Exhausting device used for improving exhausting quality of packaging bag

A technology for exhaust devices and packaging bags, applied in packaging and other directions, can solve problems such as inflation damage, medical safety hazards, packaging bag damage, etc., and achieve the effects of meeting support strength, improving exhaust quality, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

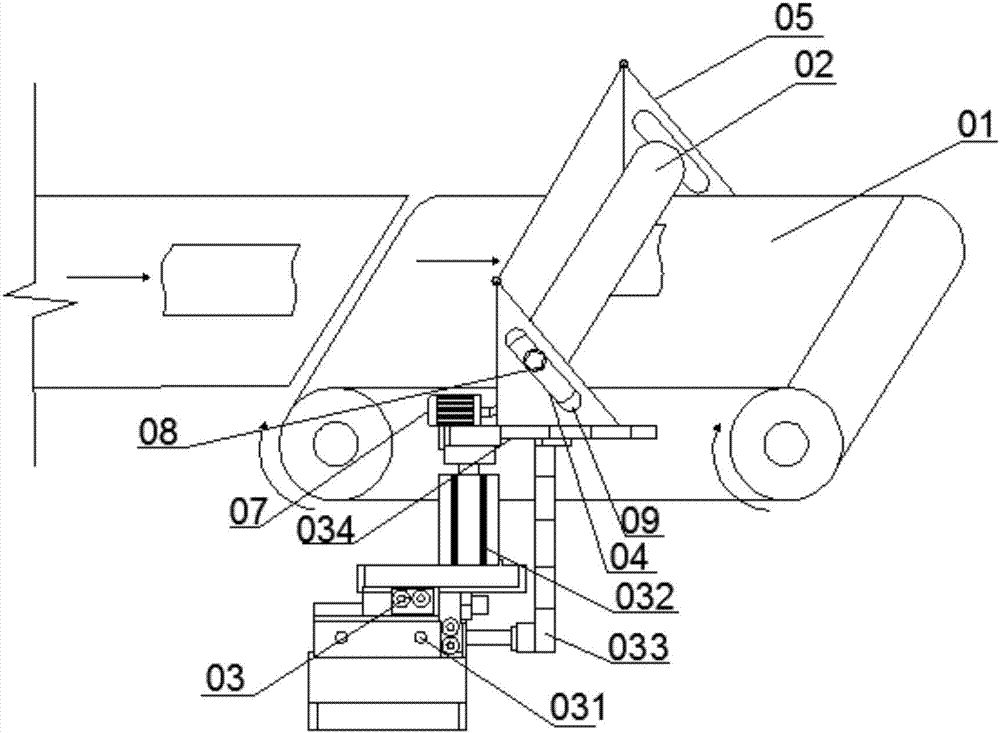

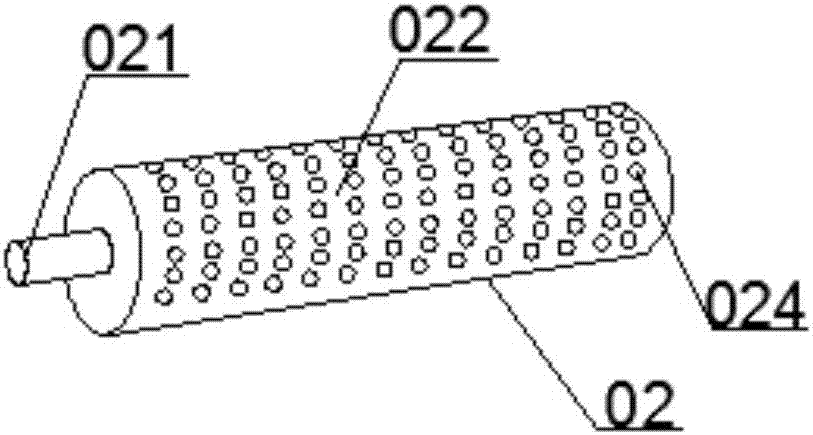

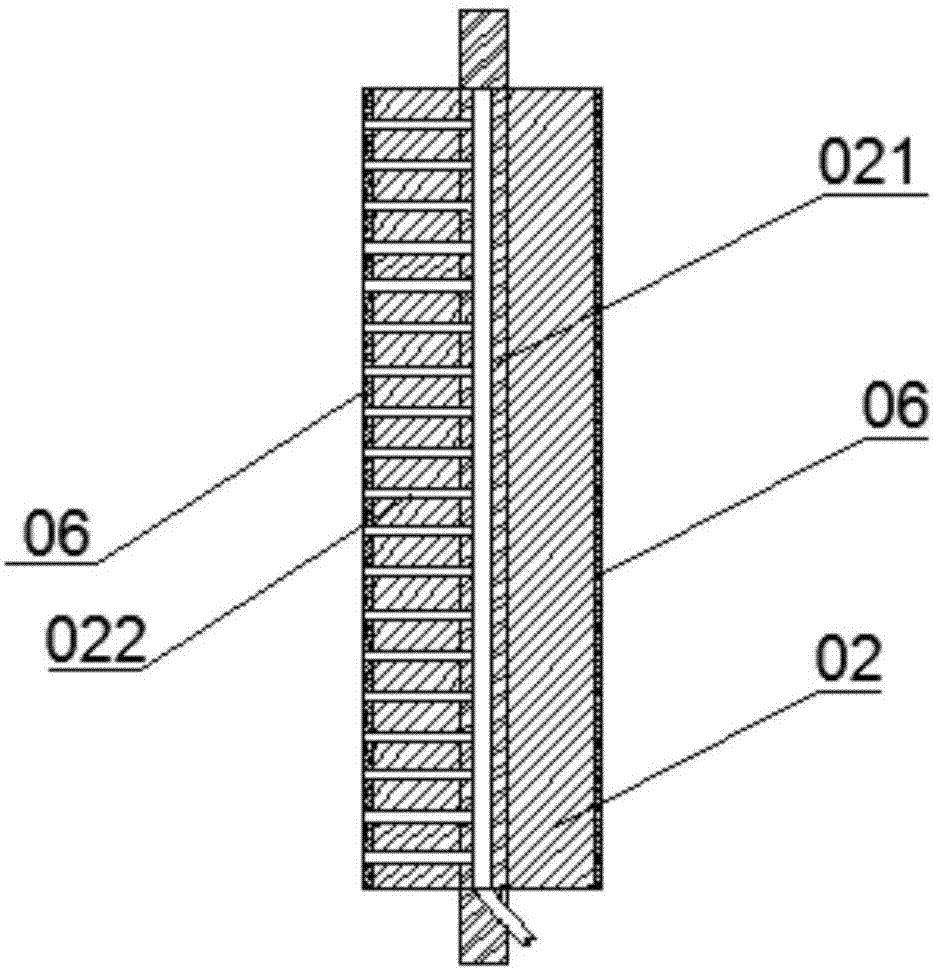

[0031] Such as figure 1 As shown, the exhaust device used to improve the exhaust quality of the packaging bag includes a conveyor belt 01, an exhaust roller 02, and a drive mechanism 03 erected on both sides of the conveyor belt 01. The conveyor belt 01 is supported by the rollers at both ends, and as the roller moves Rotation and synchronous movement, motor or other power devices can be used to drive the drum to rotate; both sides of the driving mechanism 03 are equipped with guide rails 04, and the guide rails 04 are inclined relative to the belt, and the exhaust drum 02 is equipped with the same The roller shaft 021 arranged on the shaft, and through the cooperation of the inner roller shaft 021 and the guide rail 04, straddles the conveyor belt 01. Specifically, the guide rail 04 is provided with a roller 08, and the roller shaft 021 and the roller 08 at both ends of the exhaust roller 02 Welding, and the roller 08 is clearance-fitted with the guide rail 04 and rolls on th...

Embodiment 2

[0039] Such as Figure 4 As shown, embodiment 2 is basically the same as embodiment 1, the difference is that the guide rail 04 is an arc guide rail 04, and the arc guide rail 04 can make the exhaust roller 02 move up and down while moving horizontally. 02 This compound movement method can further improve the exhaust quality of the packaging bag; furthermore, the support plate 05 is arranged in a rectangular shape on the horizontal telescopic plate 034, and the rectangular support plate 05 has a large outline volume to provide the activity space for setting the exhaust drum 02 Larger, and the rectangular support plate 05 also has the characteristics of high mechanical strength, which can meet the support strength of the high-quality rotating speed of the exhaust drum 02.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com