Polymeric strain sensor

A strain sensor and polymer technology, applied in the field of strain sensors, can solve the problems of short service life and unsatisfactory polymer strain gauges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

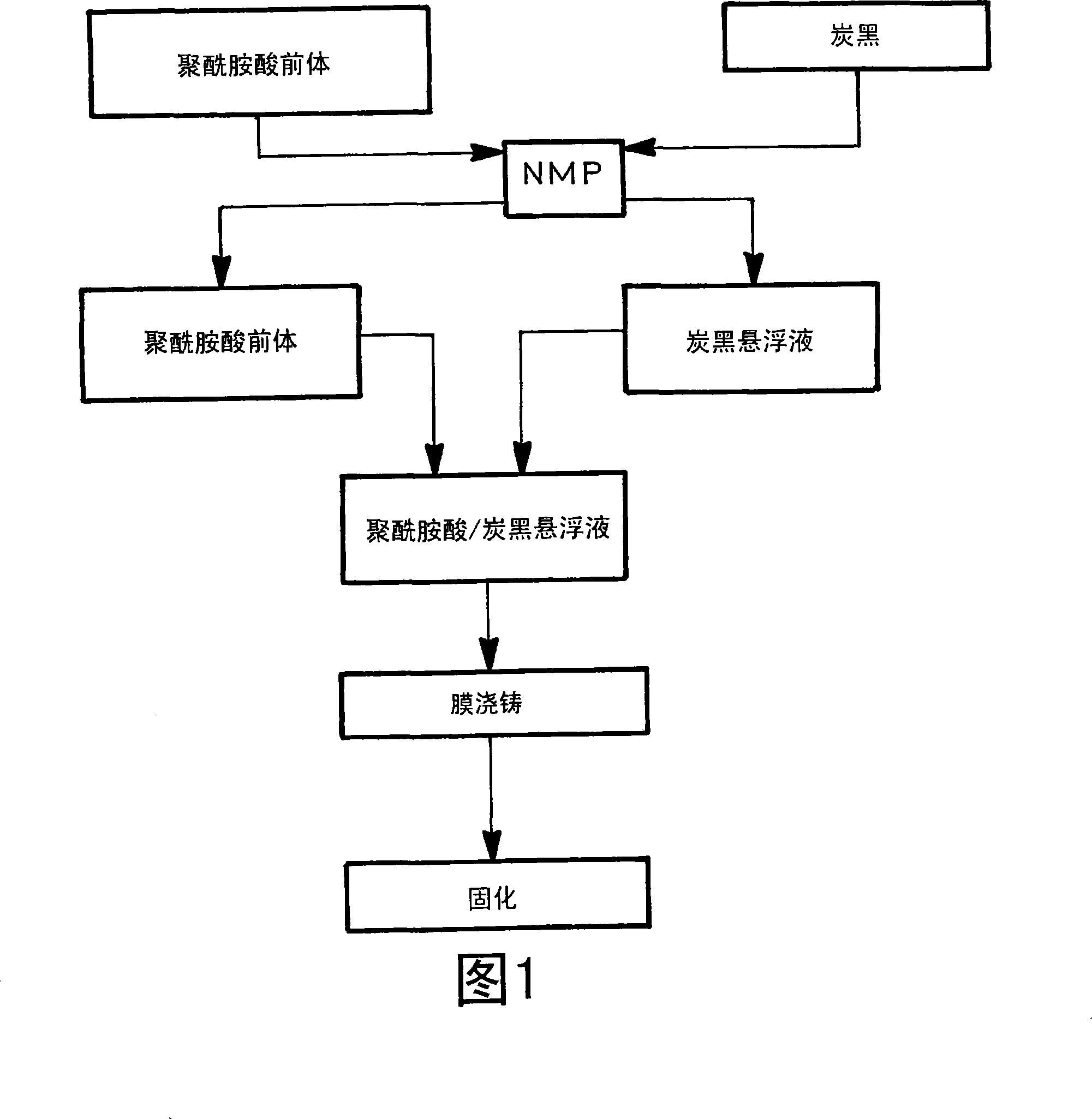

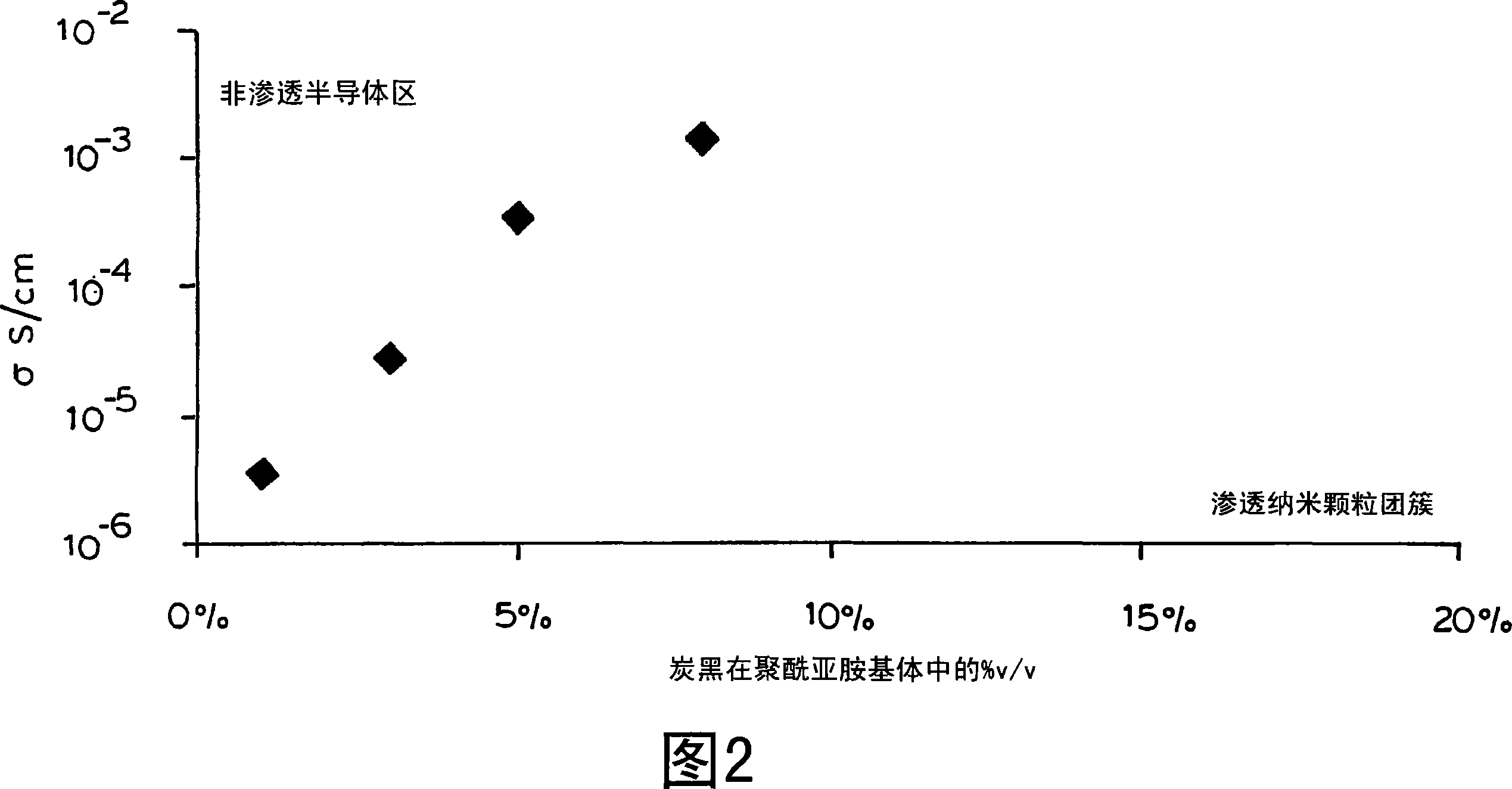

[0040] As shown in Figure 1, the nanocomposite film is prepared by mixing carbon black into the precursor of polyimide (i.e. polyamic acid of benzophenone tetracarboxylic dianhydride), and using n-methyl 2- Film formation of 4,4'-aminodiphenyl ether (BPDA-ODA) in pyrrolidone (NMP) solvent. The cast film is in the range of 50-100 microns. The carbon black has an average particle diameter of 30-70 nm and an aggregate particle size of 100-200 nm. The carbon loading is kept below 10% v / v, resulting in a conductivity of 10 -6 to 10 -2 Scm -1 and within the range of semiconductors, as shown in Figure 2.

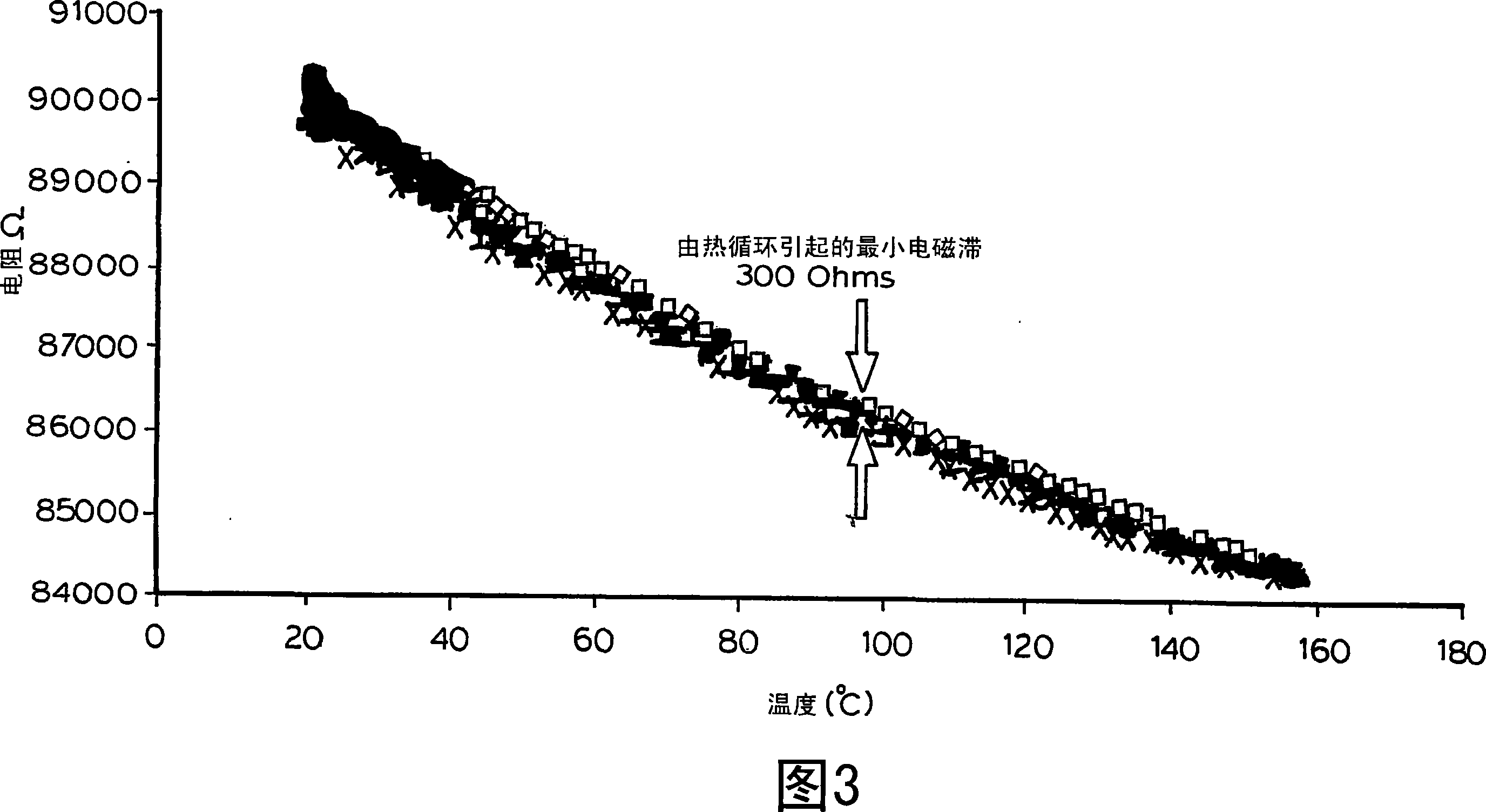

[0041] Figure 3 shows the resistance-temperature diagram of a nanocomposite film with a carbon content of 5% v / v cast on a silicon substrate. Resistance decreases with increasing temperature, which is typical for semiconductors. The figure also shows reduced resistive hysteresis behavior upon thermal cycling.

[0042] Figure 4 shows the temperature-dependent resistance chang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com