Patents

Literature

60results about How to "Uniform wind pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

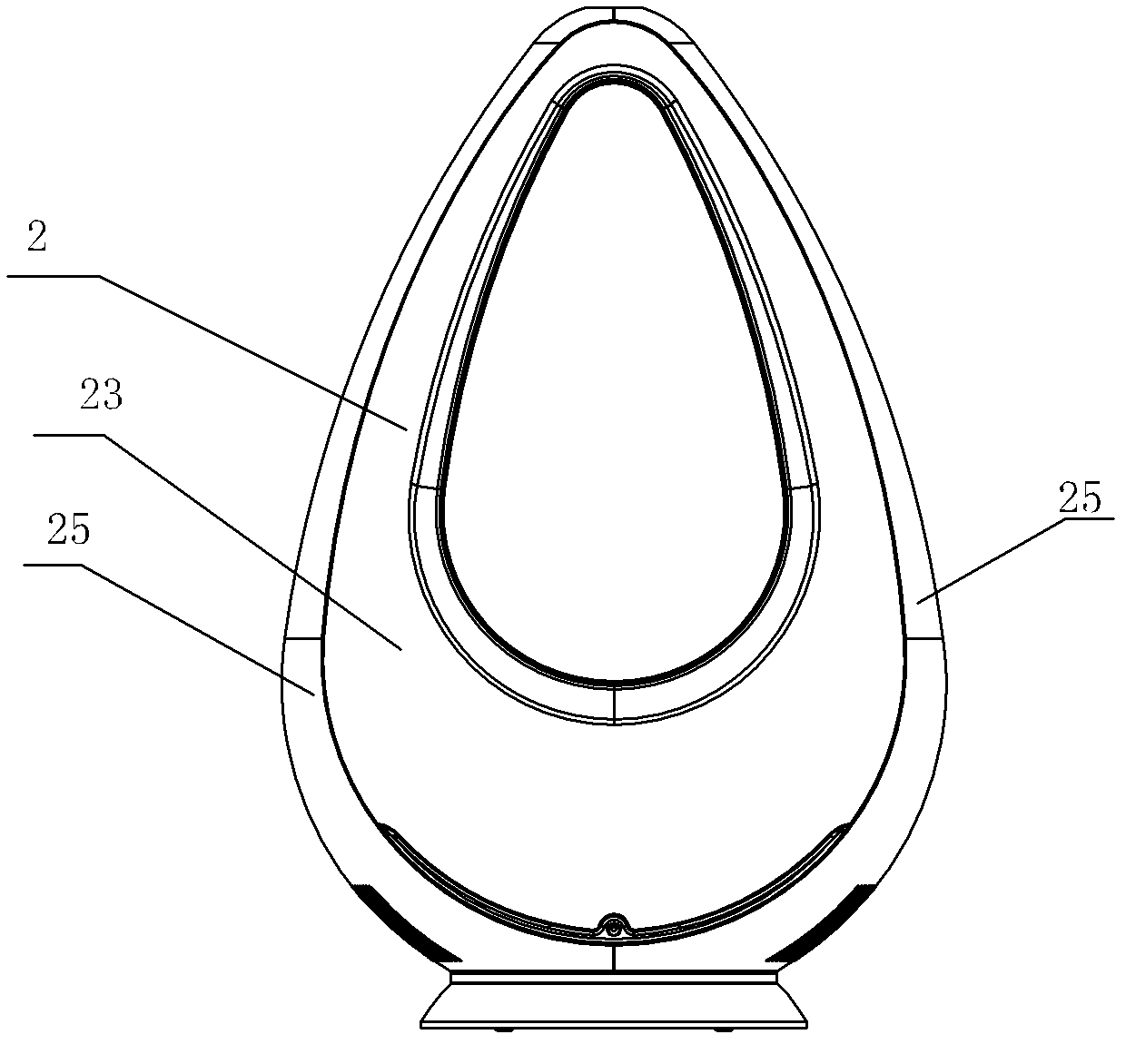

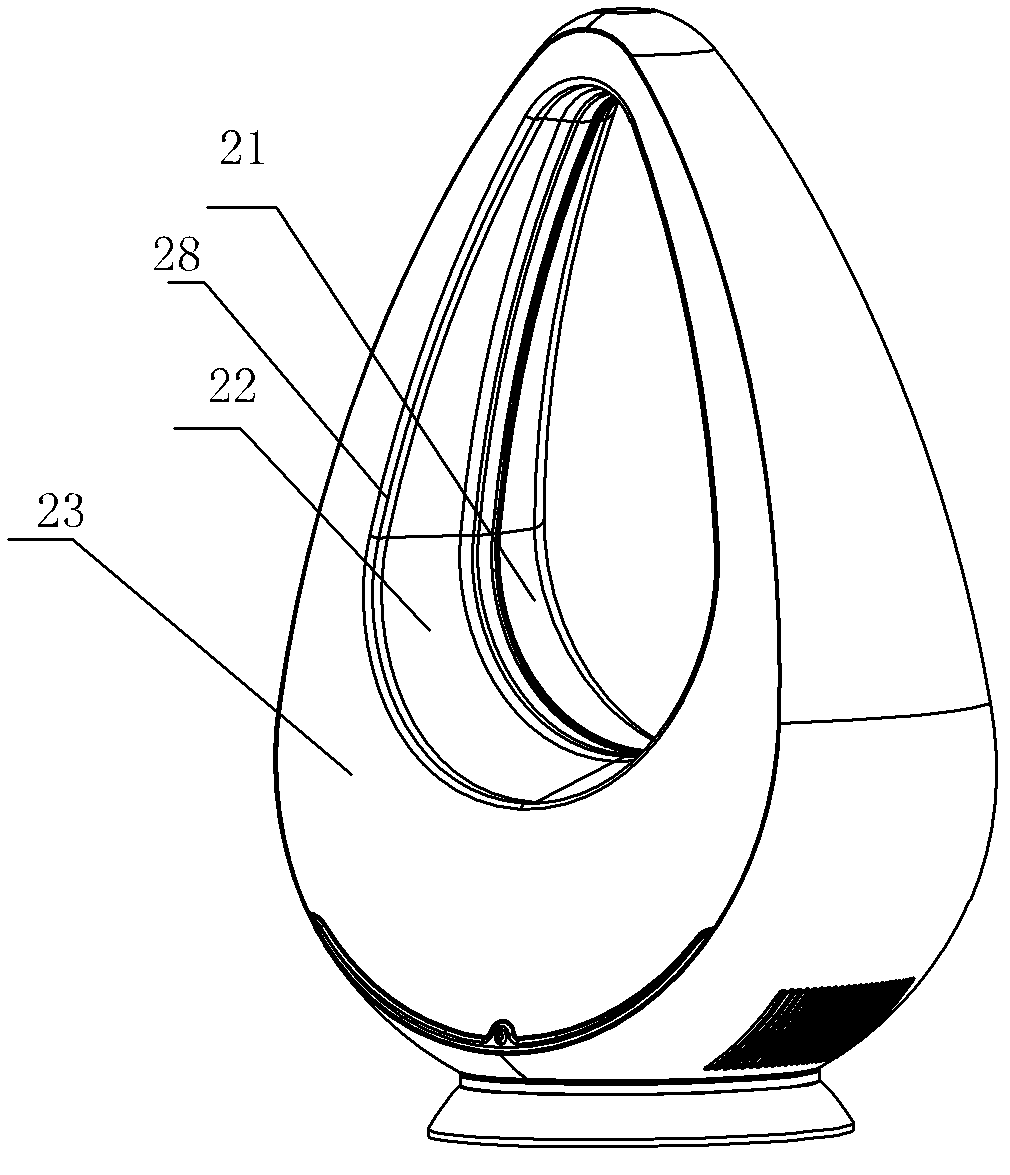

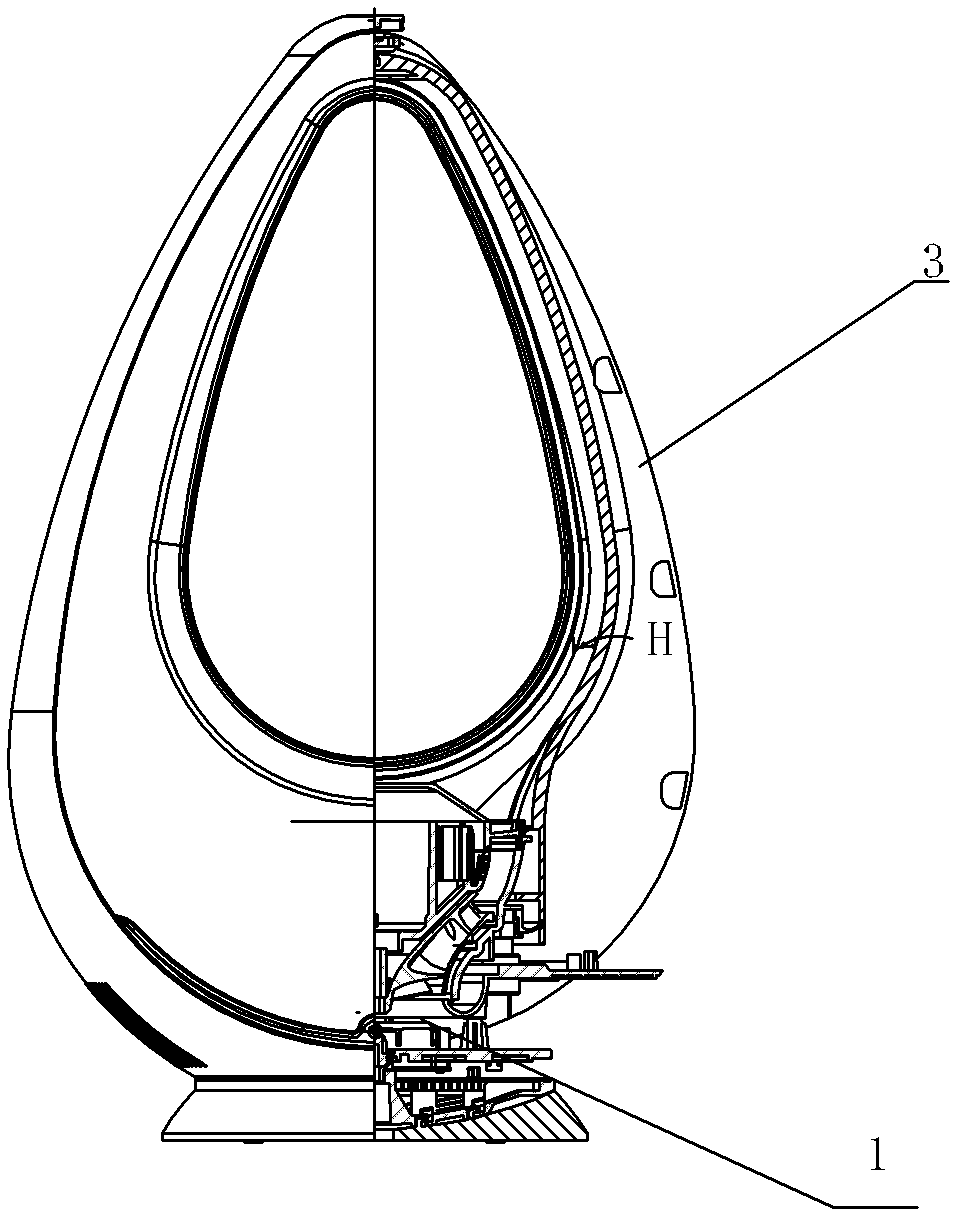

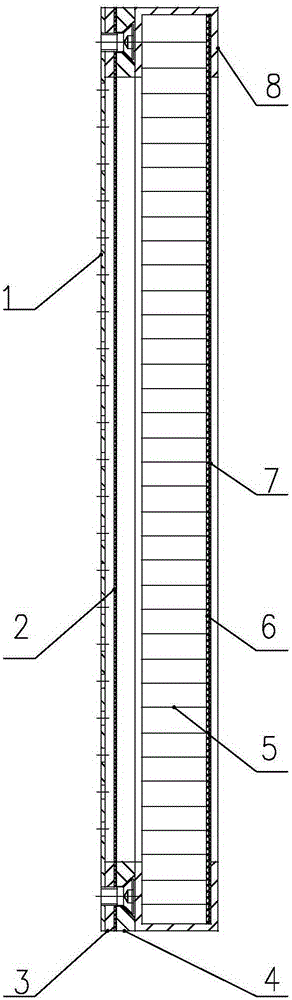

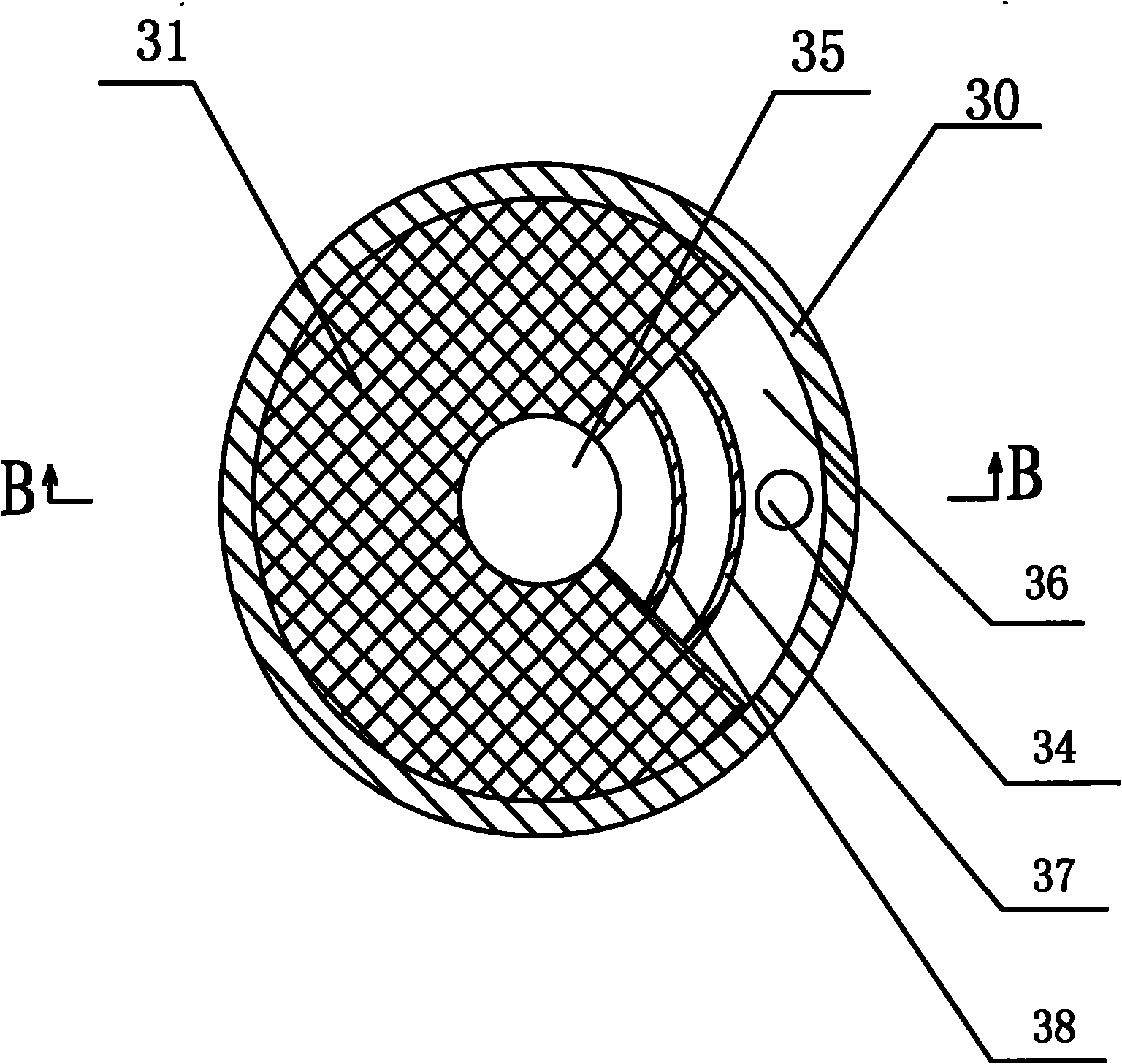

Bladeless fan

The invention discloses a bladeless fan, which comprises a device for forming an air flow and an annular spray nozzle. The annular spray nozzle includes an annular cavity and an opening for air flow jetting. In the annular cavity is arranged an isolation cover assembly which divides the annular cavity into an outer annular cavity and an inner annular channel for receiving the air flow, the cross sectional area of the inner annular channel gradually decreases from bottom up, and silencer cotton is arranged in the outer annular cavity. According to the characteristics of a high pressure air flow, the high pressure air flow at the lower part of the annular channel of an electric fan in prior arts gathers around the upper part of the annular channel from bottom up, while the inventive inner annular channel has the cross sectional area gradually decreasing from bottom up to realize uniform air pressure in the inner annular channel, so that the velocity of the air flow jetted from the opening is identical and that the velocity of the air from the annular spray nozzle is uniform. The silencer cotton arranged in the outer annular cavity can eliminate noise generated by the high-velocity air flow in the inner annular channel, so that noise is low during electric fan operation.

Owner:NINGBO HANMING TECHNOLOGY CO LTD

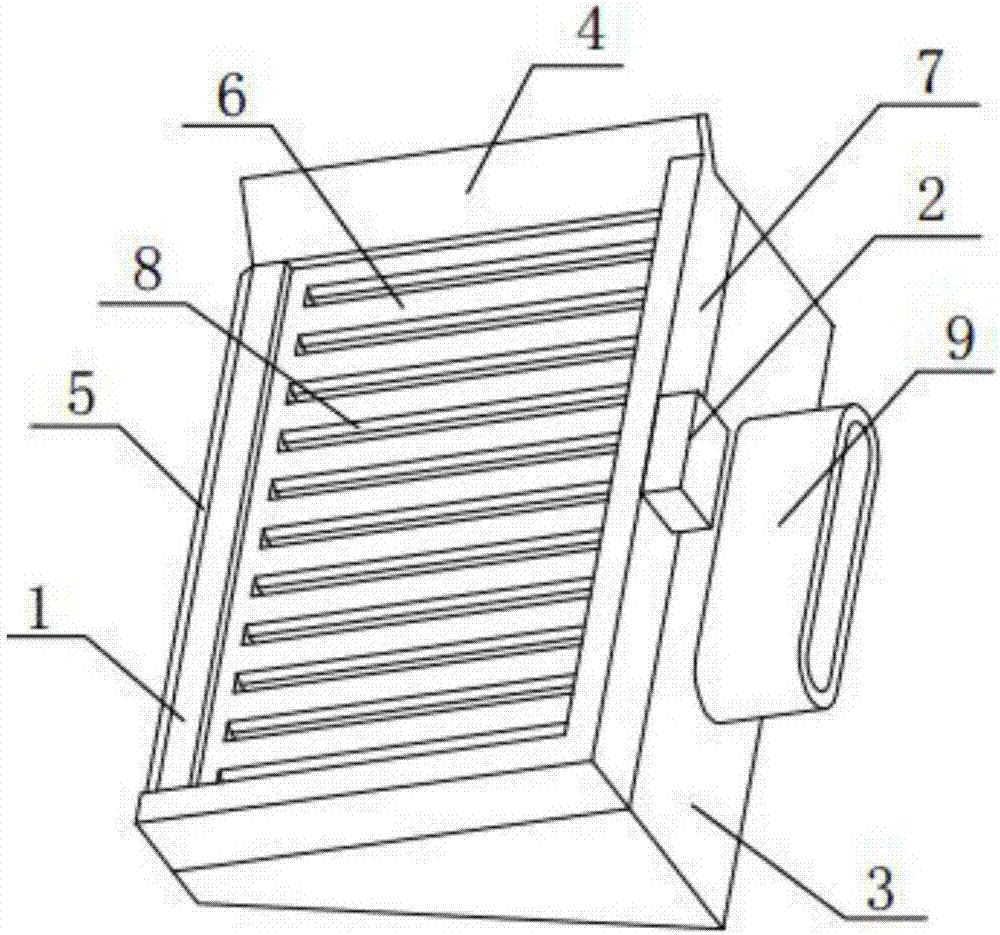

Blown air rectifying device of chemical fiber spinning equipment

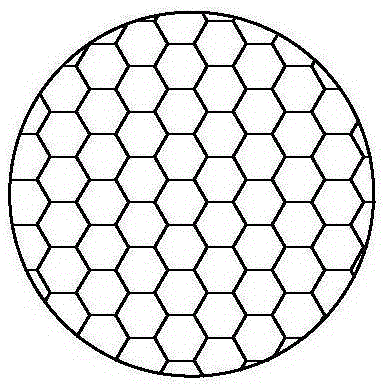

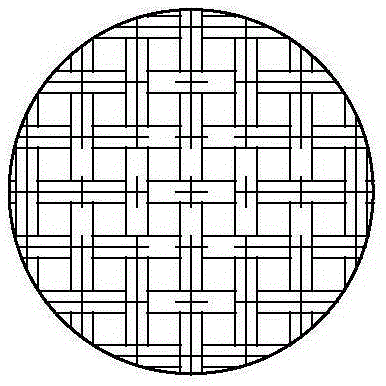

ActiveCN105220249AUniform wind pressureUniform wind speedFilament/thread formingAir velocityHoneycomb

The invention discloses a blown air rectifying device of chemical fiber spinning equipment, which is mounted at the air outlet of an air blowing device of chemical fiber spinning equipment. The blown air rectifying device comprises the components of a perforated plate, a filtering net, a honeycomb plate and an air uniforming net; wherein the perforated plate, the filtering net, the honeycomb plate and the air uniforming net are successively arranged from bottom to top. A plurality of small holes are uniformly distributed on the perforated plate. The filtering net is clamped between an upper flange and a lower flange and is fixed on the perforated plate. A honeycomb plate frame is arranged outside the honeycomb plate and the air uniforming net. The lower flange is fixedly connected with the honeycomb plate frame. The blown air rectifying device of the chemical fiber spinning equipment is advantageous in that the blown air rectifying device is mounted at the outlet of the air blowing device; uniform air pressure and uniform and stable air speed of outgoing air can be realized; balanced air blowing in cooling spun filament can be ensured; and furthermore uneven wind velocity rate is lower than 10%.

Owner:苏州金纬化纤装备有限公司

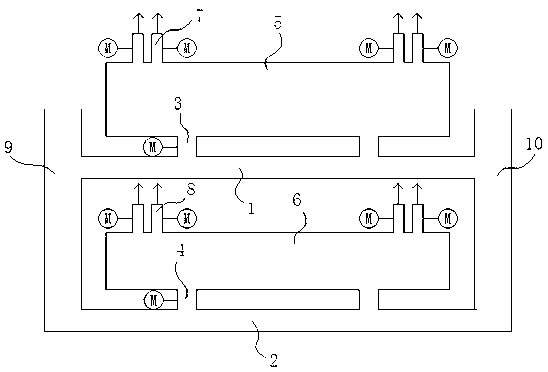

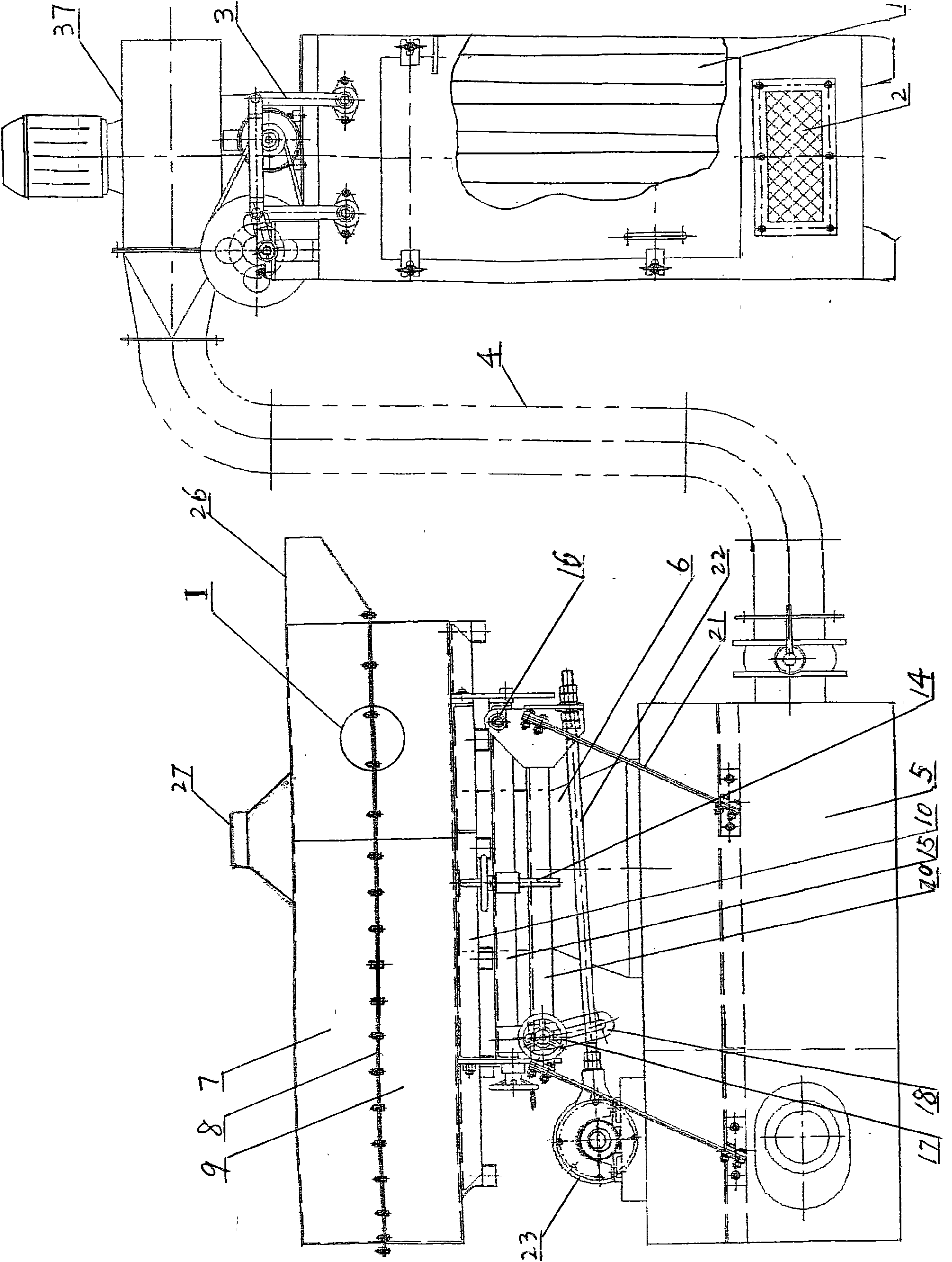

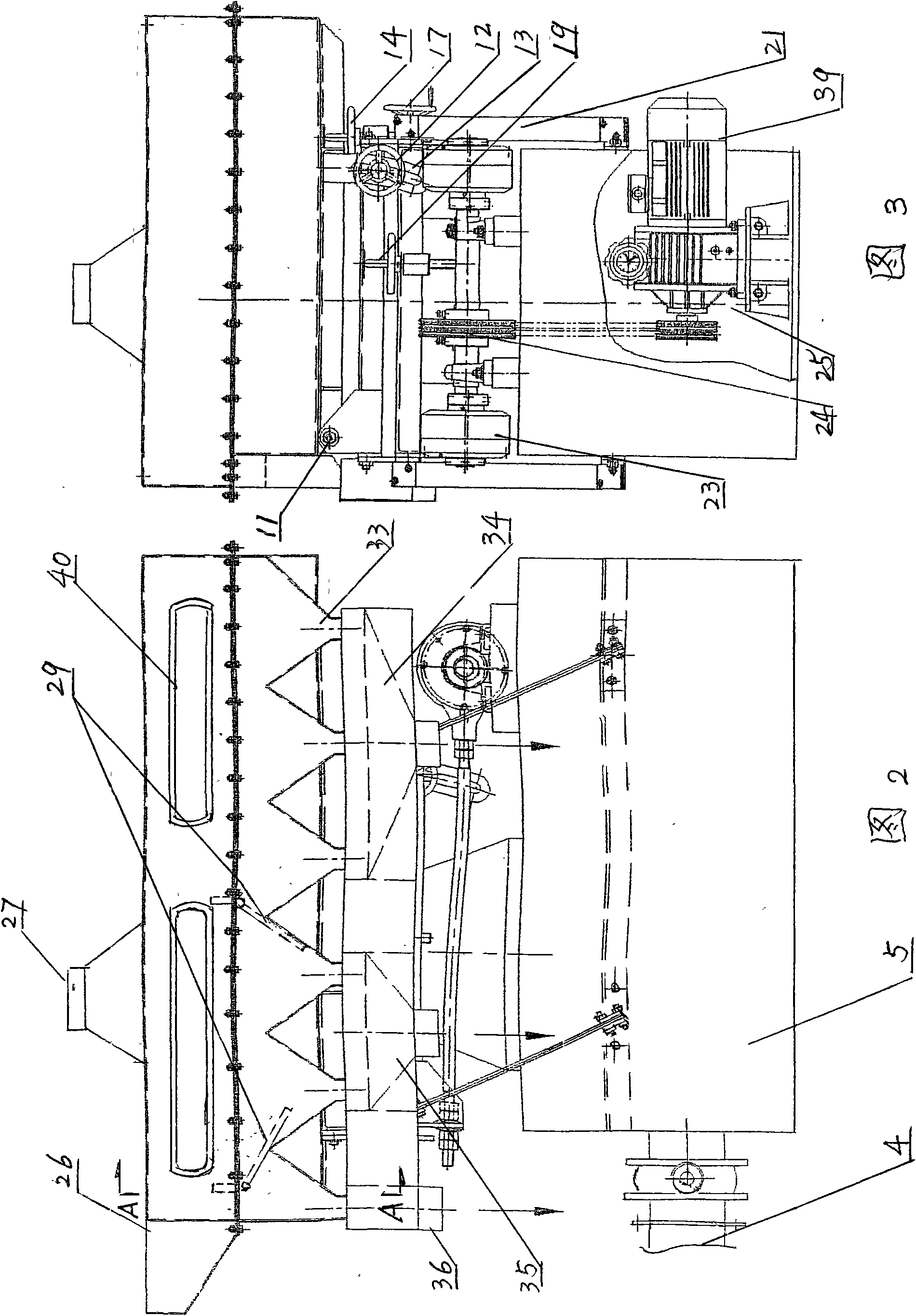

Novel gravity separator

InactiveCN102728552AEasy to sortAvoid cloggingSievingGas current separationAir filterElectric machinery

The invention relates to a novel gravity separator. The novel gravity separator is characterized by comprising a machine frame, wherein an air filter, an air blower and an air box are arranged on an underbed of the machine frame; a vibrating box is arranged on the machine frame; an outlet of the air filter is connected with an inlet of the air blower, and an outlet of the air blower is connected with an inlet of the air box; vibrating motors are respectively arranged in the middle rear positions of the two outer sides of the vibrating box, and an air pressure gauge is arranged in the middle of one outer side of the vibrating box; a box cover is arranged on the vibrating box, and a material inlet is formed on the box cover; a plurality of material outlets are formed at the side face of the vibrating box, and the underside of the vibrating box is connected with an outlet of the air box through a flexible pipe; a gravity separating sieve is arranged in the upper position in the vibrating box; a vibrating sieve is arranged at the front end of the gravity separating sieve; and an air uniformizing plate is arranged below the gravity separating sieve. The novel gravity separator provided by the invention is especially suitable for being used for separating two types of particles with relatively large difference on specific weight from the mixed particles of the two particles under a dry condition and has a good effect.

Owner:杭州太阳铸造工程技术有限公司

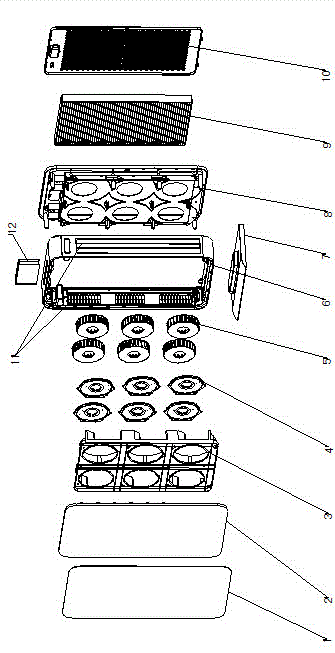

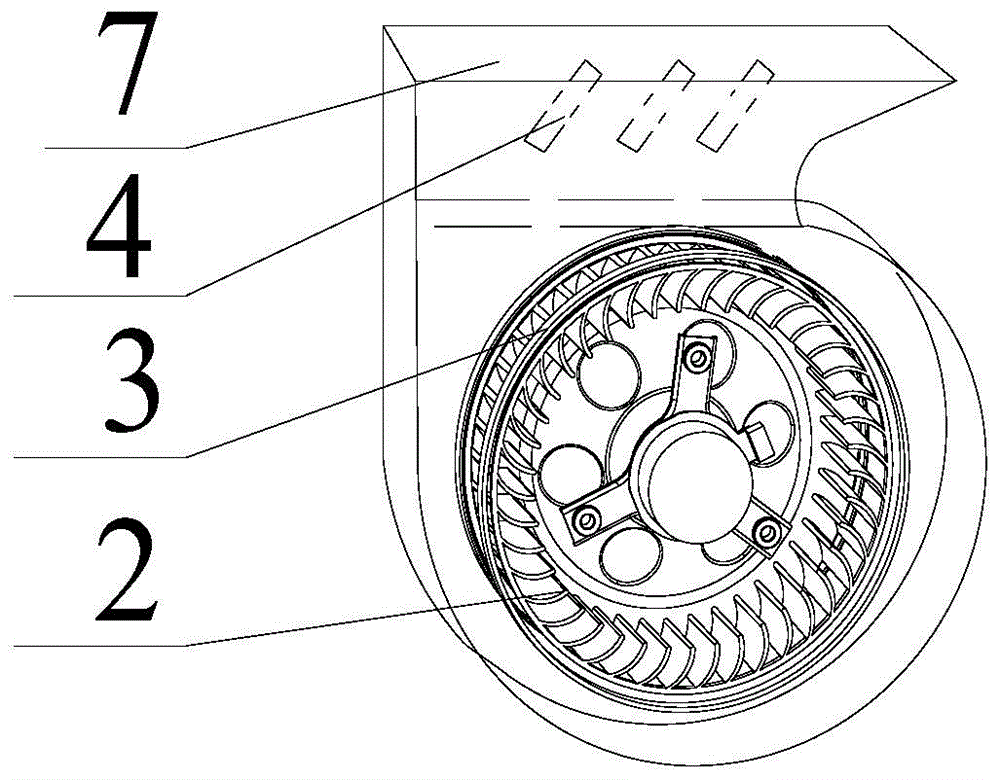

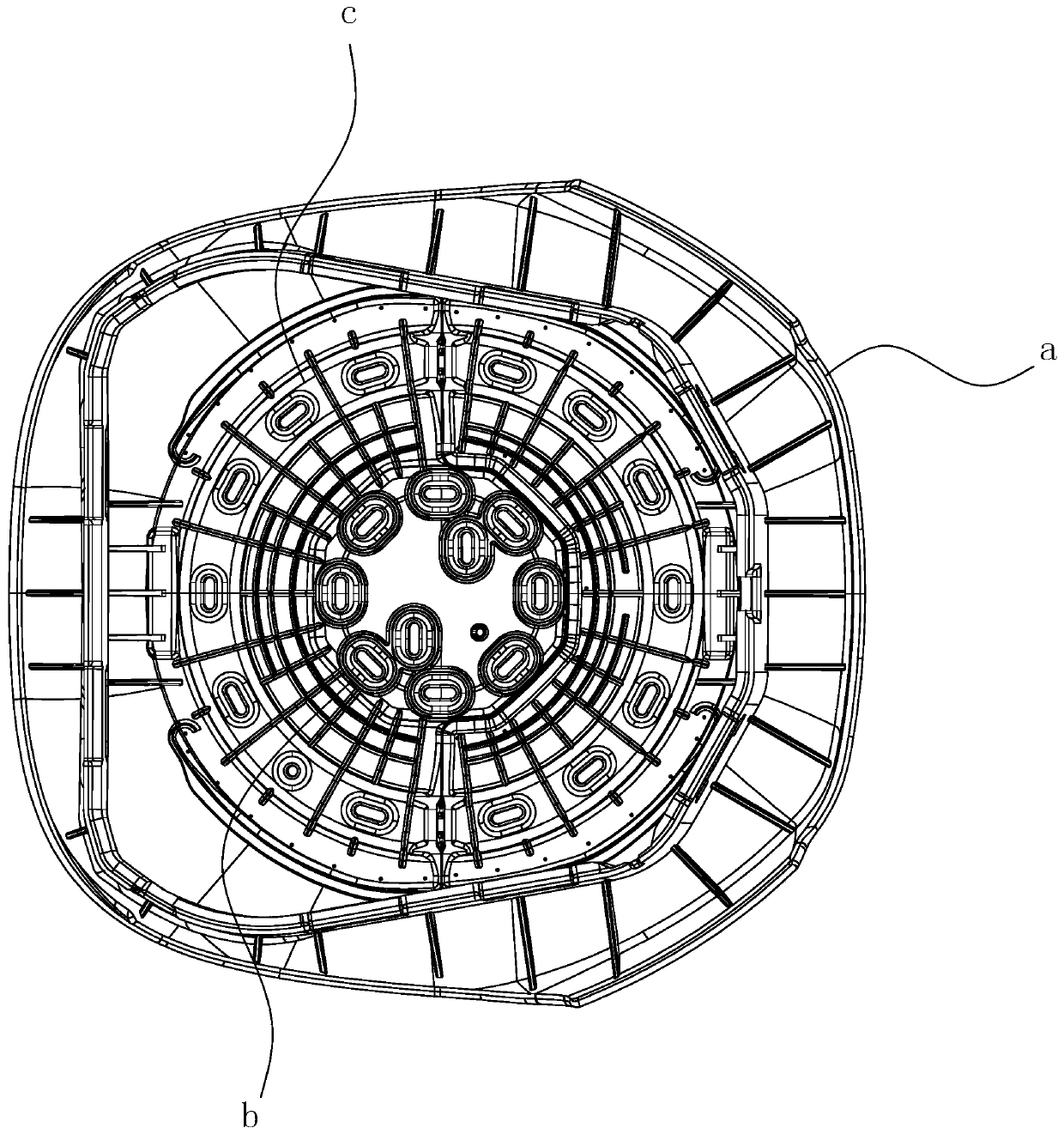

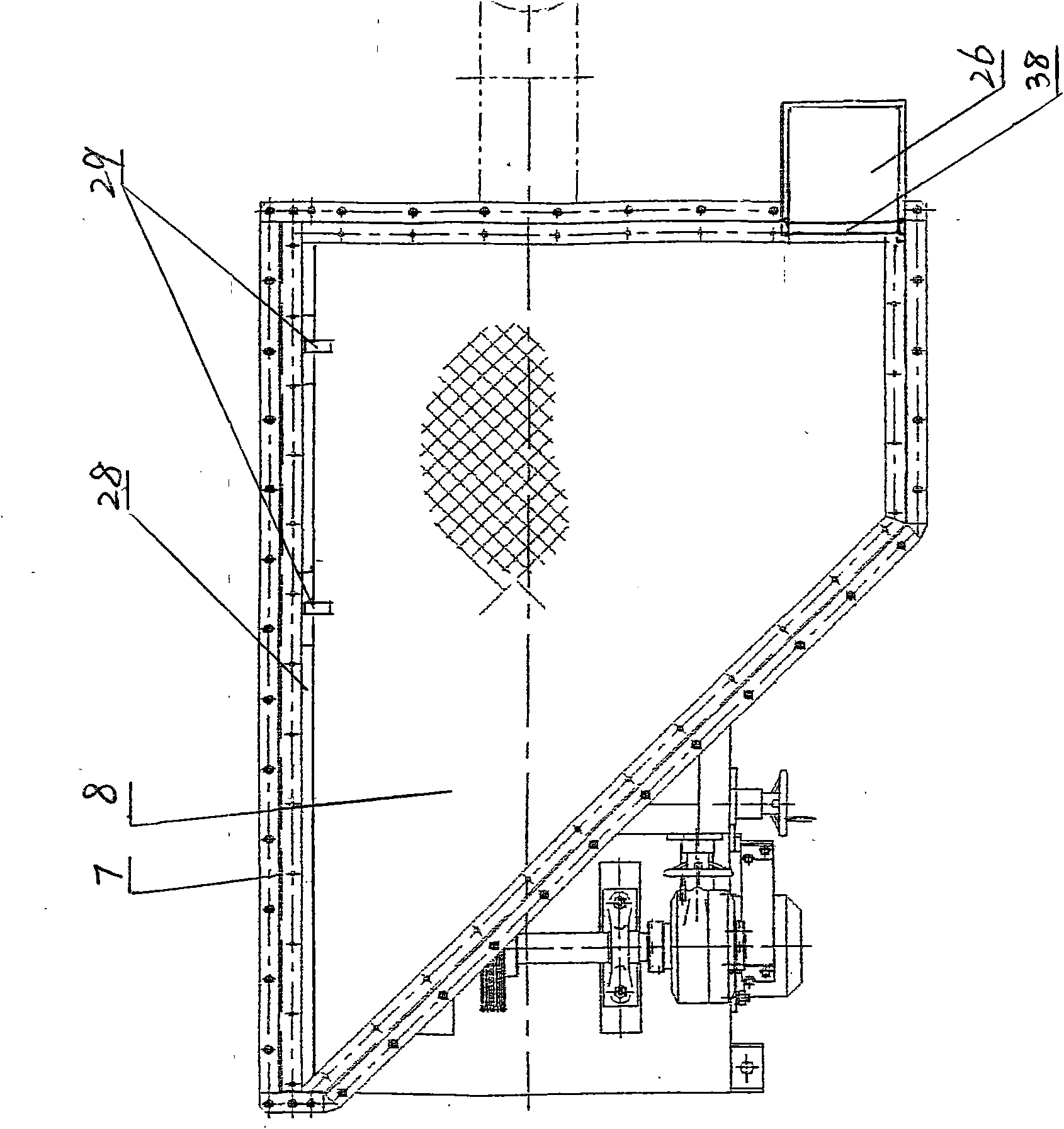

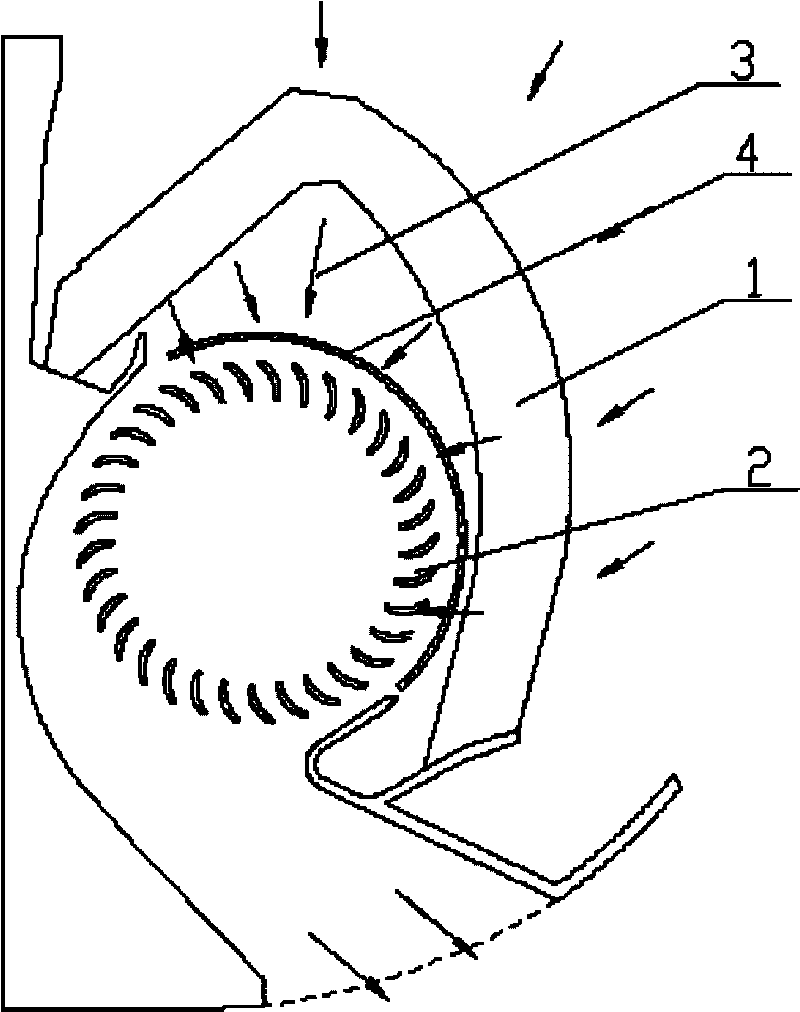

Multi-combination wind wheel air purifying device

ActiveCN103949120AIncrease usageImprove energy efficiencyMechanical apparatusDispersed particle filtrationEngineeringAir purification

The invention discloses a multi-combination wind wheel air purifying device. The multi-combination wind wheel air purifying device comprises a main body (8) and a frame (6) arranged outside the main body (8); two sides of the frame (6) are provided with air exhaust grids (11), and the main body (8) is connected with a wind wheel fixing frame (3); the wind wheel fixing frame (3) is provided with a plurality of wind wheel installation grooves; the wind wheel installation groove or the wind wheel fixing frame (3) is provided with wind wheels (5), and the main body (8) is provided with a plurality of corresponding air inlets; and the frame (6) is provided with a plurality of corresponding air outlets. According to the invention, after the scheme is adopted, the noise and the air pressure which are caused by a single motor can be dispersed by means of the plurality of wind wheels installed on the wind wheel installation grooves, and the motors are dispersed, and the power is dispersed; moreover, by adopting the scheme, because the areas of wind inlets and the wind outlets of the multi-combination wind wheels increase, the energy efficiency increases, the noise decreases, the air pressure is uniform, the filter using rate is improved, and the multi-combination wind wheel air purifying device becomes thin and light.

Owner:FIRMSTARS HOUSEHOLD APPLIANCES SHENZHEN

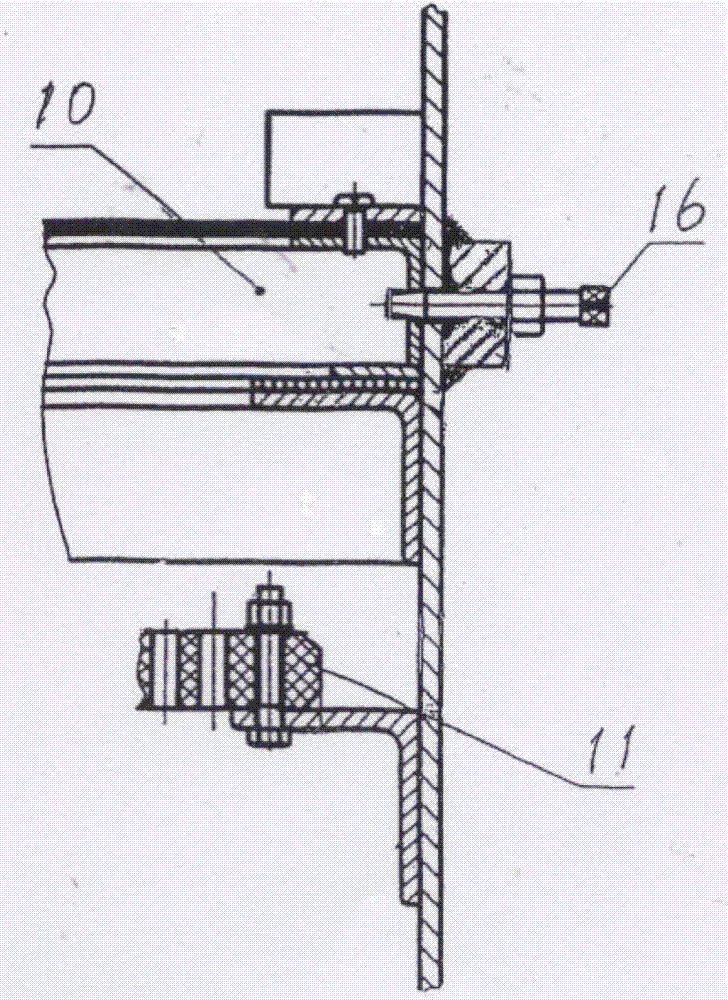

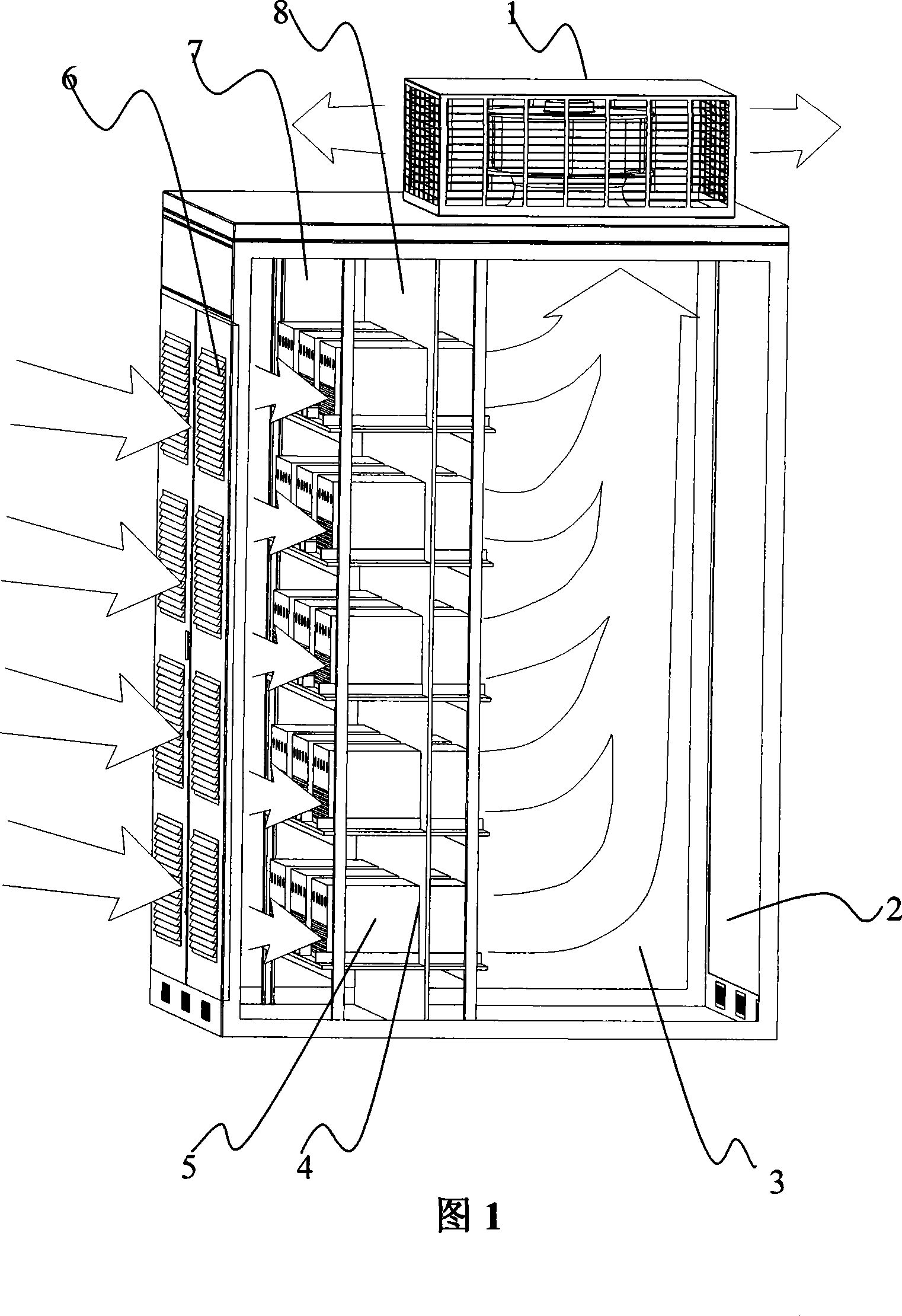

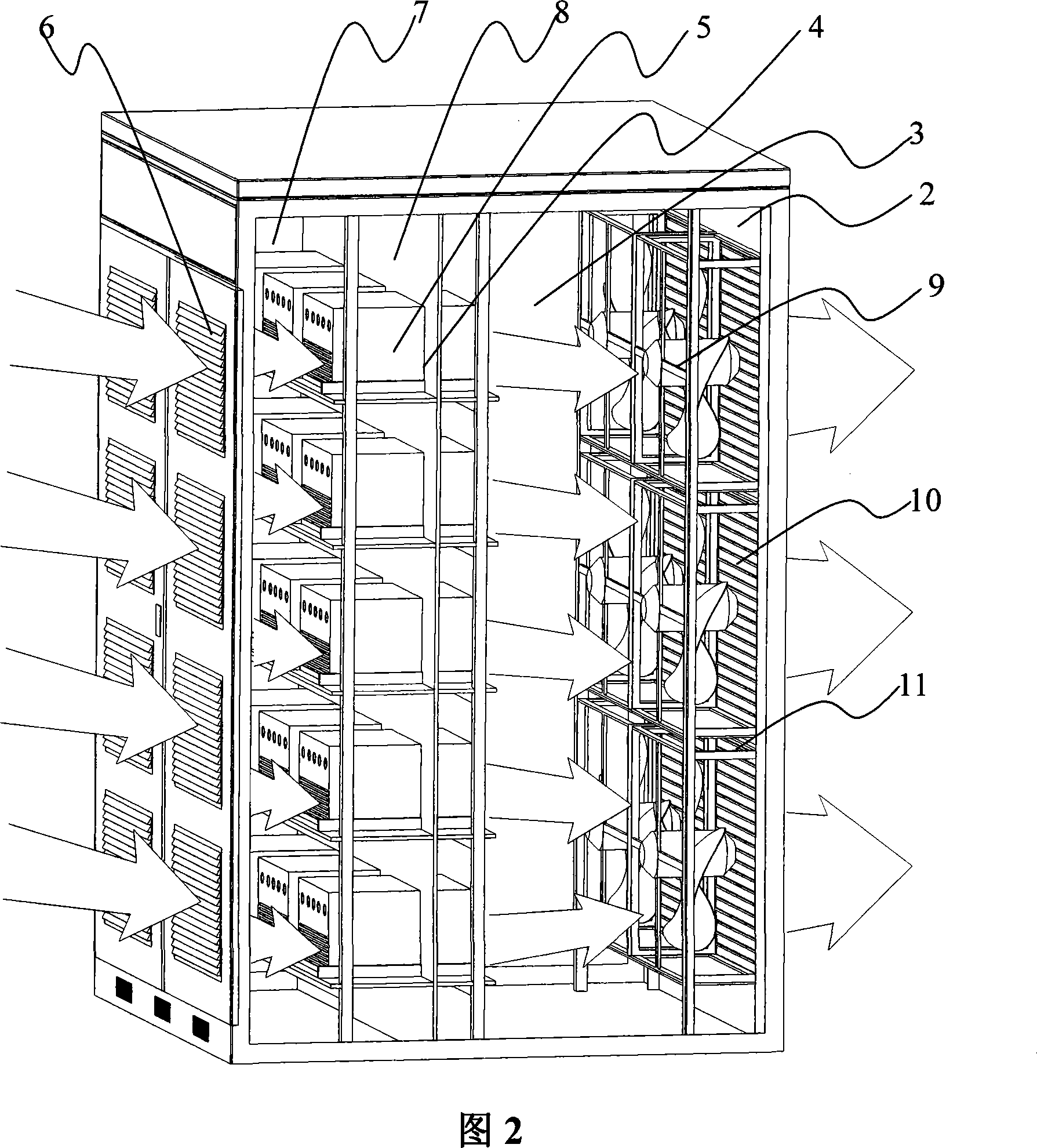

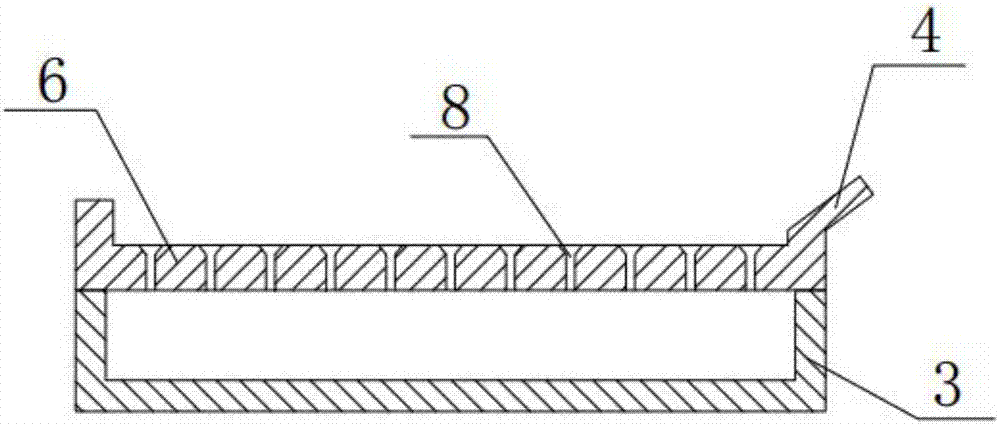

Heat radiation device for middle and high voltage high-power case frequency converter

InactiveCN101145727AIncreased operating lifeImprove cooling efficiencyCooling/ventilation/heating modificationsPower conversion systemsLow noiseLow speed

The invention relates to a heat radiator for middle and high-voltage high-power cabinet frequency converter. The heat radiator comprises a cabinet back plate (2), an air chamber (3) at the back part of the frequency converter, a power unit (5), a plurality of windows for ventilation of the power unit, a front air inlet (6), an air chamber (7) at the front part of the cabinet, an air partitioning plate (8), at least an axial flow blower (9) at the inner side of the cabinet back plate (2), a back air outlet screen (10) on the cabinet back plate (2), and an axial flow blower bracket (11). Compared with the prior art, the invention has the advantages of improved heat radiation efficiency due to a horizontal air duct, good heat radiation effect, low noise, improved reliability due to the shared air chambers, low cost, a blower array composed of a plurality of blower sets, uniform air pressure and airflow, improved service life due to the low-speed blower, reduced noise and mechanical vibration, and wide application range.

Owner:SHANGHAI STEP ELECTRIC

Secondary air box structure of coal-fired W-flame boiler in power station

ActiveCN103225818AAvoid interferenceImprove quality stabilityNon-combustible gases/liquids supplyAir volumePower station

The invention discloses a secondary air box structure of a coal-fired W-flame boiler in a power station. The secondary air box structure comprises an arch-zone secondary air box, an under-arch secondary air box and left and right main air ducts, wherein the arch-zone secondary air box and the under-arch secondary air box are independently arranged on the front and rear walls of the W-flame boiler respectively; the left and right main air ducts are arranged at both ends of the arch-zone secondary air box and the under-arch secondary air box; two arch-zone secondary air inlets and two under-arch secondary air inlets are respectively arranged in one sides of the arch-zone secondary air box and the under-arch secondary air box in the width direction; an arch-zone secondary small air door and an under-arch secondary small air door are respectively arranged on the other sides of the arch-zone secondary air box and the under-arch secondary air box in the width direction; the two arch-zone secondary air inlets of the arch-zone secondary air box are communicated with the left and right main air ducts through an arch-zone air box air inlet duct; and the two under-arch secondary air inlets of the under-arch secondary air box are communicated with the left and right main air ducts through an under-arch air box air inlet duct. The secondary air box structure has the advantages of uniformity in air distribution, stable air pressure and easiness in control.

Owner:HUNAN XIANGDIAN POWER TEST & RES TECH LTD +2

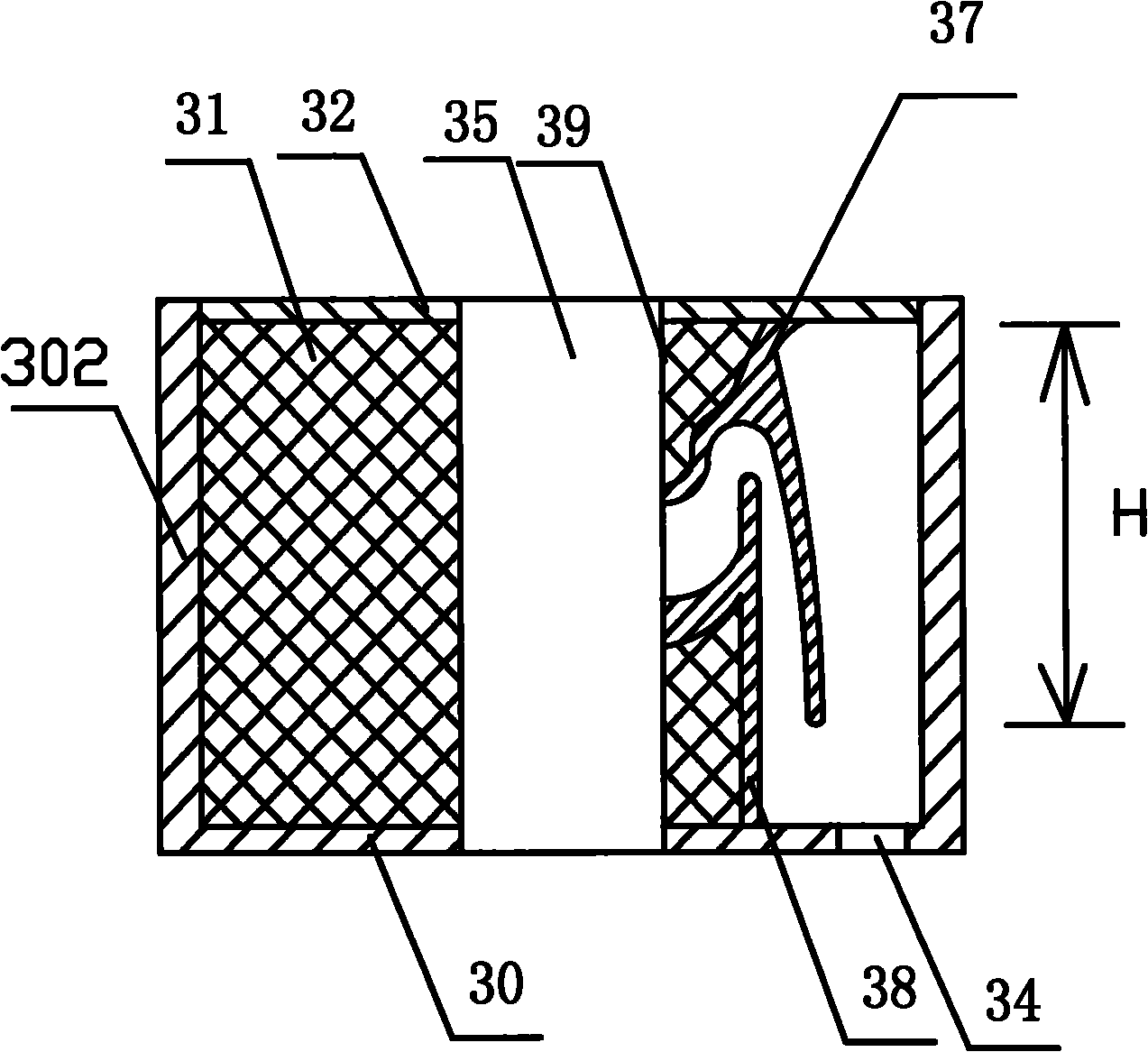

Thick and thin bag production device

The invention relates to a thick and thin bag production device which comprises an extruder, a die connected with a discharge port of the extruder, and a standard air ring and an upper traction roller arranged on the upper end of the die; the upper end of the standard air ring is provided with a mold air ring; a through hole for a film bubble crude embryo to pass through is arranged in the middle of the mold air ring; one side in the mold air ring is provided with a cavity communicated with the through hole; the upper end of the cavity is provided with an upper windshield which extends downwards, and the lower end thereof is provided with a lower windshield which extends upwards; a buffer air duct is formed between the upper and the lower windshields; the mold air ring is provided with an air inlet hole of a connecting air pipe; the air inlet hole and the cavity are communicated; and the gas enters the cavity through the air inlet hole, and is blown to the film bubble crude embryo in the through hole from the buffer air duct. The mold air ring is used to control the thickness of a side wall of a film bubble, the air outlet of the air pipe is not arranged directly to one side of the film bubble crude embryo but is blown to the film bubble crude embryo through the buffer air duct, so that the thickness of the thin side and the thick side of a produced thick and thin bag is uniform, and the strength is good.

Owner:NANTONG HUASHENG PLASTIC PRODS

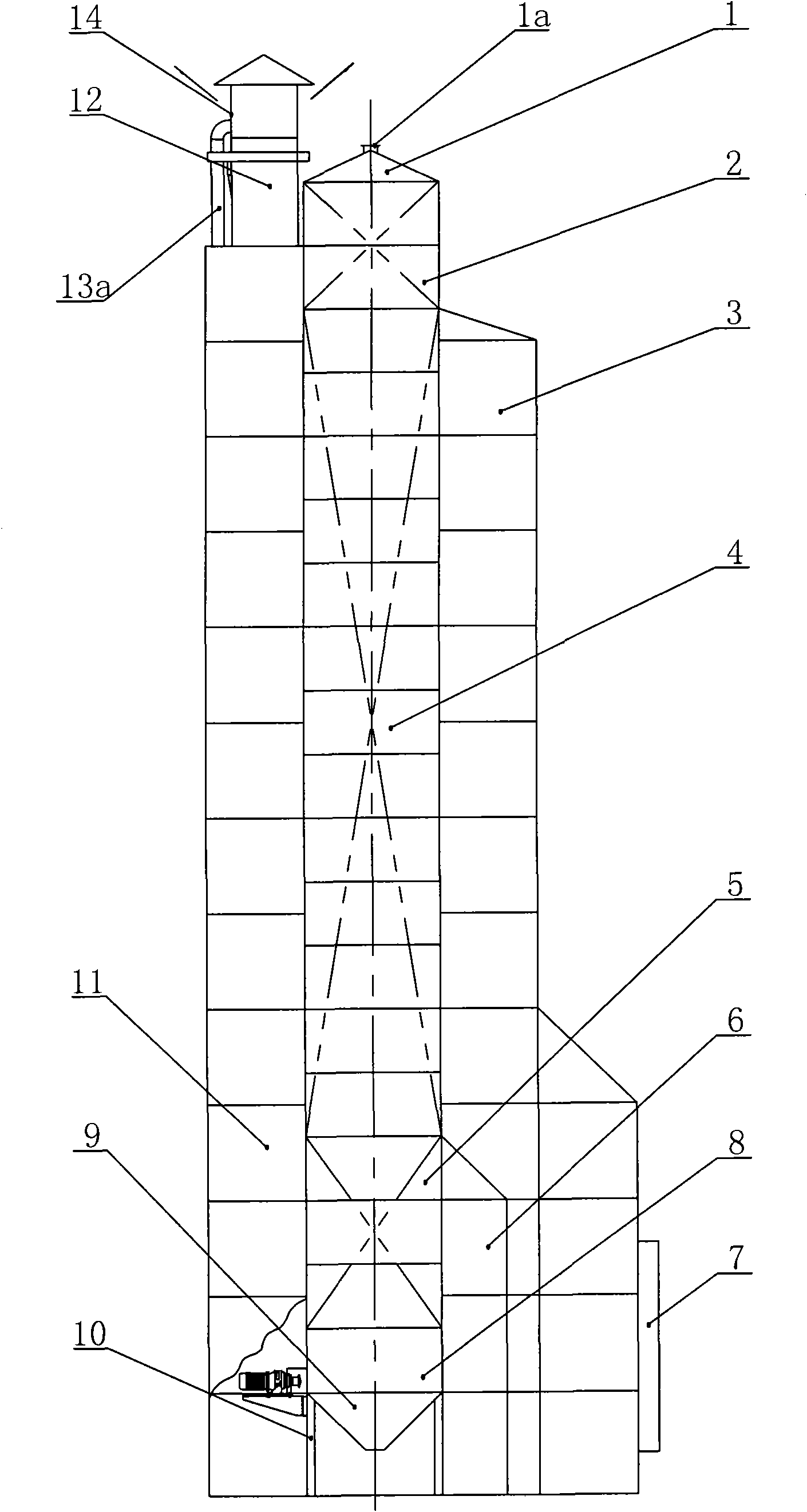

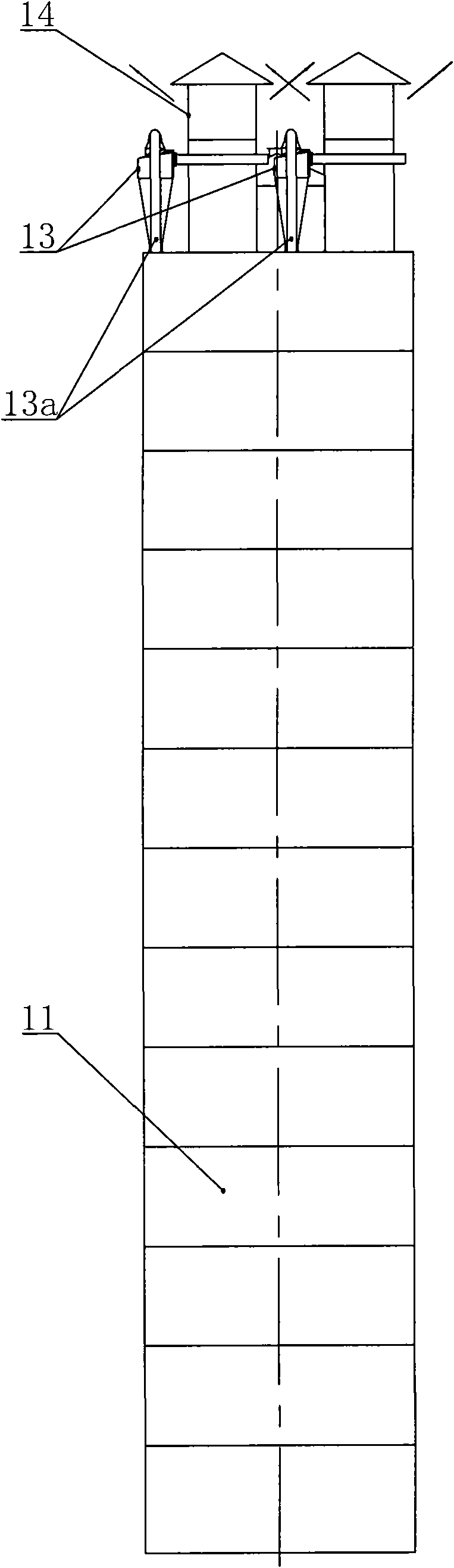

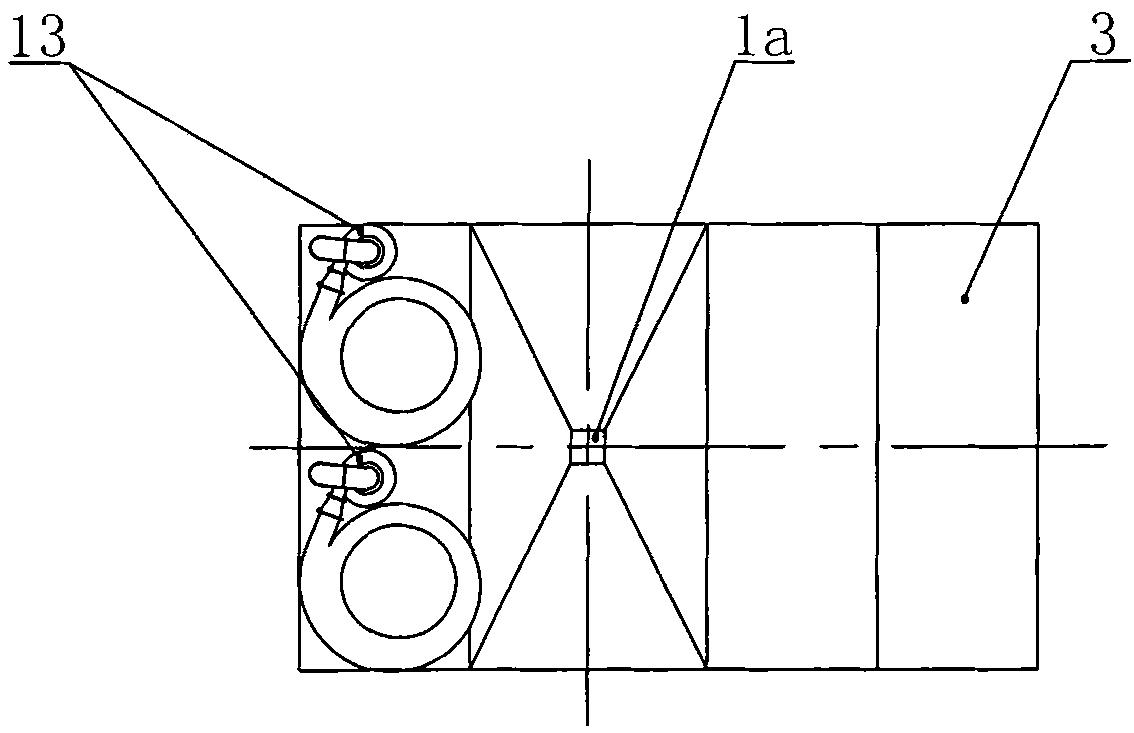

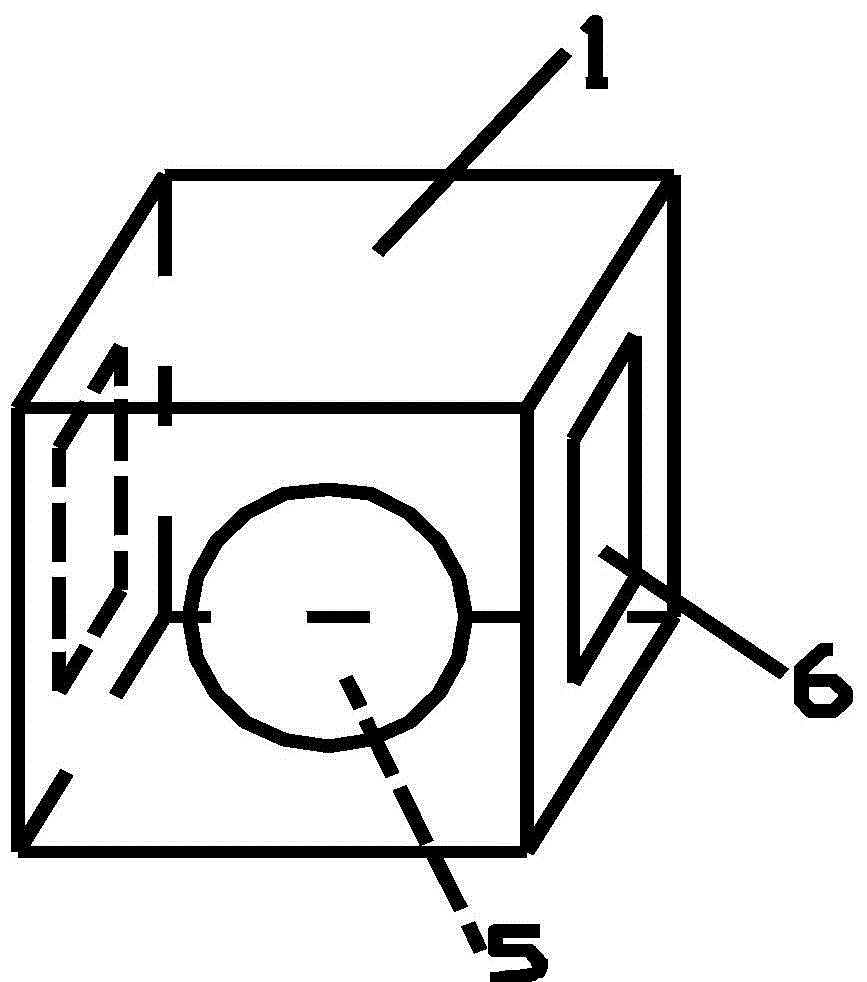

Isobaric grain-drying tower

InactiveCN101911969ASmall sizeCompact and beautiful appearanceSeed preservation by dryingElectric machineryExhaust gas

The invention discloses an isobaric grain-drying tower, belonging to the field of grain machinery. The tower body comprises a grain feeding layer, a grain storing layer, a drying bin, a cooling bin and a grain discharging layer which are laminated sequentially from top to bottom, wherein one side of the tower body is provided with a hot wind channel and a cold wind channel which are respectively as equal wide as the tower body; the other side of the tower body is provided with an exhaust gas channel as equal wide as the tower body; the cold wind channel is arranged at the inner side the hot wind channel; the lower end of the cold wind channel is provided with an atmosphere inlet; the upper side of the cold wind channel is provided with a cold wind outlet of the cold wind channel; the cold wind outlet of the cold wind channel is abutted with a cold wind inlet of the cooling bin; the lower end of the hot wind channel is provided with a hot wind inlet of a heat source; the upper end side of the hot wind channel is provided with a hot wind outlet of the hot wind channel; the hot wind outlet of the hot wind channel is abutted with the hot wind inlet of the drying bin; the cold wind outlet of the cooling bin and the hot wind outlet of the drying bin is respectively abutted with an exhaust gas channel; and the upper end of the exhaust gas channel is provided with an exhaust fan and an ash separating and discharging system. The wind resistance and the motor power consumption of the drying tower are small, and the wind quantity and the wind pressure of the hot wind or the cold wind are uniform, therefore, the quality of the dried grains is excellent.

Owner:JIANGSU MUYANG GRP CO LTD

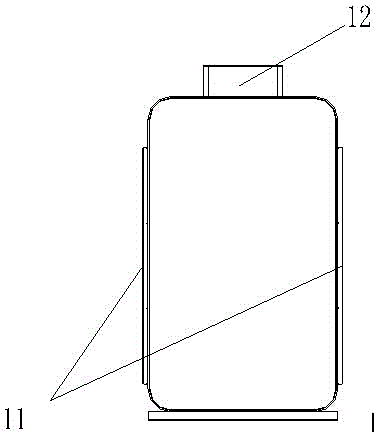

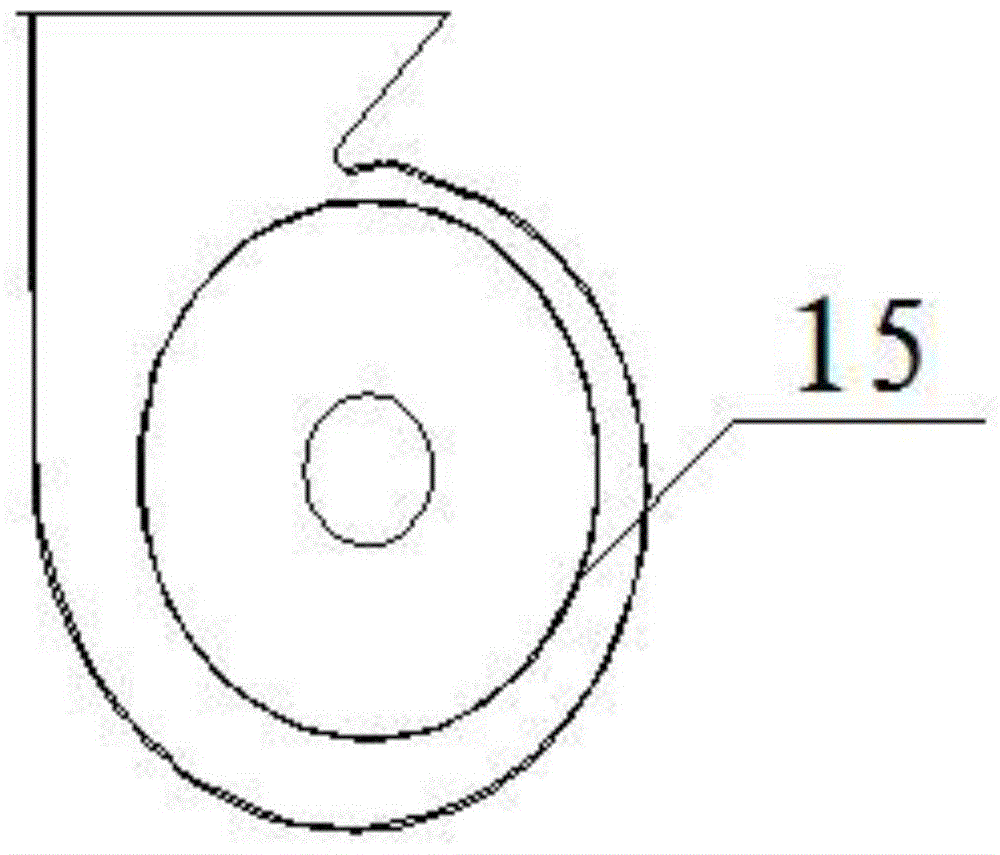

Wall-hanging air purifier

InactiveCN105107299AImprove performanceAvoid backflow phenomenonCombination devicesDispersed particle filtrationImpellerAir filter

The invention relates to a wall-hanging air purifier. The wall-hanging air purifier comprises a purifier shell with an air purifying apparatus inside, wherein an air inlet is formed in a front panel of the shell, air outlets are formed in two side walls of the shell, the purifying apparatus comprises two fans, air outlets of the two fans are respectively communicated with the air outlets in the two side walls of the shell, air inlets of the two fans are respectively communicated with an outlet of an air filter, an inlet of the air filter is communicated with the air inlet in the front panel of the shell, each fan comprises an impeller shell and an impeller which is arranged in an inner cavity of the impeller shell and fixed on an impeller shaft, the impeller shaft is connected with a driving apparatus. A key point of the invention is that a gap between the impeller shell and the impeller forms a ventilation air duct, an air protection ring 15 which is coaxial with the impeller is arranged on the impeller shell inner wall, adjacent to a peripheral ring of the impeller, of the ventilation air duct, and the diameter of an air stop annular plate is 6 to 10mm greater than that of the impeller. The wall-hanging air purifier is small in air resistance, smooth in air discharging, high in working efficiency, good in performance, capable of greatly lowering the noise, high in air outlet efficiency and capable of greatly improving the performance.

Owner:北京卫家环境技术有限公司

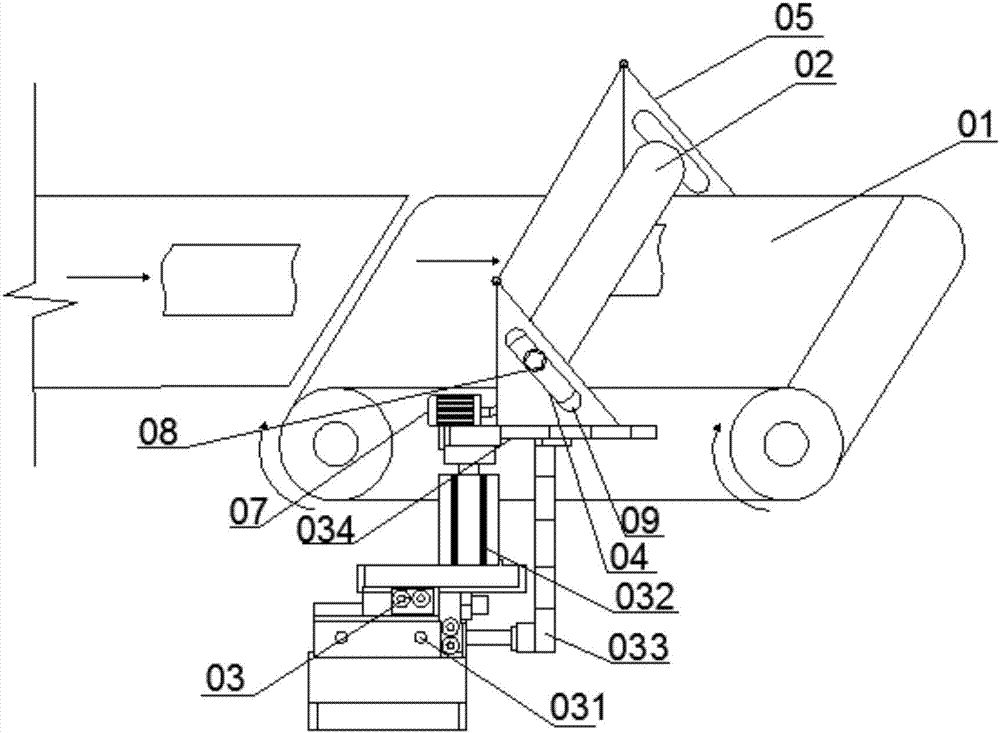

Four-station turntable type hot air welding machine and welding method thereof

The invention belongs to the technical field of automobile part processing, and particularly relates to a four-station turntable type hot air welding machine and a welding method thereof. The four-station turntable type hot air welding machine comprises a machine frame with a working table board, and a turntable assembly, a hot air assembly and a riveting assembly which are arranged at the side ofthe turntable assembly are arranged at the machine frame. The four-station turntable type hot air welding machine has the advantages that automatic welding operation of a company mark and a company mark ring at a safety air bag cover can be realized, and the operation threshold is low, time and labor are saved in the welding process, and no harm is caused to workers in the welding process, and the welding quality of the company mark and the company mark ring can be effectively guaranteed. The welding method applying the four-station turntable type hot air welding machine comprises the following steps of 1) a pre-processing process; 2) a code scanning process; 3) a hot air process; 4) a riveting process; and 5) a shooting and discharging process. The welding method has the advantages thatthat the actual processing efficiency of the welding process is systematically improved.

Owner:明光利拓智能科技有限公司

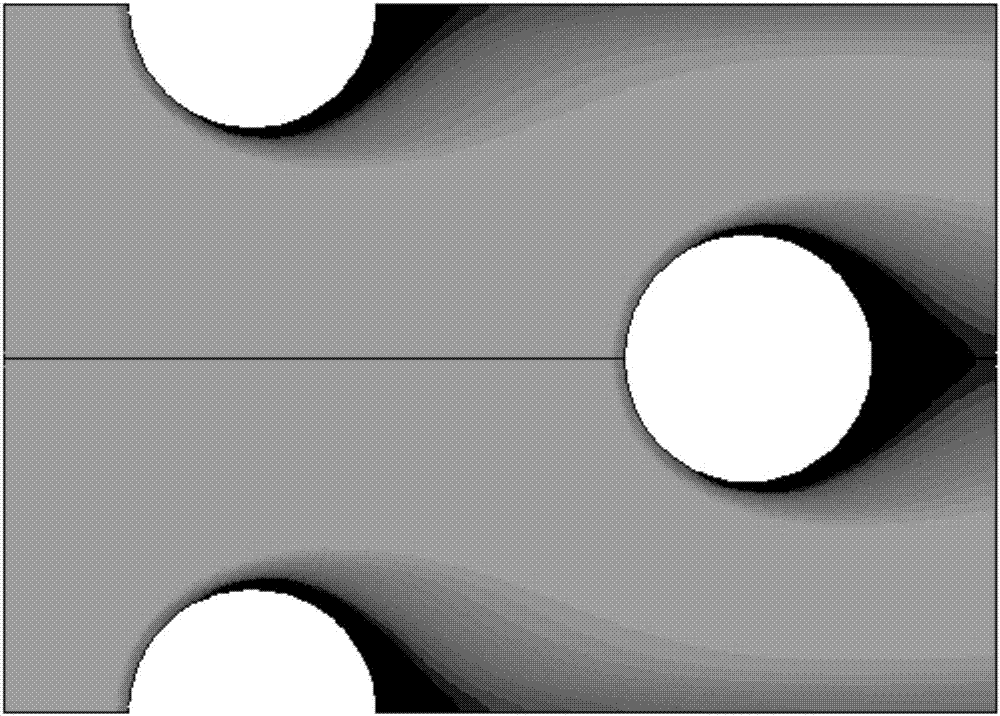

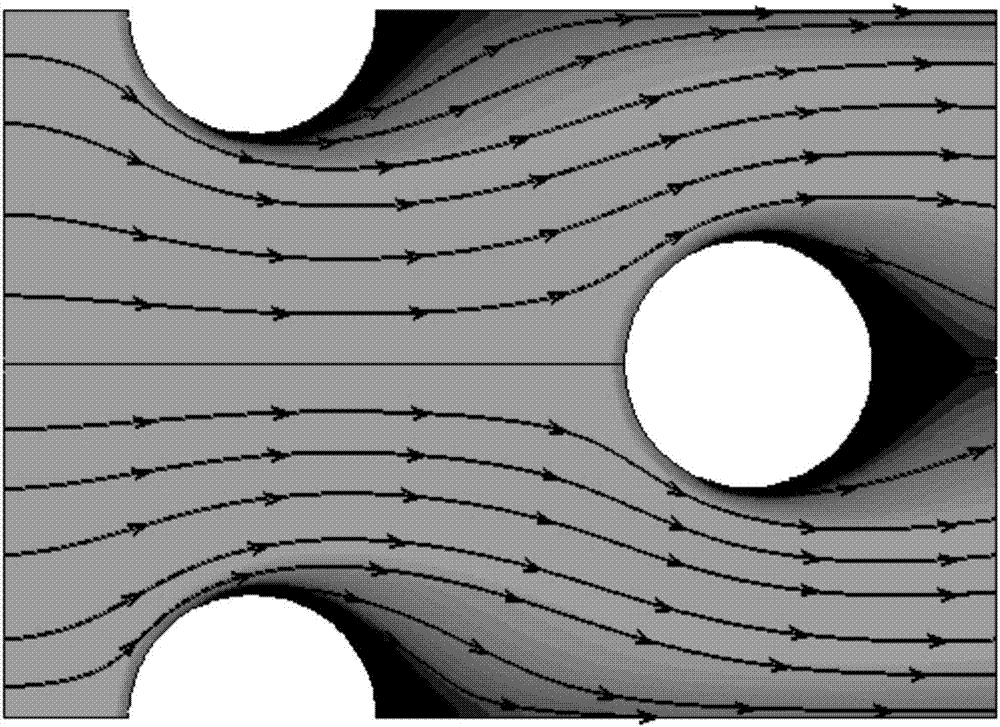

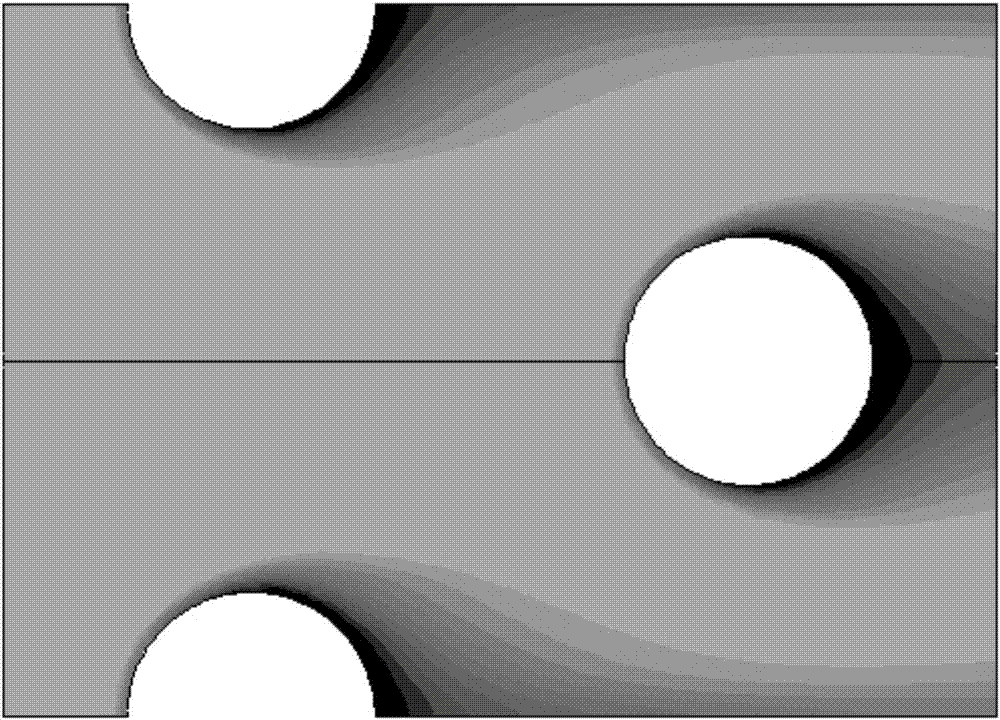

Heat exchange device and air-conditioning equipment

InactiveCN108006941AGuaranteed heat transfer efficiencyFull play of heat exchange effectLighting and heating apparatusSpace heating and ventilation detailsBusiness efficiencyBlind zone

The invention provides a heat exchange device and air-conditioning equipment. The heat exchange device comprises at least two subsidiary heat exchangers arranged in the wind direction; each subsidiaryheat exchanger comprises at least one row of refrigerant pipes and fins mounted on the refrigerant pipes in a sleeving manner; and the transverse pipe center distance of the refrigerant pipes betweenany two adjacent subsidiary heat exchangers ranges from 8 mm to 35 mm. According to the heat exchange device provided in the scheme, an air flow can extend fully and smoothly when flowing among the refrigerant pipes of the adjacent subsidiary heat exchangers, air flow blind zones and weak wind zones on the leeward sides of the refrigerant pipes can be reduced, all the refrigerant pipes in the subsidiary heat exchangers in the upstream and downstream positions of the wind direction can make full contact with the air flow, the problem that the refrigerant pipes in the subsidiary heat exchangersin the downstream position of the wind direction cannot exchange heat effectively due to the fact that the refrigerant pipes are located in the air flow blind zones or the weak wind zones is avoided,the problem that the wind force on the subsidiary heat exchangers in the downstream position of the wind direction is greatly reduced due to the excessively large transverse pipe center distances ofthe refrigerant pipes between among any subsidiary heat exchangers can also be avoided with the design, and the overall energy efficiency ratio of the air-conditioning equipment is increased.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Central air-conditioning air flue with slit valve

InactiveCN105020869AOptimize layoutFlexible layoutDucting arrangementsAir-flow control membersPorositySEMI-CIRCLE

The invention relates to a central air-conditioning air flue with a slit valve. The air flue is provided with an air flue body and 3-5 air outlets; and the air outlets are square, the side length of the air outlets is a, the air outlets are formed on a base plate of the air flue, and the cross section of the air flue body is rectangular. The central air-conditioning air flue is characterized in that an air guide passage installed in a manner of being closely attached to the base plate of the air flue body is arranged inside each air outlet, and each air guide passage is divided into an air inlet, a passage body and an air outlet flow guide section, wherein each air inlet faces the direction of an air source, and the air inlets and the passage bodies are in shapes of arches with same semi-circle cross sections. The passage bodies are connected with the air outlets through the air outlet flow guide sections in an arc-shaped smoothing manner, the distances between the sides, close to the outer airs, of the edges of projections of the passage bodies on the base plate of the air flue body and the lateral edges of the air outlets range from 0.1 a to 0.2 a, the length of the passage bodies ranges from 1 a to 2 a, and the length of the air inlets ranges from 0.5 a to 0.8 a; one-way valves opening inwards are arranged at inlets of the air inlets, the valves are opened and closed through torsion springs, slit-shaped holes are arranged on the valves, and the slit directions of the slit-shaped holes are parallel to the base plate of the air flue body; and the door plank porosity of the valve closest to the air source ranges from 55% to 60%, the door plank porosities of the valves are decreased along with increase of the distances between the valves and the air source, and the lowest door plank porosity is 20%.

Owner:TIANJIN YAZHAO TECH DEV

Protection device for online infrared temperature measuring instrument during rare earth pyrometallurgical process

The invention relates to a protection device for an online infrared temperature measuring instrument during the rare earth pyrometallurgical process. The protection device comprises a protection outer shell, a filtering part and a rectification part, wherein the protection outer shell is made of an electromagnetic shielding material, and air inlet holes are formed in the side surface; the filtering part is an assembly for filtering fluoride and dust, is arranged in the protection outer shell and covers an outer shell of the infrared temperature measuring instrument; one end of the rectification part is in sealed connection with the protection outer shell, and a probe end of the infrared temperature measuring instrument is arranged inside the rectification part; a space between the filtering part and the infrared temperature measuring instrument is communicated with the interior of the rectification part; and the other end of the rectification part is provide with a protective gas outlet. The protection device effectively eliminates the influence of environmental factors such as high temperature, dust, corrosive atmosphere and strong electromagnetic field on the infrared temperature measuring instrument, and ensures the long-term and stable operation of the infrared temperature measuring instrument.

Owner:北京三博中自科技有限公司 +2

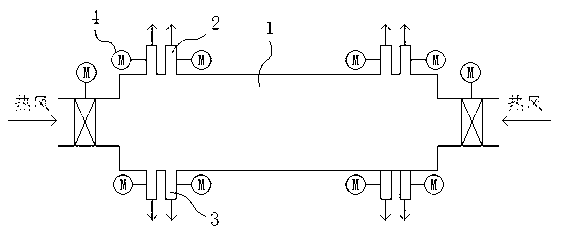

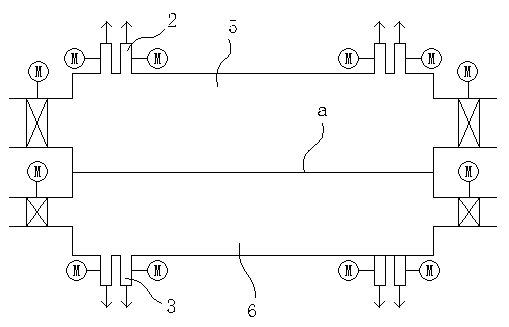

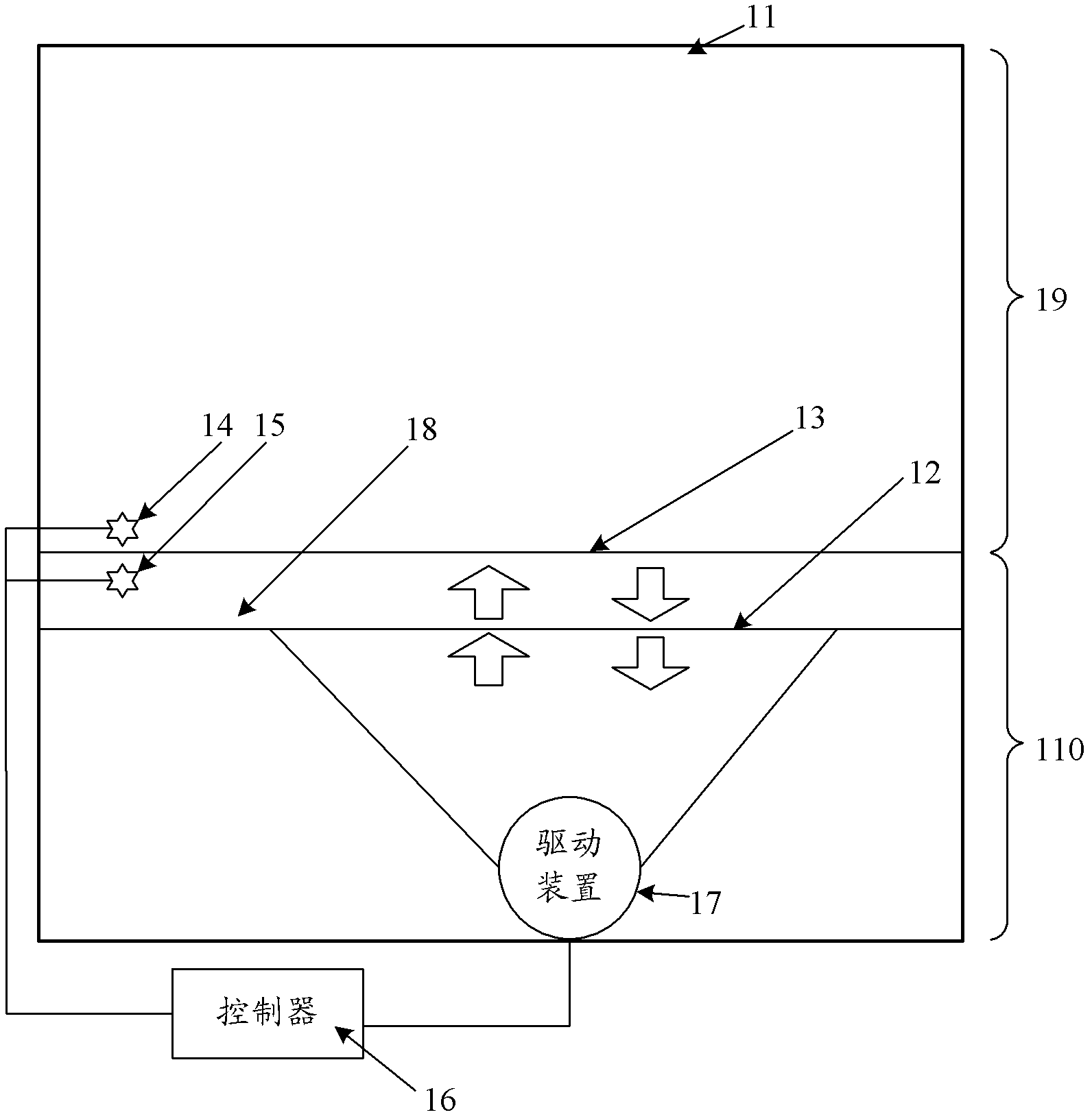

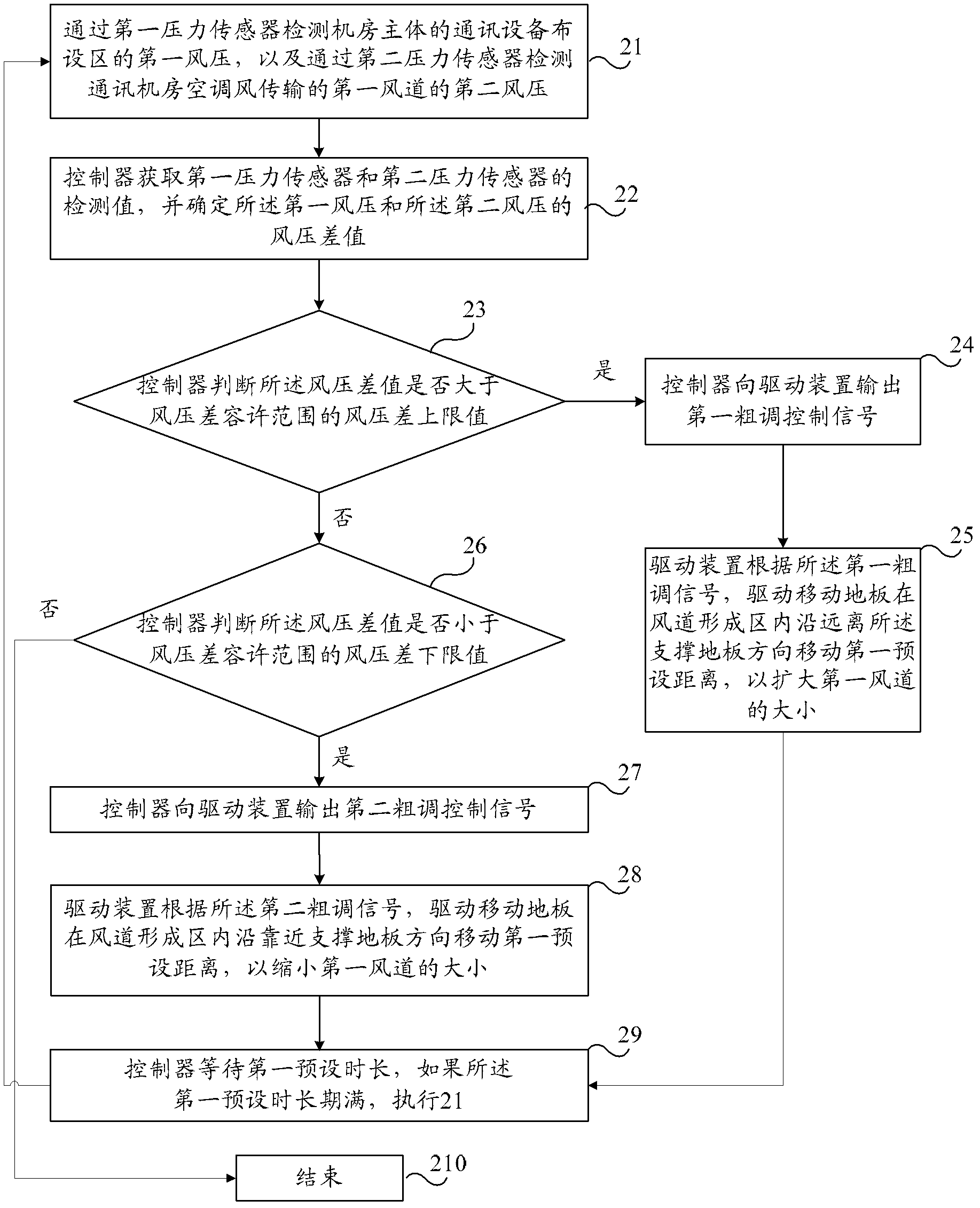

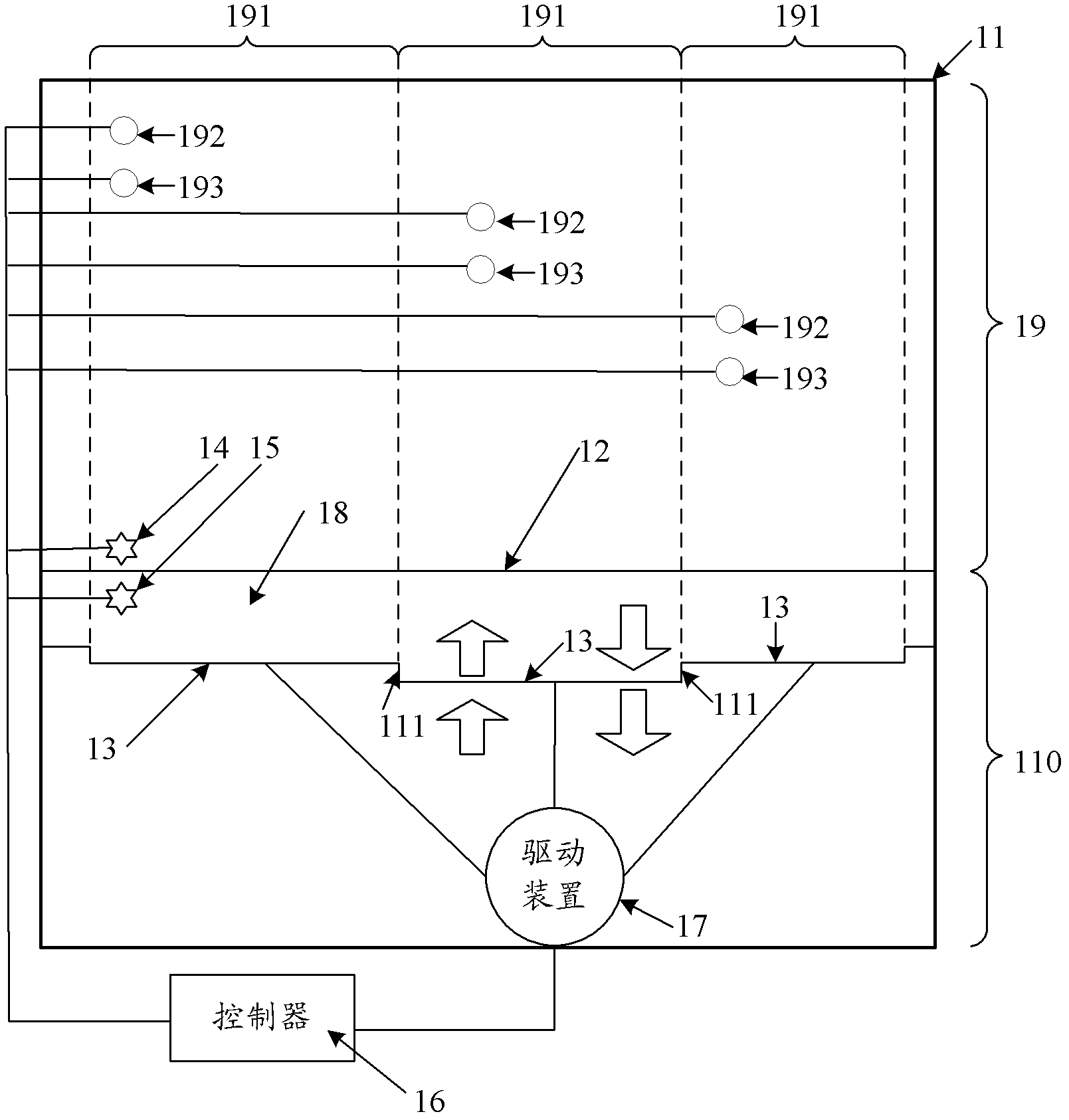

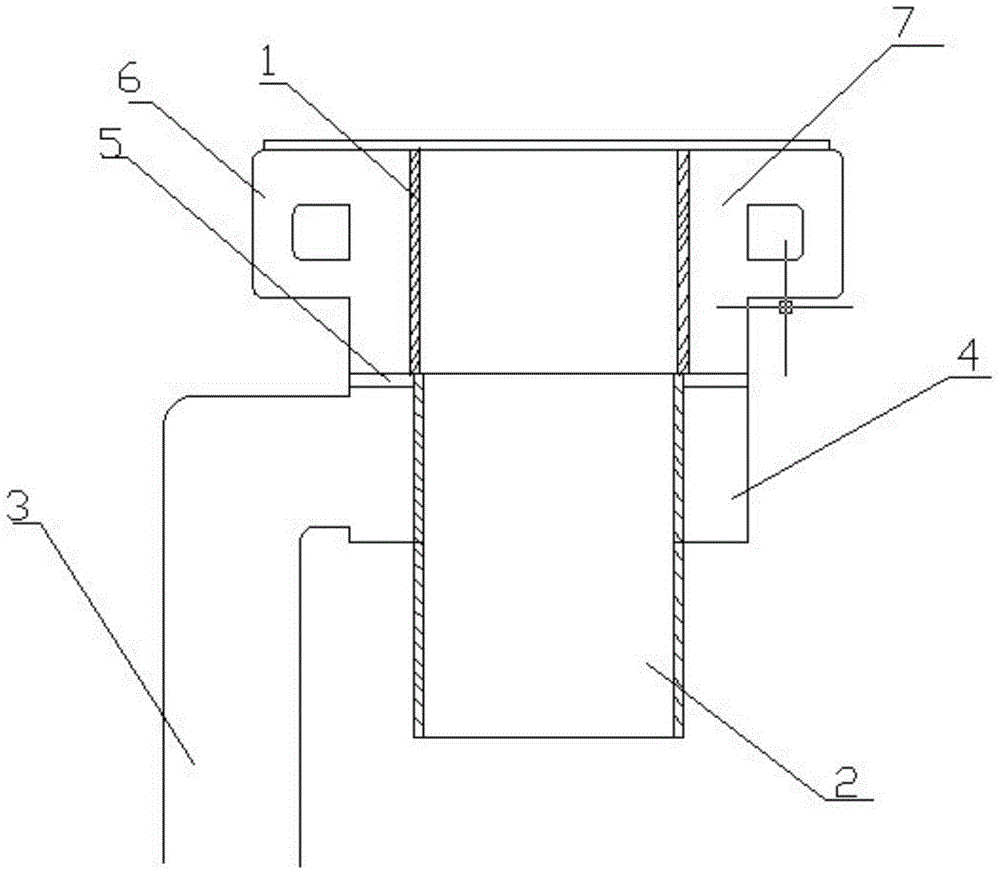

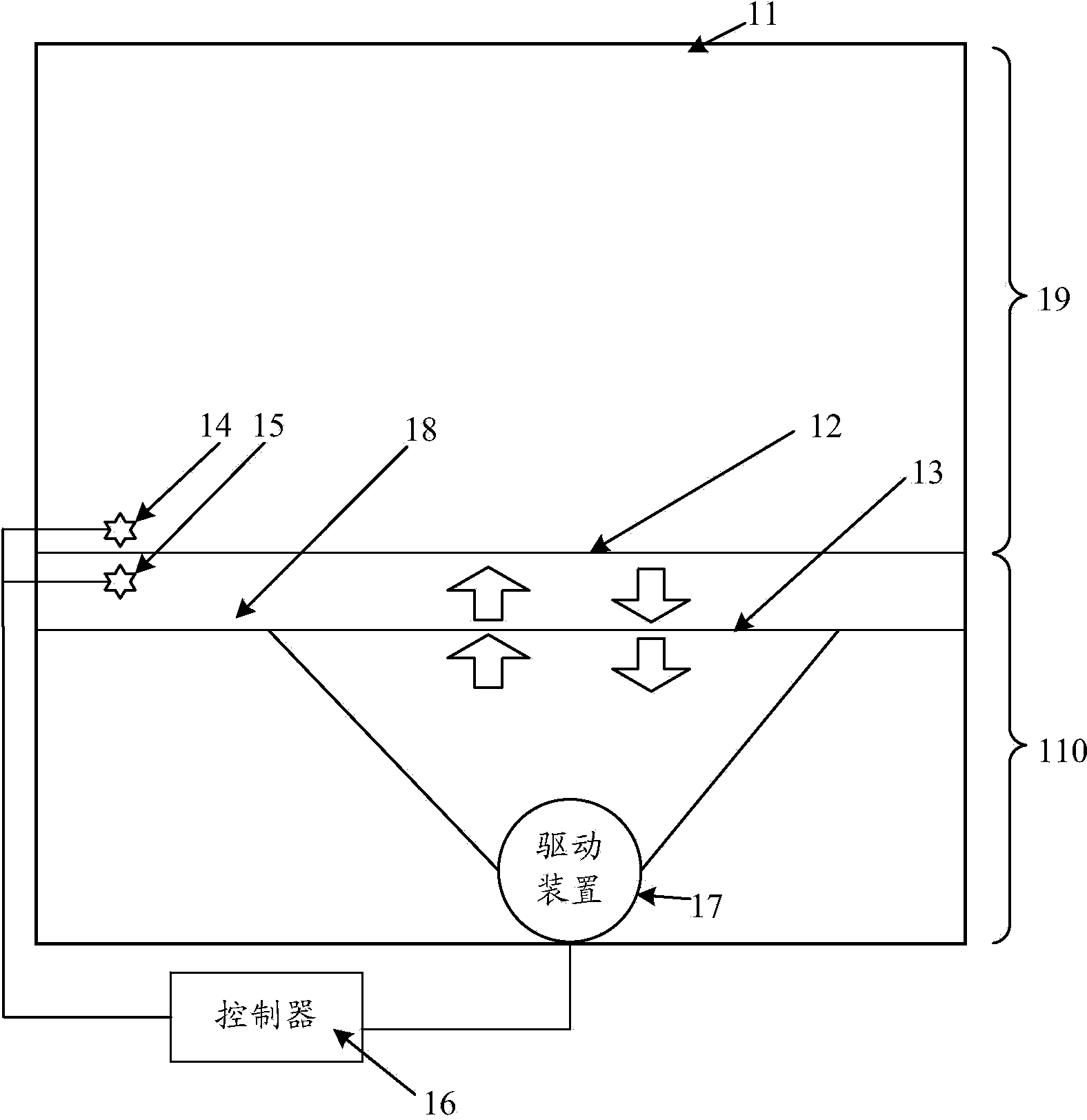

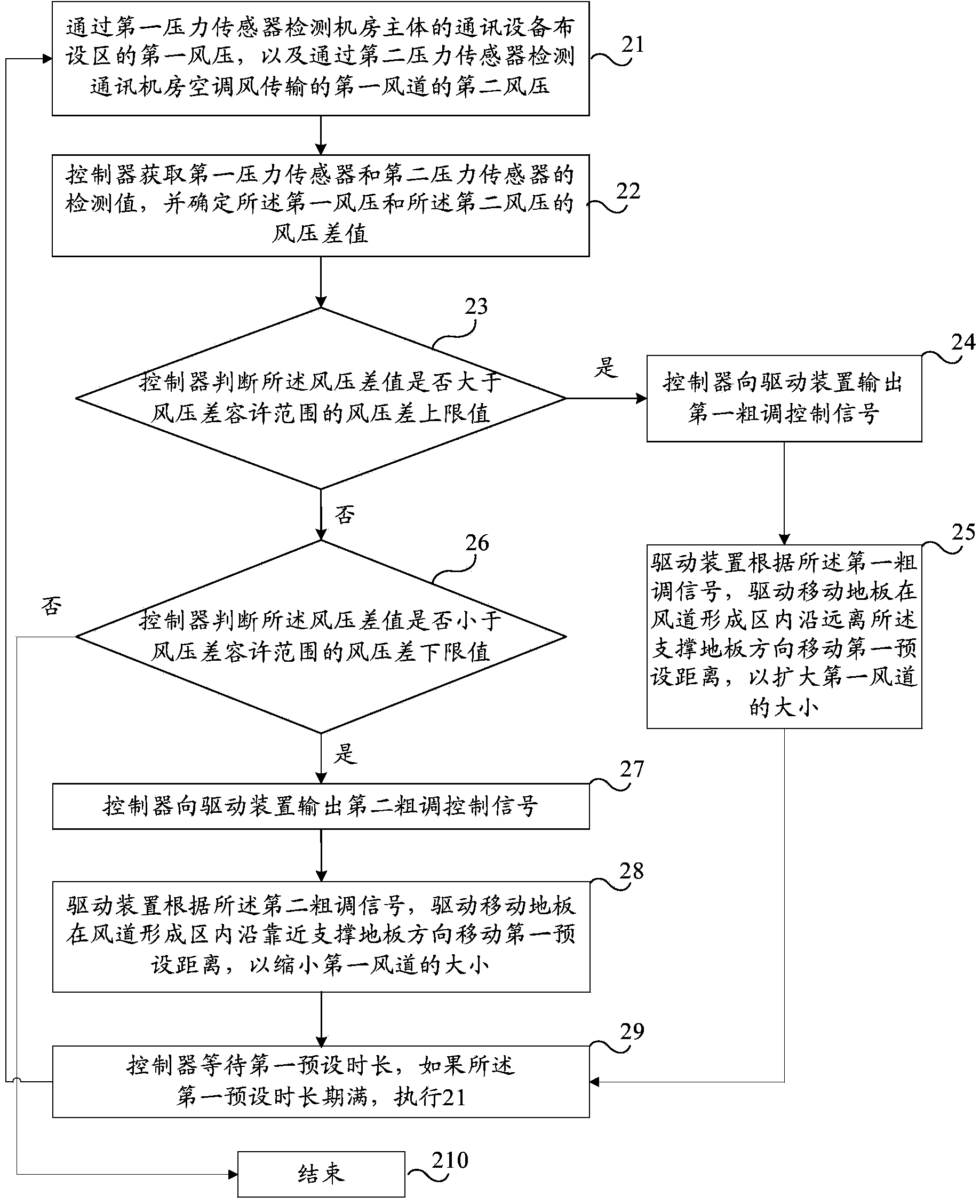

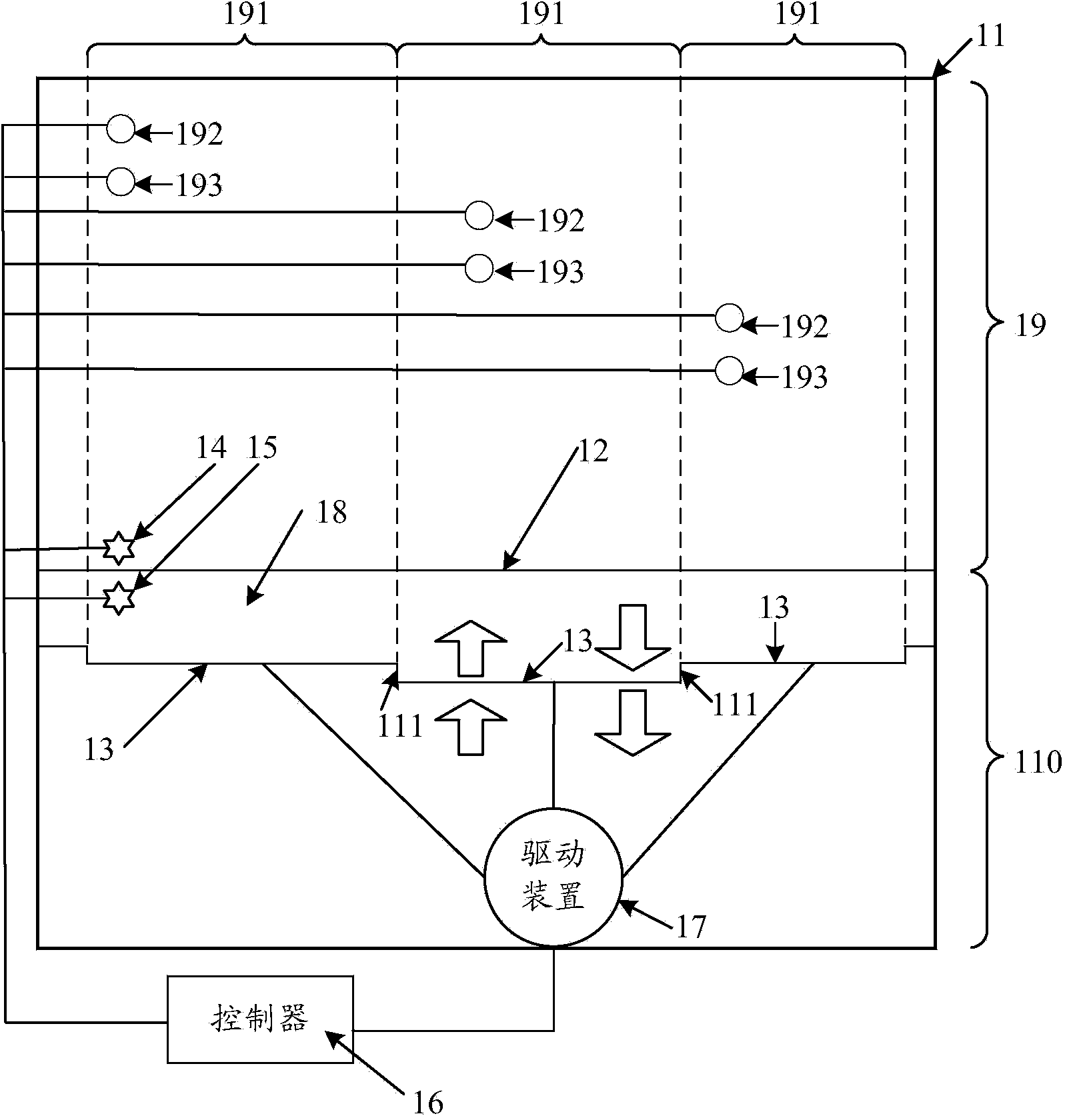

Communication equipment room and air flue regulation method thereof

ActiveCN103161328AImprove cooling effectAdjustable sizeSpace heating and ventilation safety systemsLighting and heating apparatusControl signalEngineering

The invention discloses a communication equipment room and an air flue regulation method thereof. The communication equipment room comprises an equipment room body, a supporting plate which divides the equipment room body vertically into a communication equipment arrangement area and an air flue forming area, a mobile plate which is located in the air flue forming area, an air flue, a first pressure sensor which is arranged in the communication equipment arrangement area and used for detecting first wind pressure in the communication equipment arrangement area, a second pressure sensor which is arranged in the air flue and used for detecting second wind pressure in the air flue, a controller which is respectively connected with the first pressure sensor and the second pressure sensor and used for ascertaining a wind pressure difference value and outputting a first control signal, and a driving device which is respectively connected with the mobile plate and the controller and used for driving the mobile plate to move in the air flue forming area according to the first control signal, wherein the area between the mobile plate and the supporting plate is the air flue and air conditioner wind of the communication equipment room is transmitted through the air flue. According to the communication equipment room and the air flue regulation method thereof, the size of the air flue of the communication equipment room can be regulated, so that the heat radiation effect of the communication equipment room can be improved at a low cost.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Chrome sand sorter

A chrome sand sorter relates to fine sorting recovery equipment of chrome sand for foundry. The chrome sand sorter comprises a blowing unit, a separating screen and a vibration mechanism, the separating screen comprises a screen box, screen meshes and an air distribution chamber, one side of the screen mesh is provided with a long strip-shaped blanking hole, and the air distribution chamber is connected with an air storage cabinet and the blowing unit by a hose. Various stainless steel sintering screen meshes with certain rigidity and strength are adopted in the chrome sand sorter, which meets requirements of a sorting process including boiling and jumping; an air filter is adopted in the blowing unit for filtering intake air and then blowing the intake air to the screen meshes, which effectively prevents dust-laden air from blocking the screen meshes; the air storage cabinet and the air distribution chamber can ensure uniformity and stability of wind pressure; an adjustable vibration frame can be adjusted longitudinally and horizontally, thus being capable of realizing arbitrary tilting of the screen meshes; a compound eccentric gear can cause the oscillation amplitude of the vibration frame to be adjustable for a plurality of levels; and a stepless speed changing motor causes the vibration frequency of the vibration frame to be adjustable. A sorting principle of combining wind power and vibration is adopted in the chrome sand sorter based on different specific weights of materials, thus the chrome sand sorter has the advantages of scientific and reasonable structure, good sorting effect and recovery ratio up to more than 95%.

Owner:QINGDAO BAICHUAN TONGDA MACHINERY CO LTD

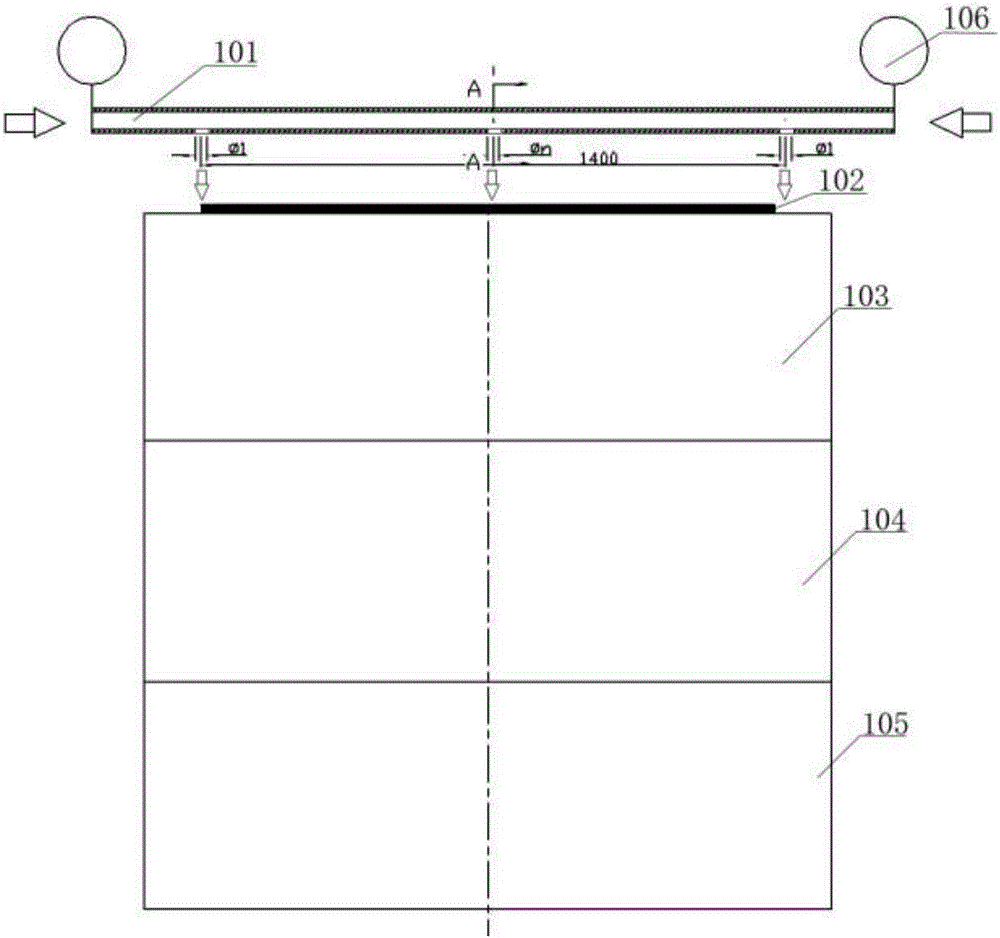

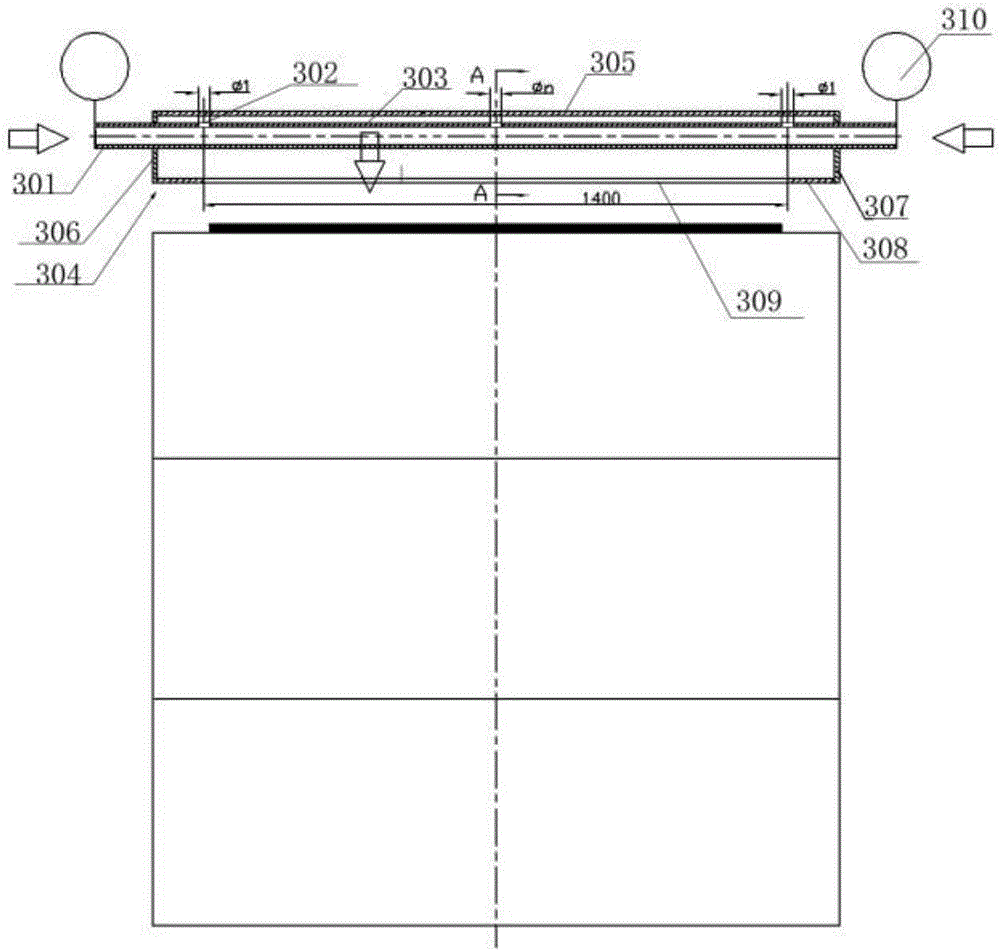

Uniform ventilation wall device for cooling three rolls in extrusion process of diffusion plate

The invention discloses a uniform ventilation wall device for cooling three rolls in the extrusion process of a diffusion plate. The uniform ventilation wall device comprises a cooling air pipe. The two ends of the cooling air pipe are connected with air compression pumps, a plurality of air holes are formed in the upper wall of the cooling air pipe, and compressed air penetrating through the air holes is vertically upward. The distance between the adjacent air holes is not larger than 5 mm, the cross sectional areas of the air holes are gradually decreased from the air hole in the middle of the cooling air pipe to the air holes in the two ends of the cooling air pipe, and the cross sectional areas of the adjacent air holes differ by 0.0135 mm<2>. The cooling air pipe is eccentrically sleeved with a stainless steel pipe, and the cooling air pipe is close to the upper wall of the stainless steel pipe. The two ends of the stainless steel pipe are sealed, and a cutting opening with the width ranging from 0.30 mm to 0.40 mm is cut in the lower wall of the stainless steel pipe in the axial direction of the stainless steel pipe. A ventilation wall formed by the device is uniform in overall air pressure, and in the extrusion production process of the diffusion plate cooled through the device, the quality defects of warping, roll grain and the like are overcome.

Owner:CHENGDU CECEP TRAILBLAZER TECH STOCK LTD

Air outlet net cleaning device

InactiveCN102260935ABlock the fallFall won't stopFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesFiberEnvironmental engineering

The invention discloses an impurity cleaning device of an air outlet mesh. The device is provided with an upper-layer air exhaust chamber and a lower-layer air exhaust chamber, an overflow cotton conveyor belt is arranged between the two layers of the air exhaust chambers and a cotton discharge port is arranged at the tail end of the overflow cotton conveyor belt; and a foreign fiber conveyor belt is arranged at the bottom of the lower-layer air exhaust chamber and an impurity discharge port is arranged at the tail end of the foreign fiber conveyor belt. Impurity blocking meshes are arranged on the outer side surfaces of the upper-layer air exhaust chamber and the lower-layer air exhaust chamber. A track is arranged on the upper side of the impurity cleaning device of the air outlet mesh,a mobile fan is further mounted on the track, a vertical air knife is mounted on an air outlet of the mobile fan and travel switches are mounted on two sides of the track respectively. By adopting the device, seed cotton which is blown up along with air pressure in a foreign fiber clearing device can be effectively separated when the seed cotton is in the suspended rolling state, and the barrier type conveyor belt and the belt type conveyor belt are adopted for conveying different separated materials respectively, thereby achieving the purpose of effective separation.

Owner:张连军

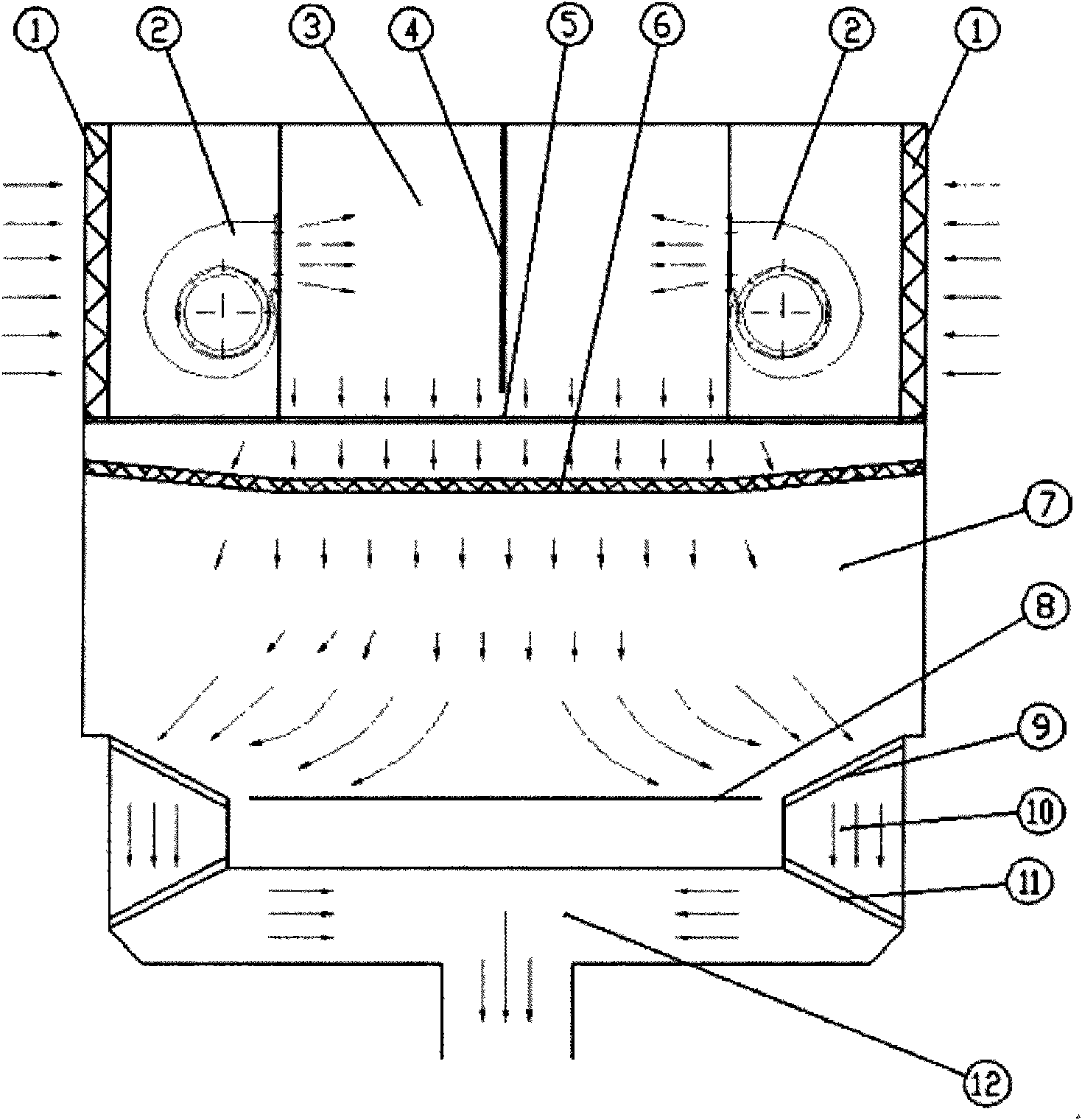

Ventilating system of painting house

InactiveCN101618374AEasy to solveReduce dustLiquid surface applicatorsLighting and heating apparatusFilter systemEngineering

The invention relates to a ventilating system of a painting house, which removes the paint mist, purifies the air and has environmental protection and energy saving. The ventilating system of the painting house comprises a fan, a filtering system and a workpiece platform, wherein the upper part of a shunting mesh in a painting room is divided into a left wind pressure box and a right wind pressure box by a wind shield plate; two fans are installed in the wind pressure boxes; the outermost sides of the fans are provided with primary dust filtering meshes; the lower part of the shunting mesh is provided with a secondary dust filtering mesh; the workpiece platform at the relative side is positioned in the bottom of the painting room; the upper ends of a left suction opening and a right suction opening are respectively provided with filter paper in an inclined way, and the lower ends of the left suction opening and the right suction opening are provided with secondary filter meshes in the inclined way; and the bottom of the painting room is provided with a suction air duct and a suction fan. The invention thoroughly removes the paint mist, purifies the air and has environmental protection and energy saving.

Owner:杭州景生木业机械有限公司

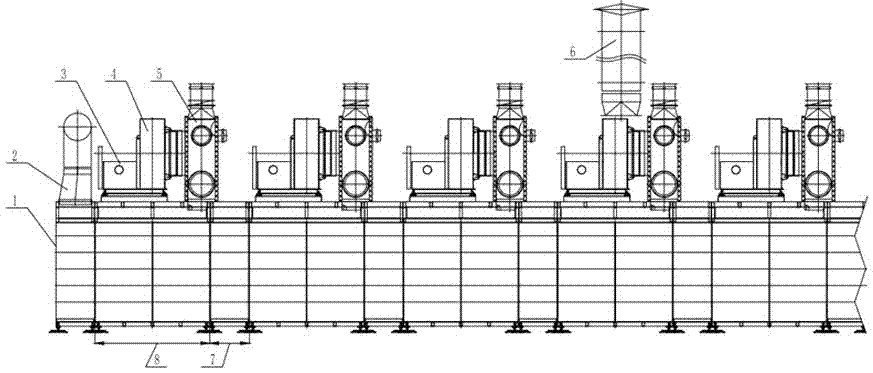

Compact energy-saving drying kiln

PendingCN107131740ASolve the blockageSmall temperature differenceDrying gas arrangementsDrying chambers/containersEngineeringKiln

The invention discloses a compact energy-saving drying kiln. The drying kiln consists of multiple standard kiln bodies; vertical heat supply wind pipes and transverse wind blowing pipes are arranged in the standard kiln bodies; heat supply fans arranged on the standard kiln bodies are connected with the heat supply wind pipes; the heat supply wind pipes are connected with wind blowing pipes; hot wind is fed in the standard kiln bodies by the heat supply wind pipes and the wind blowing pipes; one ends of one set of wind blowing pipes are connected with the heat supply wind pipes on a driving side, and the other ends are fixed by first brackets; one ends of the other set of wind blowing pipes are connected with the heat supply wind pipes on a driven side, and the other ends are fixed by second brackets; detachable sealing plates are arranged at the ends of all the wind blowing pipes fixed by the first or second brackets; small pipe mouths are welded on the sealing plates; and square holes are formed in corresponding kiln walls, and are sealed by plugs. Pipe sections for extending out of the kiln are designed at one ends of all the wind blowing pipes, so that steel wire brushes can extend in from the pipes to clean dust, and compressed air pipes can extend in from the pipes to perform forced blowing so as to solve the blockage problem.

Owner:DLT TECH CO LTD

Dedusting equipment

InactiveCN106338106AImprove shielding effectUniform wind speedMechanical apparatusLighting and heating apparatusBiochemical engineering

The invention discloses dedusting equipment. The dedusting equipment comprises a box body, wherein a negative ion generator is arranged at the inlet end of the box body, a filter cartridge which is closed at one end is arranged at the outlet end in the box body, a filter screen is arranged around the wall of the filter cartridge, the end surface of the opened end of the filter cartridge is hermetically attached to the end wall of the outlet end of the box body, the opening of the filter cartridge communicates with the outlet of the box body, a fan is fixedly arranged between the negative ion generator and the filter cartridge, the fan and the filter cartridge are coaxial, and the closing end of the filter cartridge props against the fan. The dedusting equipment disclosed by the invention is better in noise reducing effect and more thorough to dedust, and the work efficiency of the fan and the utilization ratio of an air duct are improved.

Owner:倪静

Exhausting device used for improving exhausting quality of packaging bag

The invention provides an exhaust device for improving the exhaust quality of packaging bags, which relates to the technical field of packaging bag exhaust, and includes a conveyor belt, an exhaust roller, and drive mechanisms respectively erected on both sides of the conveyor belt. All are equipped with guide rails, and the exhaust rollers straddle the conveyor belt through the cooperation of the roller shafts with the guide rails. The exhaust rollers include a first binder surface and a second binder surface, and the first binder surface There are several ventilation holes on the top, and the second pressing surface is solidly set; when the packaging bag moves with the conveyor belt and passes under the exhaust roller, the driving mechanism can drive the exhaust roller to roll back and forth on the packaging bag The way to discharge the gas in the bag. By implementing the technical solution, the exhaust quality of the packaging bag is improved, residual air in the packaging bag is avoided, and the risk of damage to the packaging bag is reduced.

Owner:弘毅天承知识产权股份有限公司

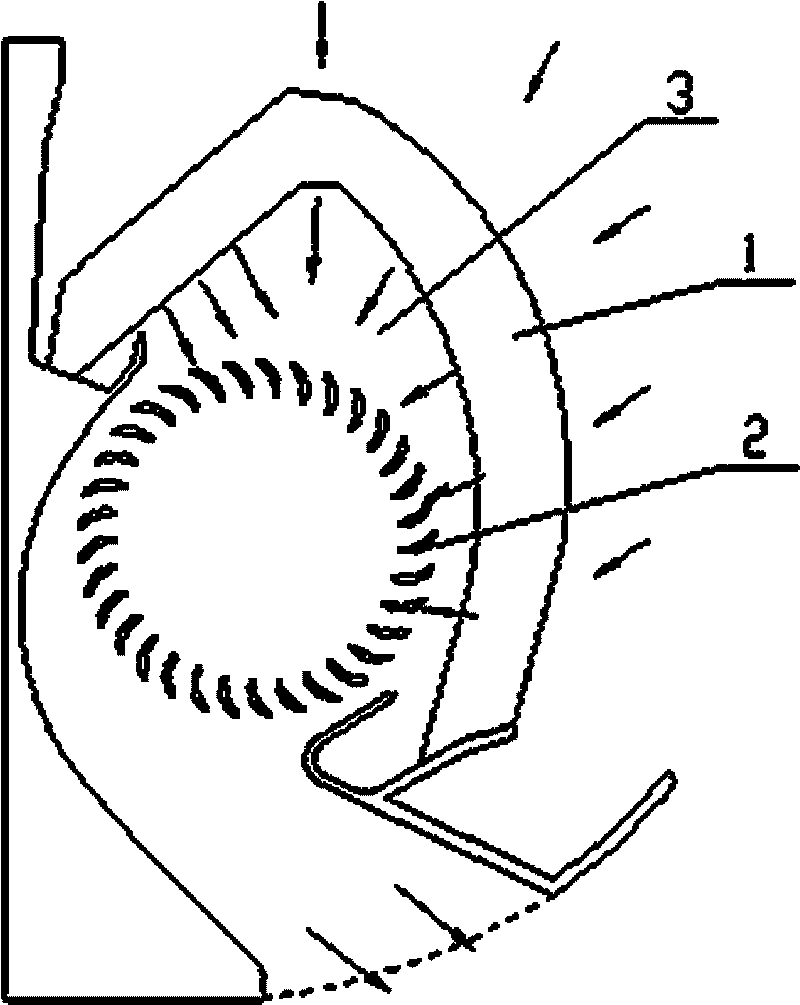

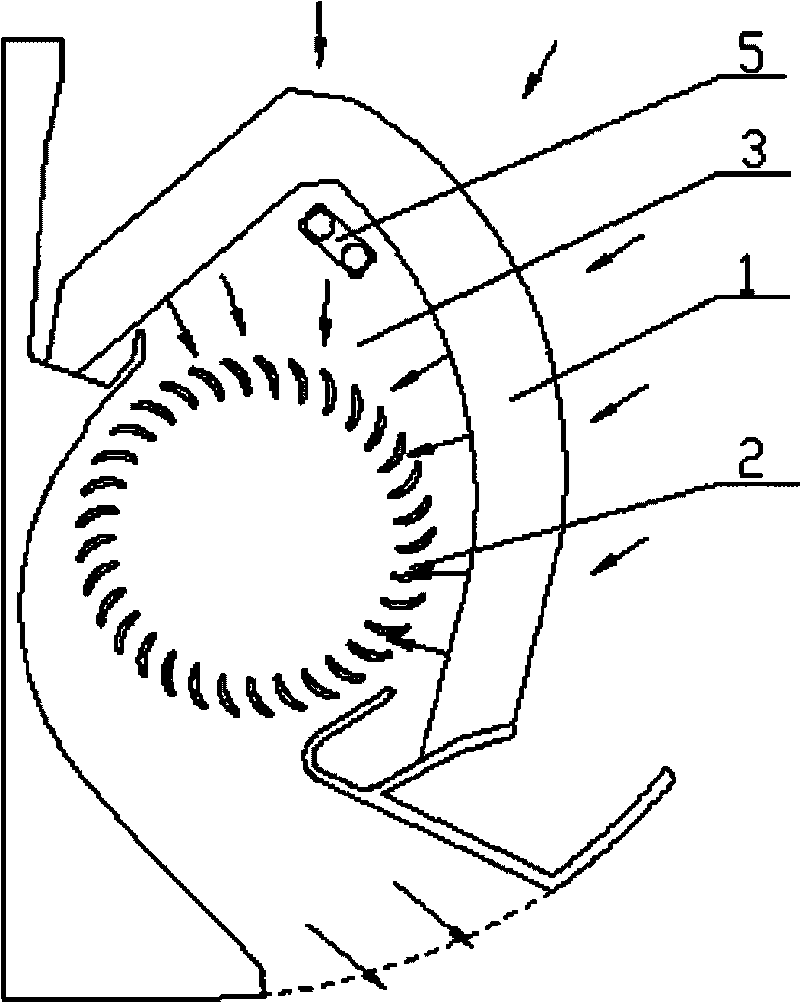

Device for reducing noise of indoor unit of air conditioner and method thereof

ActiveCN101701742AReduce noiseUniform wind pressureNoise suppressionAir-flow control membersEngineeringHeat exchanger

The invention discloses a device for reducing the noise of an indoor unit of an air conditioner and a method thereof. The device can lead the air beam to be homogenized; and the method comprises: in the process that the air beam inside an air duct is discharged outside the air duct through an air outlet fan after being treated by heat exchanged by a heat exchanger, the air beam is treated by homogenization by using the device before the air beam flows into the air outlet fan. After being homogenized by the device, the homogenized air beam flows to the fan, so that uniform wind is applied to the fan; therefore, the fan is more stable in operation, the noise caused by shock and unbalance can be avoided, and the quality of the indoor unit of the air conditioner is improved.

Owner:四川长虹空调有限公司

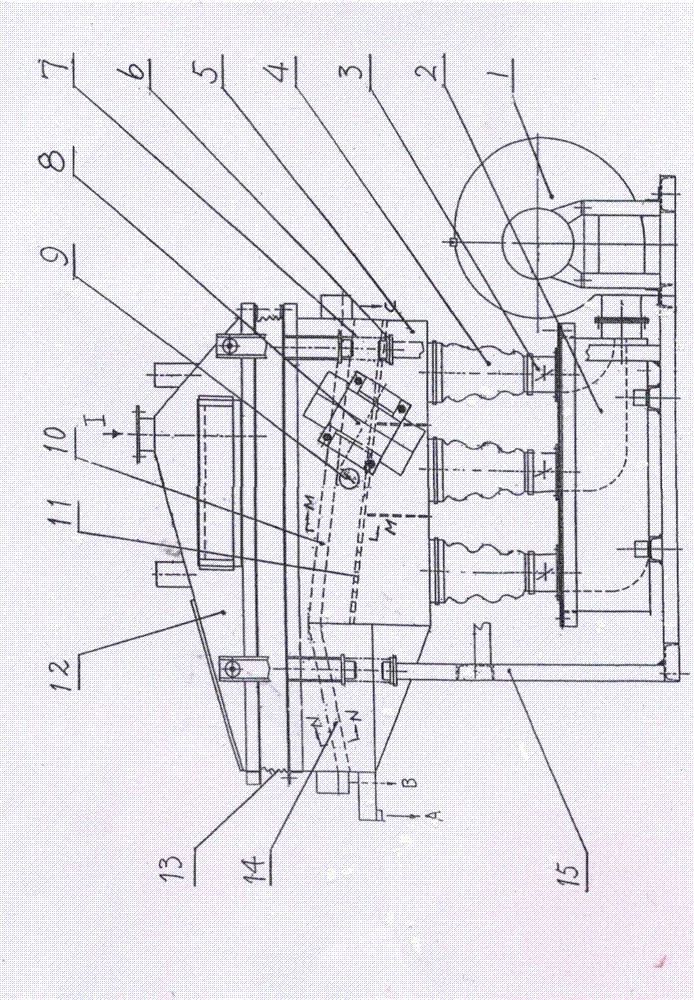

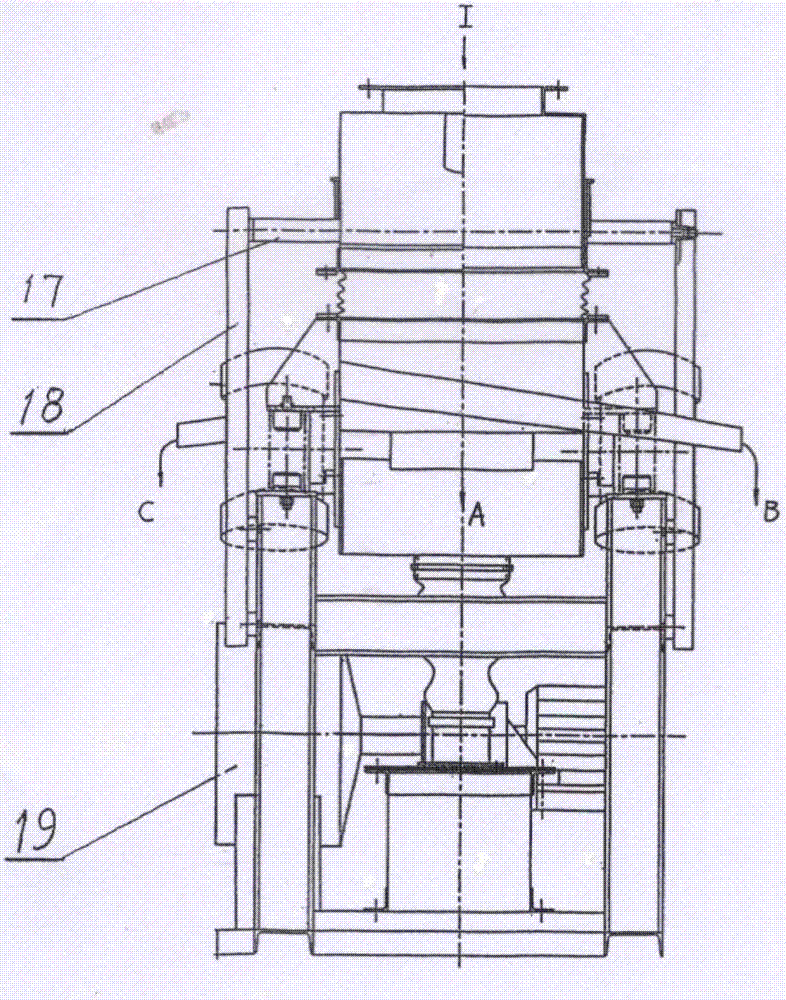

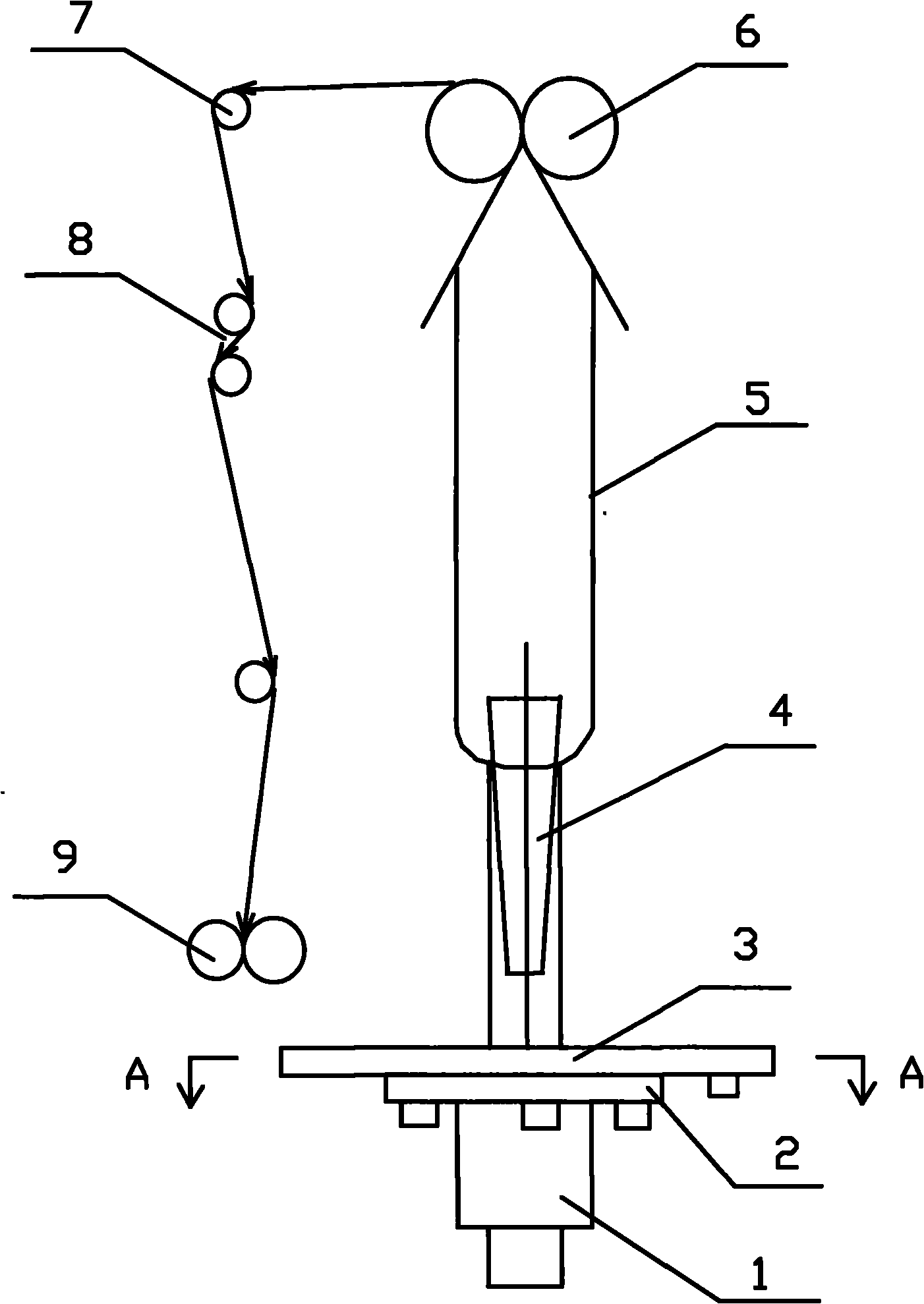

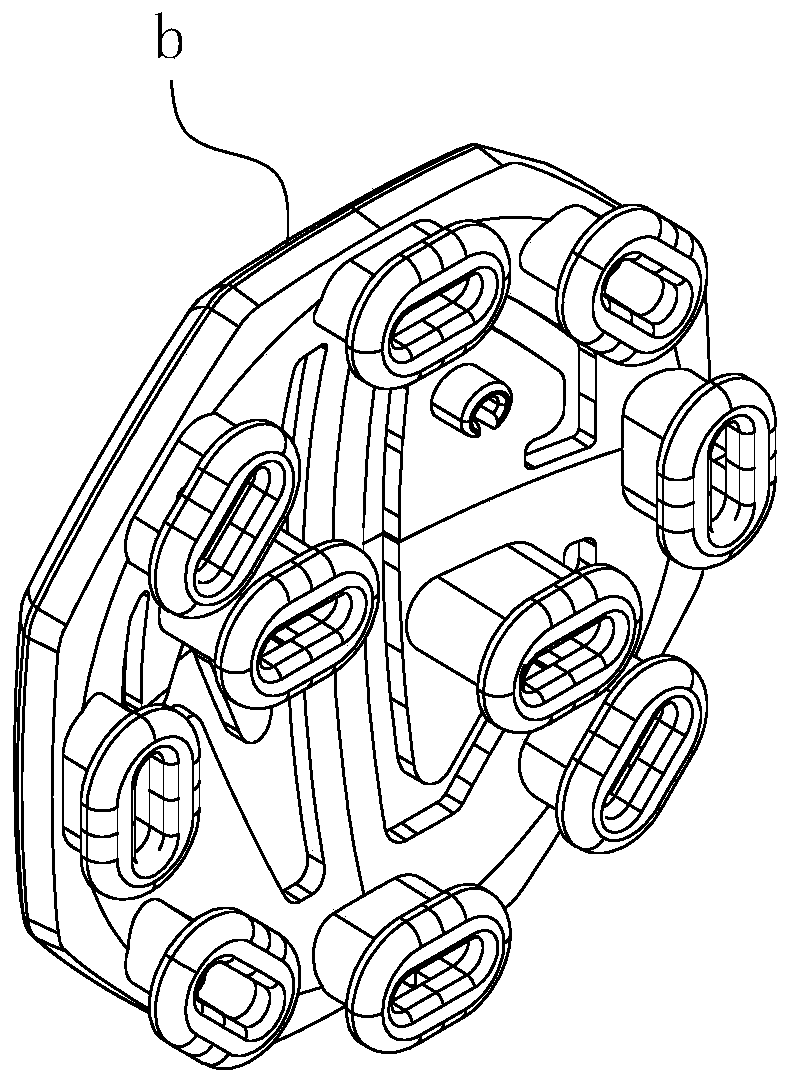

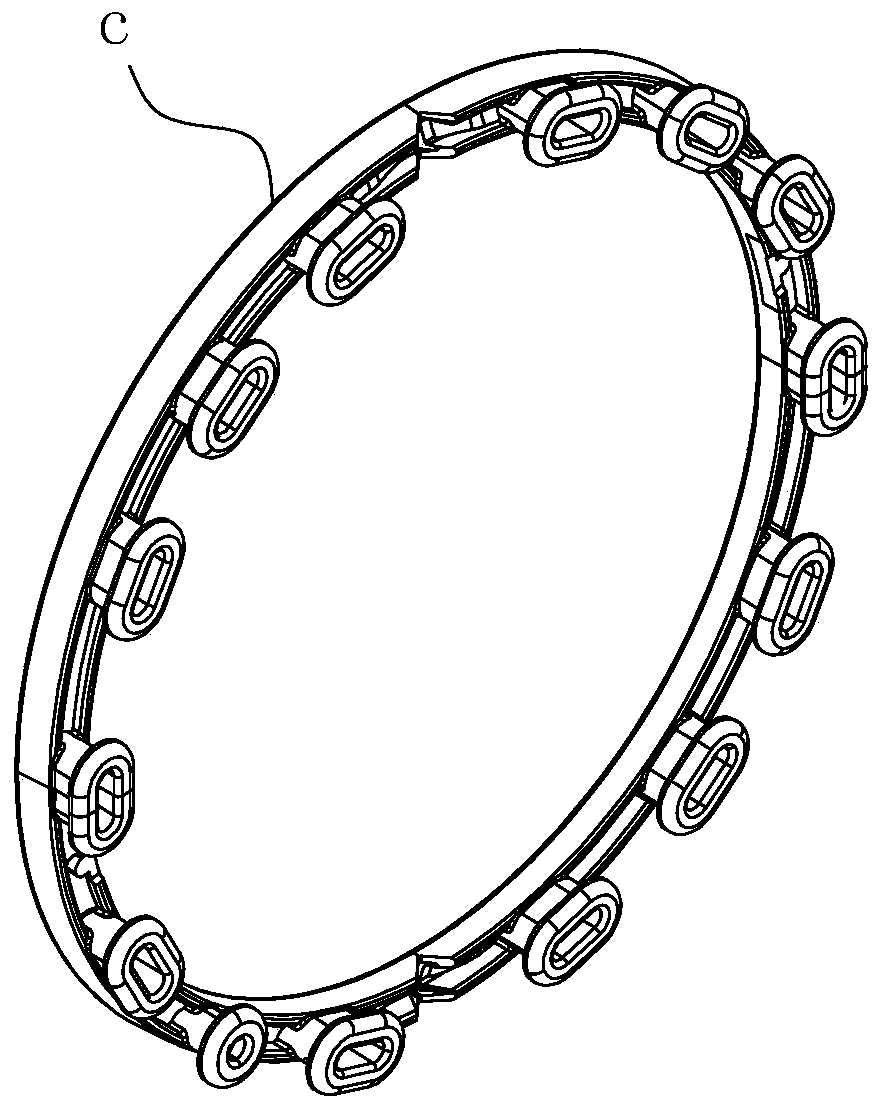

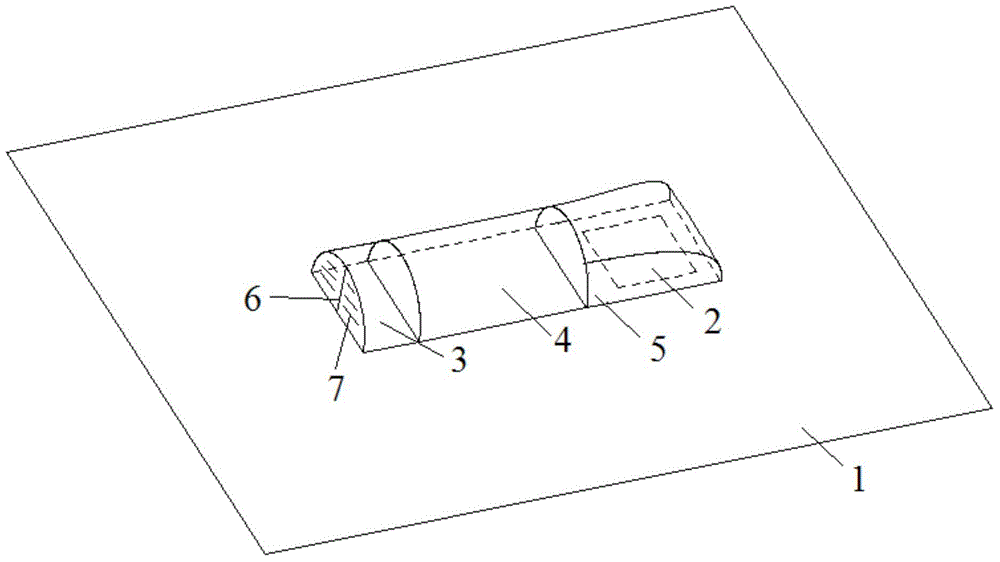

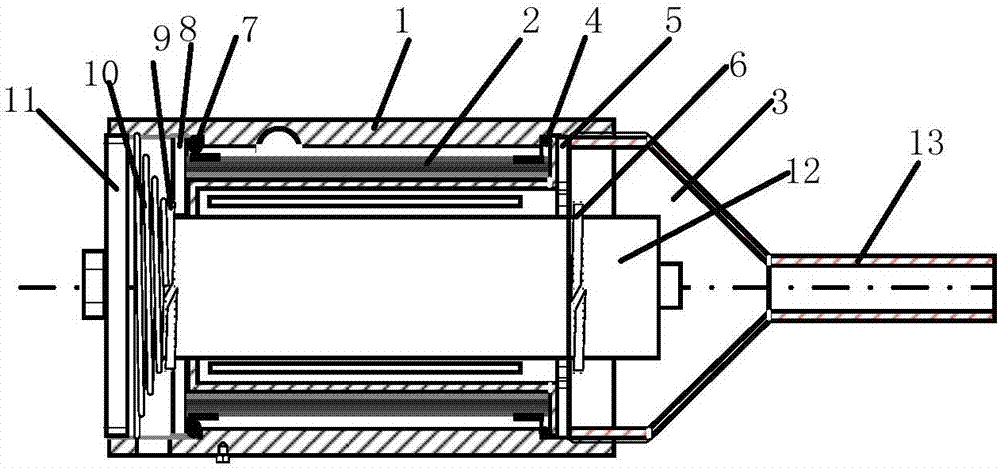

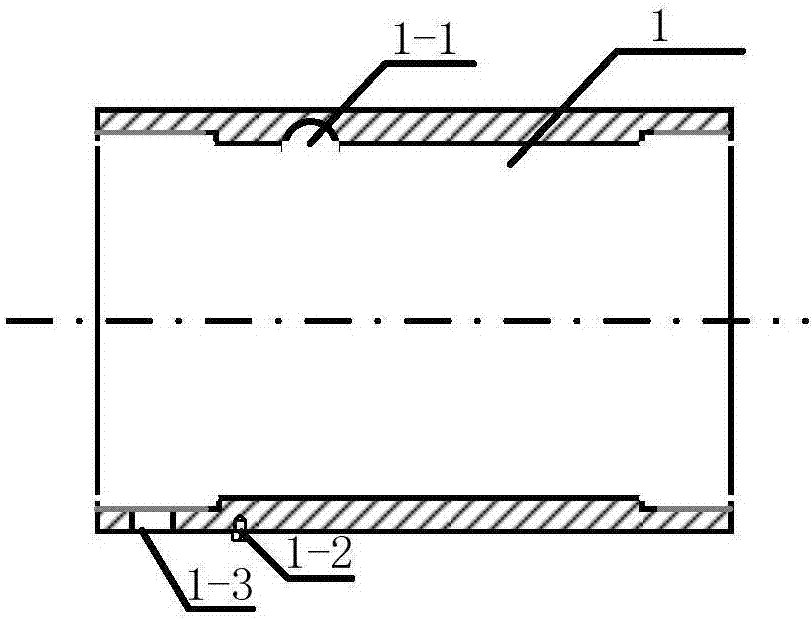

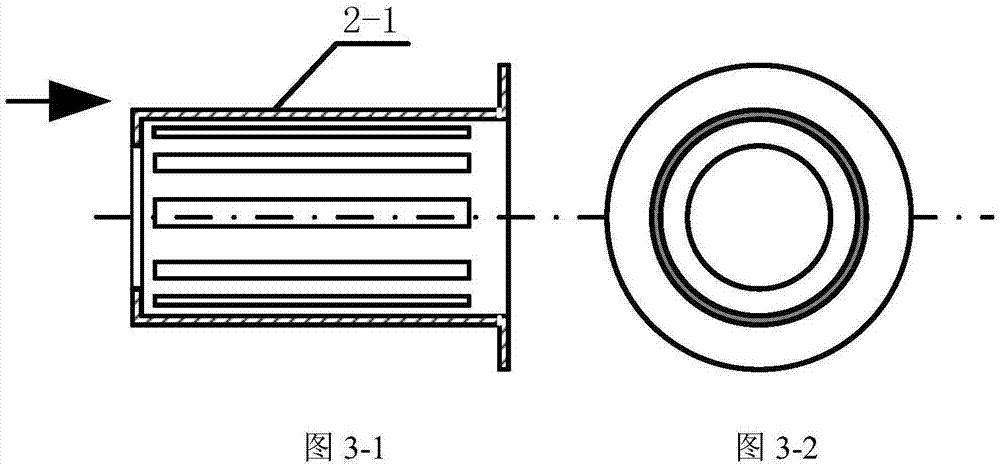

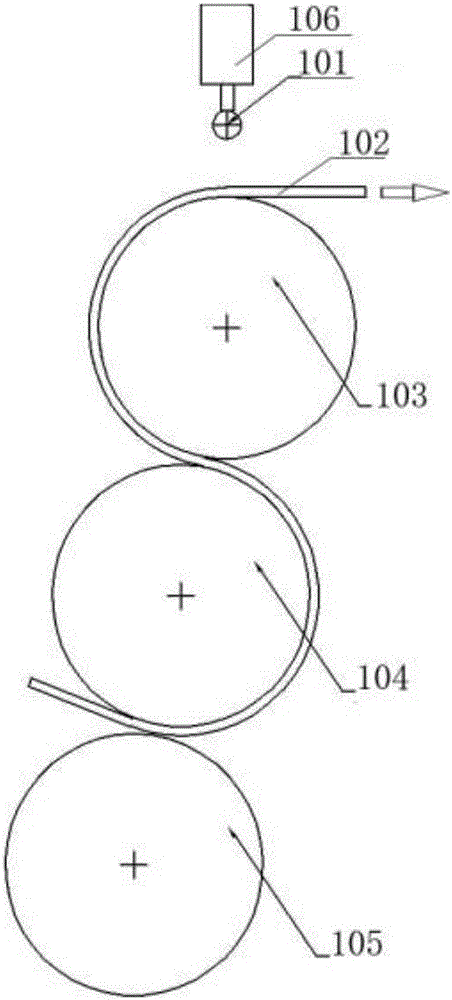

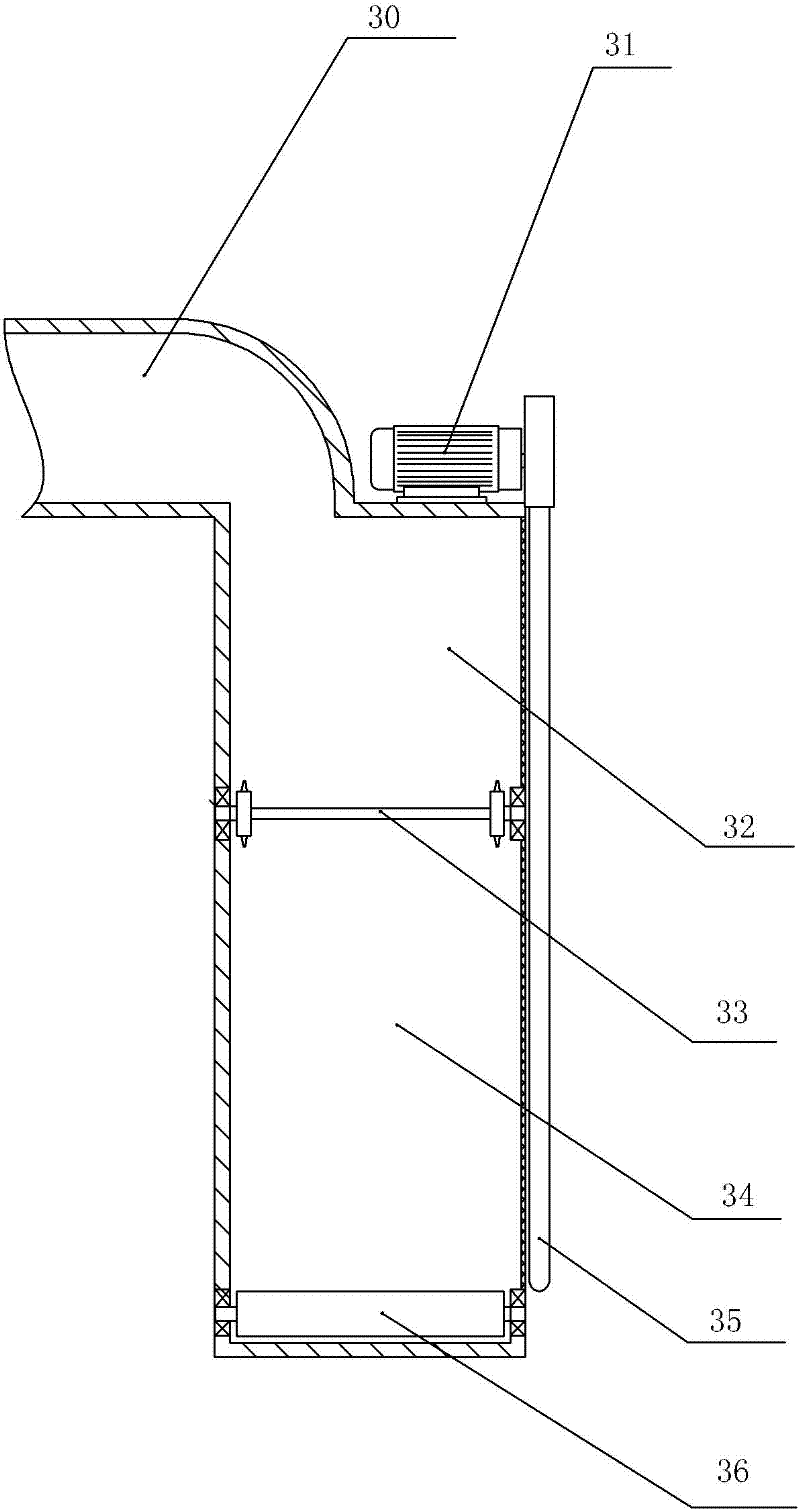

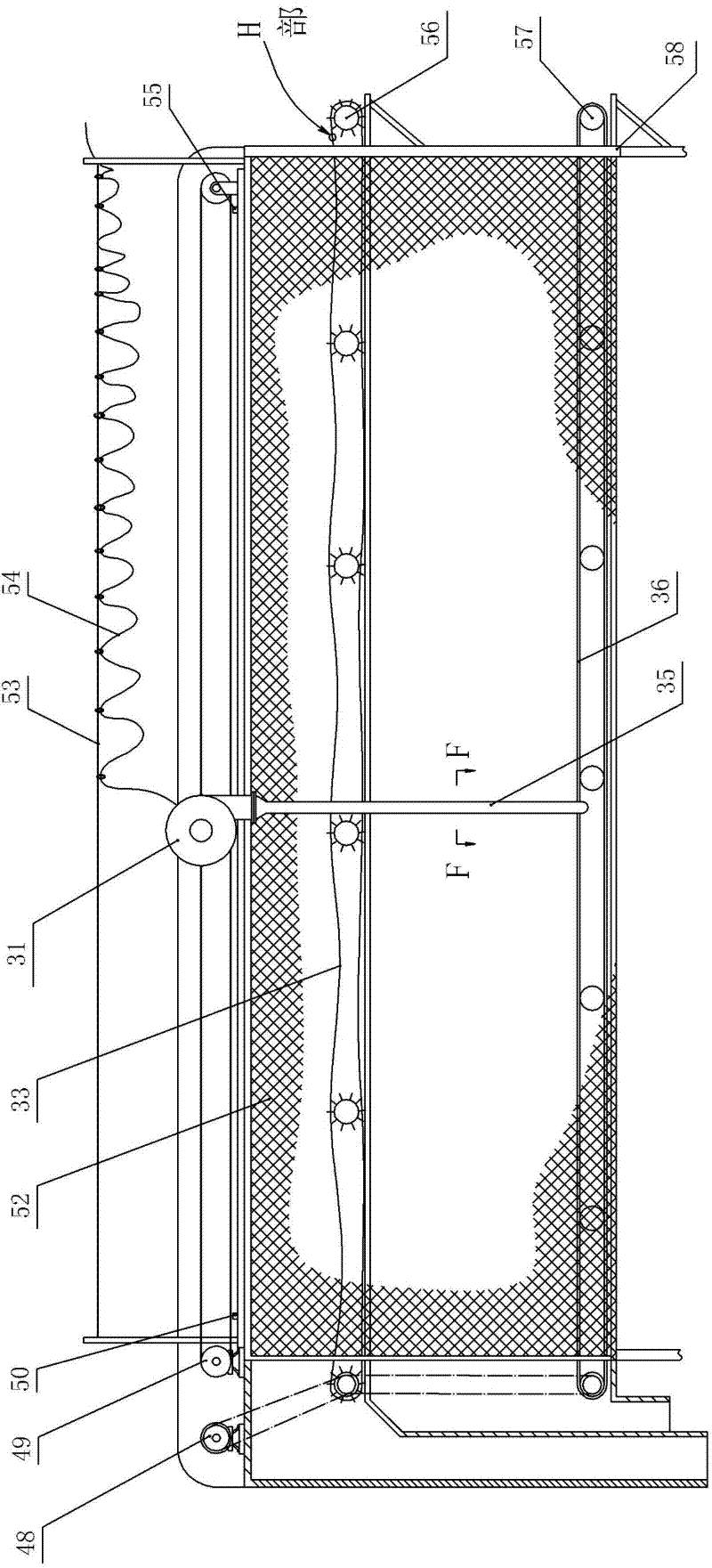

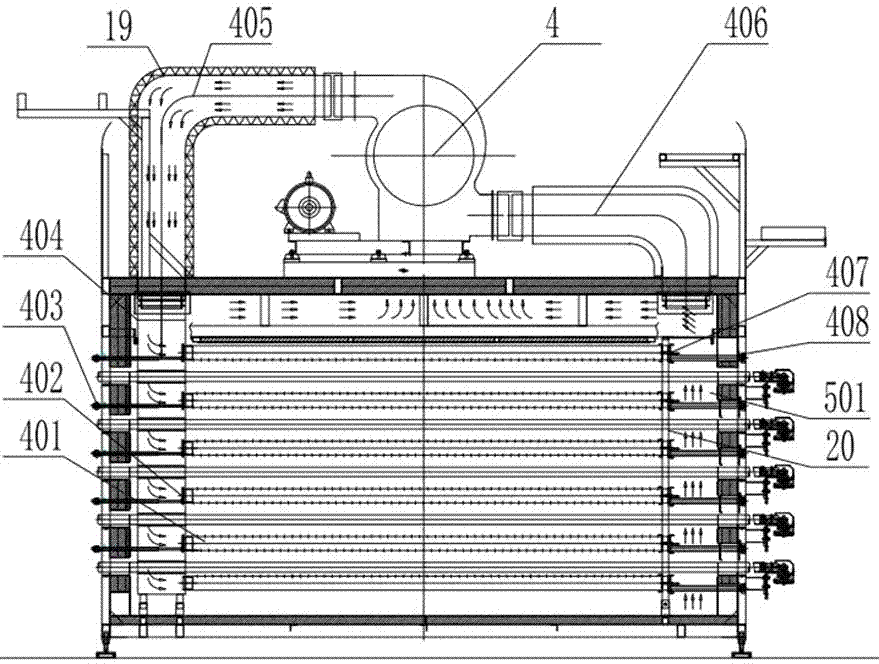

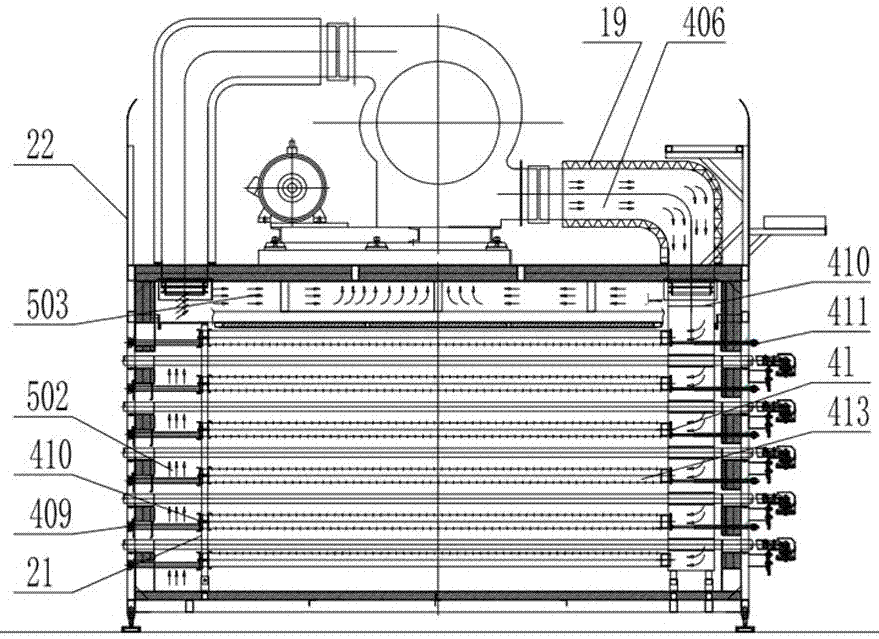

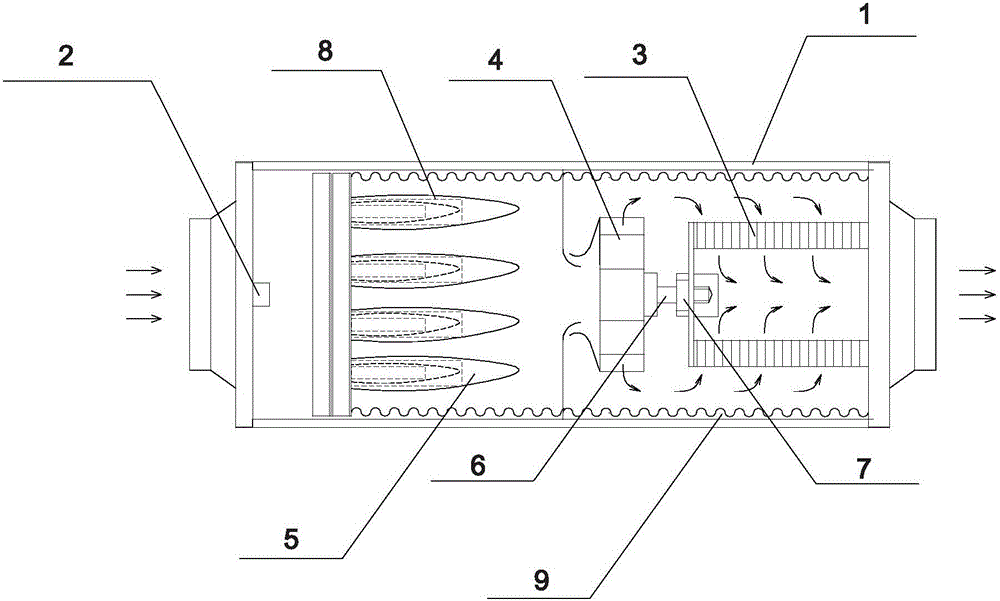

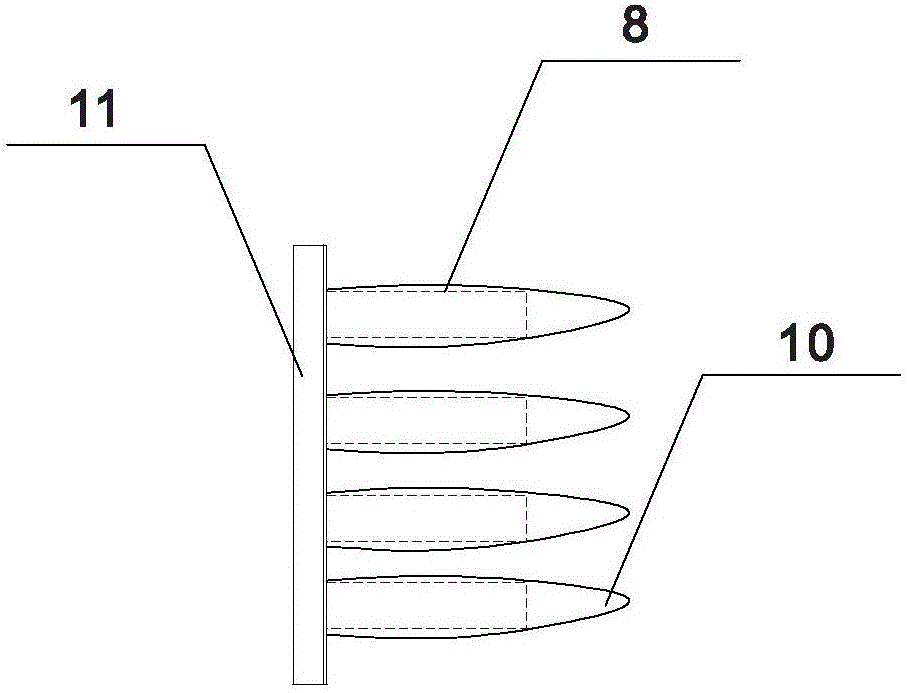

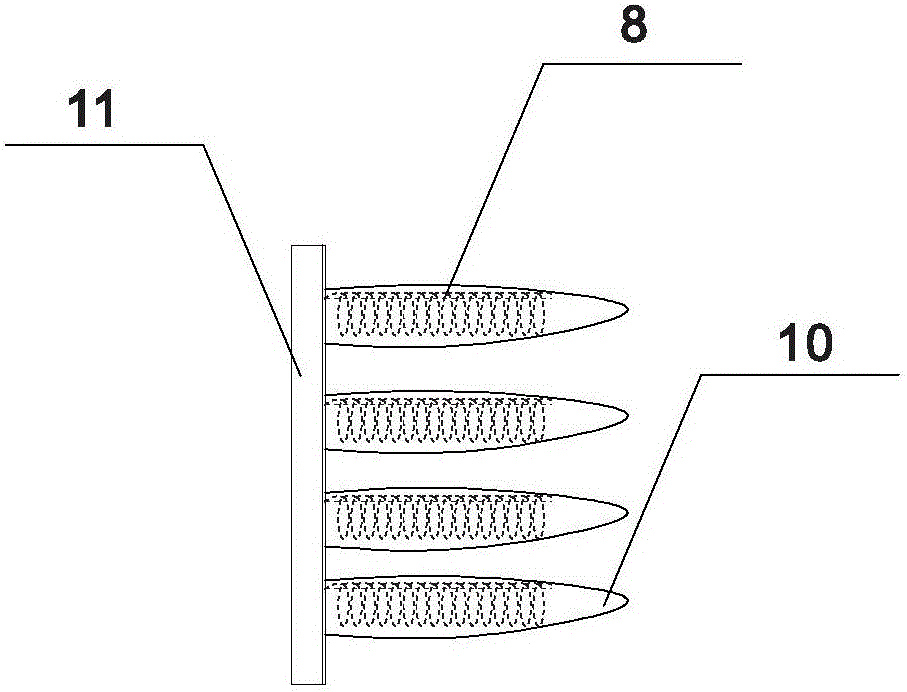

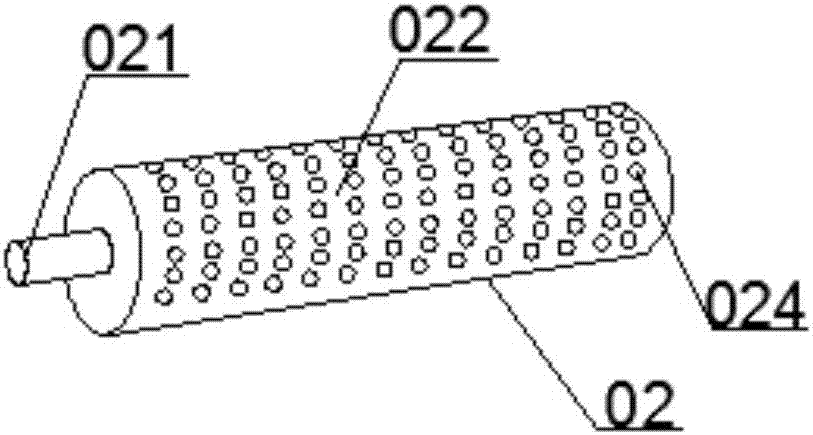

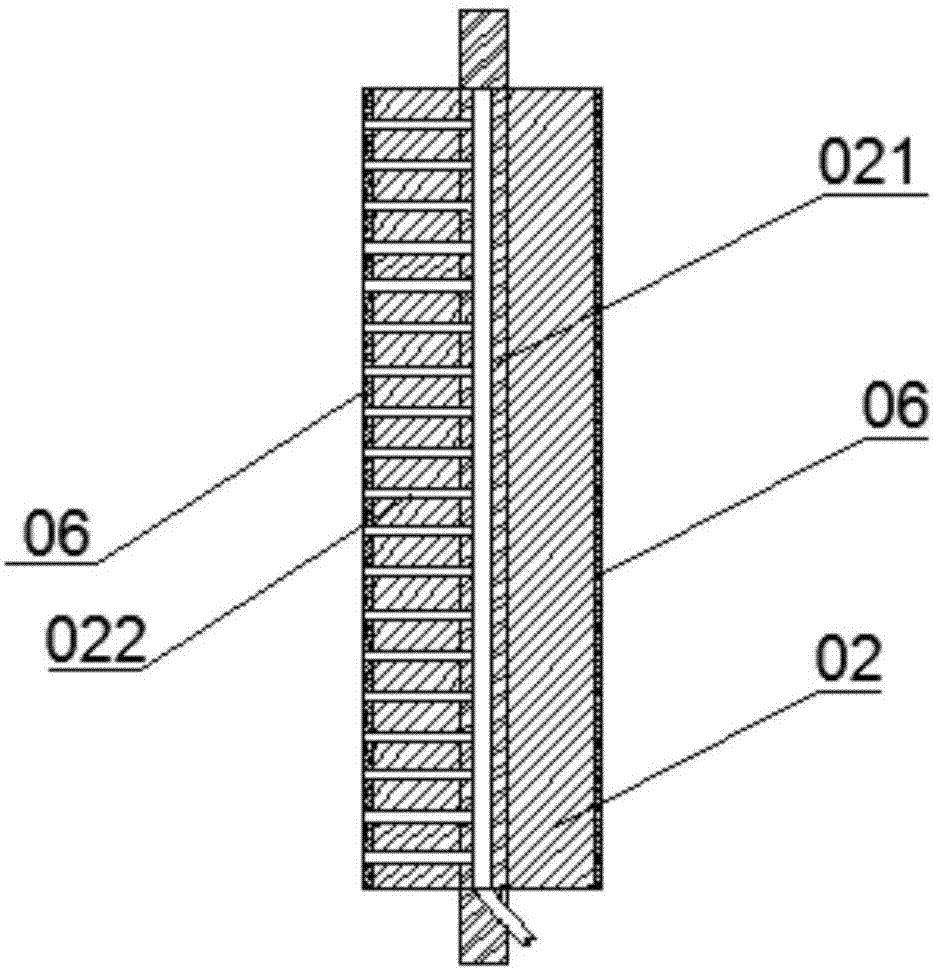

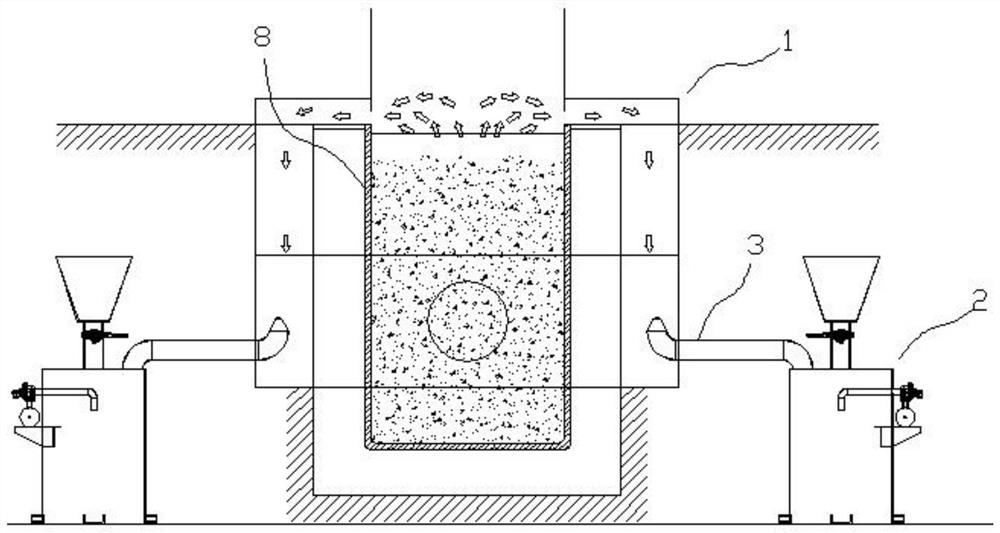

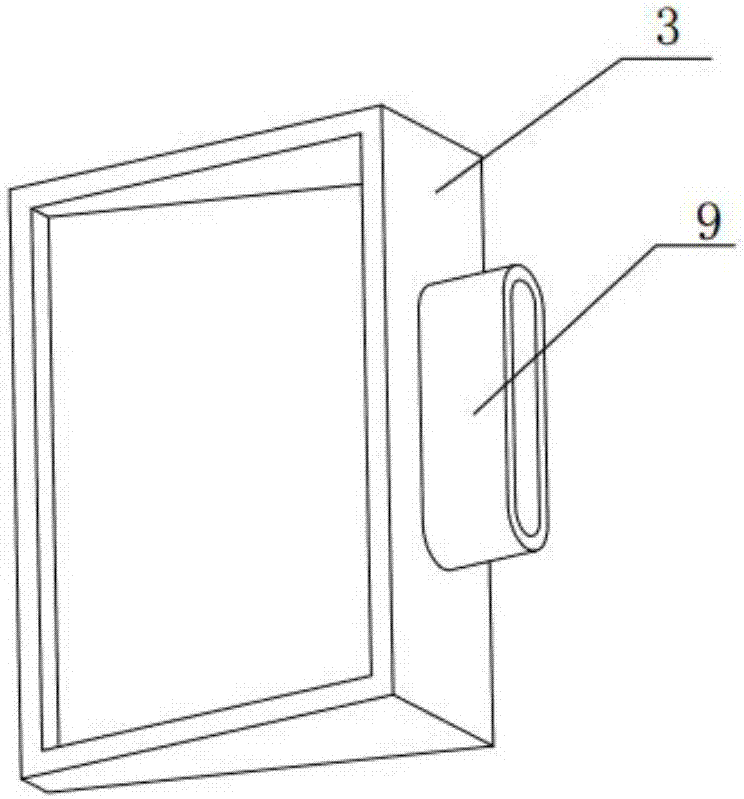

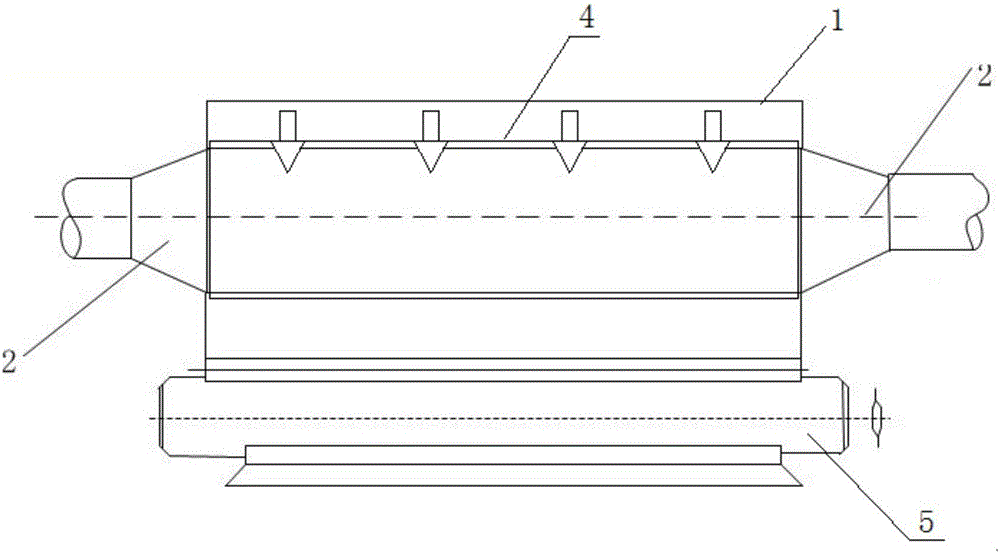

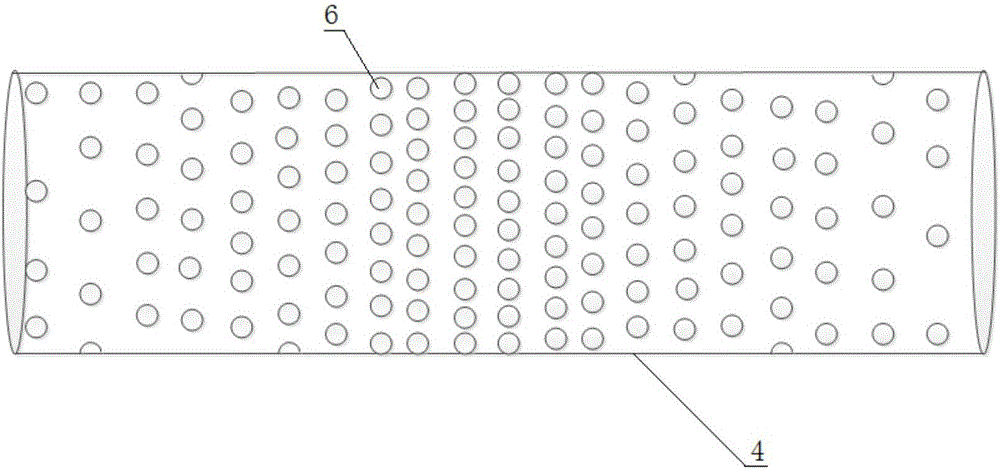

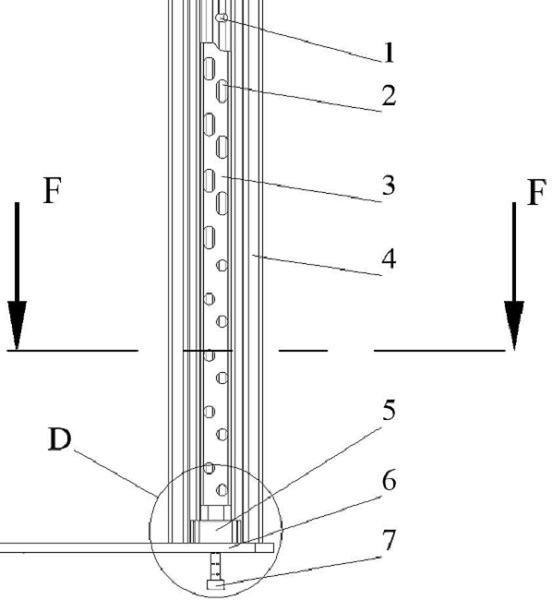

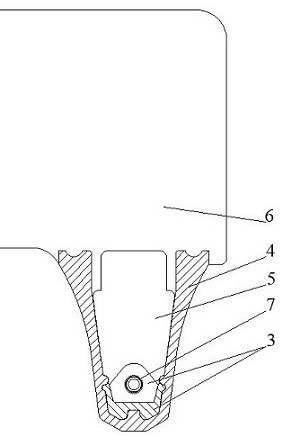

A spinning annular blast apparatus

InactiveCN105274636AUniform wind pressureGuaranteed balance of blowingFilament/thread formingEveningBellows

The invention provides a spinning annular blast apparatus comprising a rectifying drum, a straight drum, an air inlet pipe, an air distributing box, an air evening net, flow guide air pipes, and an annular blast box. The air inlet pipe is connected with the air distributing box. The air evening net is arranged between the air distributing box and the annular blast box. The inner wall of the annular blast box is the rectifying drum. The outer wall of the annular blast box is provided with a plurality of flow guide air pipes. The air pressure in the rectifying drum is even, so that the blast balance in spinning cooling is guaranteed and the quality of the process section in the spinning process is improved.

Owner:JIANG SU TIANDI CHEM FIBER

Communication equipment room and air flue regulation method thereof

ActiveCN103161328BImprove cooling effectAdjustable sizeSpace heating and ventilation safety systemsLighting and heating apparatusControl signalEngineering

The invention discloses a communication equipment room and an air flue regulation method thereof. The communication equipment room comprises an equipment room body, a supporting plate which divides the equipment room body vertically into a communication equipment arrangement area and an air flue forming area, a mobile plate which is located in the air flue forming area, an air flue, a first pressure sensor which is arranged in the communication equipment arrangement area and used for detecting first wind pressure in the communication equipment arrangement area, a second pressure sensor which is arranged in the air flue and used for detecting second wind pressure in the air flue, a controller which is respectively connected with the first pressure sensor and the second pressure sensor and used for ascertaining a wind pressure difference value and outputting a first control signal, and a driving device which is respectively connected with the mobile plate and the controller and used for driving the mobile plate to move in the air flue forming area according to the first control signal, wherein the area between the mobile plate and the supporting plate is the air flue and air conditioner wind of the communication equipment room is transmitted through the air flue. According to the communication equipment room and the air flue regulation method thereof, the size of the air flue of the communication equipment room can be regulated, so that the heat radiation effect of the communication equipment room can be improved at a low cost.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Hot galvanizing pot smoke exhaust gas collecting device

ActiveCN112011751ASave space for production operationsSimple production operationHot-dipping/immersion processesDirt cleaningExhaust gasExhaust fumes

The invention discloses a hot galvanizing pot smoke exhaust gas collecting device, and relates to the technical field of zinc pot smoke exhaust gas treatment. The hot galvanizing pot smoke exhaust gascollecting device comprises a gas collecting hood and powder spraying equipment, the gas collecting hood comprises gas collecting boxes and an air mixing box, and a conveying pipeline is connected between the powder spraying equipment and each gas collecting box; each gas collecting box comprises a gas collecting strip opening, and an air outlet is formed in each gas collecting box; and an innerspace of each gas collecting box is divided into an air equalizing chamber and a smoke dust channel from top to bottom, each smoke dust channel is communicated with the corresponding air outlet, the air mixing box comprises an air mixing channel arranged inside and a pair of air inlets communicated with the air mixing channel, the air inlets are communicated with the air outlets in the corresponding gas collecting boxes, and an air exhaust pipeline communicated with the air mixing channel is arranged on the air mixing box. The hot galvanizing pot smoke exhaust gas collecting device is constructed around a zinc pot heat preservation layer, the influence on production operation is reduced to the maximum extent, meanwhile, the viscosity of smoke particles of a hot galvanizing pot can be greatly reduced, the dust removal efficiency of a dust remover is improved, the service life of a filter material is prolonged, and the maintenance period is prolonged.

Owner:安徽徽柏环保科技有限公司

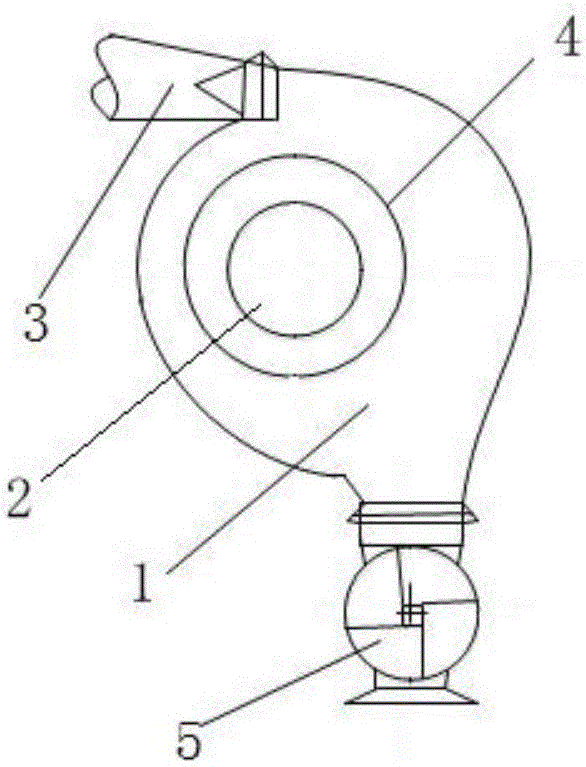

Fluidized bed dry-method sorting device

The invention relates to a fluidized bed dry-method sorting device. The fluidized bed dry-method sorting device comprises a sorting bed, a vibrating component, an air chamber and an air inlet pipe. The sorting bed comprises a bed plate and a back plate, wherein the back plate is fixed to the side edge of the bed plate. The bed plate is provided with multiple air holes. The cross section of each air hole is in a horn shape. The vibrating component is fixed to the back plate. The air chamber is of a box body structure, wherein one end of the box body structure is opened. The air chamber comprises a base plate, a front panel, a rear panel and two side plates, and the front panel, the rear panel and the two side plates are fixedly connected with corresponding side edges of the base plate. The height of the rear panel is greater than that of the front panel. The bed plate is fixed to the opened end of the air chamber and is perpendicular to the front panel, the rear panel and the two side plates. The base plate is inclined relative to the bed plate. An air cavity is formed inside the air chamber. The rear panel is provided with an air inlet, wherein the air inlet communicates with the air cavity. The air inlet pipe is fixed to the air inlet. An air channel of the air inlet pipe is parallel with the bed plate. The air inlet pipe is connected with external air blowing equipment. By means of the fluidized bed dry-method sorting device, it is guaranteed that the air holes are not blocked; wind power is distributed uniformly and reasonably; and sorting precision is improved.

Owner:WUHAN UNIV OF SCI & TECH

Threshing and pneumatic separating discharging device of screen with pneumatic balancing function and for pneumatic separating

InactiveCN106213574AFalling smoothlyReasonable structureTobacco preparationTobacco treatmentPulp and paper industryWind speed

The invention belongs to the field of tobacco industry and relates to threshing and re-drying machinery and equipment, in particular to a threshing and pneumatic separating discharging device of screen with a pneumatic balancing function and for pneumatic separating. The threshing and pneumatic separating discharging device comprises a device body, an exhaust barrel penetratingly and transversely arranged in the device body, and a feeding flat pipe connected at the upper end of the device body, the screen wraps the exhaust barrel to be arranged in the device body, a star-like discharging roller is arranged at the lower bottom end of the device body, a plurality of meshes are distributed in the screen, and number of the meshes is decreased progressively from the middle to two ends of the screen. The threshing and pneumatic separating discharging device is reasonable in structure, simple in mechanism, easy to manufacture and low in cost. A novel discharging device screen is creatively designed, so that air speed and air pressure in the inner exhaust barrel are uniform, blockage of the meshes at two ends of the screen is eliminated, the old problem of material accumulation on two sides of a material flat pipe above a threshing and re-drying tangential discharging device is solved, materials fall uniformly, pneumatic separating efficiency is improved, and threshing and re-drying processes are improved effectively.

Owner:HONGTA TOBACCO GRP

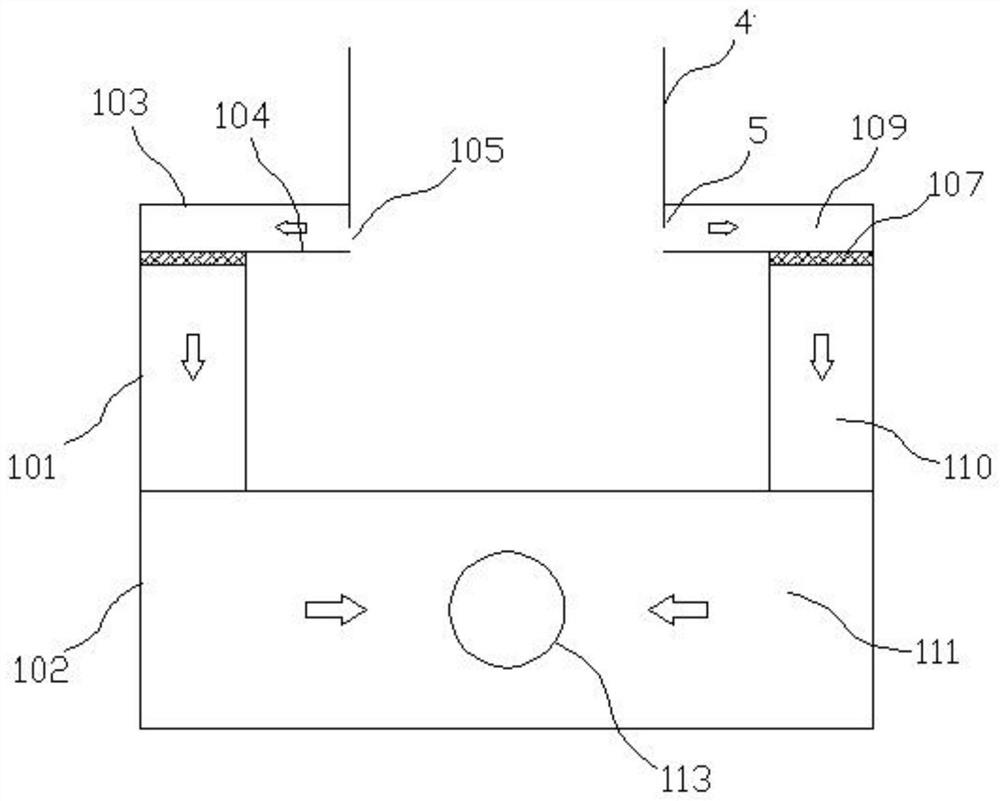

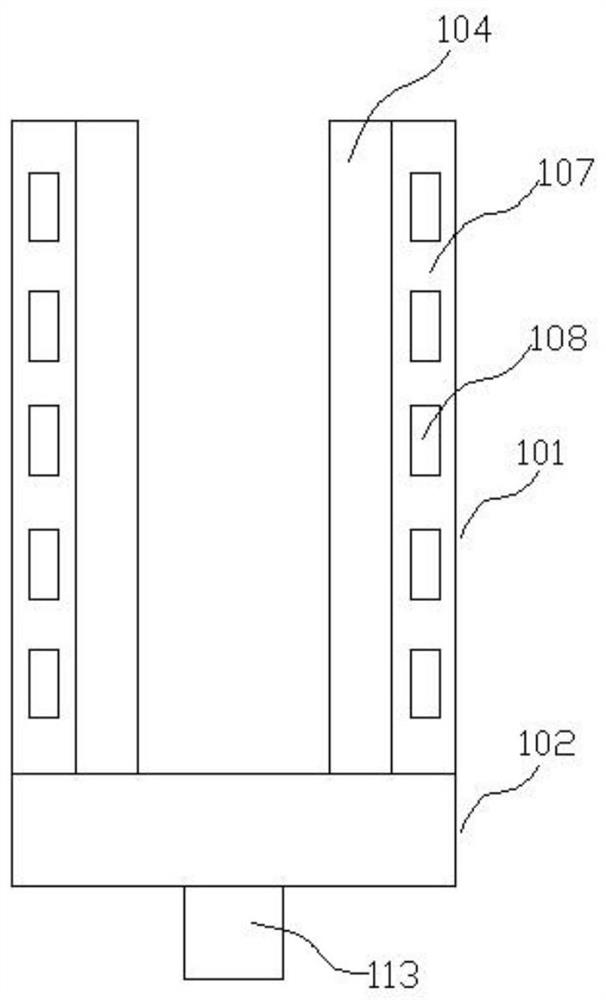

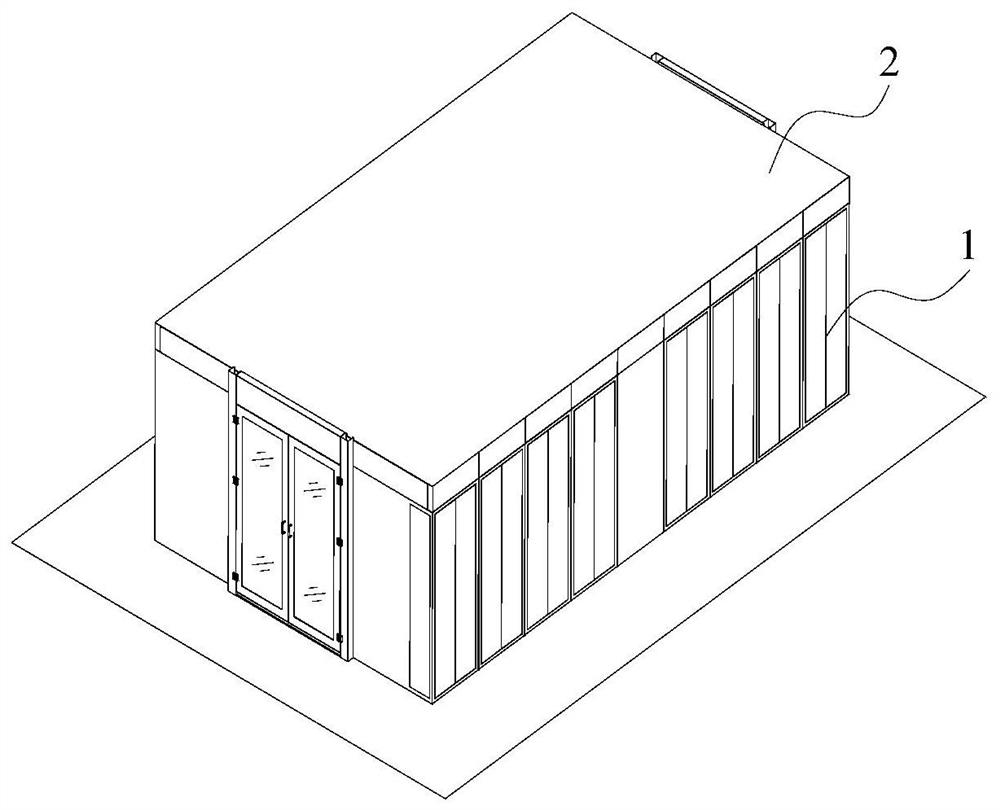

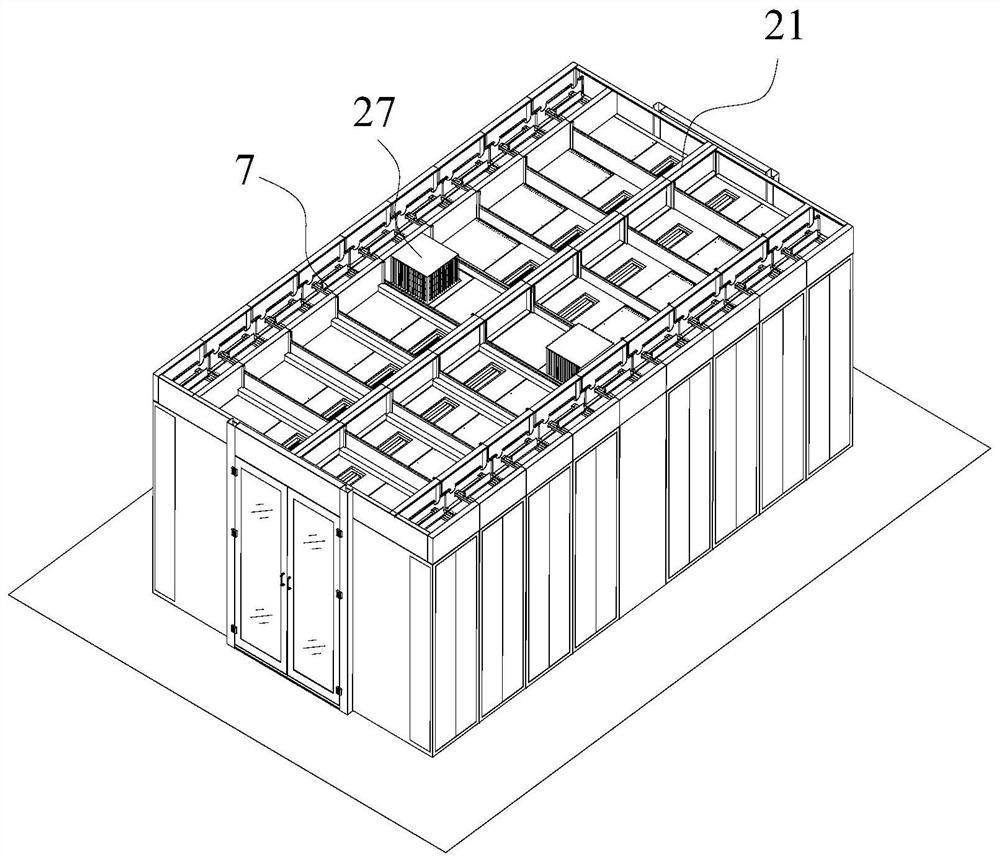

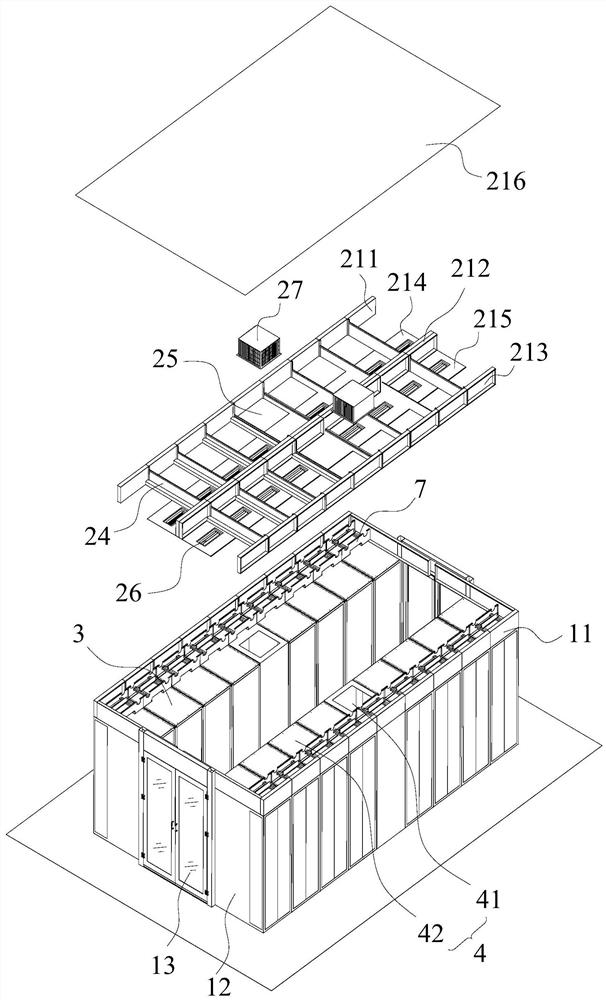

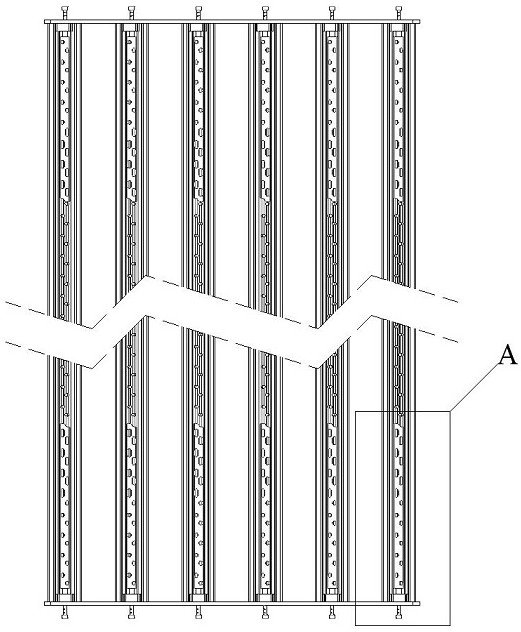

Air duct structure, micro-module machine room and micro-module control method

PendingCN112601435AUniform wind pressureUniform air volumeCooling/ventilation/heating modificationsThermodynamicsAir volume

The invention belongs to the technical field of communication integrated equipment, and particularly relates to an air duct structure, a micro-module machine room and a micro-module control method. The air duct structure comprises a main framework, a static pressure channel and a plurality of damping plates; the main framework is arranged at the top of a cabinet group, the main framework is provided with an air inlet and a plurality of air outlets, the static pressure channel is arranged on the main framework, airflow enters the static pressure channel through the air inlet and flows out of the static pressure channel through the plurality of air outlets, and the air outlets are arranged above a single cabinet in a one-to-one correspondence manner; and the multiple damping plates are arranged at intervals in the extending direction of the static pressure channel, the damping plates are movably connected to the main framework, and the damping plates ascend and descend so that the pressure difference between each air outlet and the corresponding air inlet can be within the preset pressure difference range. Through the plurality of damping plates with different heights, the air pressure and the air volume in the static pressure channel are balanced, the air flow temperature difference in the static pressure channel is reduced, accurate air supply is carried out as required, the temperature difference between cabinets is reduced, and the air supply waste is avoided.

Owner:SHENZHEN KEXIN COMM TECH

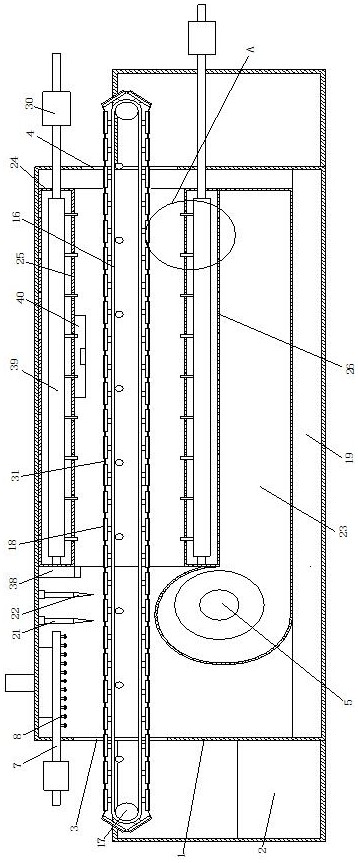

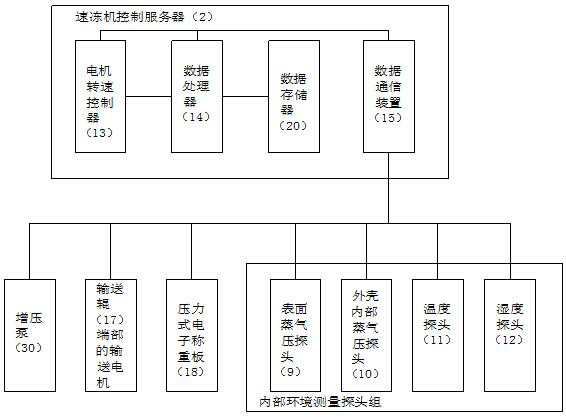

Cooling instant freezer capable of ensuring safe preservation of frozen food

PendingCN112806515AGuaranteed freezing effectDetermine quick freezing timeFood preservationThermodynamicsFood safety

The invention discloses a cooling instant freezer capable of ensuring safe preservation of frozen food. The cooling instant freezer comprises an instant freezer channel type shell (1) and an instant freezer control server (2); an inlet (3) and an outlet (4) are formed in the two ends of the instant freezer channel type shell (1) respectively; a metal net-shaped conveying belt (16) is arranged in the instant freezer channel type shell (1) and arranged in the length extending direction of the instant freezer channel type shell (1); and the two ends of the metal net-shaped conveying belt (16) are matched with the inlet (3) and the outlet (4) of the instant freezer channel type shell (1) respectively. According to the technical scheme, the freezing time of the to-be-frozen object is calculated and determined by weighing the to-be-frozen object and detecting the freezing environment, the freezing time of the to-be-frozen object is controlled, the freezing quality of frozen food is guaranteed, and the situation that food goes bad due to insufficient freezing, and food safety is affected is prevented.

Owner:周丽君

Adjustable tuyere mechanism of glass tempering furnace

PendingCN113845298AImprove tempering efficiencyReduce the cost of temperingGlass tempering apparatusTemperingEngineering

The invention relates to the field of glass physical tempering cooling, in particular to an adjustable tuyere mechanism of a glass tempering furnace. The mechanism comprises a plurality of air exhausts which are arranged up and down; each air row comprises a plurality of strip-shaped air nozzles which are arranged in parallel, and a plurality of air outlet holes are formed in the surfaces, facing the toughening furnace roller way, of the strip-shaped air nozzles; the two ends of each strip-shaped tuyere are each internally provided with a tuyere inner sealing plate, and the perforated faces of the tuyere inner sealing plates are parallel to the perforated faces of the strip-shaped tuyeres; and the tuyere inner sealing plate can translate or slide in the strip-shaped tuyere so as to control the opening and closing of air outlet holes in the strip-shaped tuyere and change the air outlet hole number of the strip-shaped tuyere. According to the size of glass, the number of actual air outlet holes of the strip-shaped tuyere is reasonably controlled through the tuyere inner sealing plate, so that the energy waste is reduced, and the tempering cost is reduced. Meanwhile, according to the structure, the blowing area is reduced, the wind power is more concentrated, the cooling wind pressure distribution is more uniform, and due to the fact that the blowing area is reduced, the heat dissipation space is enlarged, the heat dissipation time is shortened, and the efficiency is improved.

Owner:杭州精工机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com