Mercury gun with double exhaust stroke

An exhaust rod and exhaust through-hole technology, which is applied in the manufacture of electrical components, discharge tubes/lamps, cold cathode manufacture, etc. The vacuum effect of the gun is not good, and the qualified rate of the finished lamp tube is reduced, so as to achieve the effect of good cooling effect, improved lamp tube production capacity and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

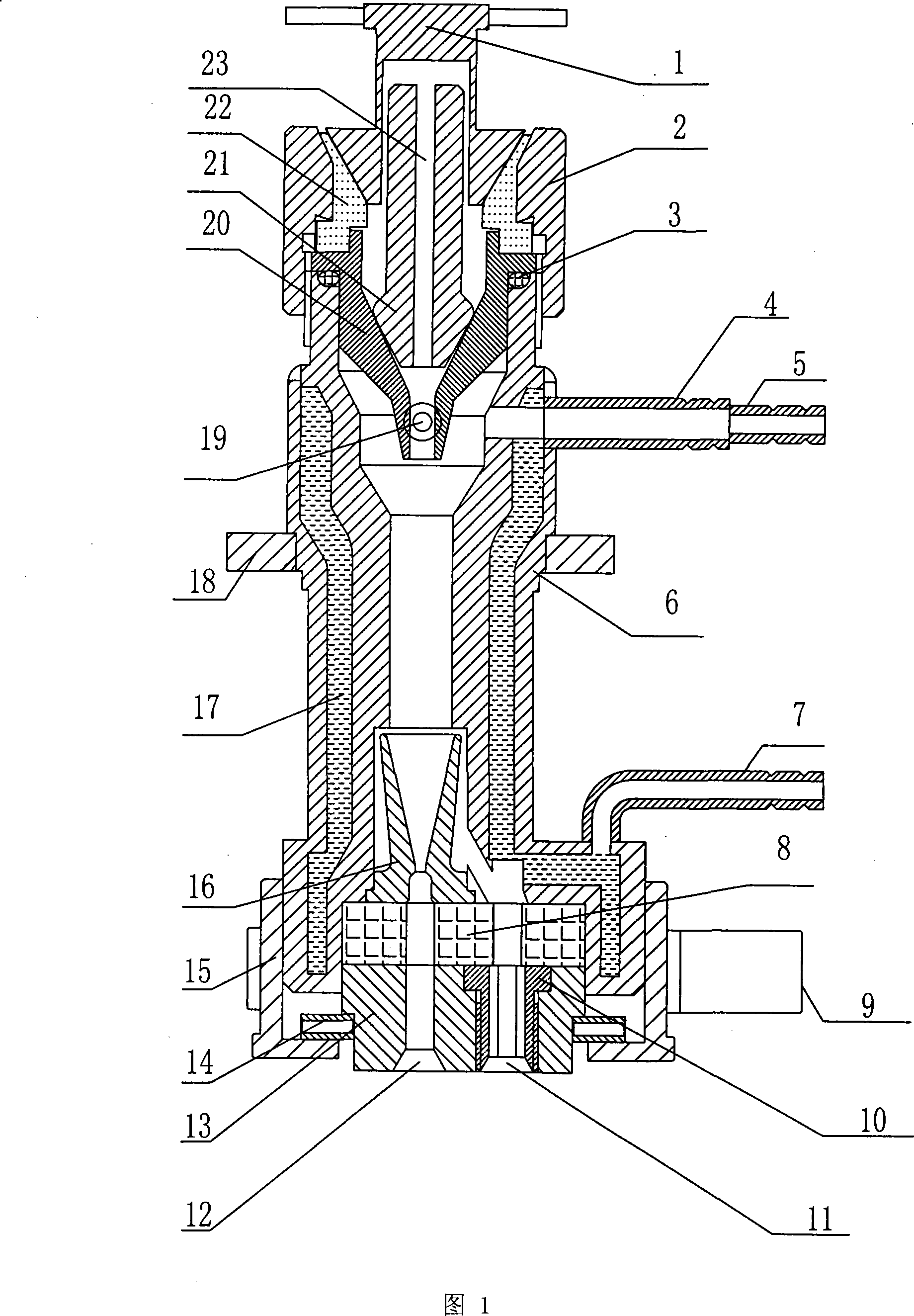

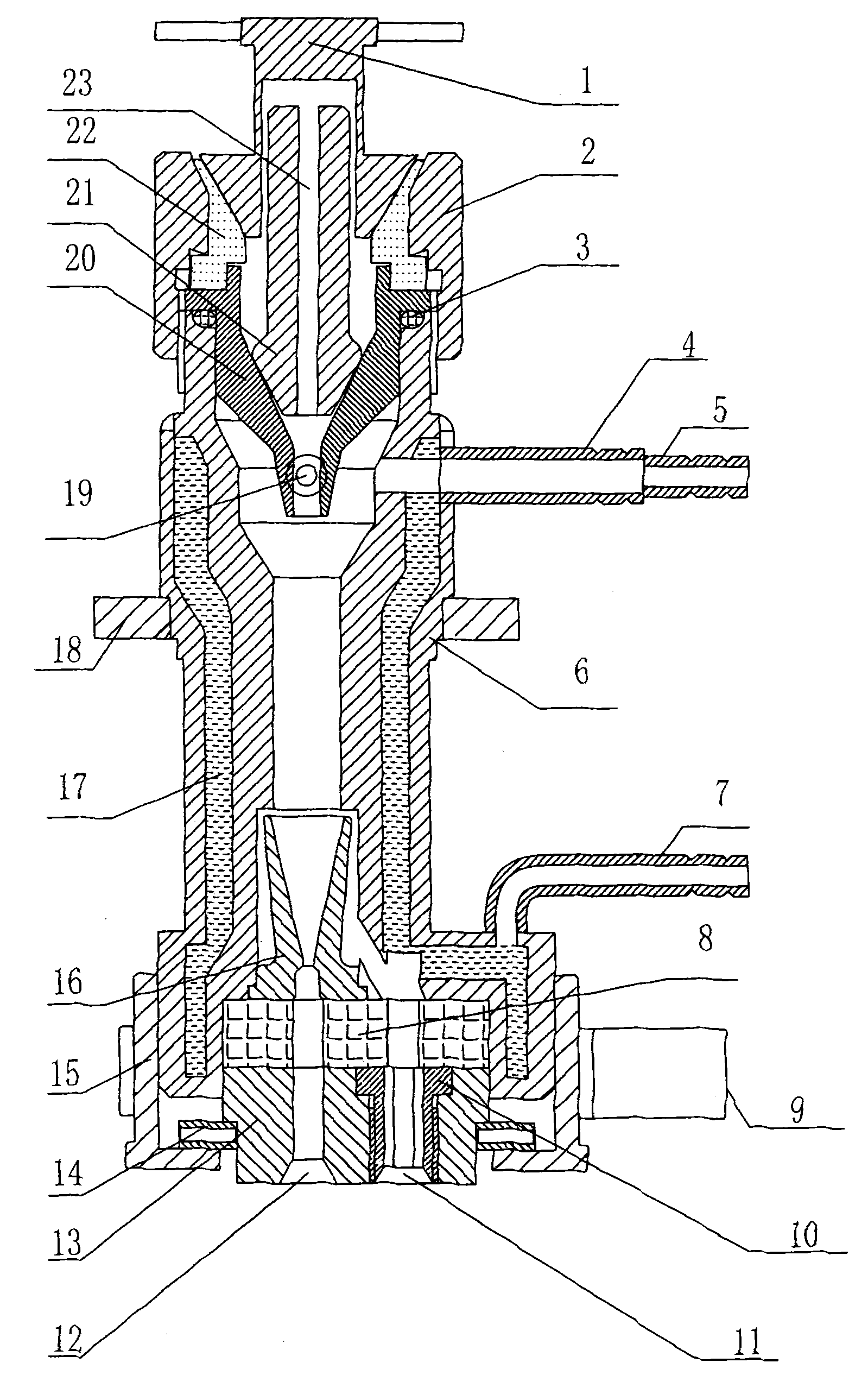

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] Double exhaust bar mercury gun as shown in Figure 1, comprises the gun body 6 of a band inner chamber, and mercury gun is installed on the round row car (not shown in the figure) by the mercury gun seat 18 of side, and gun inner cavity side is provided with There is a connected exhaust pipe 4, the gun body 6 is hollow around the side wall of the inner cavity, the gun body side is provided with a water inlet pipe 5 and an outlet pipe 7 and communicates with the hollow side wall, and the gun body side wall is provided with water outlet holes 19 and The water inlet pipe is butted so that the cooling water 7 is poured into the hollow side wall of the gun body;

[0013] The upper end of the inner cavity of the gun is equipped with a mercury drop seat composed of a sealing cap 1, a sealing member 22, a sealing ring 3, an upper pressure cap 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com