Methane carbon dioxide reforming catalyst and preparation method and using method thereof

A technology for reforming catalysts and carbon dioxide, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve the problem of long reaction time, high reaction temperature, and multiple catalyst steps And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

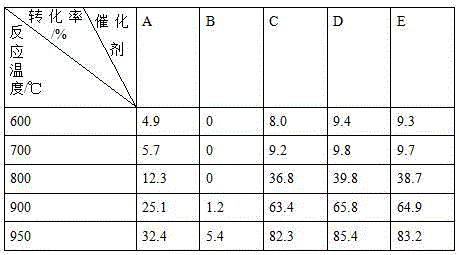

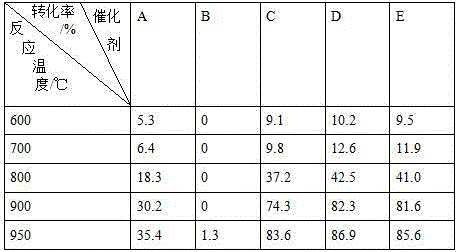

Embodiment 1

[0044] 1) Take 30g of lignite below 100 mesh, add H with the same quality as lignite 2 O, 5g of cobalt-based-metal mixture, fully stir the three evenly. The cobalt-based metal mixture is Co-FeS with a Co content of 5%wt.

[0045] 2) Put the mixture prepared in step 1) into the high-pressure reactor, feed the CO pressure to 4MPa, set the heating rate in the reactor to 5°C / min, raise the temperature to 350°C, and set the stirring speed at the same time It is 250r / min.

[0046] 3) Let the reaction system of step 2) continue for 30 minutes, stop heating, cool the system to room temperature, take out the modified lignite, filter, dry and carbonize;

[0047] 4) Activate at low temperature after carbonization. Set the reaction temperature at 600°C and the reaction pressure at 7 MPa. Activate by passing in water vapor activated by an anion device. The reaction time is 4 hours. After natural cooling, the methane carbon dioxide reforming catalyst C is prepared.

Embodiment 2

[0049] 1) Take 30g of lignite below 100 mesh, add H with the same quality as lignite 2 O, 5g of cobalt-based-metal mixture, fully stir the three evenly. The cobalt-based metal mixture is Co-FeS with a Co content of 5%wt.

[0050] 2) Put the mixture prepared in step 1 into the autoclave, and then feed CO and H into the autoclave 2 The mixture to 4MPa, set the stirring speed of the autoclave to 250r / min, and the heating rate of the reaction system to 5°C / min, raise the temperature of the system to 350°C, and at the same time turn on the ultrasonic vibrator installed outside the autoclave, Allow the lignite in the system to fully react.

[0051] 3) According to steps 3 and 4) in Example 1, the catalyst D containing Co metal was prepared.

Embodiment 3

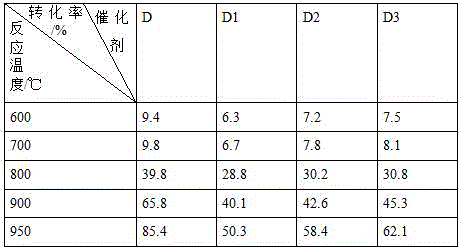

[0053] 1) Take 30g of lignite below 100 mesh, add H with the same quality as lignite 2 O, 5g of cobalt-based-metal mixture, fully stir the three evenly. Cobalt-based metal mixtures are Co-Fe 2 o 3 、Co-Fe 3 o 4 , Co-FeO, wherein the content of Co is 5%wt.

[0054] 2) Catalysts D1, D2, and D3 prepared according to steps 2) and 3) in Example 2.

[0055] 3) Using Co-based metal catalysts containing different iron oxides for reforming reaction, the corresponding methane and carbon dioxide conversion rates are shown in Tables 3 and 4 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com