Internal combustion engine

A technology for internal combustion engines and engines, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as unfavorable layout and utilization of structural space, and achieve the effects of improving exhaust quality, increasing power, and good noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

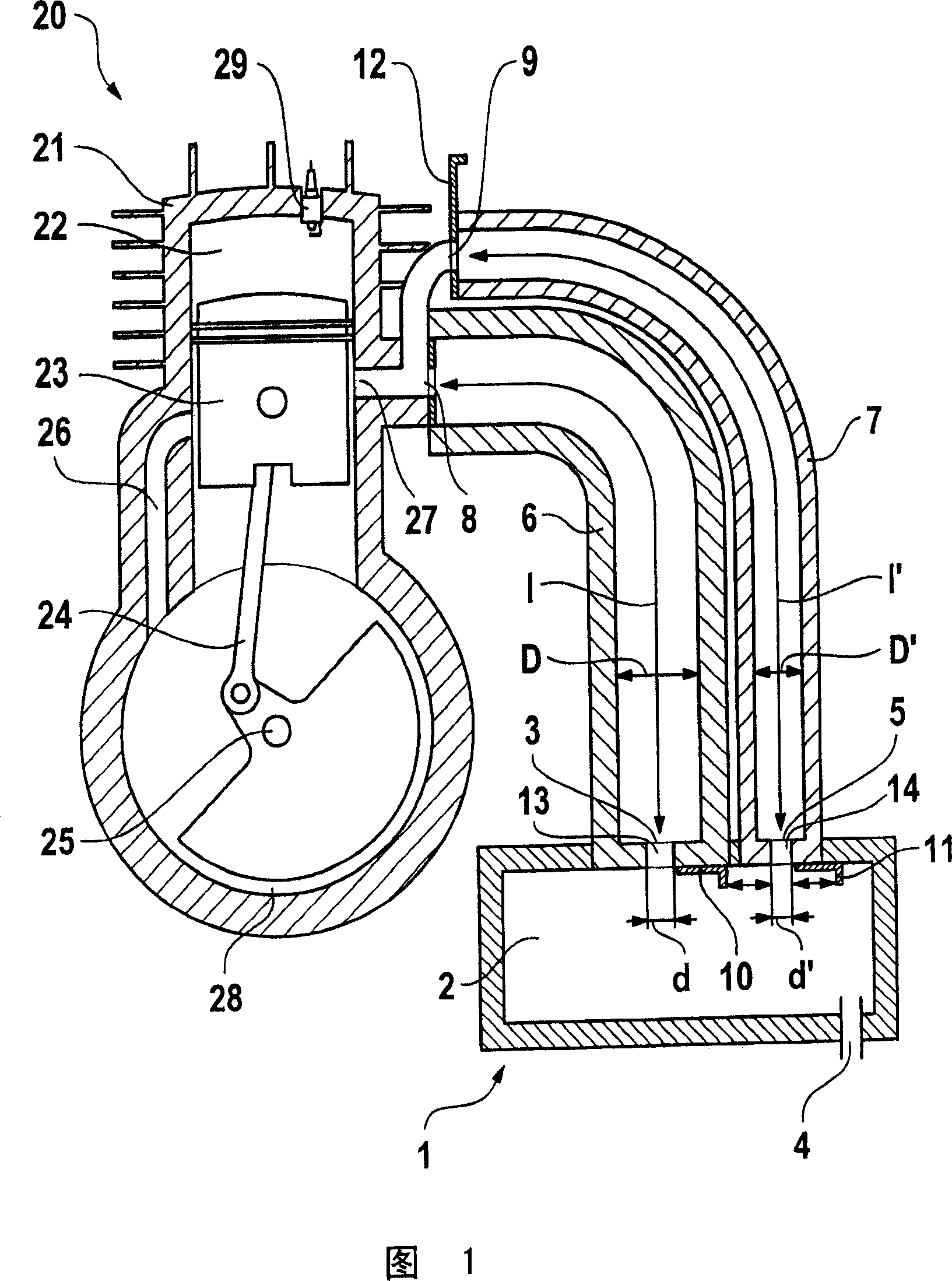

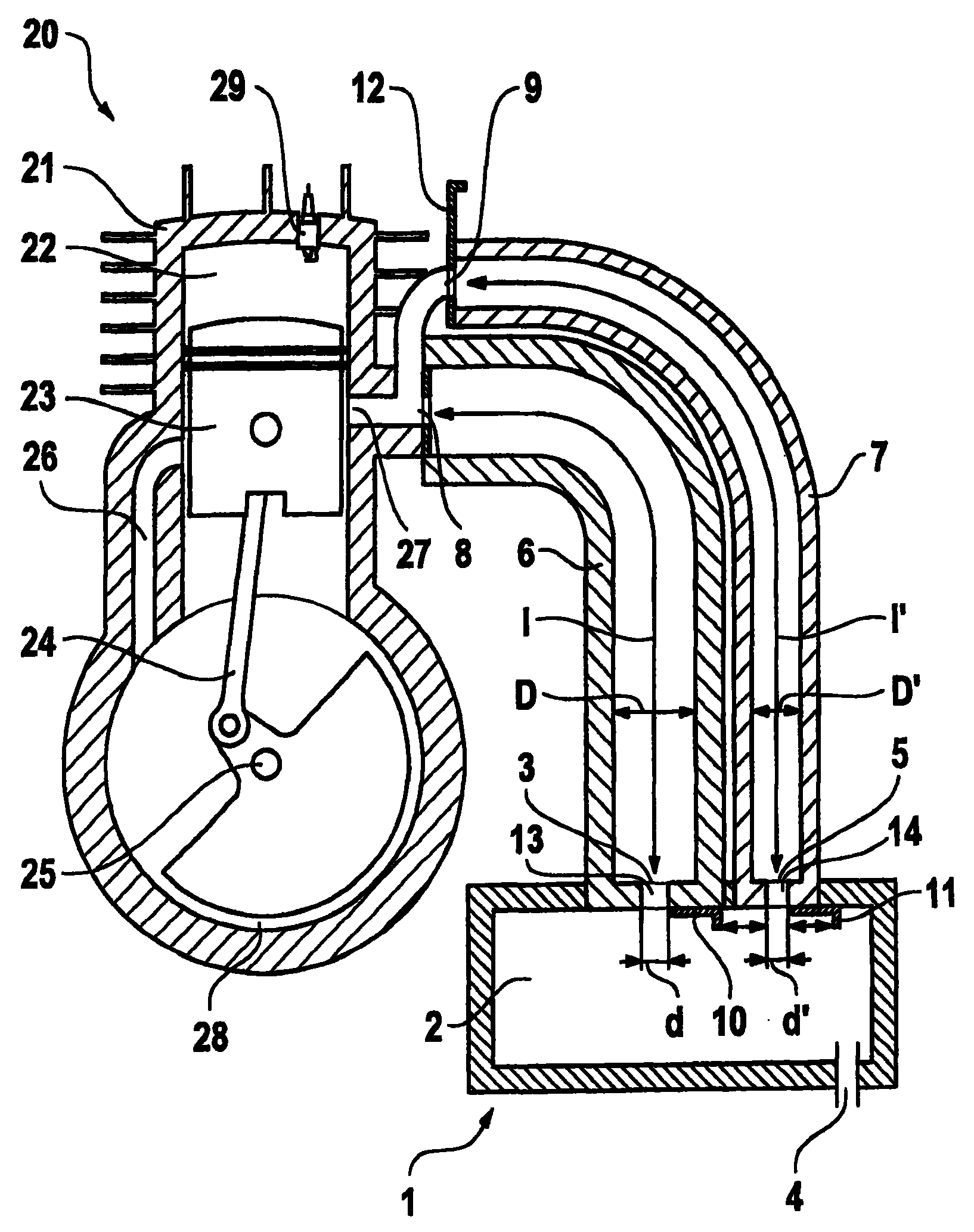

[0009] The internal combustion engine 20 is designed as a two-stroke engine and has two cylinders 21 in which a combustion chamber 22 is arranged. The combustion chamber 22 is delimited by a reciprocating piston 23 , which drives a crankshaft 25 rotatably mounted in a crankcase 28 via a connecting rod 24 . The crankcase 28 is connected to the combustion chamber 22 at a predetermined position of the piston 23 via at least one overflow pipe 26 .

[0010] During operation of the internal combustion engine 20 , the fuel / air mixture is supplied to the crankcase 28 via an inlet (not shown). As the piston 23 moves downward, the mixture is compressed in the crankcase 28 and flows into the combustion chamber 22 through one or more overflow tubes 26 at the bottom dead center of the piston 23 . The mixture is compressed in the combustion chamber 22 by the upwardly moving piston 23 and ignited by the spark plug 29 at the top dead center. Exhaust gases flow out of the combustion chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com