Gasifying method for biomass gasifier and hearth air intake device

A technology for air inlet devices and gasifiers, which is applied in the field of household furnaces or stoves. It can solve the problems of uneven wind field and wind pressure in the furnace, easy to generate slagging, and the inability of the gasifier to work continuously for a long time, so as to prevent air ducts Clogging, uniform wind pressure, and uniform temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

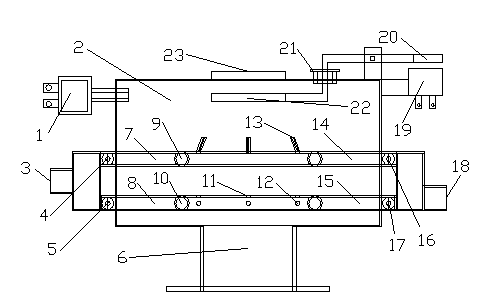

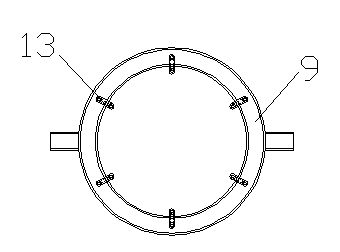

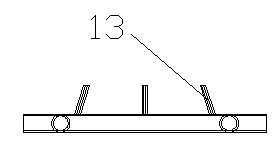

[0023] Embodiment 1: The furnace air inlet device is located above the furnace feed port 6, below the igniter 1 and the material level detection plate 22, the material level detection plate 22 is located directly below the gas outlet 23, and the annular air duct is located at the furnace 2 Inside, it is divided into an upper annular air duct 9 and a lower annular air duct 10. The radial end of the upper annular air duct 9 is connected to the air inlet 3 through the upper air duct air inlet pipe 7 and the upper air duct air inlet valve 4. The upper air duct The other end of the radial direction of the annular air duct 9 is connected to the sewage outlet 18 through the upper air duct blowdown pipe 14 and the upper air duct blowdown valve 16; The same end of the same) is connected to the air inlet 3 through the air inlet pipe 8 of the lower air duct and the air inlet valve 5 of the lower air duct. 17 is connected with sewage outlet 18. Air inlet 3, upper air duct air inlet valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com