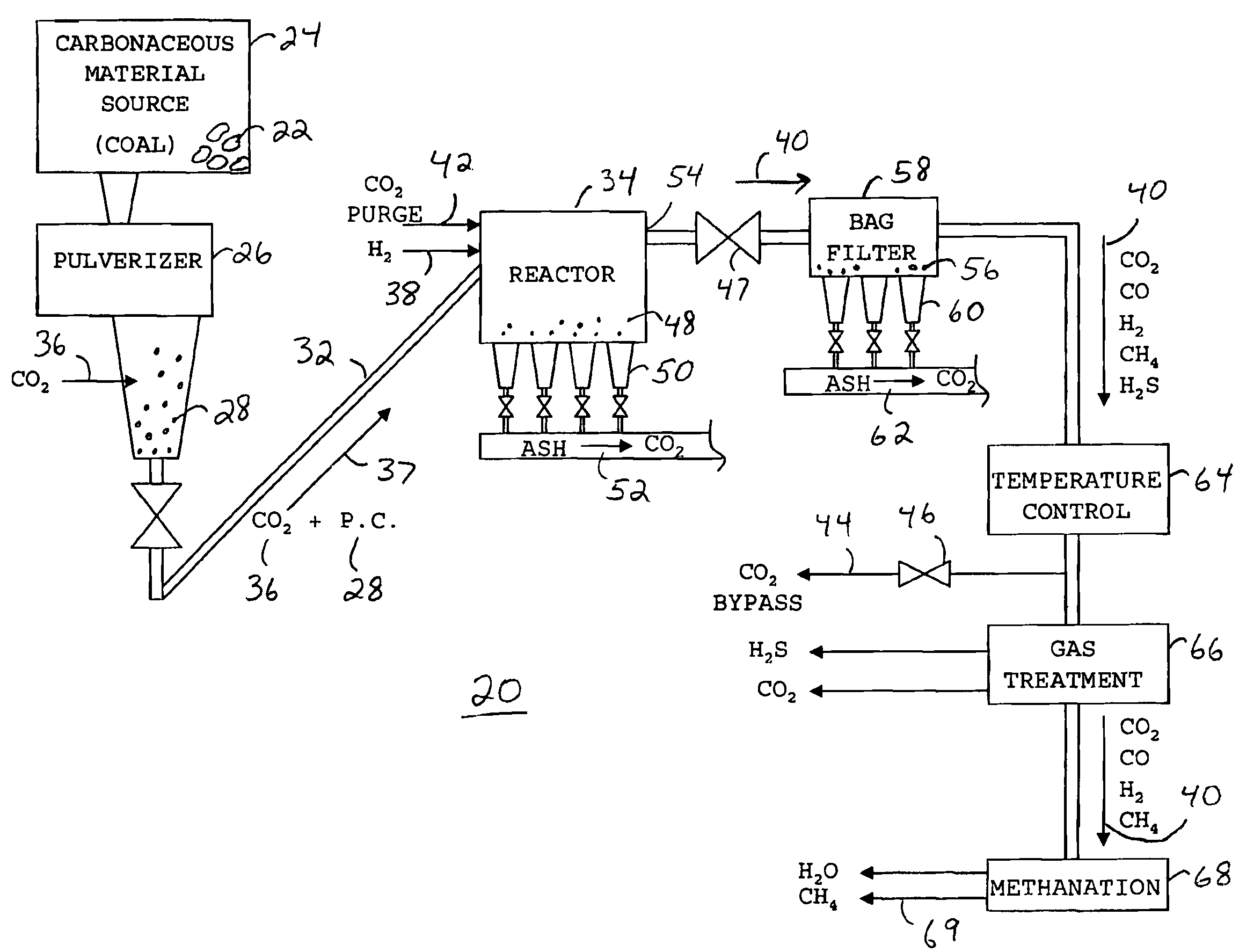

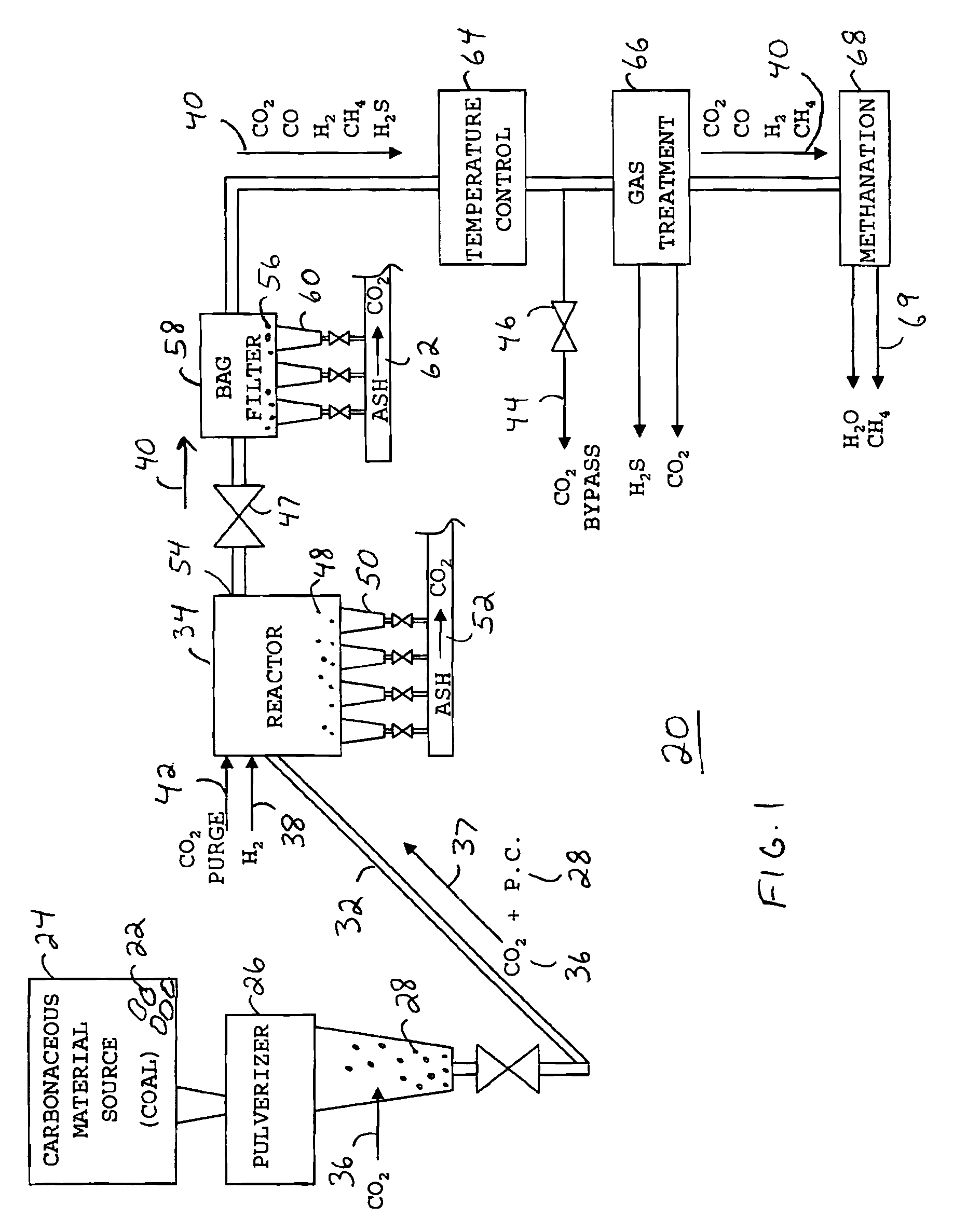

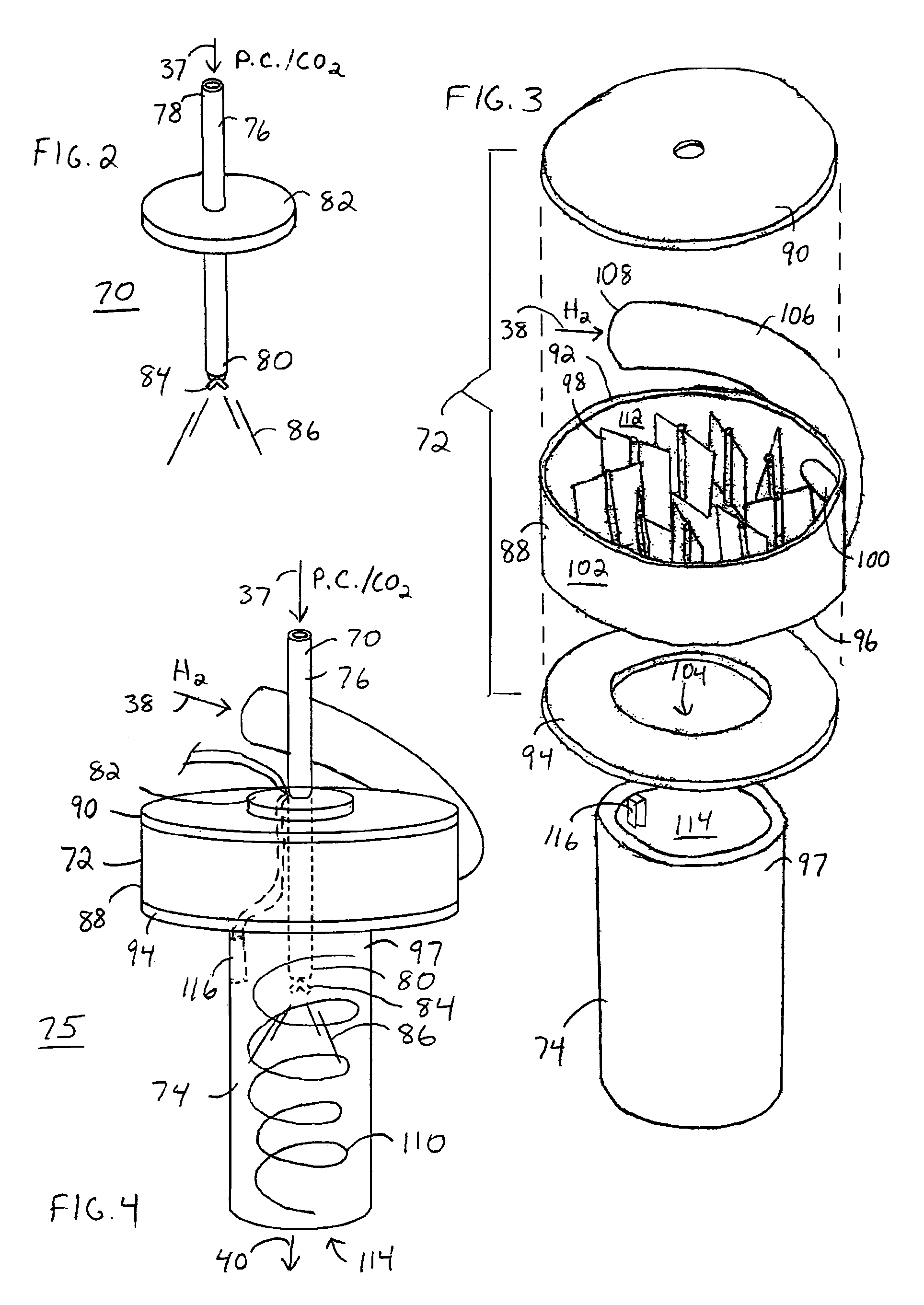

Method and apparatus for producing methane from carbonaceous material

InactiveUS7575613B2Efficient productionEfficient deliveryHydrogen productionHydrogen/synthetic gas productionHydrogenReaction zone

A method for producing methane (69) from a carbonaceous (22) material includes conveying pulverized carbonaceous material (28) entrained in an inert carrier fluid, such as carbon dioxide (36), into a reactor (34). The reactor (34) includes a vortex region (72) for receiving hydrogen gas (38) and imparting a swirling motion to the hydrogen gas (38). The pulverized carbonaceous material (28) is exposed to the swirling stream of hydrogen gas (38) in a first reaction zone (114) within the reactor (34) to form an exit gas (40) that includes methane (69). Remaining unreacted carbonaceous material (28) is further exposed to the hydrogen gas (38) in a second, low velocity, reaction zone (120). The methane rich exit gas (40) is subsequently extracted from the reactor (34) for further processing.

Owner:ARIZONA PUBLIC SERVICE

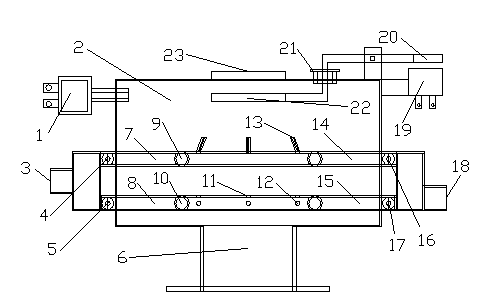

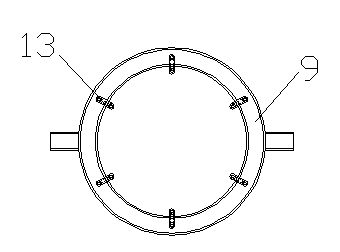

Gasifying method for biomass gasifier and hearth air intake device

ActiveCN103013569AGasification stabilityAvoid cloggingDomestic stoves or rangesCarburetting gasesCombustible gasWind field

The invention discloses a gasifying method for biomass gasifier and a hearth air intake device. One or two combustion zones is / are arranged at the bottom of fuel and the air intake device has one or two zones; after a combustible is ignited, local combustion is formed at an air outlet of the air intake device; carbon dioxide generated after the local combustion contacts scorching fuel carbon on the upper layer and a reduction reaction is performed to generate combustible gas carbon monoxide; after gasification, the carbon monoxide is combusted again; when a biomass gasifier works normally, a combustible inlet is closed, the fuel is supplemented by feed and the carbon monoxide is further generated; when the air intake device has two zones, a reduction zone is arranged above a higher combustion zone; and when the biomass gasifier works normally, the combustible inlet is closed, the fuel is supplemented by feed and the carbon monoxide is further generated. The biomass gasifier is stable in gasification, can achieve a uniform wind field and wind pressure and can control the hearth temperature at 600-650 DEG C easily; and through design of a drain pipe, a drain valve and a drain port, blockage of an air passage can be prevented easily.

Owner:孙吉章

Fuel reforming process for internal combustion engines

InactiveUS20100071263A1Carburetting gasesInternal combustion piston enginesExternal combustion engineProcess engineering

A fuel reforming system, process, and device including a catalytic chamber and a heating chamber. The catalytic chamber, further including a fluid fuel intake and a gaseous fluid exit port and at least one heat exchanger for distributing heat between the heating chamber and the catalytic chamber. The catalytic chamber further including a screen member having a surface, wherein the member includes a catalytic deposit made from a combination of platinum and rhodium alloy. A catalytic conversion of converting liquid fuel to gaseous fuel occurs within the catalytic chamber. Fuel exits the fuel reforming device through a gaseous fluid exit port.

Owner:PENMAN ROBERT R

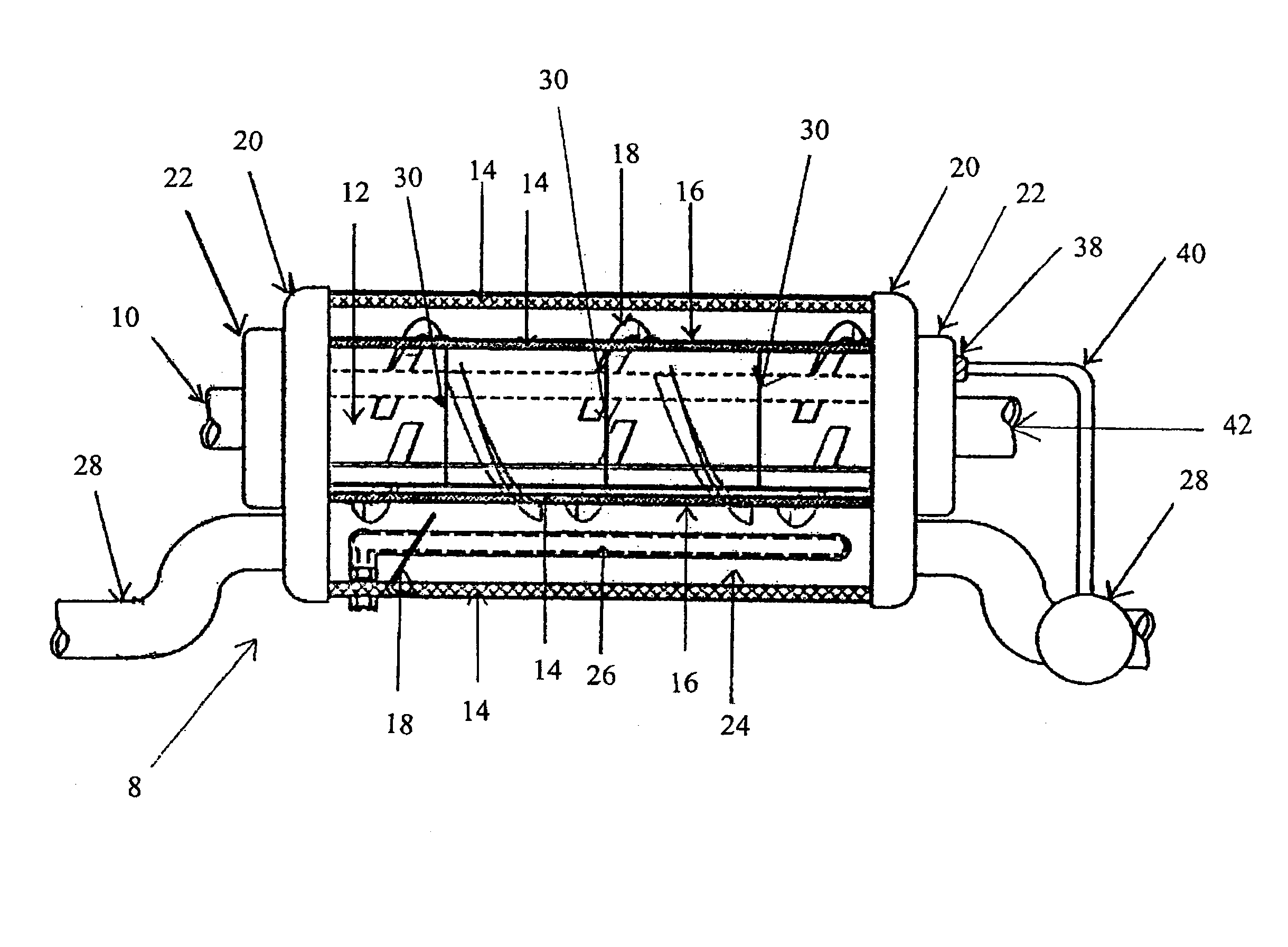

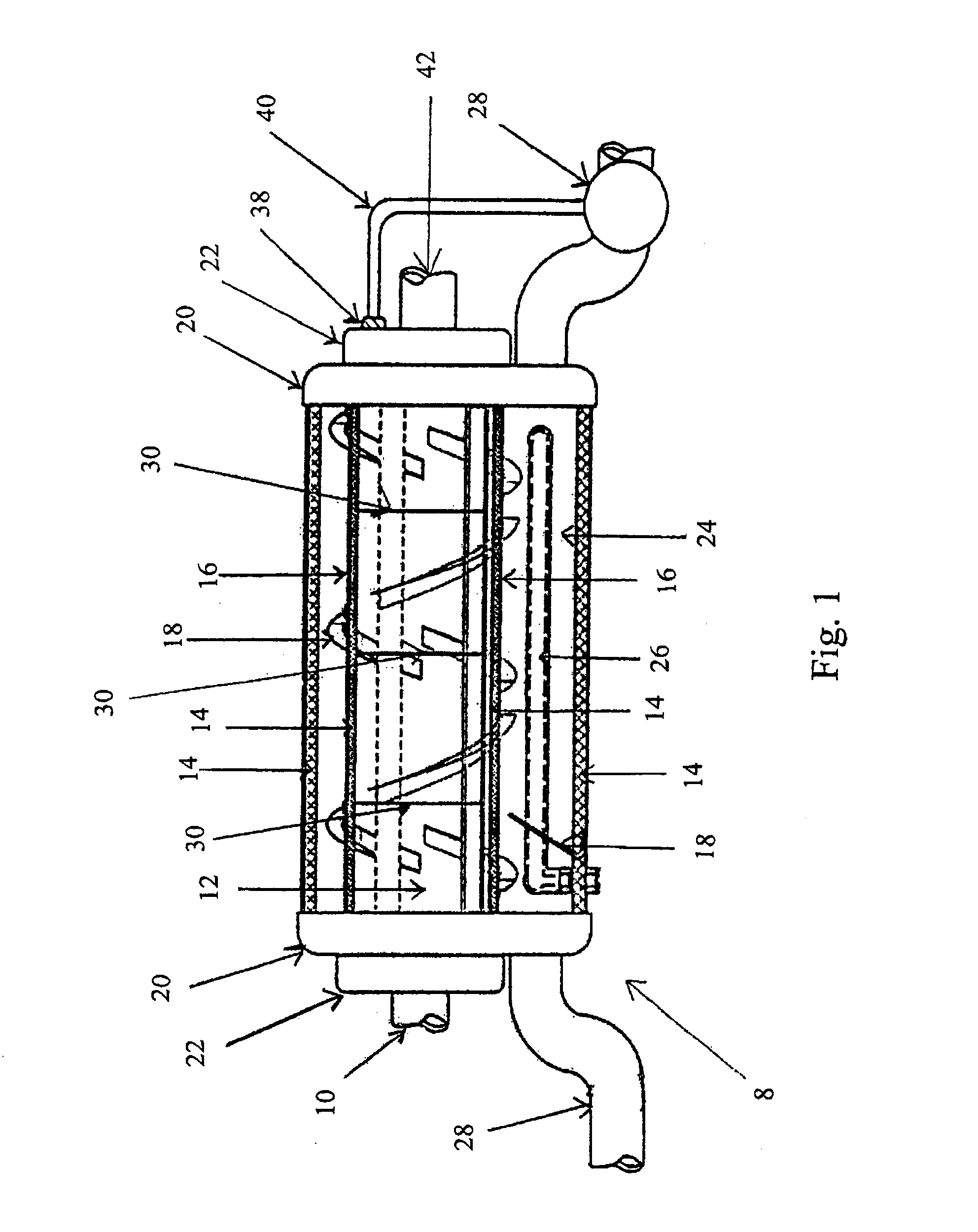

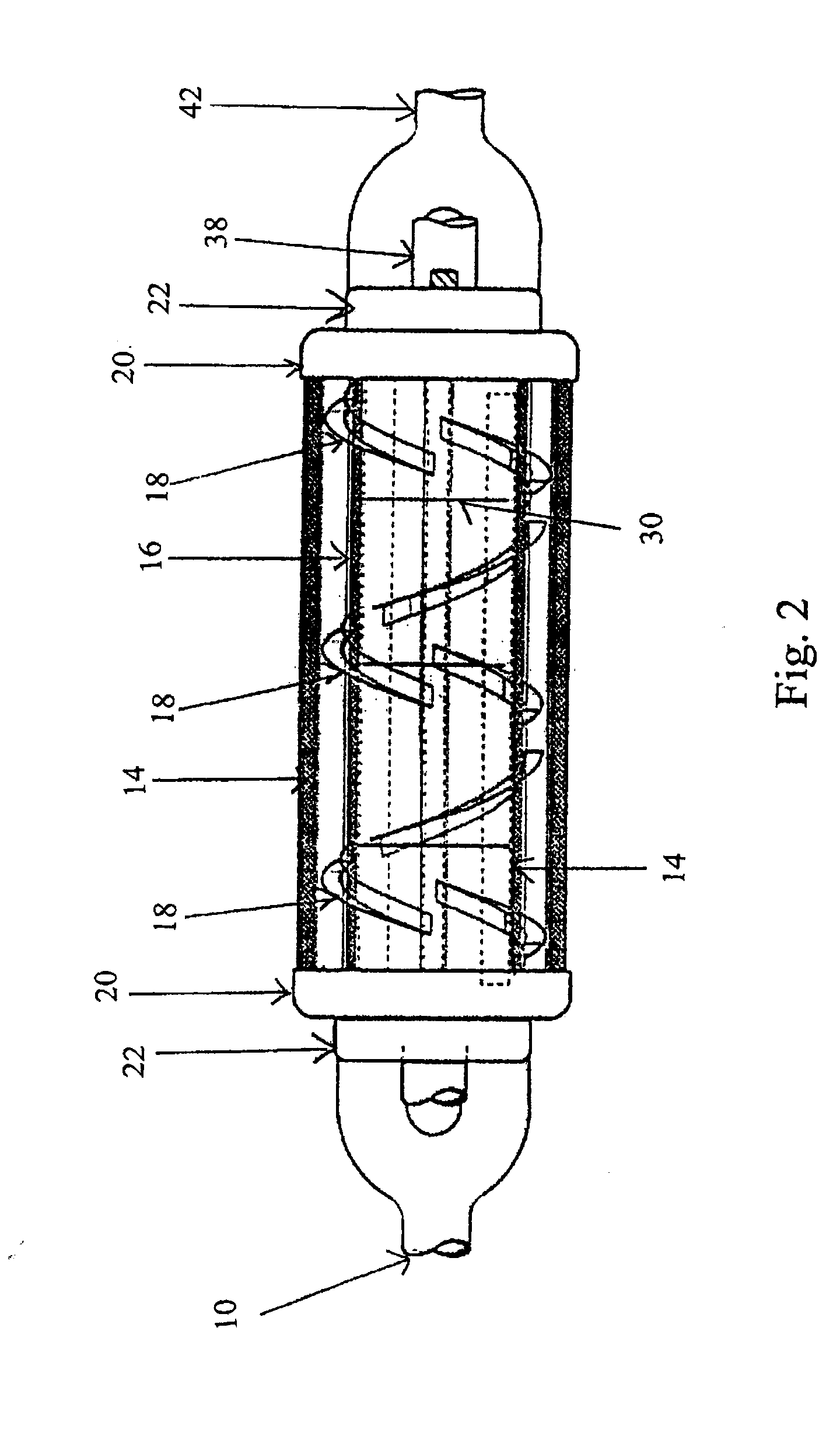

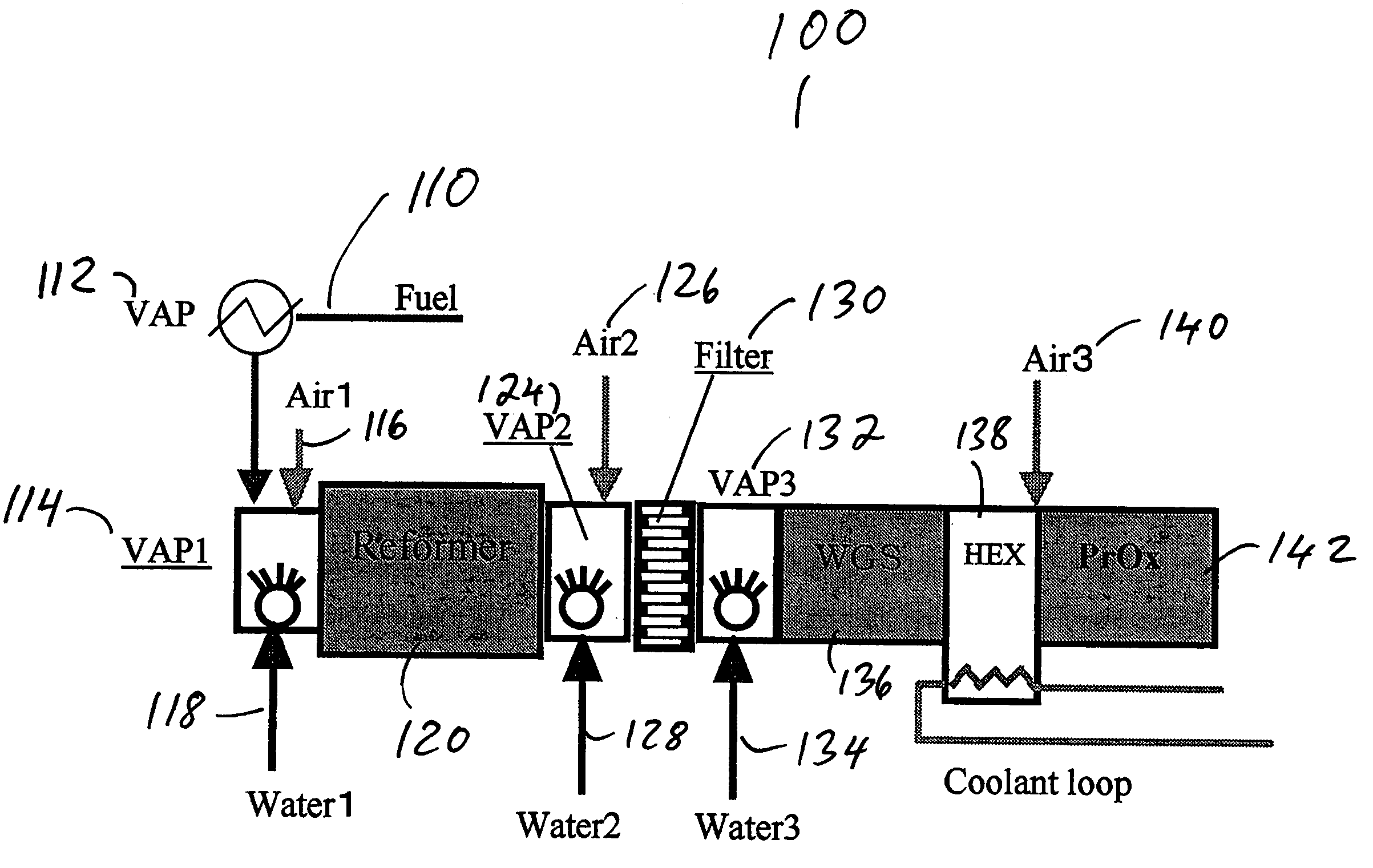

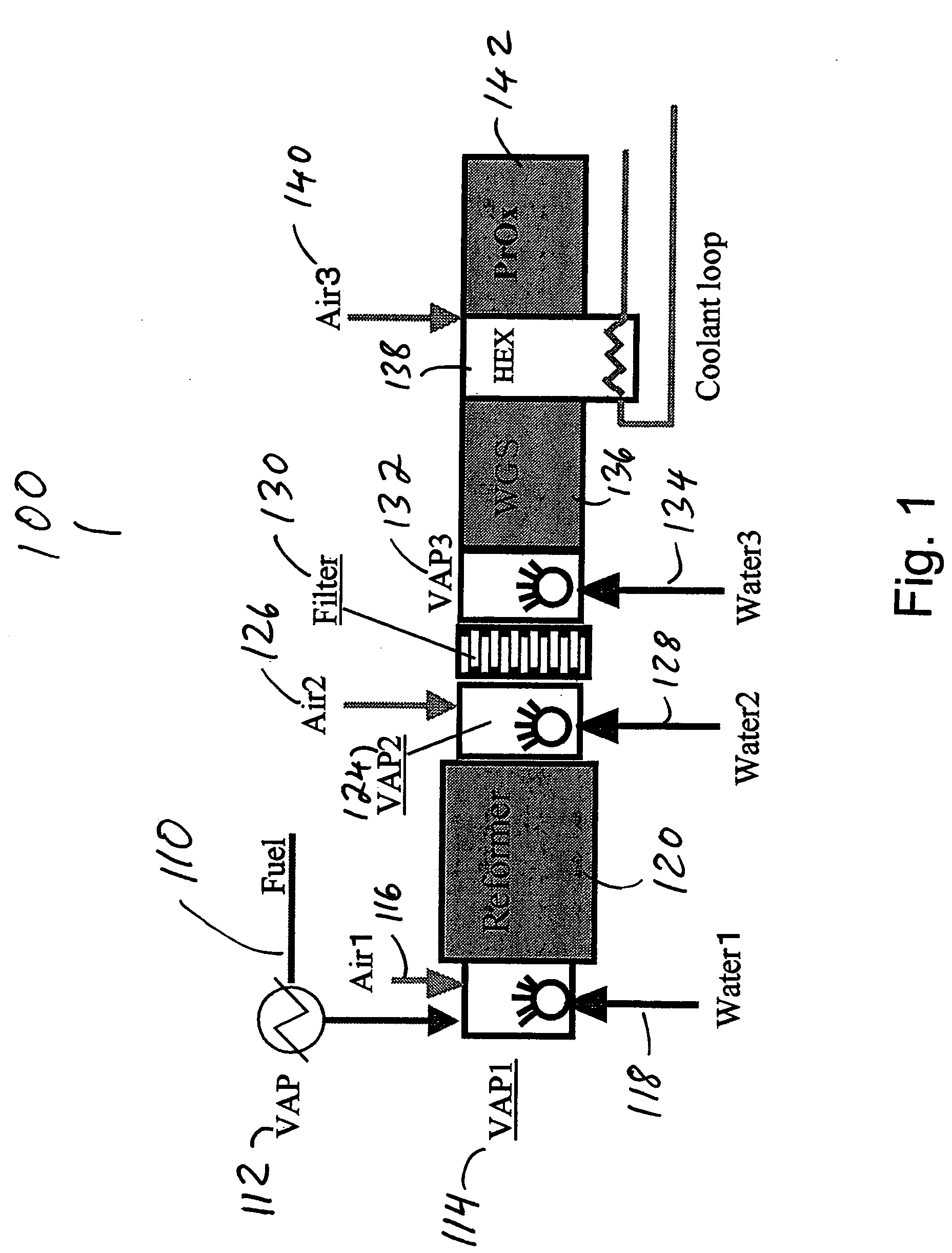

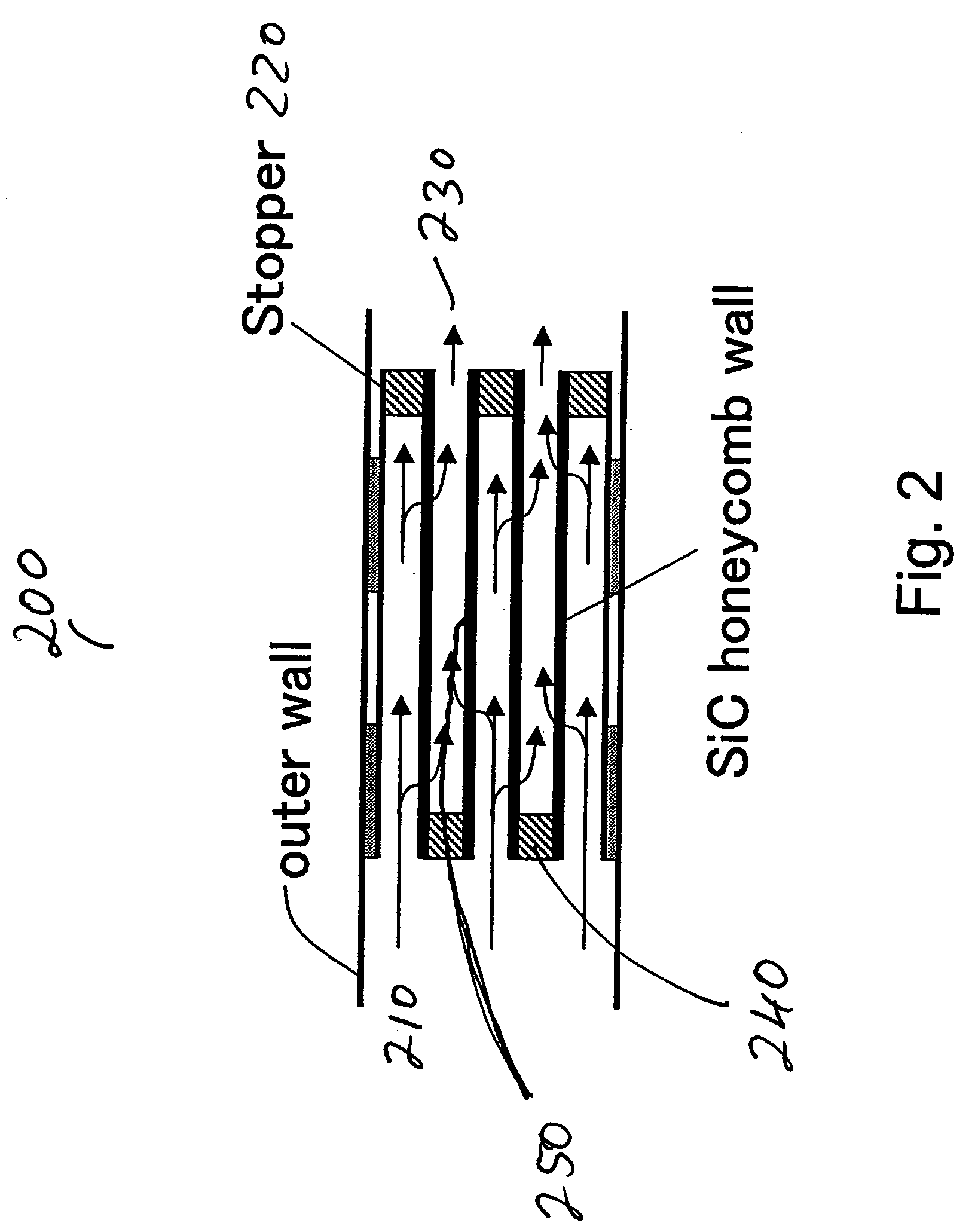

Fuel processing system for reforming hydrocarbon fuel

InactiveUS7267699B2Minimize adverse affectAffect operationExhaust apparatusLayered productsHydrogenProcess engineering

A fuel processing system including a filter for reforming a hydrocarbon fuel and its operation is disclosed. The system includes a first chamber for receiving a hydrocarbon fuel and combining it with air or water; a reformer in fluid connection with and down stream of the first chamber, which receives the hydrocarbon fuel combined with either air or water to reform the fuel to a reformate stream, which contains a hydrogen rich atmosphere; a second chamber in fluid connection with the reformer which is capable of receiving the reformate stream from the reformer; a water inlet connected to the second chamber capable of introducing water to the reformate stream; and a filter in fluid connection with and down stream of the second chamber, which is capable of preventing a substantial portion of any solid particles contained in the reformate stream from passing therethrough. The filter can be regenerated by introducing water as an oxidant to the reformate stream to oxidize any collected soot on the filter in the hydrogen rich atmosphere of the reformate stream.

Owner:NISSAN MOTOR CO LTD

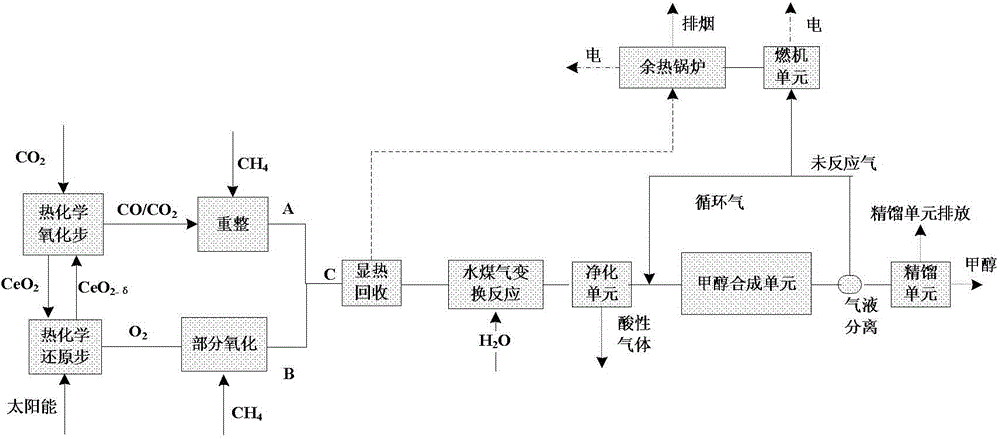

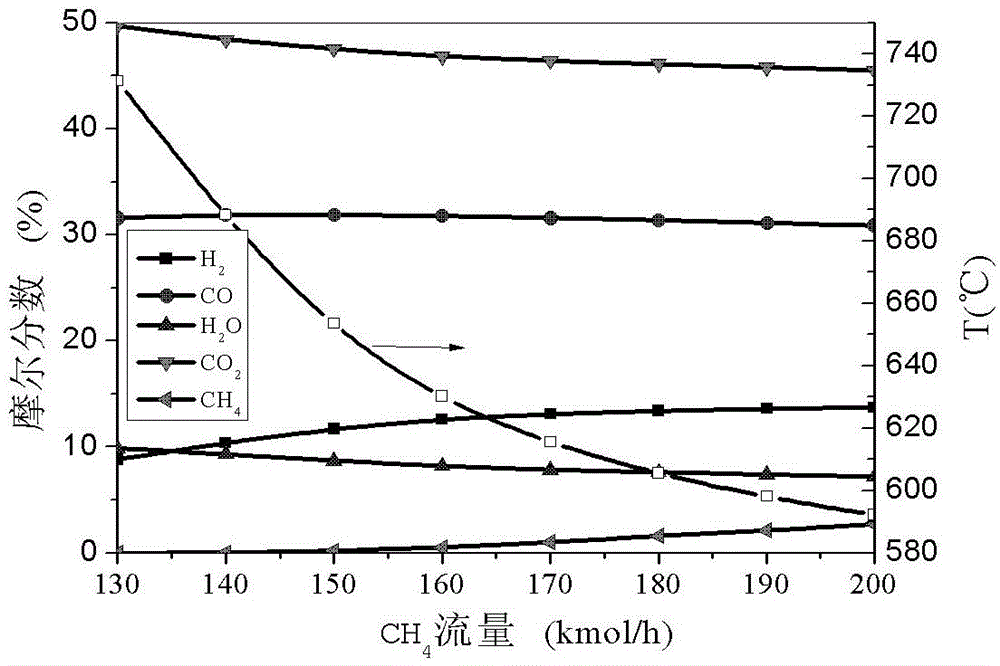

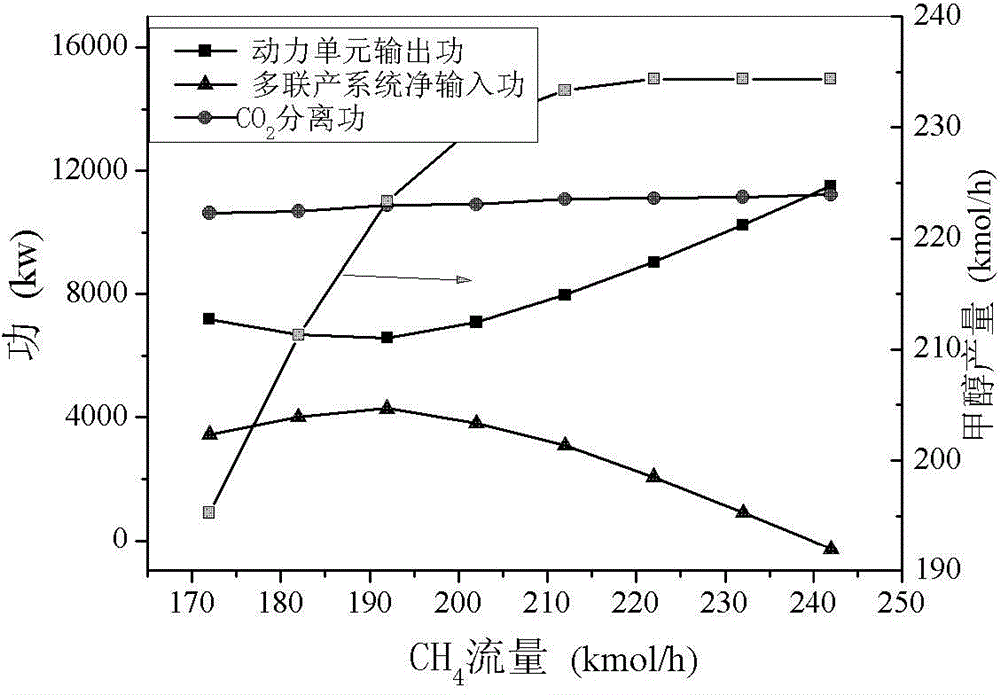

Comprehensive utilization method for high-temperature energy

ActiveCN104445060ARealize rational utilizationReduce dependenceCarburetting gasesOrganic compound preparationChemical reactionCombustion

The invention discloses a comprehensive utilization method for high-temperature energy. The comprehensive utilization method for high-temperature energy comprises the following steps: charging reaction raw materials in a reactor, and carrying out a thermal chemical reaction through a two-step method at a high temperature; adding a hydrocarbon compound in the generated product, carrying out waste heat and waste gas recycling by virtue of a chemical reaction, and lowering the temperature of a fuel to the temperature range of the mature solution of the existing heat exchange technology while further increasing the calorific value of the fuel. The comprehensive utilization method disclosed by the invention is capable of decomposing H2O and CO2 into H2 and CO, and the net carbon emission of the fuel generated in this way during combustion is zero; reasonable utilization for waste heat and waste gas in the two-step method can be realized through complementation with fossil energy, thus methanol-power poly-generation can be realized while an ultra-high-temperature heat exchange is not used, and moreover, for an overall effect, the carbon emission of the unit calorific value of the fuel is reduced, and dependence on the fossil energy is reduced; if heat recovery is carried out on a system, the efficiency of the system can be further increased, and the carbon emission of the unit calorific value can be reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

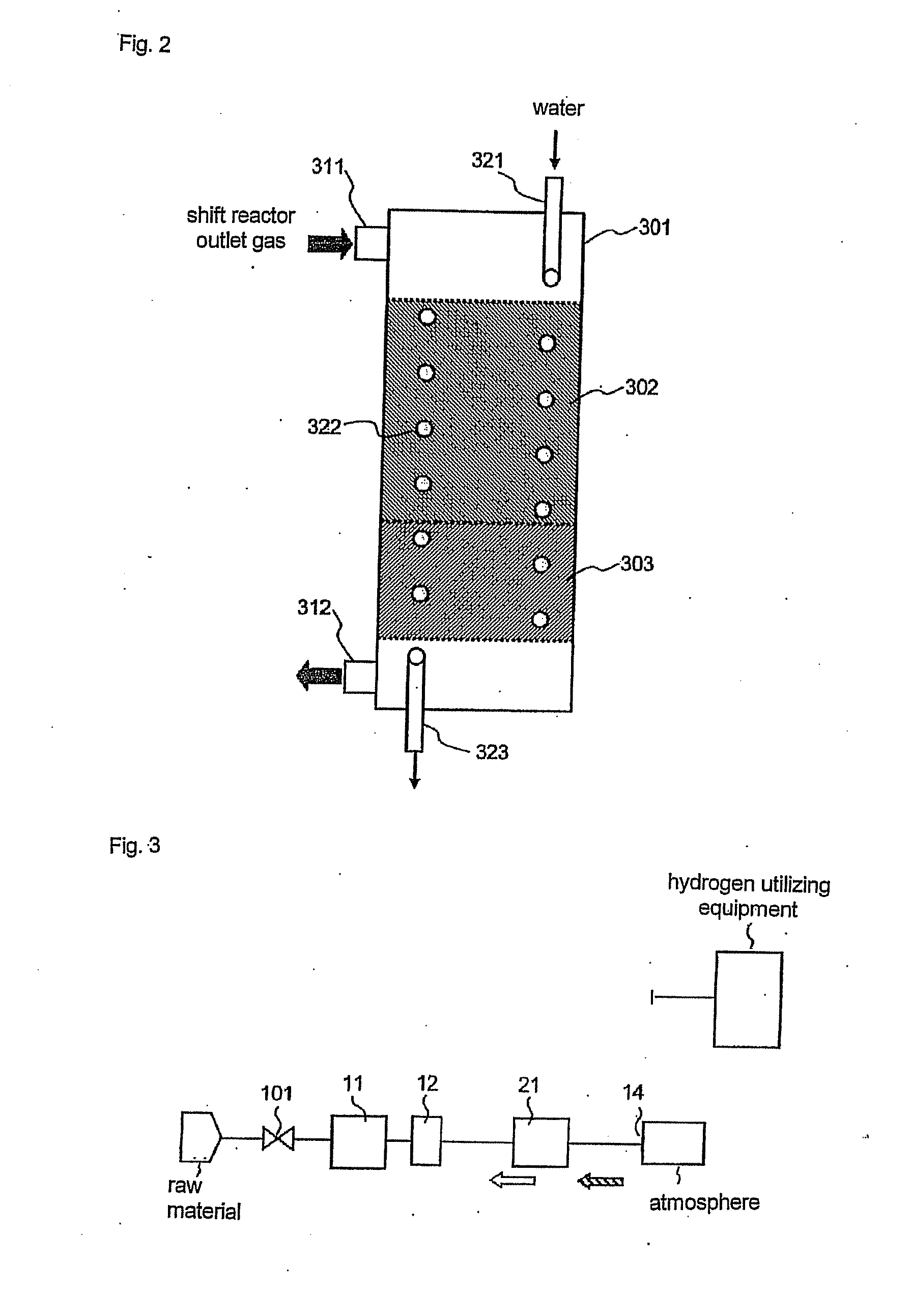

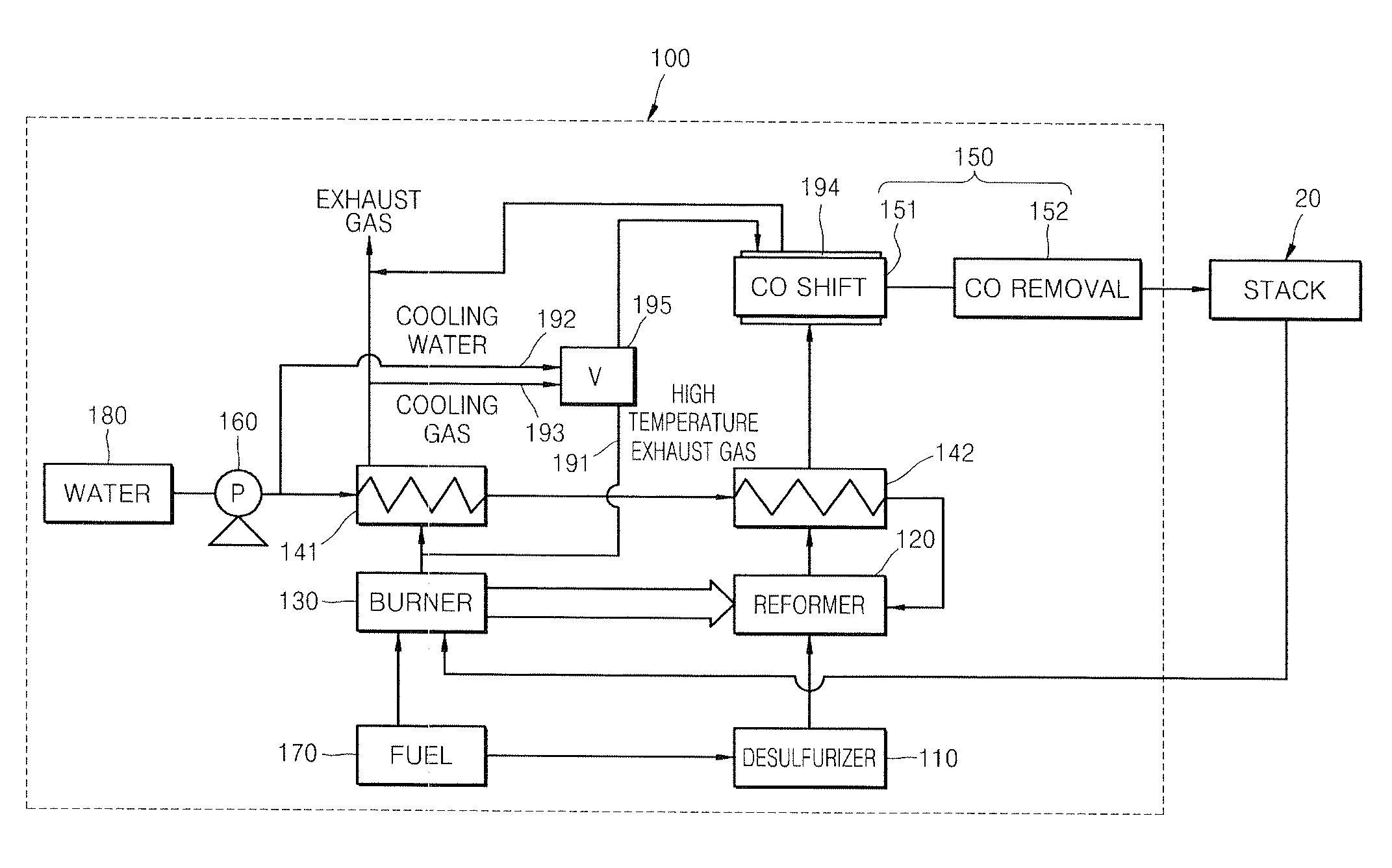

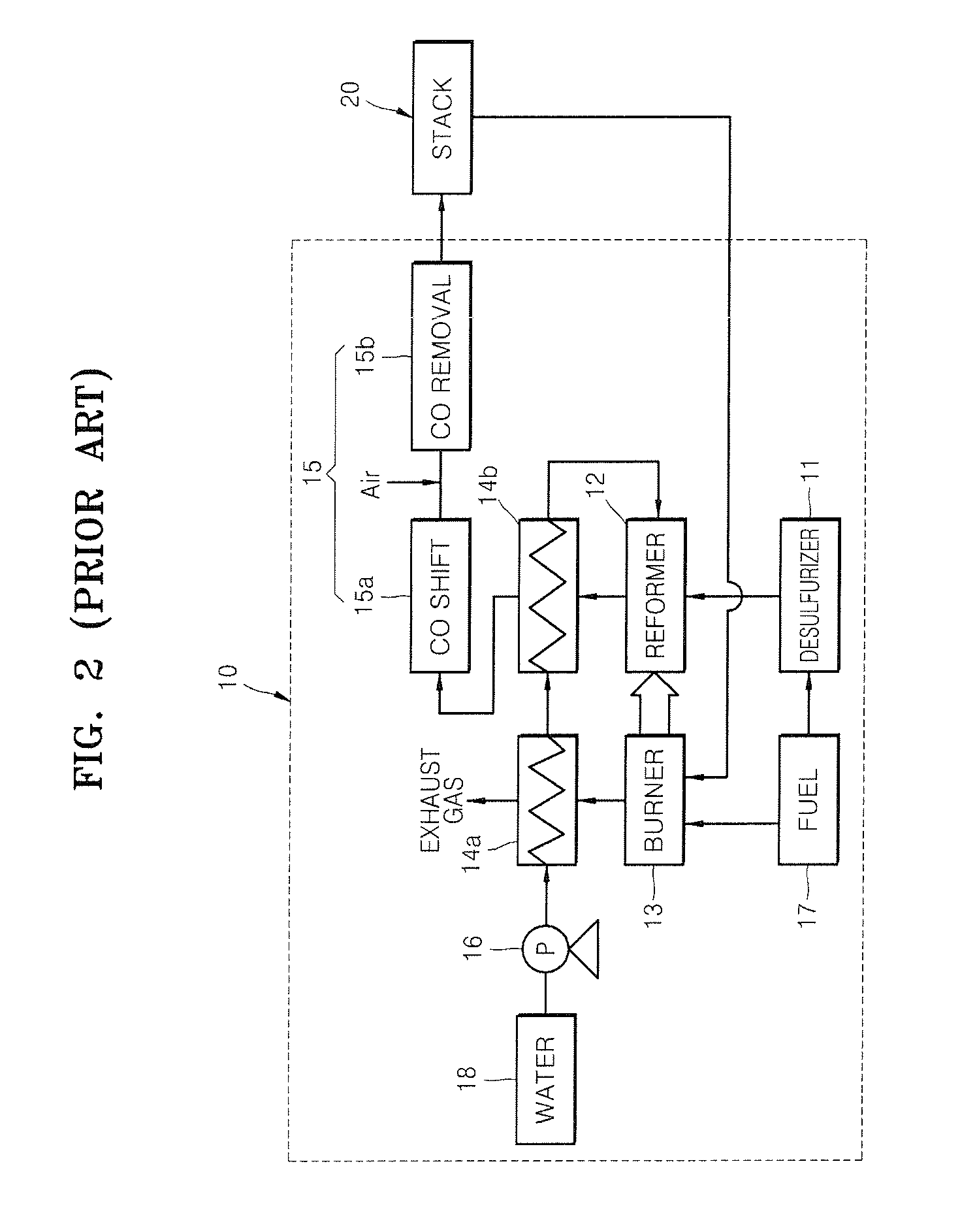

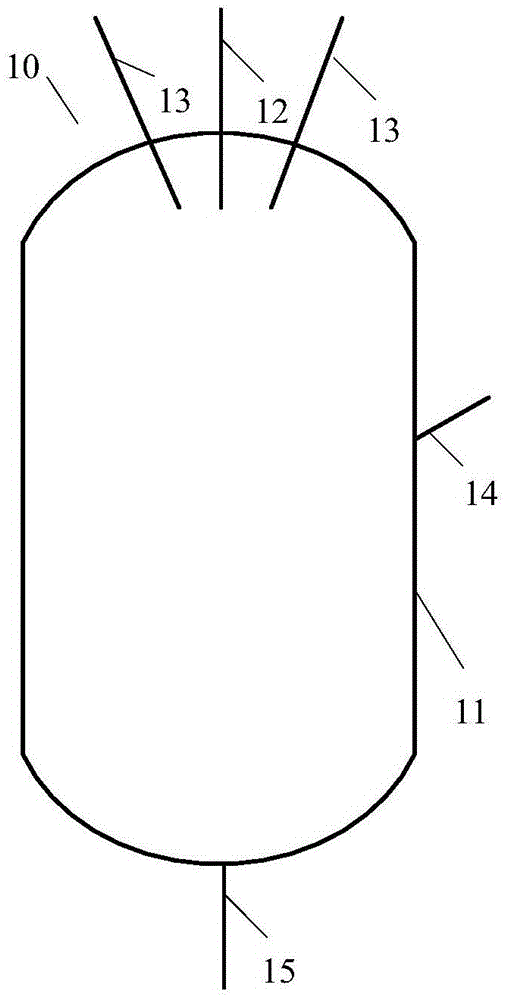

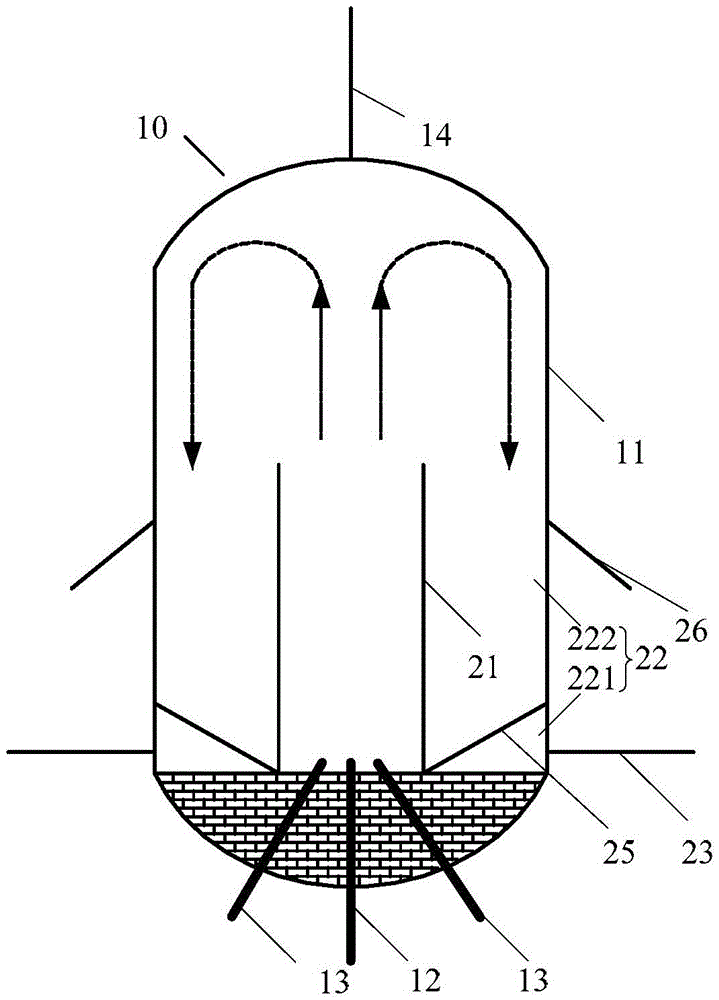

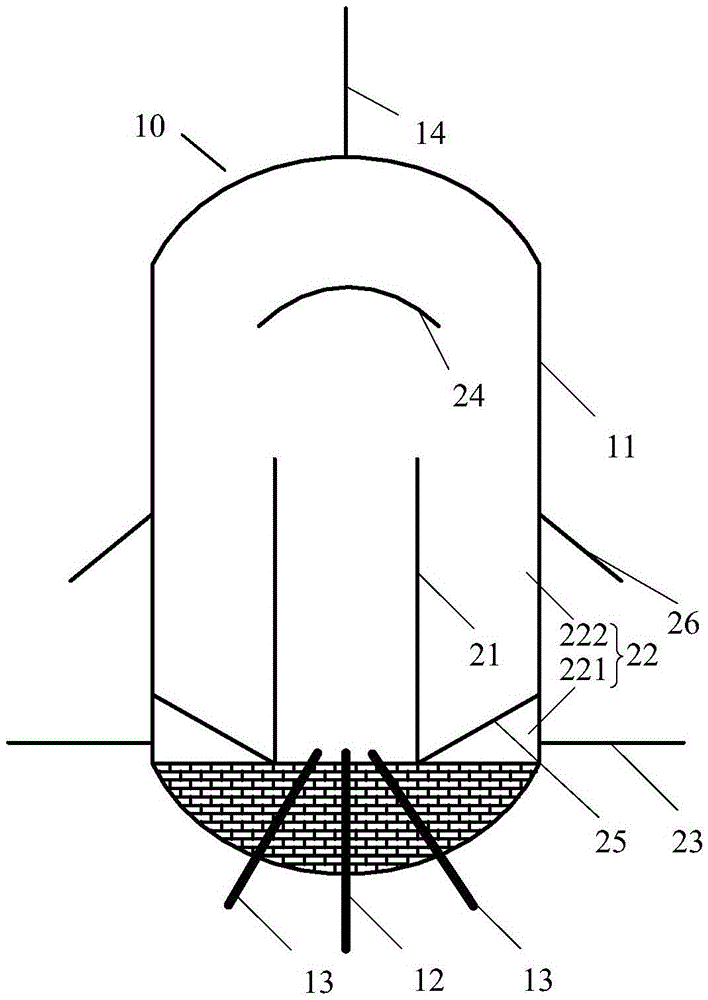

Fuel processor having temperature control function for co shift reactor and method of operating the fuel processor

A fuel processor includes a reformer that generates hydrogen gas by reacting a fuel source and water; a burner that heats the reformer to a temperature suitable for a hydrogen generation reaction; a CO shift reactor that removes CO generated during the hydrogen generation reaction in the reformer; a heating element for heating the CO shift reactor; and a cooling element for cooling the CO shift reactor, wherein the cooling element comprises at least one of a cooling water flow line for heat exchange with the CO shift reactor when cooling water flows through the cooling water flow line and a cooling gas flow line for heat exchange with the CO shift reactor when a cooling gas, which is a burner exhaust gas that has heat exchanged with cooling water, flows through the cooling gas flow line. When the fuel processor is operated, a stable CO removal performance can be maintained since the temperature of the CO shift reactor can be actively controlled.

Owner:SAMSUNG SDI CO LTD

Gasification furnace and hydrogasification method for coal

ActiveCN105482852AAvoid wastingSave energyCarburetting gasesGasification processes detailsHydrogenProcess engineering

The invention provides a gasification furnace and a hydrogasification method for coal to overcome the problem of waste of energy in re-gasification of semi-coke during hydrogasification of coal, belonging to the technical field of coal gasification. The gasification furnace comprises a furnace body, a coal dust nozzle, a hydrogen-containing gas nozzle, an inner reaction cylinder with an open top and a gasification agent inlet, wherein the coal dust nozzle and the hydrogen-containing gas nozzle are both installed at the bottom of the furnace body, the inner reaction cylinder is arranged at the lower part in the furnace body, the coal dust nozzle and the hydrogen-containing gas nozzle are communicated with the interior of the inner reaction cylinder, the inner reaction cylinder is used for hydrogasification of coal to produce crude gas and semi-coke, the gasification agent inlet is communicated with the bottom of an annular space located between the inner reaction cylinder and the furnace body, and the gas velocity of a gasification agent introduced via the gasification agent inlet enables the semi-coke to fall into the annular space and to undergo gasification reaction with the gasification agent again so as to produce crude gas. The gasification furnace and the hydrogasification method for coal provided by the invention are used for hydrogasification of coal and graded conversion of low-rank coal.

Owner:ENN SCI & TECH DEV

Catalytic Reformer Recycle Gas Compressor Efficiency

InactiveUS20090320370A1Improving catalytic reforming hydrogen productionHigh trafficHydrogenCarburetting gasesCatalytic reformingGas compressor

Methods for improving the efficiency of a catalytic reforming recycle gas compressor by combining a high molecular weight light hydrocarbon process stream from a unit operation associated with the catalytic reforming process with a lower molecular weight reactor off gas recycle stream to form a combined recycle gas stream.

Owner:UOP LLC

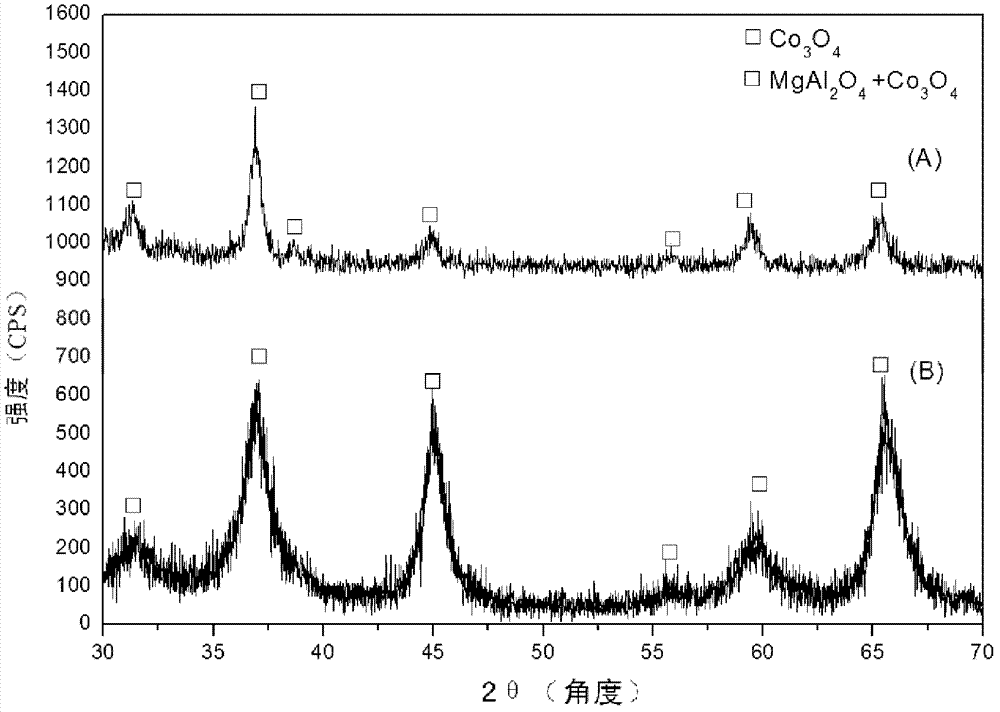

Effective carbon dioxide conversion catalyst and preparing method thereof

InactiveCN103170335AIncrease generation ratioStable conversion rateCarburetting gasesMetal/metal-oxides/metal-hydroxide catalystsForming gasSpinel

The invention relates to a preparing method of catalysts, and particularly relates to a preparing method of cobalt catalysts in [Formula 1], as well as a method for converting carbon dioxides to forming gases by using the method. In [Formula 1] (a) Co / (d)Z, [in Formula 1, Z denotes a spinel carrier formed by A, B, and O; A denotes more than one substance selected from the group formed by Mg, Cr, Mn, Fe, Co, Ni, Cu, Zn, Cd, and Sn; B denotes more than one substance selected from the group formed by A1, Ga, In, Ti, V, Cr, Mn, Fe, Ni, and Co; a denotes the weight of Co, D denotes the weight of spinel carrier Z; with respect to the d accounting for 100 by weight, a accounts for 1-100 by weight.] Compared with the catalysts in the prior art, the activity degree of hydrocarbon and carbon dioxide continuously maintain in the same conversion speed to maintain higher activity and stability.

Owner:KOREA RES INST OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com