Patents

Literature

37results about How to "Improve exhaust quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

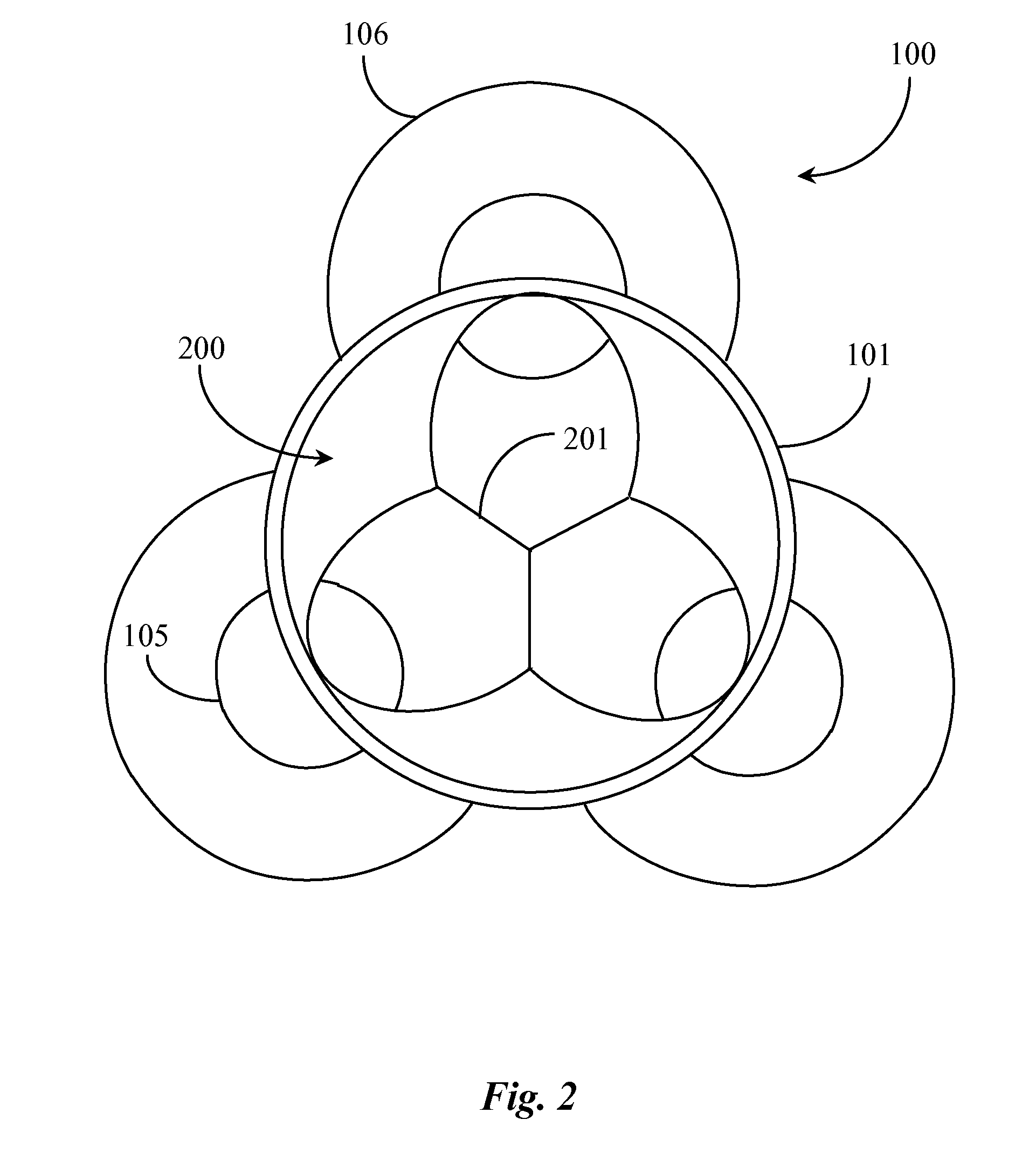

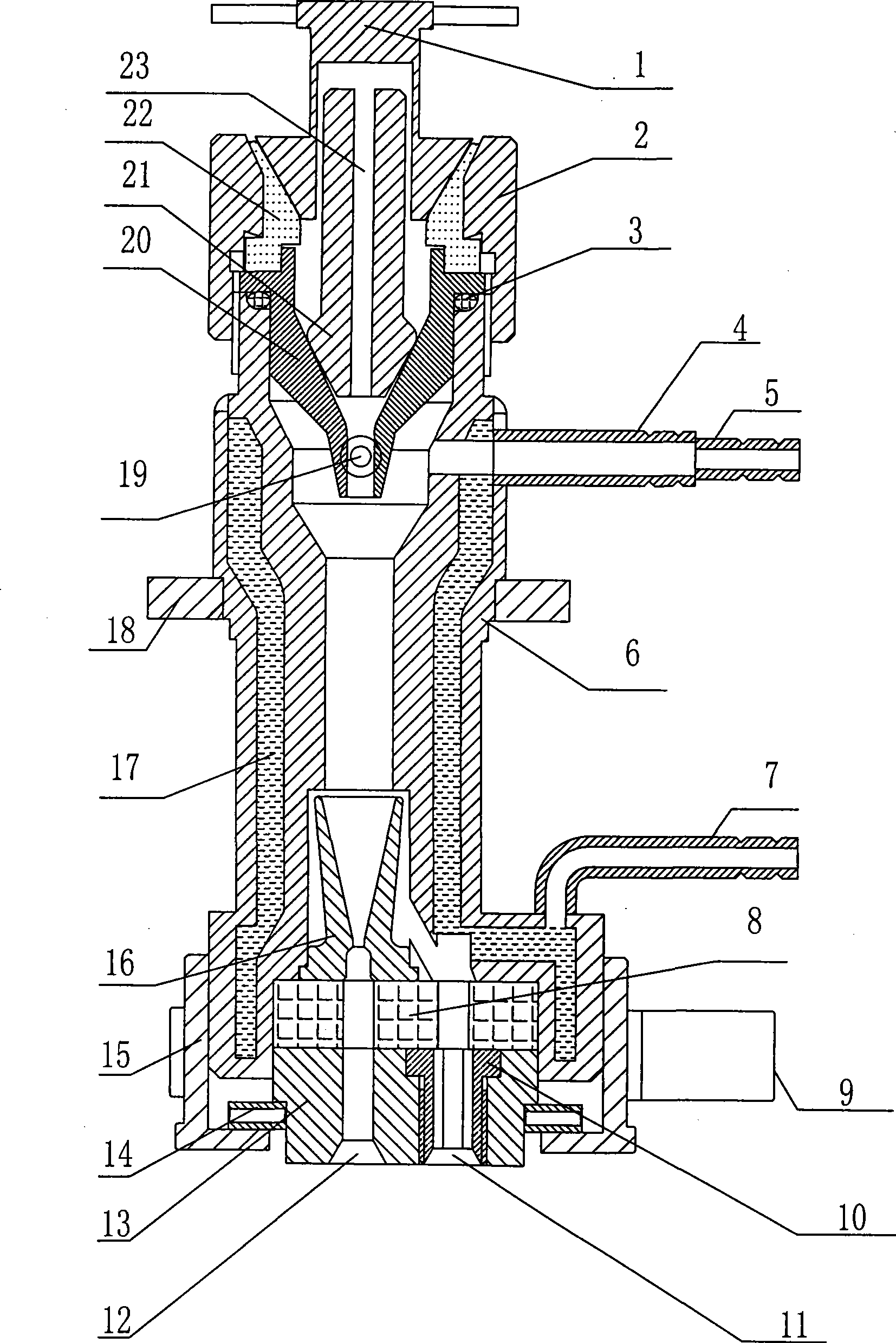

Intake device

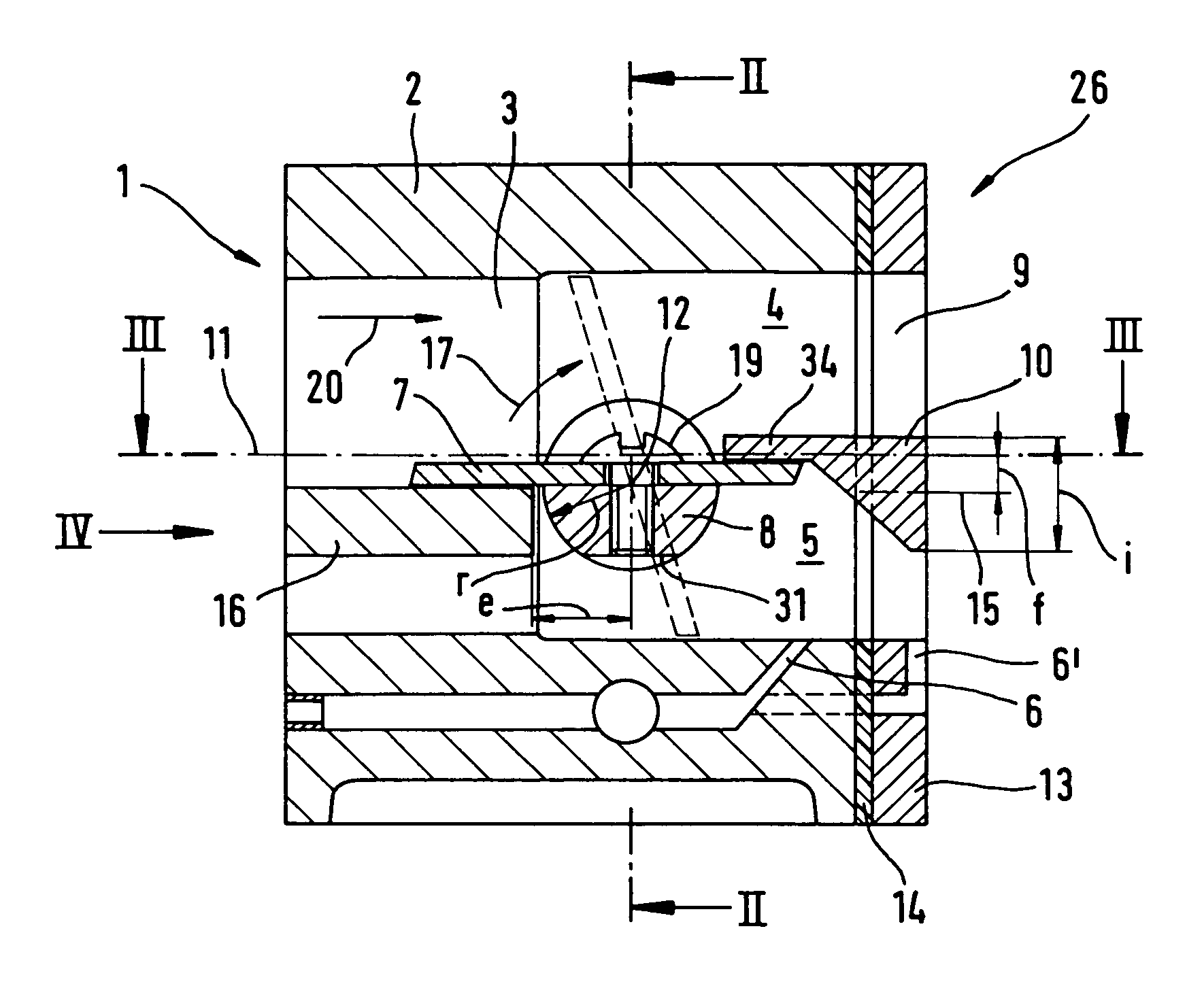

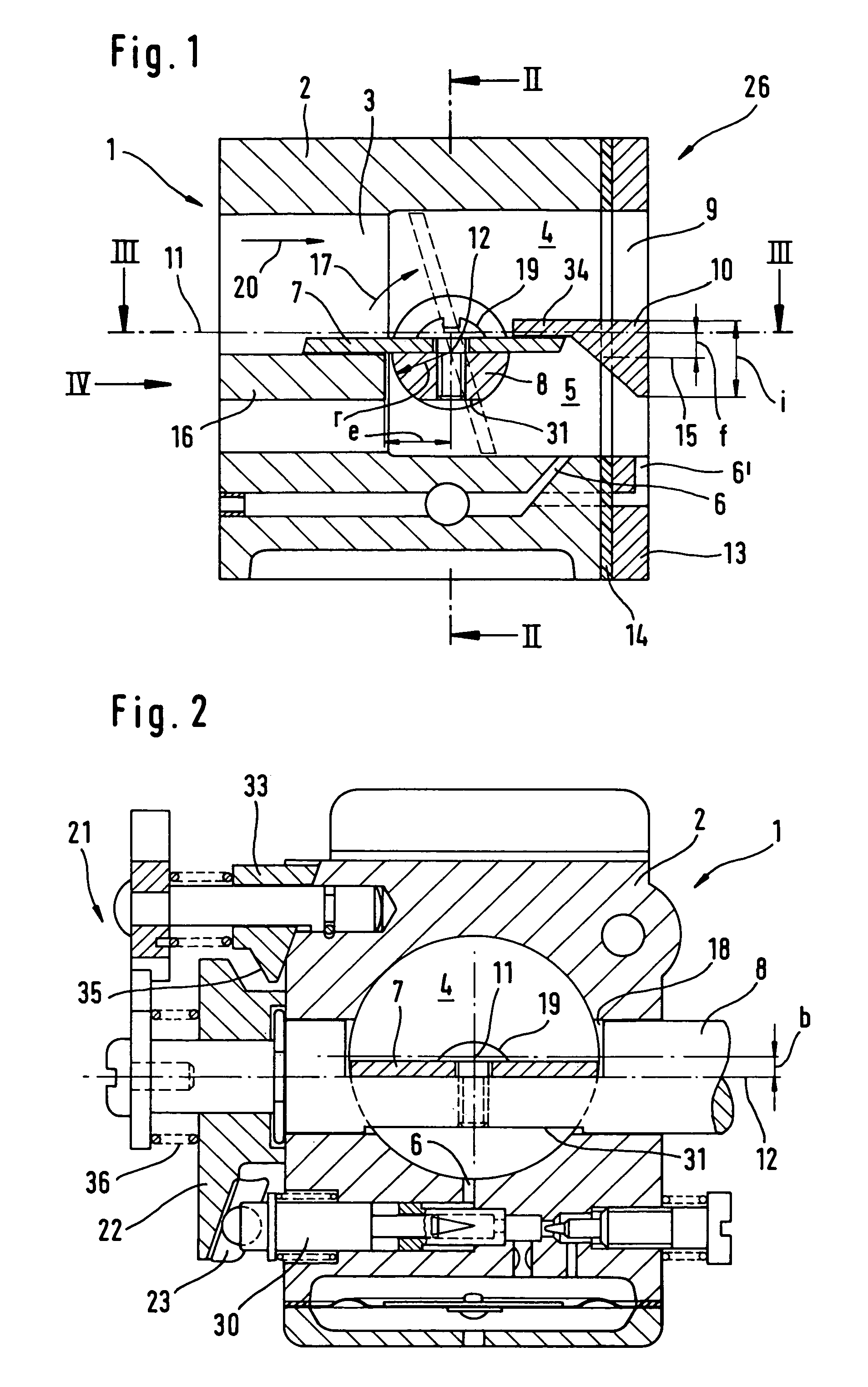

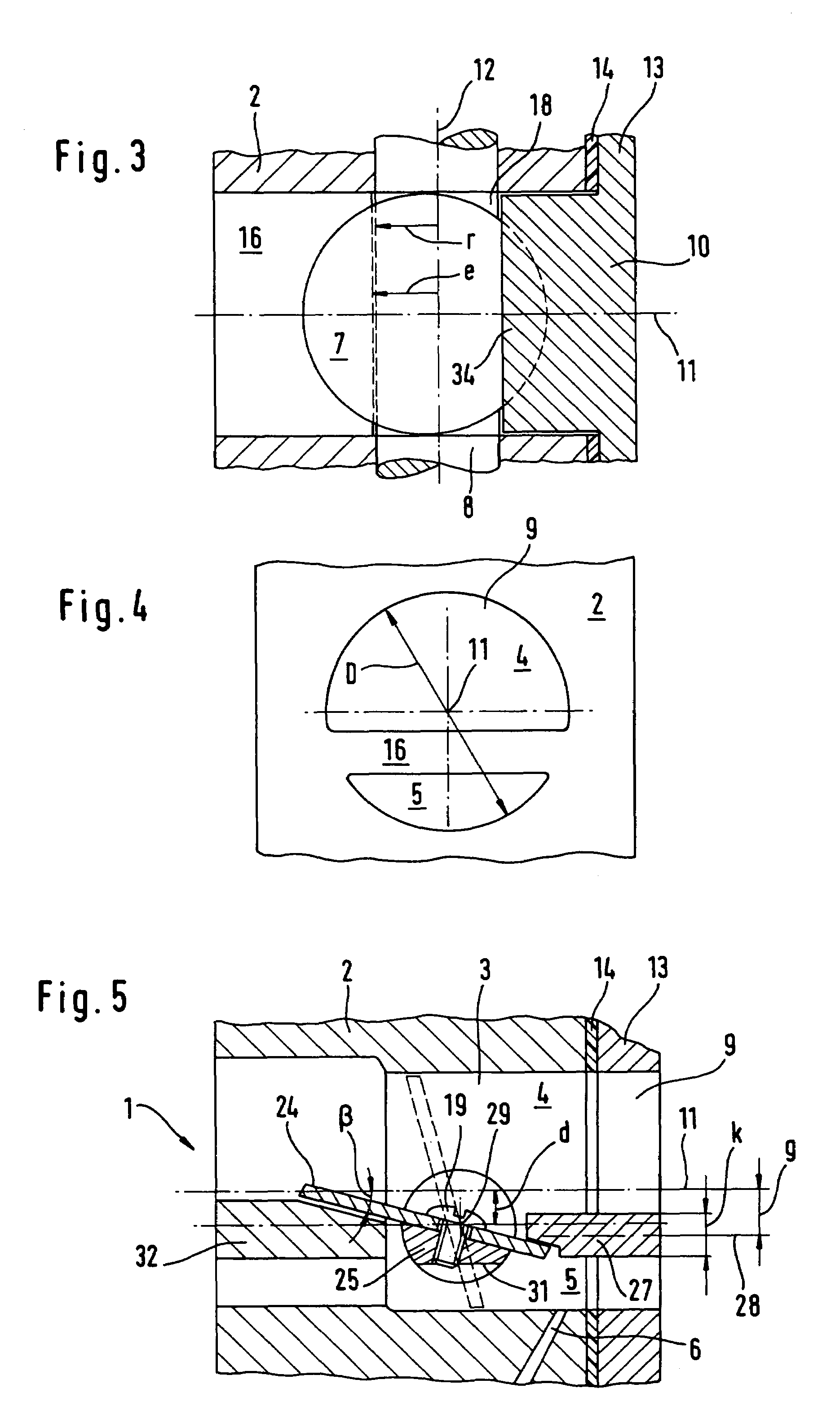

ActiveUS7011298B2Improve sealingEasy to assembleLighting and heating apparatusUsing liquid separation agentEngineeringButterfly valve

An intake device having an intake channel that includes an intake channel section is provided. A butterfly valve is pivotably mounted in the intake channel section. A dividing wall is disposed downstream of the butterfly valve and divides the intake channel section into an air duct and a mixture duct. The air duct has a flow cross-section that is greater than the flow cross-section of the mixture duct. A fuel jet opens into the mixture duct.

Owner:ANDREAS STIHL AG & CO KG

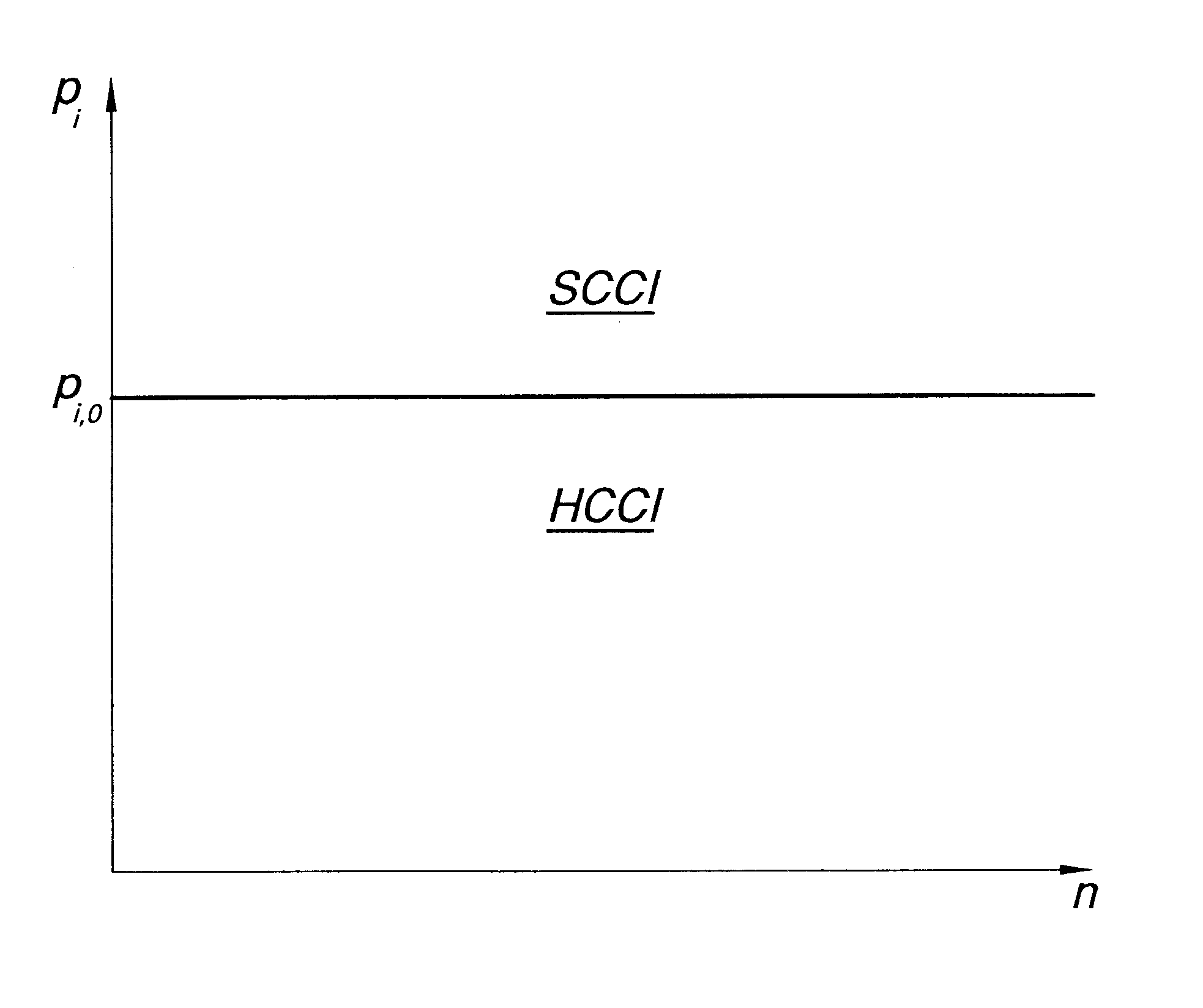

Method of operating an internal combustion engine operated on gasoline type fuels

InactiveUS6668790B2Improve exhaust qualityImprove efficiencyElectrical controlCombustion enginesCombustion chamberTop dead center

Owner:AVL LIST GMBH

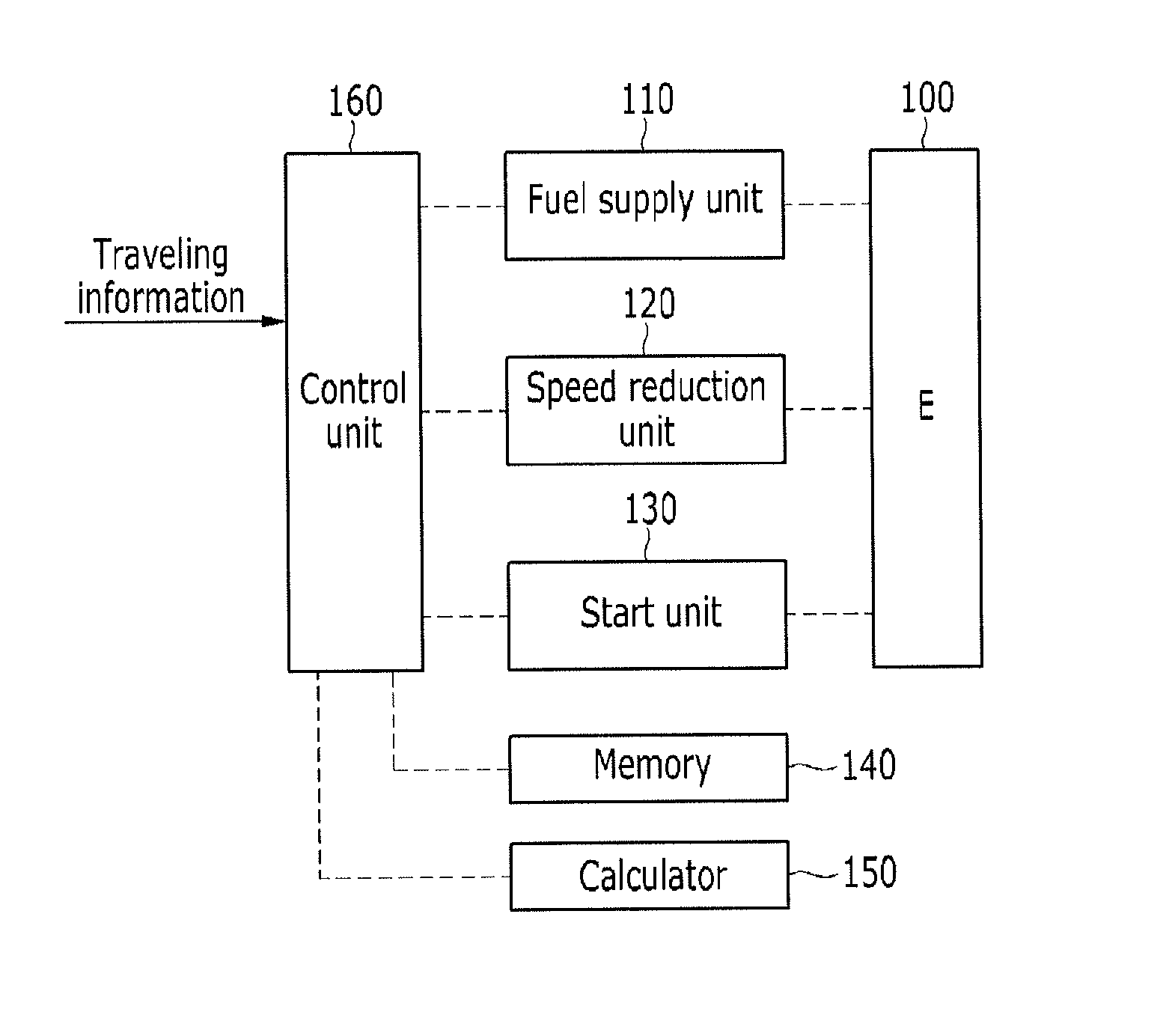

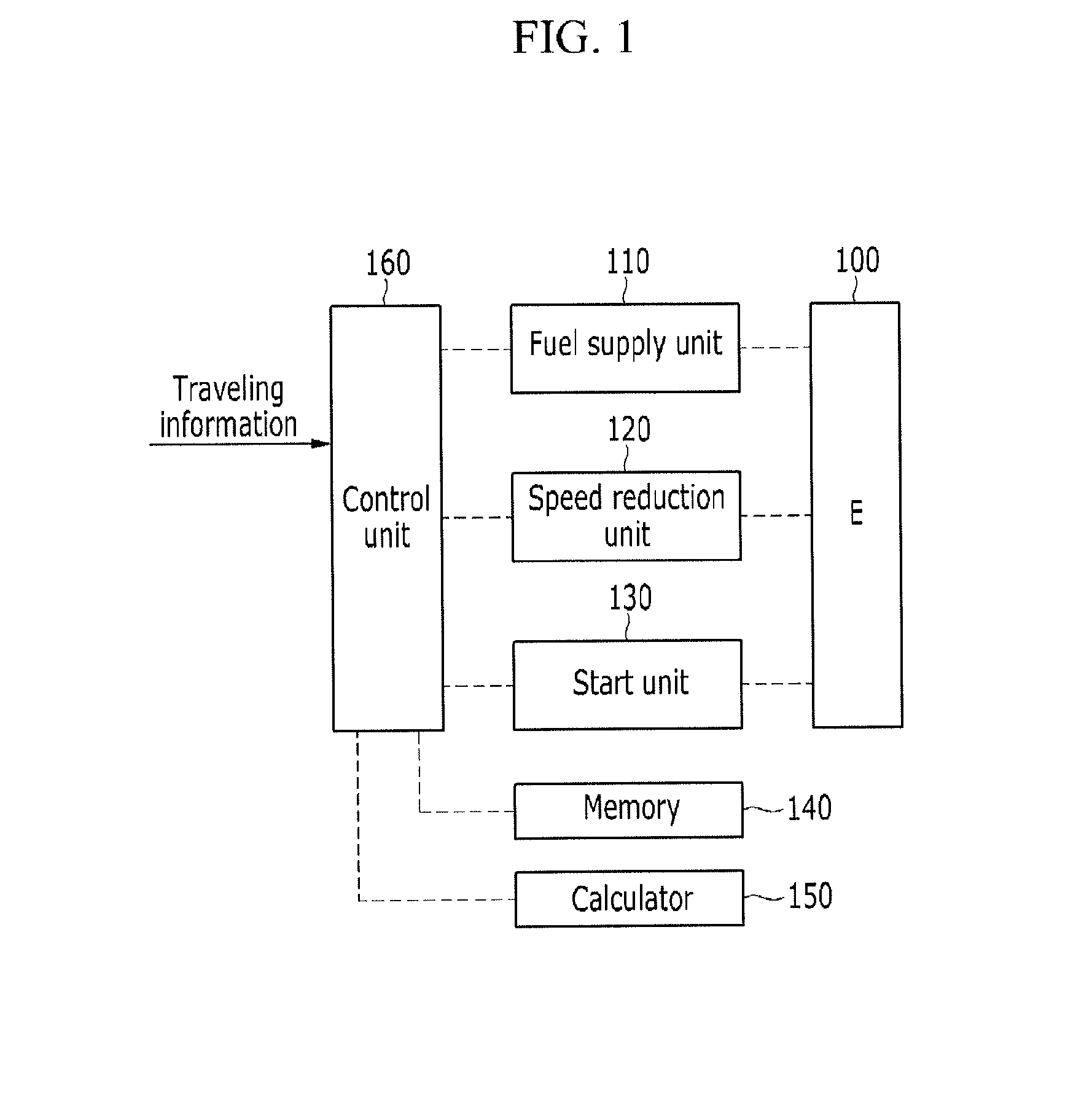

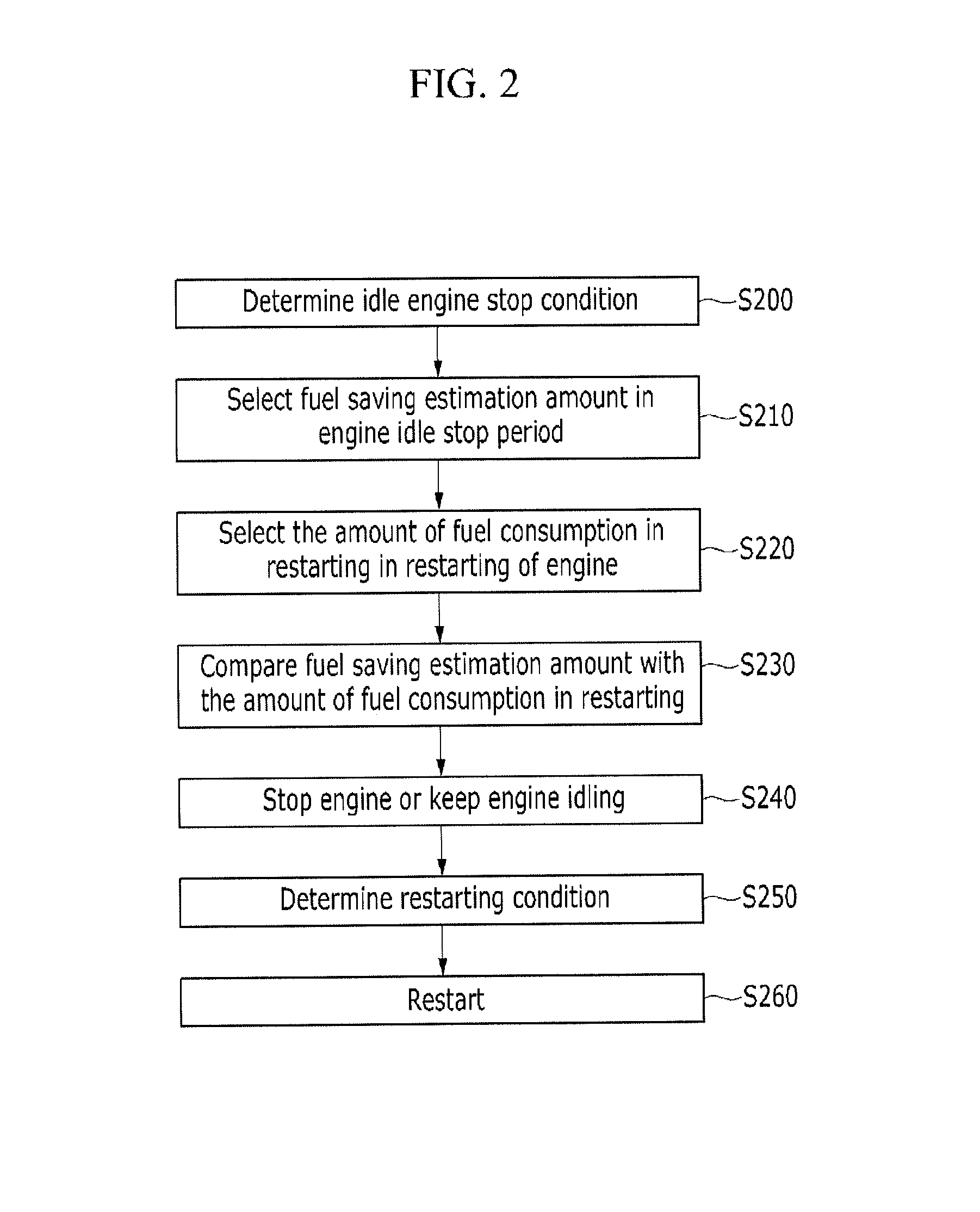

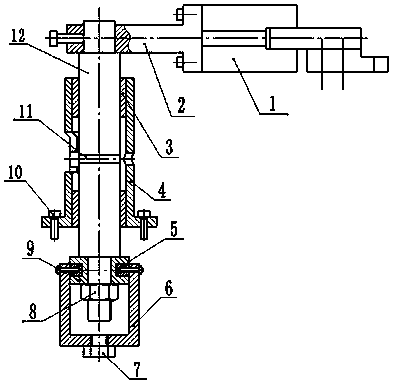

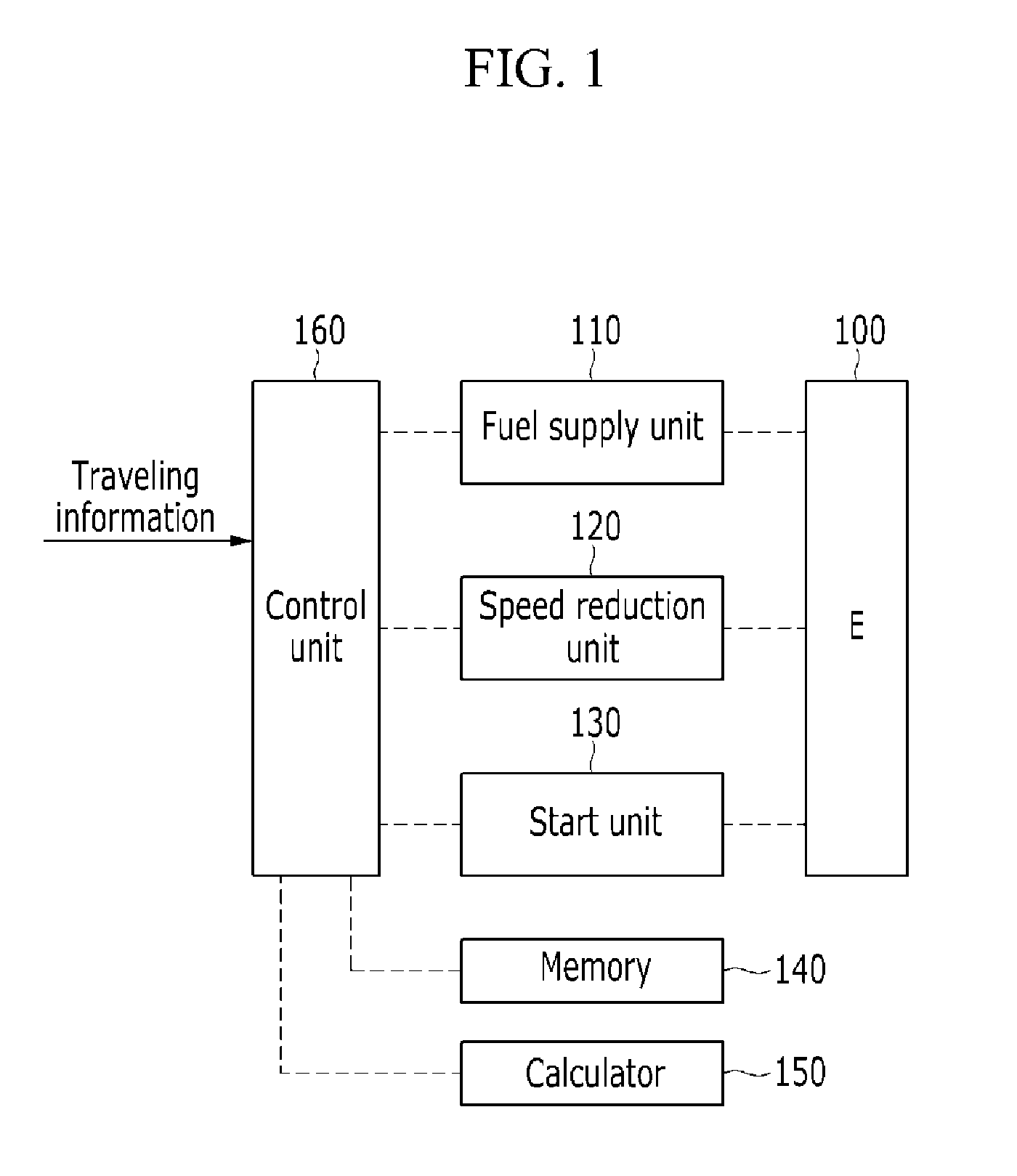

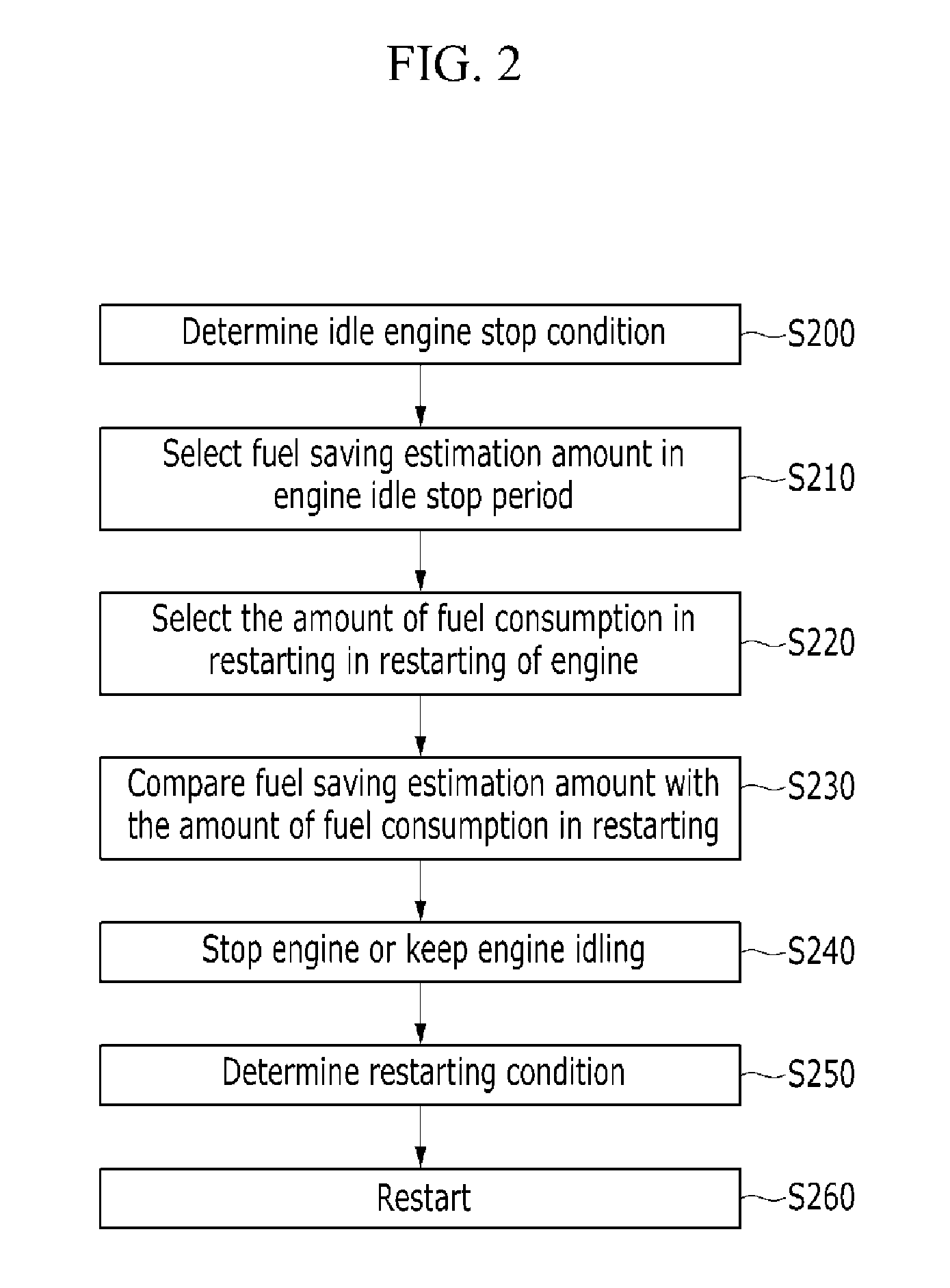

Idle stop condition determination method of engine

ActiveUS20150075491A1Reduce wasteImprove exhaust qualityElectrical controlInternal combustion piston enginesIdle speedEngineering

An idle stop condition determination method of an engine includes: calculating and storing a fuel saving estimation amount in idle stop of an engine on the basis of traveling information; calculating the amount of fuel consumption in restarting for restarting, when an idle stop condition of the engine is satisfied; comparing the magnitudes of the fuel saving estimation amount with the amount of fuel consumption in restarting, and stopping the engine in accordance with the result of the comparing; and restarting the engine, when a restarting condition of the engine is satisfied.

Owner:HYUNDAI MOTOR CO LTD

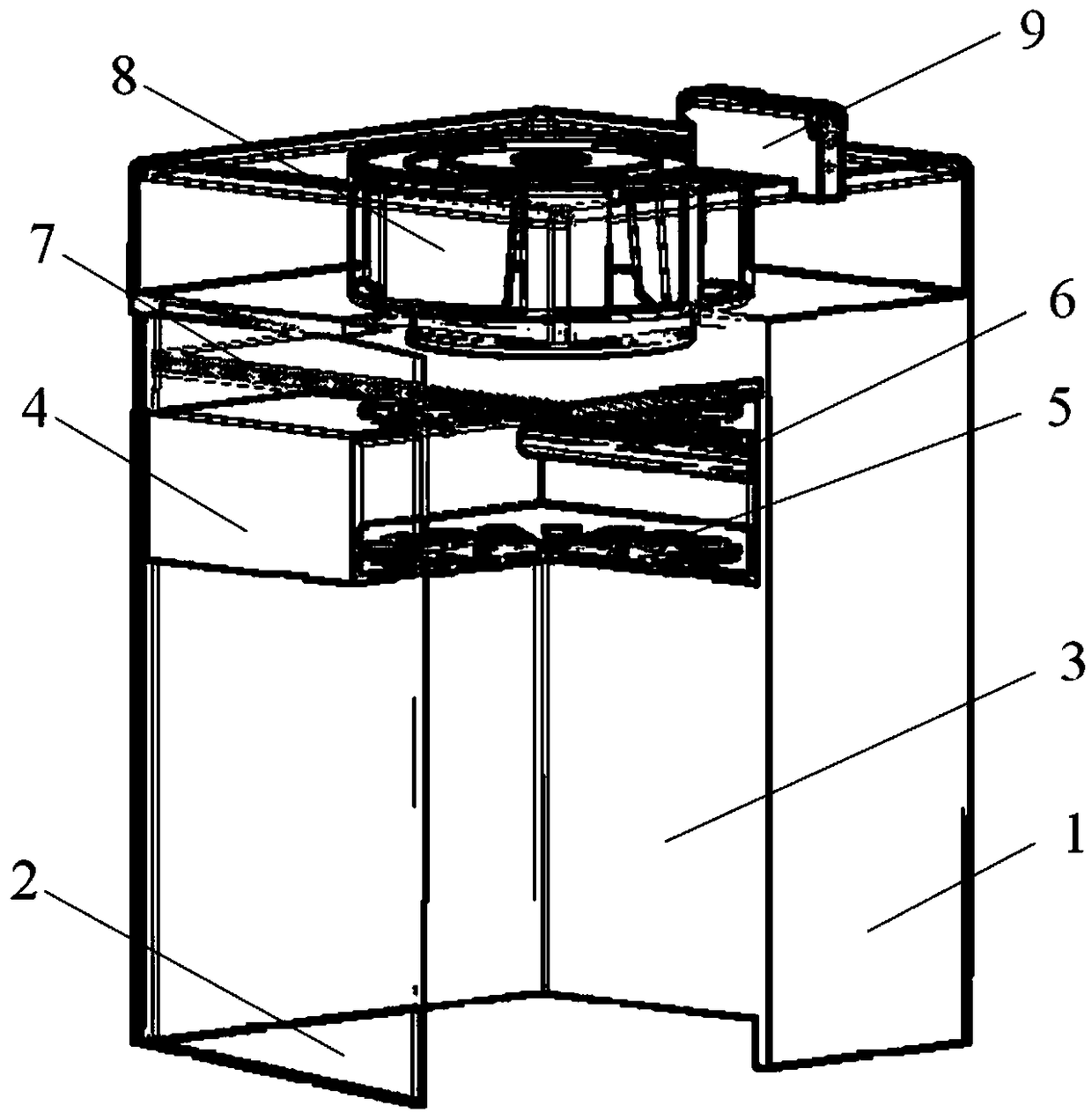

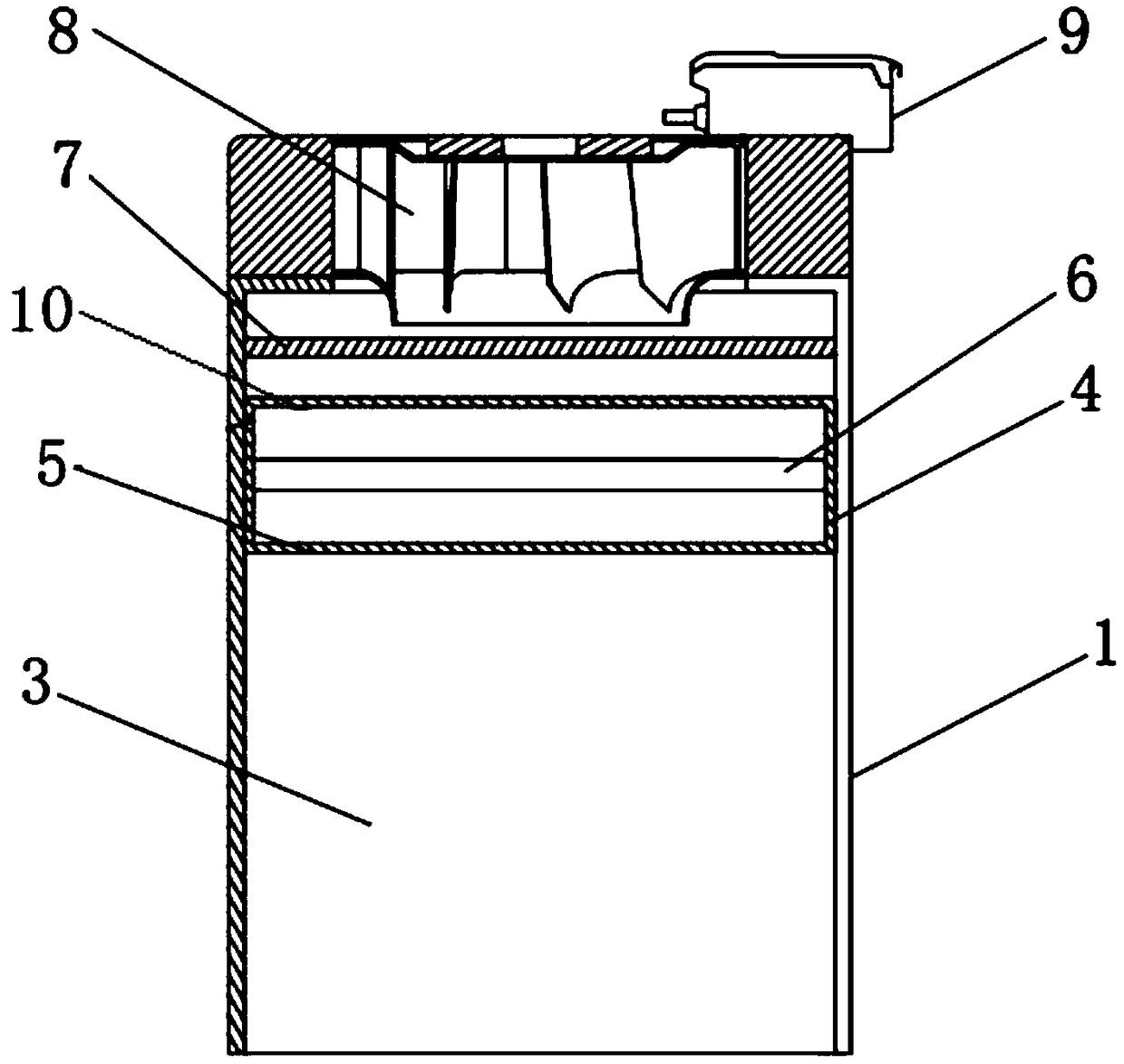

Opposite piston type engine

InactiveCN101871389AImprove efficiencyReduce oil consumptionCasingsInternal combustion piston enginesExhaust valveCombustion chamber

The invention discloses an opposite piston type engine, which comprises a cylinder body, an intake valve, an exhaust valve, a first piston and a second piston which can move in a way of facing to each other or reversing to each other, a first crankshaft connected with the first piston and a second crankshaft connected with the second piston, wherein the first piston and the second piston are arranged in the cylinder body in a way of facing to each other, and the intake valve and the exhaust valve are arranged on the wall of the cylinder body between the first piston and the second piston. Since two pistons which can move in the way of facing to each other are arranged in the cylinder body, the invention has the advantages that the heat energy generated by gas in a combustion chamber between the two pistons can be converted into mechanical energy to a large extent and the work efficiency of the engine is greatly improved.

Owner:西安大劲发动机有限公司

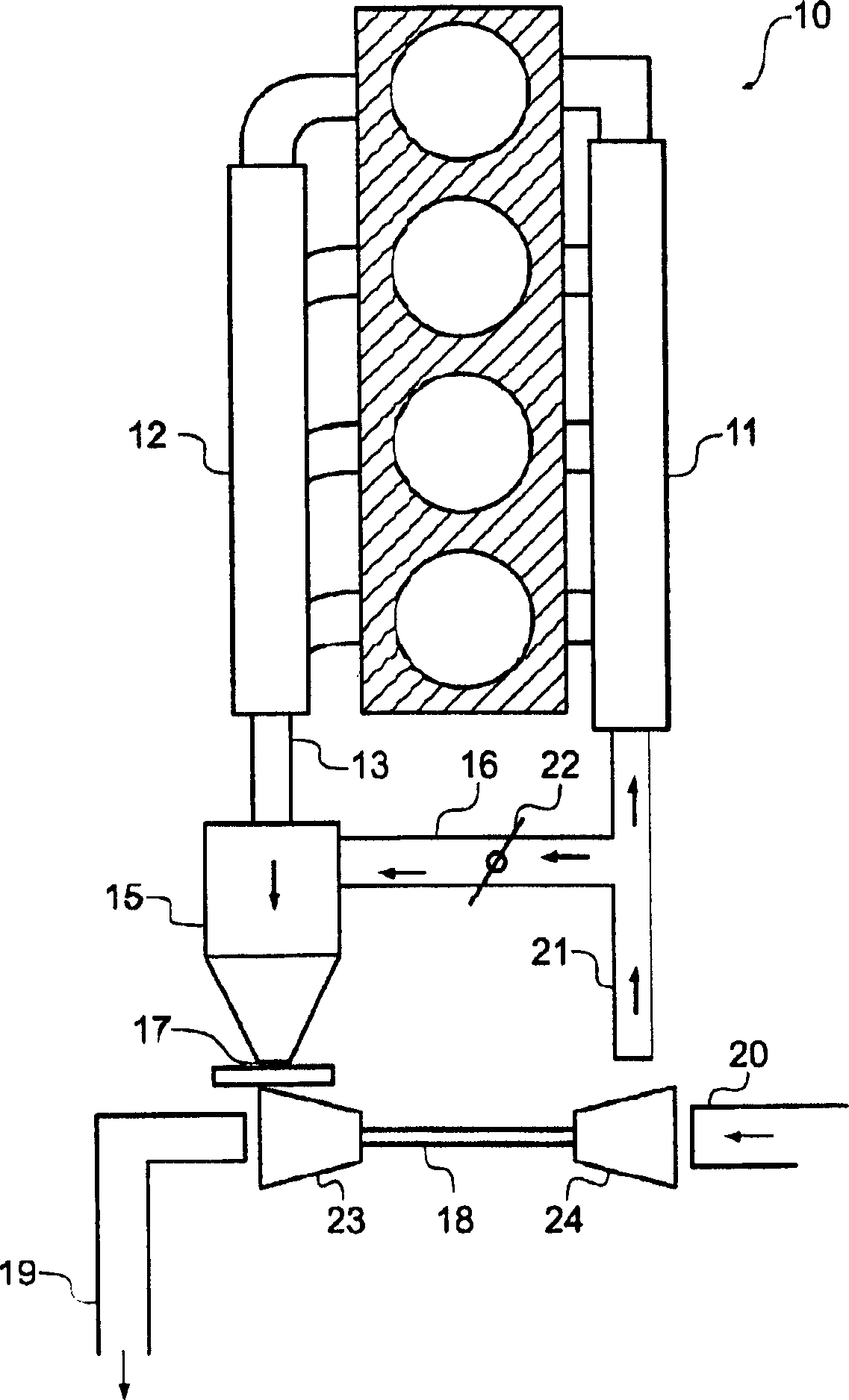

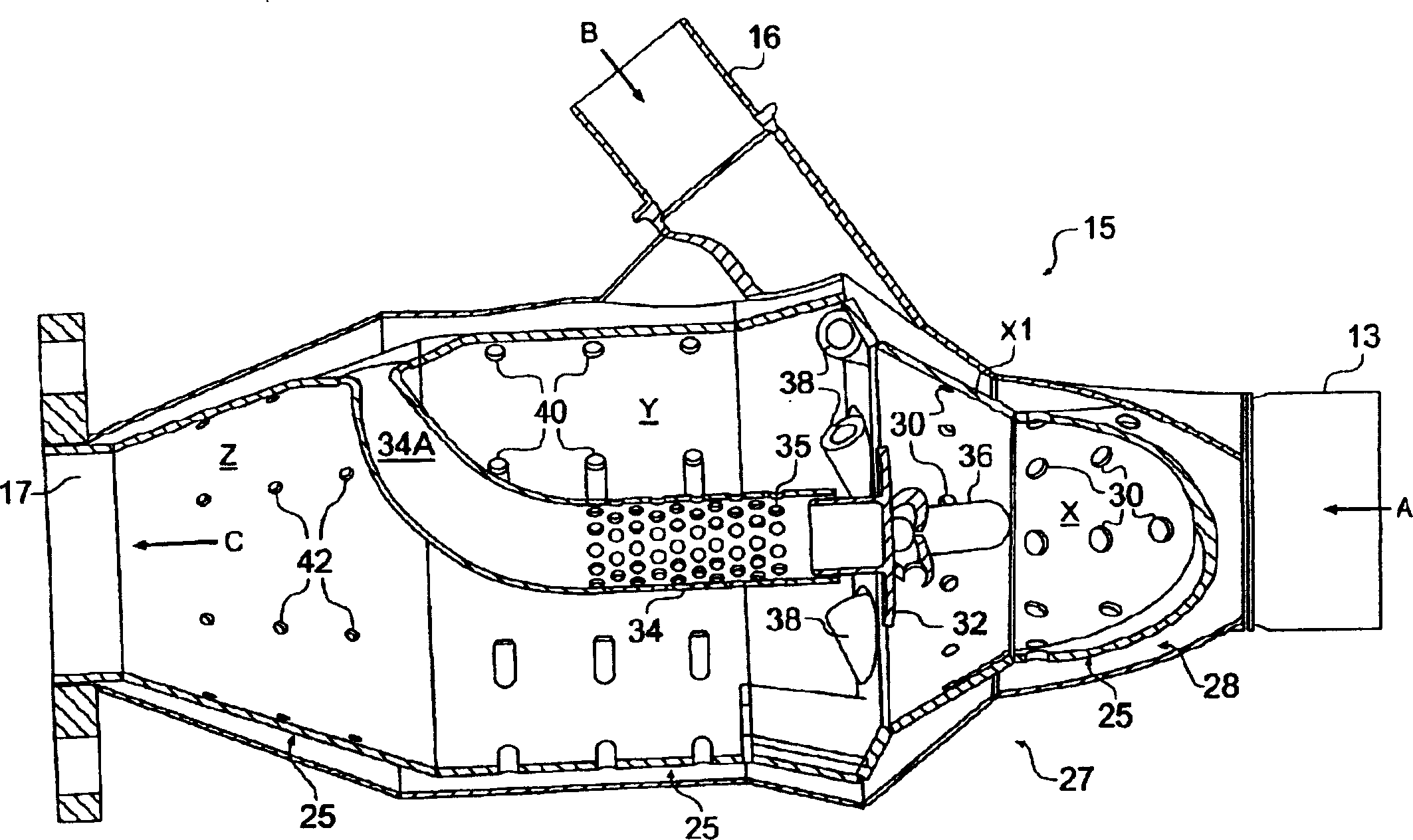

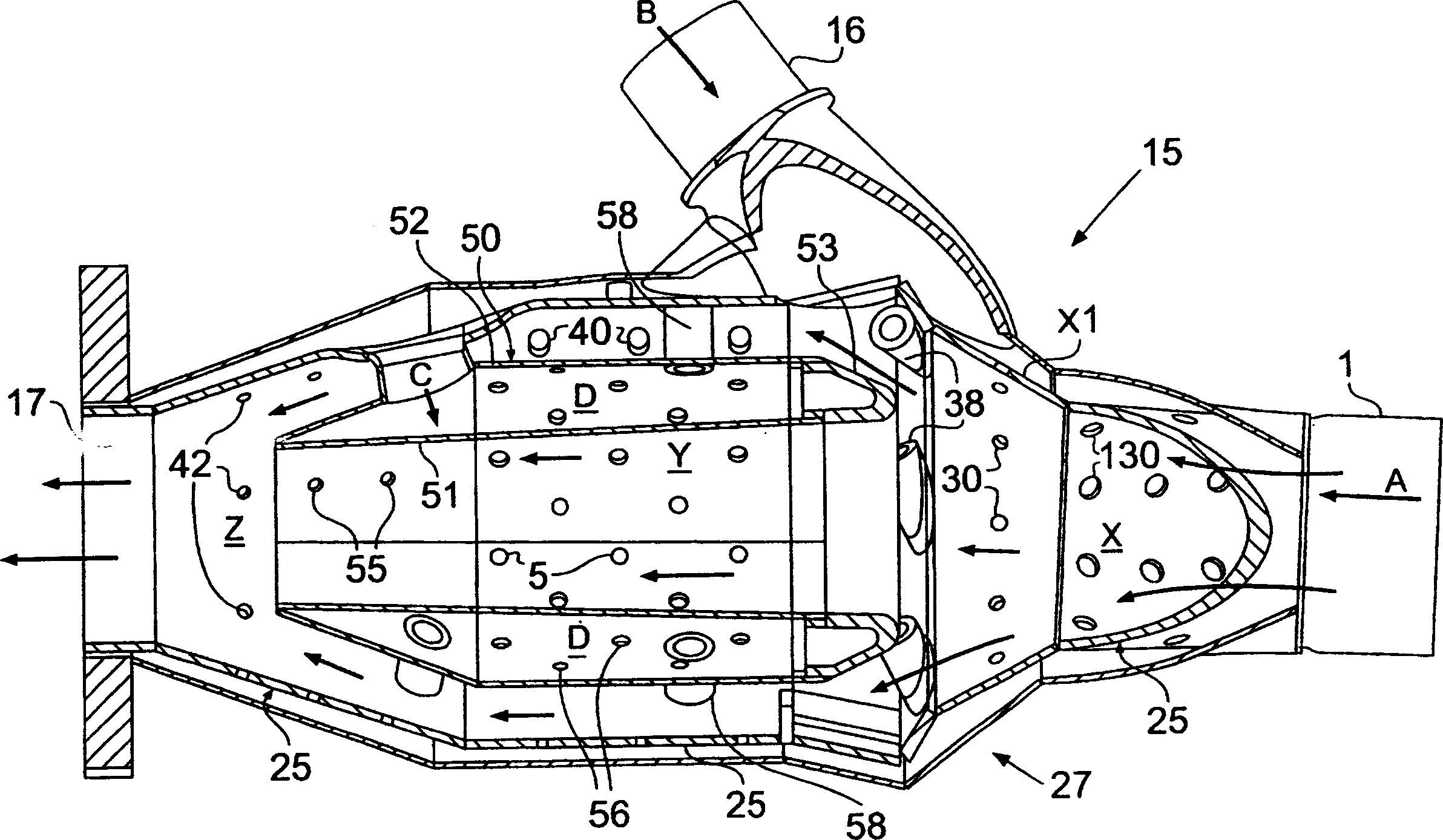

Combustion unit for turbocharger

InactiveCN1768194ASmall hysteresisHigh power outputInternal combustion piston enginesSilencing apparatusExhaust gasInternal combustion engine

A combustion device (15) is mainly used to feed a turbocharger (18) to generate compressed air for supply to an internal combustion engine (10). The device (15) is supplied with exhaust gases from the internal combustion engine and these gases are mixed with the air in the exhaust gas from the combustible material of the device, thus providing and enhancing the supply to the turbocharger. The combustion device is generally cylindrical, and air is added to the exhaust gas at the inlet (13) to promote combustion, and the combustion gases pass through the annular shape at high speed towards the outlet (17) leading to the turbocharger (18) space.

Owner:PRODRIVE 2000

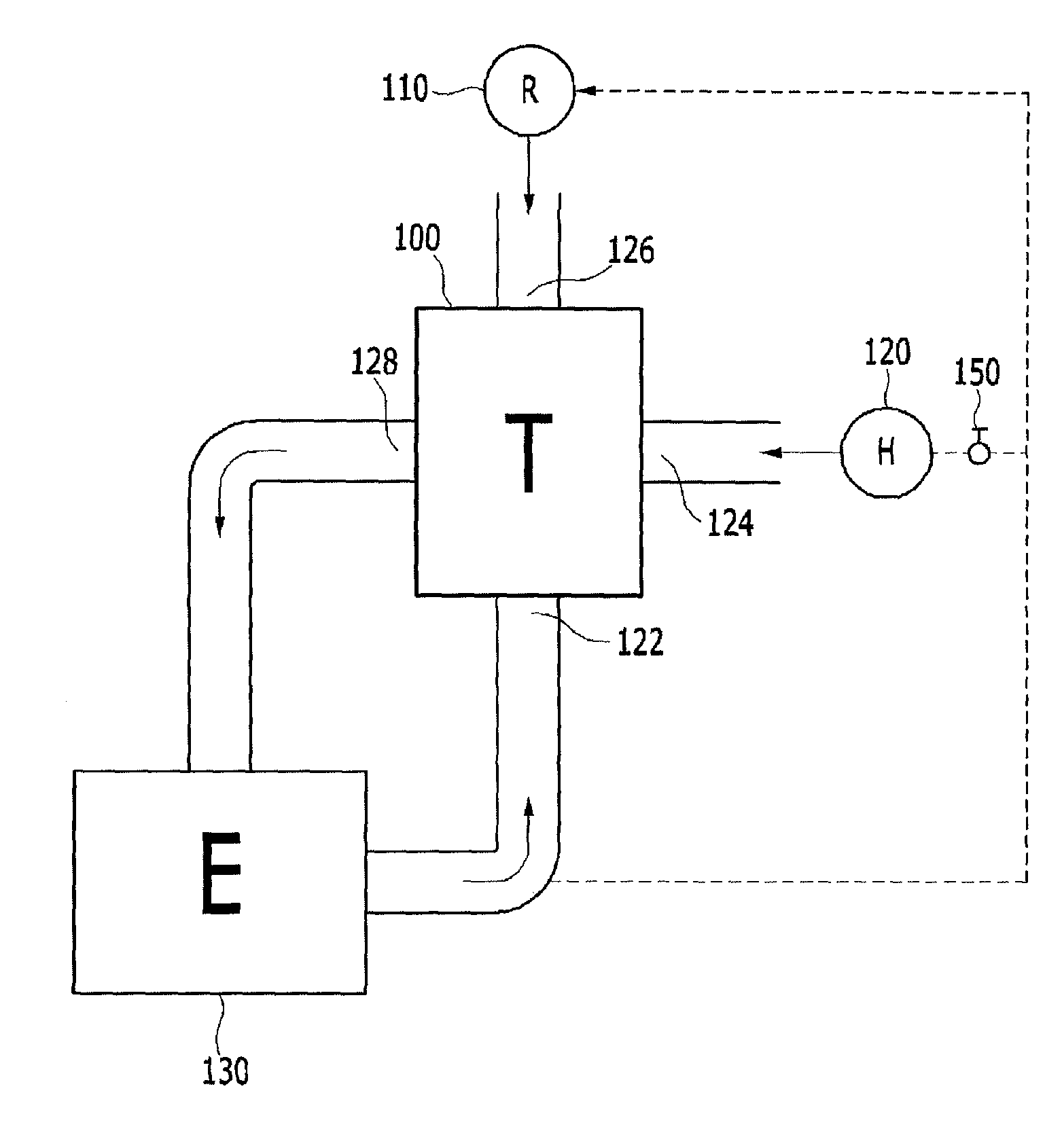

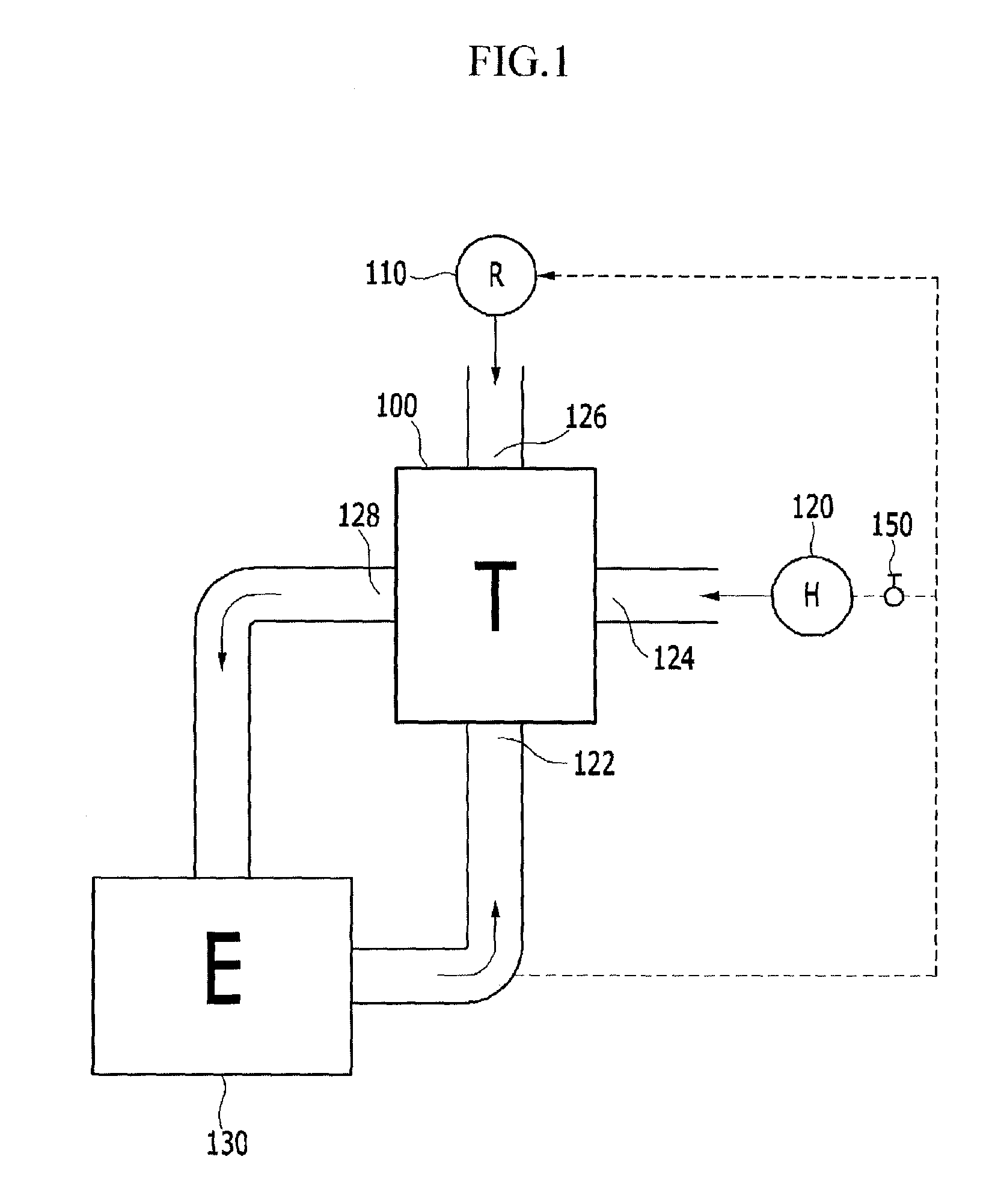

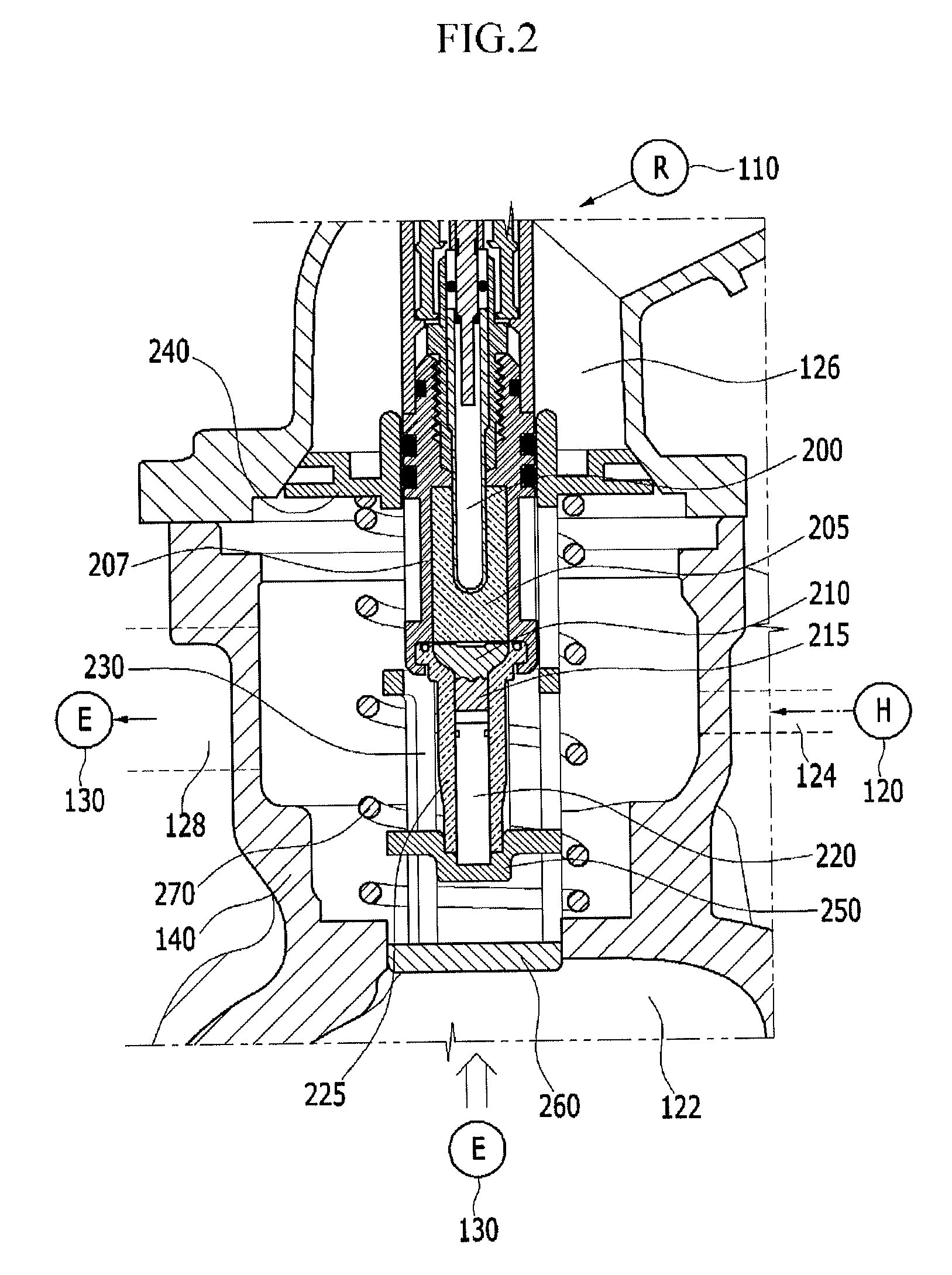

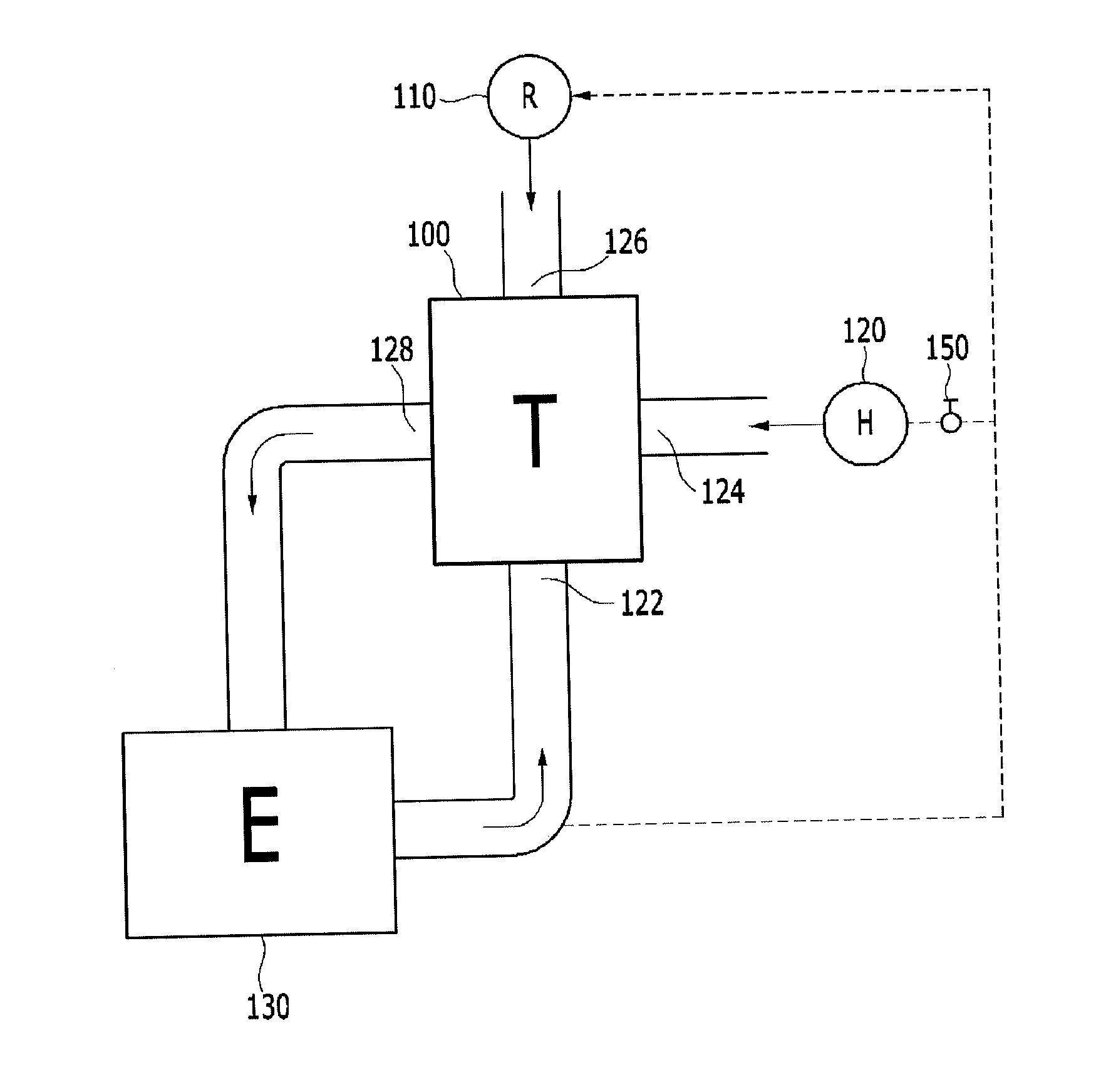

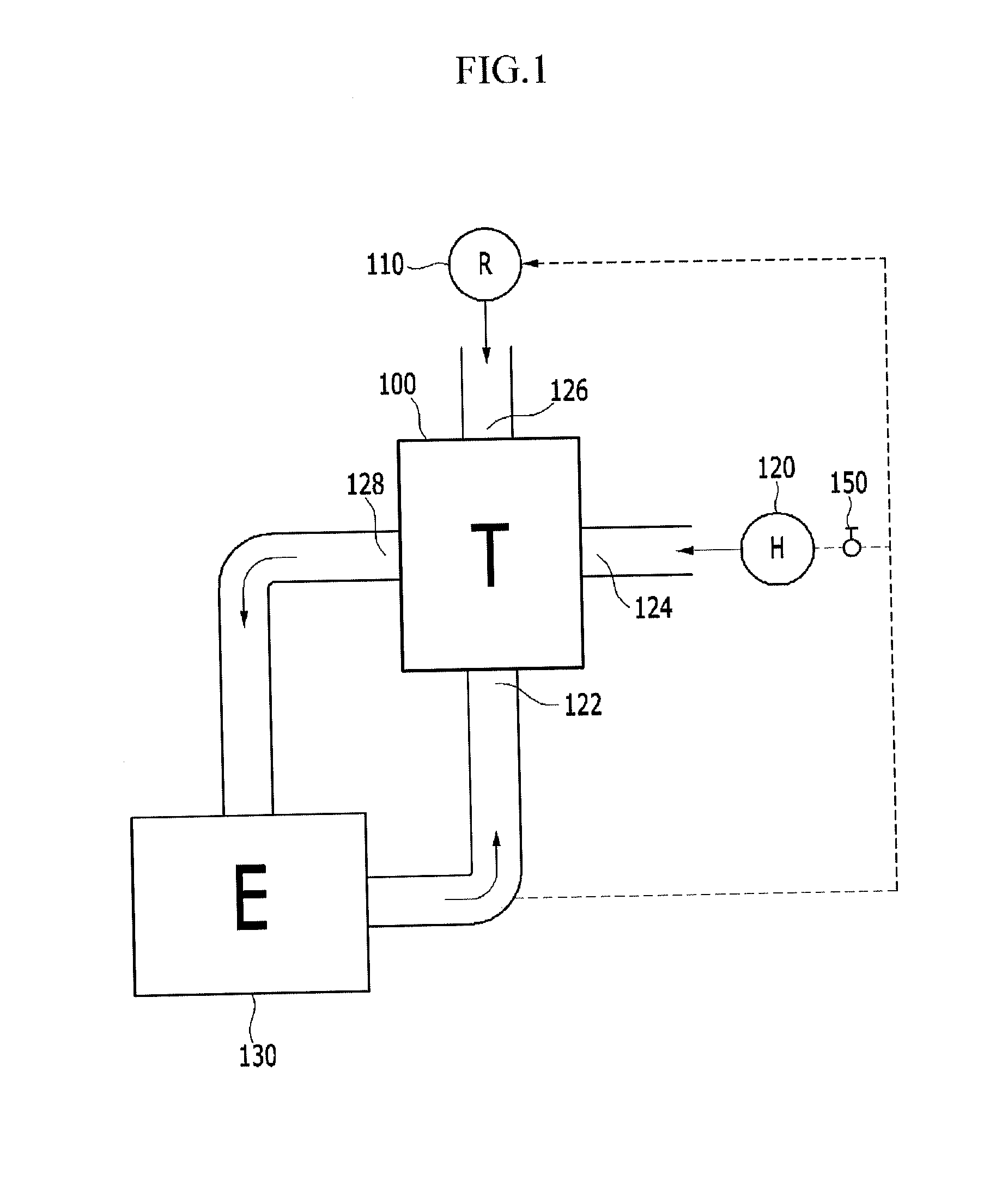

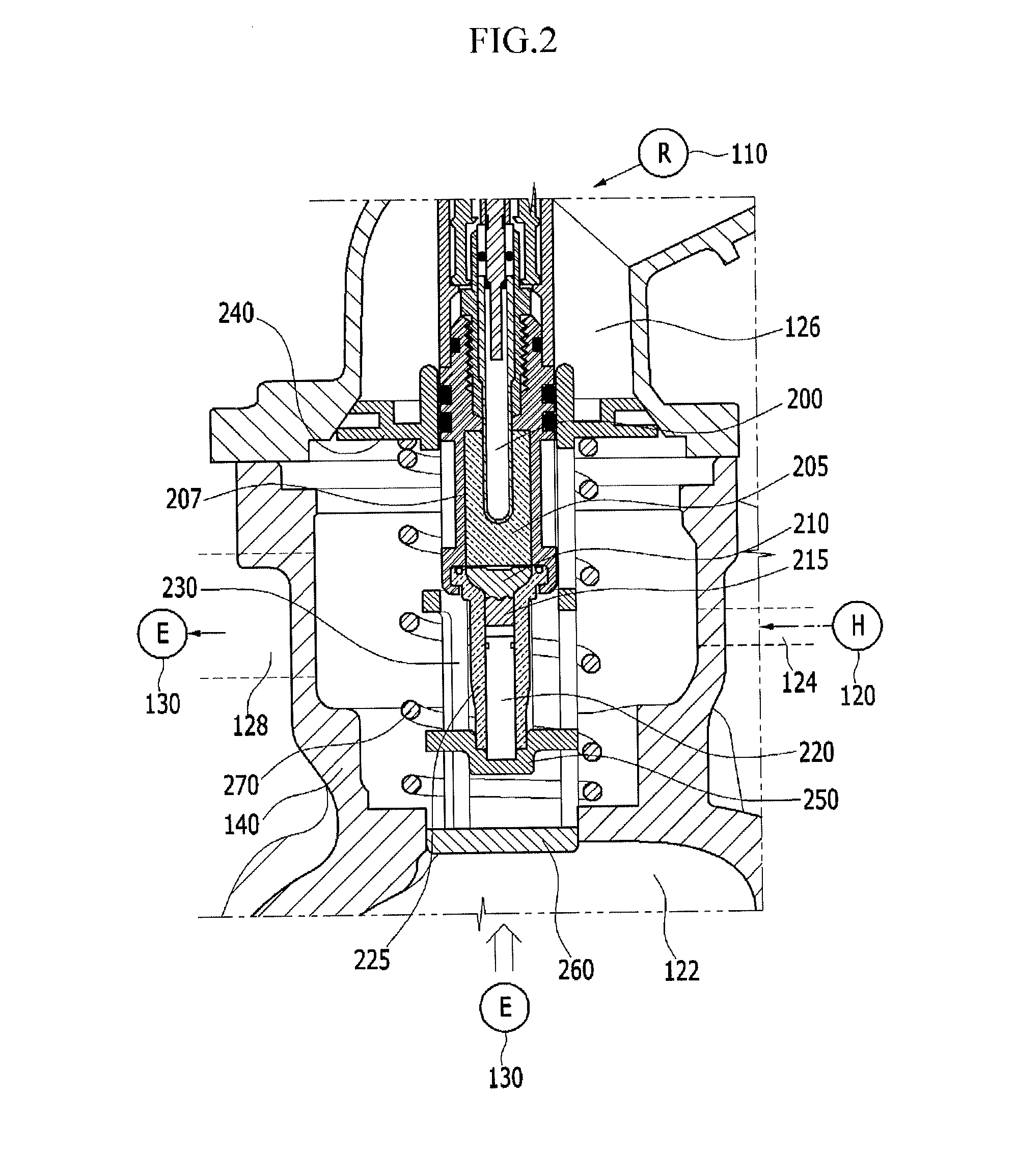

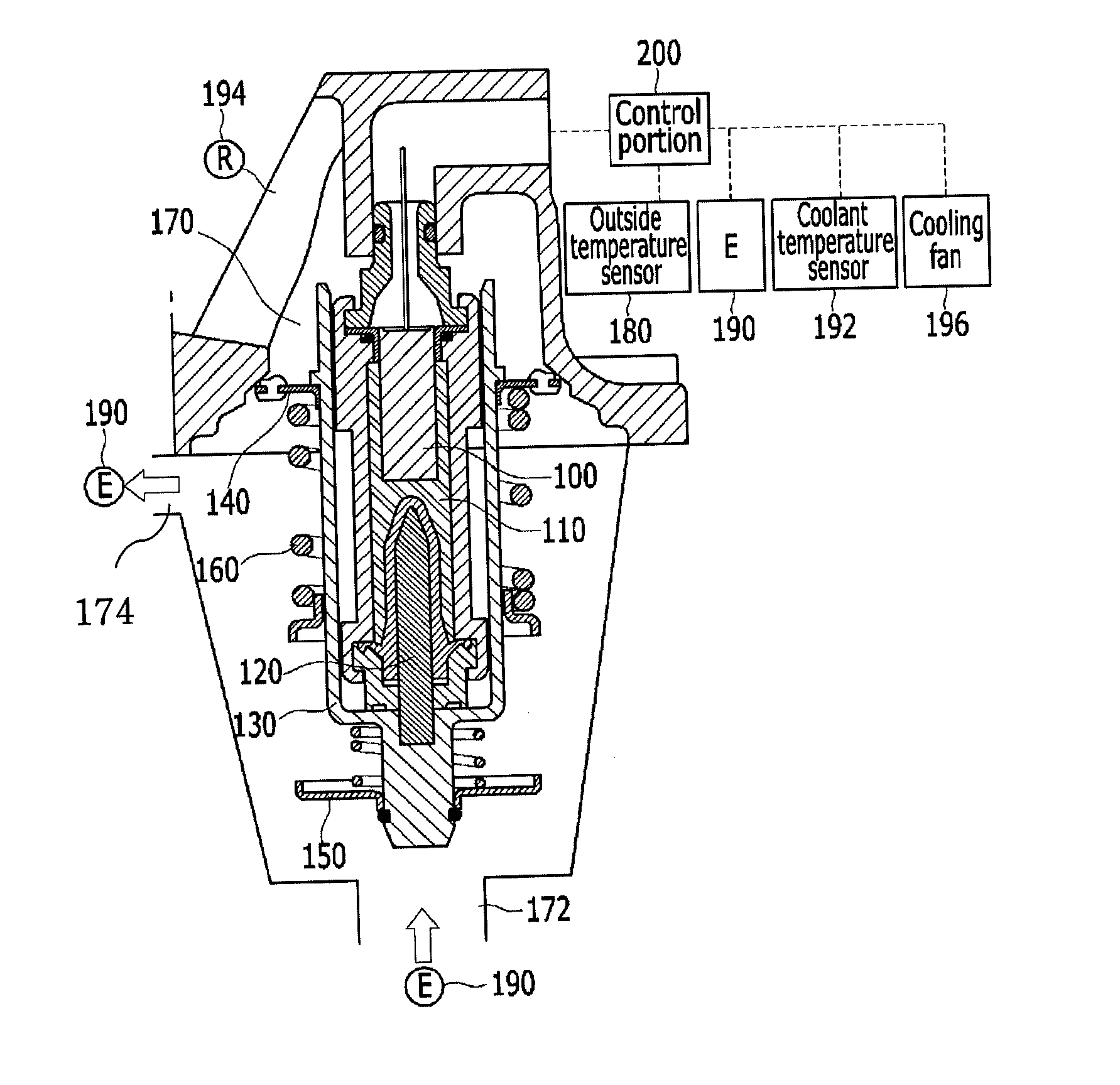

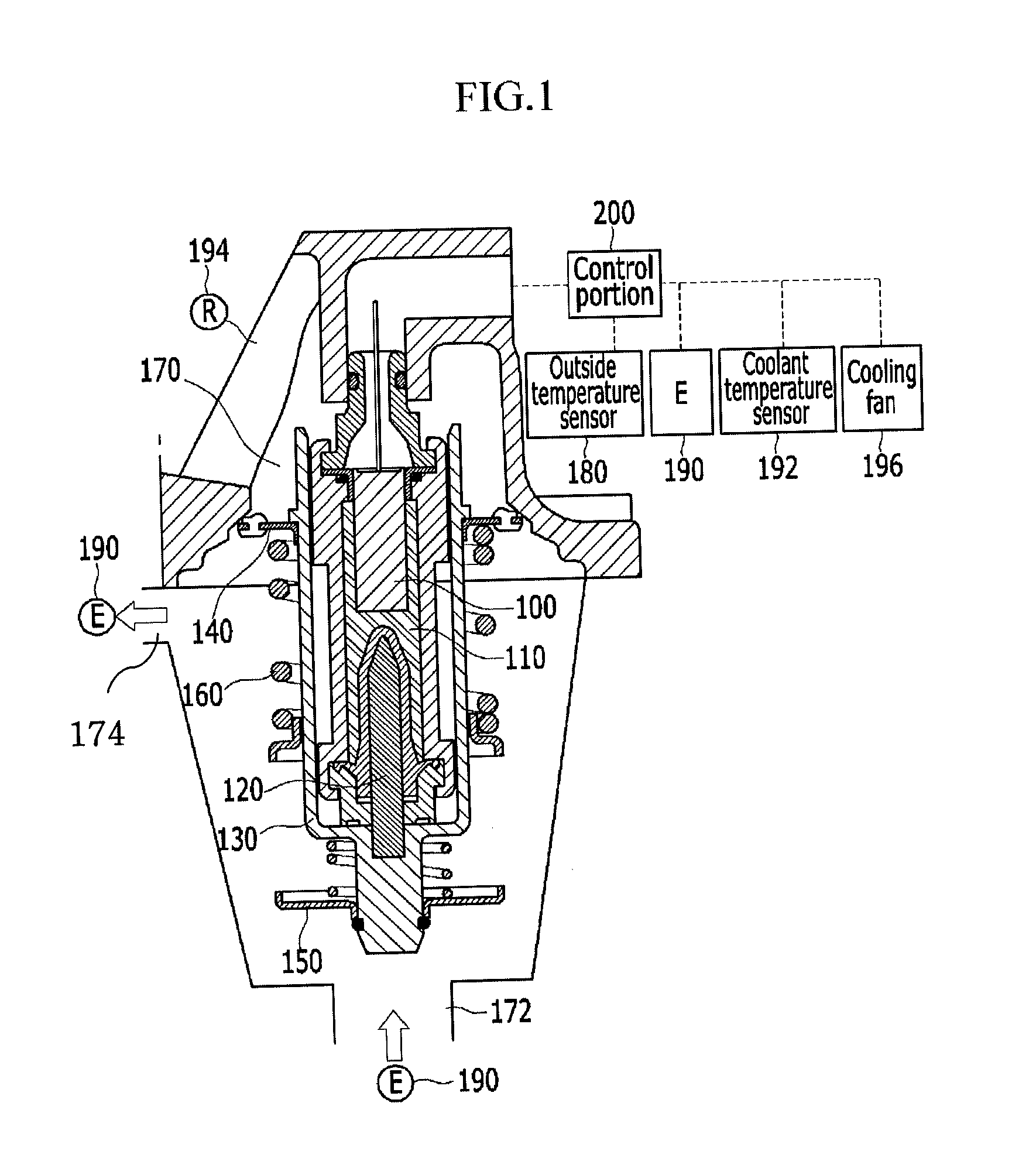

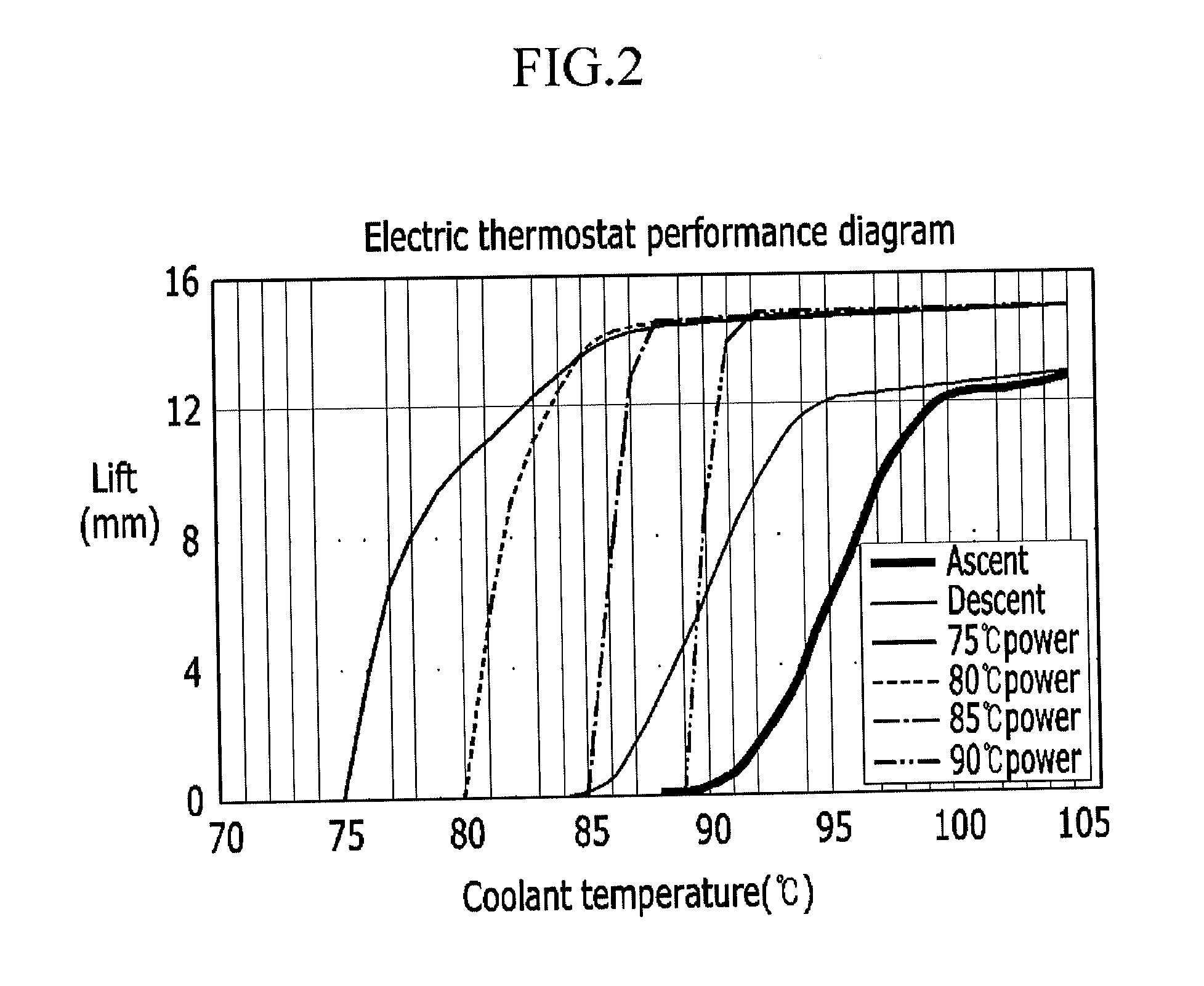

Engine having thermostat and system thereof

InactiveUS8973537B2Improve exhaust qualityHeating fastLiquid coolingOperating means/releasing devices for valvesThermostatValve guide

An engine system may include a thermostat casing connected to a first, second, third, and fourth flow channels, a valve guide in which a main valve that opens and closes the first flow channel is formed at one side, a closing valve that opens and closes the second flow channel is formed at the other side, and a bypass valve is formed adjacent to the closing valve, an elastic member that elastically supports the valve guide to enable the main valve to block the first flow channel and the closing valve to block the second flow channel, a driver that moves the valve guide so that the main valve opens the first flow channel and the closing valve opens the second flow channel according to a temperature of a coolant, and a control unit that controls the temperature and a flow of the coolant by controlling the driver.

Owner:HYUNDAI MOTOR CO LTD +1

Engine having thermostat and system thereof

InactiveUS20140182522A1Reduce fuel consumptionImprove exhaust qualityOperating means/releasing devices for valvesCoolant flow controlEngineeringThermostat

An engine system may include a thermostat casing connected to a first, second, third, and fourth flow channels, a valve guide in which a main valve that opens and closes the first flow channel is formed at one side, a closing valve that opens and closes the second flow channel is formed at the other side, and a bypass valve is formed adjacent to the closing valve, an elastic member that elastically supports the valve guide to enable the main valve to block the first flow channel and the closing valve to block the second flow channel, a driver that moves the valve guide so that the main valve opens the first flow channel and the closing valve opens the second flow channel according to a temperature of a coolant, and a control unit that controls the temperature and a flow of the coolant by controlling the driver.

Owner:HYUNDAI MOTOR CO LTD +1

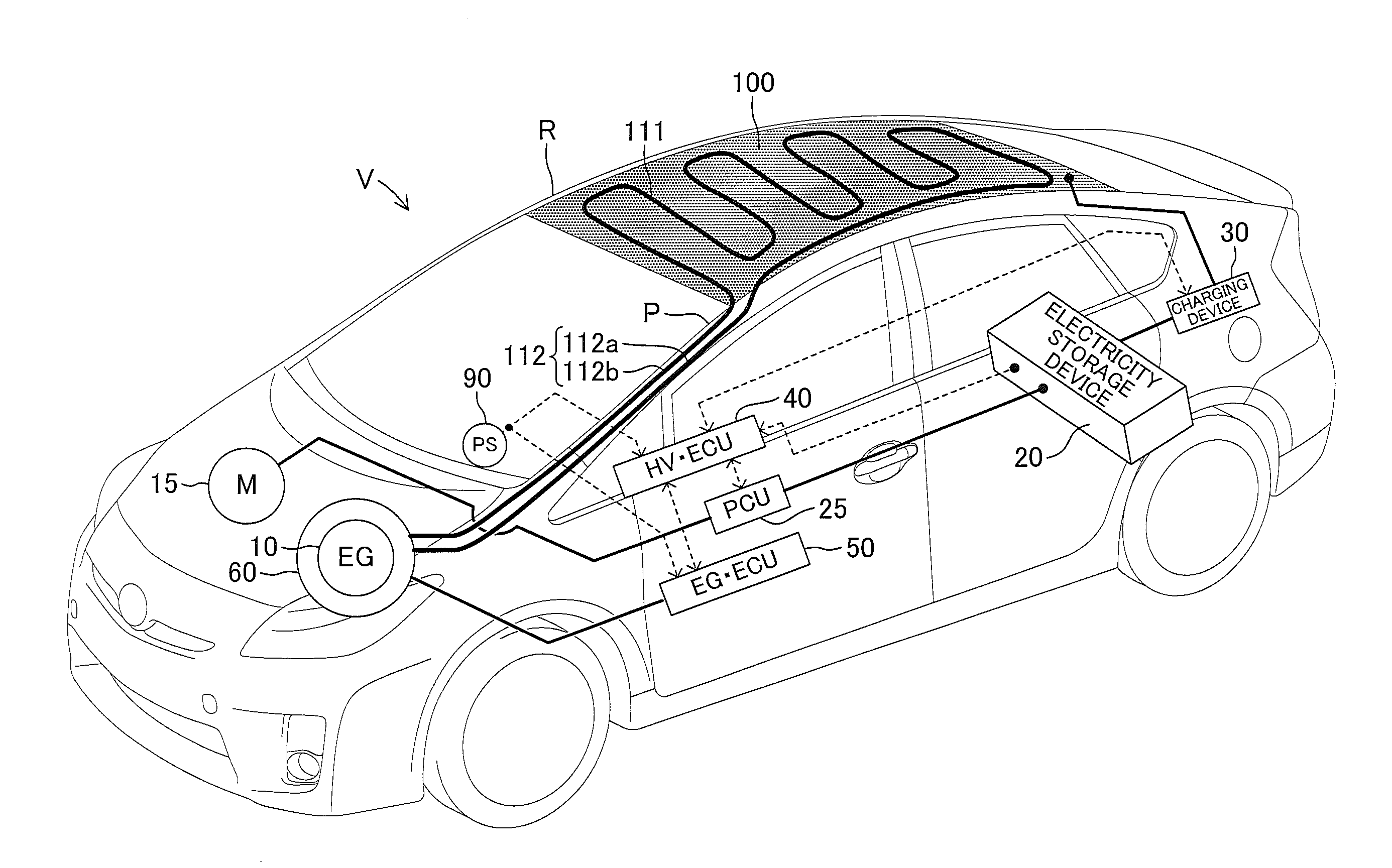

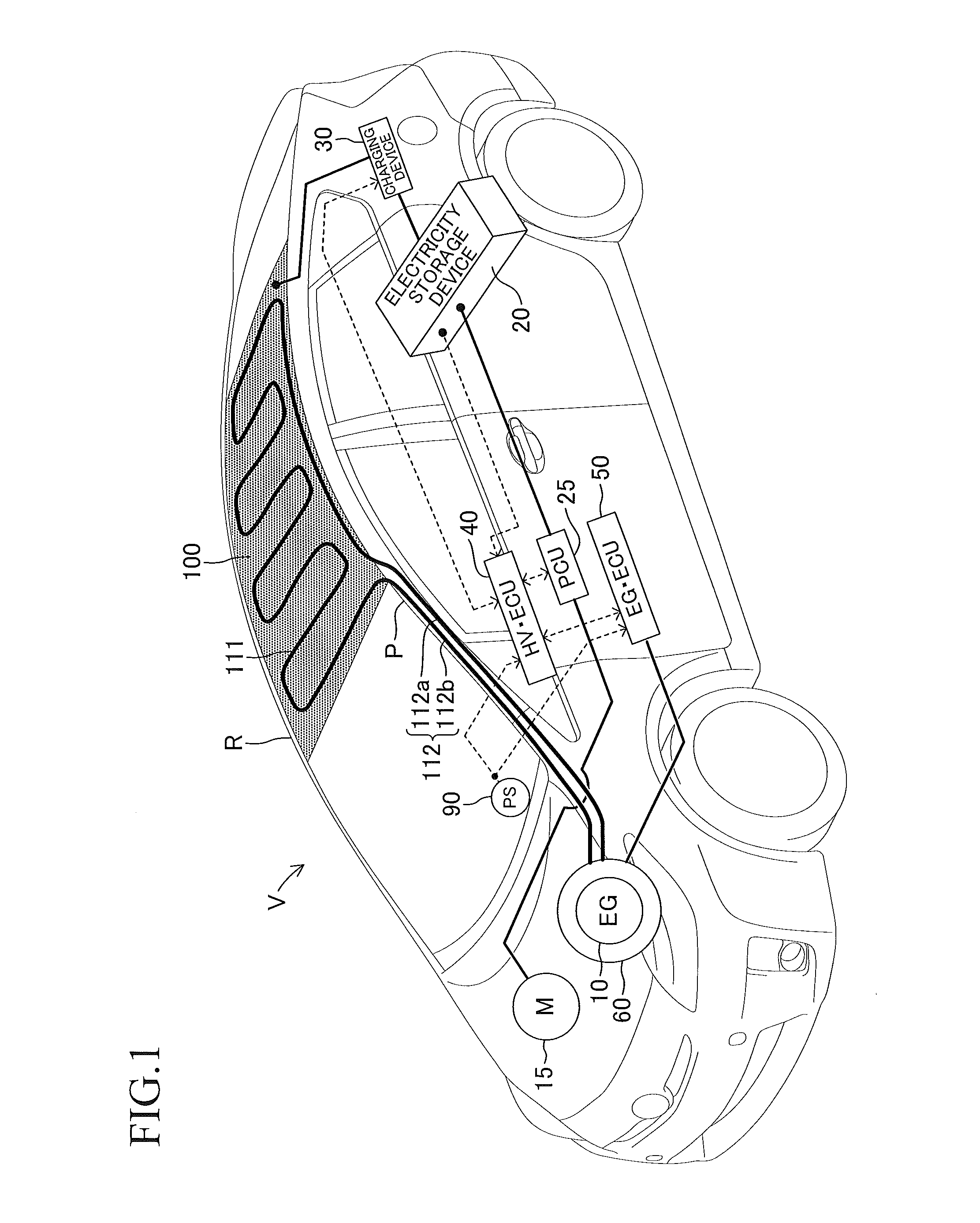

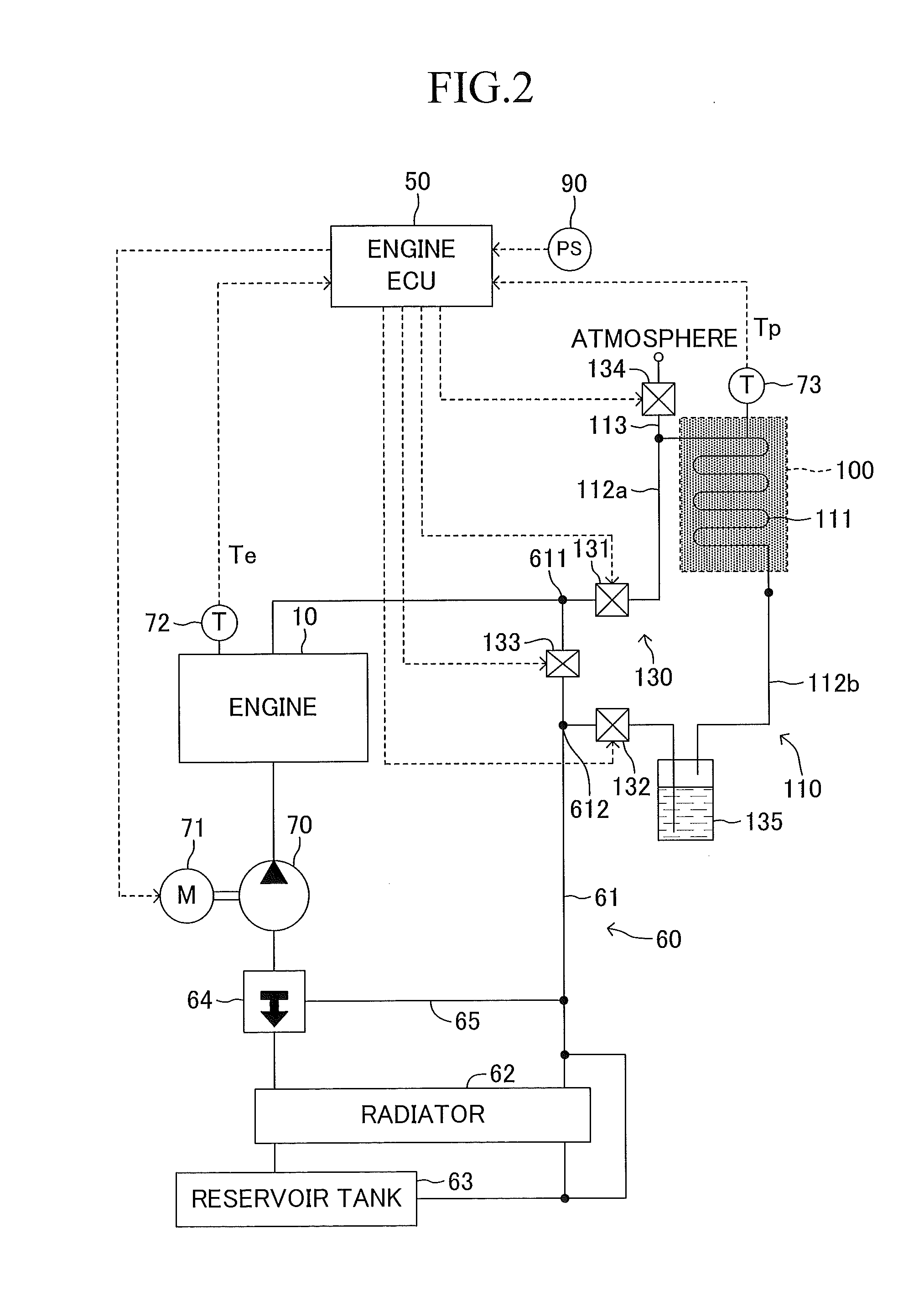

Vehicle

InactiveUS20150360558A1“warm up”Easy to useHybrid vehiclesElectric propulsion mountingElectric powerCoolant

To increase electric power generation efficiency of a solar panel while effectively using heat accumulated in the solar panel, a panel-side pipe is installed on a rear surface of the solar panel. The panel-side pipe is connected to an engine coolant passage. When a power switch is in an OFF state, and an exchange condition for a coolant is satisfied, an engine ECU drives a water pump to circulate the coolant to the panel-side pipe. Consequently, the cool coolant accumulated in the engine coolant passage and the warmed coolant accumulated in the panel-side pipe are exchanged with each other. As a result, the solar panel is cooled, and the engine is warmed.

Owner:TOYOTA JIDOSHA KK

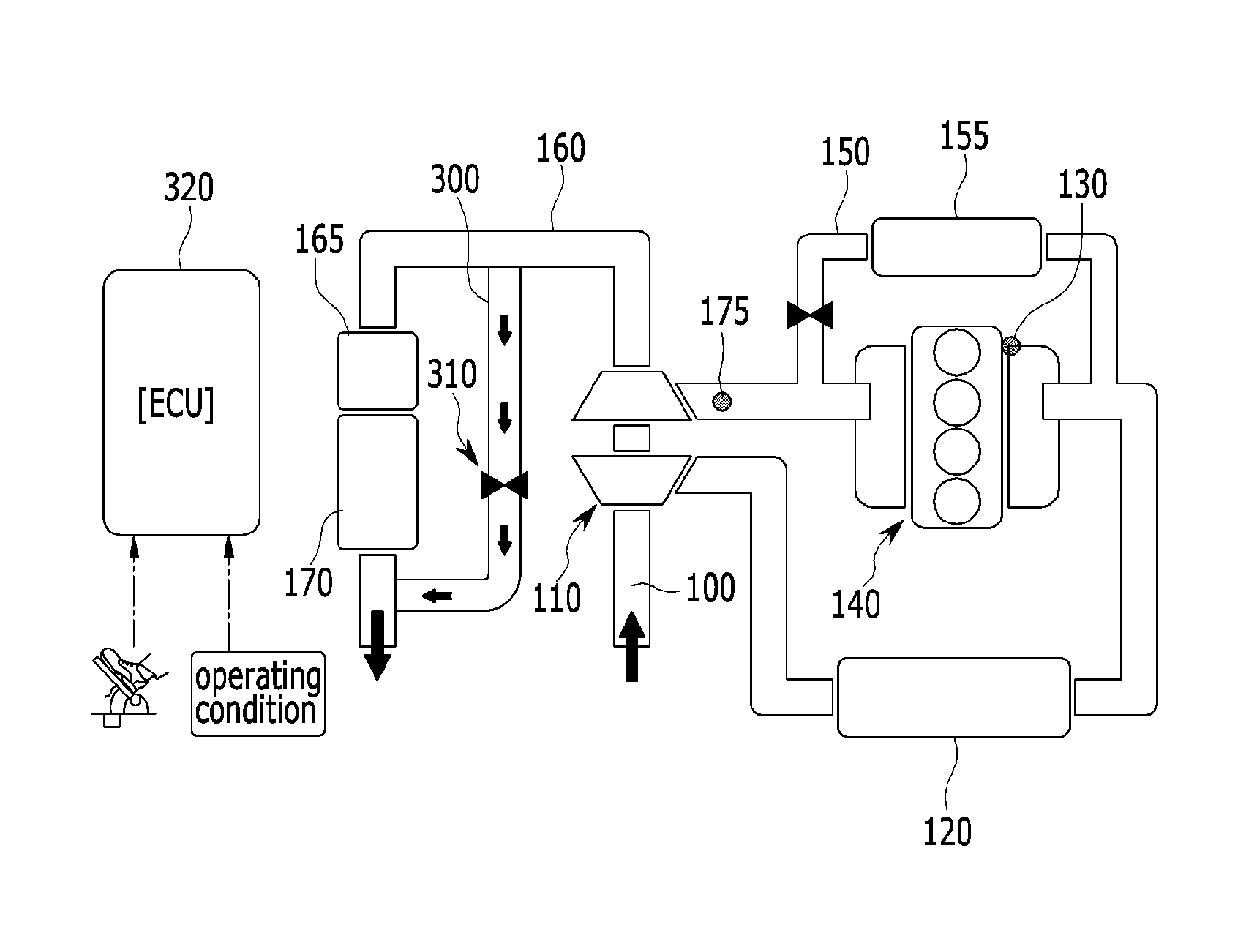

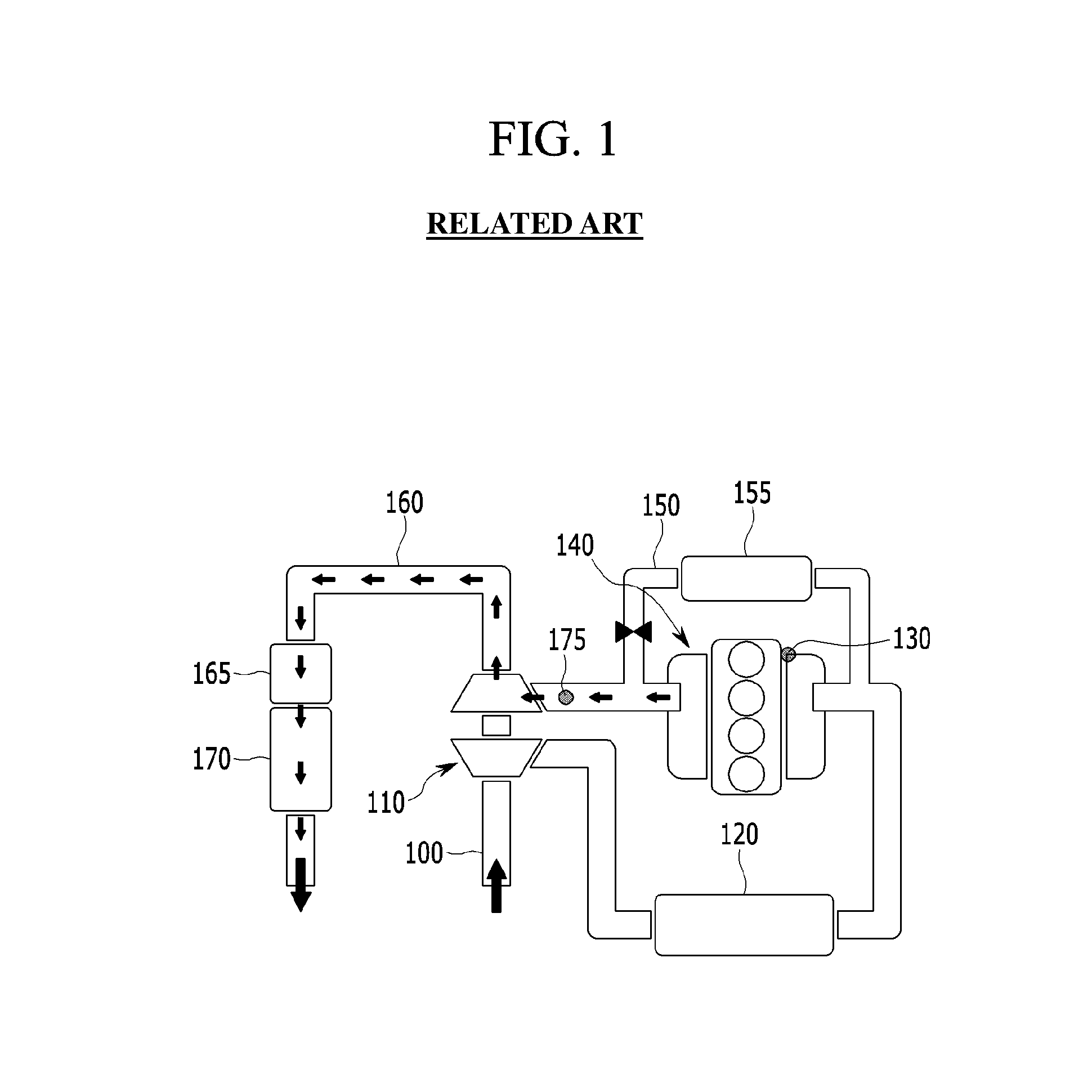

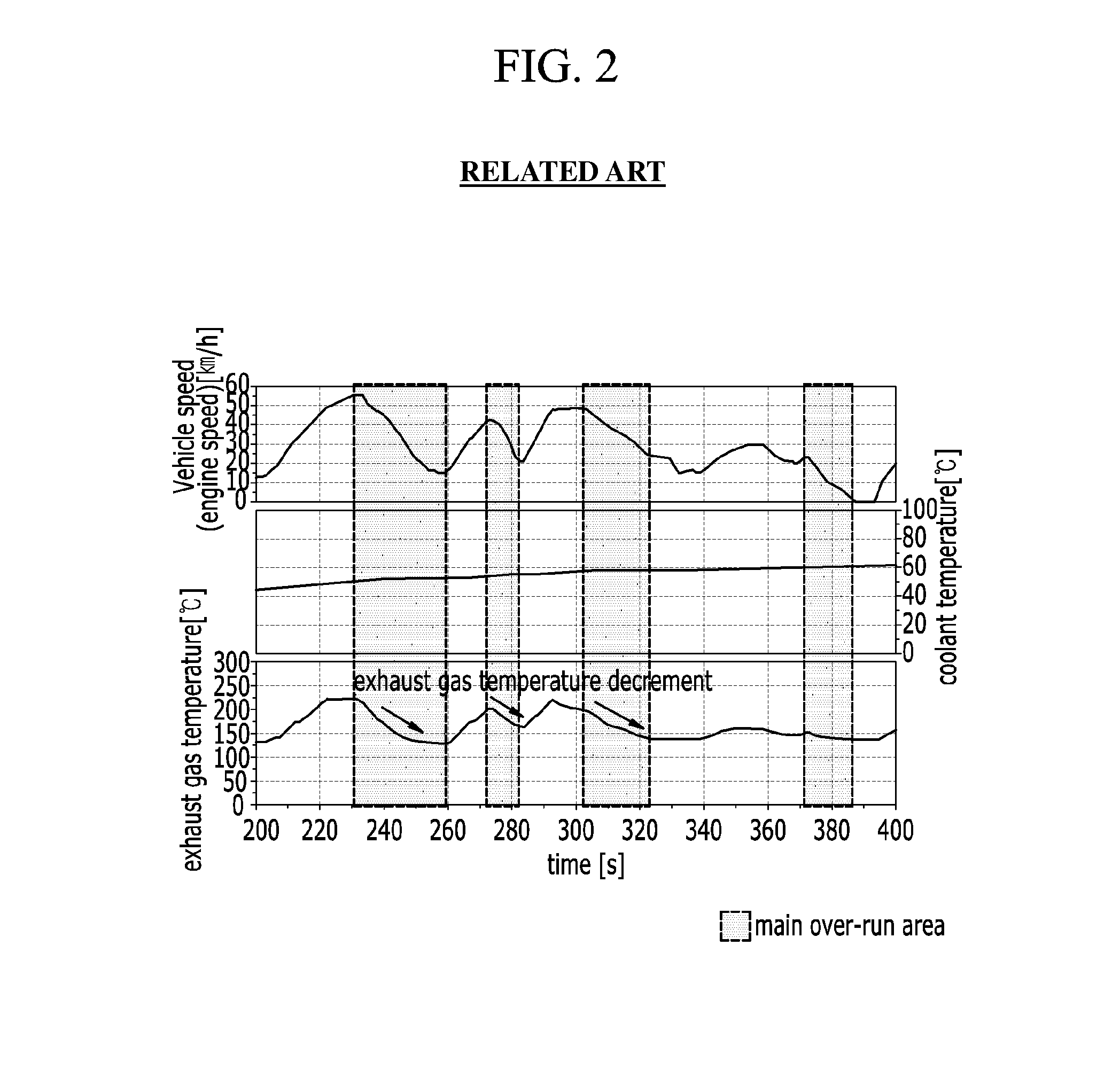

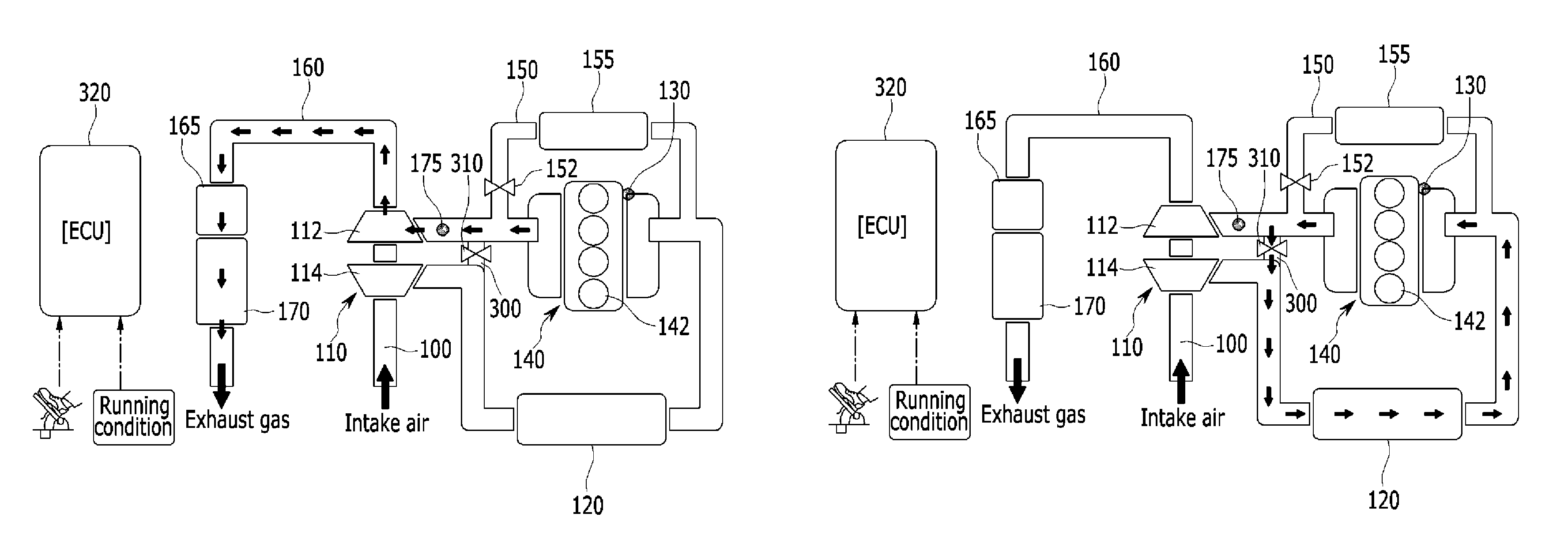

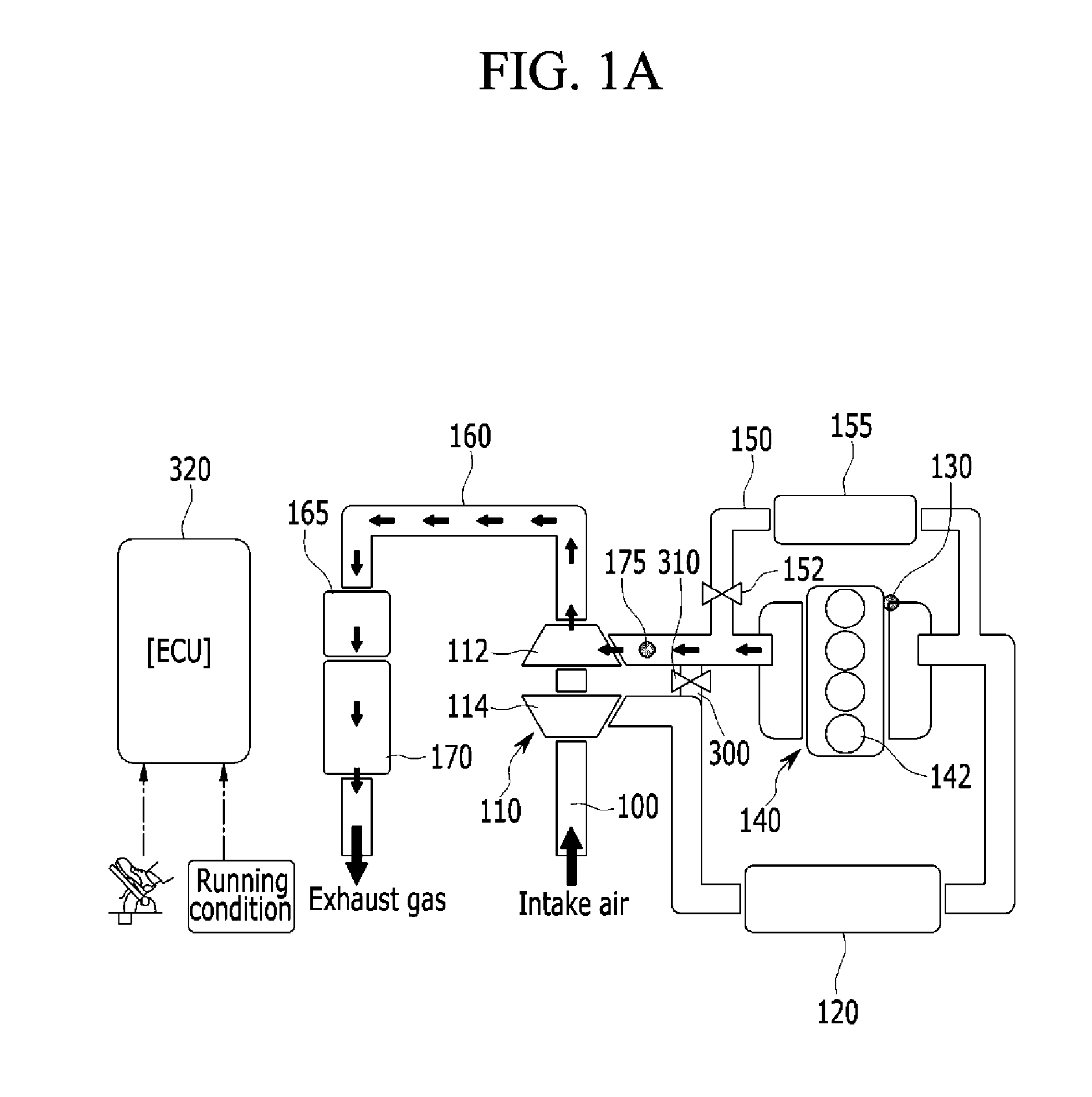

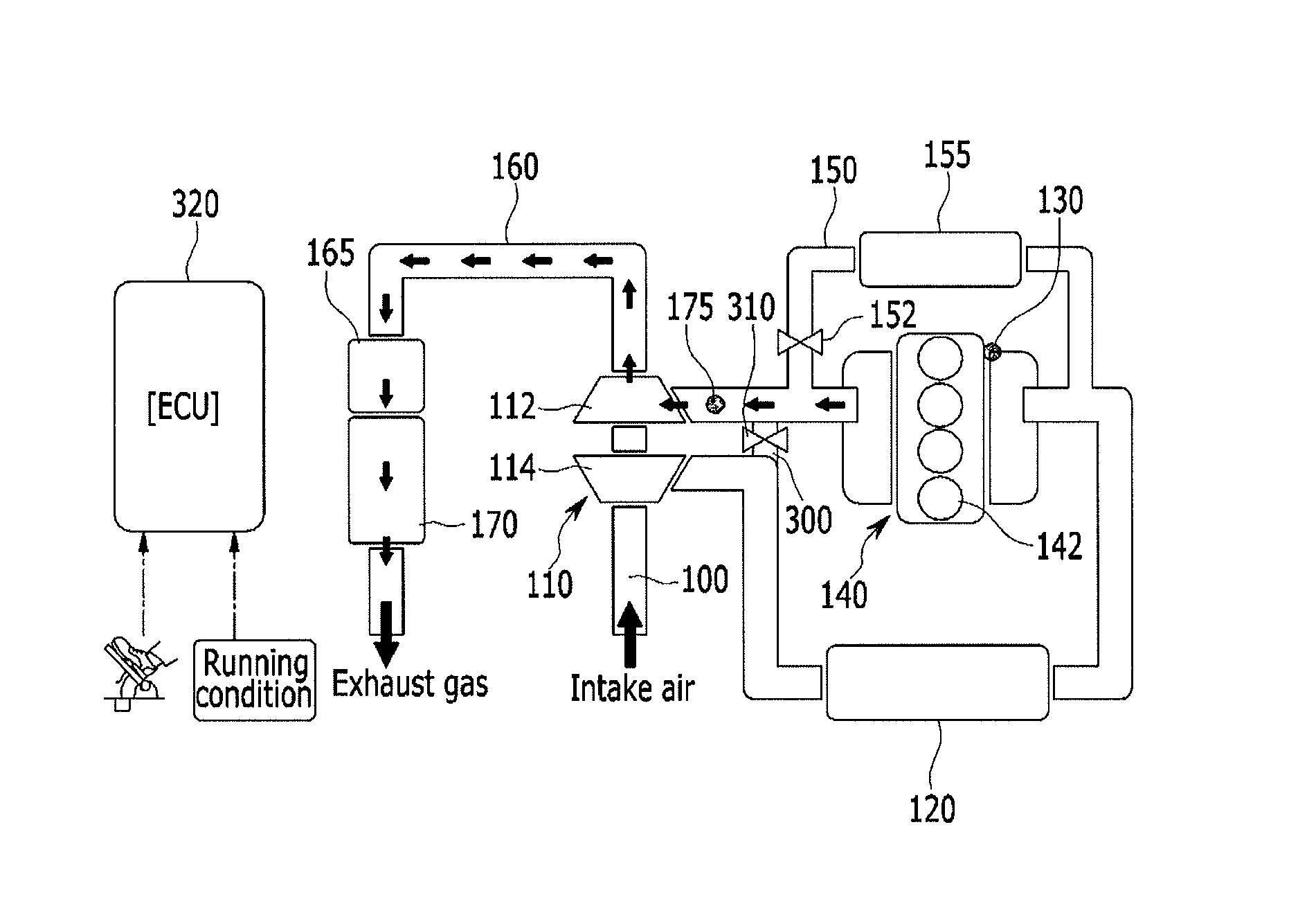

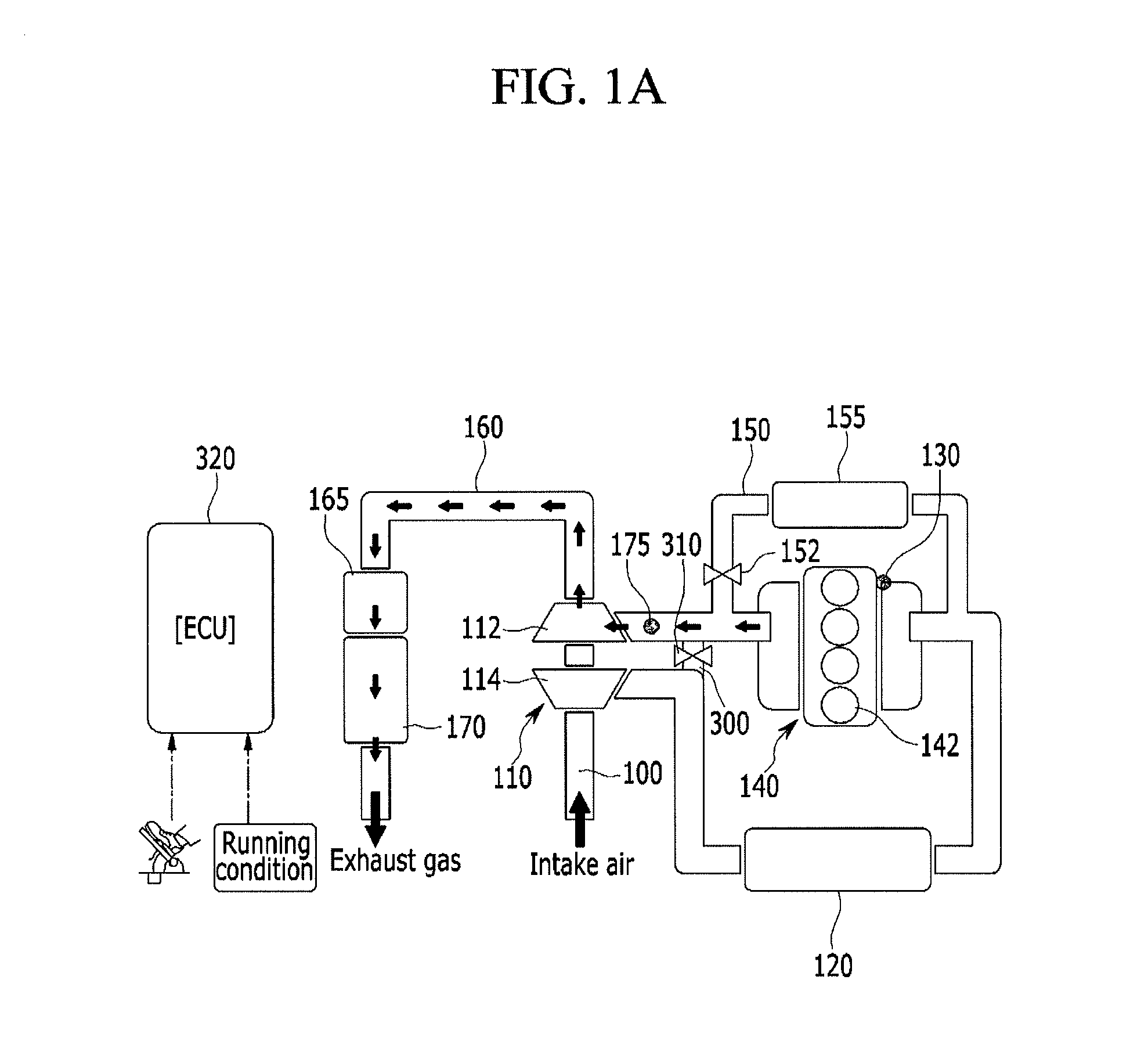

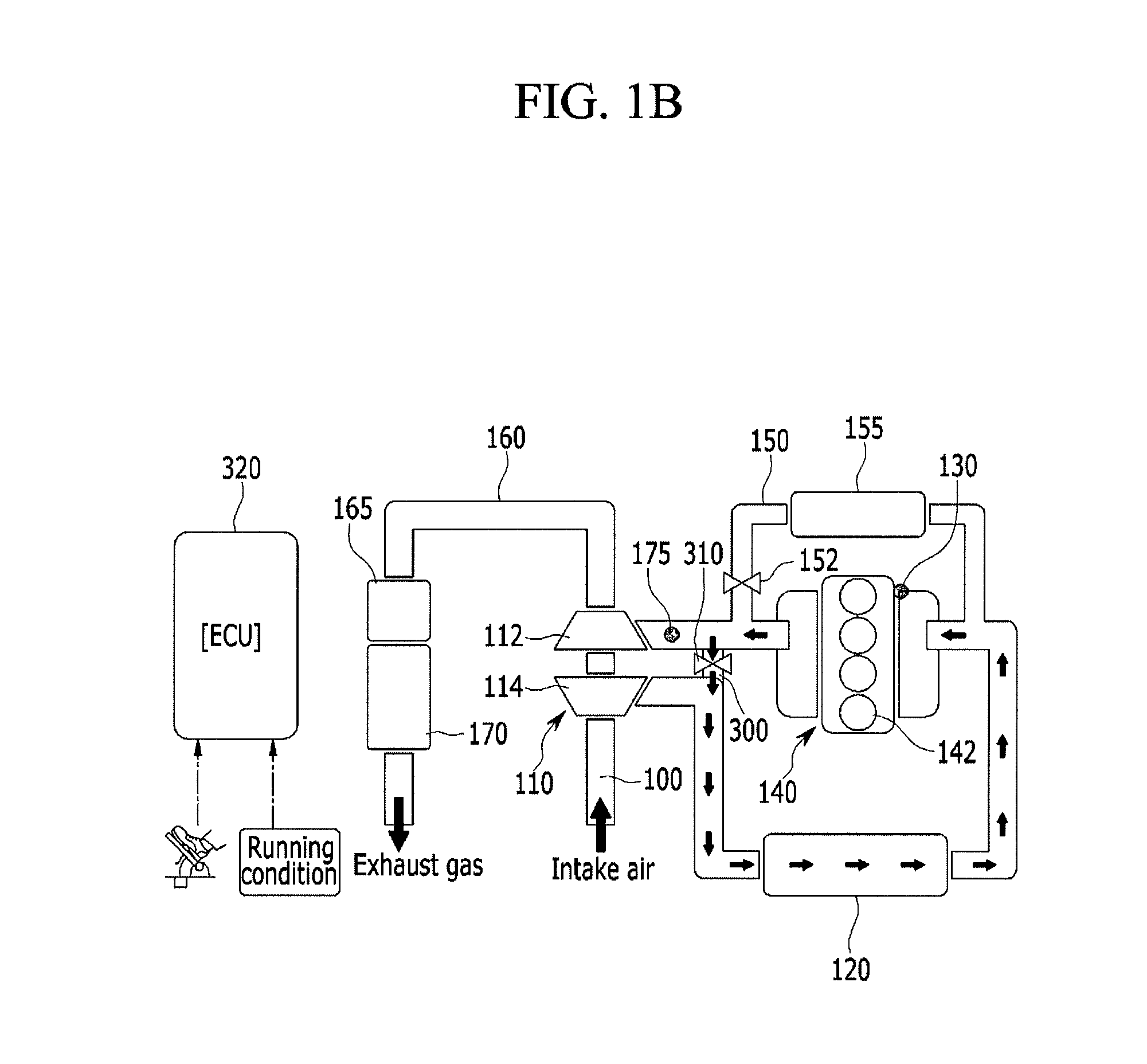

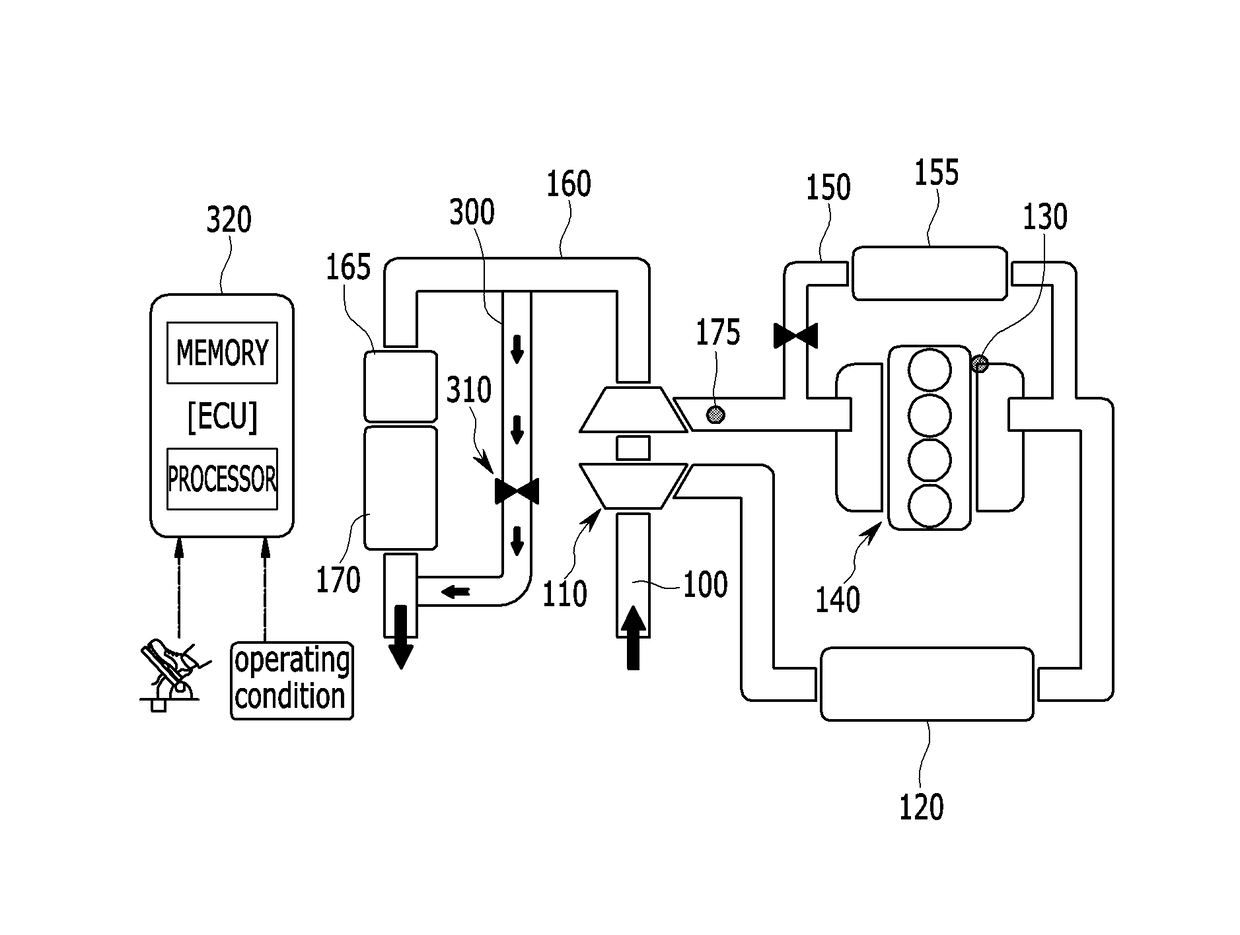

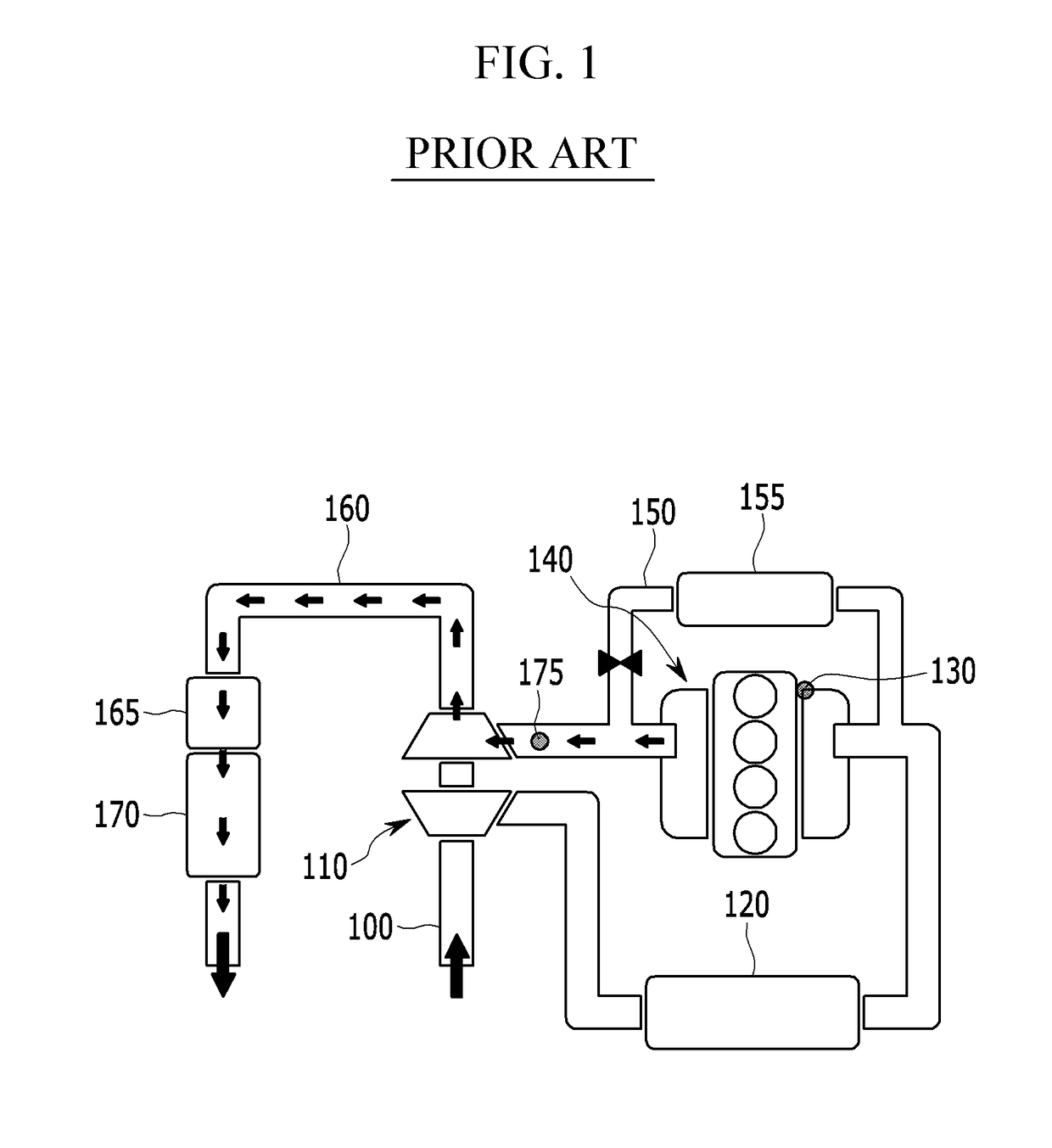

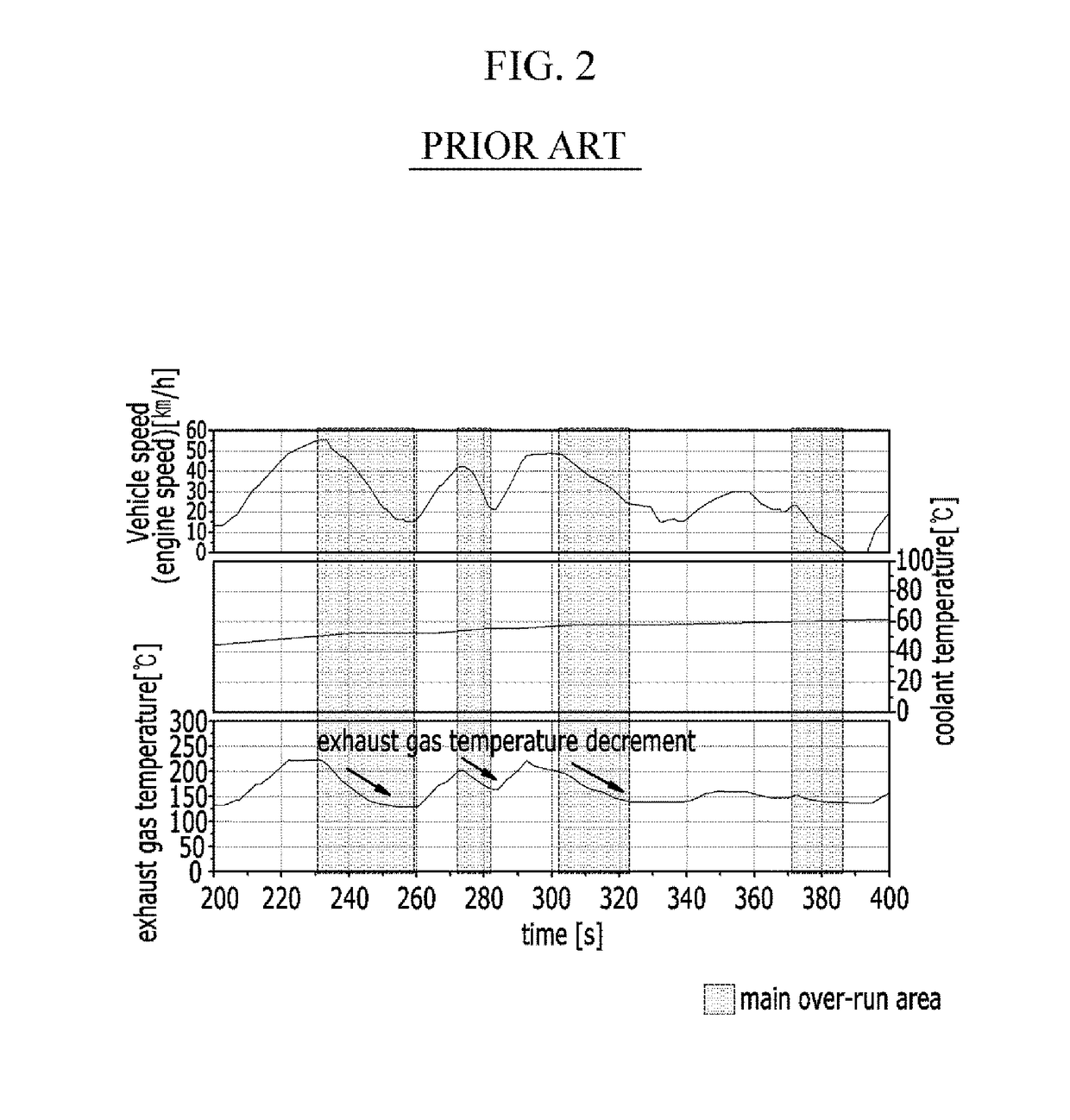

Method and system for controlling exhaust gas flow in engine system

ActiveUS20160108788A1Avoid temperature dropImprove exhaust qualityElectrical controlInternal combustion piston enginesExhaust fumesCoolant temperature

A method and system for controlling an exhaust gas flow in an engine system are provided. The method includes detecting operating conditions of an engine and operating a valve that is disposed on a line bypassing a catalyst unit based on the operating conditions such that exhaust gas bypasses the catalyst unit. The operating conditions include a vehicle speed, an engine rotation speed, a fuel injection amount, an accelerator pedal signal, a coolant temperature, or a lambda value of exhaust gas.

Owner:HYUNDAI MOTOR CO LTD

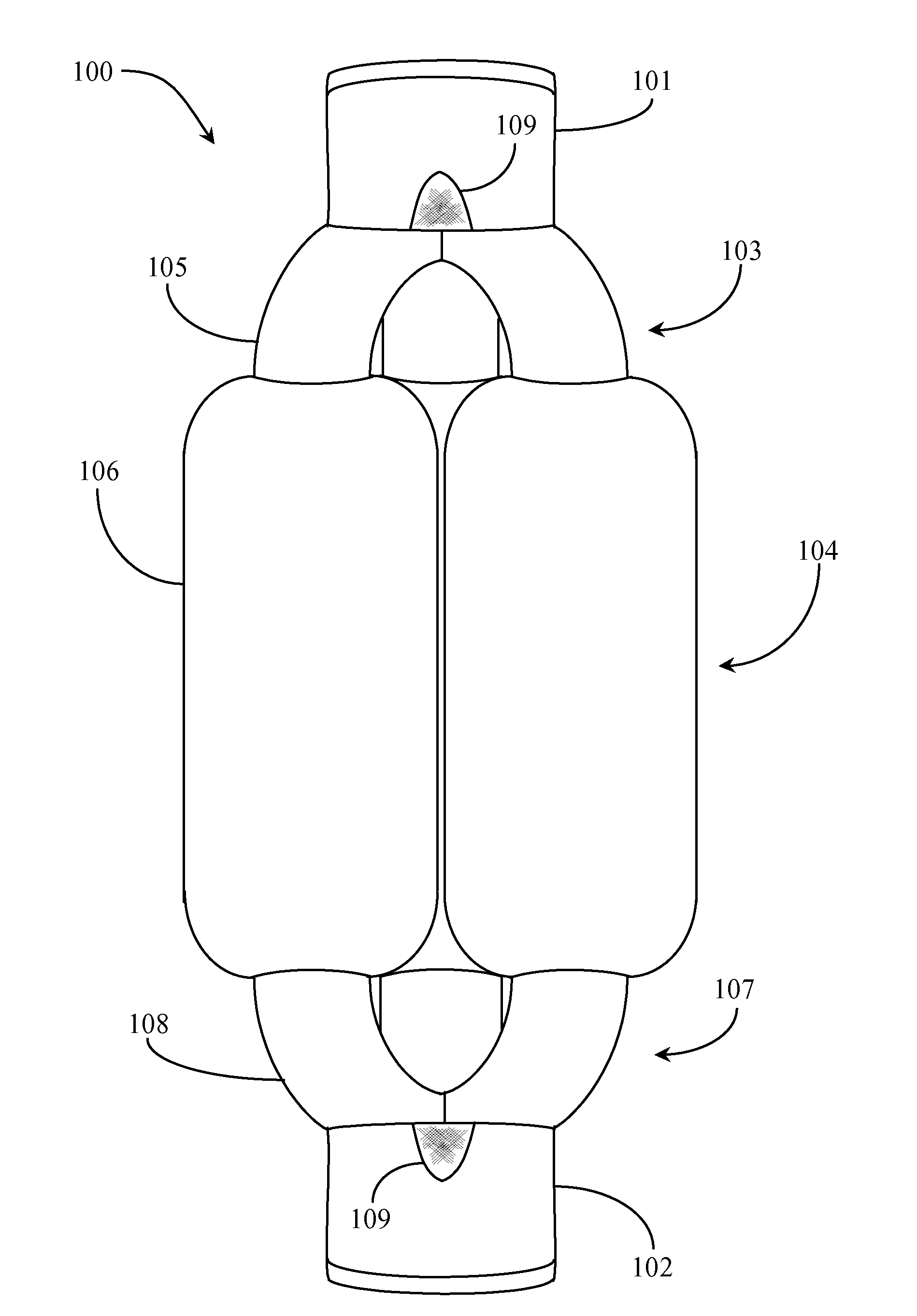

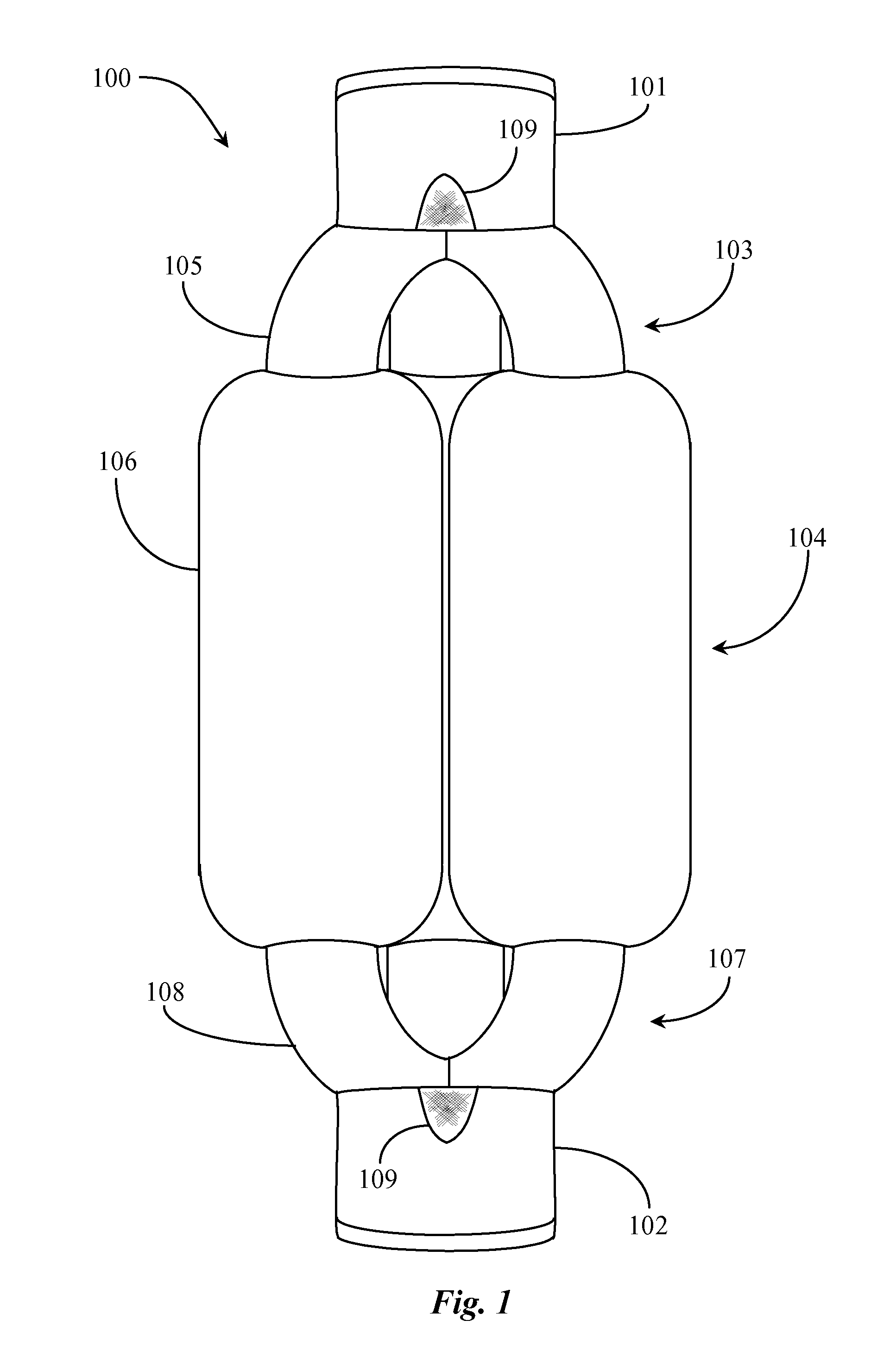

Exhaust Component

InactiveUS20110073405A1Improve exhaust qualityOptimization definitionSilencing apparatusThermometers using physical/chemical changesEngineeringThermodynamics

An exhaust component is provided including an inlet portion for accepting an exhaust stream entering therein from an exhaust system, two or more separator components fixed to the inlet portion for separating the exhaust stream into two or more streams at the point of egress from the inlet portion, two or more chambers fixed to the separator components, the chambers for muffling sound of the exhaust stream, two or more collector components fixed to the chambers opposite the separator components for collecting the separated exhaust streams upon egress from the chambers, and one or more outlet portions fixed to the collector components at the end opposite the chambers for carrying separated or merged exhaust streams out of the exhaust component.

Owner:STANLEY RONALD LEE

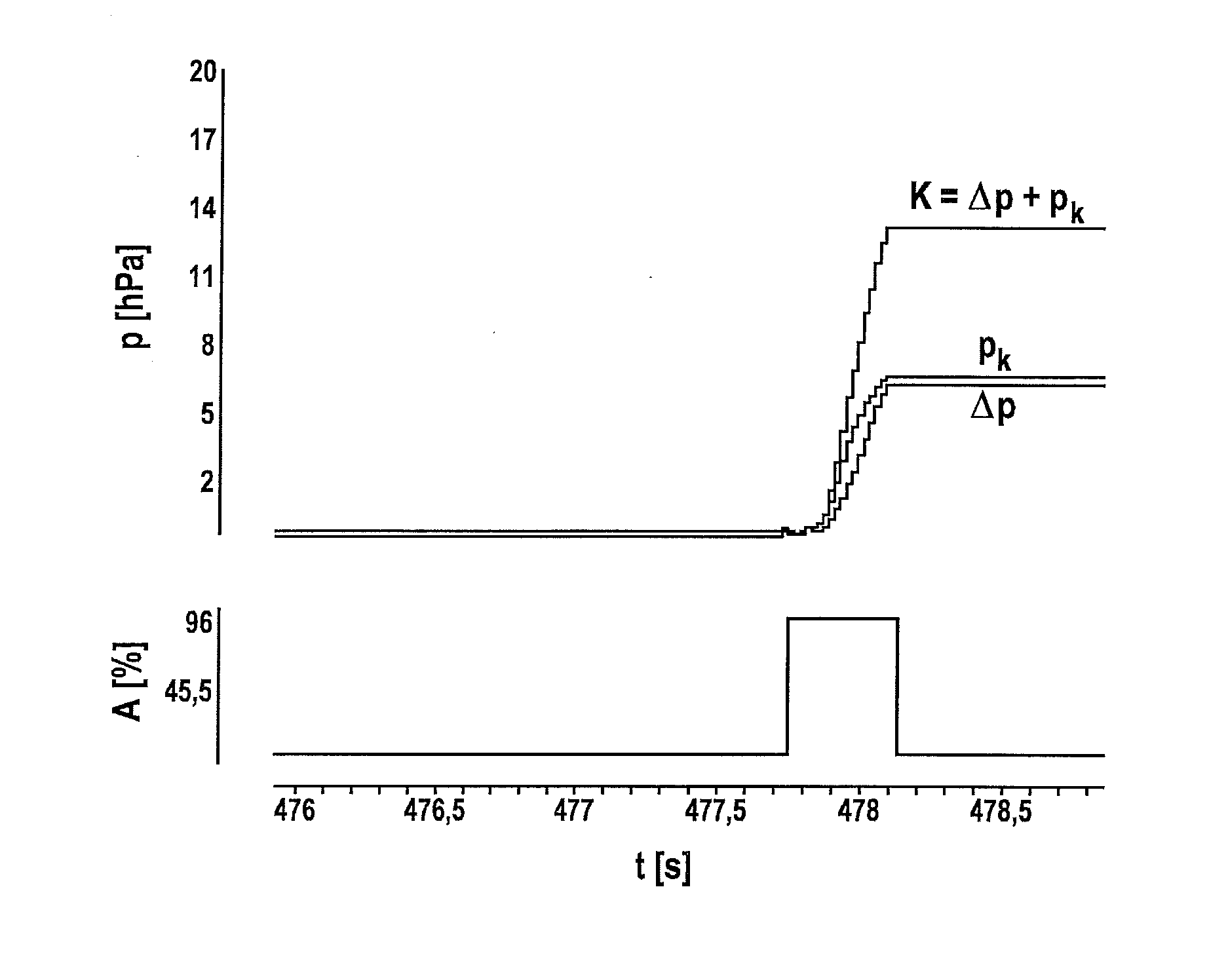

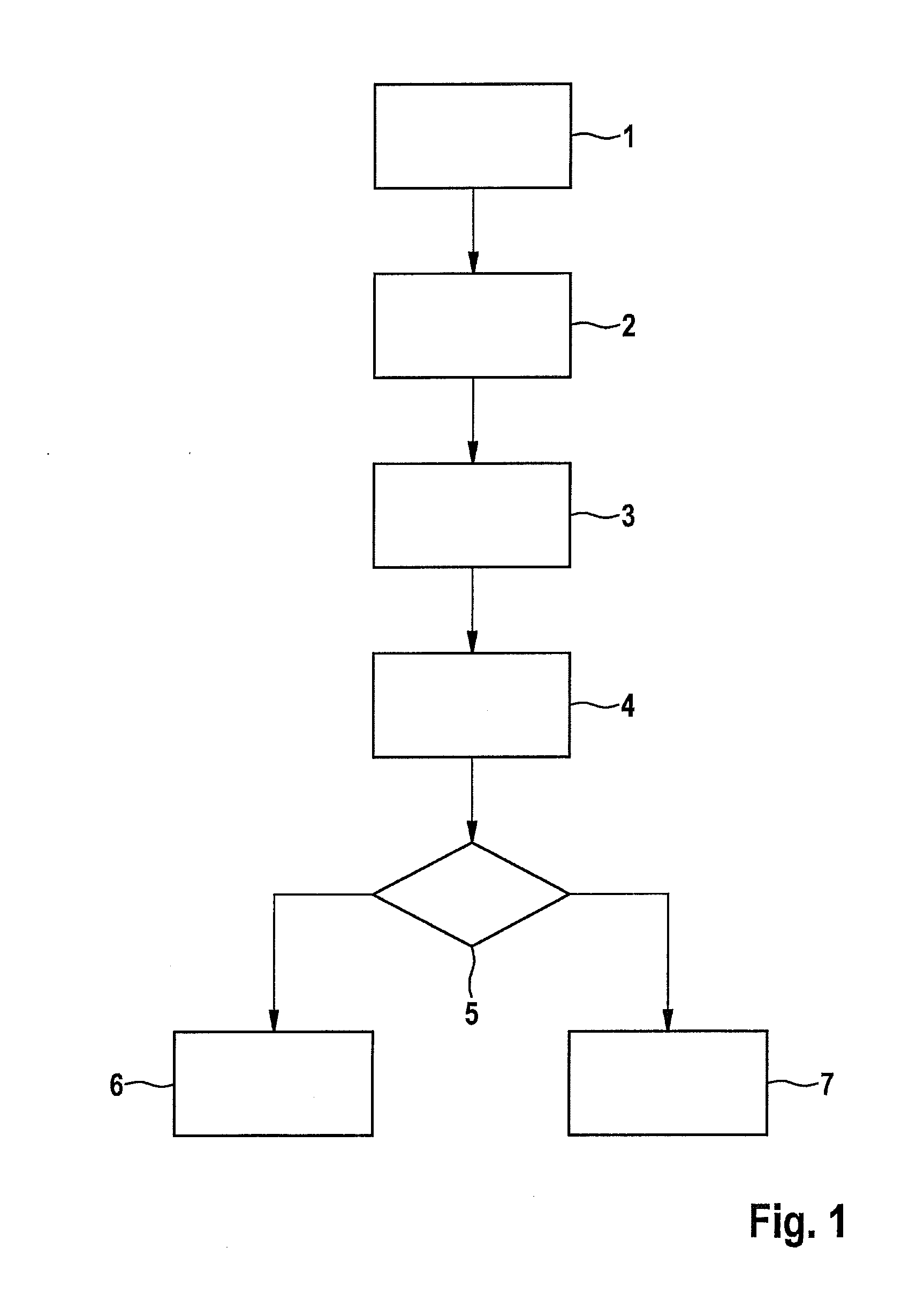

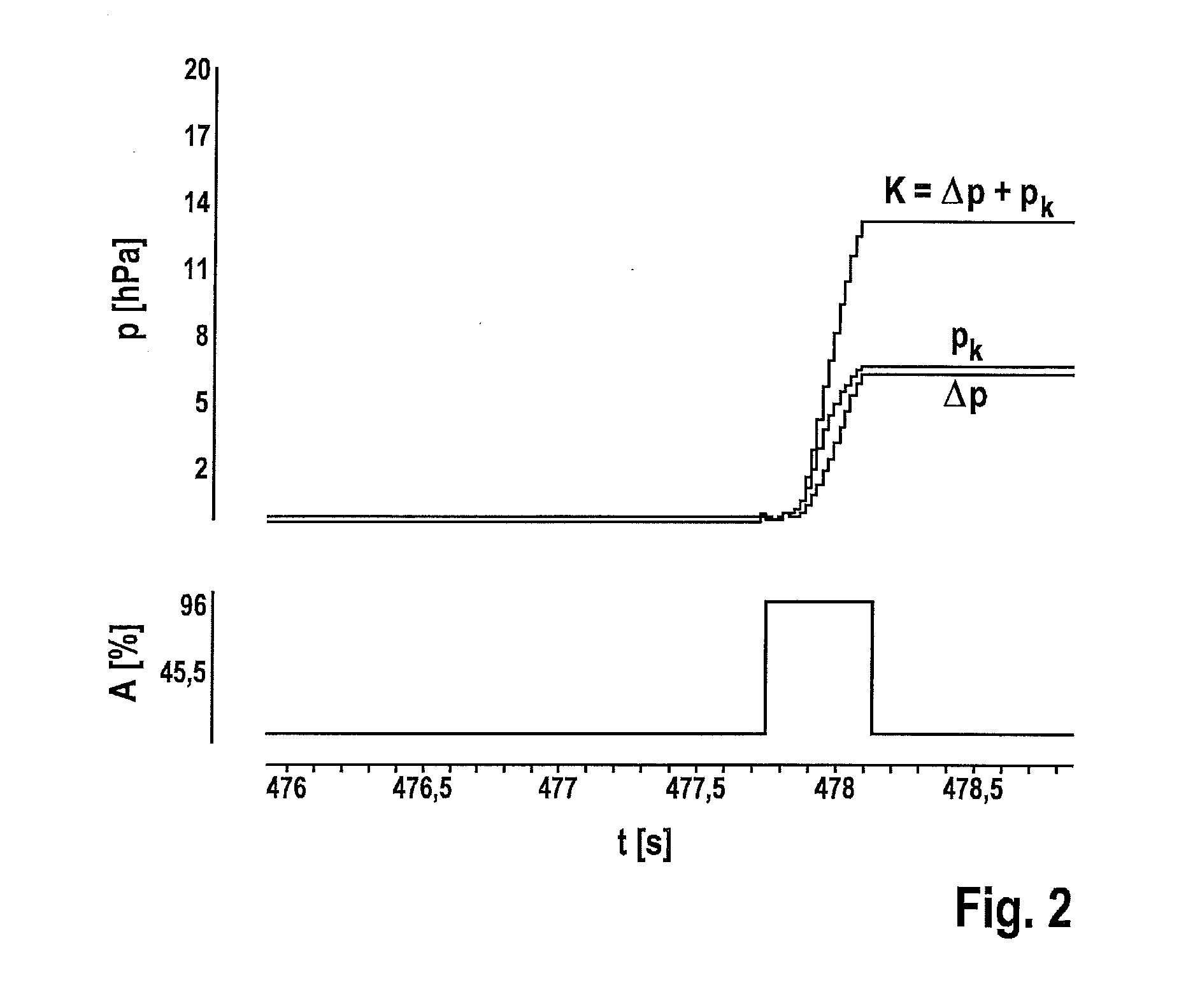

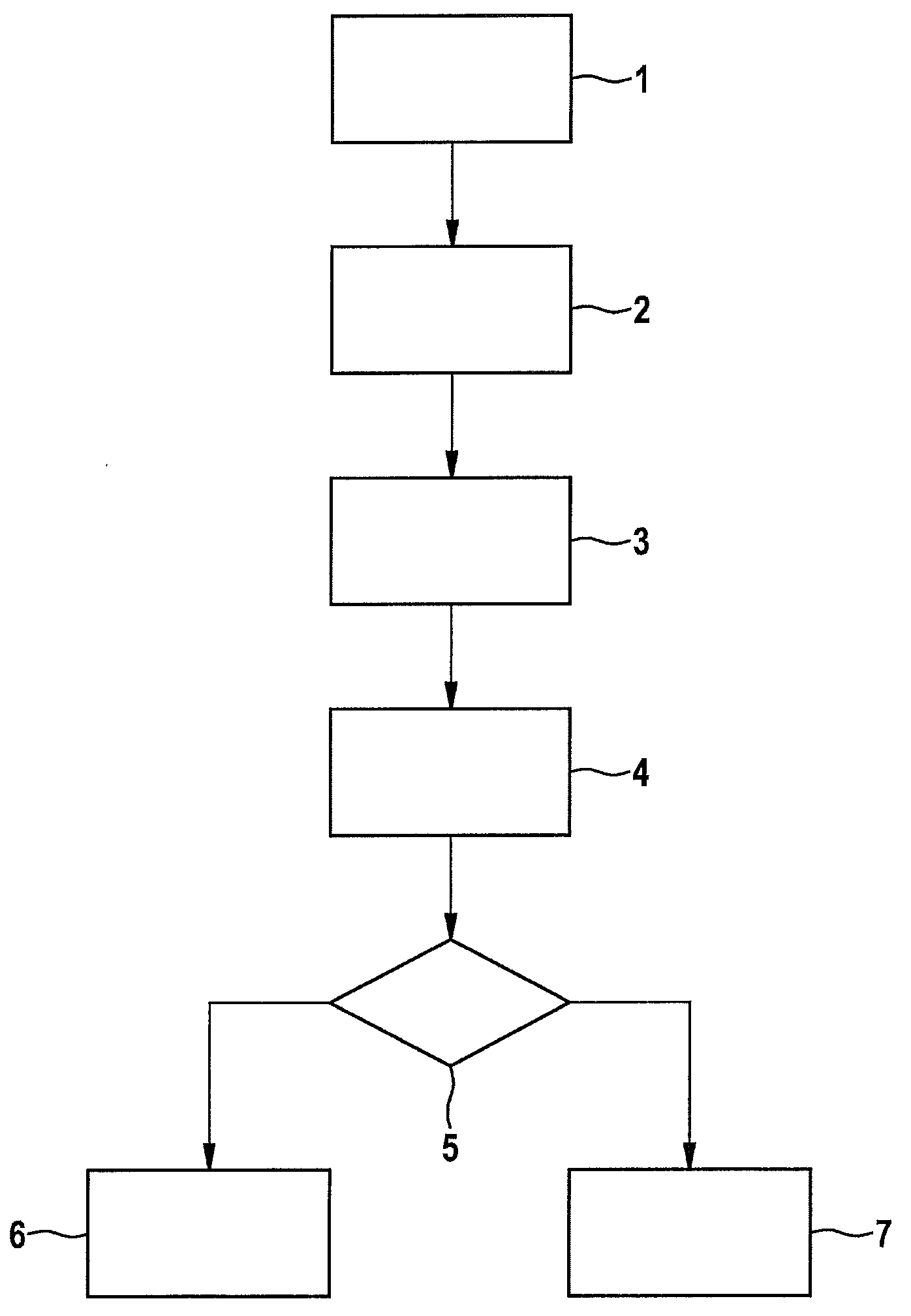

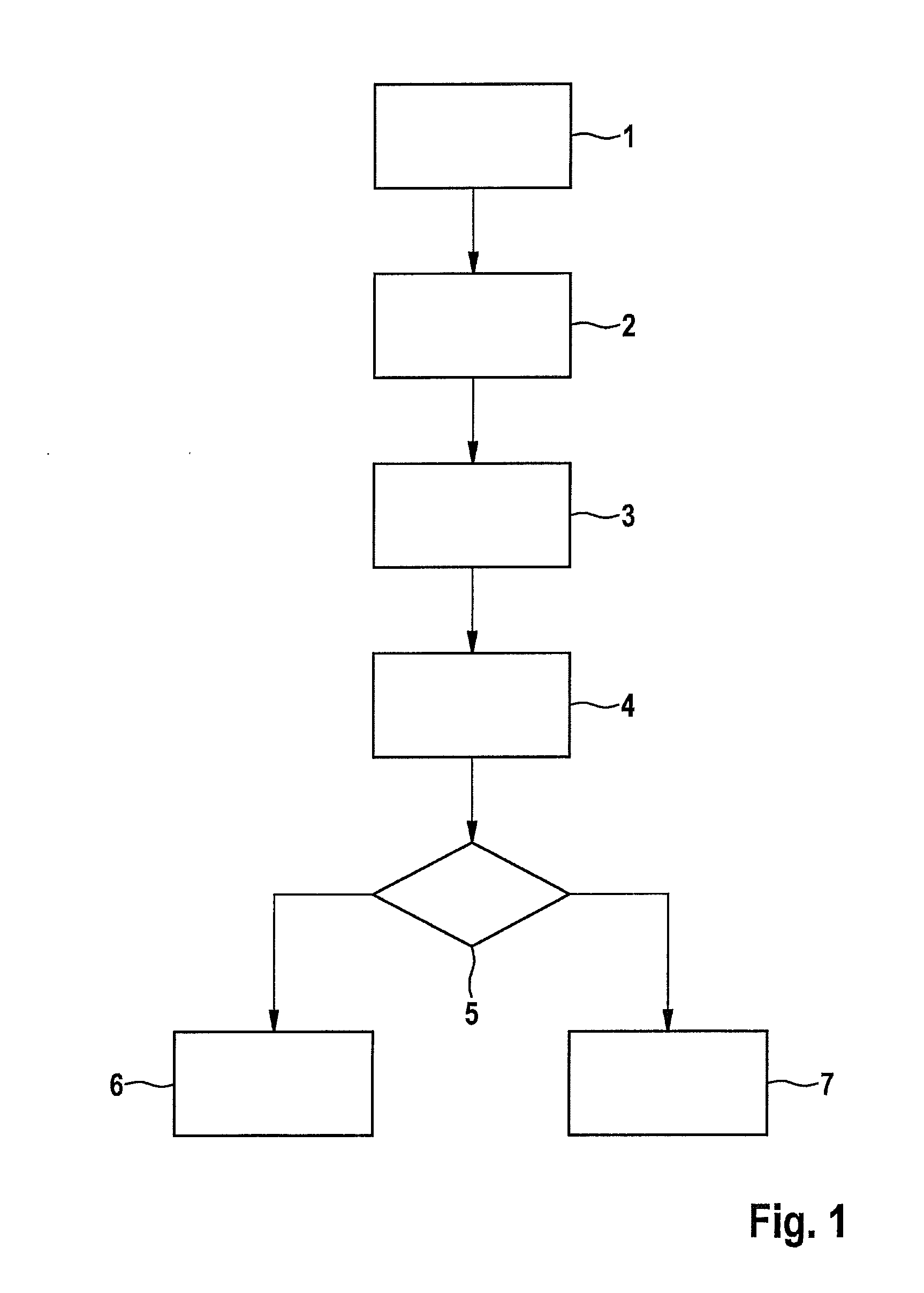

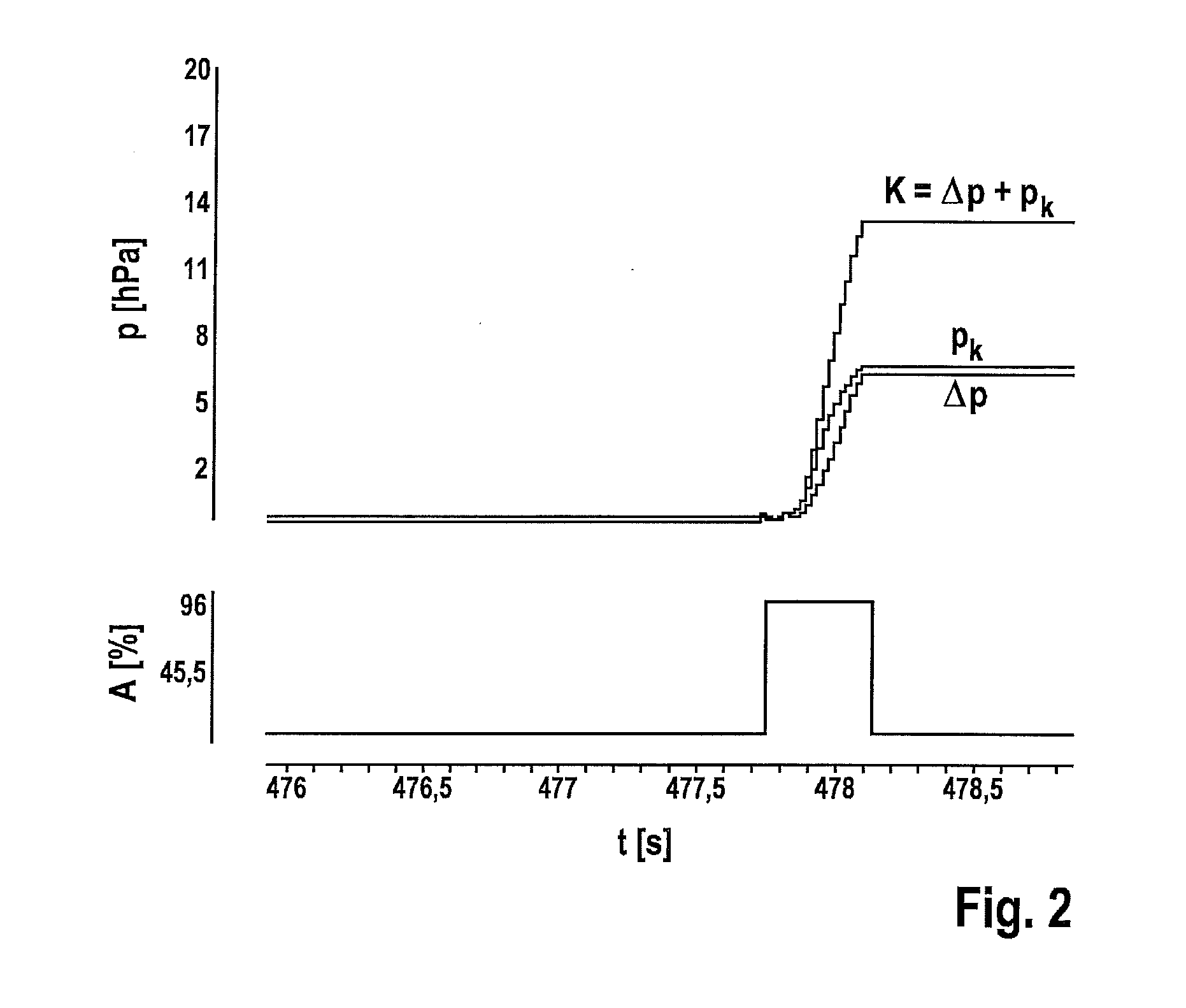

Method for diagnosing a tank venting valve

ActiveUS20150052986A1Reduce opening timeHigh selectivityElectrical controlNon-fuel substance addition to fuelFuel tankEngineering

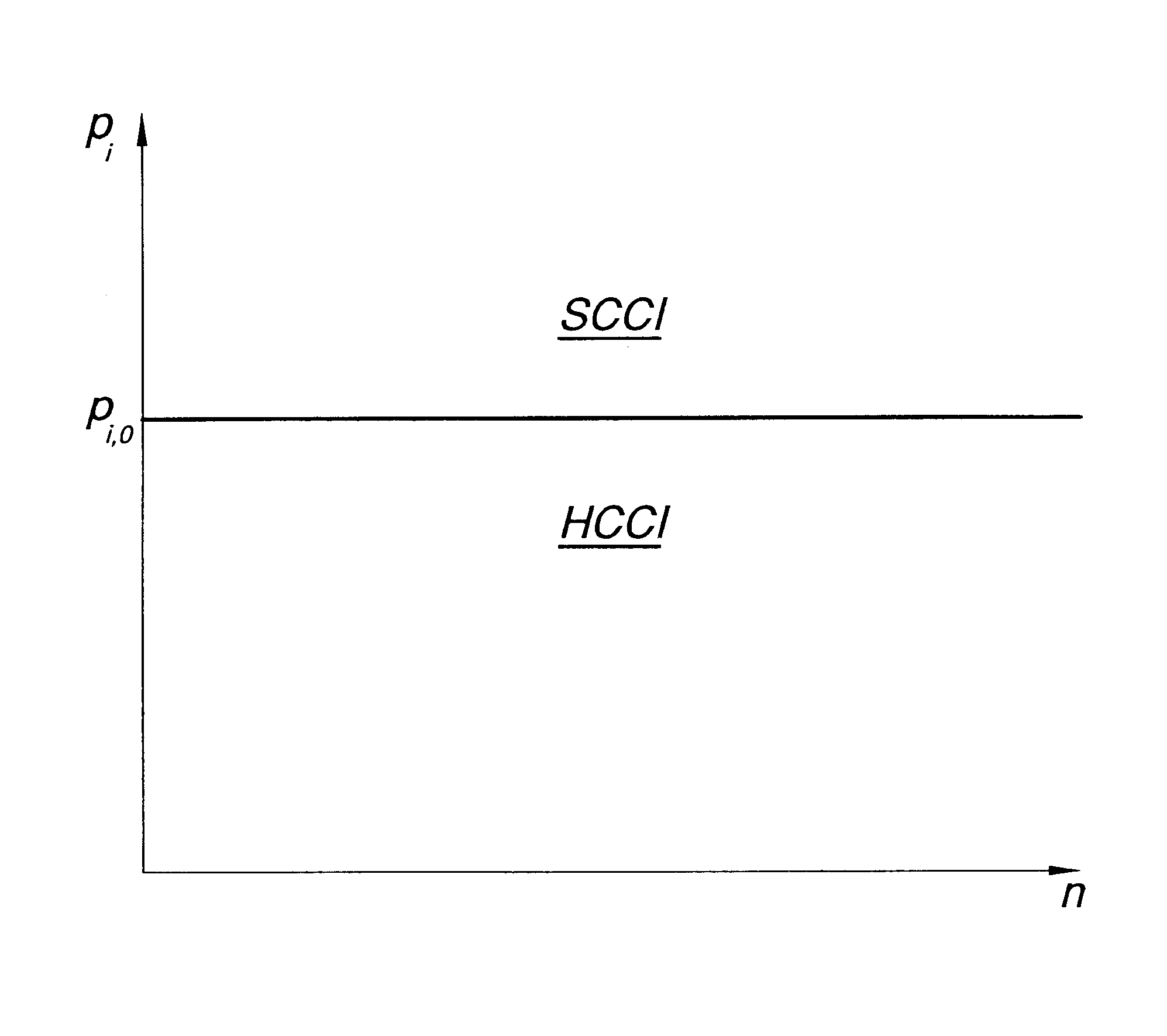

A method for diagnosing a tank venting valve. This includes measuring a first pressure p1 in the induction pipe of an internal combustion engine; activating the tank venting valve so as to open; measuring a second pressure p2 in the induction pipe of the internal combustion engine after the opening activation of the tank venting valve; calculating a control value K by subtracting the first induction pipe pressure p1 from a second induction pipe pressure p2 and adding a correction pressure pK, which is calculated from the leakage air adaptation of an internal combustion engine; and detecting A defect of the tank venting valve, when the control value K falls below a threshold value.

Owner:ROBERT BOSCH GMBH

Engine system having thermostat

InactiveUS20140137816A1Reduce energy wasteReduce wasteCoolant flow controlMachines/enginesElectricityLine tubing

An engine system may include an engine configured to generate a torque, a coolant temperature sensor configured to detect a temperature of a coolant circulating the engine, an atmosphere temperature sensor configured to detect an atmosphere temperature, a thermostat disposed on a coolant line to regulate a coolant passage, an operating portion disposed in the thermostat and electrically regulating the coolant passage, and a control portion that variably controls the coolant temperature. The operating portion is operated according to the coolant temperature transmitted from the coolant temperature sensor, the atmosphere temperature transmitted from the atmosphere sensor, and / or an engine load.

Owner:HYUNDAI MOTOR CO LTD +1

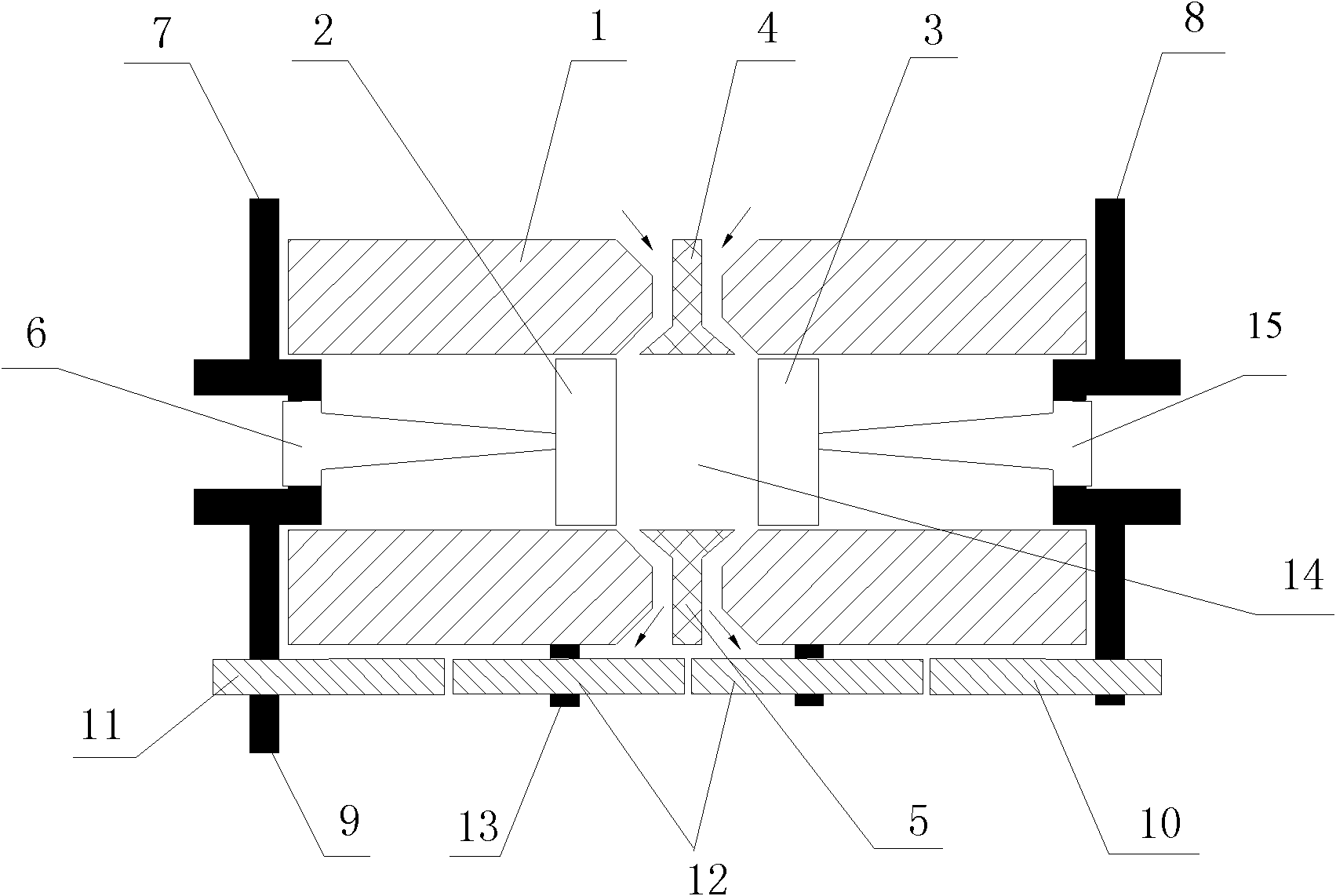

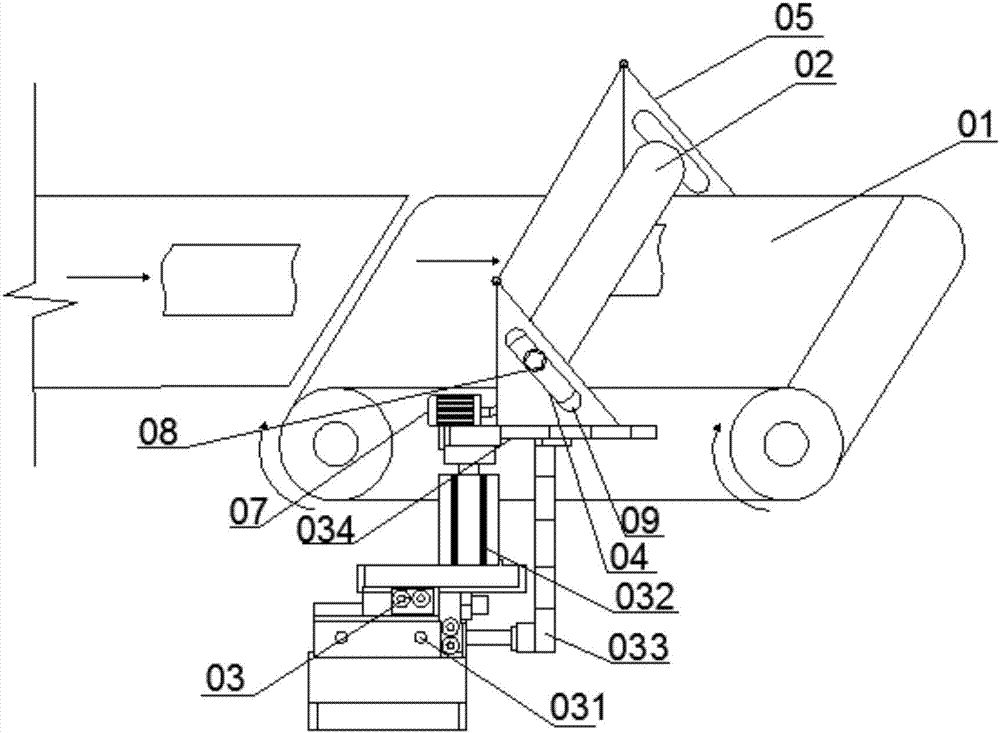

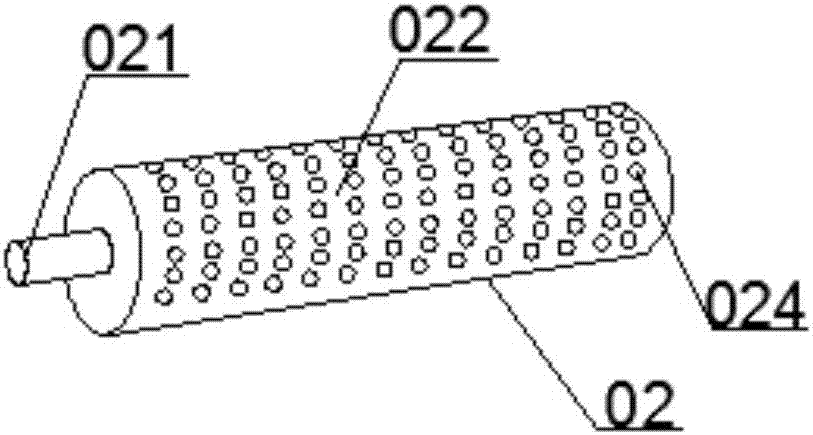

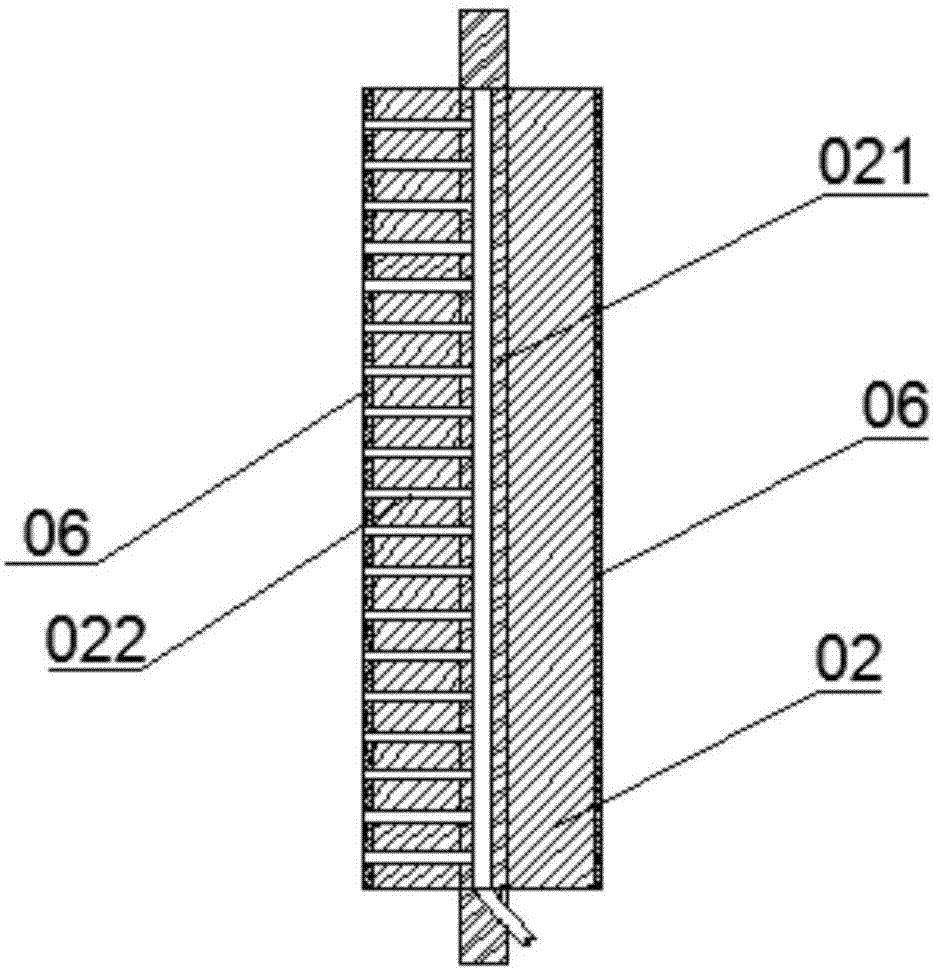

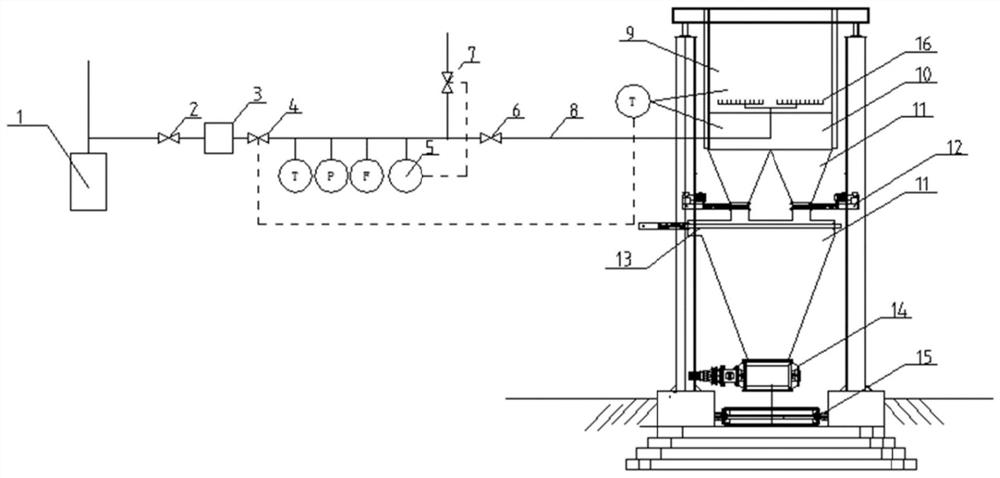

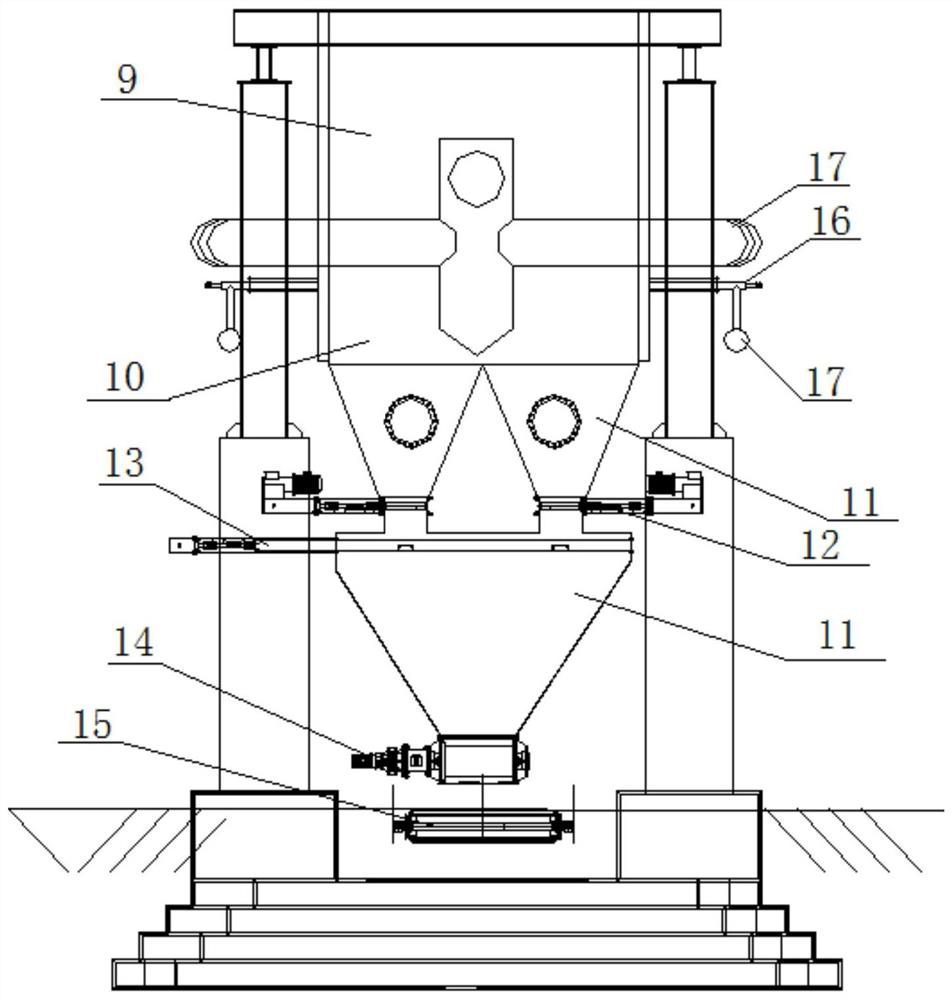

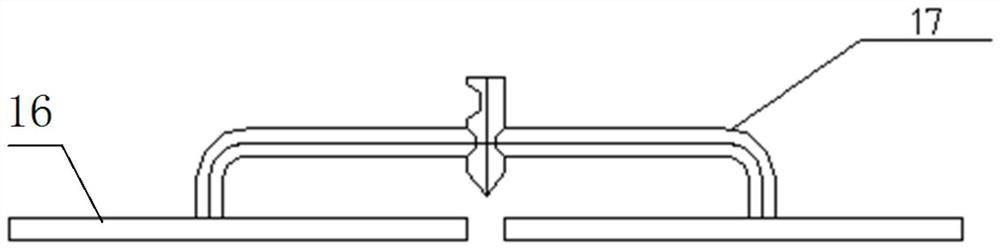

Exhausting device used for improving exhausting quality of packaging bag

The invention provides an exhaust device for improving the exhaust quality of packaging bags, which relates to the technical field of packaging bag exhaust, and includes a conveyor belt, an exhaust roller, and drive mechanisms respectively erected on both sides of the conveyor belt. All are equipped with guide rails, and the exhaust rollers straddle the conveyor belt through the cooperation of the roller shafts with the guide rails. The exhaust rollers include a first binder surface and a second binder surface, and the first binder surface There are several ventilation holes on the top, and the second pressing surface is solidly set; when the packaging bag moves with the conveyor belt and passes under the exhaust roller, the driving mechanism can drive the exhaust roller to roll back and forth on the packaging bag The way to discharge the gas in the bag. By implementing the technical solution, the exhaust quality of the packaging bag is improved, residual air in the packaging bag is avoided, and the risk of damage to the packaging bag is reduced.

Owner:弘毅天承知识产权股份有限公司

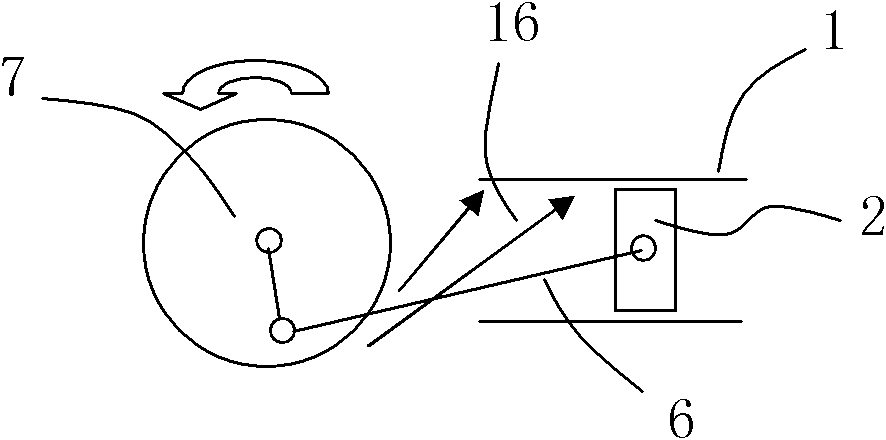

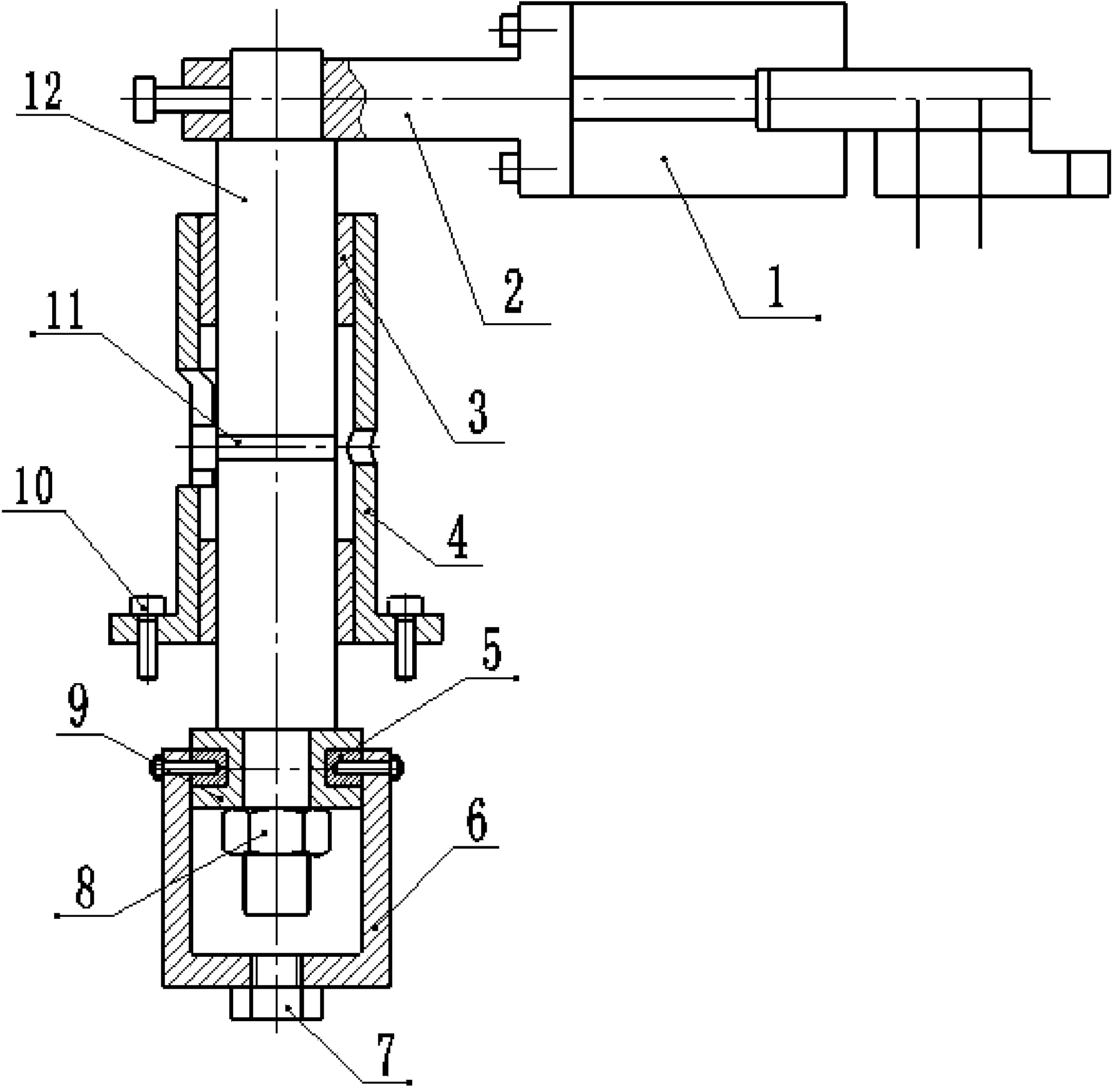

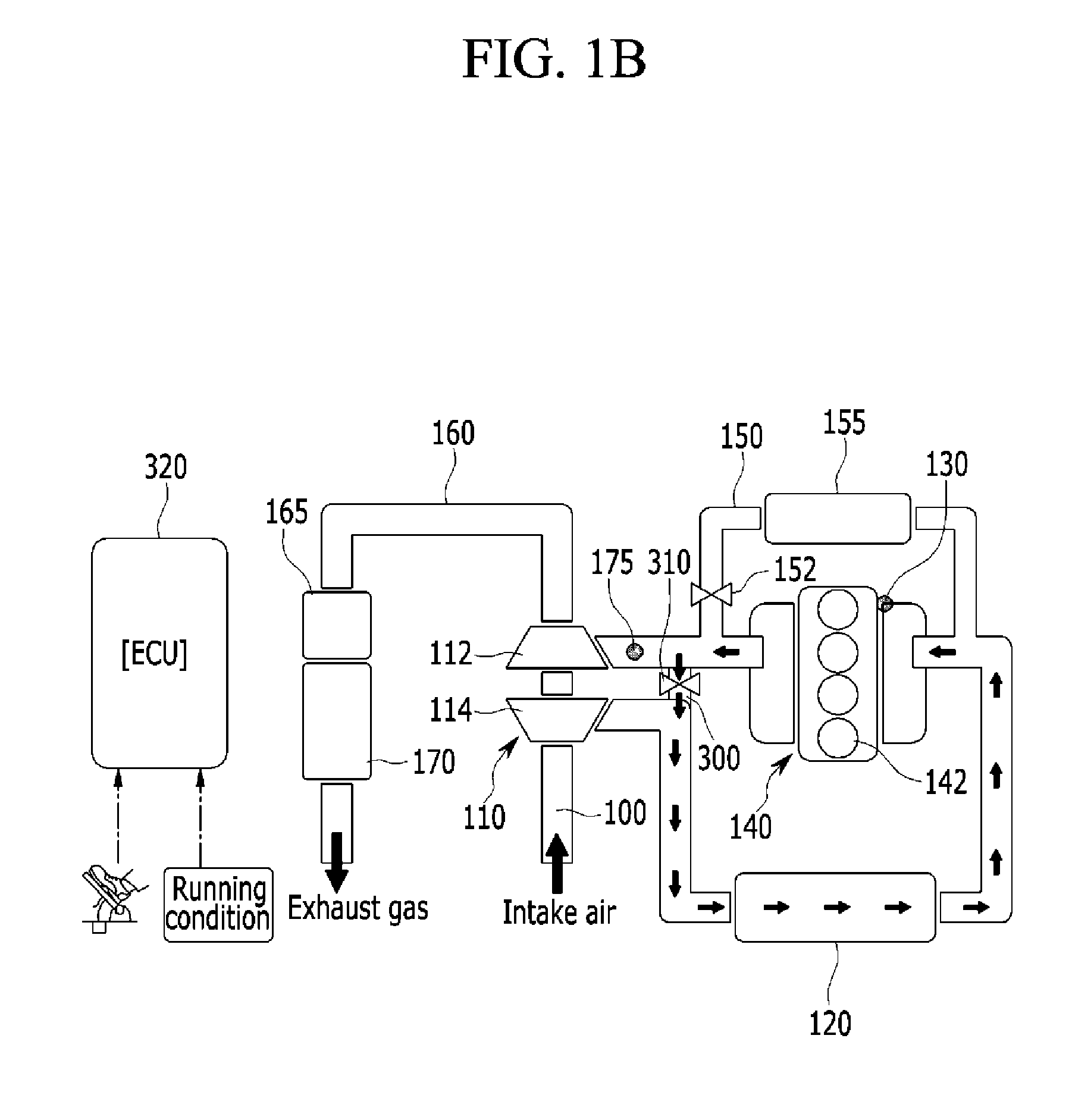

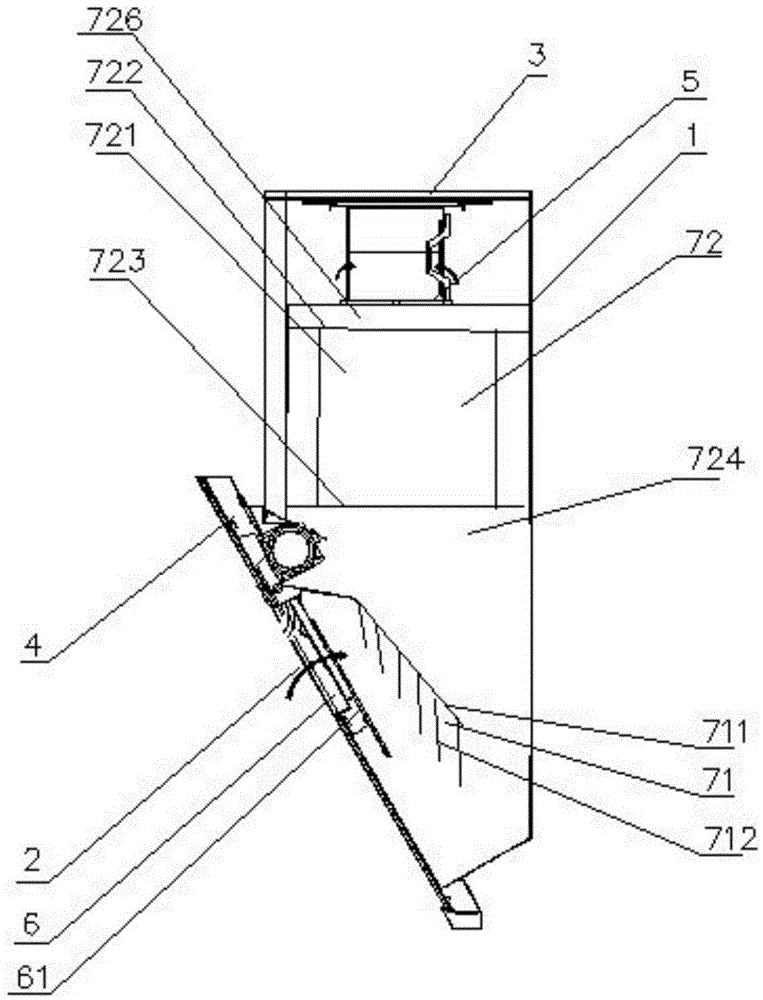

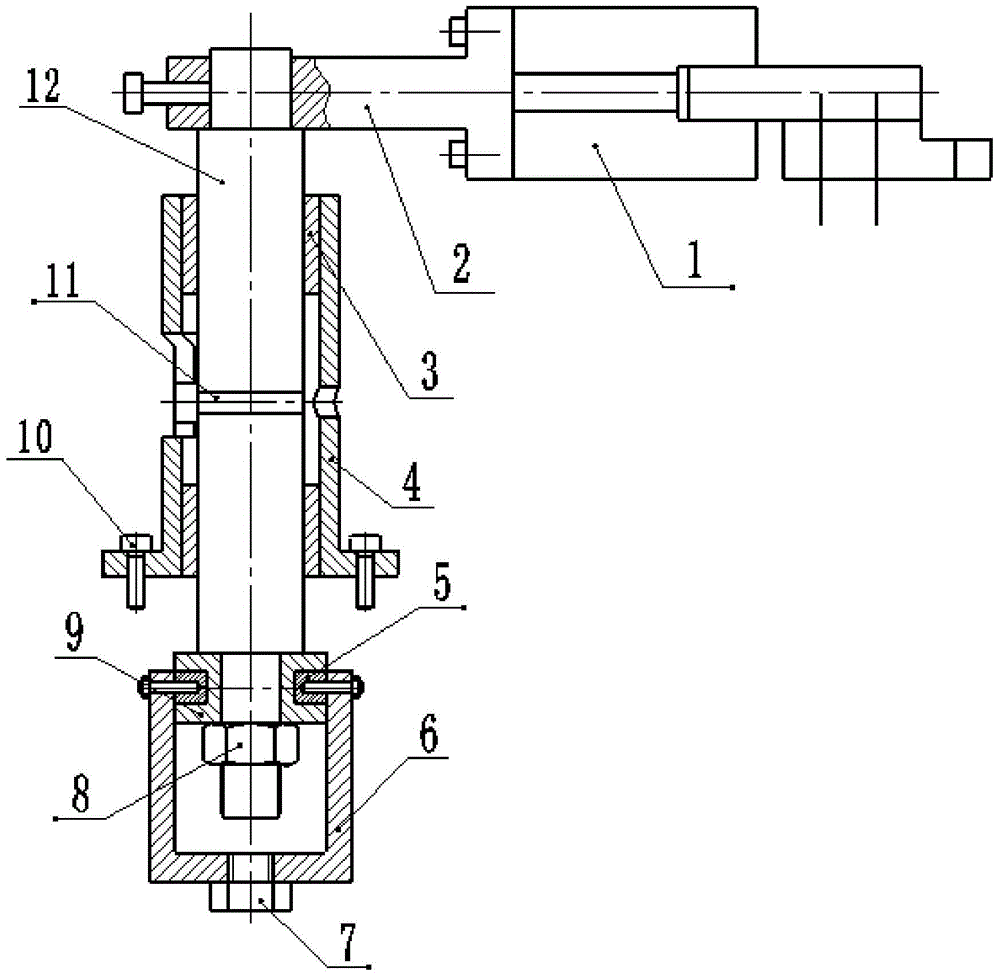

Exhauster tail pipe pulling mechanism for machining bulb of road motor vehicle

InactiveCN104347333AReduce power consumptionImprove exhaust qualityTube/lamp vessels exhaustionMotorized vehicleMechanical engineering

The invention discloses an exhauster tail pipe pulling mechanism for machining a bulb of a road motor vehicle. The mechanism is characterized in that a clamping exhaust cylinder is fixedly arranged on a cylinder bracket through bolts, wherein the cylinder bracket is arranged at the top end of a rotating shaft and is radially pressed by using screws; inner holes are formed in the horizontal direction and the vertical direction of the left end of the cylinder bracket; a support is arranged on the rotating shaft through one inner hole; the upper and lower ends of the inner hole of the support are both provided with bearing bushes; the middle part of the support is radially provided with a guide groove; a pin is arranged in the guide groove and penetrates into the radial inner hole of the rotating shaft; a boss of the support is provided with screws; a supporting bushing is arranged on the rotating shaft; a nut is arranged at the lower end of the rotating shaft and is abutted against the lower end face of the supporting bushing; a hydraulic sub-spindle is arranged in a hole of the supporting bushing and is connected with a connecting bushing through a screw and a nut; a threaded hole in a central position of the bottom of the connecting bushing is blocked by using a plug. According to the mechanism, the workload of operation workers can be reduced, and conditions are created for increasing the productivity of the equipment.

Owner:镇江震东电光源有限公司

Engine system for controlling flow of exhaust gas

ActiveUS20160123221A1Quality improvementAvoid temperatureElectrical controlInternal combustion piston enginesControl flowCombustion chamber

An engine system for controlling flow of exhaust gas may include an intake line to receive external air, an engine including a combustion chamber to combust the external air and a fuel supplied through the intake line, to generate driving torque, an exhaust line to exhaust the exhaust gas combusted in the combustion chamber of the engine, a turbocharger including a turbine operated according to exhaust gas flowing through the exhaust line and a compressor to compress the external air flowing through the intake line, a catalyst device to reduce a harmful component included in the exhaust gas passing through the turbine of the turbocharger, a bypass line branched from the exhaust line between the combustion chamber and the turbine and converged in the intake line between the compressor and the combustion chamber, and a bypass valve disposed in the bypass line to selectively open / close the bypass line.

Owner:HYUNDAI MOTOR CO LTD

Tail pipe drawing mechanism for exhaust machine

InactiveCN107706073AReduce power consumptionImprove exhaust qualityTube/lamp vessels exhaustionScrew threadHorizontal and vertical

The invention discloses a tail pipe pulling mechanism of an exhaust machine, which is characterized in that the cylinder is fixedly mounted on the cylinder support through mounting screws, and the cylinder support is fixedly mounted on the top of the rotating shaft and is radially pressed by mounting screws. tight, the left end of the cylinder support is processed with inner holes in the horizontal and vertical directions, the inner hole of the mounting seat is installed on the rotating shaft, the upper and lower ends of the inner hole of the mounting seat are equipped with bearing bushes, and the pins are installed In the radial inner hole of the rotating shaft, mounting screws are installed on the boss of the mounting seat, the fixed sleeve is mounted on the rotating shaft, the mounting nut is mounted on the lower end of the rotating shaft, and the liquid shaft is mounted on a fixed The sleeve hole is connected with the connecting sleeve through mounting screws and mounting nuts. The connecting sleeve has a cylindrical structure and the threaded hole at the center of the bottom is sealed with a sealing plug.

Owner:CHANGZHOU CHANGTONG PLASTIC PIPE

Idle stop condition determination method of engine

ActiveUS9556808B2Reduce wasteImprove exhaust qualityElectrical controlInternal combustion piston enginesIdle speed

An idle stop condition determination method of an engine includes: calculating and storing a fuel saving estimation amount in idle stop of an engine on the basis of traveling information; calculating the amount of fuel consumption in restarting for restarting, when an idle stop condition of the engine is satisfied; comparing the magnitudes of the fuel saving estimation amount with the amount of fuel consumption in restarting, and stopping the engine in accordance with the result of the comparing; and restarting the engine, when a restarting condition of the engine is satisfied.

Owner:HYUNDAI MOTOR CO LTD

Particle processing device of printer

InactiveCN109049710AAvoid direct dischargeAvoid Inhalation AffectedAdditive manufacturing apparatus3D object support structuresParticulatesFiltration

The invention discloses a particle processing device of a printer. The particle processing device mainly comprises a closed casing, and an ultraviolet degradation box and a centrifugal fan and a discharge detecting structure built in the casing. An inner lower part of the casing is a printing studio for installing a 3D printer; the ultraviolet degradation box is disposed above the printing studio;an inlet of the ultraviolet degradation box is connected to the printing studio; an outlet of the ultraviolet degradation box is connected to the inlet of the centrifugal fan; the centrifugal fan isdisposed at an inner upper portion of the casing; and the emission detecting structure is disposed at an outlet of the centrifugal fan. According to the particle processing device of printer, the beneficial effects are that: the ABS ultrafine particles produced by the 3D printer during printing process are degraded into low molecular compounds and discharged from the centrifugal fan after high-frequency filtration by using the ultraviolet degradation box, so that undegraded ABS ultrafine particles are prevented from being directly discharged into air, quality of environment is ensured, and user inhalation is prevented from being affected.

Owner:WUHAN UNIV OF TECH

Acid pickling process for tail gas of H-acid monosodium salt

The invention provides an acid pickling process for tail gas of an H-acid monosodium salt, and particularly relates to the technical field of production of the H-acid monosodium salt. The process comprises the following process steps of: S1, introducing the tail gas obtained after a neutralization reaction of the H-acid monosodium salt is conducted into a first bath tower, and performing water washing; S2, introducing the tail gas discharged from the first bath tower into a second bath tower, and performing water washing; S3, introducing the tail gas discharged from the second bath tower intoan acid pickling tower, and performing acid pickling; and S4, finally performing adsorption on the tail gas discharged from the acid pickling tower by using molecular sieves, and discharging the adsorbed tail gas. The process has the advantages that the cost is saved, the quality of the treated tail gas is improved, and discharging is more environmentally friendly.

Owner:江苏力禾颜料有限公司

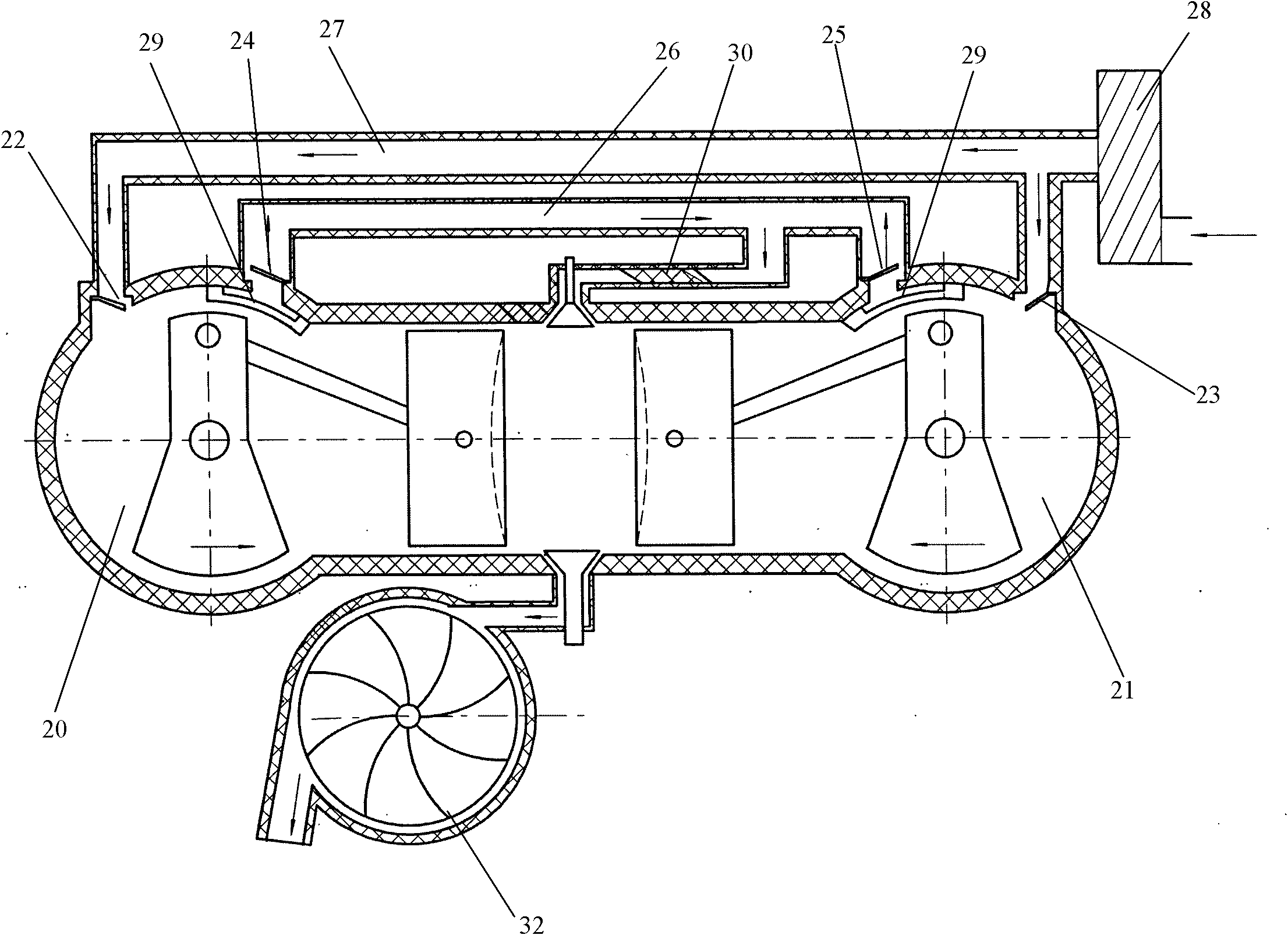

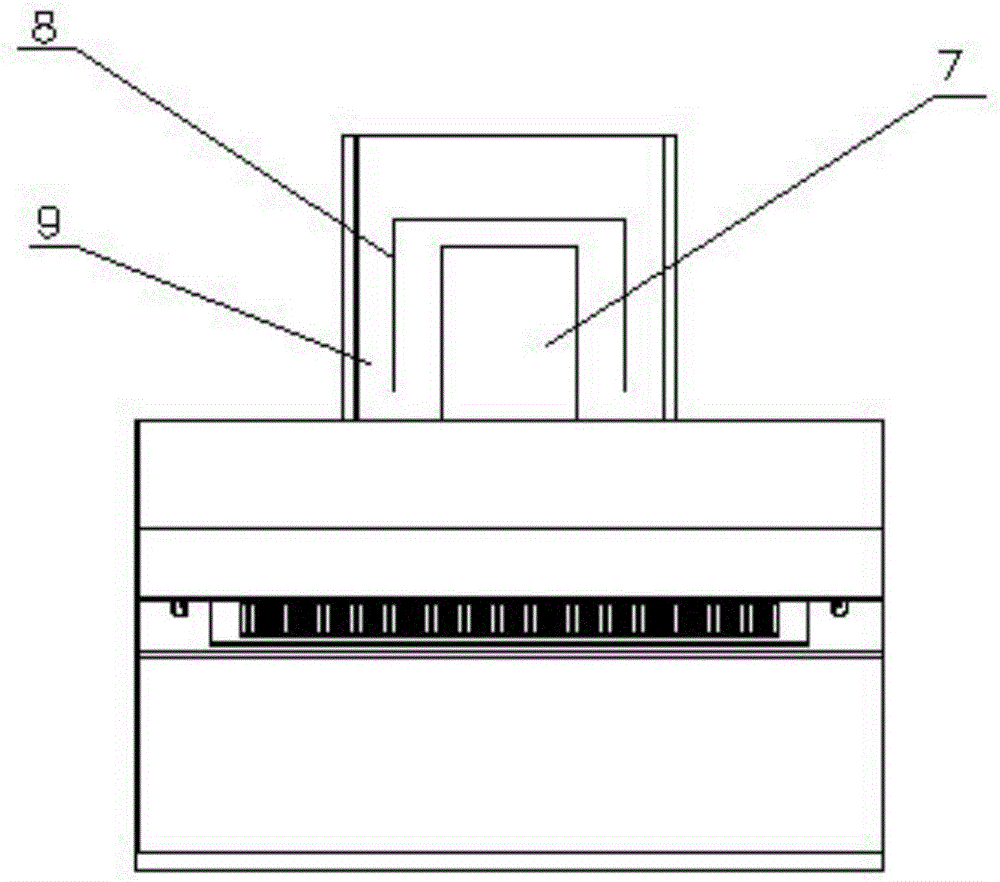

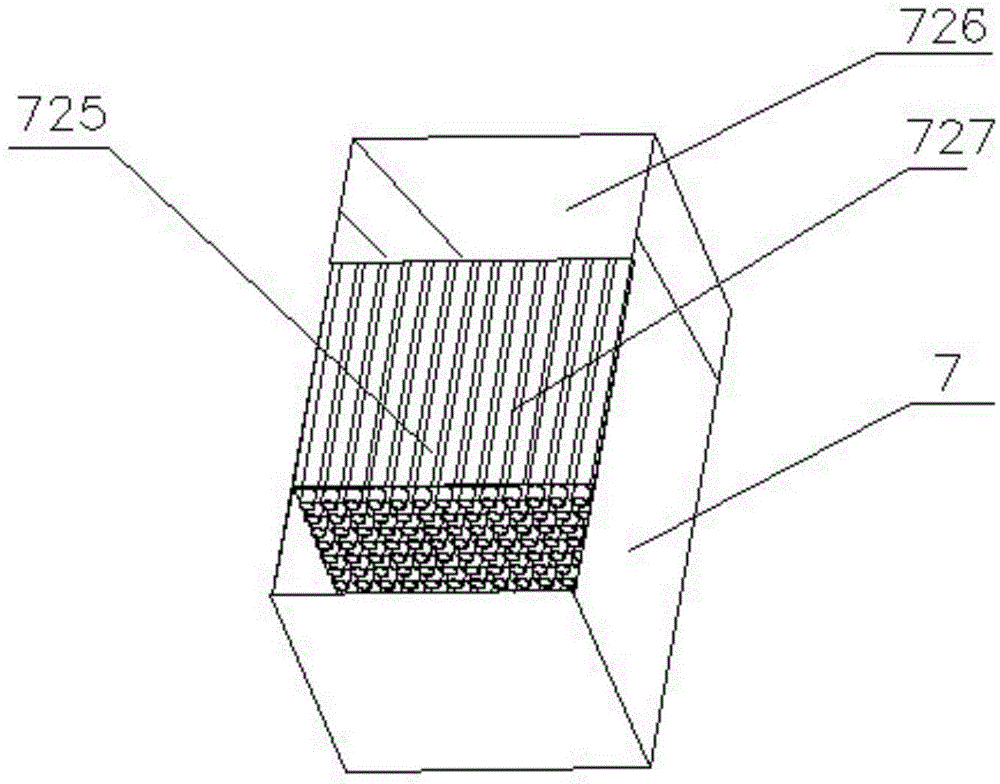

Curvilinear air exhausting extractor hood

InactiveCN106196204AEfficient depositionImprove exhaust qualityDomestic stoves or rangesLighting and heating apparatusAcute angleEngineering

The invention discloses a curvilinear air exhausting extractor hood comprising a case having an air suction opening and an air exhausting opening. The air exhausting opening is located in the top of the case, while the air suction opening is located in the sidewall of the bottom of the case, and a sloping baffle forming an acute angle with the horizontal plane is arranged on the air suction opening. An induced draft fan is disposed in the case, and an air inlet end and an air outlet end of the induced draft fan communicate with the air suction opening and the air exhausting opening, respectively. The curvilinear air exhausting extractor hood is characterized in that two ends of the sloping baffle extend out of the case and a first filtration mechanism is arranged on the sloping baffle, and in that an oil fume adsorption device is arranged in the case. The curvilinear air exhausting extractor hood is capable of effectively removing oil drops in smoke, thus achieving the effect of cleaning air.

Owner:广东苗悦电器有限公司

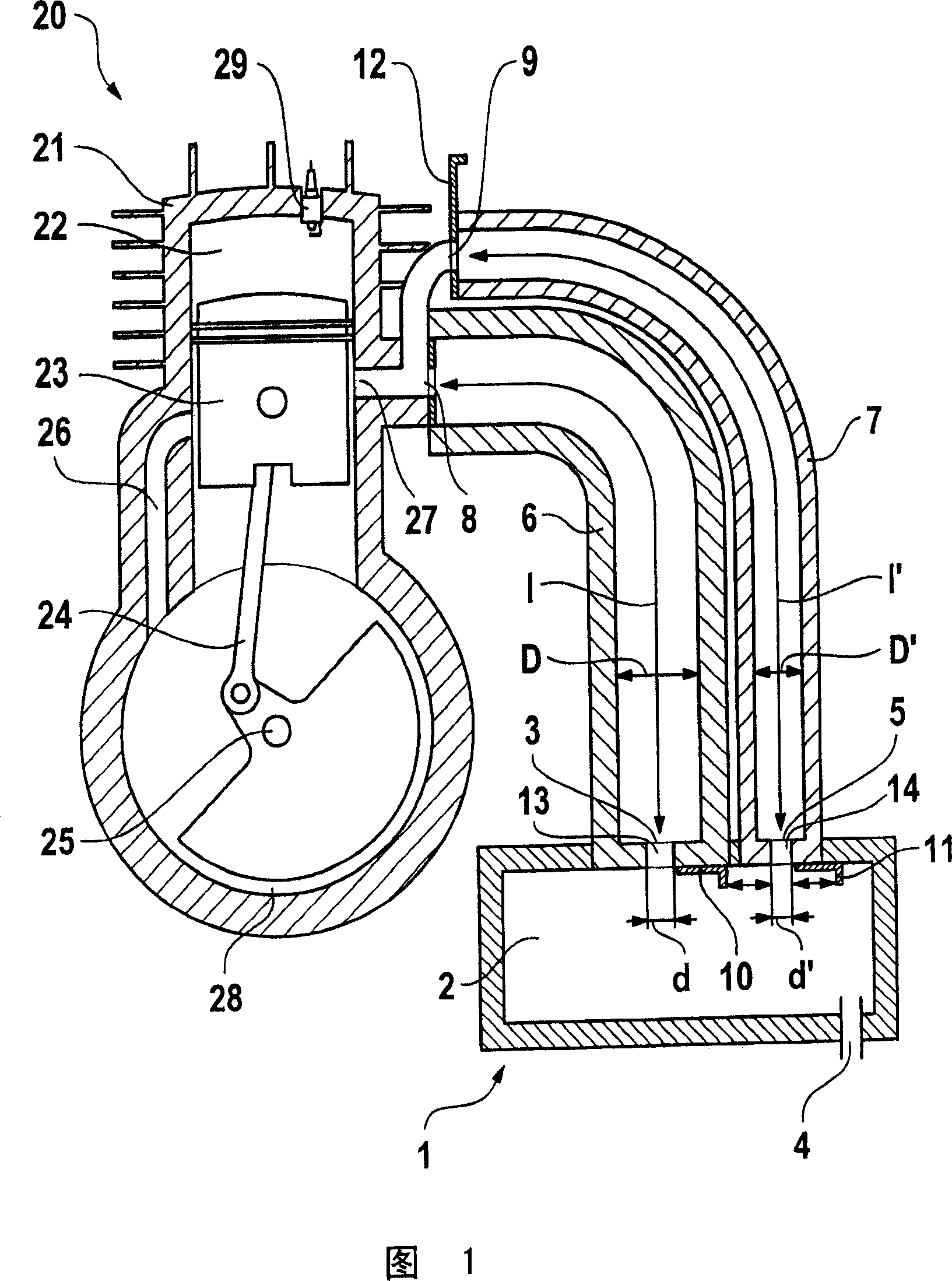

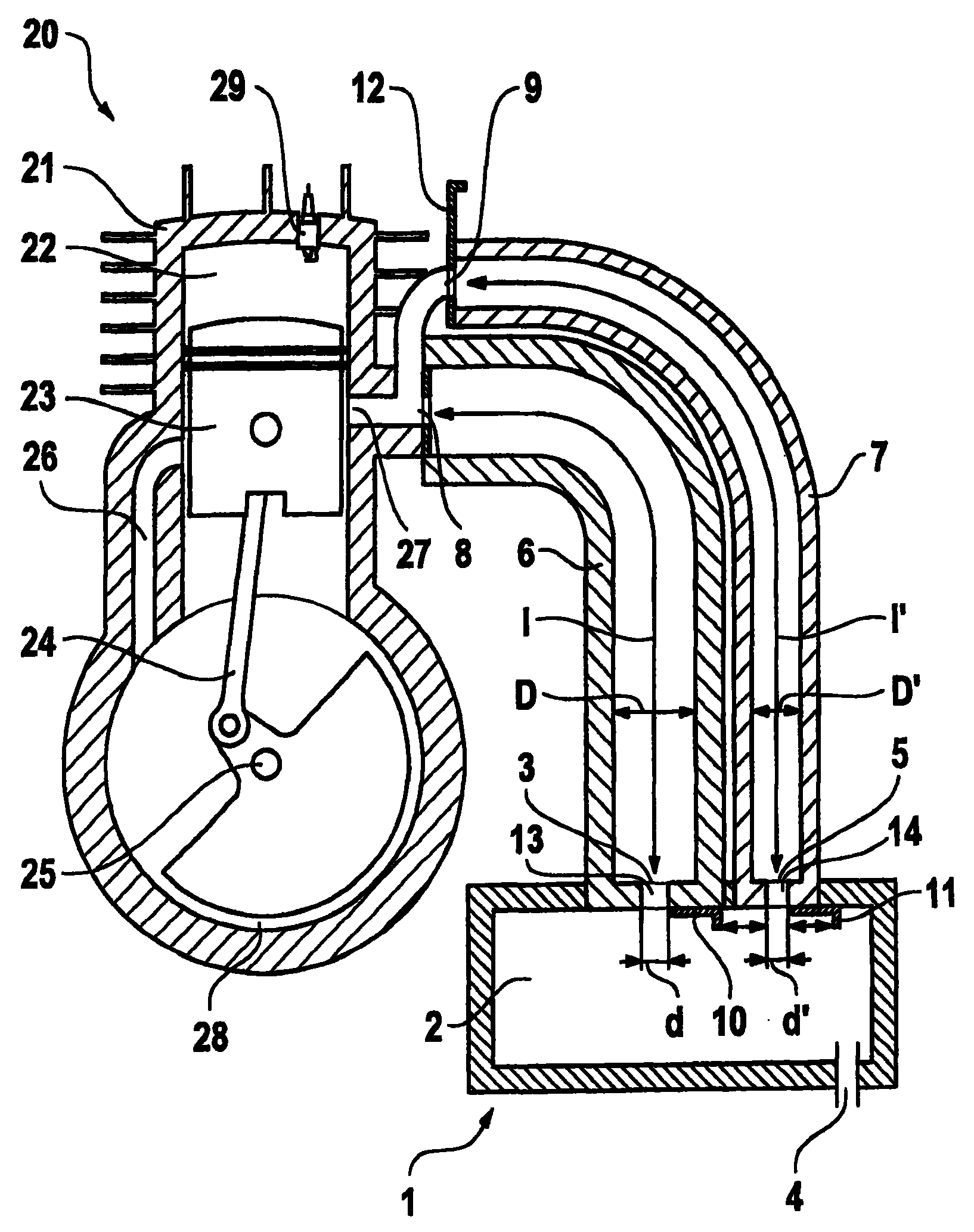

Internal combustion engine

InactiveCN100351499CIncrease powerTake advantage ofInternal combustion piston enginesExhaust apparatusResonanceInternal combustion engine

An internal combustion engine, especially of a two-stroke engine in a portable handheld work apparatus, includes an outlet (27) for the exhaust gases which is fluidly connected with at least one inlet opening (13, 14) in an exhaust-gas muffler (1). At least one resonance pipe (6, 7) is mounted in flow direction between the outlet (27) from the engine (20) and the inlet opening (3, 5) into the exhaust-gas muffler (1) in order to obtain a good noise attenuating result and simultaneously make possible an advantageous, space-saving mounting of the engine (20).

Owner:ANDREAS STIHL AG & CO KG

Boiler flue gas dry quenching system and use method

The invention provides a boiler flue gas dry quenching system and a use method. Semi-coke is cooled through a gas distribution system arranged in a flue gas-semi-coke heat exchange system, a disc furnace flue gas pipeline is coiled on the side wall of the flue gas-semi-coke heat exchange system, and a plurality of nozzles are embedded in the side wall of the flue gas-semi-coke heat exchange system; and the input end of the disc furnace flue gas pipeline is connected with the output end of a flue gas pipeline in front of a furnace, the output end of the disc furnace flue gas pipeline is connected with the plurality of nozzles, and boiler flue gas is conveyed into the flue gas-semi-coke heat exchange system through the nozzles by the disc furnace flue gas pipeline, so that the boiler flue gas is in direct contact with semi-coke for heat exchange, and the semi-coke is effectively cooled. The semi-coke cooled by the boiler flue gas is secondarily cooled by a water jacket heat exchanger and extinguished by a coke discharge bin, so that effective recovery of the semi-coke is realized. The boiler flue gas is in direct contact with the semi-coke for heat exchange, the heat of the high-temperature semi-coke is absorbed, the heat enters the carbonization section to participate in carbonization reaction, the energy consumption of the carbonization furnace is reduced, and the quality of semi-coke tail gas is improved.

Owner:中煤能源研究院有限责任公司

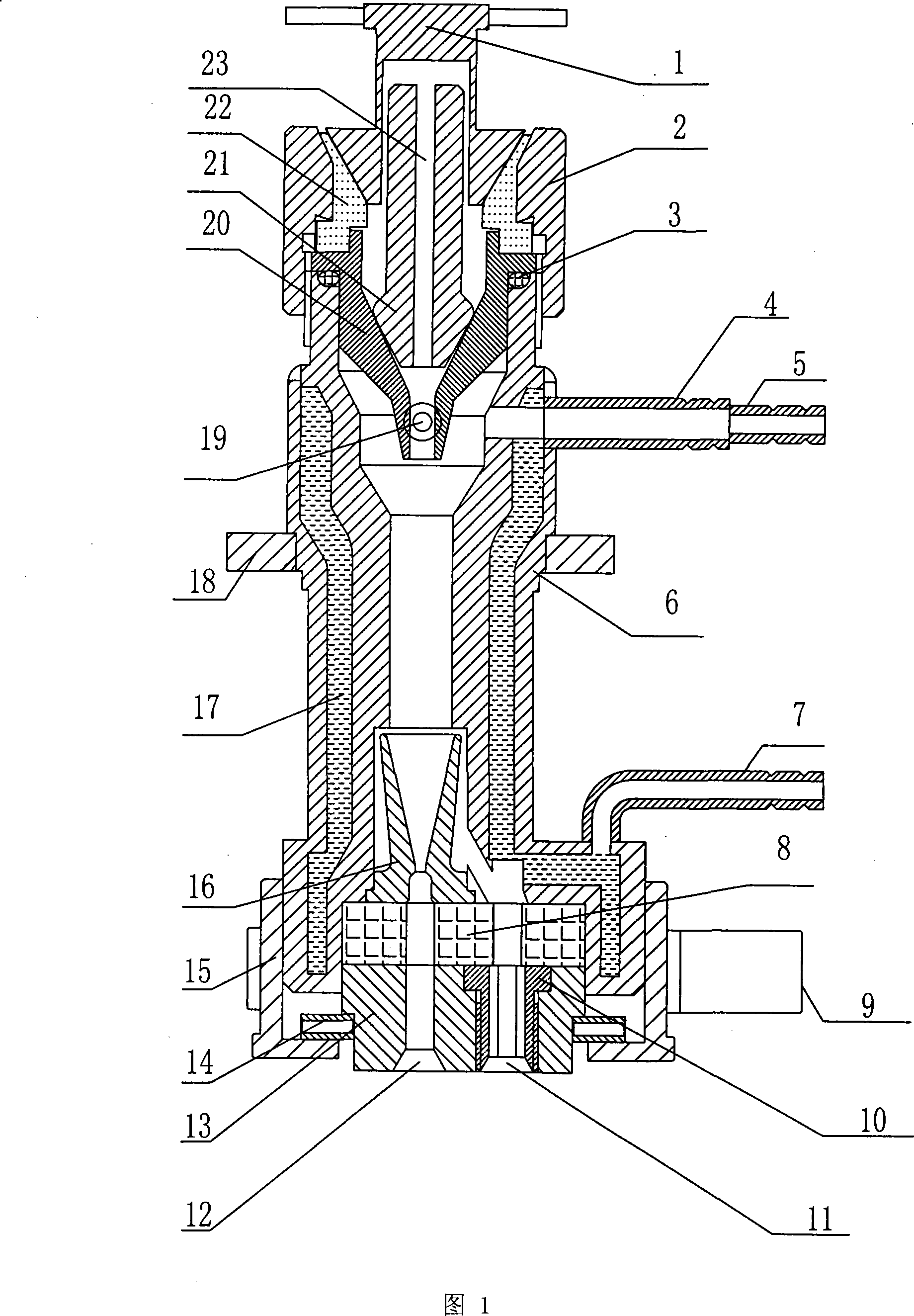

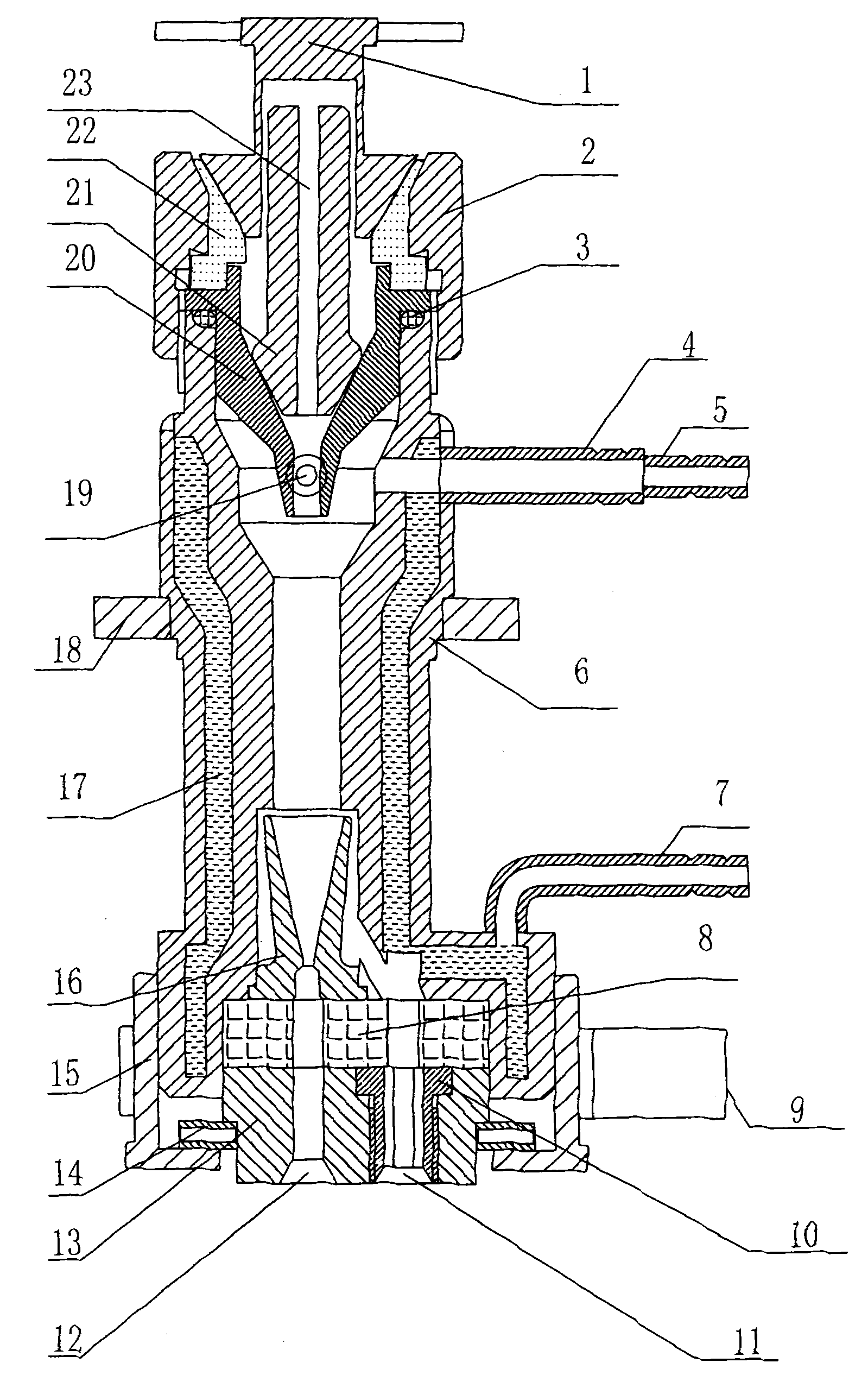

Mercury gun with double exhaust stroke

InactiveCN101477929BIncrease production capacityFast exhaustCold cathode manufactureEngineeringRisk stroke

The invention relates to an energy-saving lamp manufacturing machine, in particular to a dual exhaust rod mercury gun. The prior single exhaust rod mercury gun has a poor vacuum result and can not meet production requirements. The dual exhaust rod mercury gun is provided with two butt glass rods and has a better vacuum result; the dual exhaust rod mercury gun comprises a gun body with an inner cavity; an exhaust pipe communicated with the inner cavity is arranged on one side of the gun body; a mercury dropping seat consists of a sealing cap, a sealing element, a seal ring, an upper pressure cap, a seat cover and a magnetic conductive inner core are arranged at the upper end of the inner cavity; a seal fitting connected with the lamp glass rods is arranged at the lower end of the inner cavity of the gun body; the seal fitting comprises a mercury receiving bucket, a gasket and a hold down part axially connected in series from up to down; an external thread is arranged at the bottom of the gun body and screwed with a lower pressure cap upward supporting the hold down part; through holes communicated with the inner cavity of the gun body pass through the gasket and the upper off axis position of the hold down part; an adjustment blockage is arranged in the through hole on the hold down part; and an axial exhaust through hole is formed on the adjustment blockage. The dual exhaust rod mercury gun has the advantages of good vacuum result, and helps accelerate production speed and raise production capacity.

Owner:江山菲普斯照明有限公司

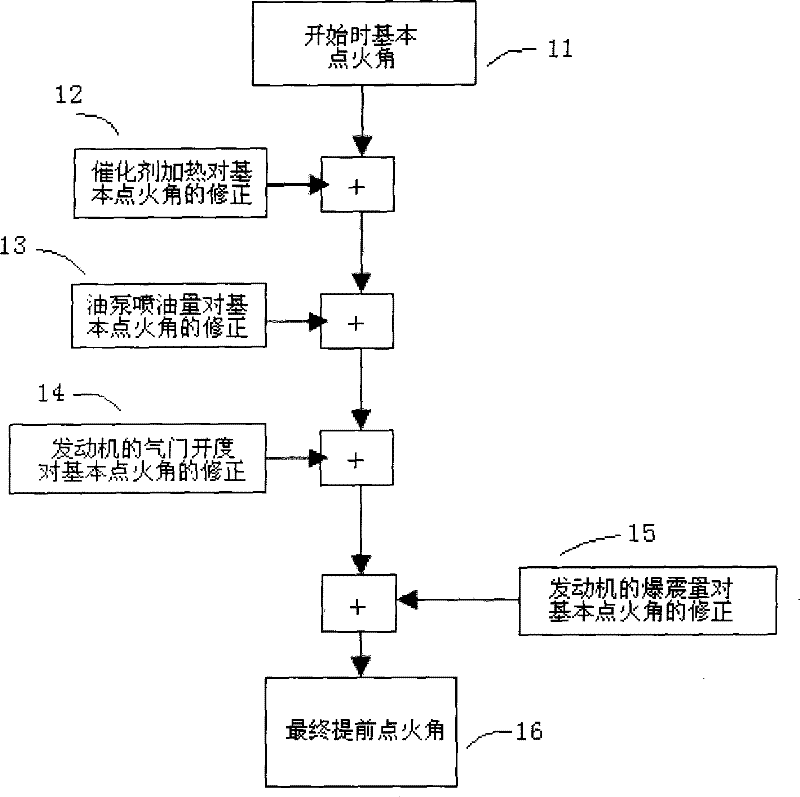

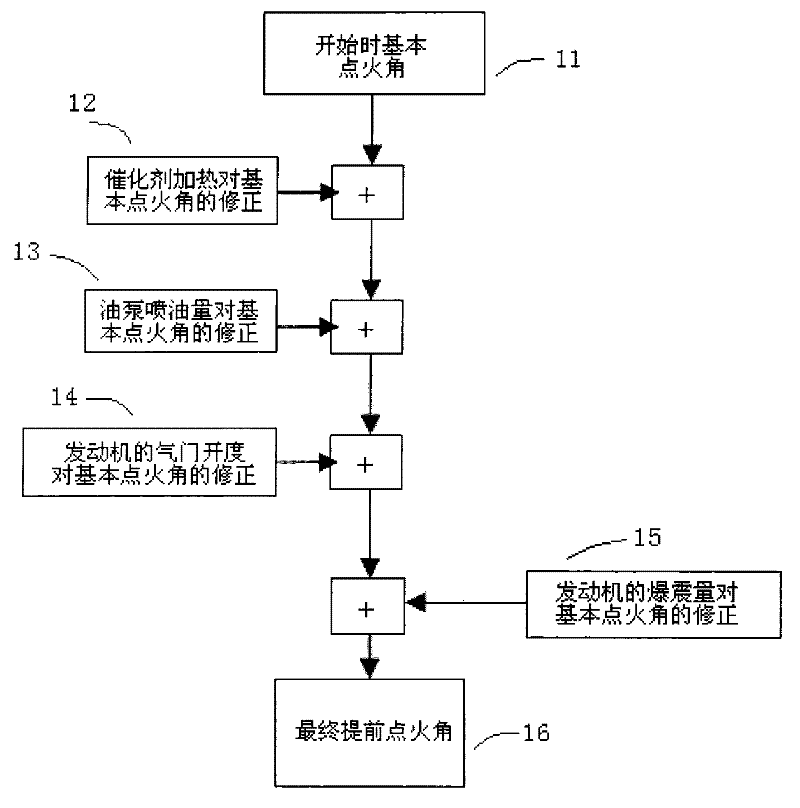

Ignition control method for motorcycle engine

InactiveCN101392712BImprove accuracyBurn fullyIgnition automatic controlAutomatic controlControl systemIgnition coil

The method relates to an electronically controlled system of a motorcycle, in particular to an ignition control method of the electronically controlled system of the motorcycle. The method comprises the following steps: S1, storing calibration data in a memory of ECU; S2, acquiring position signals and status data of a piston by the ECU, after the operation of a motor, calculating data for a basic ignition angle by ECU according to the operating position of the piston; S3, comparing the calibration data of step S1 with the status data of step S2 by the ECU, and obtaining the revised data for the basic ignition angle; S4, overlapping the data of the basic ignition angle calculated in the step S1 and the revised data for the basic ignition angle calculated in step S3 by the ECU to obtain data of a preignition angle; and S5, transmitting the obtained data of the preignition angle calculated in step S4 to an ignition coil by the ECU and controlling the ignition of the ignition coil by the ECU. The method well controls the ignition process, allows an engine to ignite at the best moment and causes the mixed air in the cylinder to fully burn, therby reaching effects of diminishing the oil consumption and improving the quality of tail gas.

Owner:CHINA VAGON AUTOMOTIVES HLDG CO LTD

Mercury gun with double exhaust stroke

InactiveCN101477929AIncrease production capacityFast exhaustCold cathode manufactureEngineeringExhaust pipe

The invention relates to an energy-saving lamp manufacturing machine, in particular to a dual exhaust rod mercury gun. The prior single exhaust rod mercury gun has a poor vacuum result and can not meet production requirements. The dual exhaust rod mercury gun is provided with two butt glass rods and has a better vacuum result; the dual exhaust rod mercury gun comprises a gun body with an inner cavity; an exhaust pipe communicated with the inner cavity is arranged on one side of the gun body; a mercury dropping seat consists of a sealing cap, a sealing element, a seal ring, an upper pressure cap, a seat cover and a magnetic conductive inner core are arranged at the upper end of the inner cavity; a seal fitting connected with the lamp glass rods is arranged at the lower end of the inner cavity of the gun body; the seal fitting comprises a mercury receiving bucket, a gasket and a hold down part axially connected in series from up to down; an external thread is arranged at the bottom of the gun body and screwed with a lower pressure cap upward supporting the hold down part; through holes communicated with the inner cavity of the gun body pass through the gasket and the upper off axis position of the hold down part; an adjustment blockage is arranged in the through hole on the hold down part; and an axial exhaust through hole is formed on the adjustment blockage. The dual exhaust rod mercury gun has the advantages of good vacuum result, and helps accelerate production speed and raise production capacity.

Owner:江山菲普斯照明有限公司

Method for diagnosing a tank venting valve

ActiveUS9316182B2Reduce opening timeHigh selectivityInternal-combustion engine testingElectrical controlFuel tankEngineering

A method for diagnosing a tank venting valve. This includes measuring a first pressure p1 in the induction pipe of an internal combustion engine; activating the tank venting valve so as to open; measuring a second pressure p2 in the induction pipe of the internal combustion engine after the opening activation of the tank venting valve; calculating a control value K by subtracting the first induction pipe pressure p1 from a second induction pipe pressure p2 and adding a correction pressure pK, which is calculated from the leakage air adaptation of an internal combustion engine; and detecting A defect of the tank venting valve, when the control value K falls below a threshold value.

Owner:ROBERT BOSCH GMBH

An exhaust machine tail pipe pulling mechanism for processing light bulbs of road motor vehicles

InactiveCN104347333BReduce power consumptionImprove exhaust qualityTube/lamp vessels exhaustionProduction rateEngineering

Owner:镇江震东电光源有限公司

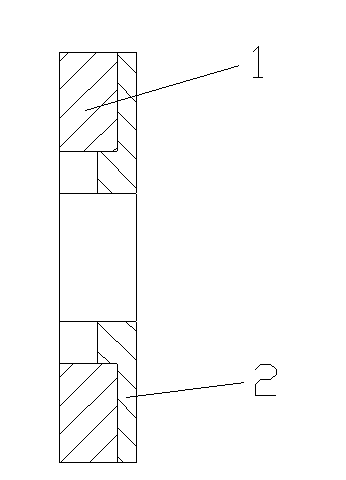

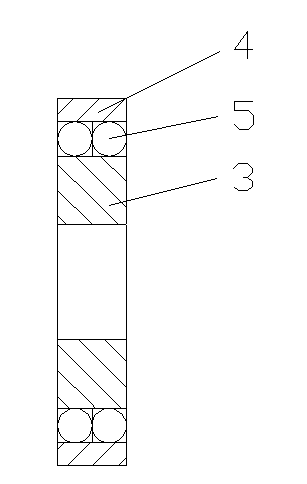

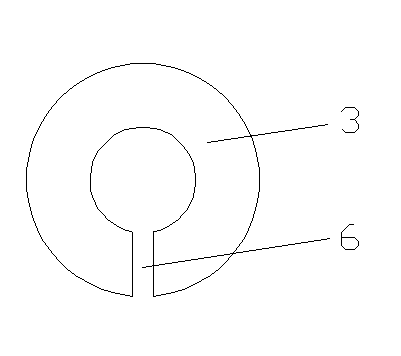

Axial seal ring of air compressor piston rod

InactiveCN103122840AReduce energy consumptionPrevent leakagePositive displacement pump componentsPositive-displacement liquid enginesGas compressorEngineering

The invention discloses an axial seal ring of an air compressor piston rod. The axial seal ring of the air compressor piston rod comprises driving fit rings, outer sleeves and tension springs, wherein the outer sleeves are arranged on the outer rings of the driving fit rings, the tension springs are arranged between each driving fit ring and each outer sleeve, and notches are formed in the driving fit rings and the outer sleeves. The notches in the driving fit rings are staggered with the notches in the outer sleeves. The driving fit rings and the outer sleeves are made of teflon. The axial seal ring of the air compressor piston rod can automatically adjust when the piston rod is abraded, seal effects are increased, the phenomenon that lubricating oil in a roller box can seep in an air cylinder through the piston rod is prevented, oil content in compressed air is reduced, venting quality is improved, use energy consumption of the air compressor is reduced, and energy is saved.

Owner:翁雪元

Engine system for controlling flow of exhaust gas

ActiveUS20170022889A1Quality improvementAvoid temperatureElectrical controlInternal combustion piston enginesControl flowCombustion chamber

An engine system for controlling flow of exhaust gas may include an intake line to receive external air, an engine including a combustion chamber to combust the external air and a fuel supplied through the intake line, to generate driving torque, an exhaust line to exhaust the exhaust gas combusted in the combustion chamber of the engine, a turbocharger including a turbine operated according to exhaust gas flowing through the exhaust line and a compressor to compress the external air flowing through the intake line, a catalyst device to reduce a harmful component included in the exhaust gas passing through the turbine of the turbocharger, a bypass line branched from the exhaust line between the combustion chamber and the turbine and converged in the intake line between the compressor and the combustion chamber, and a bypass valve disposed in the bypass line to selectively open / close the bypass line.

Owner:HYUNDAI MOTOR CO LTD

Method and system for controlling exhaust gas flow in engine system

ActiveUS9909476B2Avoid temperature dropImprove exhaust qualityElectrical controlInternal combustion piston enginesCoolant temperatureFuel injection

A method and system for controlling an exhaust gas flow in an engine system are provided. The method includes detecting operating conditions of an engine and operating a valve that is disposed on a line bypassing a catalyst unit based on the operating conditions such that exhaust gas bypasses the catalyst unit. The operating conditions include a vehicle speed, an engine rotation speed, a fuel injection amount, an accelerator pedal signal, a coolant temperature, or a lambda value of exhaust gas.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com