Curvilinear air exhausting extractor hood

A range hood and curve technology, which is applied in the field of curve exhaust range hoods, can solve problems affecting air quality and the effect of range hoods, and achieve the effects of improving exhaust quality, increasing oil fume adsorption, and reducing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

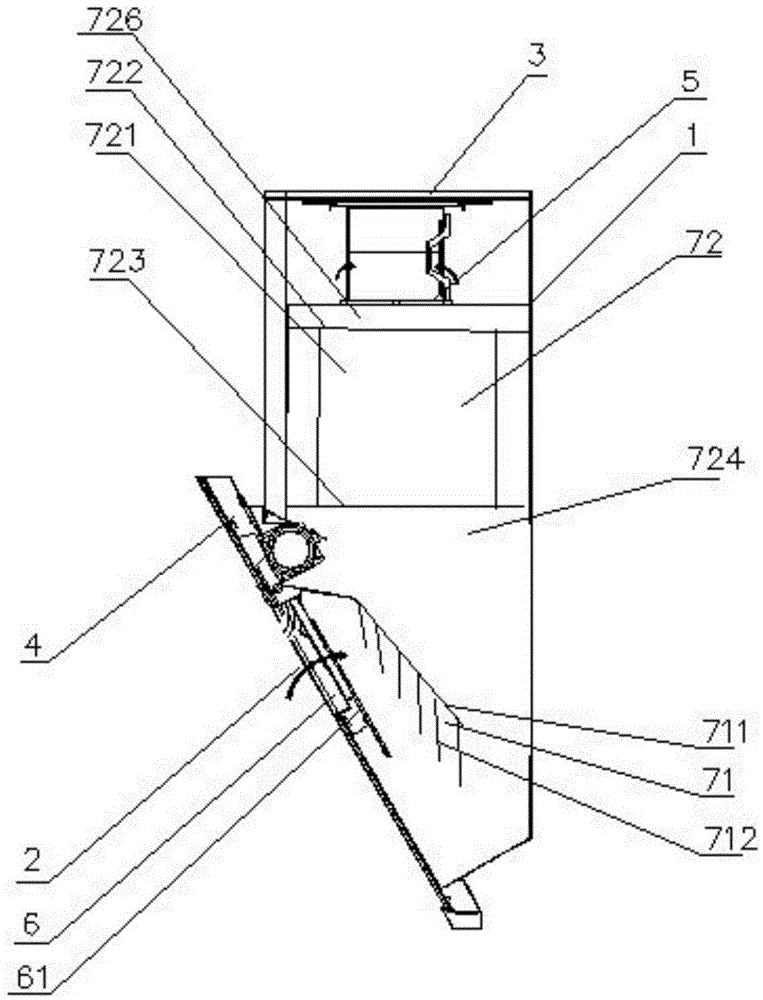

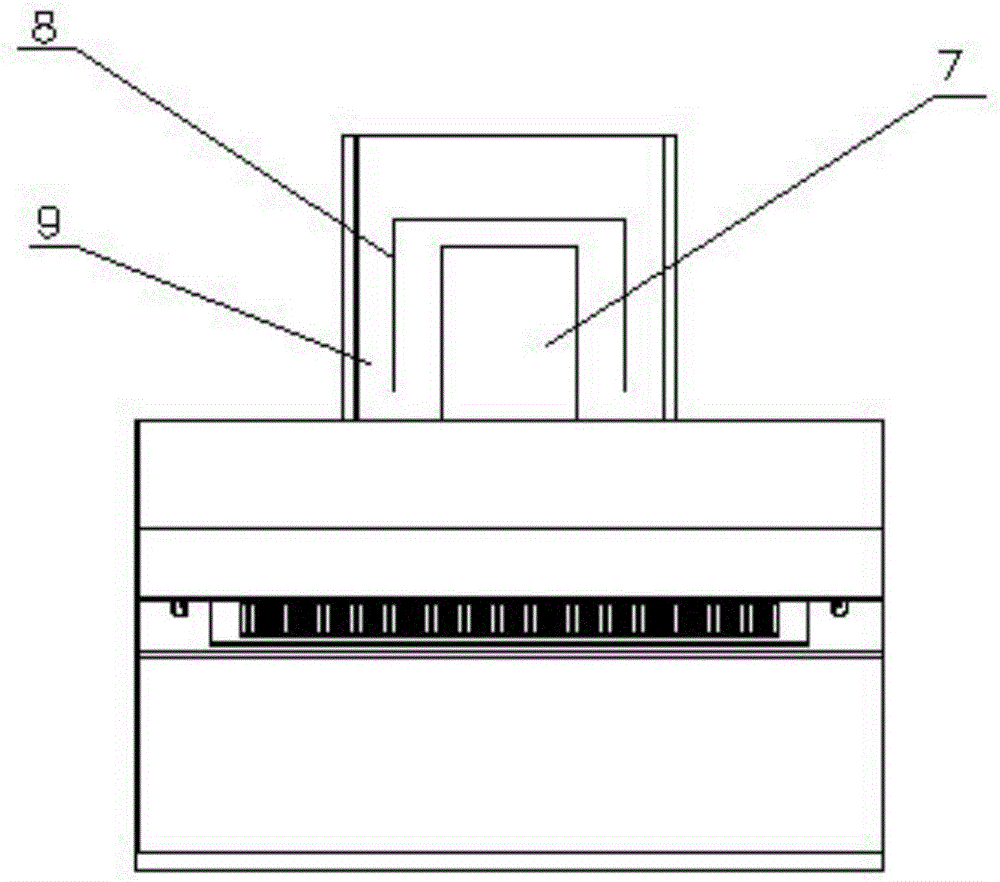

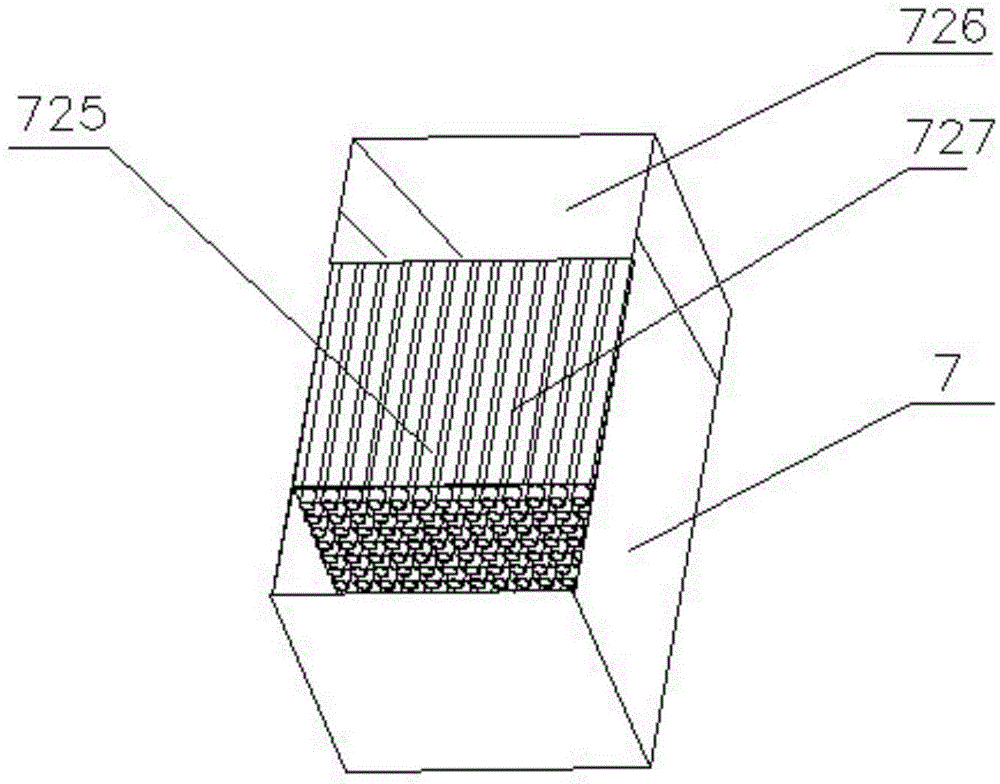

[0022] The present invention will be further described below in conjunction with accompanying drawing.

[0023] Such as Figure 1-Figure 3 As shown, a curved exhaust range hood includes a cabinet 1 with an air suction port 2 and an air exhaust port 3. The air exhaust port 3 is located on the top of the cabinet 1, and the air suction port 2 is located on the side wall of the bottom of the cabinet 1. The tuyere 2 is provided with an inclined baffle plate 4 at an acute angle with the horizontal plane, and an induced draft fan 5 is provided in the cabinet 1, and the air inlet end and the air outlet end of the induced draft fan 5 are respectively connected with the air suction port 2 and the air exhaust port 3. Both ends of the inclined baffle 4 extend out of the case 1 , a first filtering mechanism 6 is provided on the inclined baffle 4 , and an oil fume adsorption device 7 is provided inside the case 1 .

[0024] The first filter mechanism 6 includes a first filter 61 with strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com