Combustion unit for turbocharger

A turbocharger and combustion device technology, which is applied to combustion equipment, noise reduction devices, exhaust devices, etc., can solve the problems of not being able to improve the performance of internal combustion engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

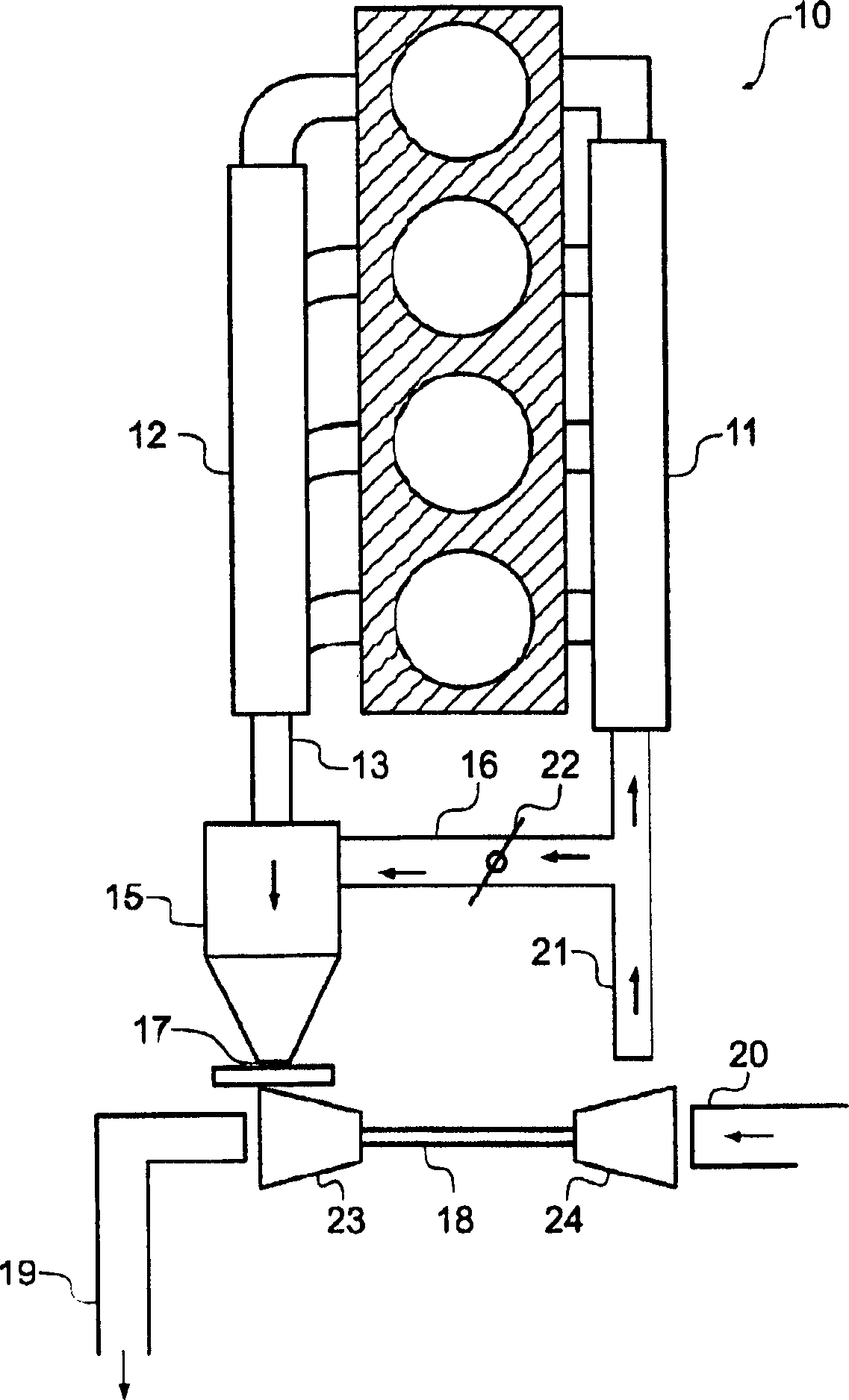

[0023] With reference to the accompanying drawings, first of all figure 1 , shows an internal combustion engine 10 which may be of any suitable form, in this case a four cylinder petrol engine, but which may also be a diesel or other internal combustion engine. The internal combustion engine 10 has: an intake manifold 11 through which air is introduced into a combustion chamber of the internal combustion engine 10; and an exhaust manifold 12 through which combustion products in the internal combustion engine 10 are collected and discharged to Exhaust outlet 13.

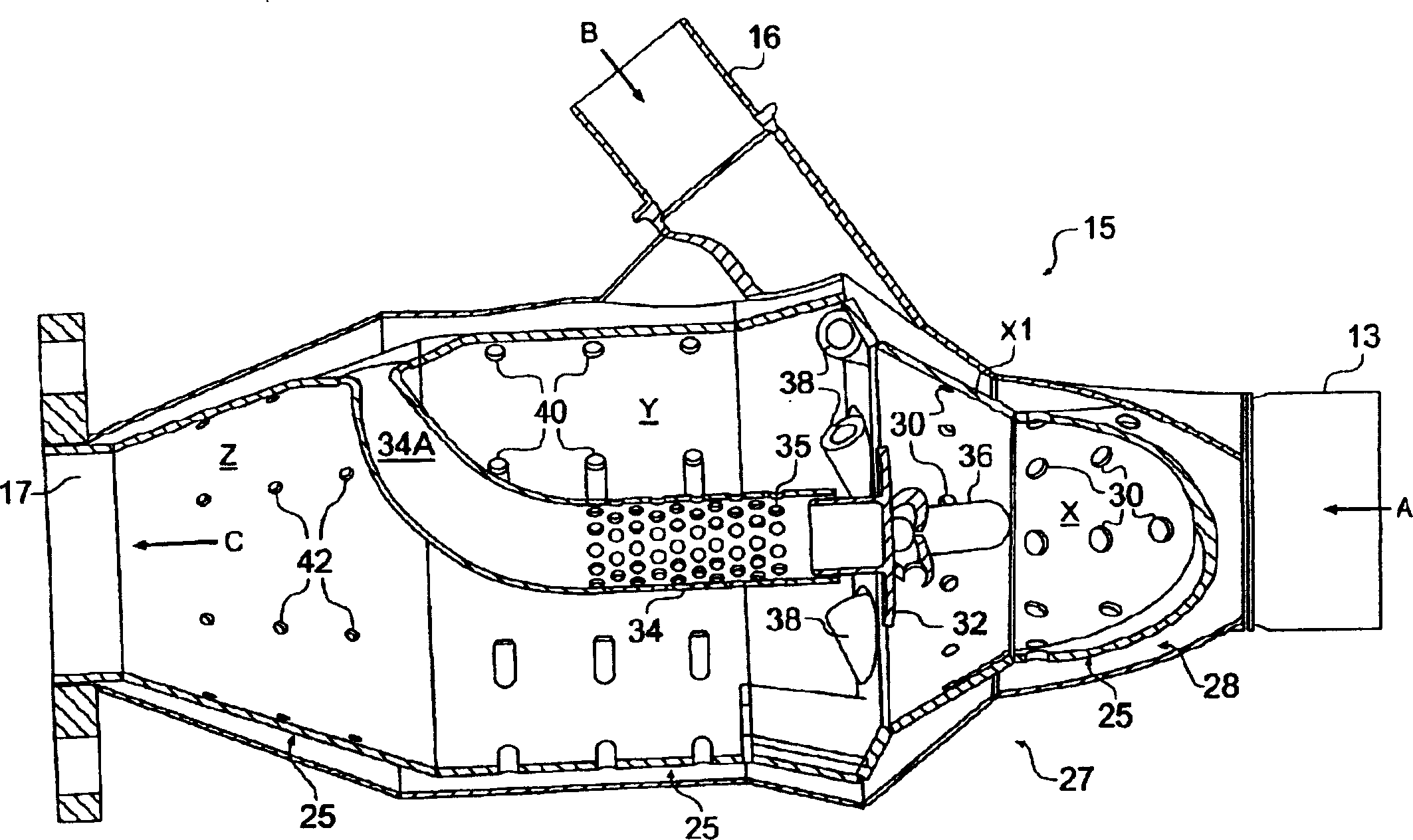

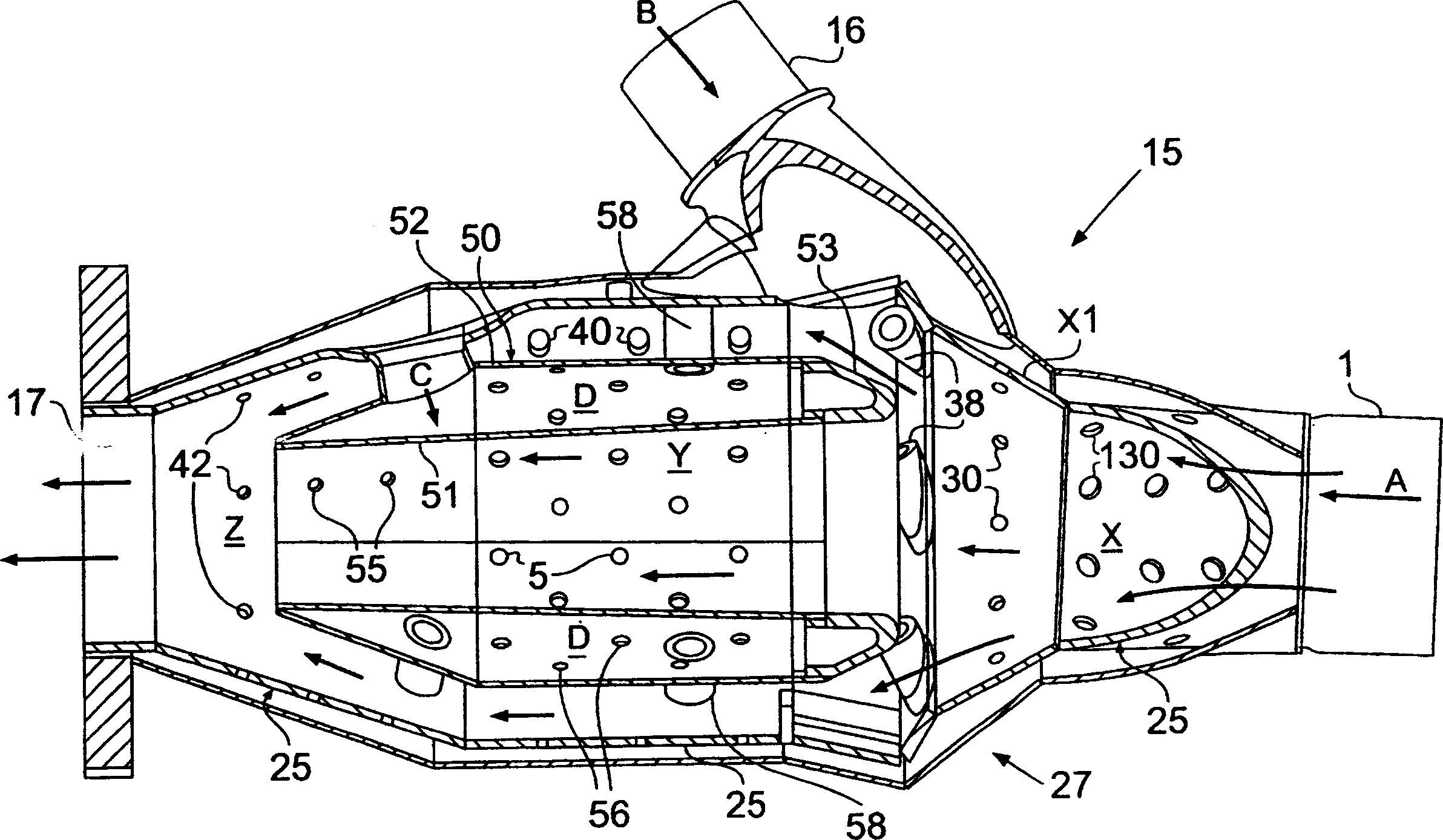

[0024] The combustion chamber 15 is supplied with exhaust gas from the internal combustion engine 10 and air from an inlet 16 and exhausts gases from an outlet 17 driving a turbine 23 of a turbocharger 18 . Gas is discharged from the turbine 23 to the exhaust pipe 19 , while the turbocharger 18 draws air compressed by the compressor 24 through the intake 20 and discharges it through the high pressure line 21 . The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com