Method for directly preparing coal gas from industrial high temperature CO2 waste gas

A waste gas, high temperature technology, which is applied in the field of directly producing gas from industrial high temperature CO2 waste gas, can solve the problems of high gas production cost, large energy consumption, large method investment, etc., and achieves a simple and practical process, saves energy and investment, and reduces costs. Effects of air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

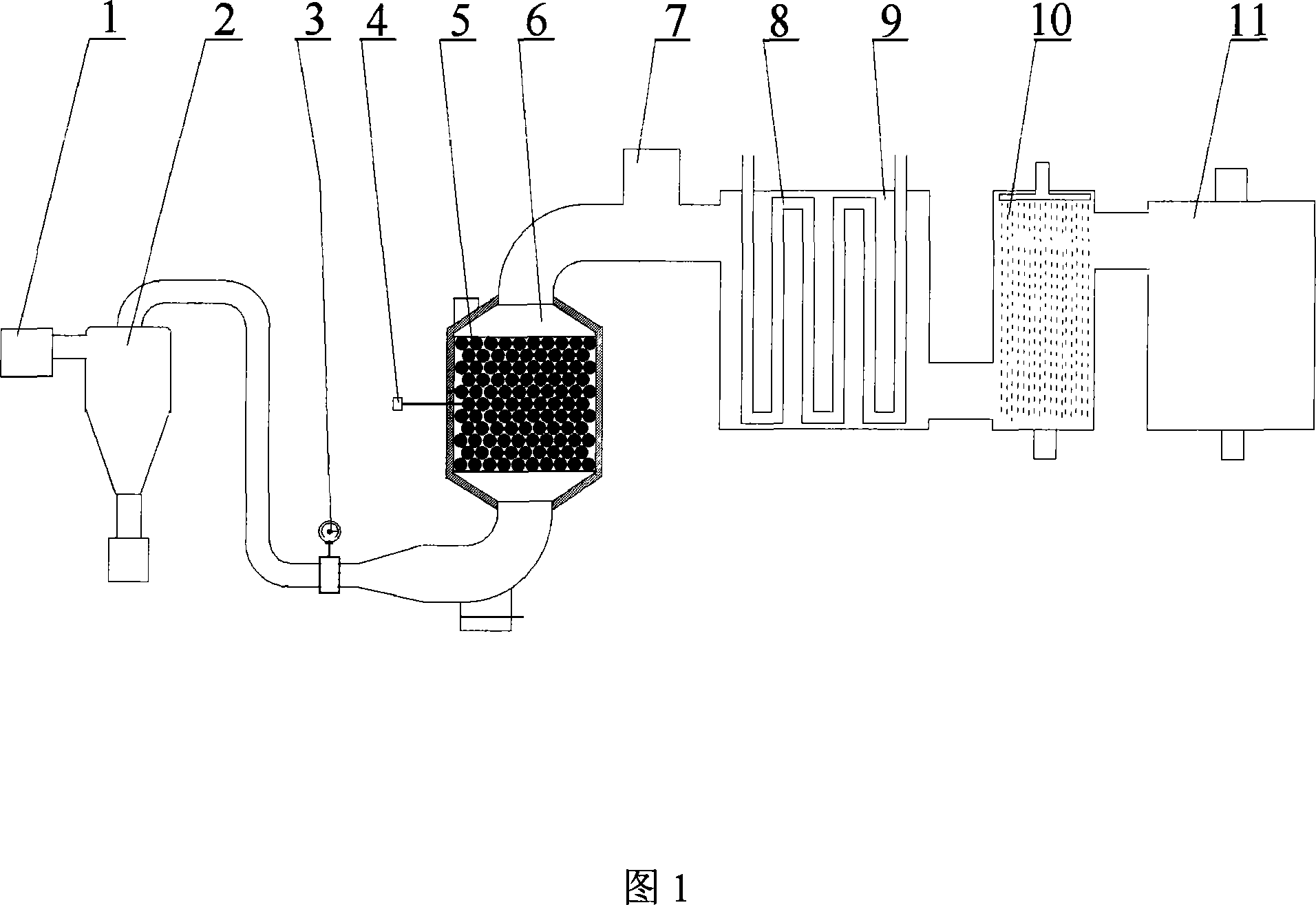

Embodiment 1

[0016] The high-temperature CO, a by-product obtained in industrial production, 2 The exhaust gas is sent into the temperature control tank 1 through the delivery pipeline to control and adjust the CO 2 Exhaust gas output temperature. The controlled temperature is about 1200°C (by controlling the temperature to adjust the reaction temperature in the charcoal reaction bed 5) CO 2 The exhaust gas is sent to the primary dedusting device 2 to remove the solid particles in the gas and then sent to the closed reactor 6 through the flow meter 3 . Set CO 2 The reaction temperature of the exhaust gas passing through the charcoal reaction bed 5 and the charcoal reaction is 1100° C., and the reaction time is 10 seconds. The reaction temperature is monitored by the thermometer 4 . If the reaction temperature is lower than 1100 °C, it is necessary to properly control the increase of CO 2 The temperature of the exhaust gas output from the temperature control tank 1; if the reaction temp...

Embodiment 2

[0018] CO at 1200°C 2 After passing through the primary dedusting device 2, the exhaust gas passes through the flow meter 3 and then is sent into the closed reactor 6. Set CO 2 The reaction temperature of the exhaust gas passing through the carbon reaction bed 5 to react with the coke is 1100°C, and the reaction time is 20 seconds. The crude gas obtained can be sent out through the crude gas outlet 7 or through the heat exchange tube 8, the dust removal heat exchange device 9 and the washing and cooling device 10 The obtained high-purity CO is sent into the high-purity CO storage tank 11.

[0019] Other embodiment parameters are listed by the following table:

[0020] Temperature control tank temperature ℃

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com