Polymer compound resistor type humidity sensitive element with nanometer fiber structure and manufacturing method thereof

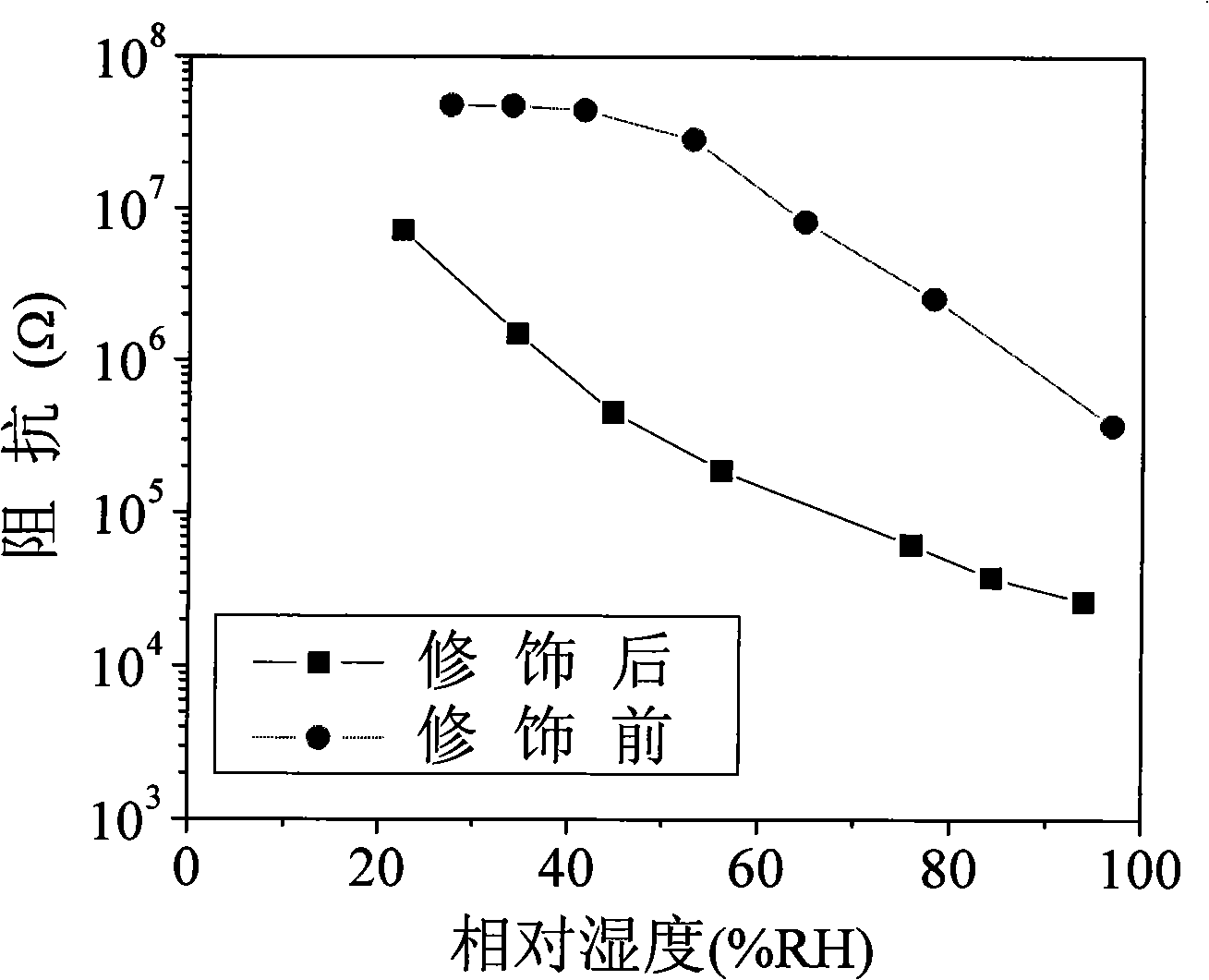

A technology of nanofibers and composite resistors, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of slow removal of water molecules, component sensitivity, response time limitation, etc., to reduce component resistance, fast response speed, and response sensitivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

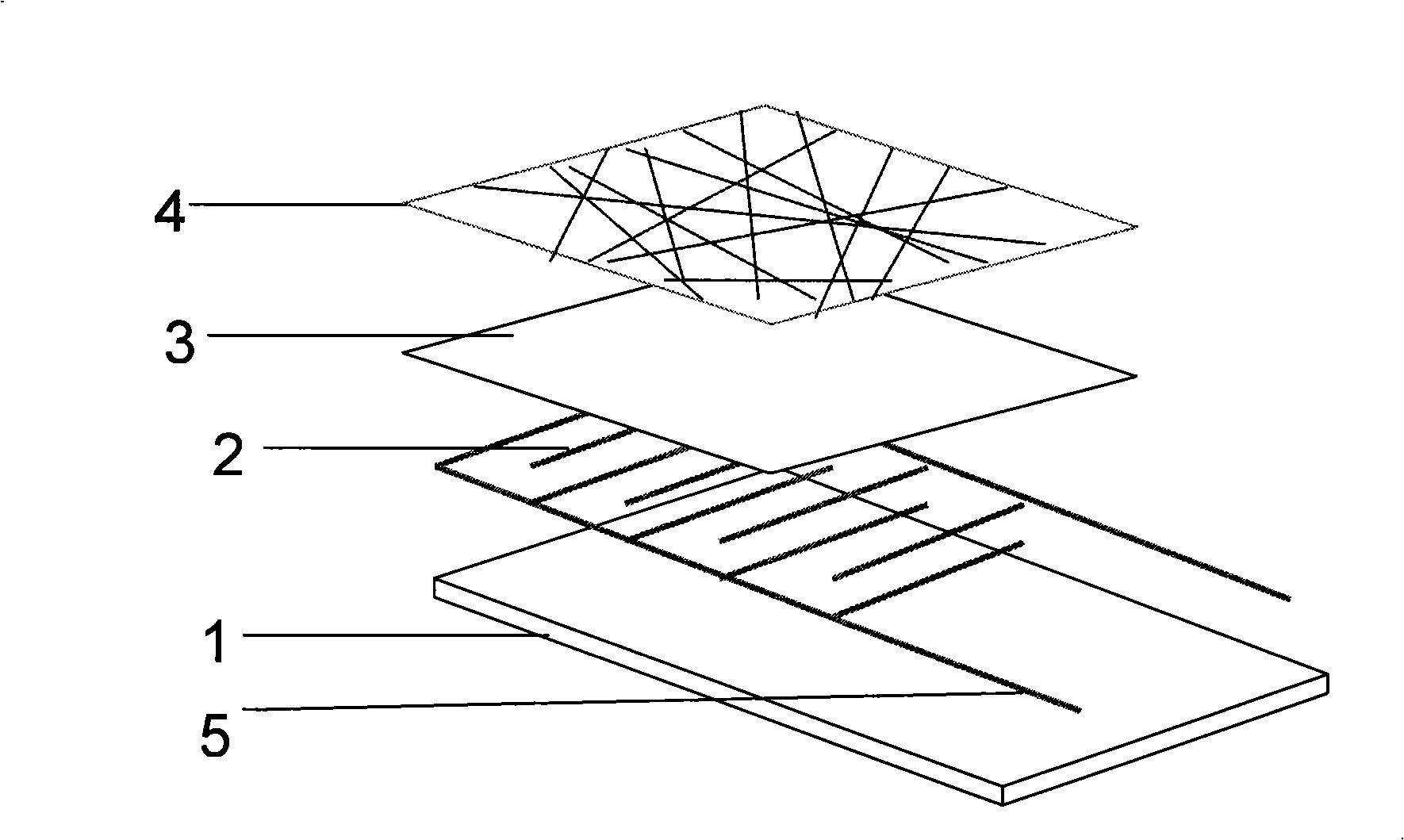

Method used

Image

Examples

Embodiment 1

[0028] 1) Soak the photoetched and evaporated ceramic substrate with interdigitated gold electrodes in absolute ethanol and acetone, ultrasonically clean it, and dry it for later use;

[0029] 2) Immerse the interdigitated gold electrode of the ceramic substrate in an aqueous solution of polydiallyldimethylammonium chloride with a mass concentration of 0.25% with a dipping machine, pull it, take it out, and dry it in the air;

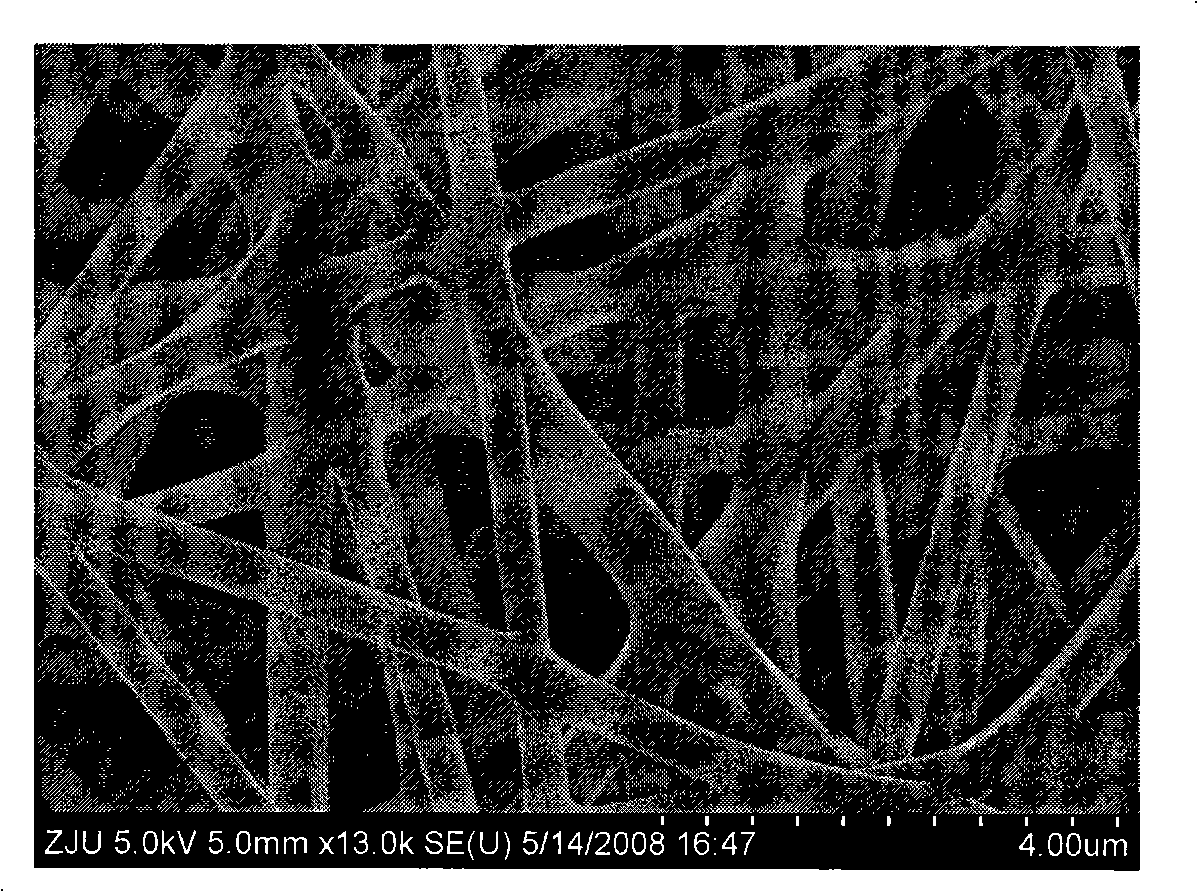

[0030] 3) The nanofiber composite film spun from the spinning solution was deposited on the ceramic interdigitated gold electrode coated with a modified film by electrospinning, and then heat-treated at 80°C for 16 hours to obtain a composite film with a nanofiber structure. Polymer composite resistive humidity sensor. The components of the spinning solution for electrospinning are calculated by weight percentage: 3-aminopropyl triethoxy silicon monobromo-n-hexane quaternary ammonium salt is 5.2%, polyethylene oxide is 5.2%, soluble basic polyaniline 0...

Embodiment 2

[0032] 1) Soak the photoetched and evaporated ceramic substrate with interdigitated gold electrodes in absolute ethanol and acetone, ultrasonically clean it, and dry it for later use;

[0033] 2) Immerse the ceramic interdigitated gold electrode in an aqueous solution of polydiallyldimethylammonium chloride with a mass concentration of 0.1% with a dipping machine, pull it, take it out, and dry it in the air;

[0034] 3) The nanofiber composite film spun from the spinning solution was deposited on the ceramic interdigitated gold electrode coated with a modified film by electrospinning, and then heat-treated at 100°C for 12 hours to obtain a composite film with a nanofiber structure. Polymer composite resistive humidity sensor. The components of the spinning solution for electrospinning are calculated by weight percentage: 6.1% for 3-aminopropyl triethoxy silicon monobromo-n-hexane quaternary ammonium salt, 6.1% for polyethylene oxide, soluble basic polyaniline 2.3%, and 2.3% o...

Embodiment 3

[0036] 1) Soak the photoetched and evaporated ceramic substrate with interdigitated gold electrodes in absolute ethanol and acetone, ultrasonically clean it, and dry it for later use;

[0037] 2) Immerse the ceramic interdigitated gold electrode in an aqueous solution of polydiallyldimethylammonium chloride with a mass concentration of 0.2% with a dipping machine, pull it, take it out, and dry it in the air;

[0038]3) The nanofiber composite film spun from the spinning solution was deposited on the ceramic interdigitated gold electrode coated with the modified film by electrospinning, and then heat-treated at 90°C for 14 hours to obtain a composite film with a nanofiber structure. Polymer composite resistive humidity sensor. The components of the spinning solution for electrospinning are calculated by weight percent: 3-aminopropyl triethoxy silicon monobromo-n-hexane quaternary ammonium salt is 5.6%, polyethylene oxide is 5.6%, soluble basic polyaniline 1.5%, and 1.5% of cam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| interdigital gap | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com