Patents

Literature

377results about How to "Extended range of movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

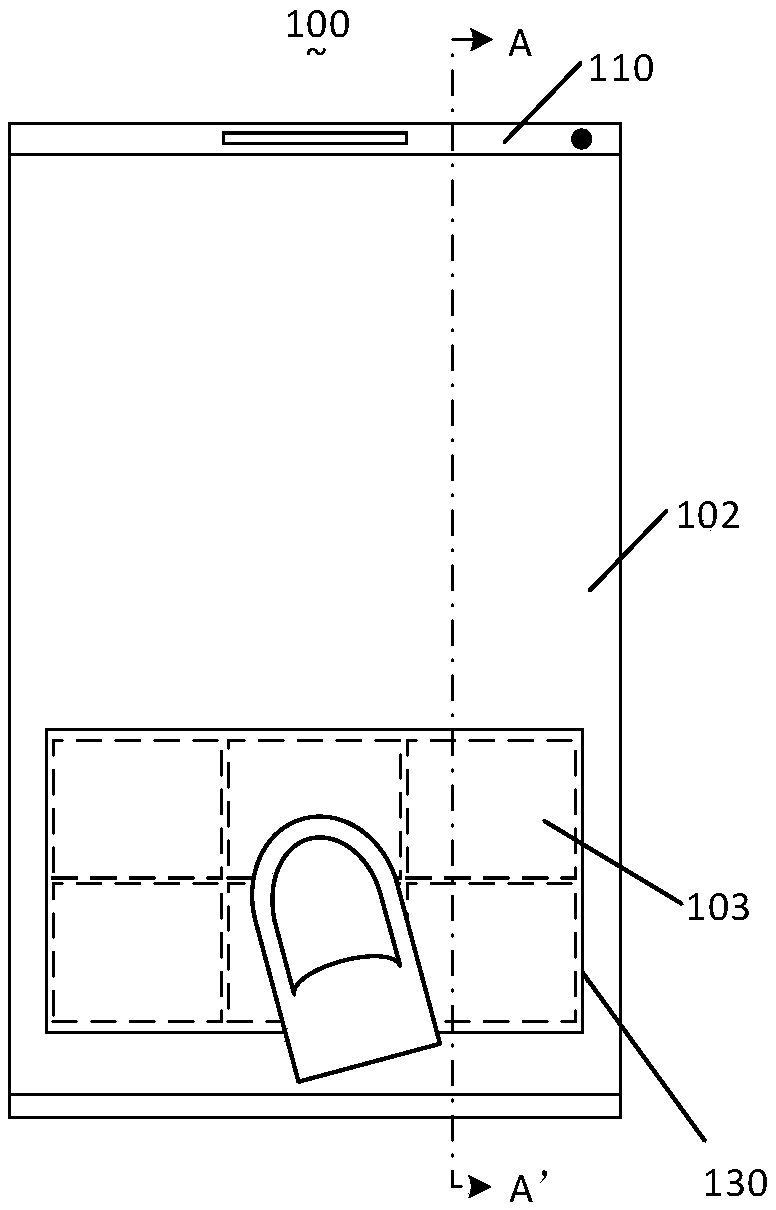

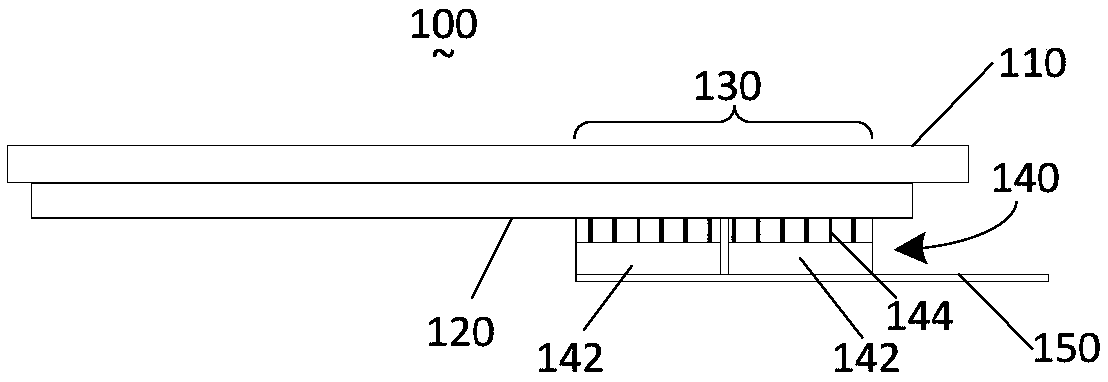

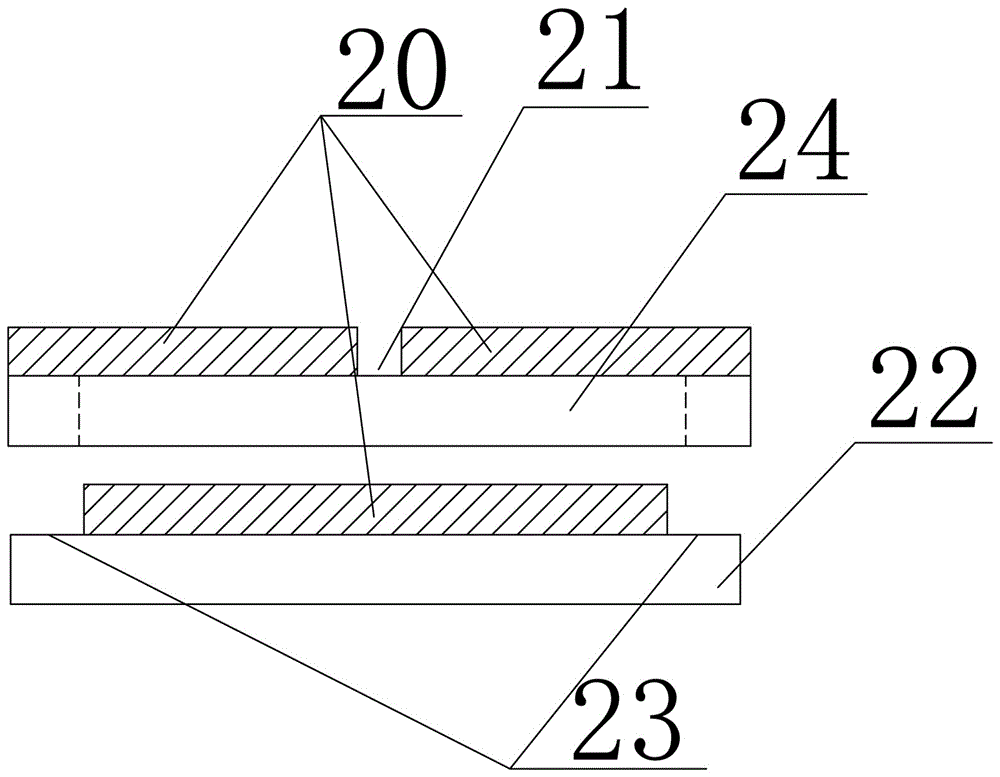

Fingerprint identification device and electronic device

PendingCN109416737AImprove securityIncrease the areaPrint image acquisitionIdentification deviceEmbedded system

The embodiment of the present invention discloses a fingerprint identification device and an electronic device. The fingerprint identification device is applied to an electronic device having a display screen, the fingerprint recognition device comprising an optical fingerprint sensor module, wherein the optical fingerprint sensor module is configured to be disposed under the display screen such that the fingerprint collection area is at least partially located in the display area of the display screen. The optical fingerprint sensor module comprises a plurality of sensor chips, and the sensing areas of the plurality of sensor chips respectively correspond to a plurality of sub-areas in the fingerprint collection area, wherein each sensor chip is used for detecting optical signals from above their corresponding sub-areas. The technical solution of the embodiment can improve the user experience in the fingerprint identification process and simultaneously improve the security of fingerprint recognition.

Owner:SHENZHEN GOODIX TECH CO LTD

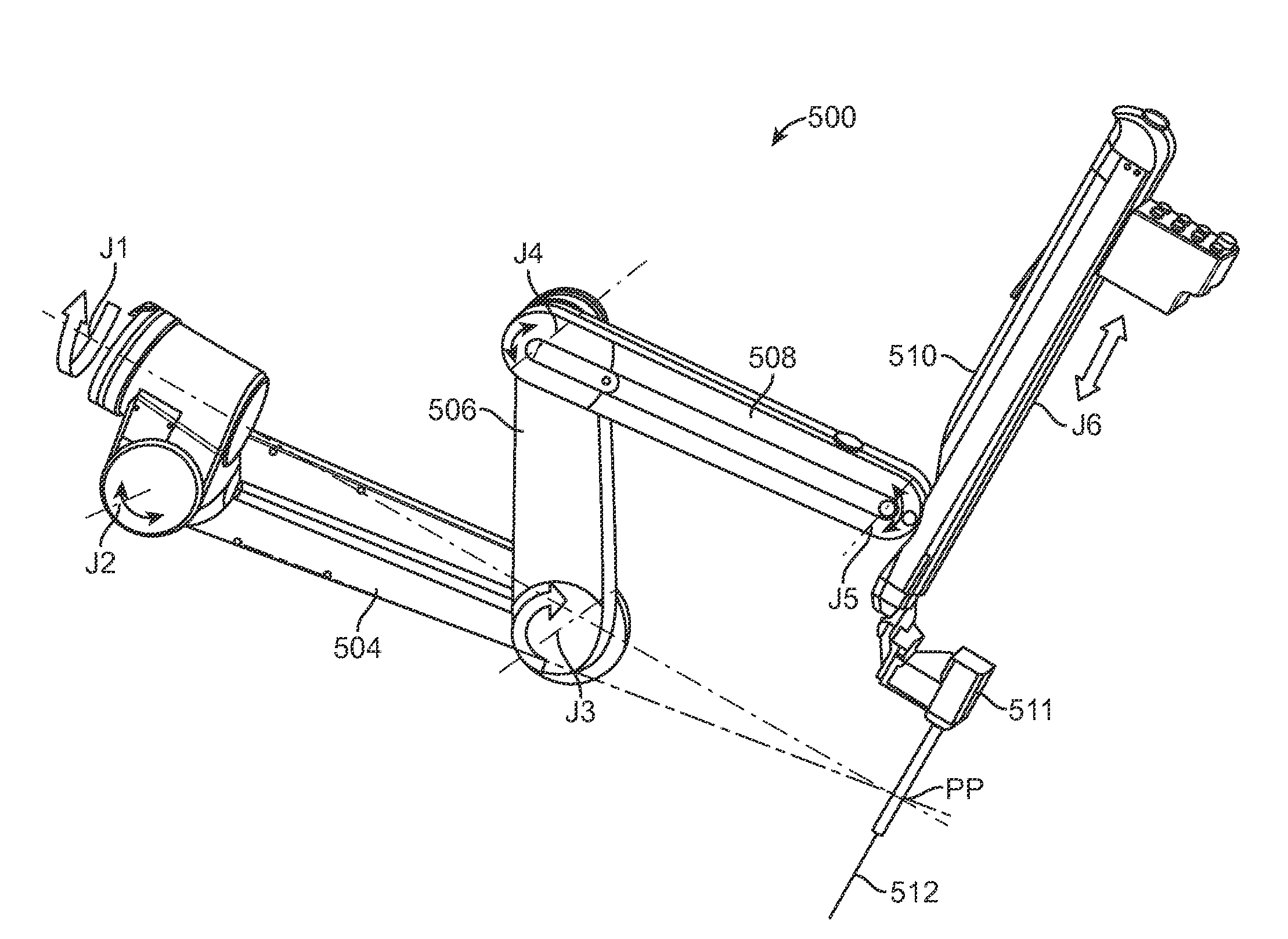

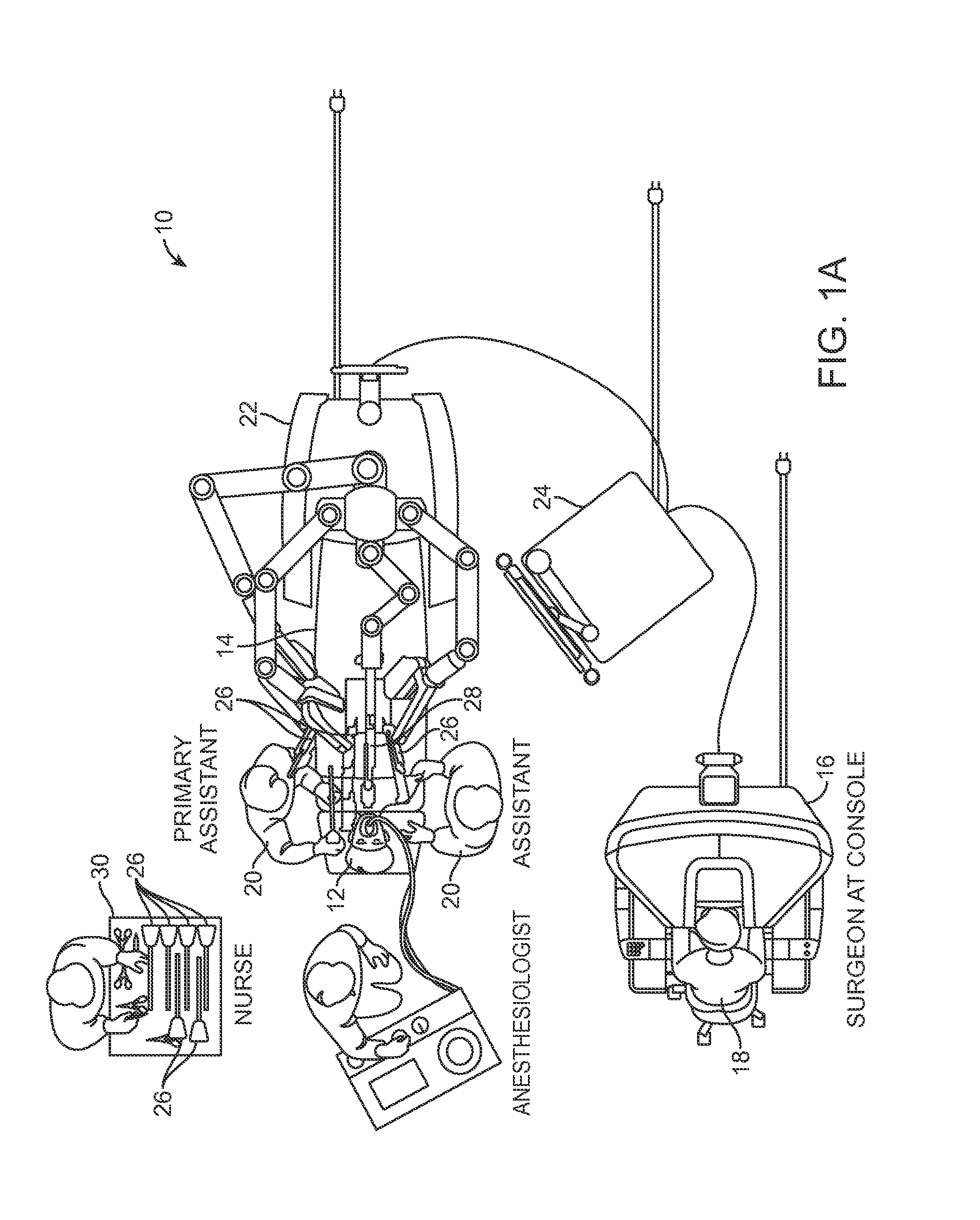

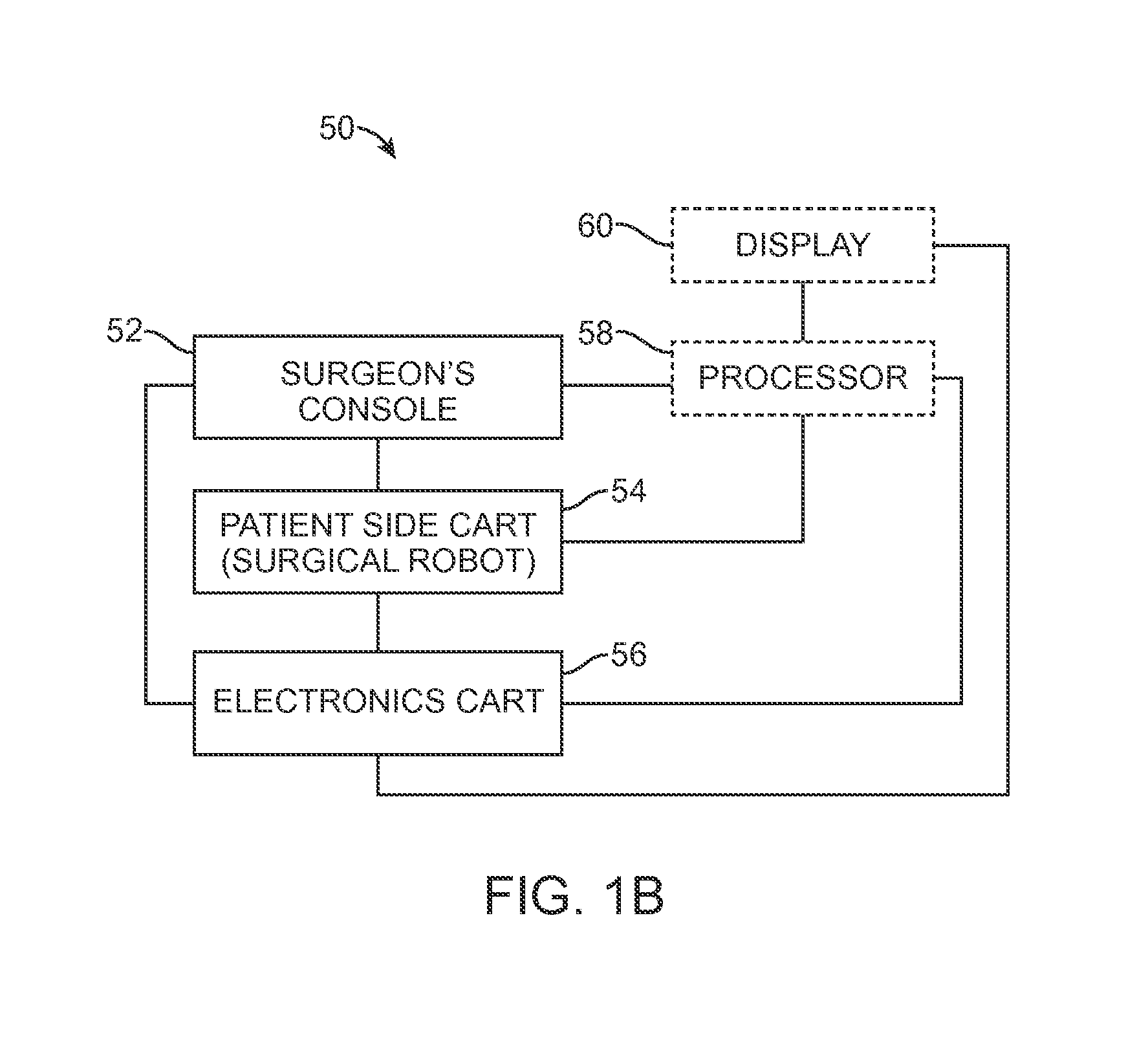

Systems and methods for facilitating access to edges of cartesian-coordinate space using the null space

ActiveUS20140276954A1Extended range of motionHighly configurableProgramme controlProgramme-controlled manipulatorDegrees of freedomEngineering

Devices, systems, and methods for providing increased range of movement of the end effector of a manipulator arm having a plurality of joints with redundant degrees of freedom. Methods include defining a position-based constraint within a joint space defined by the at least one joint, determining a movement of the joints along the constraint within a null-space and driving the joints according to a calculated movement to effect the commanded movement while providing an increased end effector range of movement, particularly as one or more joints approach a respective joint limit within the joint space.

Owner:INTUITIVE SURGICAL OPERATIONS INC

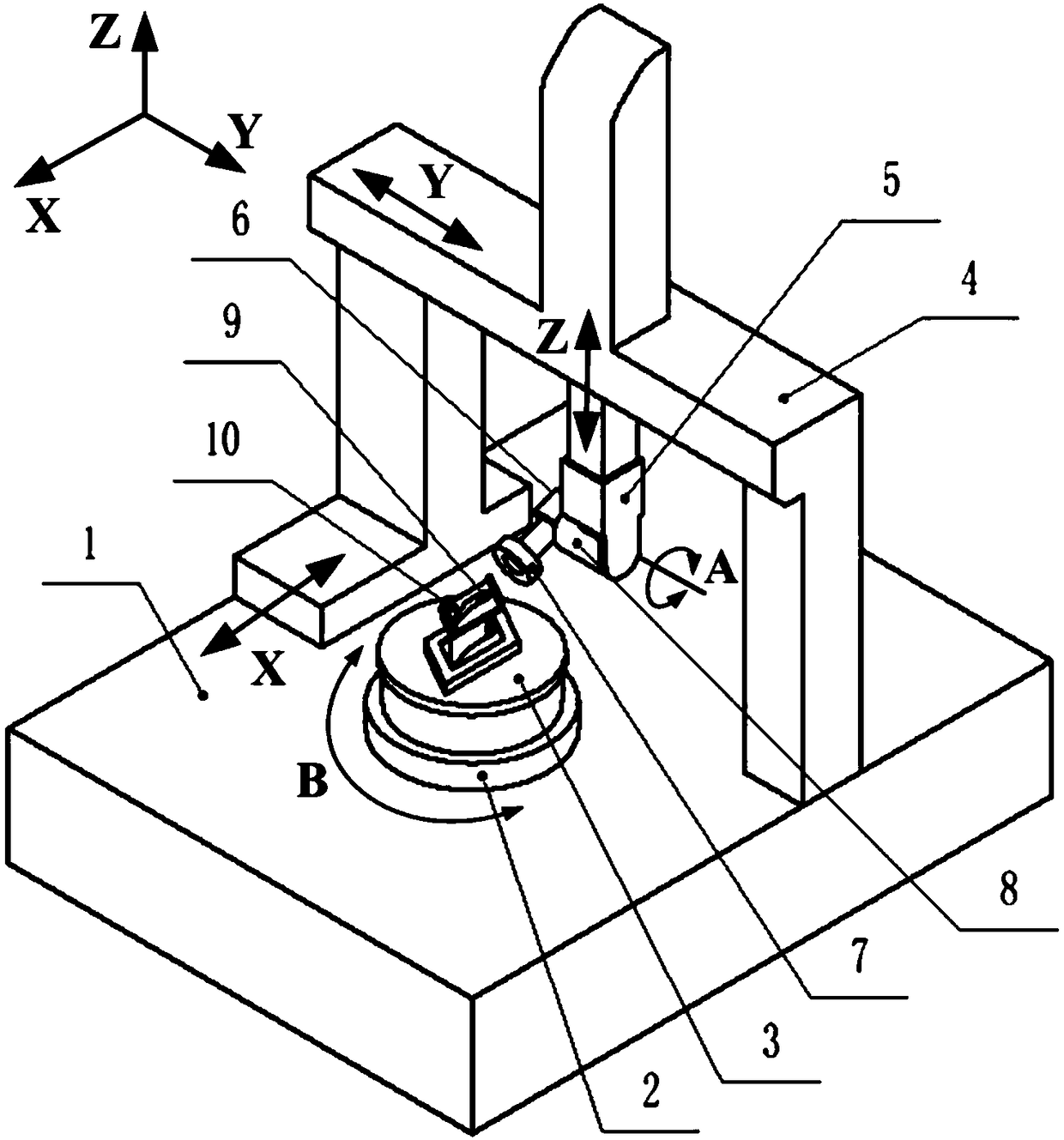

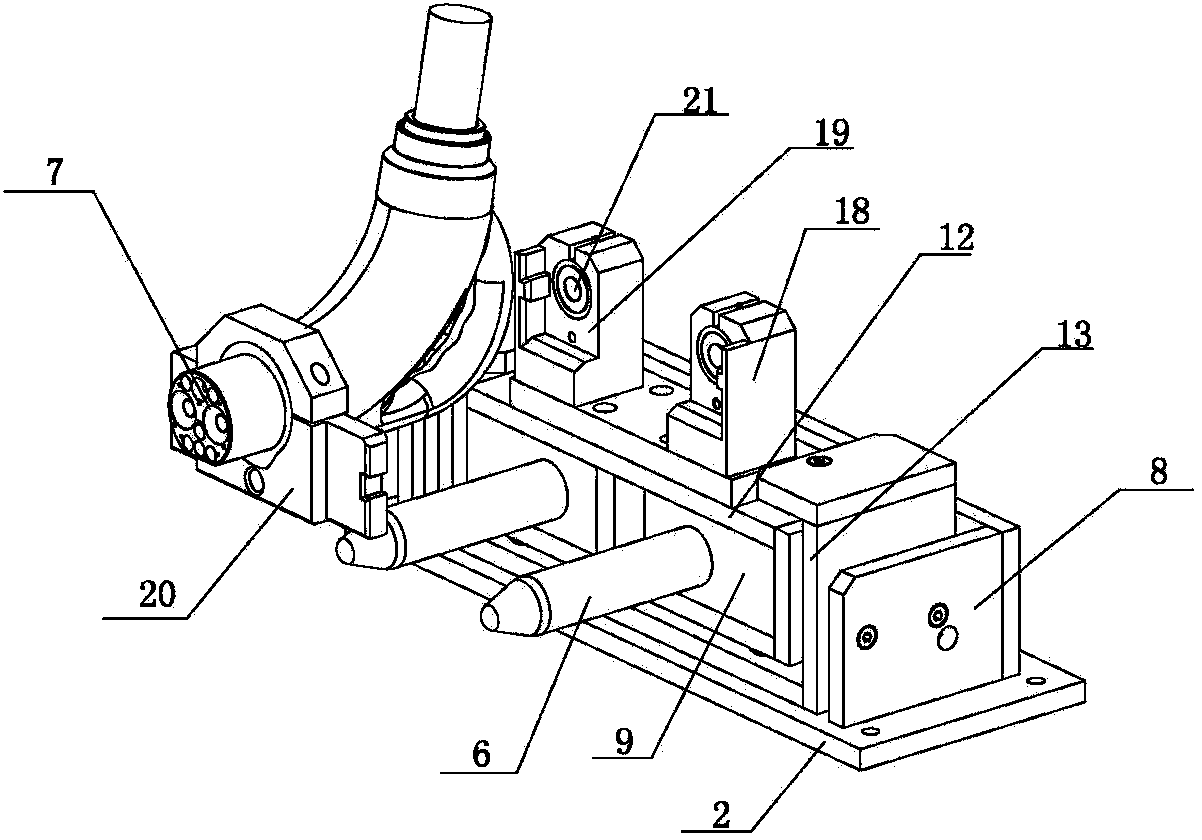

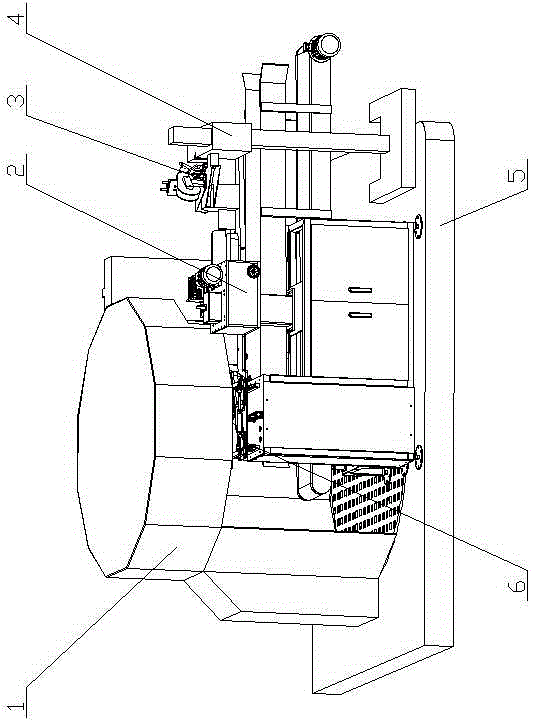

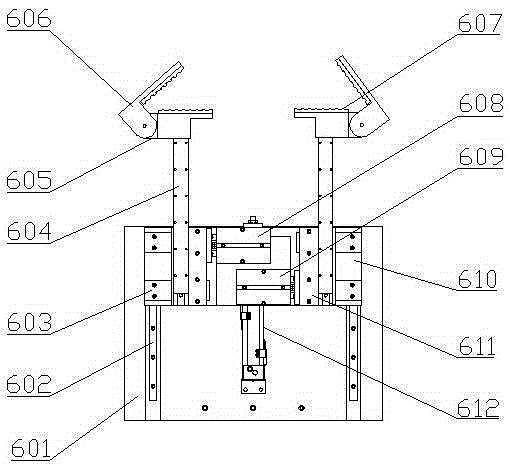

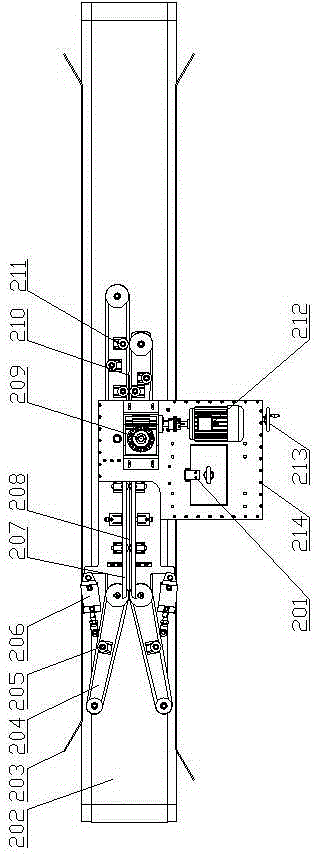

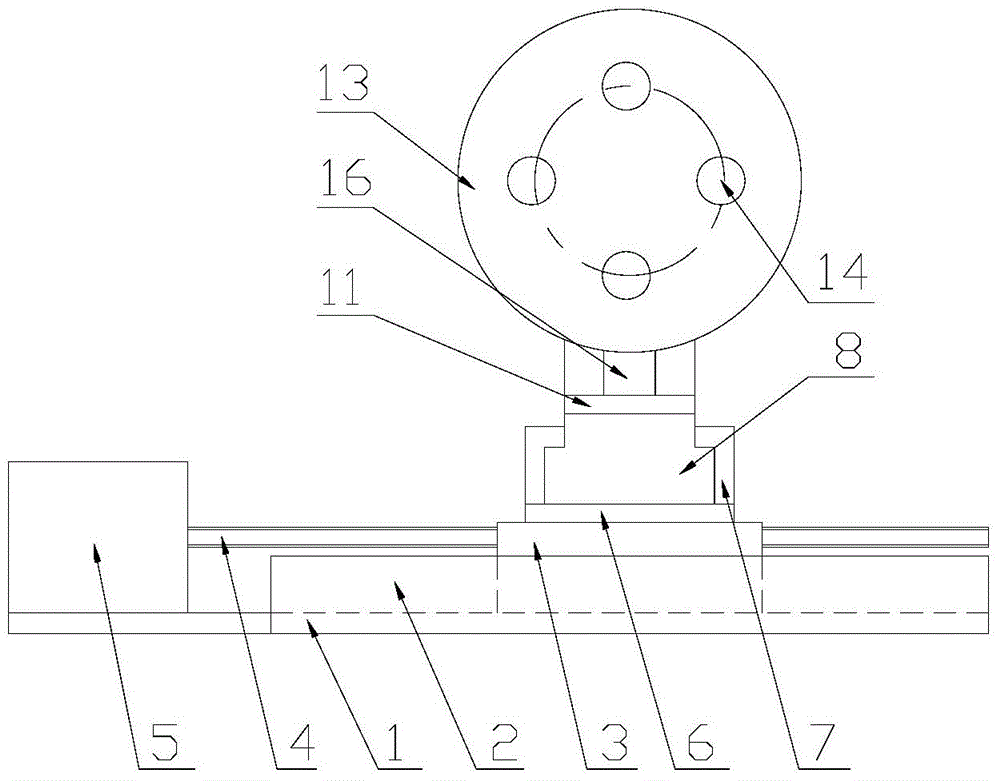

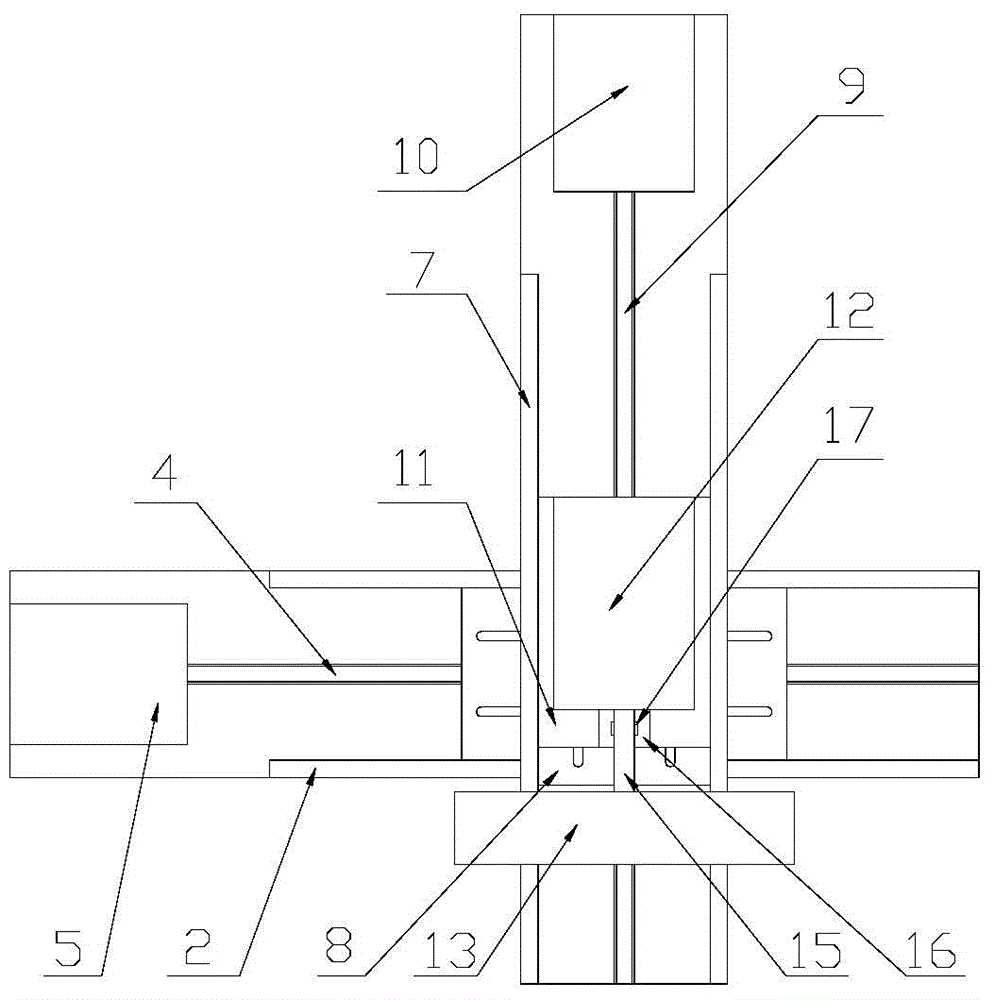

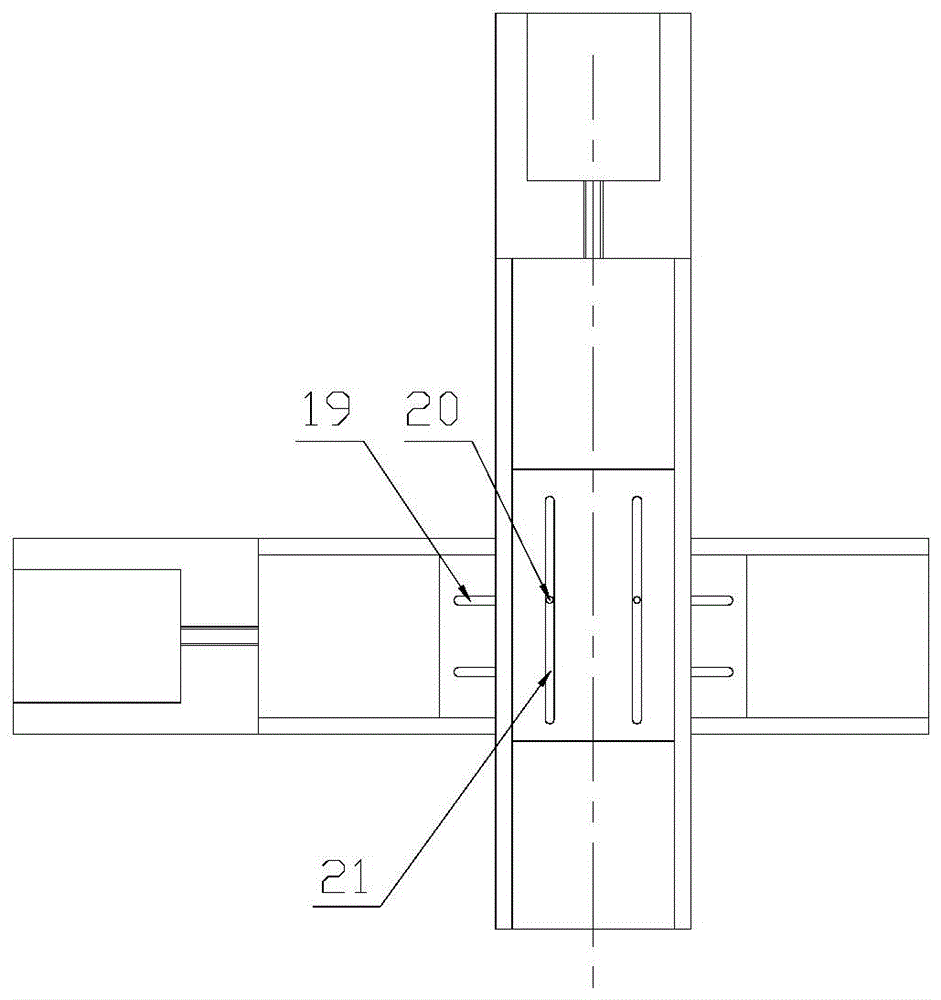

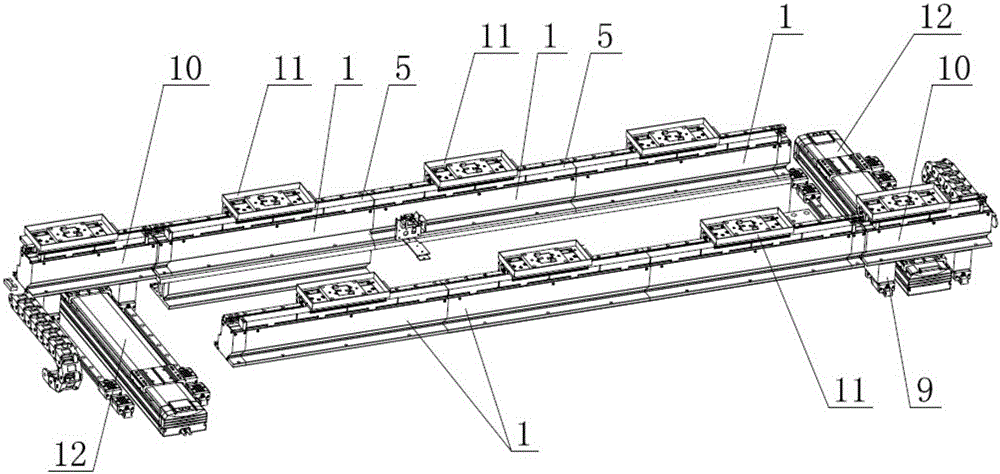

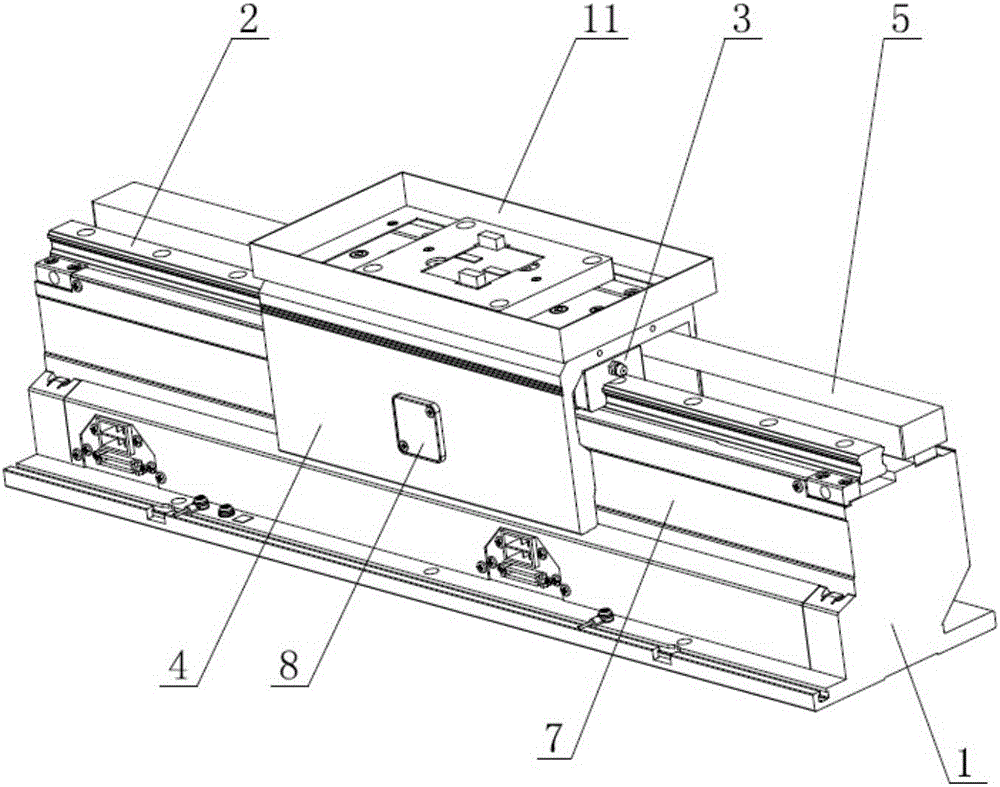

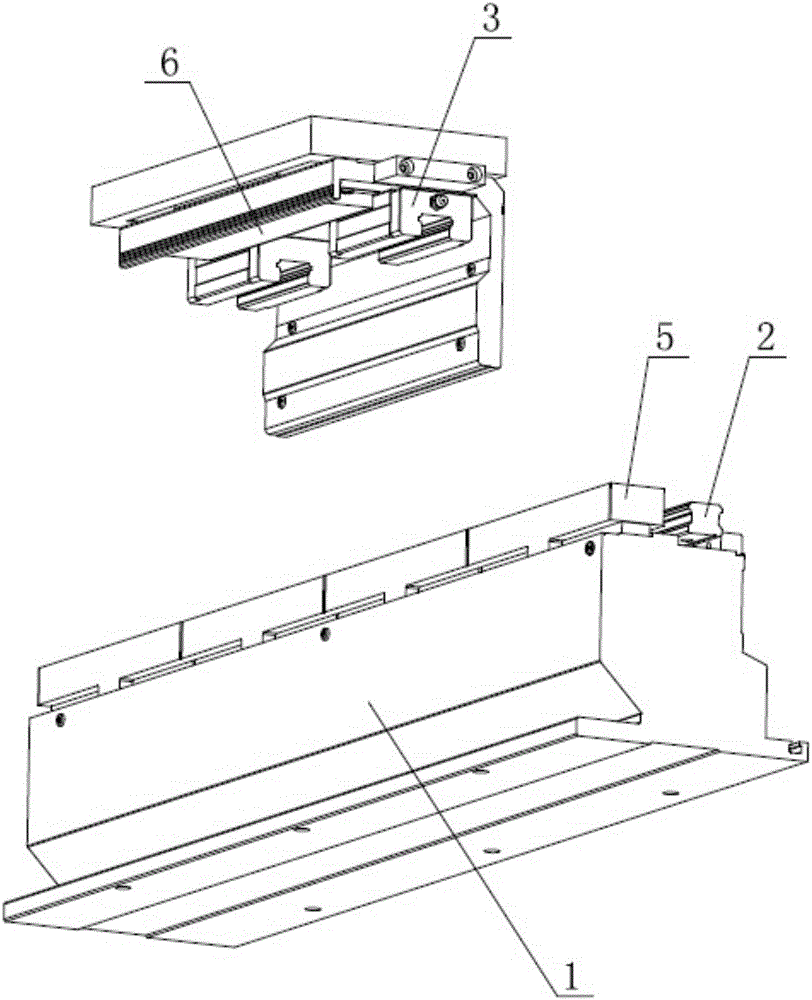

Five-shaft image measurement device used for measuring film hole shape and position parameters

ActiveCN108180851AExtended range of movementHigh positioning accuracyUsing optical meansMeasurement deviceMachine vision

The present invention relates to a five-shaft image measurement device used for measuring the film hole shape and position parameters. The five-shaft image measurement device can be used to obtain theshape and position parameters, such as the apertures of the film hole characteristics on a hollow turbine blade in an aero-engine, the axis space angle, the hole central coordinates, etc. thereby really describing the actual state of each film hole, and comprehensively evaluating the processing quality of each film hole. The five-shaft image measurement device of the present invention is based onthe machine vision measurement principle, adopts an illumination mode of combining the backward illumination and the forward illumination, changes the space position and attitude between the measuredhollow turbine blade and an image acquisition device via the linkage of three linear shafts and two rotating shafts, and determines the alignment accuracy of the image acquisition device and the measured film holes based on the shape characteristics of the acquired film hole images. The five-shaft image measurement device of the present invention is compact in structure and high in measurement precision, is convenient to use, and can measure automatically, thereby providing the technical means of detecting the processing quality of the film holes with high precision, high efficiency and highreliability. The five-shaft image measurement device also can be used as a universal five-shaft image measurement device.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

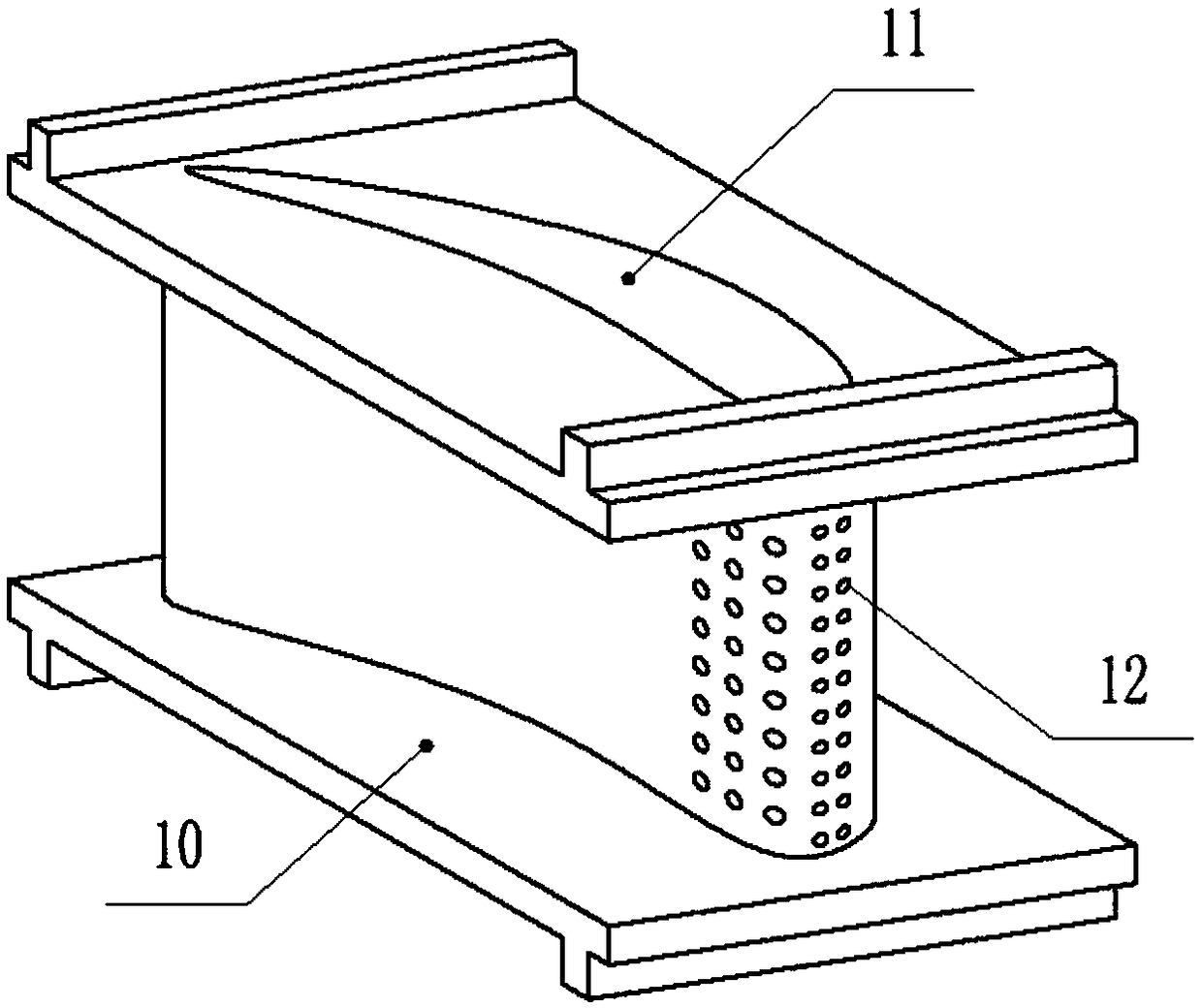

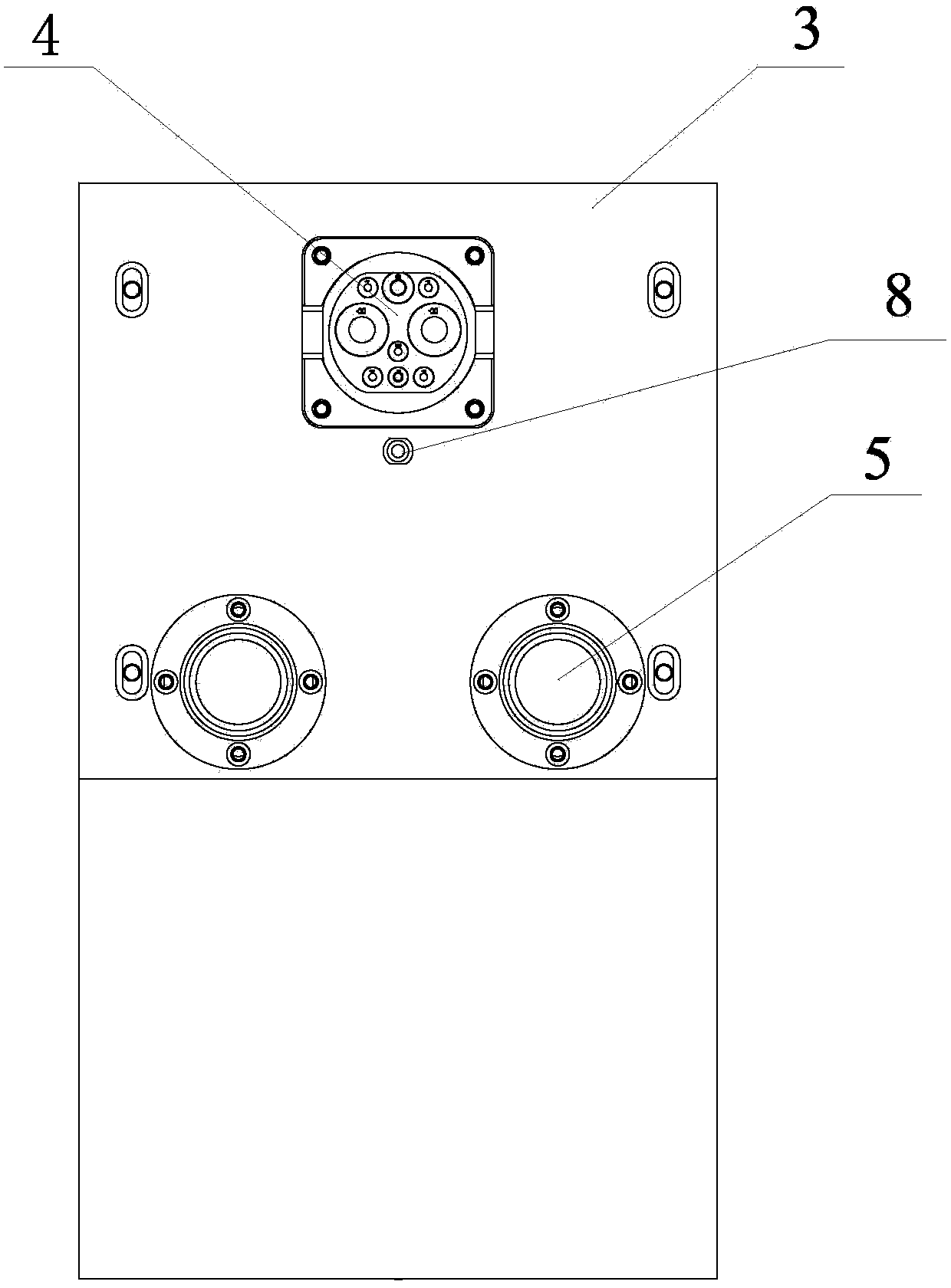

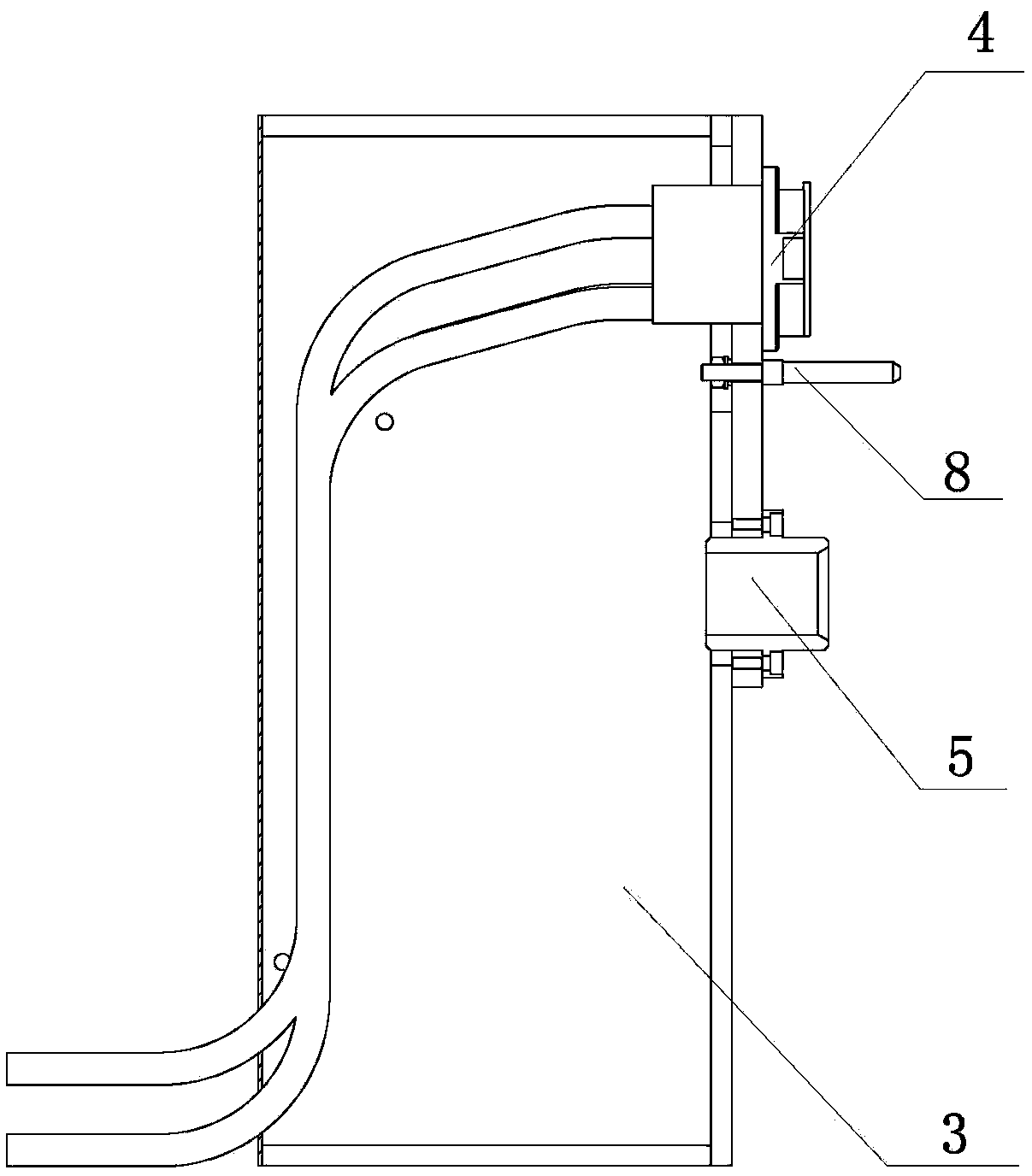

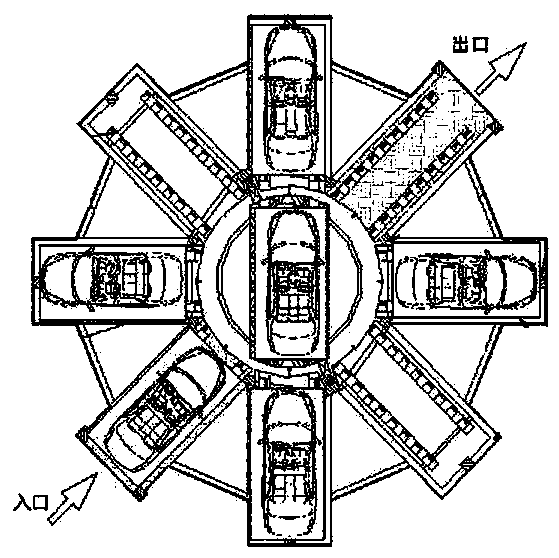

Charging connector device and three-dimensional garage with same

ActiveCN103457298AExtended range of movementHigh reuse rateVehicle connectorsBatteries circuit arrangementsEngineeringElectrical and Electronics engineering

The invention provides a charging connector device. The charging connector device comprises a plug for charging, a mounting seat for mounting the plug and a charging seat which is matched with the plug for charging. The mounting seat is provided with a guide column for facilitating insertion of the plug and limiting the plug. The charging seat is provided with a guide sleeve sleeved outside the guide column. The plug is inserted into the charging seat. The guide column is in clearance fit with the guide sleeve. By the guide column and the guide sleeve, accurate positioning and easy insertion when the plug is in butt joint with the charging seat are achieved. In addition, the invention further provides a three-dimensional garage, a charging gun is connected to a vehicle by a worker, the vehicle is conveyed to a garage unit through a conveyor to realize connection of the plug and the charging seat, and accordingly charging is simplified, and labor saving.

Owner:BYD CO LTD

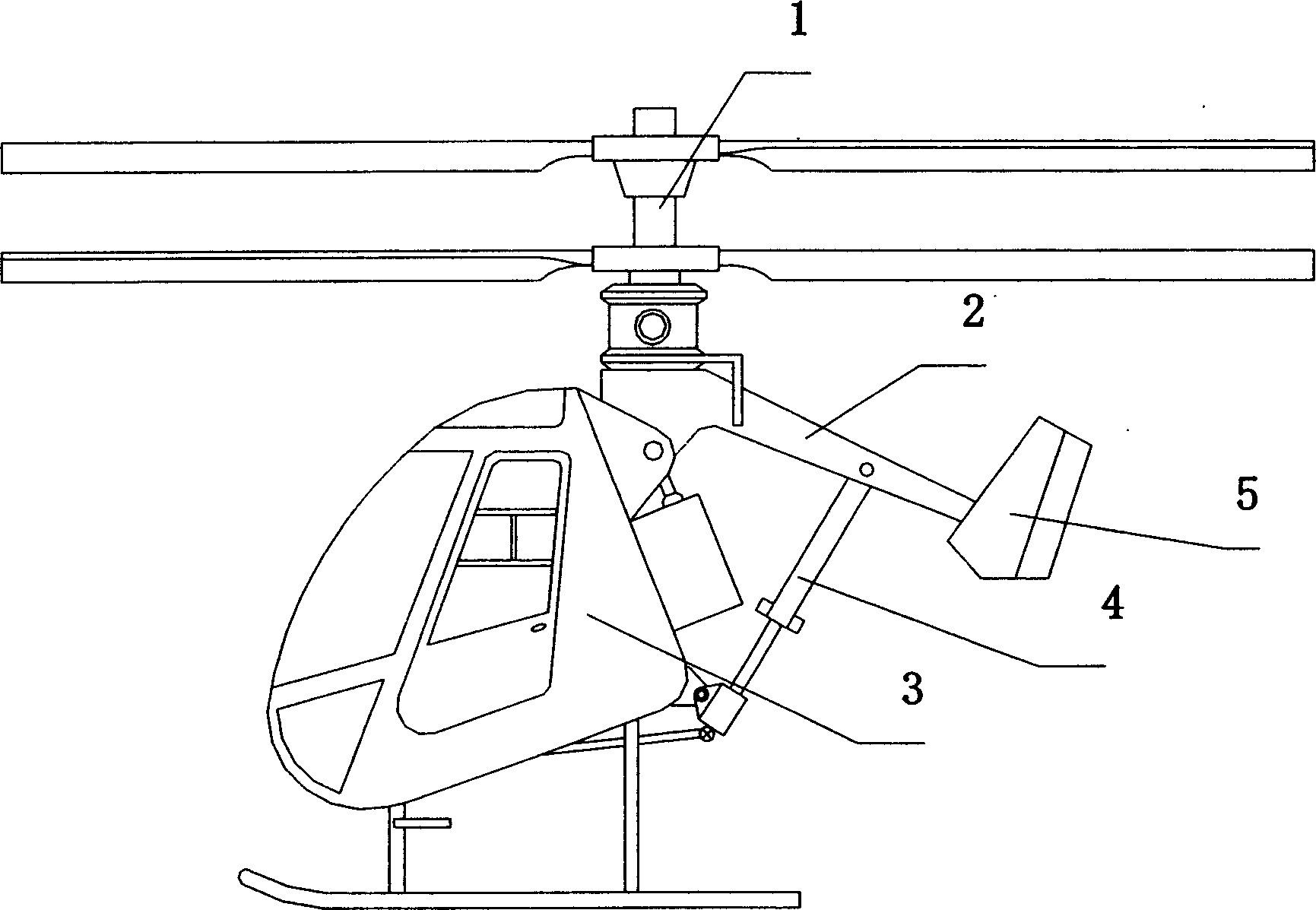

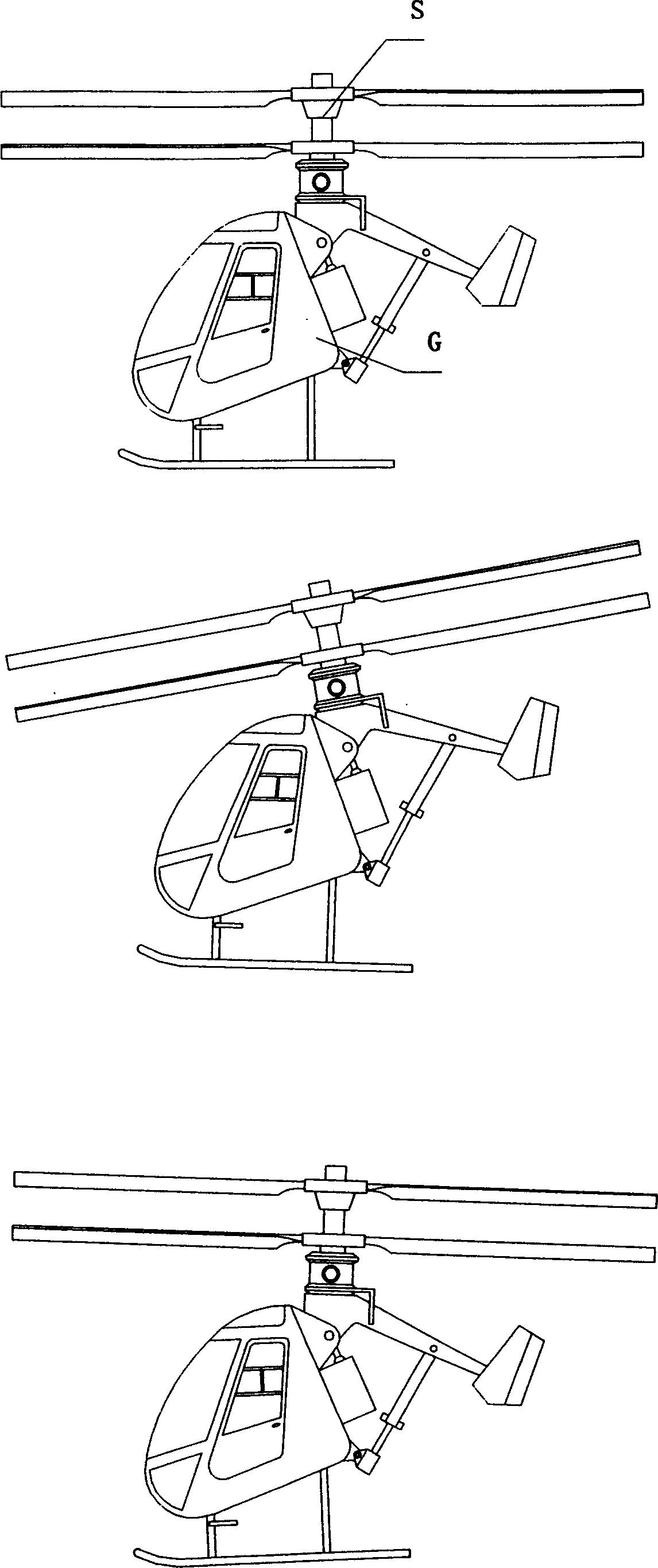

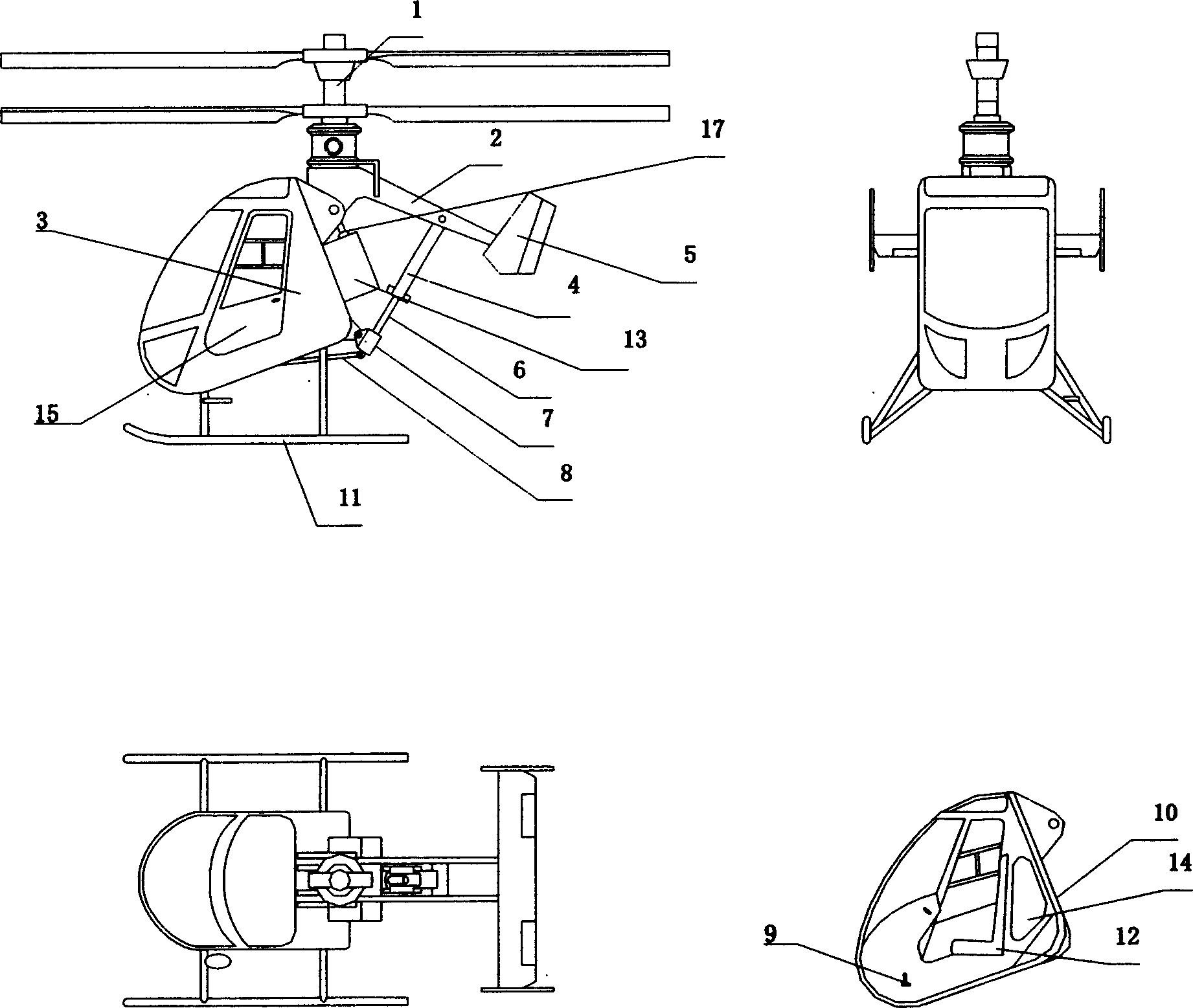

Rotor shaft controllable tilting coaxial rotor wing helicopter

InactiveCN1857965AExtended range of movementImprove efficiencyRotocraftThrottle controlFlight direction

The coaxial rotor wing helicopter with controllable inclined rotor shaft has fixed rotor elevation, rotor shaft fixed before the tailboom, hinge device connecting tailboom to the fuselage and flight attitude regulator of adjustable length connecting the tailboom to the fuselage. Regulating the length of the flight attitude regulator can regulate the position of the rotor shaft extension line relatively to the helicopter gravity center, and when the rotor shaft extension line coincides with the gravity center, the helicopter is in vertical lift state. Increasing the length of the flight attitude regulator to make the gravity center in front of the rotor shaft extension line makes the helicopter fly forwards; and decreasing the length of the flight attitude regulator to make the gravity center in back of the rotor shaft extension line makes the helicopter fly backwards. The engine throttle controls the rotation speed of the rotor wing, while vertical tail wing regulates the flying direction.

Owner:胡俊峰

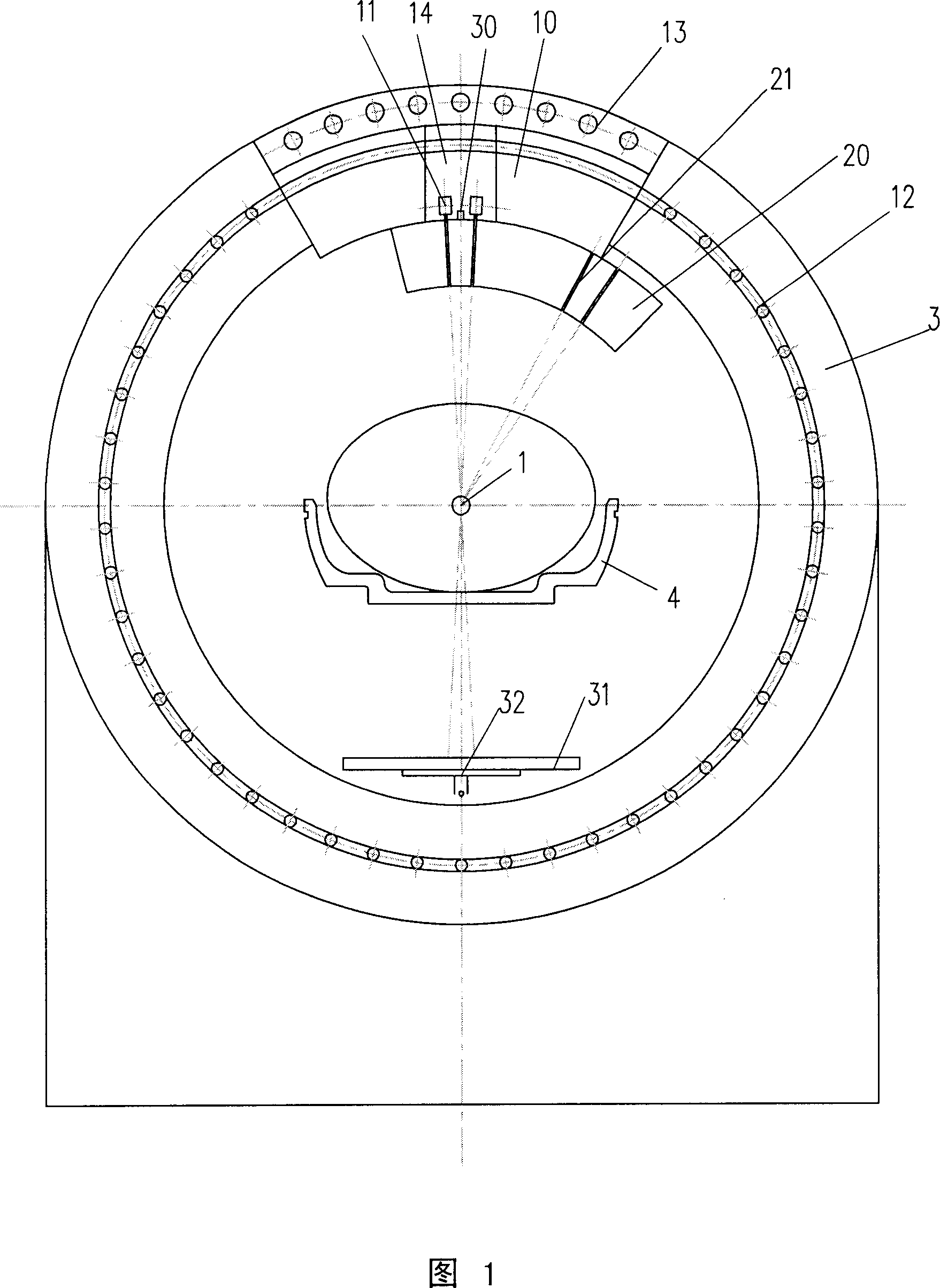

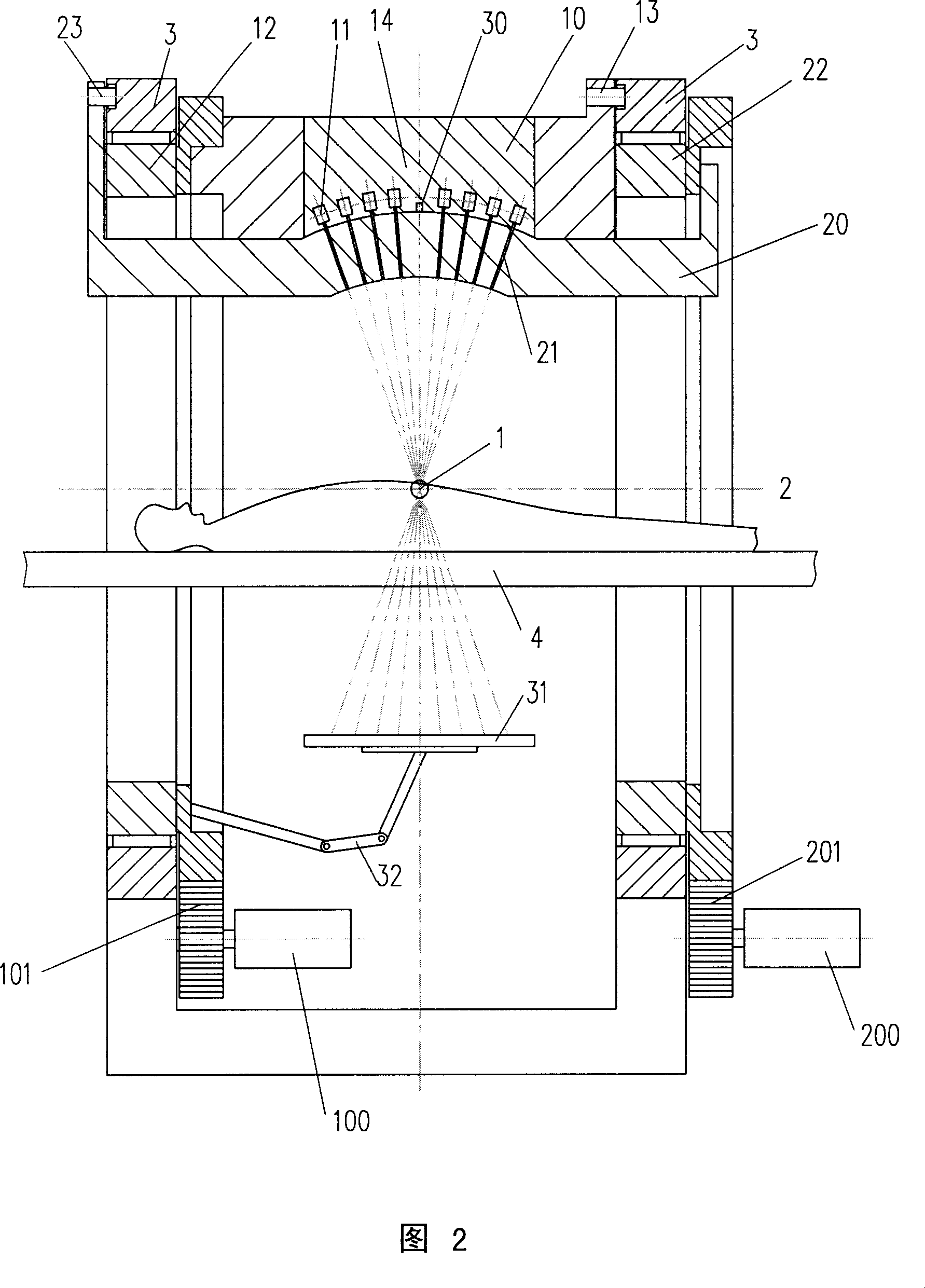

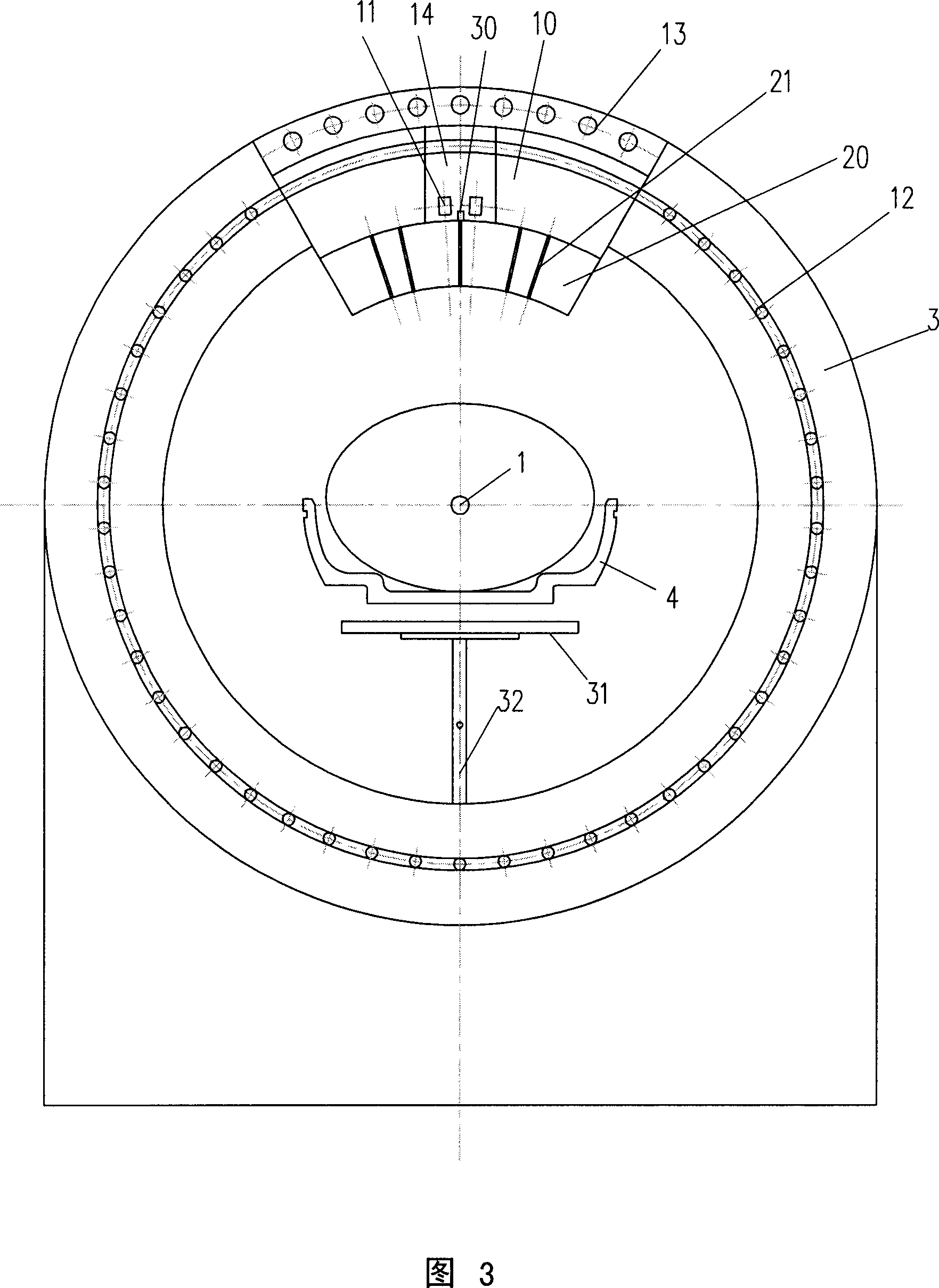

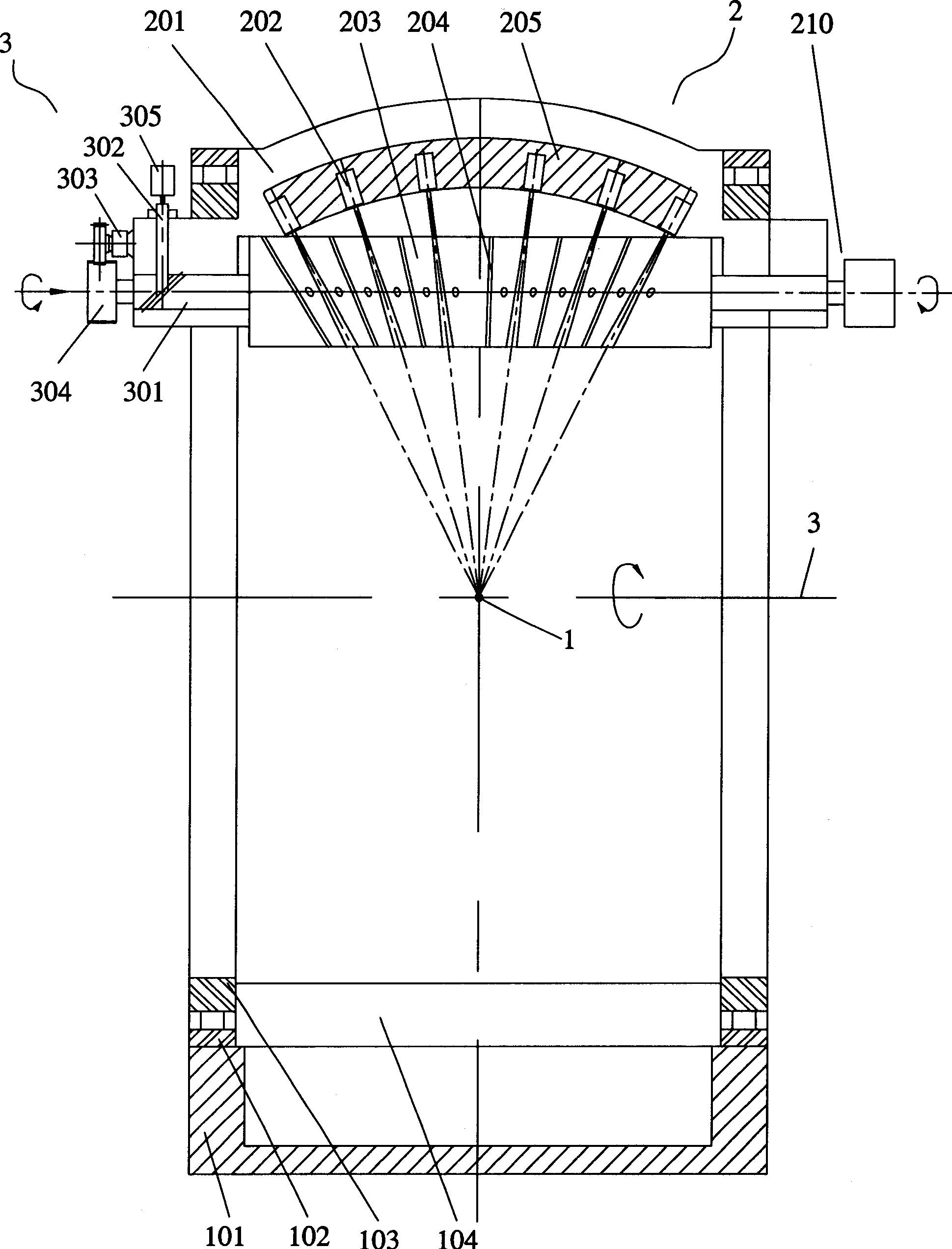

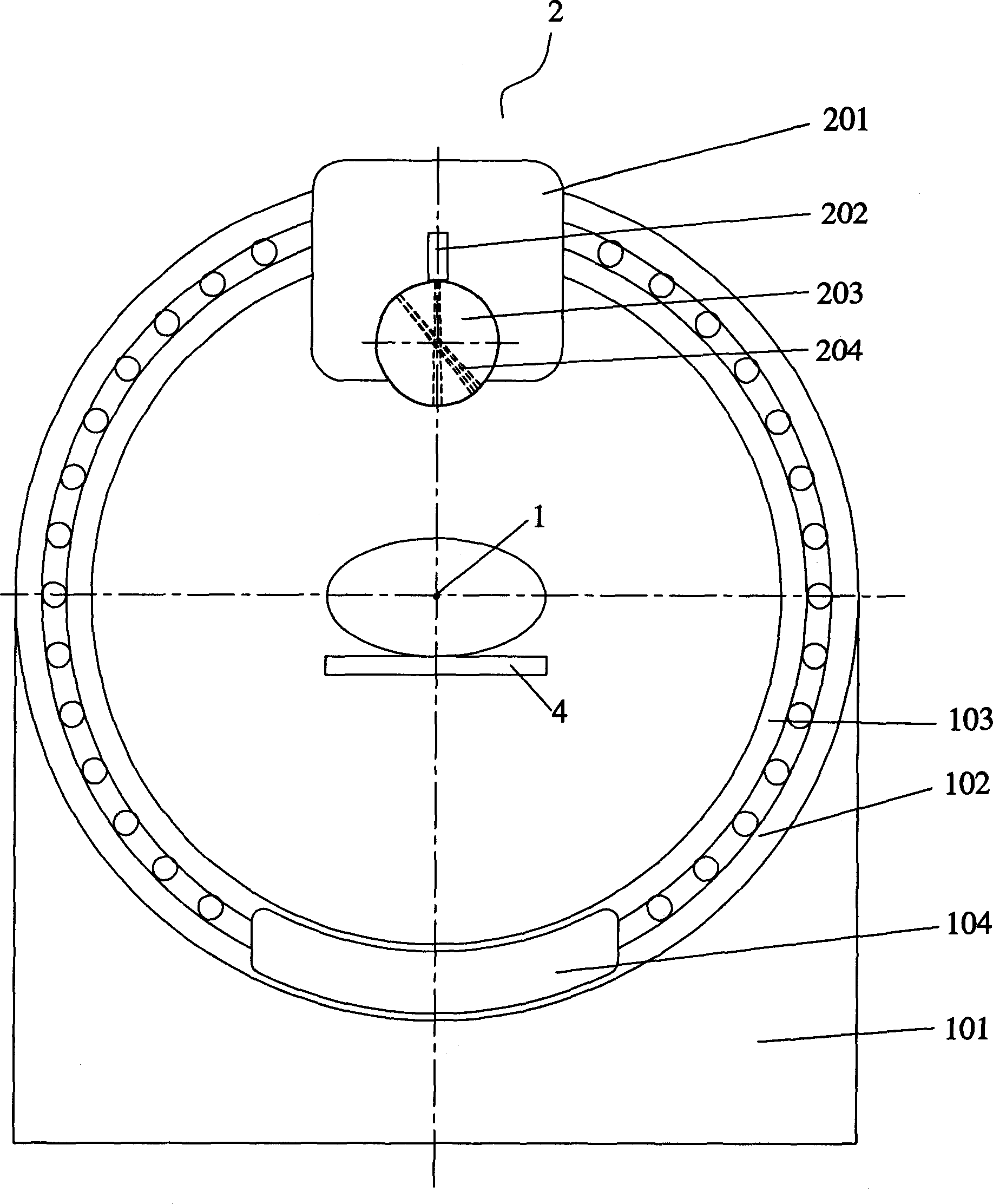

Radiation therapeutical device

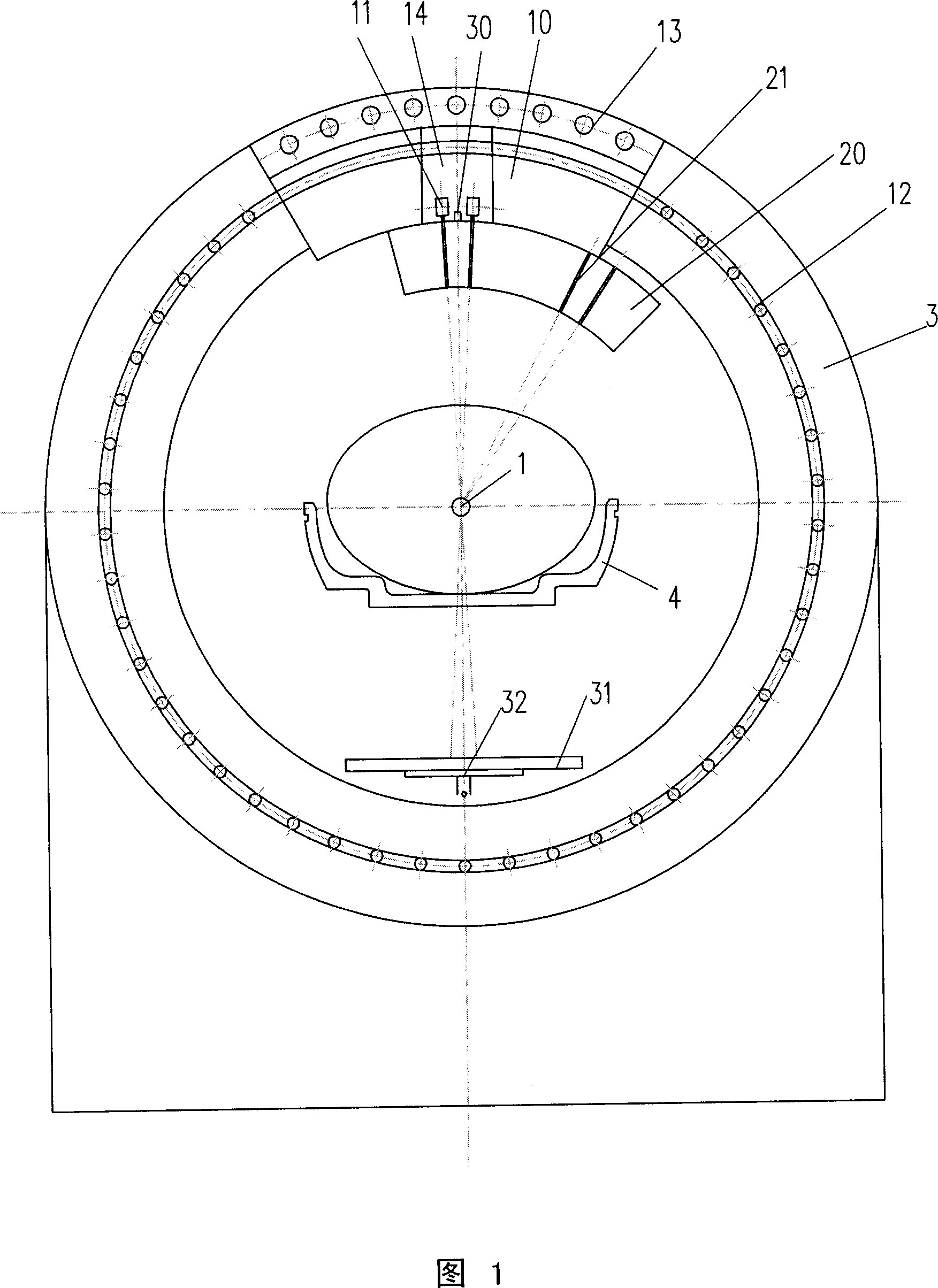

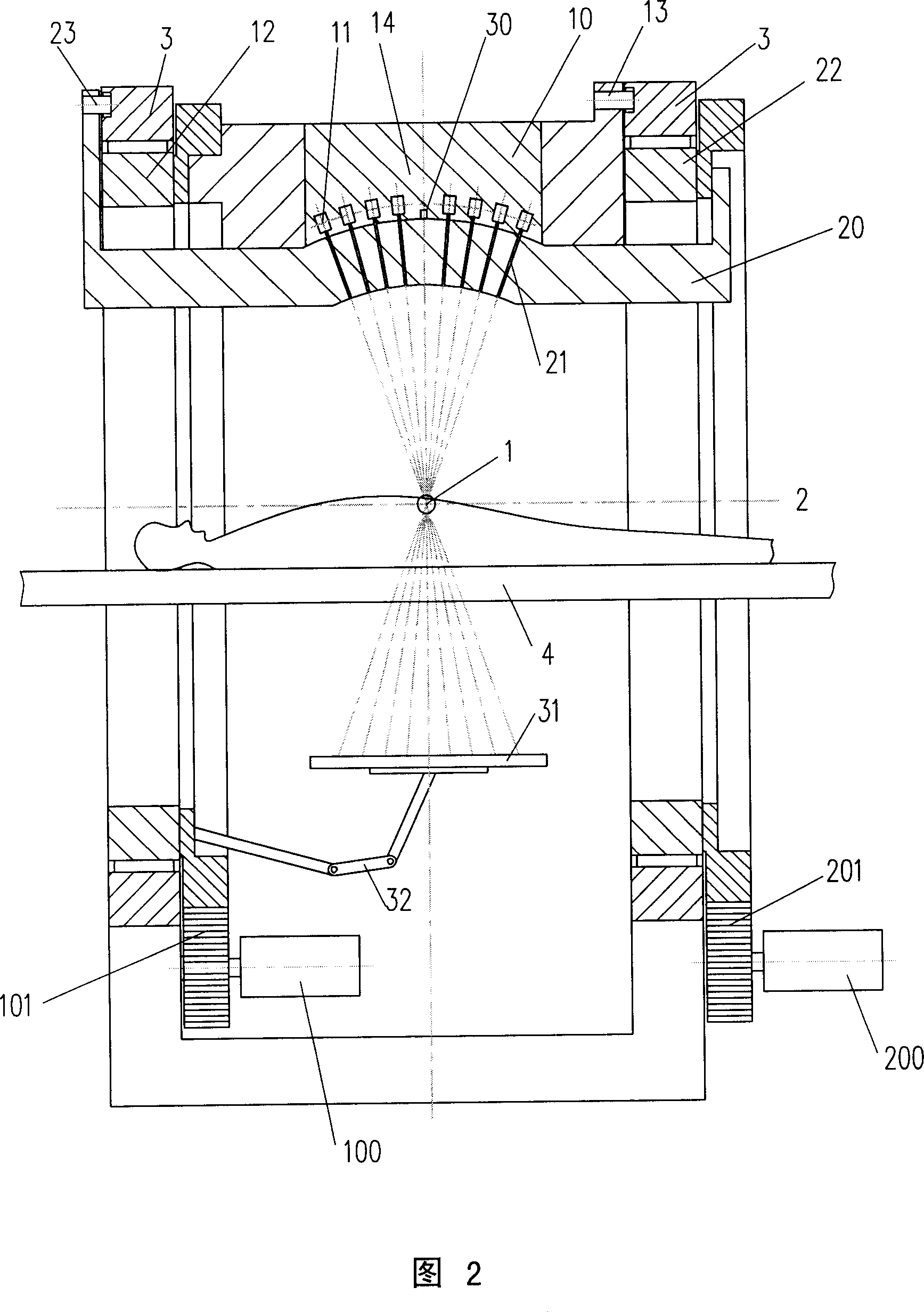

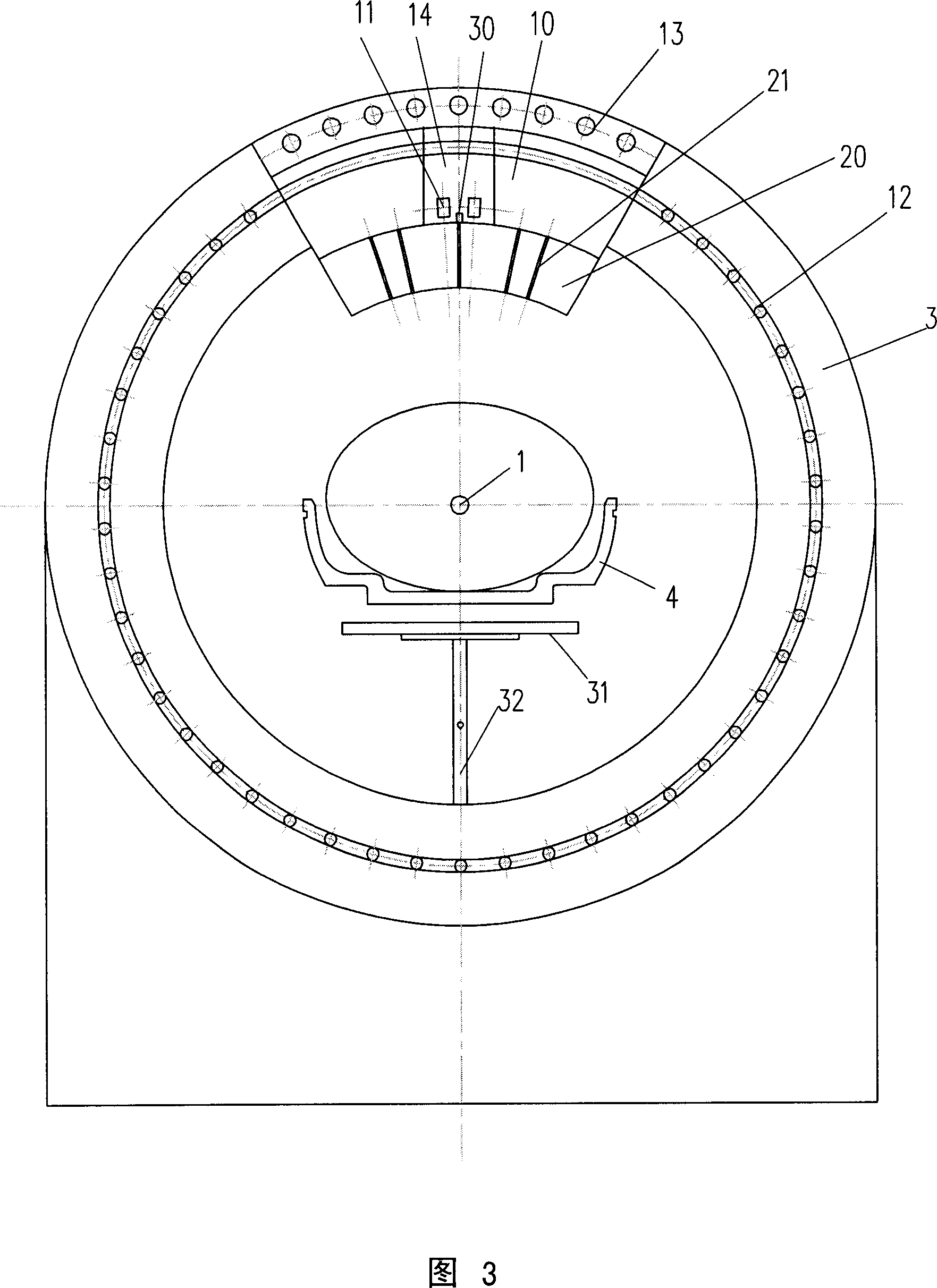

ActiveCN1919372AGood effectRealize verificationRadiation diagnosticsX-ray/gamma-ray/particle-irradiation therapyTherapeutic bedGamma ray

The invention relates to a radiotherapy device and method of gamma ray rotation and focusing, which comprises the following steps: main control unit, driver, radiation device, therapeutic bed and so on, wherein the therapeutic bed and rotatable barrier are set in the rotating ring and radiation device separately, the rotating support ring is fixed on two ends of rotating stand with the axial of rotating support ring matching rotating ring positionally, the relating radiation device is set between two rotating rings, whose the rotatable barrier center fixes a rotatable cylindrical alignment.

Owner:SHEN ZHEN HYPER TECH SHENZHEN

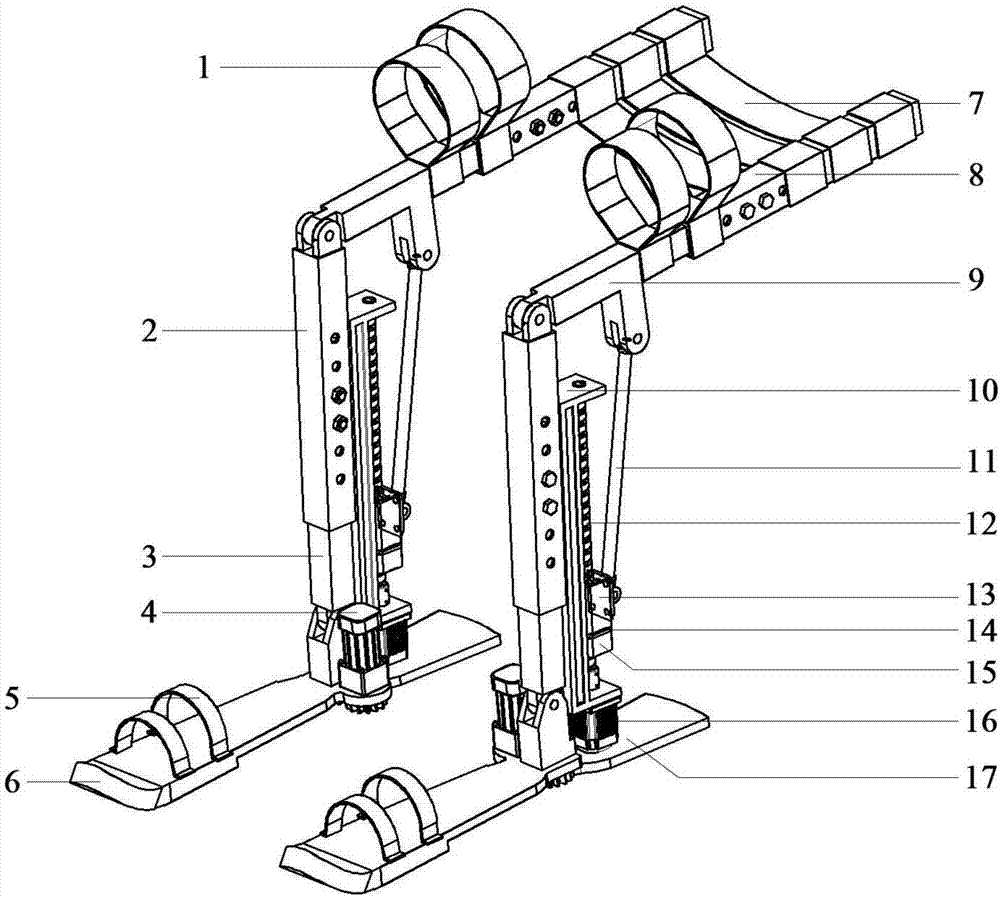

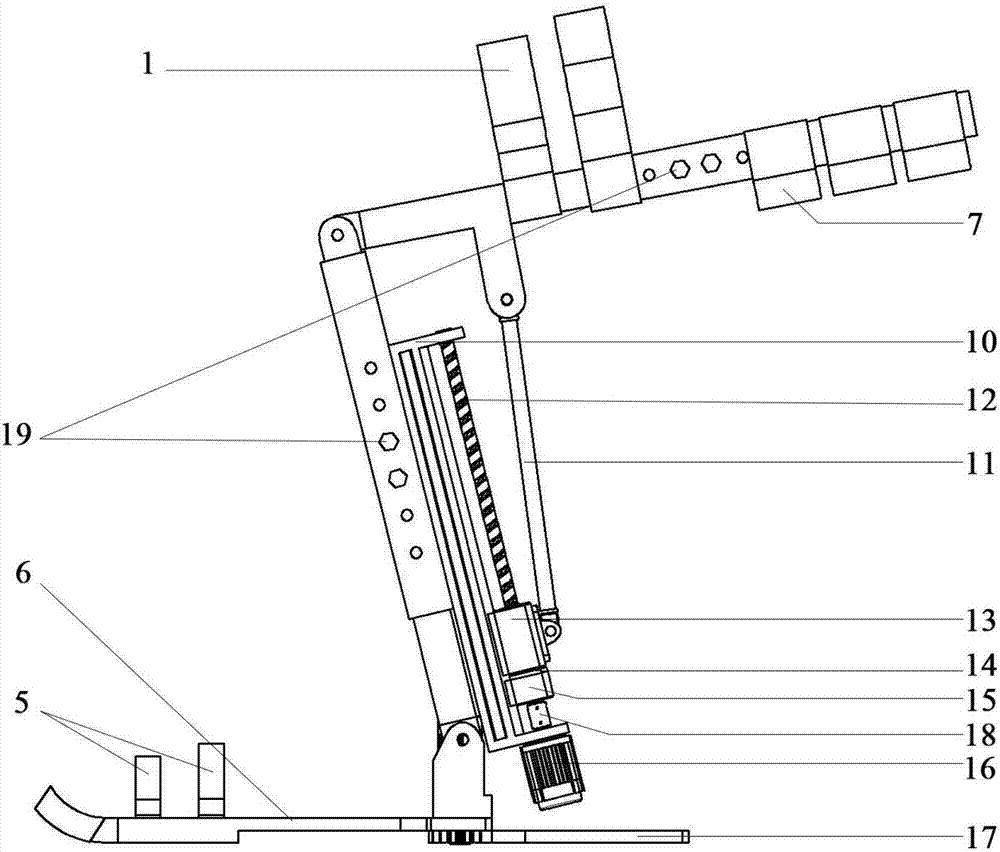

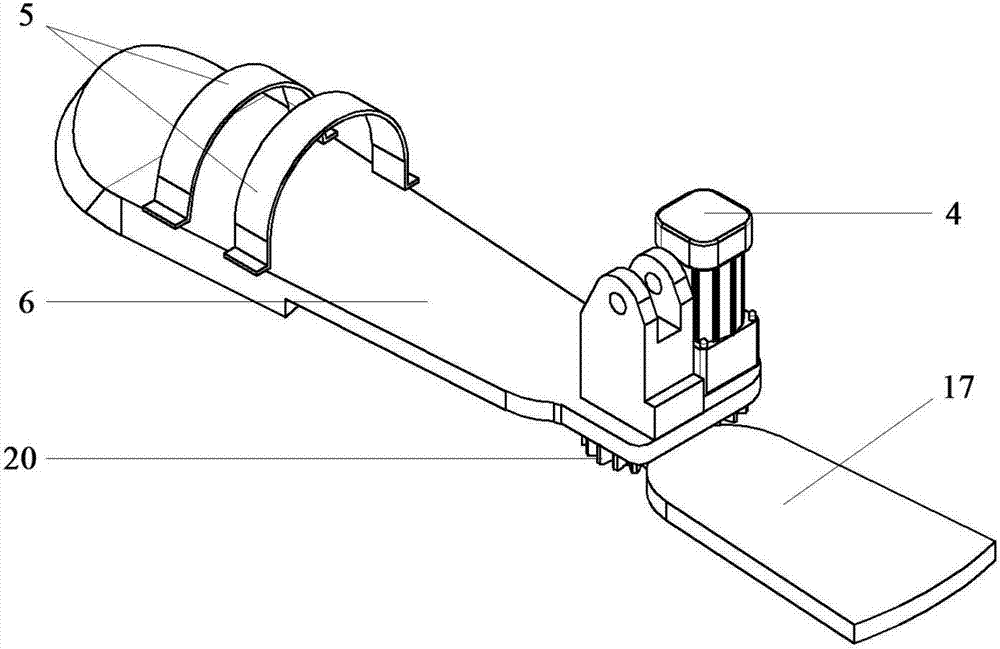

Automatically controlled wearable chair and using method

ActiveCN107252210AExtended range of movementIncrease activity spaceProgramme-controlled manipulatorStoolsControl measureAutomatic control

The invention provides an automatically controlled wearable chair. The automatically controlled wearable chair comprises a human body support module and an amplitude variable module, and further comprises an intention sensing control module and a rotation support module. The rotation support module comprises a rotation support plate connected with a foot sole support component, a motor and a driving gear. The intention sensing control module comprises a foot sole pressure sensor installed on the contact surface of the foot sole support component and the foot sole of the human body, a thigh pressure sensor installed on the contact surface of a thigh support component and thighs of the human body, and a microprocessor for judging the human body intention according to the data of the foot sole pressure sensor and the thigh pressure sensor and controlling the amplitude variable module and the rotation support plate to operate. The automatically controlled wearable chair is capable of, through the added intention sensing control module, executing the corresponding control measures according to the intention of a user. The gravity center moving range of the human body is enlarged by the rotation support module, so the upper body activity space of the human body is increased. After the intention sensing control module and the rotation support module are combined, the adaptability between the user and the chair is improved.

Owner:WUHAN UNIV OF TECH

Radiation therapeutical device

ActiveCN1919373AImprove support rigidityThe preparation process is simple and reliableTomographyDiaphragms for radiation diagnosticsGamma rayRadioactive source

Owner:SHEN ZHEN HYPER TECH SHENZHEN

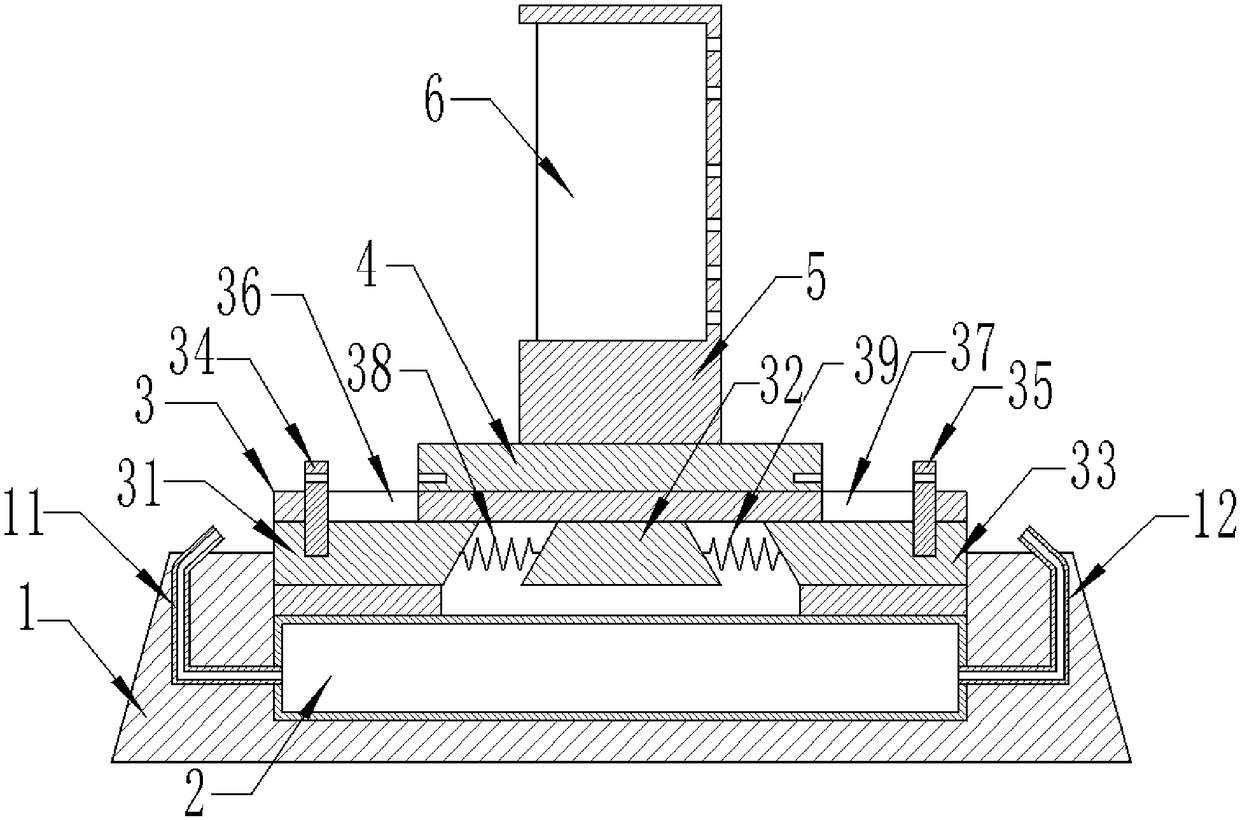

Display screen base

ActiveCN108413195ALower the altitudeIncrease frictionFluid-pressure actuatorsStands/trestlesFree stateSlide plate

The invention belongs to the field of supporting machines, and provides a display screen base with a damping effect and capable of adjusting the height and the inclination angle of a display screen. According to the specific scheme, the display screen base comprises a base body, wherein the base body comprises, from bottom to top, a seat body, a sliding plate which is installed in a groove of theseat body and can slide, a fixing plate which is fixed on the sliding plate and a support which is connected with the display screen and connected with the fixing plate; and an air bag is arranged between the bottom of the groove of the seat body and the sliding plate, the two ends of the air bag correspondingly communicate with a first hose with an electromagnetic valve and a second hose with anelectromagnetic valve, a transverse hole transversely penetrating is formed in the sliding plate, a first wedge-shaped block, a trapezoid block and a second wedge-shaped block which are sequentially connected through a pressure spring are arranged in the transverse hole, the first wedge-shaped block and the second wedge-shaped block which can slide can not extend out of the transverse hole when the pressure spring is in a free state, limiting blocks in two limiting holes in the top of the sliding plate can connect the first wedge-shaped block or the second wedge-shaped block with the fixing plate, the trapezoidal block can pass through a through hole in the bottom of the sliding plate under the extrusion of the first wedge-shaped block and the second wedge-shaped block.

Owner:山东信华电子科技有限公司

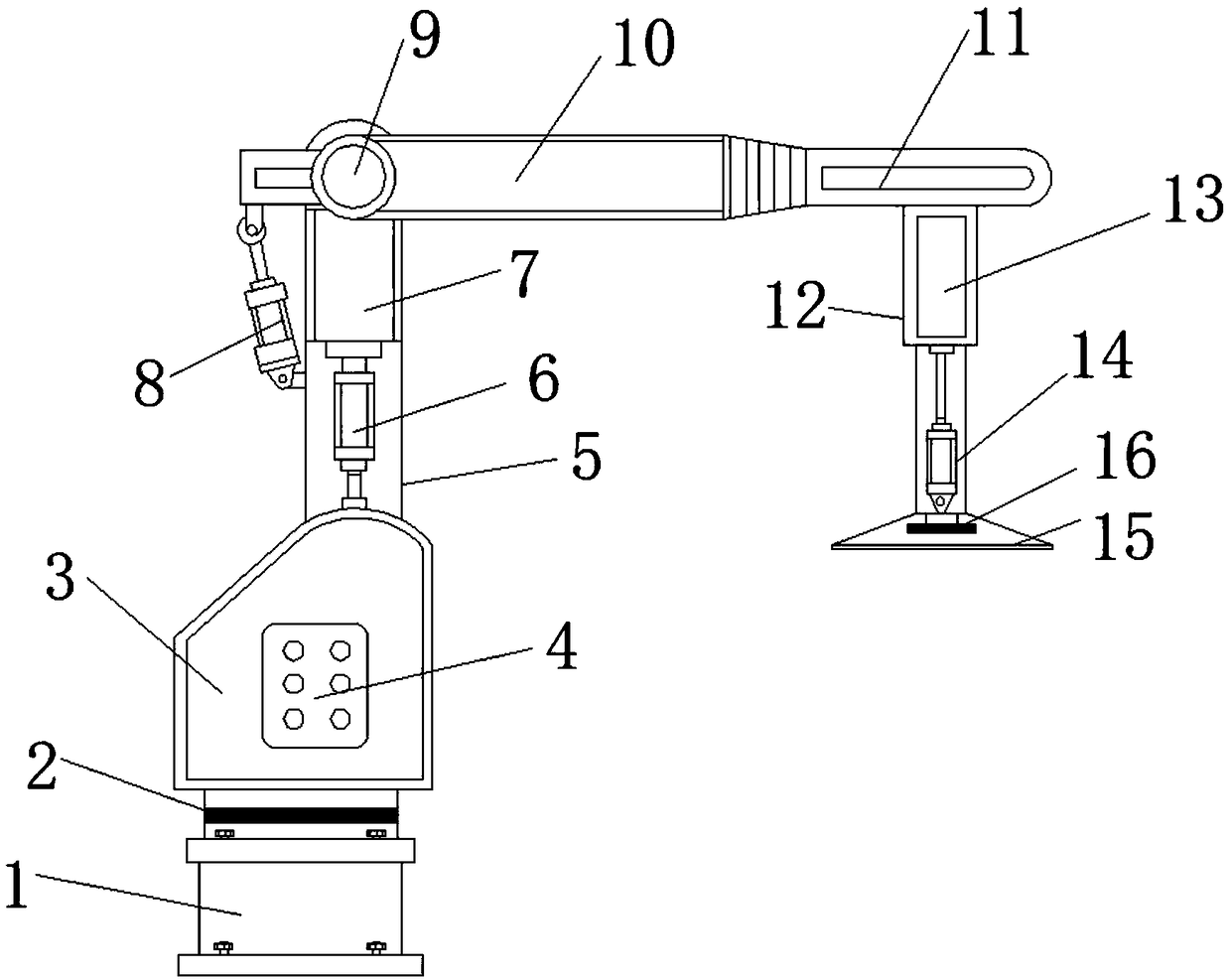

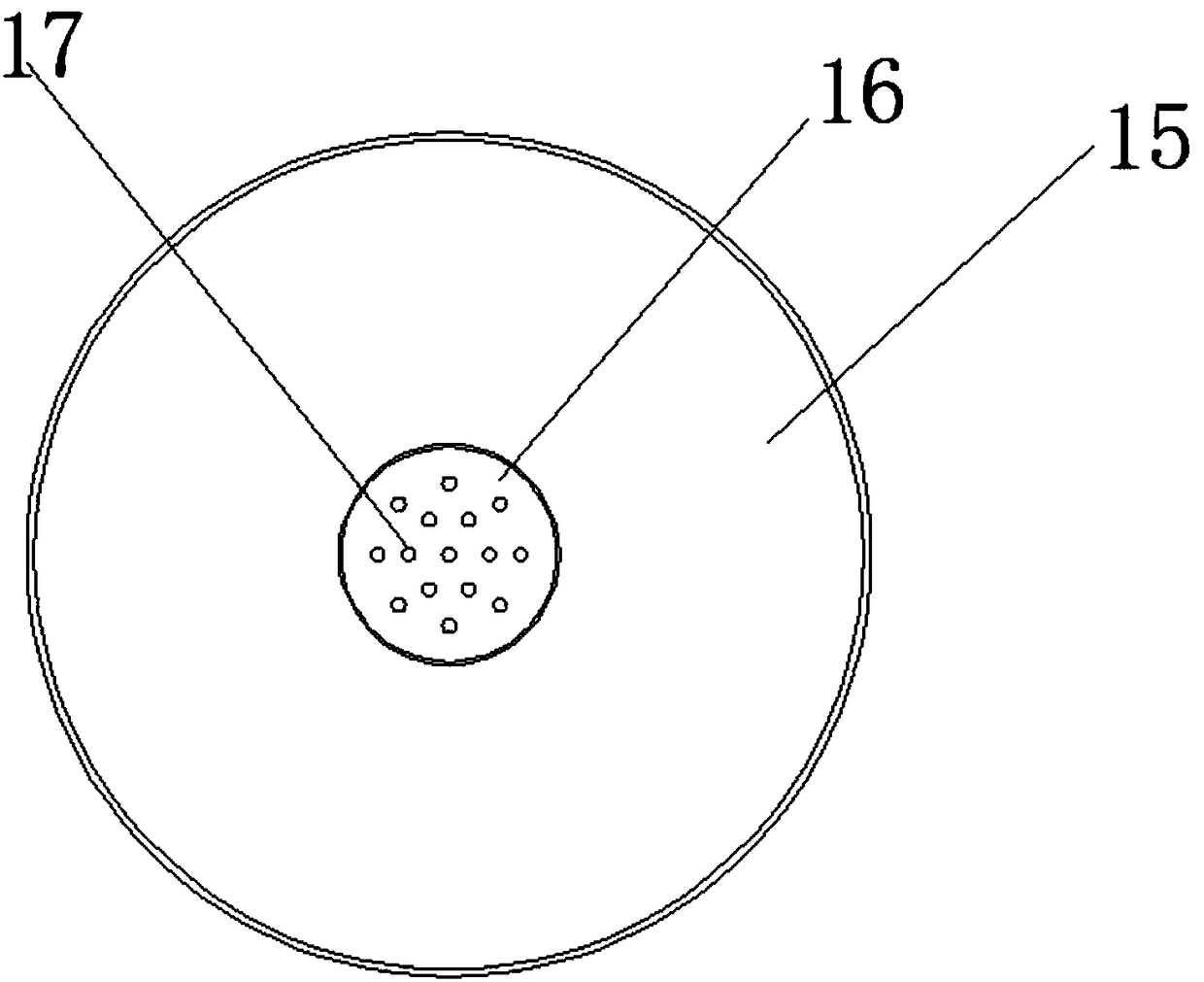

Displacement mechanical arm for glass processing

PendingCN108127641AAvoid destructionWon't slipProgramme-controlled manipulatorGripping headsHydraulic cylinderEngineering

The invention discloses a displacement mechanical arm for glass processing. The arm comprises a base, a rotary table is arranged at the upper end of the base, and a control box is arranged at the upper end of the rotary table; a control panel is arranged on the surface of the control box, a supporting column is arranged at the upper end of the control box, and a first lifting cylinder is arrangedin the supporting column; a lifting rod is arranged at the upper end of the first lifting cylinder, a hydraulic cylinder is arranged at one side of the supporting column, and a horizontal arm is arranged at the upper end of the supporting column; a rotation shaft is arranged between the supporting column and the horizontal arm; a retractable arm is arranged at one end of the horizontal arm, a hanging arm is arranged at the lower end of the retractable arm, and an air pressure pump is arranged at the upper end in the hanging arm; a second lifting cylinder is arranged at the lower end of the airpressure pump, a suction cup is arranged at the lower end of the hanging arm, an air pressure adjustment disc is arranged in the suction cup, and air pressure adjustment holes are formed in the surface of the air pressure adjustment disc. The displacement mechanical arm for glass processing is simple in structure, easy and convenient to operate, good in overall flexibility, large in movement range and high in applicability and grabs weights fully firmly, the weights cannot slide down, and the safety is high.

Owner:PINGHU HUARUI GLASS

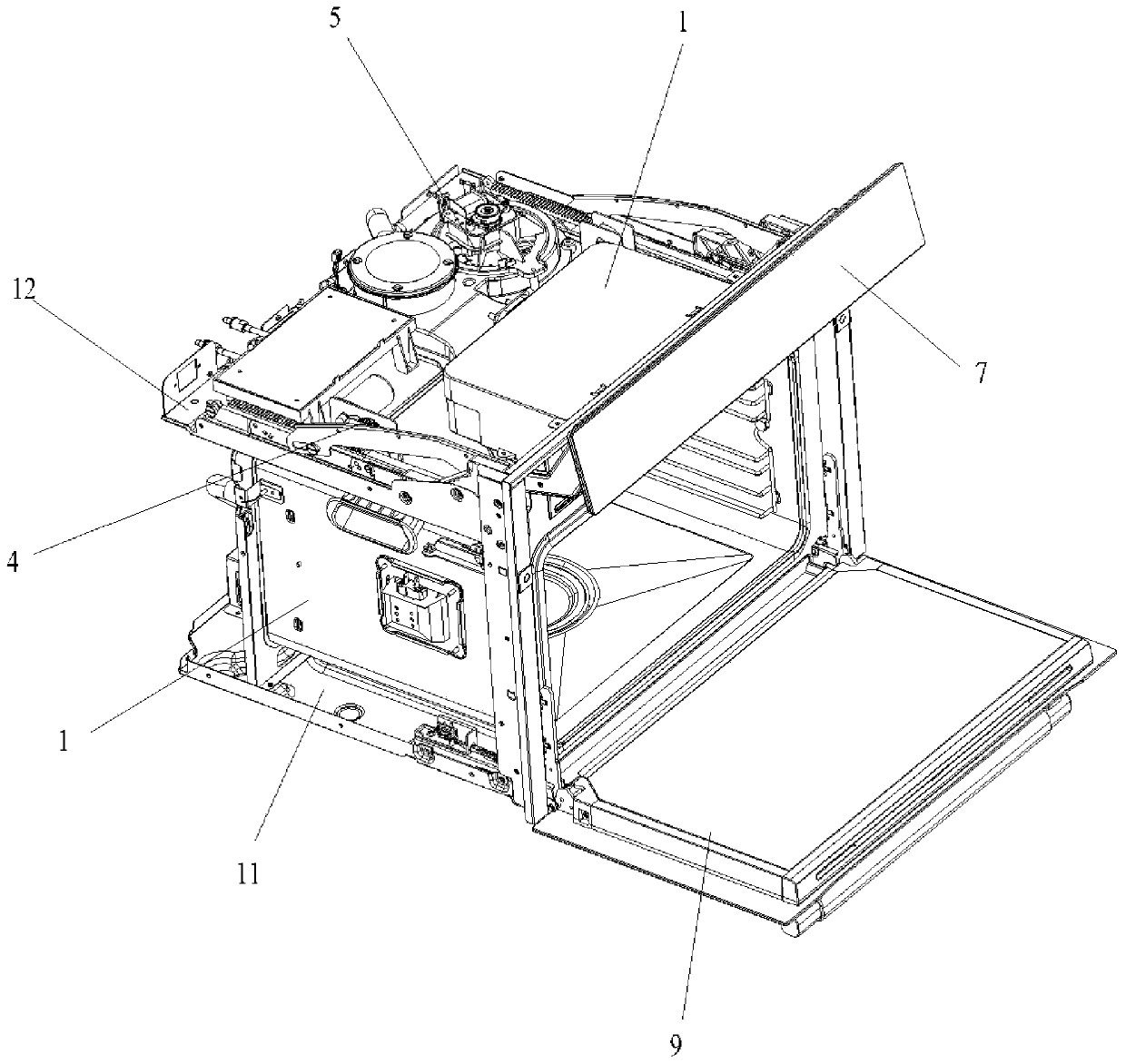

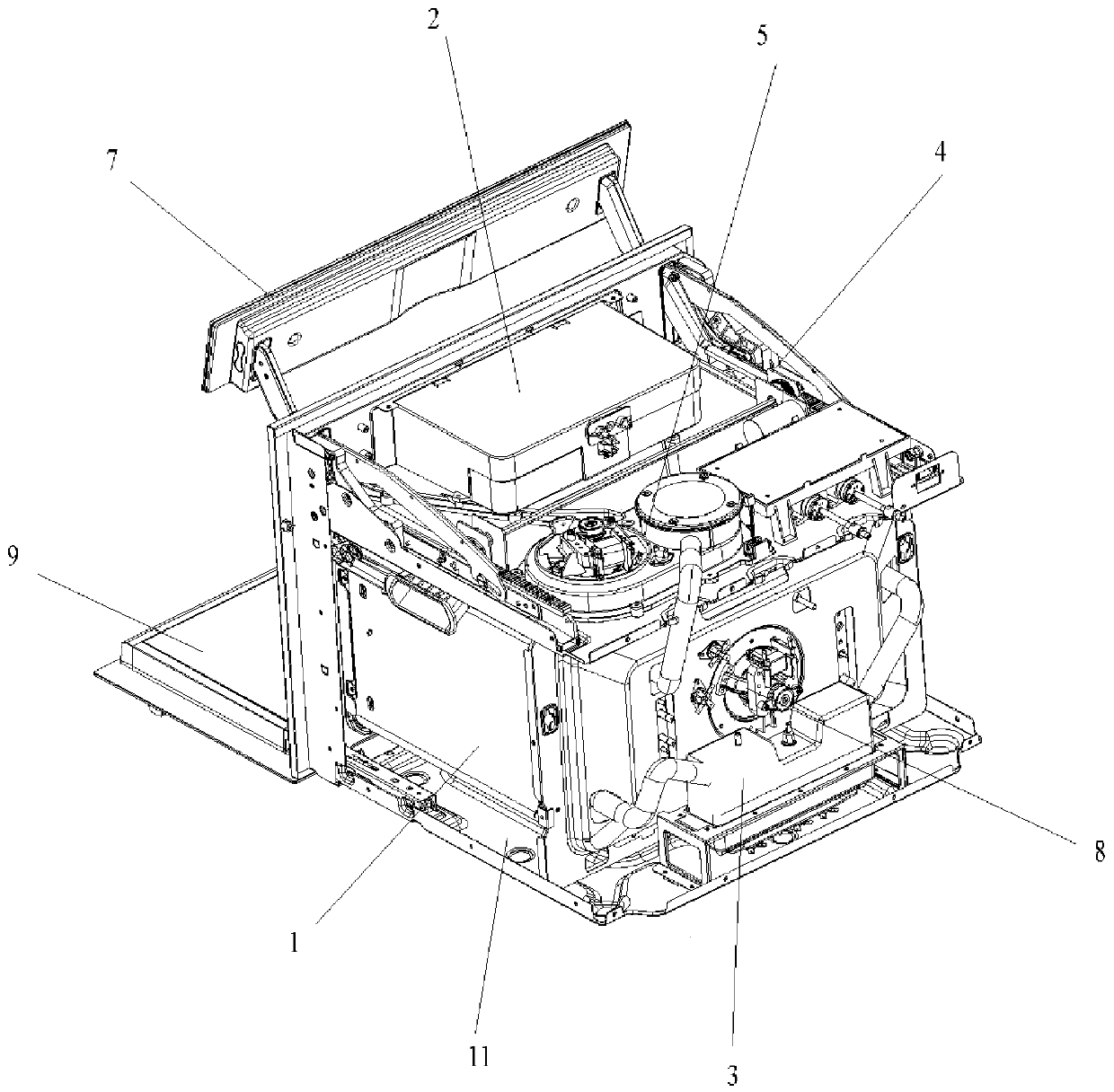

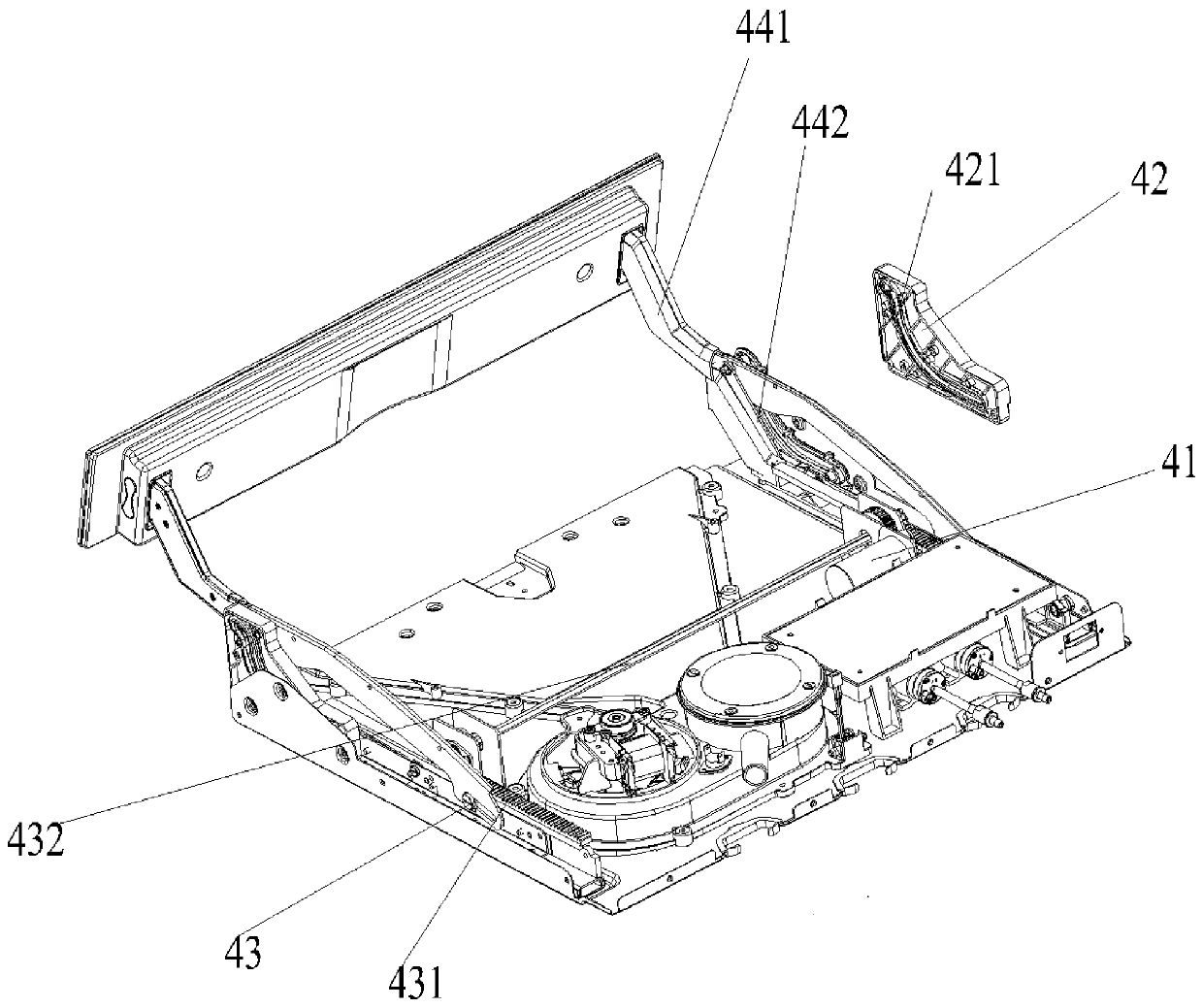

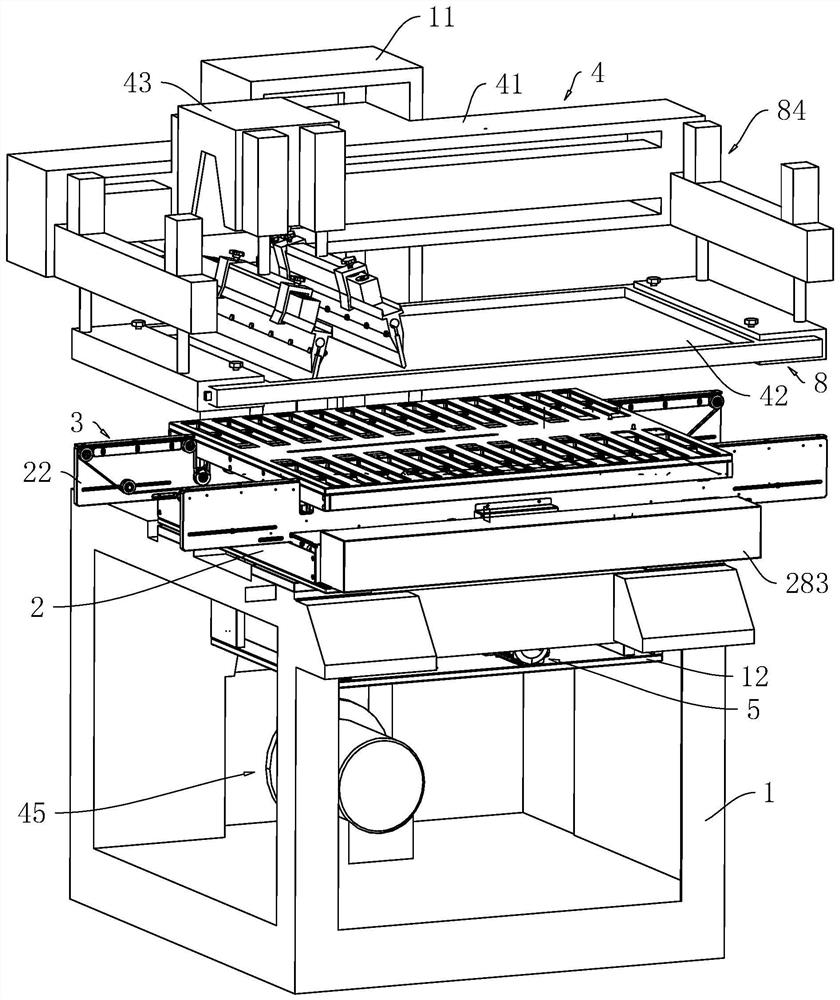

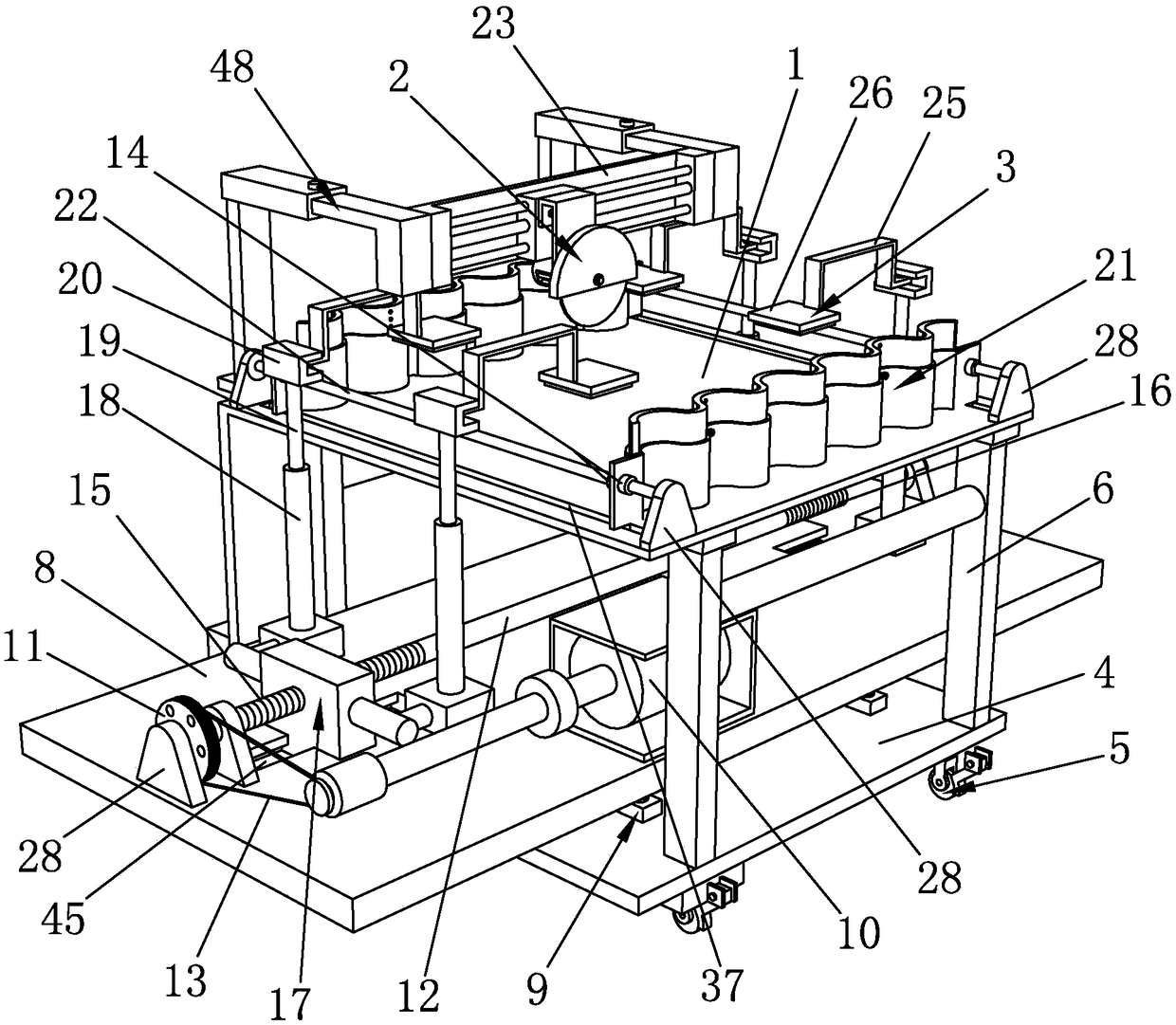

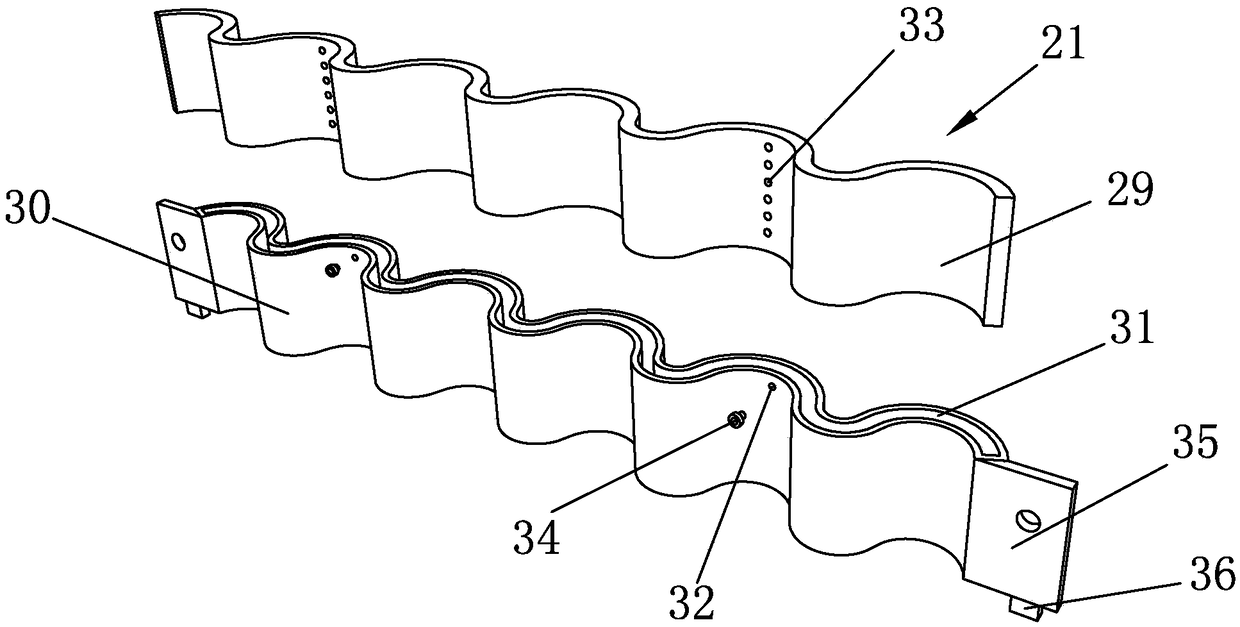

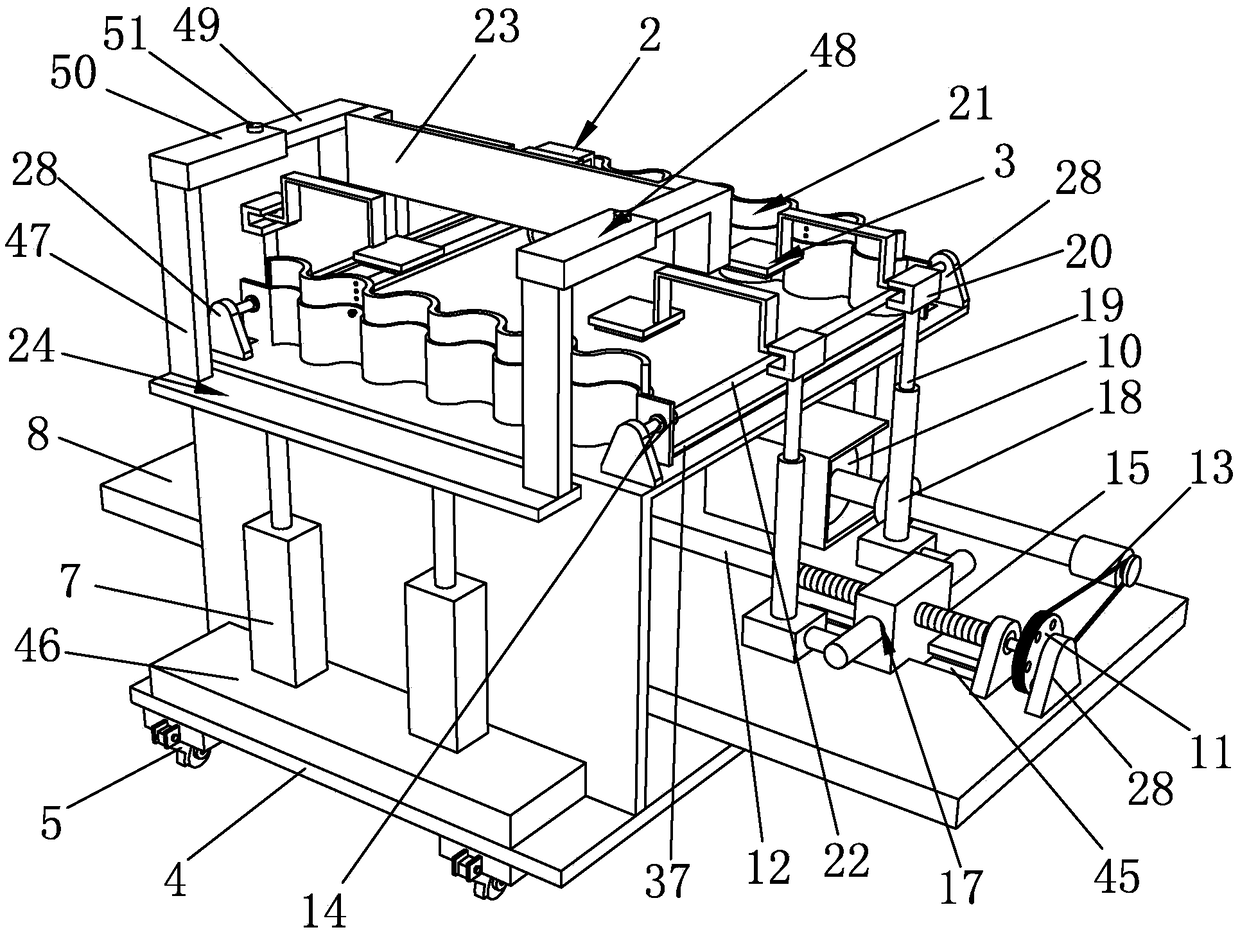

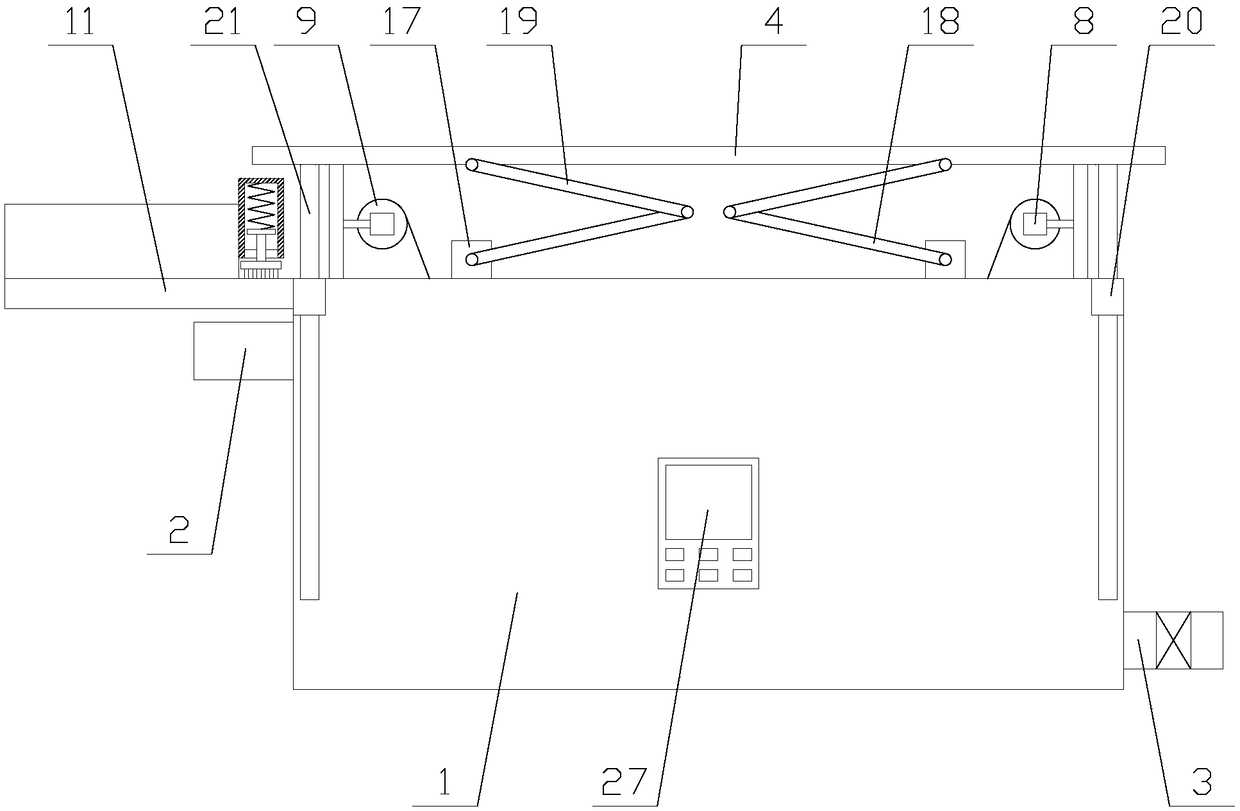

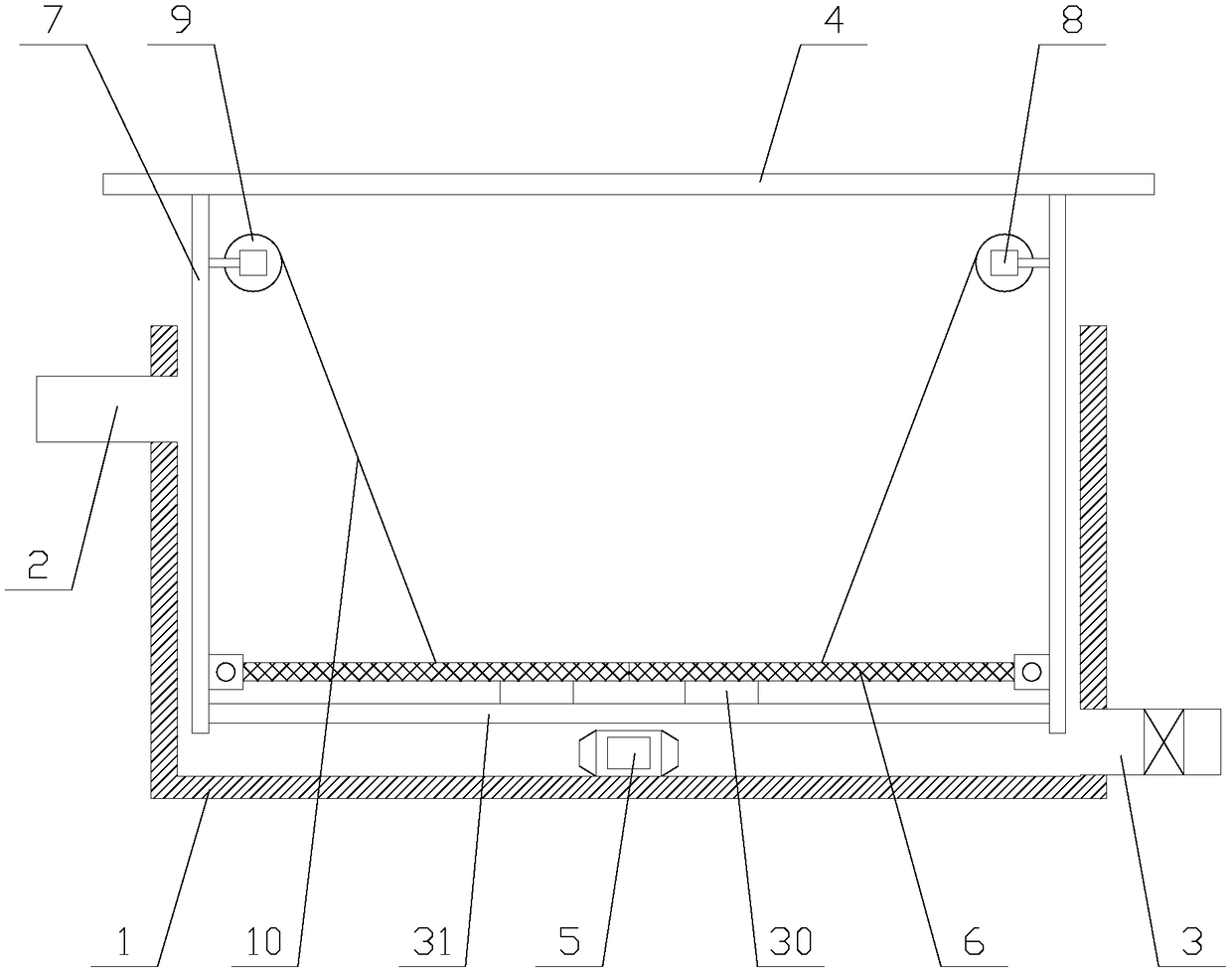

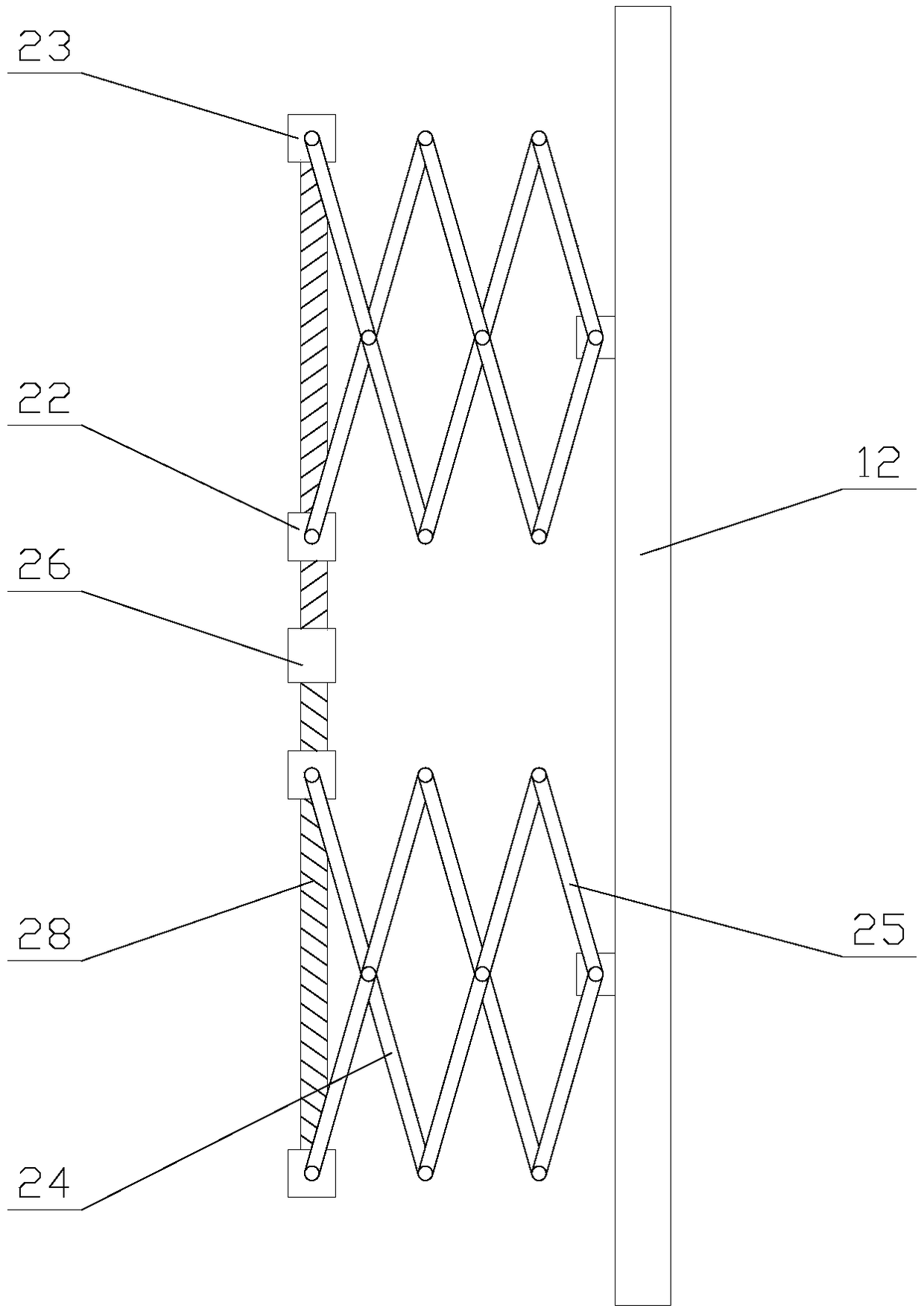

Steaming and baking oven integral machine

PendingCN110074657AExtended range of movementMeet needsSteam cooking vesselsRoasters/grillsMotor driveGear wheel

The invention relates to cooking equipment, in particular to a steaming and baking oven integral machine. The steaming and baking oven integral machine comprises an inner liner, a top plate, an operation panel and a movement mechanism, wherein the movement mechanism comprises a motor, a fixed support frame, a gear transmission mechanism and two connecting rod mechanisms, wherein the gear transmission mechanism comprises a gear, a transmission shaft, and two racks respectively arranged at the left and right sides of the top plate; the gear is engaged with one end of the transmission shaft; thetwo ends of the transmission shaft are respectively engaged with the two racks; the two connecting rod mechanisms are arranged, and the driving end of each of two connecting rod mechanisms is hinged to the racks; the driven ends are connected with an operation panel; the motor drives a rotating shaft to rotate, so that the two racks are driven to move synchronously; therefore the connecting rod mechanisms are driven to act so as to drive the operation panel to realize upward turning and restoration. The racks with relatively long stroke are used for driving the connecting rod mechanisms to actso as to drive the operation panel to realize the upward turning and restoration, so that the moving range of the operation panel can be increased by the operation panel; the requirements of customers can be met; the structure of the gear transmission mechanism is also simplified.

Owner:ZHEJIANG SHUAIKANG ELECTRIC

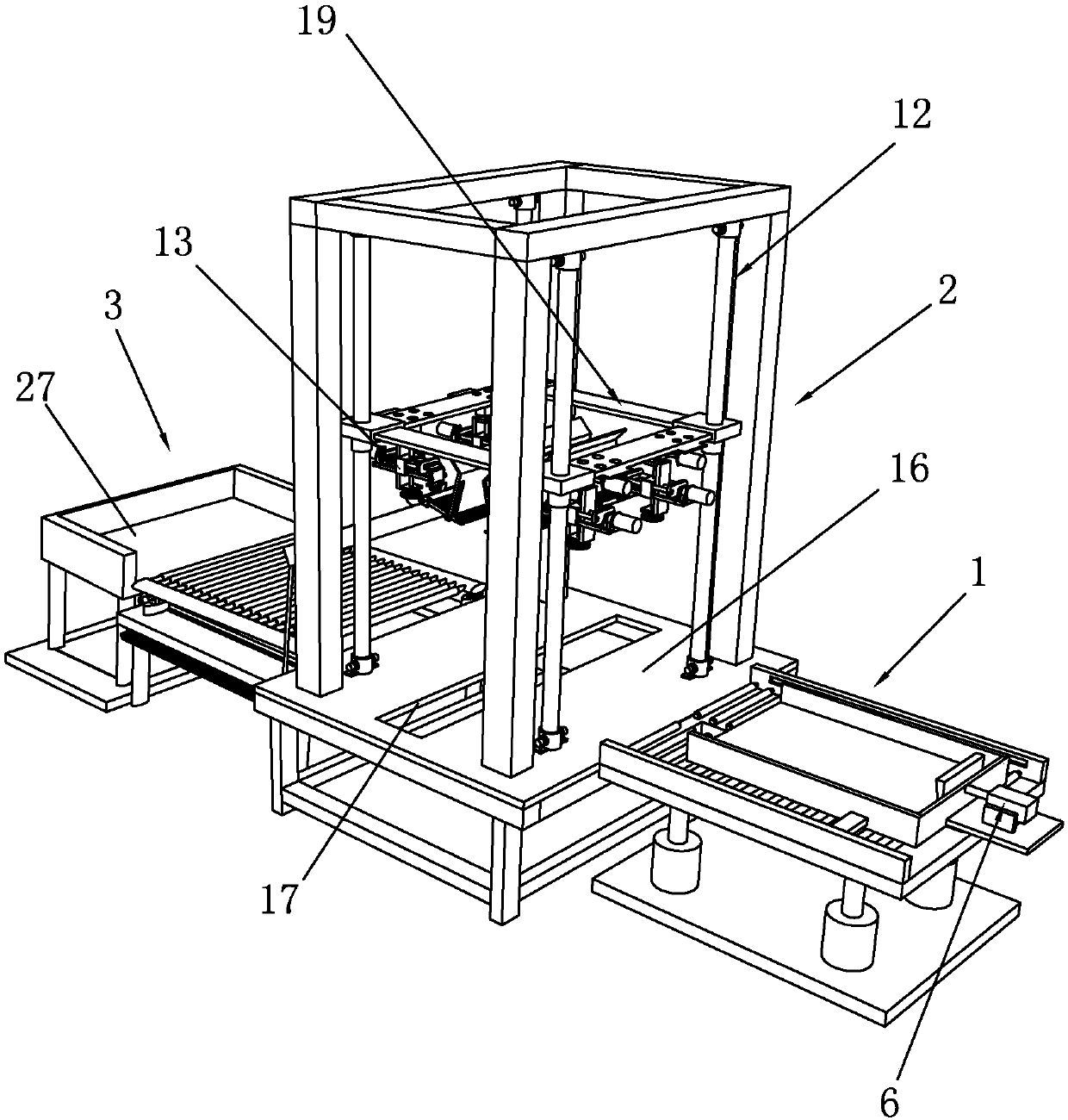

Linear flame welding machine and welding method thereof

ActiveCN107717171AEasy to handleIncrease feeding rateGas flame welding apparatusOperation safetyOperations security

The invention discloses a linear flame welding machine. The linear flame welding machine comprises a feeding mechanism, a welding mechanism and a discharging mechanism; the feeding mechanism comprisesa feeding table, a storing table and a pushing device; the welding mechanism comprises a welding room supporting frame and welding assemblies; each welding assembly comprises a welding head set, a longitudinal adjusting assembly and a transverse adjusting assembly; and the discharging mechanism comprises a discharging table, a material conveying device and a material table. A welding method comprises the following steps of (1) feeding of welded workpieces; (2) adjustment of the height of the welding assemblies; (3) adjustment of the position of the welding head sets; (4) welding; and (5) discharging of the welded workpieces. The linear flame welding machine is ingenious and reasonable in structural design, and convenient and rapid to use and operate, achieves automatic treatment operationof workpiece feeding and discharging through the feeding mechanism and the discharging mechanism, relieves labor intensity, improves operation safety performance, can conduct welding on the workpieces at the same time through design of the multiple welding assemblies, effectively increases the welding rate, and improves the work efficiency.

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

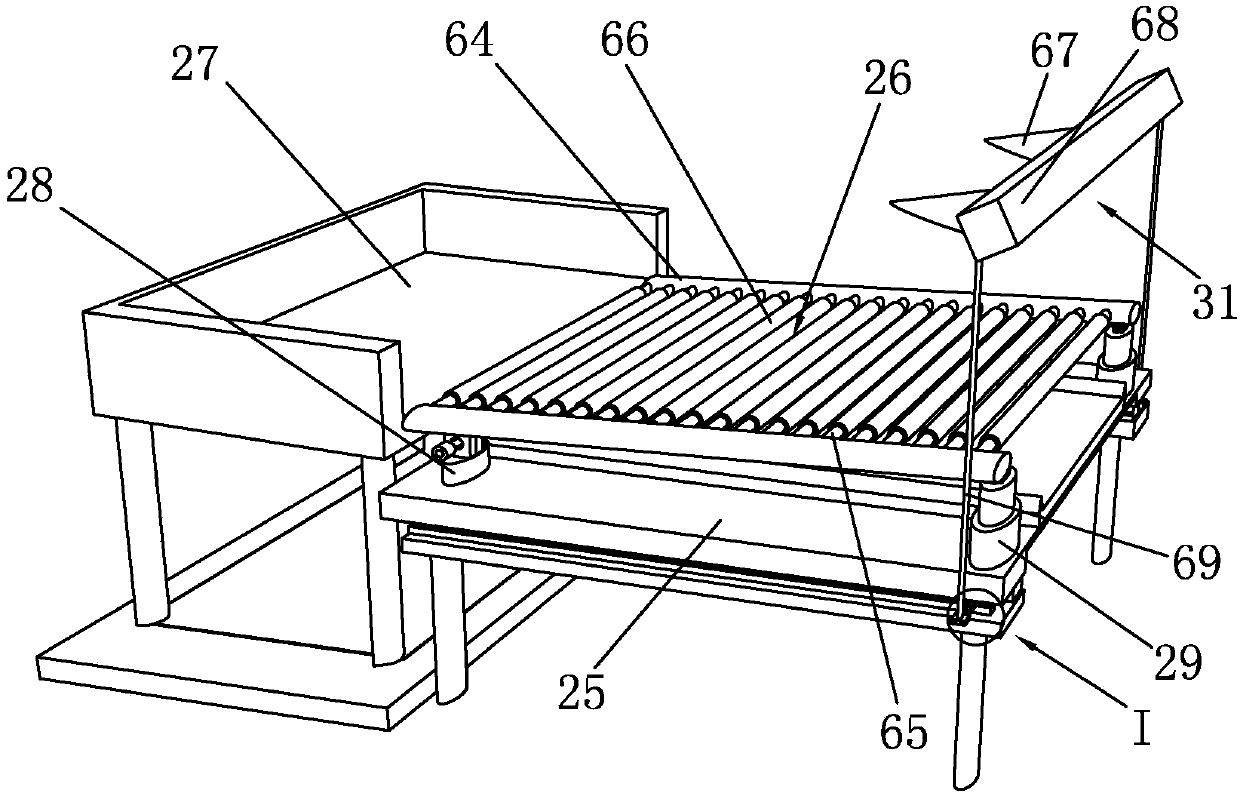

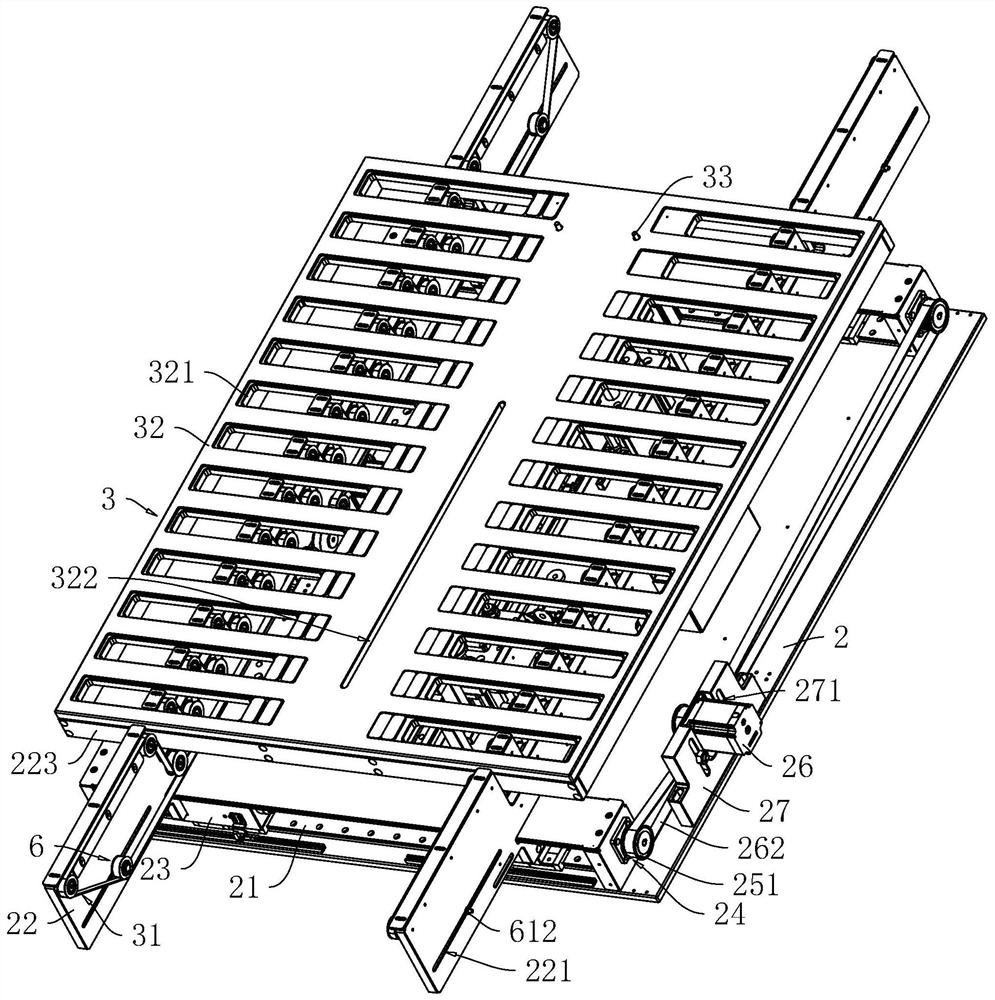

Screen printing equipment for circuit board

ActiveCN112046134AIncrease productivityShorten the timePrinted circuit assemblingScreen printersScreen printingConveyor belt

The application relates to screen printing equipment for a circuit board, and the screen printing equipment comprises a rack. A conveyor device and a screen printing mechanism are arranged on the rack; the conveyor device comprises a conveyor belt, a placing plate, a locating column and a lifting device, and the conveyor belt, the placing plate, the locating column and the lifting device are arranged on the rack; the screen printing mechanism comprises a sliding seat, a silk screen, a sliding table, an ink scraping assembly, a first driving assembly and a second driving assembly, and the sliding seat is arranged on the rack; and the silk screen and the sliding table are arranged on the sliding seat, and the ink scraping assembly is arranged on the sliding table. According to the screen printing equipment, the circuit board is driven by the conveying belt to move forwards, and the lifting device is started for driving the locating column to locate the circuit board; then, the first driving assembly is started to enable the silk screen to come into contact with the circuit board, and the second driving assembly is started to print soldering paste on the silk screen onto the circuit board; Manual work is required in the soldering paste printing process of the circuit board, and the time is saved; and the problem of lower production efficiency of a screen printing machine is solved.

Owner:SHENZHEN HAISIKE AUTOMATION TECH

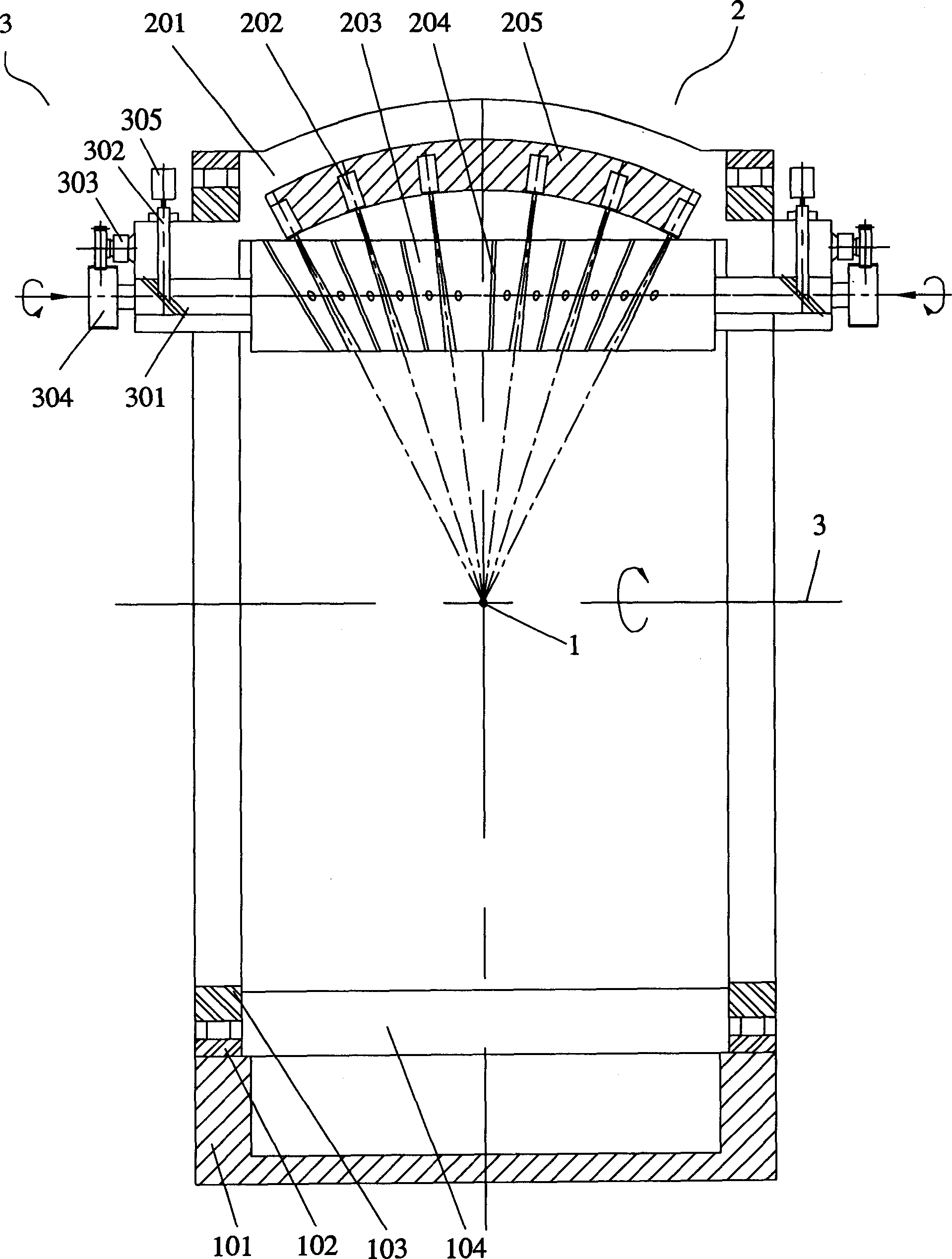

Radiotherapy apparatus

ActiveCN1810320AImprove focus accuracyExtended range of movementX-ray/gamma-ray/particle-irradiation therapyDiseaseGamma ray

The present invention relates to radiotherapy apparatus and is especially one kind rotary focused gamma-ray radiotherapy apparatus. The rotary focused gamma-ray radiotherapy apparatus includes a radiator, a treating bed, a rotary rack, a rotary bearing ring, a rotating ring, a source body with radiating source and a cylindrical collimator set between rotary bearing ring and the rotating ring. The radiating source has the ray beam outlet located on the common focus in the rotating axis, and the collimator is connected through a transmission part with at least one spiral transmission mechanism and has several radiating passages with collimating unit and shielding stopper distributed corresponding to the radiating source. The present invention has expanded treating space, lowered manufacture cost and less manufacture difficulties, and may be used in the continuous effective safe radiotherapy of several disease focuses.

Owner:SHEN ZHEN HYPER TECH SHENZHEN

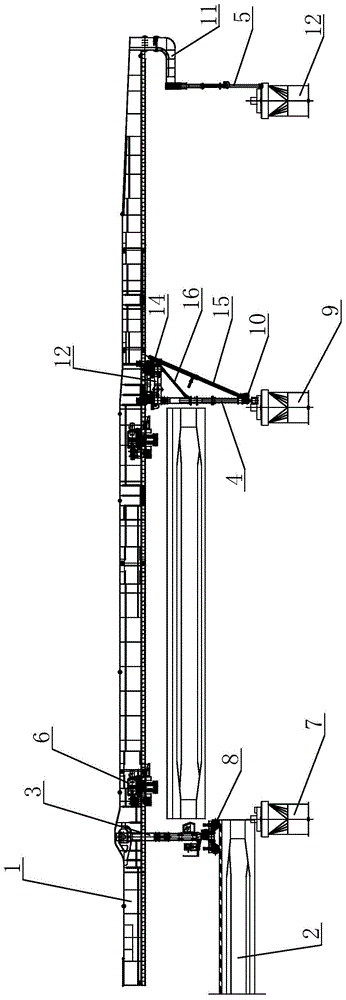

Duct piece reshipment device for shield tunnel

The invention discloses a duct piece reshipment device for a shield tunnel, comprising a walking trolley (3) arranged on a walking pathway (2), a drive mechanism used for driving the walking trolley (3) to move along the walking pathway (2), and a grabbing mechanism (4) capable of moving up and down, wherein the walking pathway (2) is arranged in a shield tunnel with a small diameter; the lower end of the grabbing mechanism (4) capable of moving up and down is connected with a duct piece (7) to be reshipped, and the upper end of the grabbing mechanism (4) is connected with the walking trolley (3). Due to rapid reshipment speed and high working efficiency, the duct piece reshipment device is particularly applicable to the shield tunnel with a small diameter.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Cutting device for glass table board of integrated cooker and cutting method by adopting cutting device

ActiveCN108943446AAvoid harmAvoid hard frictionWorking accessoriesStone-like material working toolsDrive wheelMotor drive

The invention discloses a cutting device for a glass table board of an integrated cooker. The cutting device comprises a workbench, a cutting mechanism and clamping devices, a movable seat is arrangedbelow the workbench, a mounting plate is arranged between the workbench and the movable seat, a rotating motor, a driven wheel and a rotating screw rod are arranged on the mounting plate, the rotating motor drives the driven wheel to rotate through a belt wheel, the driven wheel drives the rotating screw rod to rotate, the cutting mechanism is located above the workbench, and the clamping devicescomprise supporting rods and clamping pressing plates. A cutting method comprises the following steps that (1) a to-be-cut raw material is fed; (2) positioning and clamping are carried out on the glass plate raw material; (3) the position of the cutting mechanism is adjusted; and (4) cutting machining is carried out. According to the cutting device, the overall structural design is ingenious andreasonable, omni-directional adjustment of the position of the cutting mechanism can be realized, and accurate positioning between the cutting mechanism and the to-be-cut position is ensured; and meanwhile, the clamping devices are designed so that the to-be-cut raw material can be clamped and fixed, and the application range is wide.

Owner:浙江欧帝智能厨电有限公司

Air flotation device for conveniently collecting floating residues

InactiveCN108862450AFlexible structureGuaranteed uptimeWater/sewage treatment by flotationDrive wheelSewage

The invention relates to an air flotation device for conveniently collecting floating residues. The air flotation device comprises an air flotation tank, a water intake pipe, a water drain pipe, a lifting mechanism, a top plate, a filtering mechanism, an air flotation machine, a controller and a clearing mechanism, wherein the filtering mechanism comprises two filtering assemblies; each filteringassembly comprises a filtering net and two direction adjusting units; each direction adjusting unit comprises a lifting rod, a first motor, a drive wheel and a pull wire; the clearing mechanism comprises a side plate, a telescopic assembly, a clearing box and a clearing assembly; the clearing assembly comprises a spring, a press plate, a slide rod, a scraping plate and a plurality of brushes. Theair flotation device for conveniently collecting the floating residues has the advantages that the sewage can drive the impurities to float to the liquid surface by the filtering mechanism in the airflotation process; after air flotation, the floating residues are collected to the part above the filtering net, so as to separate solid and liquid; the scraping plate and the brushes are driven by the clearing mechanism to move above the filtering net, and the floating residues on the filtering net are swept off, and are collected by an operator, so as to improve the practicality of the equipment.

Owner:SHENZHEN LEYE TECH CO LTD

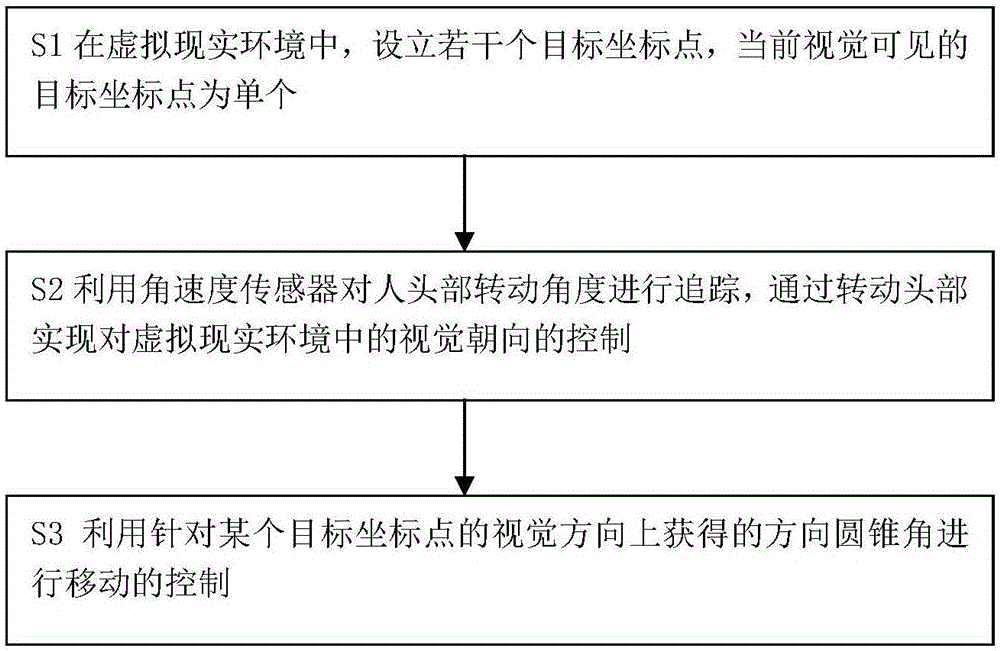

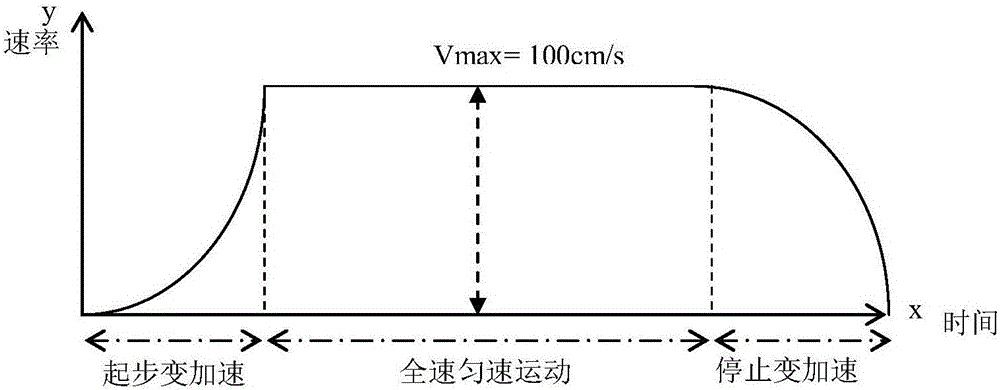

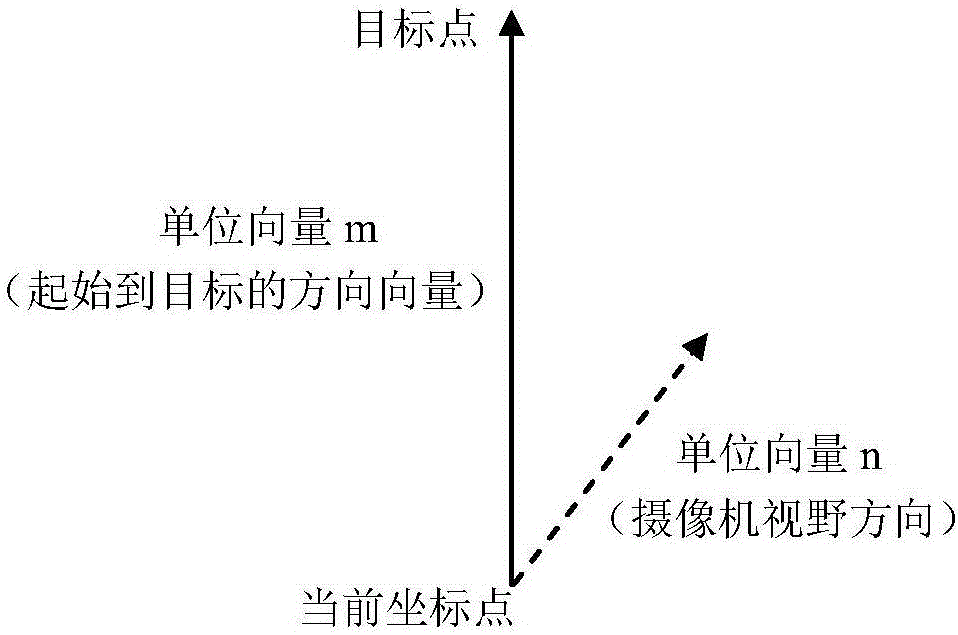

Moving control method of virtual reality

ActiveCN106354256ANot easily dizzyExtended range of movementInput/output for user-computer interactionImage data processingAngular velocityVisual control

The invention discloses a moving control method of virtual reality. The method includes the steps of S1, setting a plurality of target coordinate points in a virtual reality environment, wherein one coordinate point is currently visually visible; S2, using an angular velocity sensor to trace the rotating angle of a human head, and controlling the vision direction in the virtual reality environment by rotating the head; S3, controlling movements according to direction cone angle obtained in the vision direction of one target coordinate point. The moving control method has the advantages that the movements are control through the vision only, a user cannot feel dizziness easily, moving range is large, moving freedom degree is extremely high, and stopping can be achieved at any time during moving so as to observe the ambient environment; other auxiliary equipment and instruments are not needed, and only existing head display equipment with a gyroscope is needed; limitation on the size of the real space where the user is located is avoided, high immersion sense is achieved, the movements are close to the human moving manner in reality, and extremely high immersion sense and reality are achieved.

Owner:HANGZHOU SHAOZI NETWORK TECH CO LTD

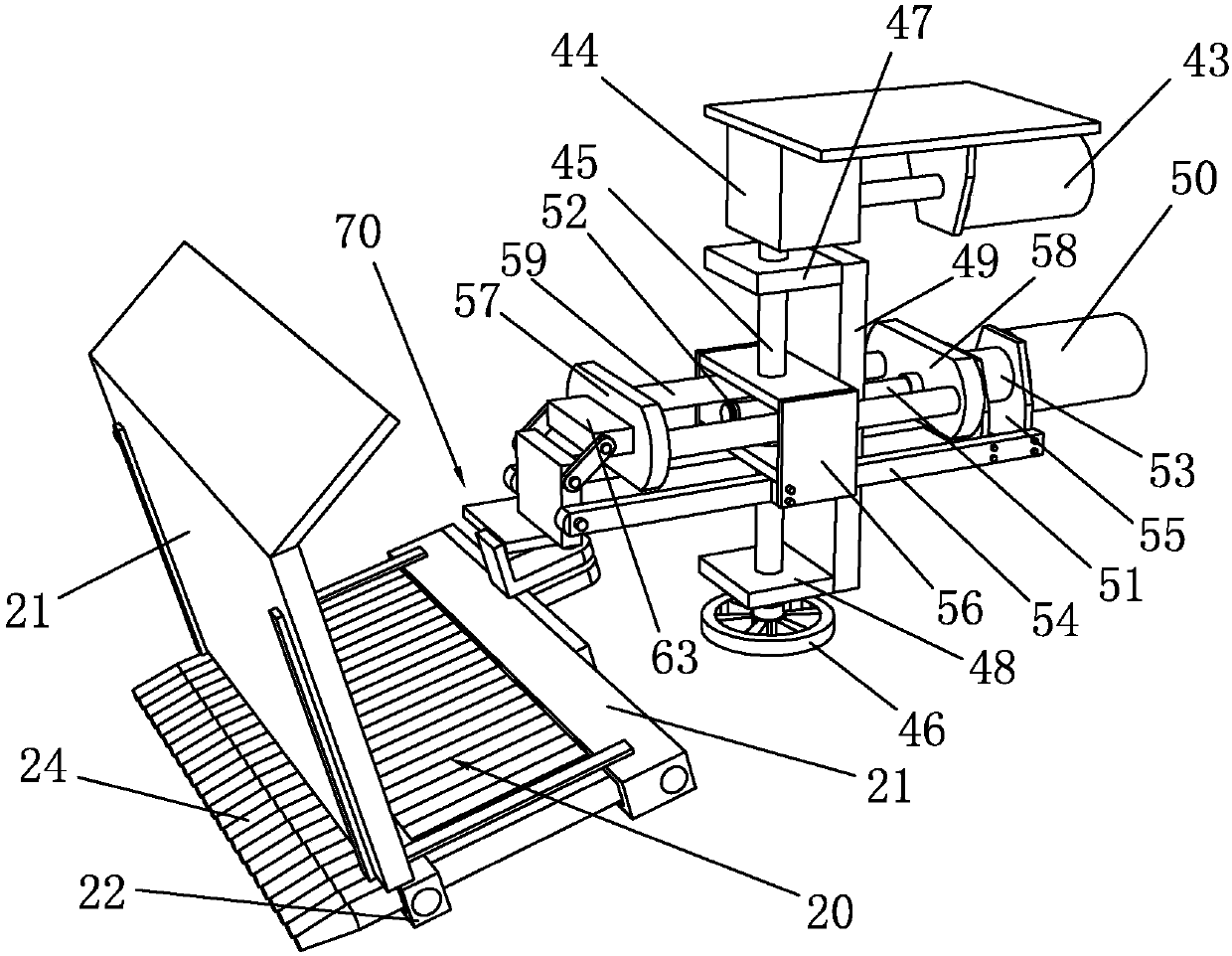

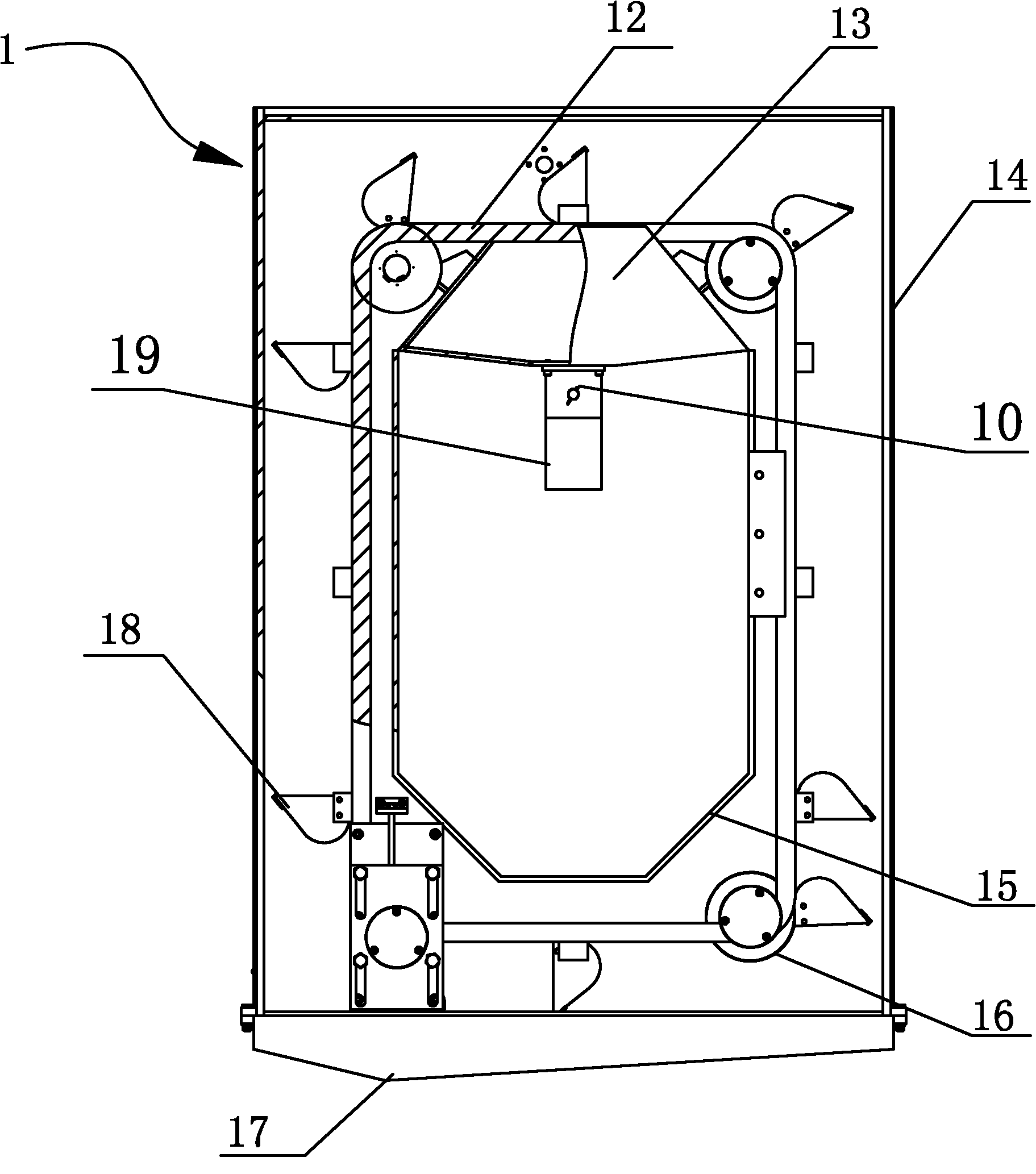

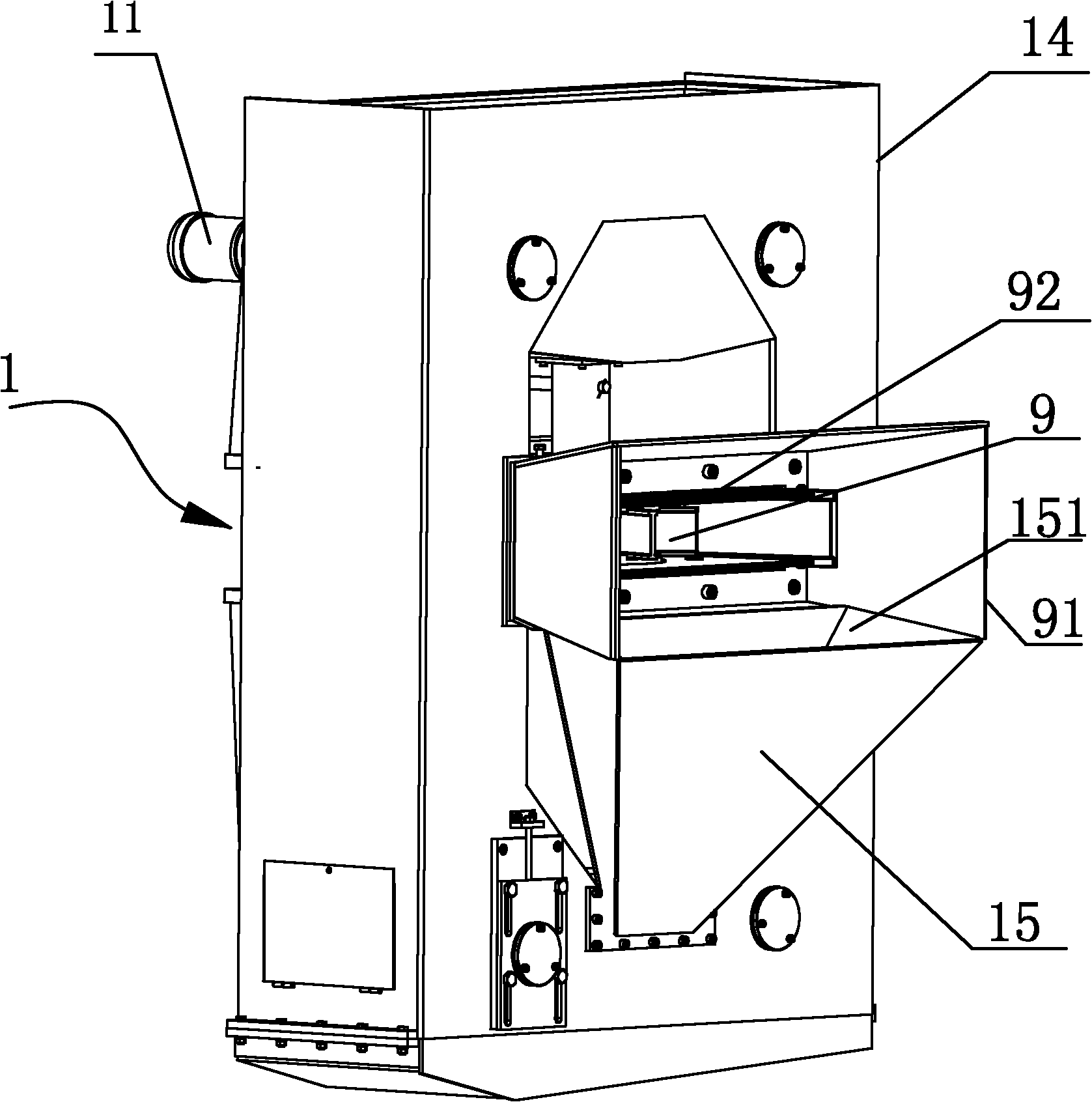

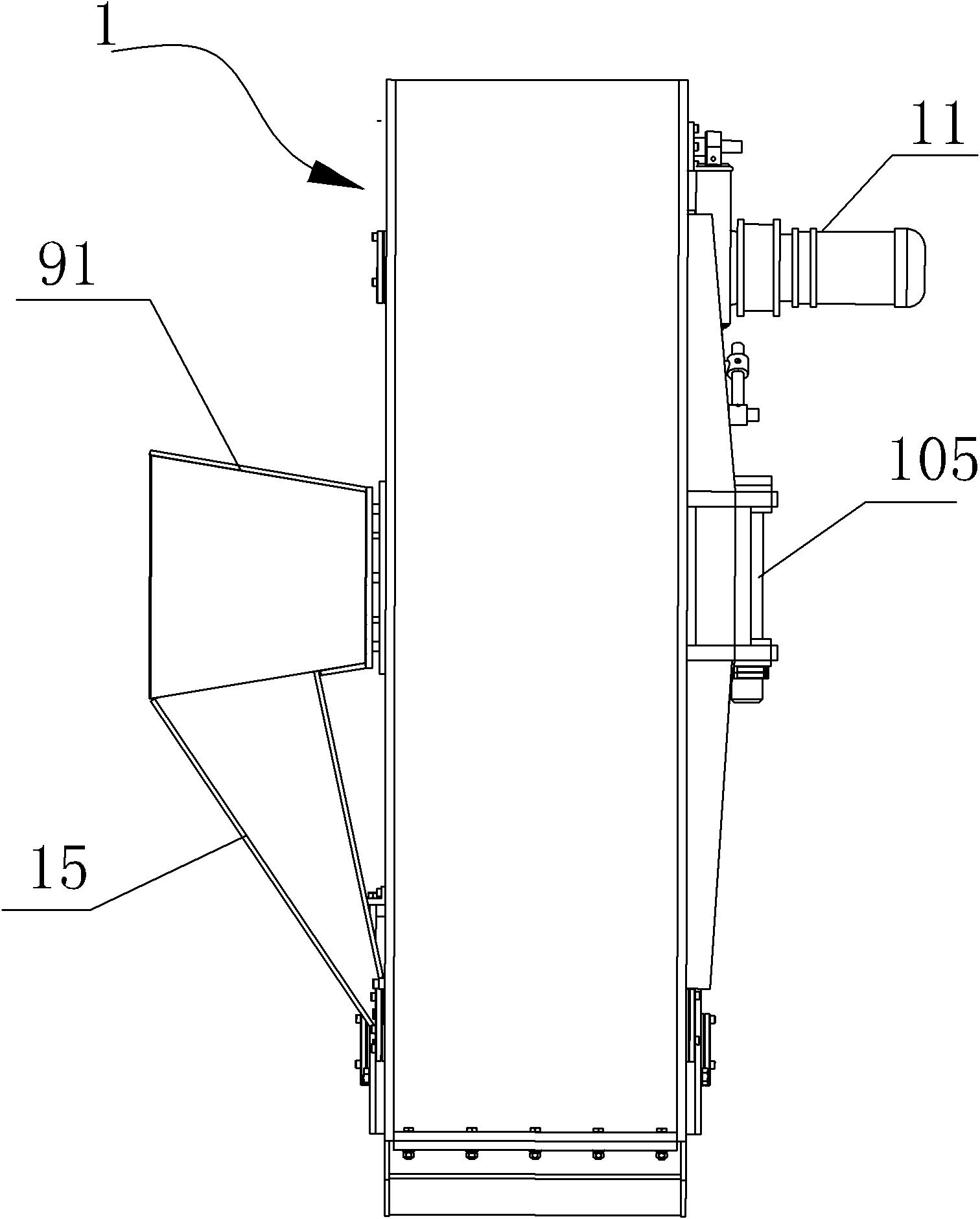

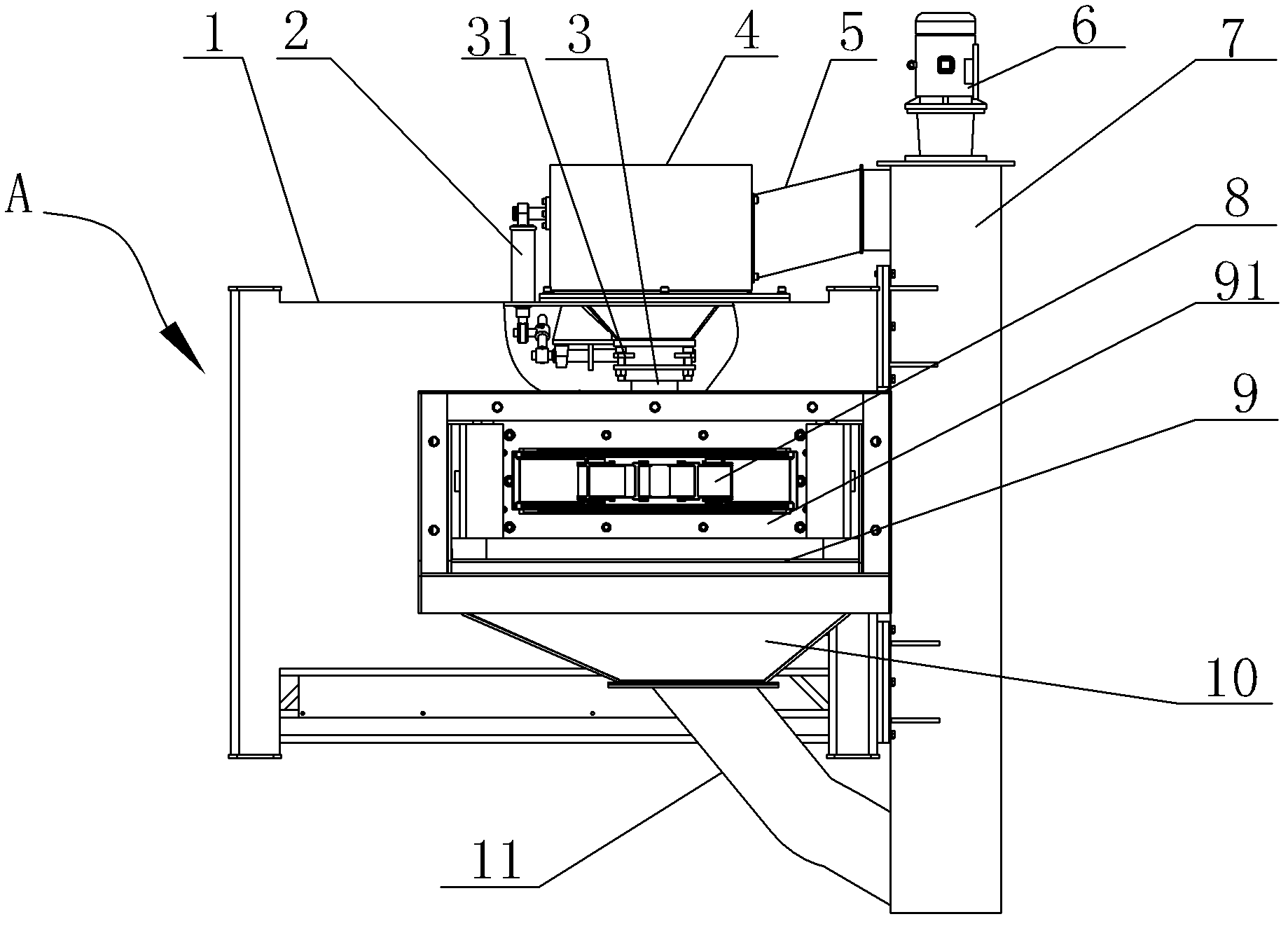

Automatic packaging machine for bulk materials

The invention belongs to the technical field of packaging equipment and particularly discloses an automatic packaging machine for bulk materials. The automatic packaging machine comprises a base and is characterized in that a multi-position discharge structure, a mechanical arm structure, a conveying system, an automatic label conveying machine, a sack sewing machine and a control system are sequentially arranged on the base. The automatic packaging machine is simple in structure, good in packaging effect and low in cost.

Owner:河南济开电器有限公司

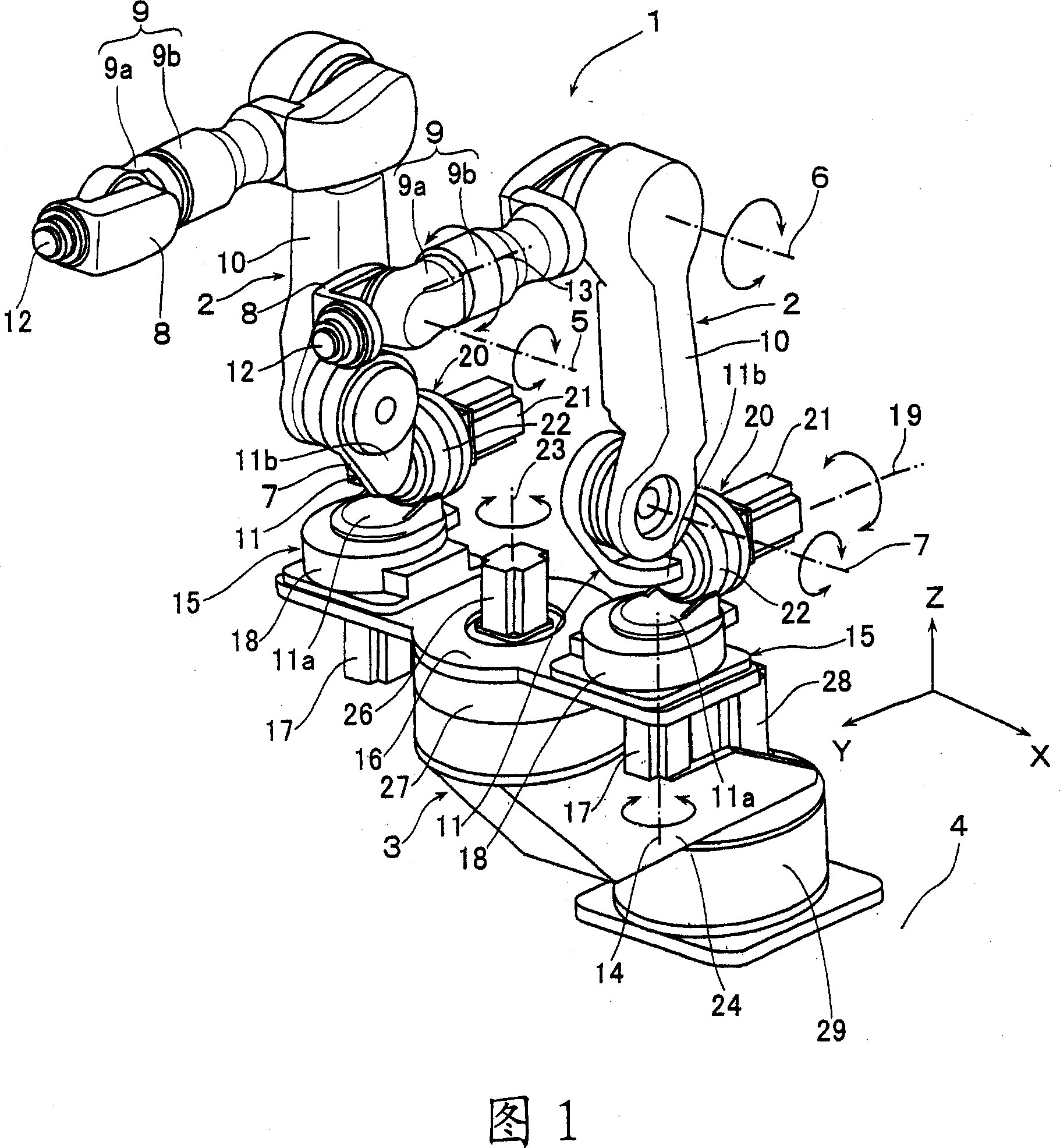

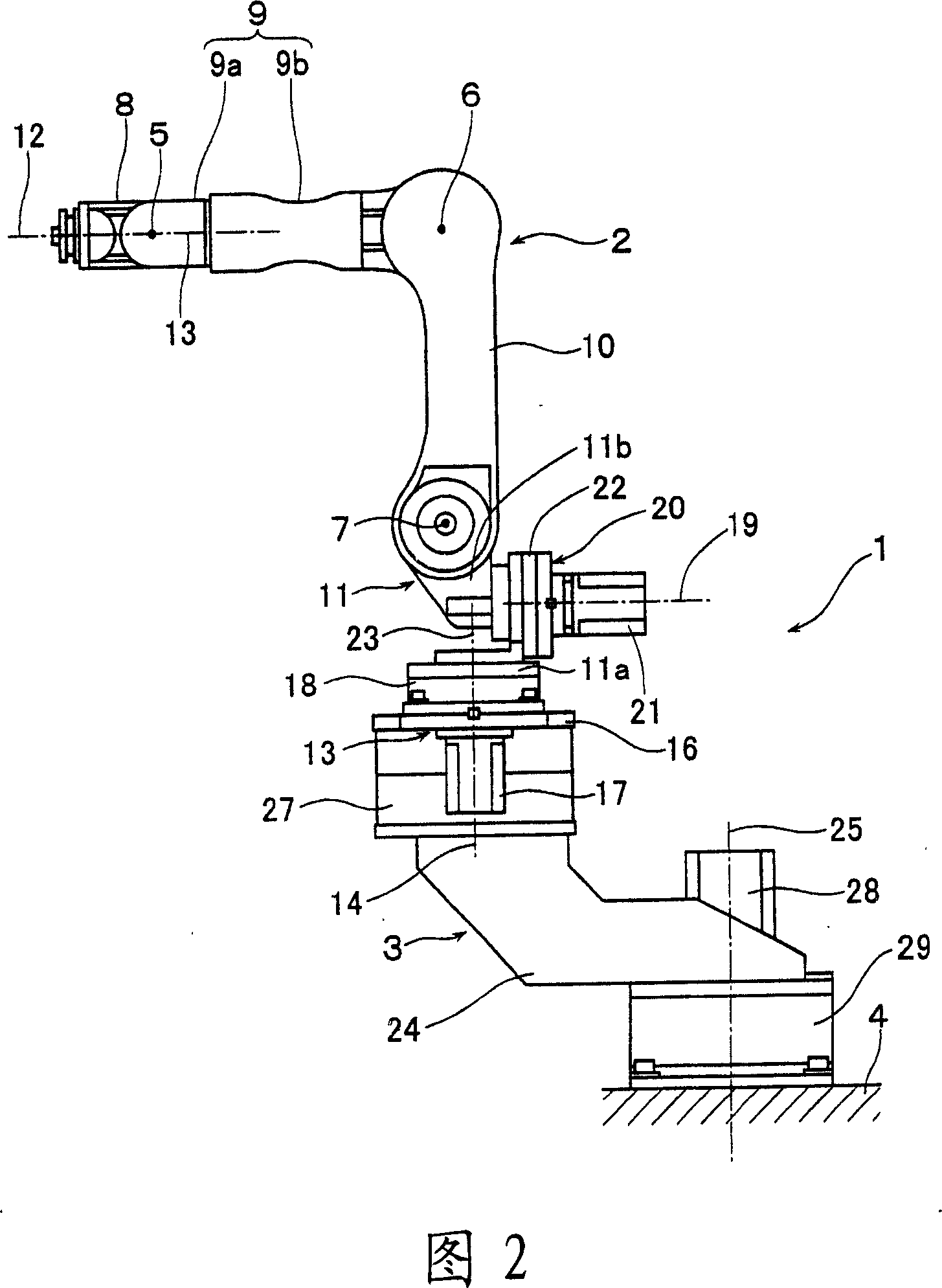

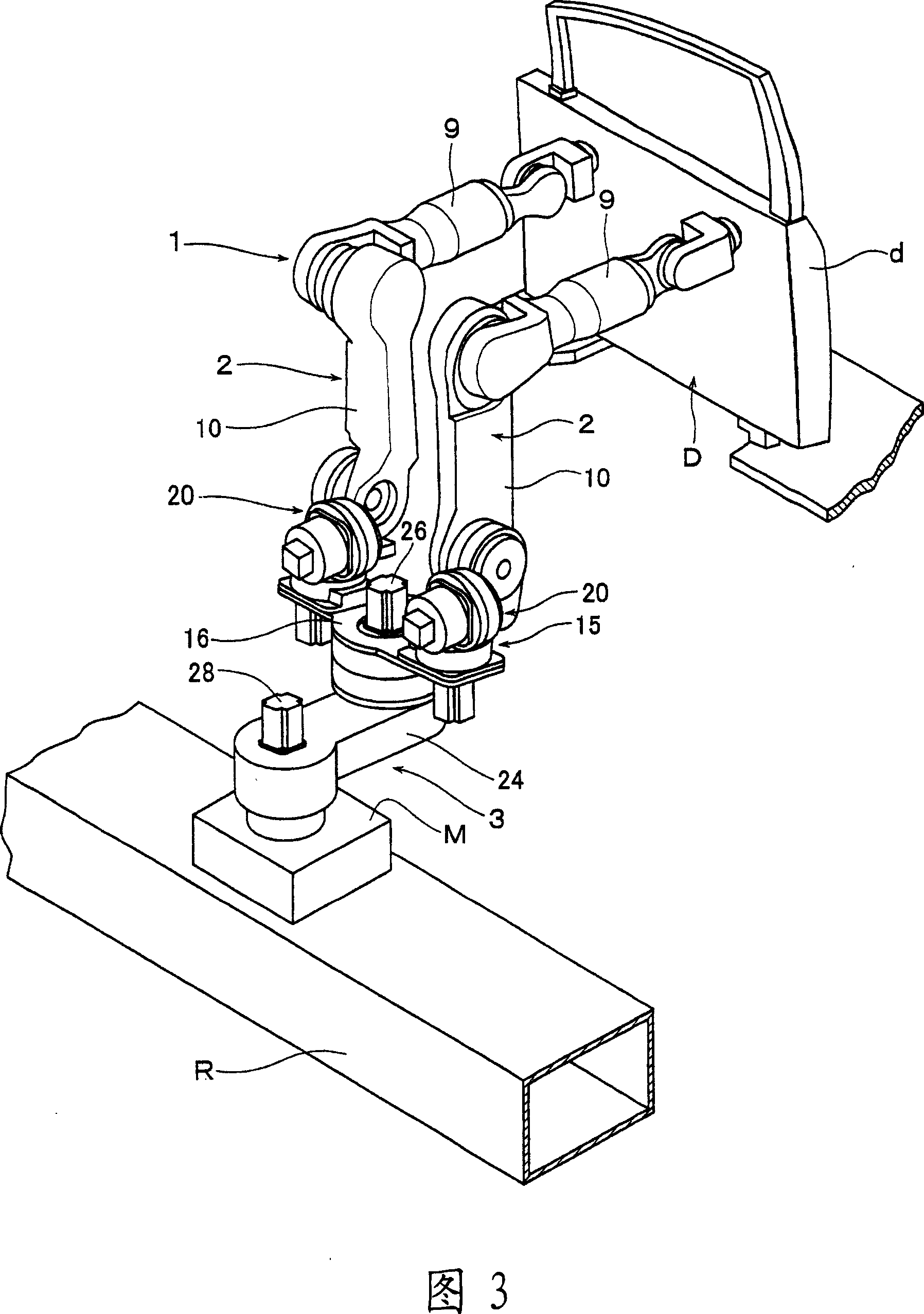

Processing and transferring apparatus

InactiveCN101035655AExtended range of movementIncrease freedomProgramme-controlled manipulatorVehiclesRotational axisEngineering

A processing and transferring apparatus (1) is provided with a first turning means (15), which is provided between a base end of a movable arm (2) and a base plate (16) so as to turn the movable arm (2) with a rotating axis (14) vertical to rotating axes (5, 6, 7) of a joint of the movable arm (2) at the center; and a second turning means (20), which is provided on a base end side arm piece (11) of the movable arm (2) so as to turn the movable arm (2) with a rotating axis (19) vertical to both a rotating axis (14) of the turning means (15) and the rotating axes (5, 6, 7) of the joint at the center.

Owner:HONDA MOTOR CO LTD

Clamping device of numerical control machine tool

InactiveCN105773211APrevent affecting processing qualityImprove clamping effectPrecision positioning equipmentExpansion mandrelsNumerical controlElectric machinery

The invention discloses a clamping device of a numerical control machine tool. The clamping device is wider in moving range, capable of clamping a plurality of workpieces at a time and conducting machining in turn and higher in working efficiency. The clamping device comprises a first base, wherein the first base is in sliding fit with a first moving plate, and a first screw rod is in internal thread fit with the first moving plate and is connected with a first driving motor arranged on the first base; the first moving plate is fixedly provided with a second base which is in sliding fit with a second moving plate, and a second screw rod is in internal thread fit the second moving plate and is connected with a second driving motor arranged on the second base; the second moving plate is provided with a mounting base, and the longitudinal direction of the mounting base is parallel to a second guide rail; the mounting base is provided with a third driving motor; a rotating shaft of the third driving motor is fixedly provided with a turntable on which four fixtures are arranged; the four fixtures form a square; and the intersection point of diagonals of the square is located on the axis of the first driving motor.

Owner:重庆丰德数控机床有限公司

Linear sliding block type rotary robot

InactiveCN105666480ALarge range of movementExtended range of movementProgramme-controlled manipulatorButt jointEngineering

The invention relates to the technical field of automatic machining equipment, in particular to a linear sliding block type rotary robot which comprises a fixed guide rail assembly, a slide rail arranged on the fixed guide rail assembly, a sliding block matched with the slide rail, and a moving part fixedly connected with the sliding block, wherein two adjacent fixed guide rail seats and slide rails on the fixed guide rail seats are all in linear butt joint; and a movable guide rail seat and a rail change driving mechanism used for driving the movable guide rail seat to laterally move are arranged at the end part of the fixed guide rail assembly. After multiple fixed guide rail seats are subjected to linear butt joint, under the control action of a driving coil, the moving part can move from one fixed guide rail seat to the other guide rail seat, so as to further widen the moving scope of the moving part, and workpiece transportation between two adjacent stations can be realized without special connecting equipment. The linear sliding block type rotary robot is used for column mounting of a production line, thus greatly reducing the occupation area and investment cost of the production line and having relatively high cost performance.

Owner:DONGGUAN SUMIDA AUTOMATION CO LTD

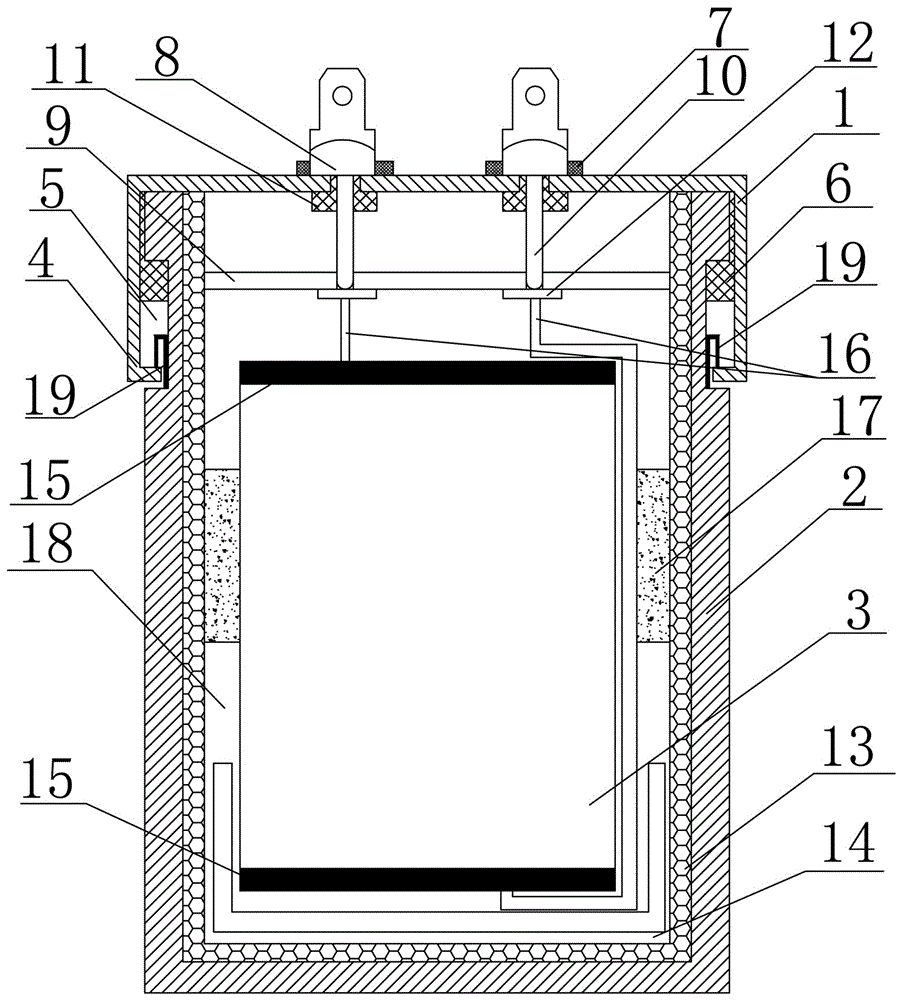

Anti-interference high-voltage metalized polypropylene film capacitor

ActiveCN105869884AImprove securityExtended range of movementThin/thick film capacitorFixed capacitor electrodesRubber ringHeat conducting

The invention discloses an anti-interference high-voltage metalized polypropylene film capacitor, which comprises a cover board (1), a housing (2) and a core body (3), wherein an annular bump (4) is formed in the inner wall of an opening of the cover board (1); an annular groove (5) is formed in the upper part of the housing (2); the annular bump (4) is arranged in the annular groove (5) and can longitudinally move in the annular groove (5); an elastic seal ring (6) is arranged between the inner wall of the lower part of the cover board (1) and the outer wall of the upper part of the housing (2); an elastic rubber ring (19) is fixedly connected between the annular bump (4) and the bottom part of the annular groove (5); a buffer layer (13) is arranged at the inner wall of the housing (2); a core body (3) is arranged in the housing (2); a positioning sleeve (14) is arranged at the bottom part of the core body (3); an elastic washer (17) registered in the middle part of the core body (3); and insulated heat-conducting oil (18) is sealed between the housing (2) and the core body (3). The capacitor is high in breakdown voltage, anti-interference, safe, stable and long in service lifetime.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

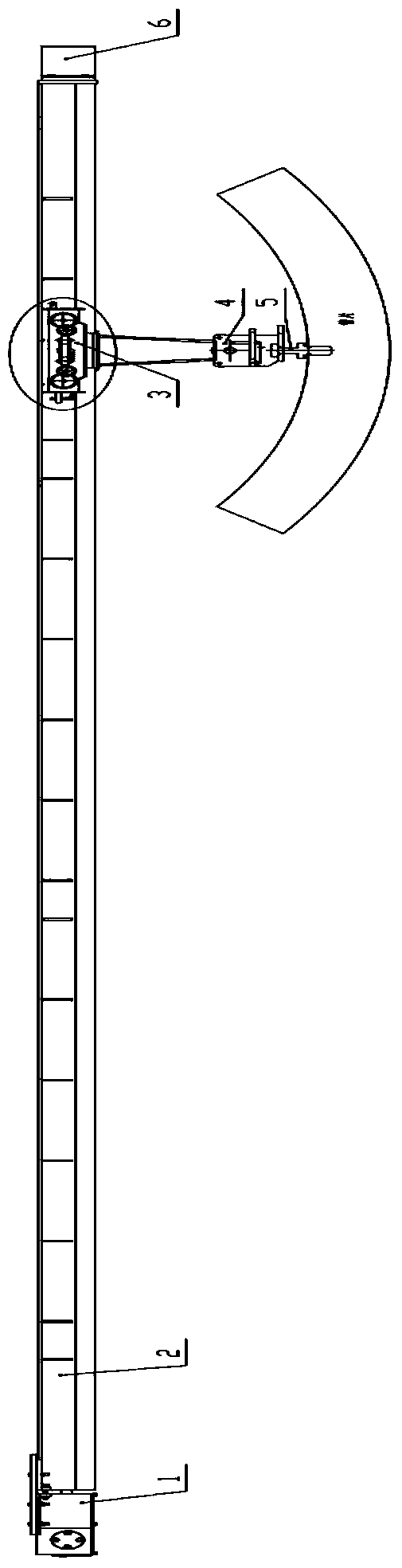

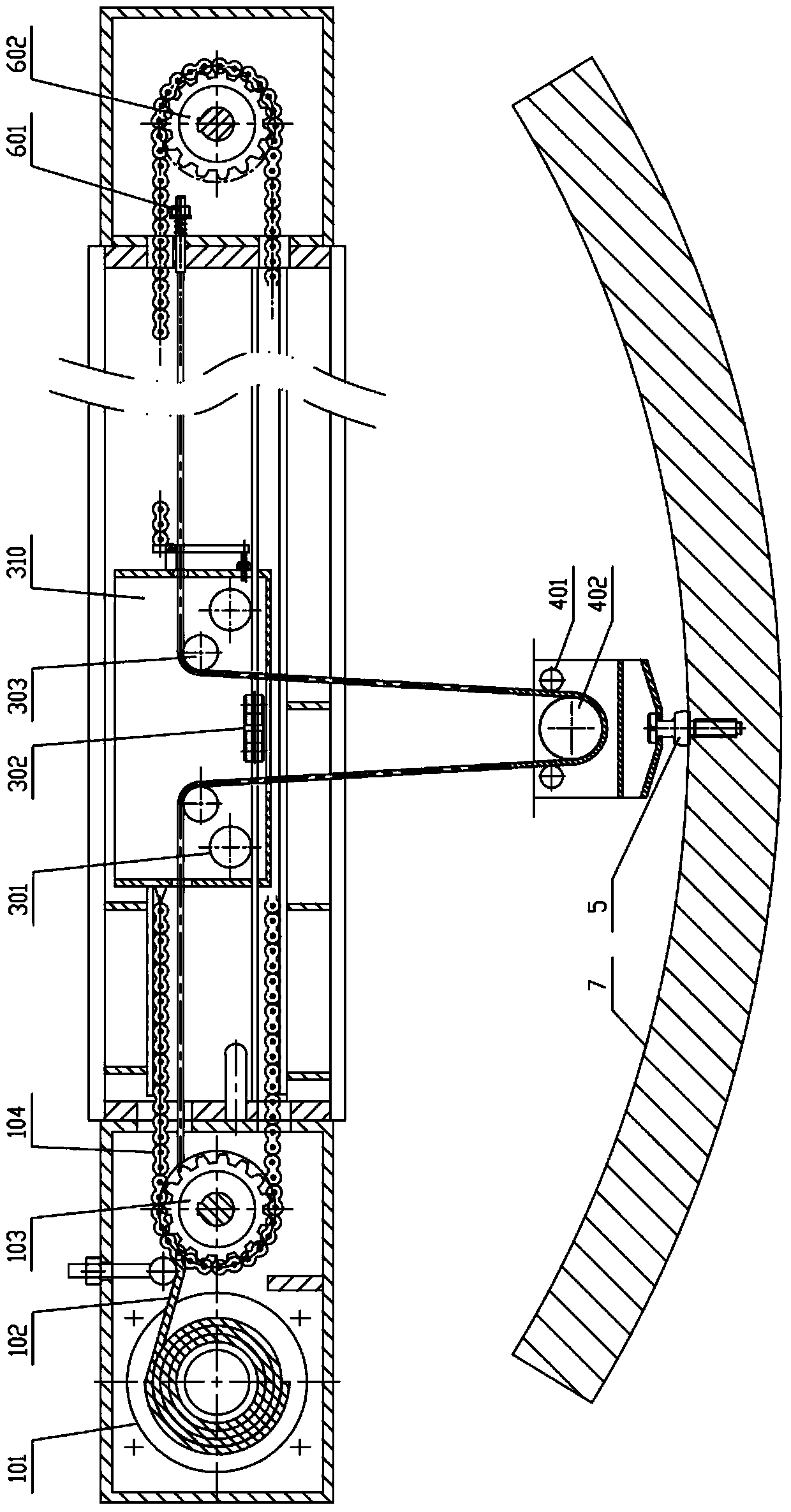

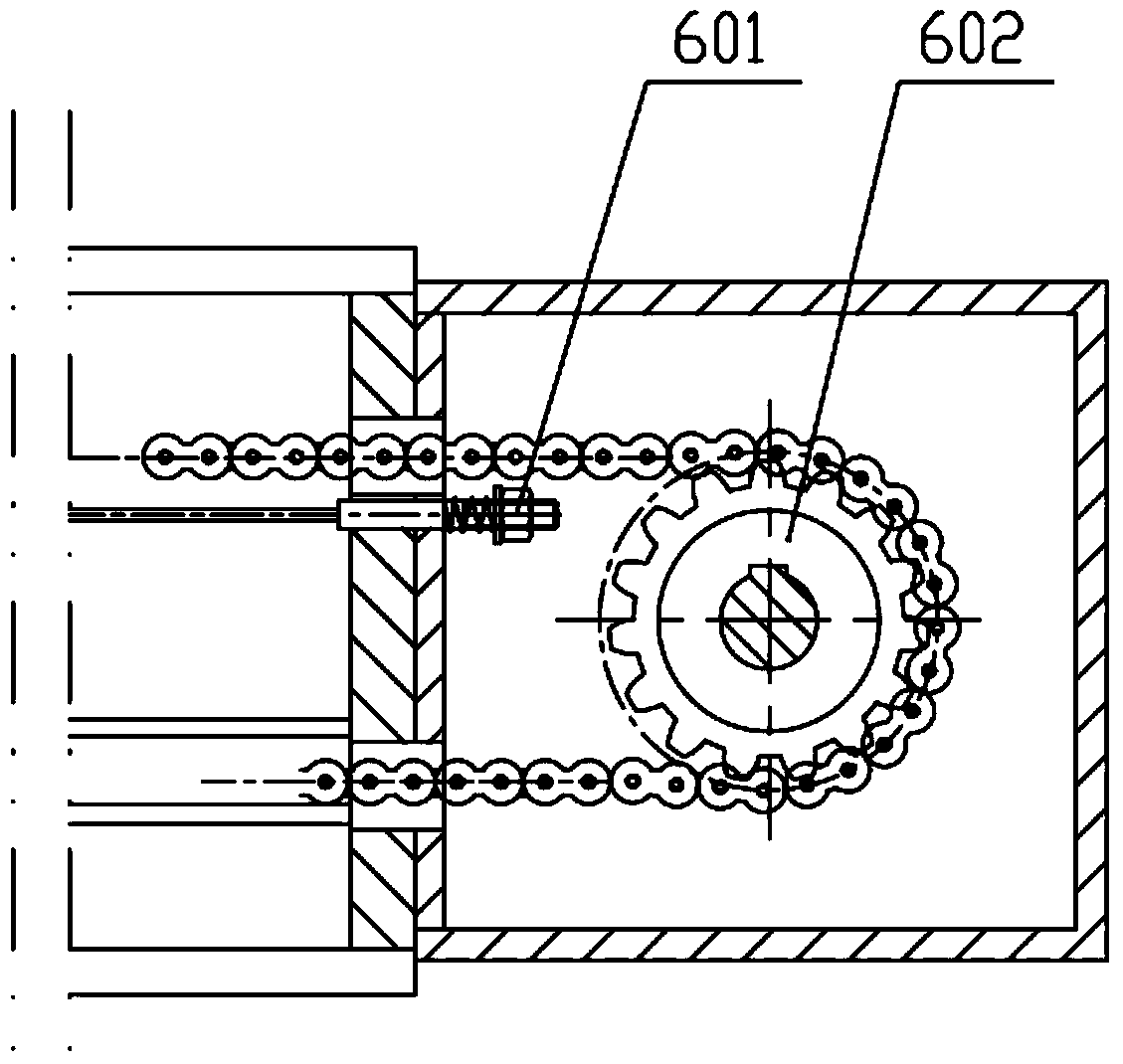

Small steel shot feeding circulator and numerical control metal surface treating machine using the same

The invention relates to a small steel shot feeding circulator, which comprises a feeding motor, a dual-layer sprocket, double chains and a plurality of feeding funnels, and is characterized in that a box body is arranged, an impeller head installation space is arranged in the box body, and a steel shot window and a seal guard are arranged on the front wall of the box body; and the feeding motor, the dual-layer sprocket, the double chains and the feeding funnels are arranged in the box body around the impeller head, a feed hopper and a return hopper are arranged, and steel shots are delivered to the feed hopper through the feeding funnels. The invention additionally relates to a numerical control metal surface treating machine, which comprises a traveling base, an operating room, a control cabinet, a hydraulic station, a dust catcher, the impeller head, a movable supporting arm and a steel shot feeding circulating system, and is characterized in that the steel shot feeding circulating system is the small steel shot feeding circulator, the two-dimensional movable supporting arm is adopted, and a plus or minus 180-degree rotating platform is arranged on the traveling base. The invention has the advantages that the volume is small and the weight is light, the structure is simplified, the moving range of the impeller head is widened, the operation flexibility of the entire machine is improved, the safety stability is improved, the cost is reduced and the application scope is widened.

Owner:天津新技术产业园区北洋世纪焊接技术有限公司

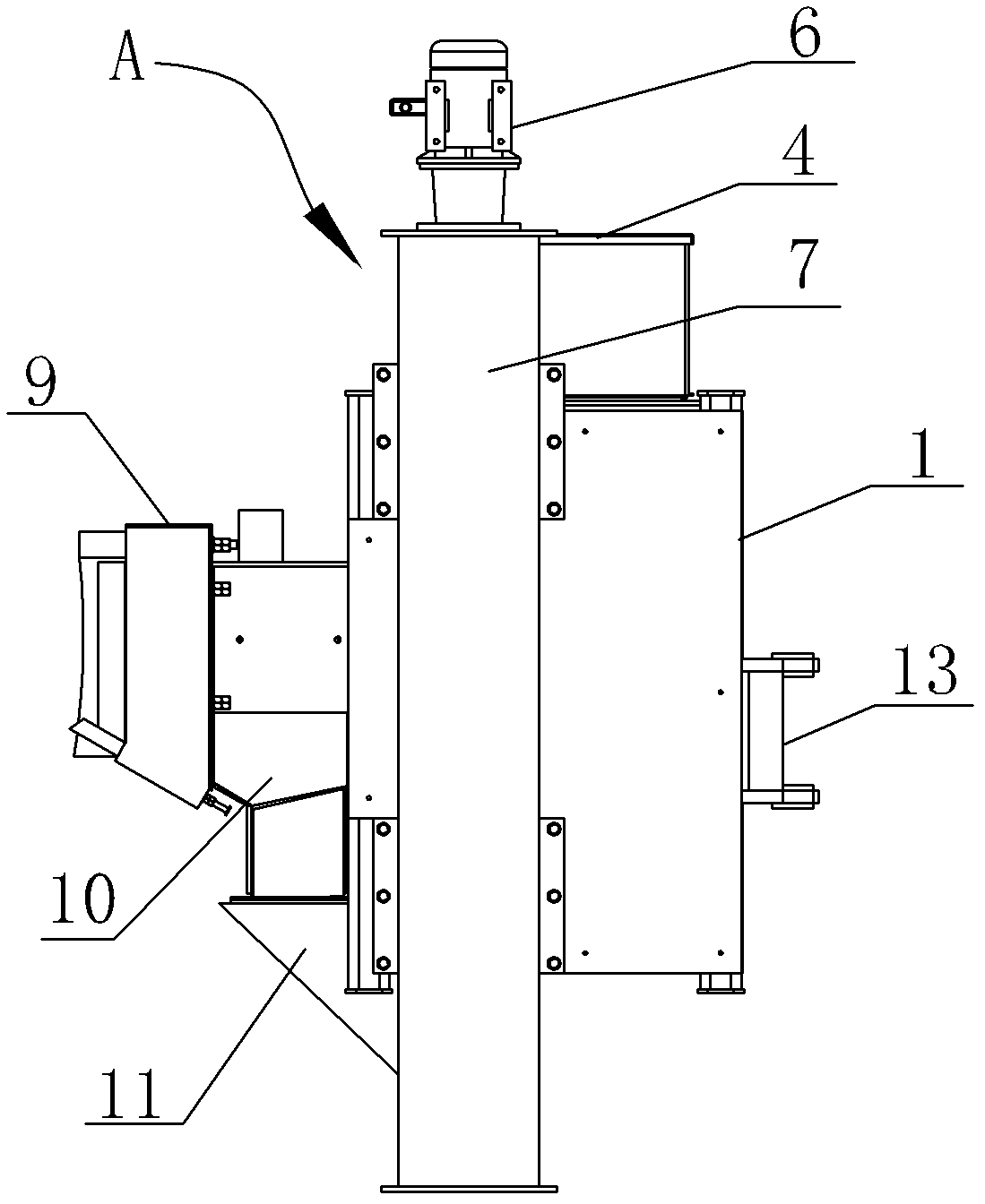

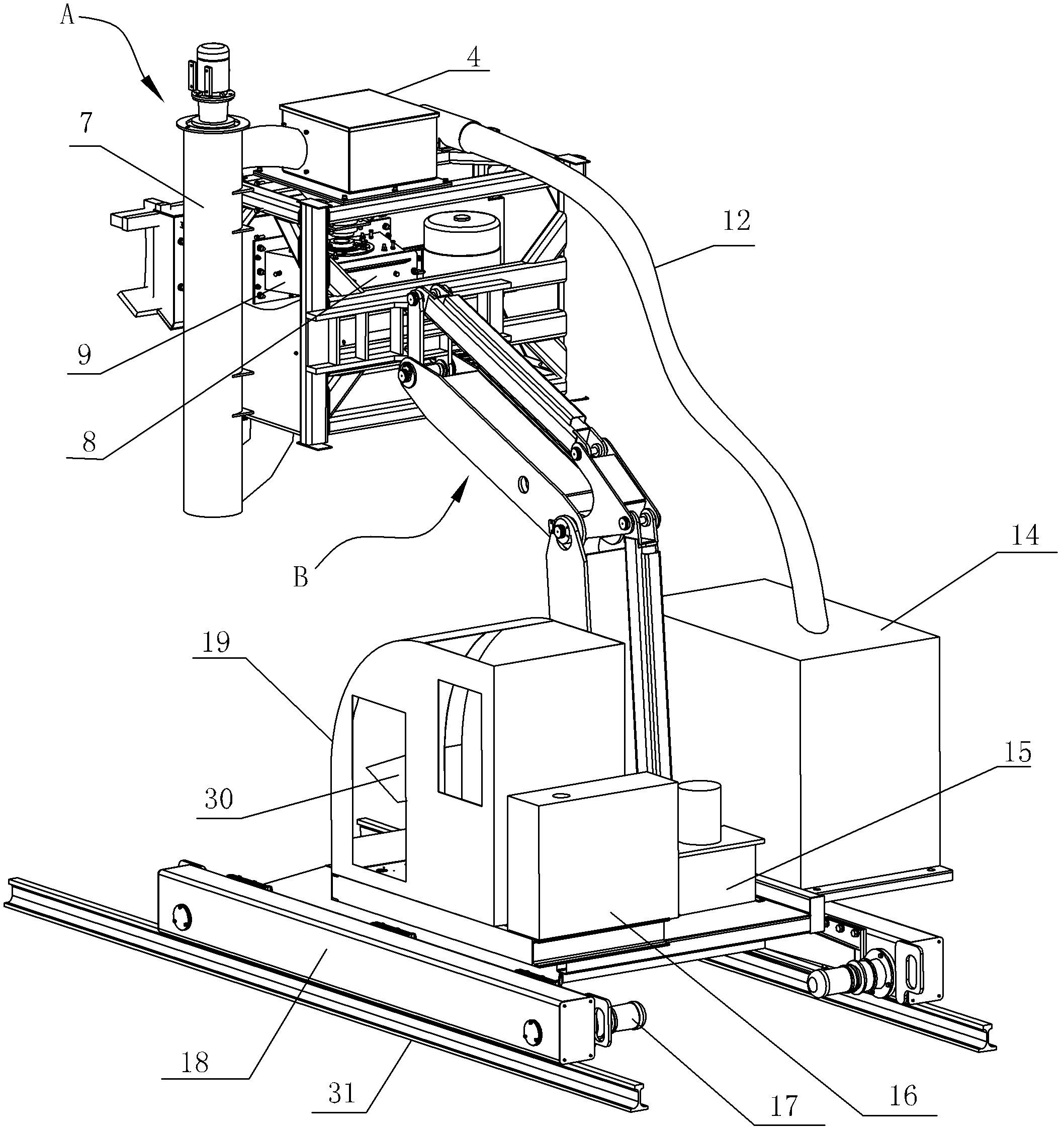

Auger type steel shot feeding circulator, and metal surface treating apparatus by using the same

The invention relates to an auger type steel shot feeding circulator. The auger type steel shot feeding circulator comprises a box body. A shot blasting machine installation space is arranged in the box body, and a shot blasting window and a seal protecting cover are arranged on the front wall of the box body. A material feeding hopper is arranged on the top of the box body, and is connected with a shot blasting machine material inlet through a material inlet pipe. A material returning hopper is arranged on the lower portion of the seal protecting cover. The auger type steel shot feeding circulator is characterized in that: an auger is vertically arranged on an outer side of the box body; a material inlet arranged on the bottom of the auger is communicated with the material returning hopper; a material inlet arranged on the top of the auger is communicated with the material feeding hopper; the steel shot are delivered from the material returning hopper to the material feeding hopper through the auger. A metal surface treating apparatus comprises a traveling base, an operating room, a control cabinet, a hydraulic station, a dust catcher, the shot blasting machine, a movable supporting arm and a steel shot feeding circulator. The metal surface treating apparatus is characterized in that: the steel shot feeding circulator adopts the auger type steel shot feeding circulator provided by the present invention; the two-dimensional movable supporting arm is adopted. The auger type steel shot feeding circulator provided by the present invention has advantages of high structure strength, large amount of the shot blasting, low failure rate, simplified maintenance, improvement of working stability, convenient and flexible operation, and prolonged working life.

Owner:天津圣弘业环保科技有限公司

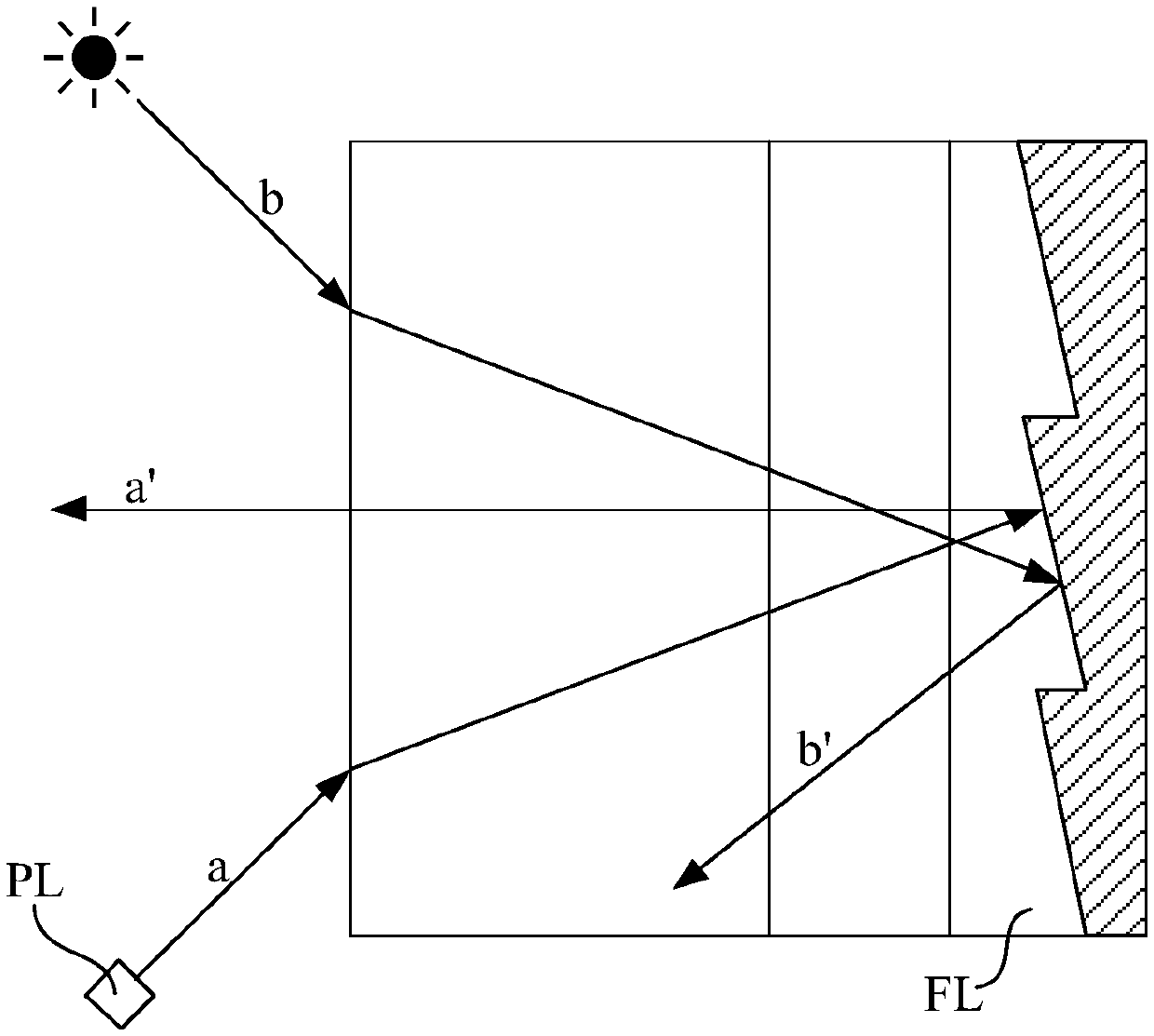

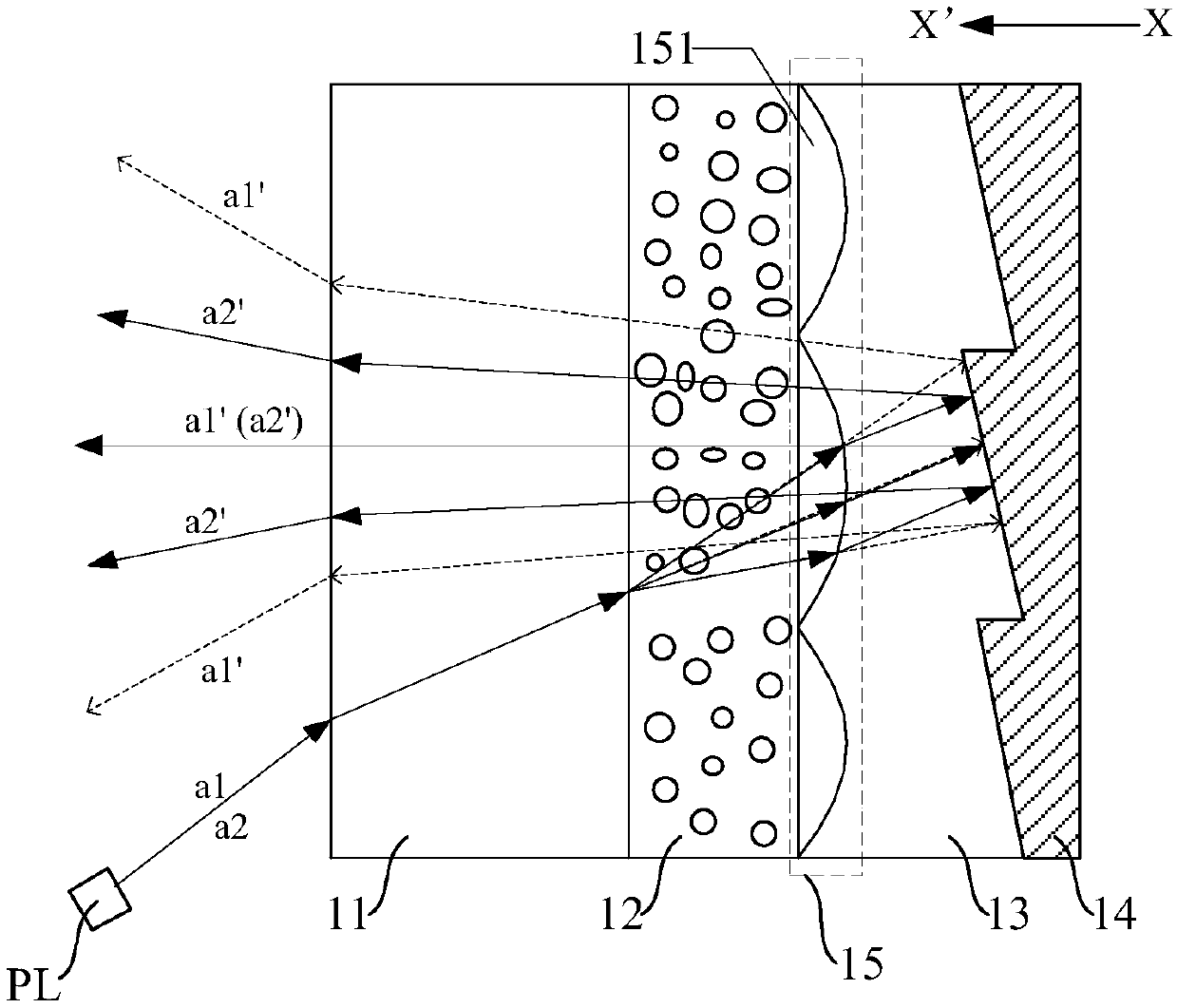

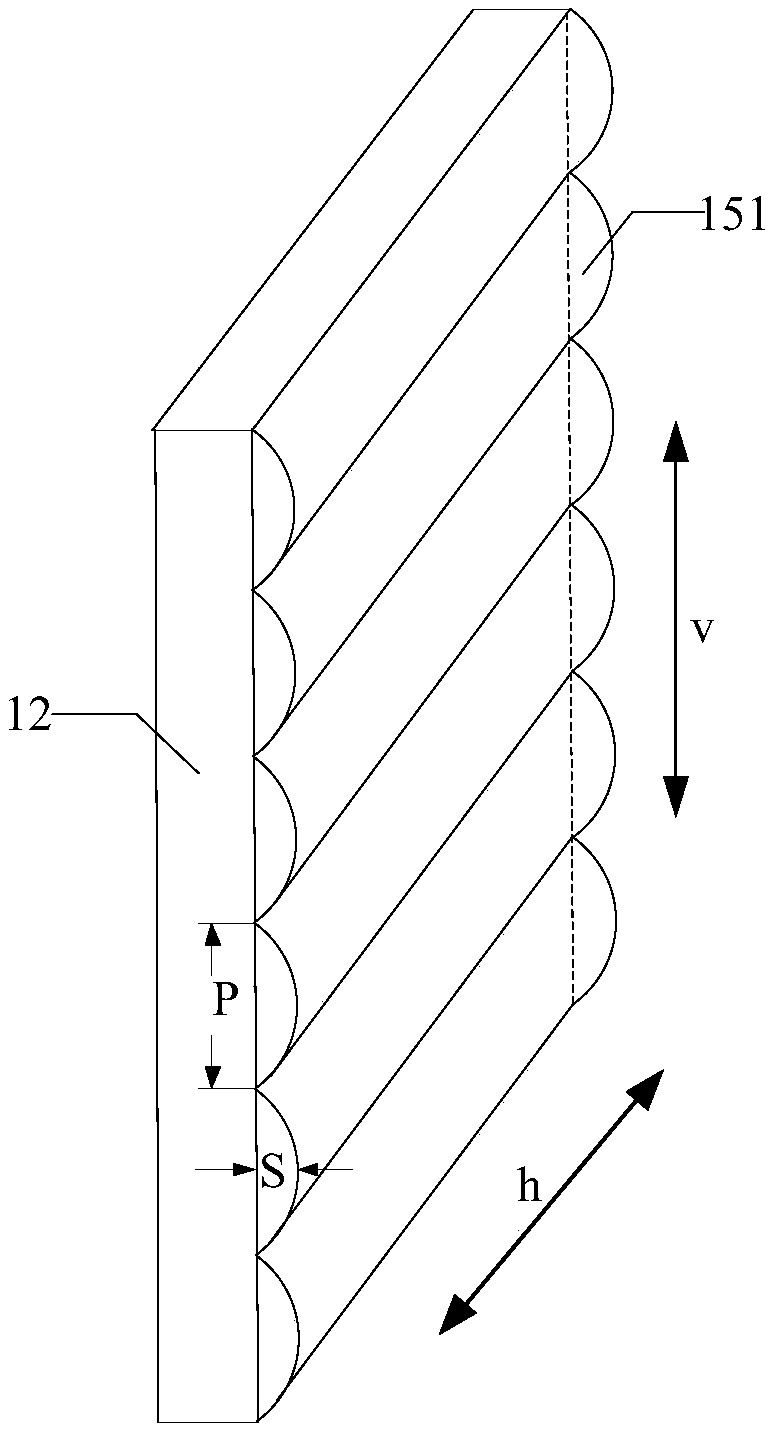

Projection screen and projection system

ActiveCN110412825AExtended range of movementImprove viewing experienceProjectorsFresnel lensProjection screen

The invention discloses a projection screen and a projection system. The projection screen comprises a light transmitting layer, a diffusion layer, a Fresnel lens layer and a reflective layer that arearranged in sequence along an incident direction of light, and further comprises a prism layer between the light transmitting layer and the Fresnel lens layer. The prism layer comprises a plurality of raised ribs extending in a horizontal direction of the projection screen and is used to converge incident light in a direction perpendicular to the extending direction of the raised ribs. The prismlayer can converge the light incoming to the projection screen in a direction perpendicular to the extending direction of the raised ribs, namely, a viewing angle in a vertical direction becomes smaller, so that a viewing angle in the extending direction of the raised ribs becomes larger according to the law of conservation of energy. Therefore, as long as the raised ribs are extended in a direction in which a viewing angle needs to be enlarged, the viewing angle in the direction can be enlarged, allowing a viewer to have a larger moving range within the viewing angle and view an image in theprojection screen in the viewing angle more clearly.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

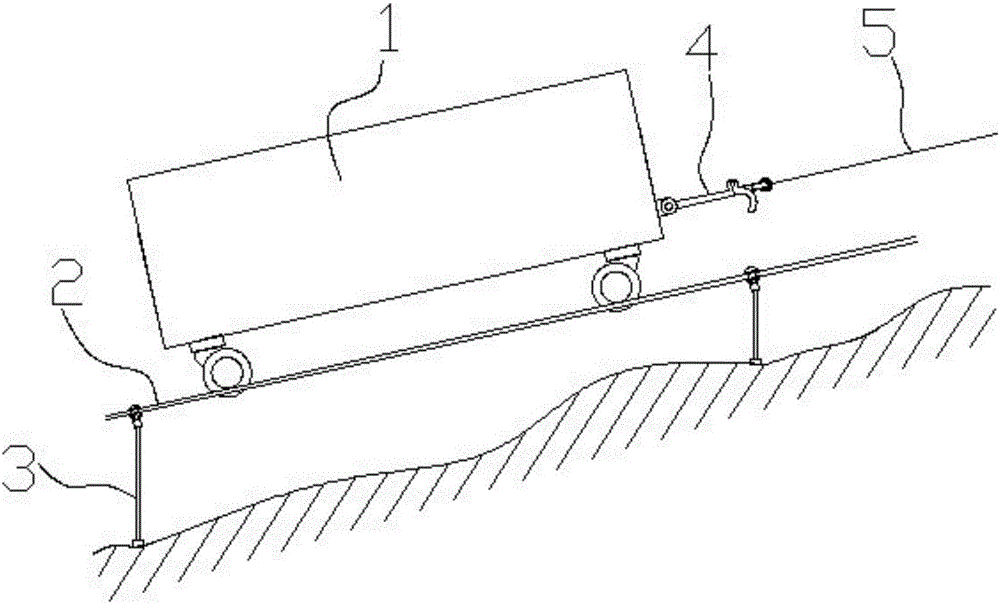

Steel wire rail transportation mechanical equipment system for mountain land

ActiveCN106241235AImprove smoothness of movementExtended range of movementMechanical conveyorsMechanical equipmentFlange

The invention discloses a steel wire rail transportation mechanical equipment system for mountain land. The system comprises travelling mechanisms at the bottom a compartment. The travelling mechanisms travel on steel cable tracks. The steel cable tracks are mounted on the mountain land through track fixing devices. The compartment is connected with a traction machine through a traction steel cable. Each pair of travelling mechanisms comprise two mounting bases. A rotating head is arranged at the lower end of each mounting base. A cylindrical rolling wheel is arranged at the lower end of each rotating head. A flange disc is arranged at one end of each cylindrical rolling wheel. Each rotating head is provided with an oriented steel wire rope. An extension spring is connected between every two oriented steel wire ropes. Each track fixing device comprises a steel cable fixing bracket and a ground fixing bracket. Each steel cable fixing bracket and the corresponding ground fixing bracket are tensioned through tensioning steel cables. The steel cable fixing brackets are uniformly arranged between the steel cable tracks. Clamping devices are arranged at the two ends of each steel cable fixing bracket, and an auxiliary rolling wheel is arranged in the middle of each steel cable fixing bracket. By means of the steel wire rail transportation mechanical equipment system for the mountain land, suspended transportation conducted between the mountain land and a road is achieved; efficiency of transporting goods and materials among areas of the mountain land can be greatly improved; labor intensity is lowered; and the system is easy to operate and stable in operation.

Owner:钦永富

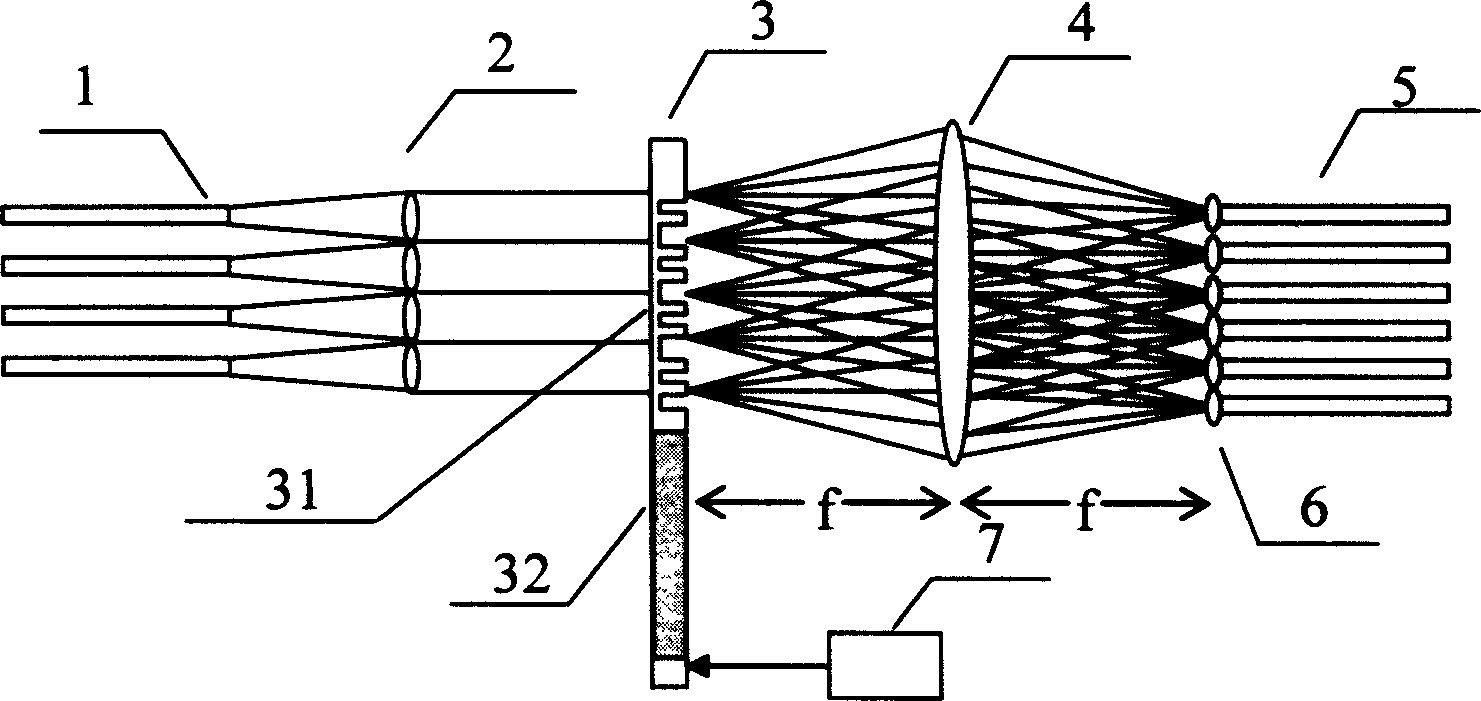

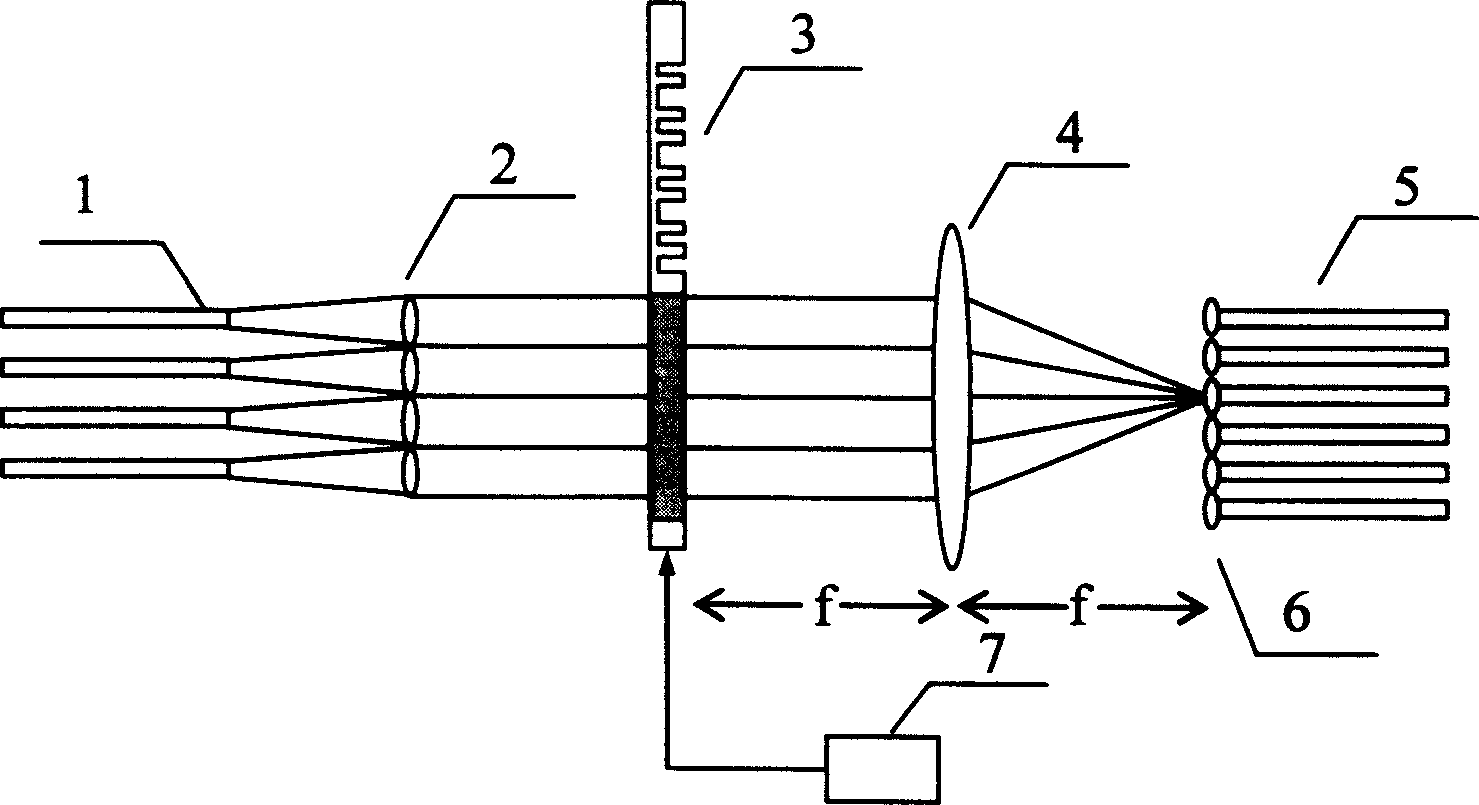

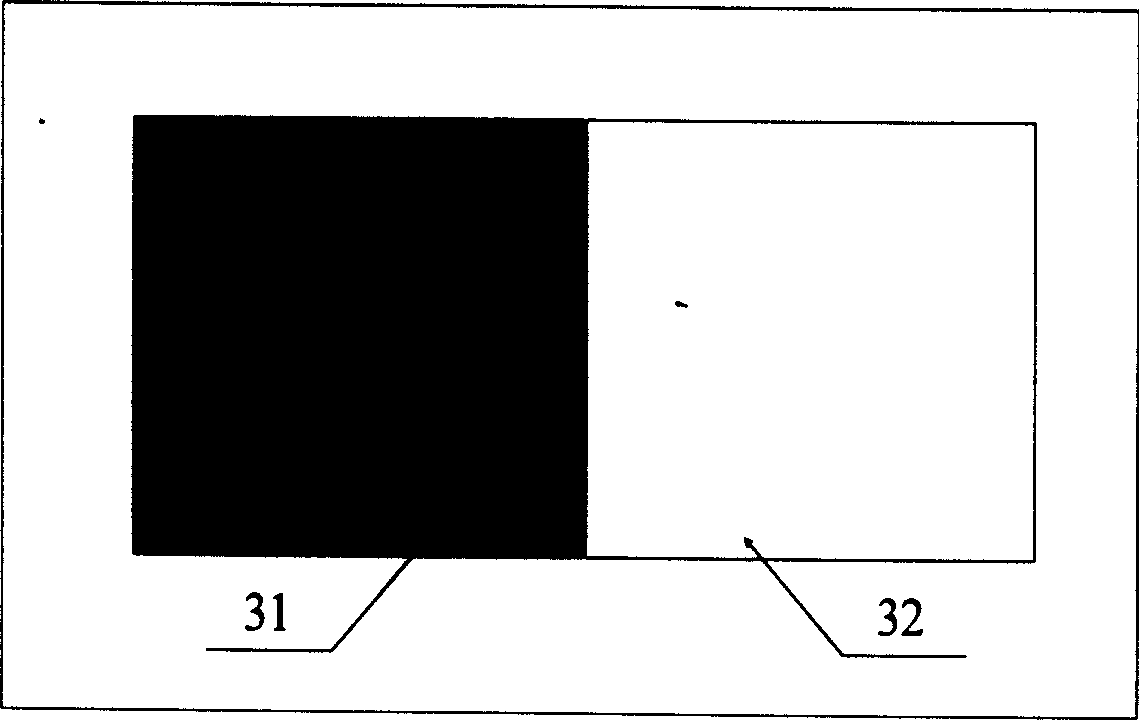

Dynamic light coupler

InactiveCN1584646AImplement beam splittingRealize dynamic conversionCoupling light guidesGratingNumerical aperture

A dynamic light coupler consists of input optical fibre set, collimation lens set, Daman grating phase plate, convergent lens and output optical fibre set in sequence on one light path. It is featured as setting input optical fibre set on front focal plane of collimation lens, phase plate at back focal plane, output optical fibre set on back focal plane of convergent lens; overlapping convergent lens front focal plane to back focal plane of collimation lens set.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Bridge erecting machine

InactiveCN104863062AImprove stability and reliabilityExtended range of movementBridge erection/assemblyAerospace engineering

The invention discloses a bridge erecting machine. The bridge erecting machine comprises a main girder, a large vehicle track, a rear landing leg, a front landing leg, an auxiliary landing leg and hoisting mechanisms, wherein one end of the large vehicle track is arranged on a first supporting pile; the rear landing leg is arranged at the rear part of the main girder and is arranged on the large vehicle track, and jacking horizontal movement supporting assemblies are arranged on the rear landing leg; one end of the front landing leg is arranged on a second supporting pile, the other end of the front landing leg is arranged on the main girder, and a horizontal movement mechanism is arranged on the front landing leg; a bended supporting girder is connected to the front end of the main girder, and the bended supporting girder extends to the inner side of the main girder; one end of the auxiliary landing leg is arranged on the bended supporting girder, and the other end of the auxiliary landing leg is arranged on a third supporting pile. According to the bridge erecting machine, the bended supporting girder is additionally arranged at the end of the main girder, so that the stability and the reliability are improved; the hoisting mechanism can operate to the front end of the bended supporting girder along the main girder, so that the moving range of a lifting girder piece is enlarged, and a bridge is convenient to erect.

Owner:WUXI XIEXING PORT MACHINERY

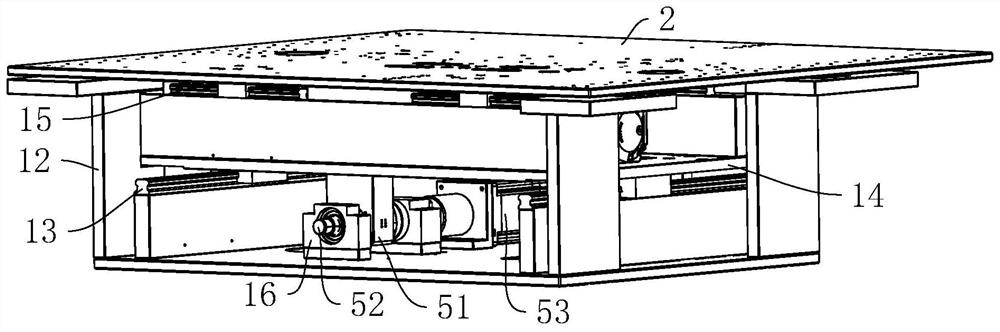

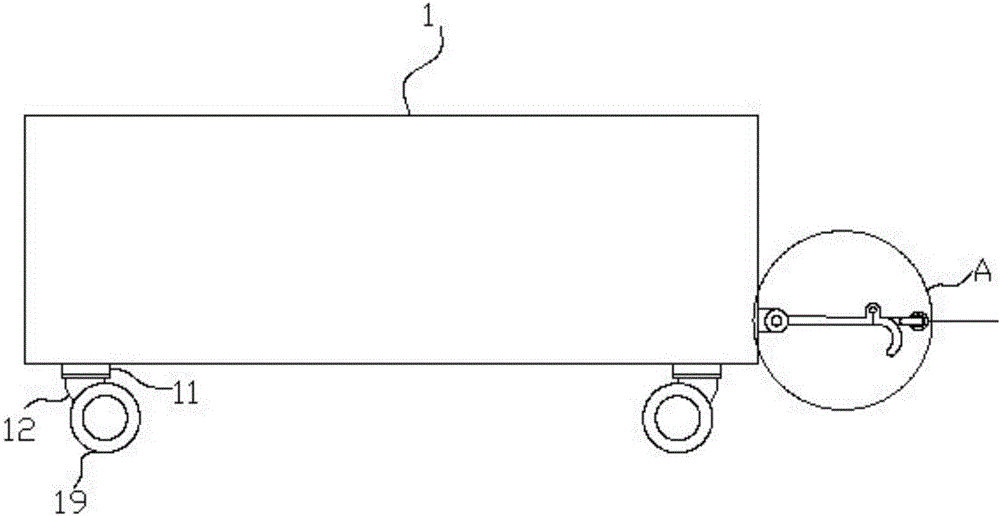

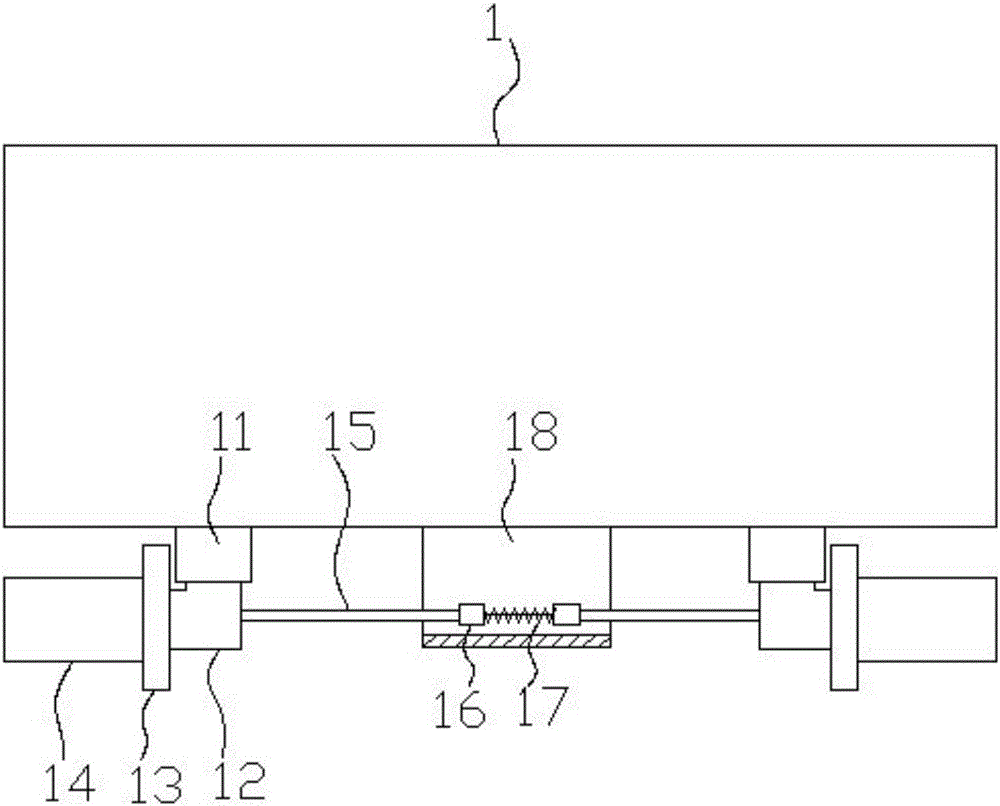

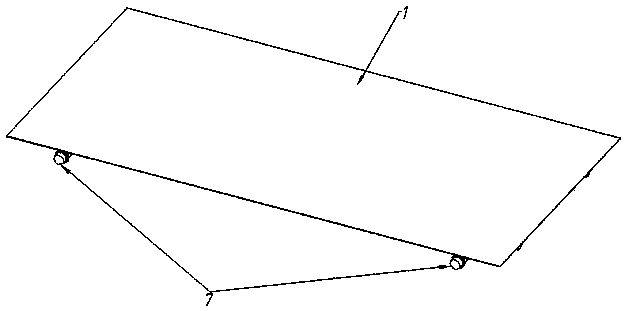

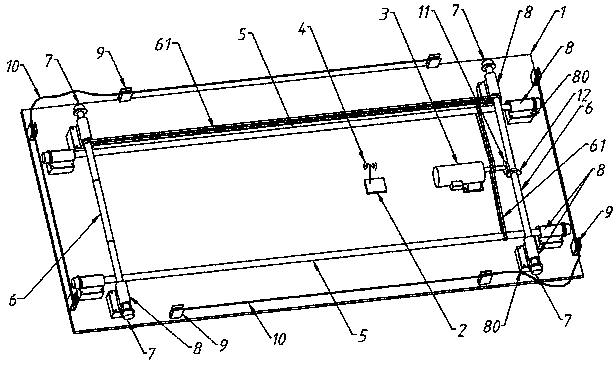

Intelligent vehicle carrying plate

The invention discloses an intelligent vehicle carrying plate, and aims to provide an intelligent vehicle carrying plate which is compact in structure, convenient to maintain and capable of moving horizontally and vertically, enables vehicle parking and picking to be fast and can be controlled wirelessly. The intelligent vehicle carrying plate comprises a parking plate body (1), a controller (2), a motor (3), a wireless communication module (4), a plurality of X-axis rotation shafts (5) and a plurality of Y-axis rotation shafts (6). The X-axis rotation shafts (5) and the Y-axis rotation shafts (6) are perpendicular in different planes and are in driving connection with the motor (3), the two ends of each X-axis rotation shaft (5) and the two ends of each Y-axis rotation shaft (6) are respectively provided with a travelling wheel (7), a supporting base (8) is further arranged below the parking plate body (1) and a lifting mechanism (80) is arranged between the supporting base (8) and the parking plate body (1). The intelligent vehicle carrying plate is applied to the technical field of intelligent parking lot construction.

Owner:易泽怀

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com