Automatic packaging machine for bulk materials

An automatic packaging machine and bulk material technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of unstable clamping, uneven sewing, and affecting the transportation of packaging bags, so as to ensure the effect of clamping, Enhance the clamping effect and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

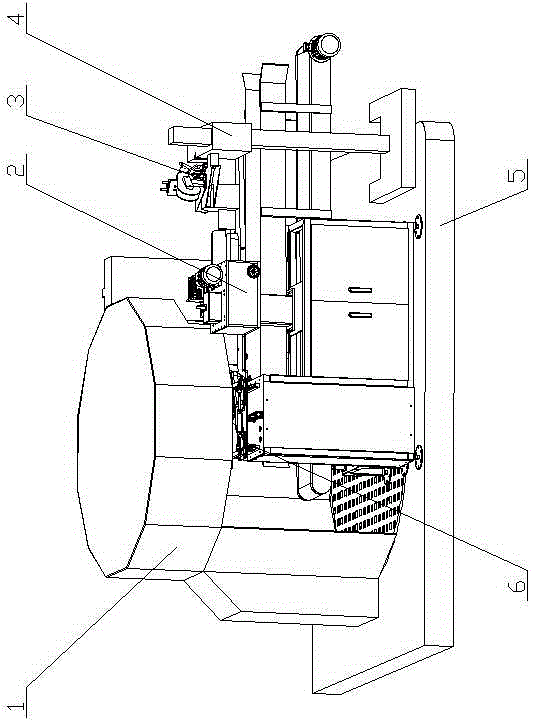

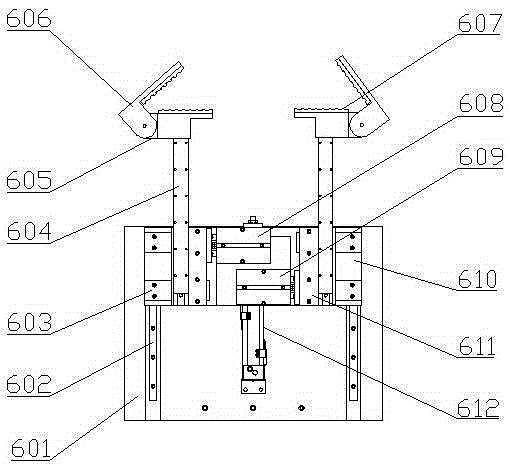

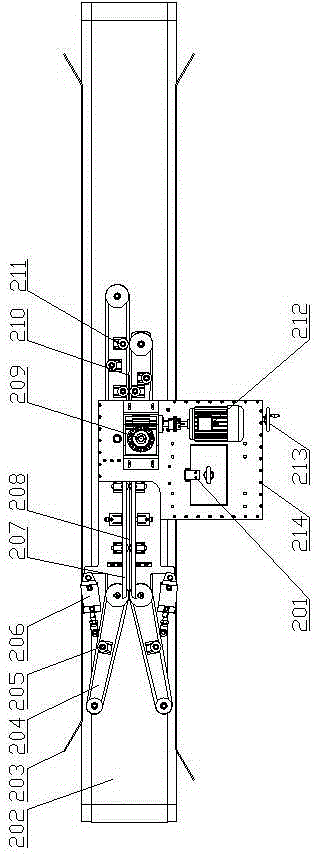

[0016] Automatic packaging machines for bulk materials such as Figure 1-6 As shown, it includes a base 5, a multi-station blanking structure 1, a manipulator structure 6, a conveying system 2, an automatic label feeder 3, a bag sewing machine 4 and a control system that are sequentially arranged on the base 5, and the control system transmits control signals to each components to control each process; the manipulator structure 6 includes a fixed platform 601, a pair of longitudinal slide rails 602 are arranged in parallel on the fixed platform 601, and a supporting plate 610 is arranged on the longitudinal slide rails 602; a longitudinal cylinder 612 is also fixed on the fixed platform 601 , the longitudinal cylinder 612 is connected with the supporting plate 610; the supporting plate 610 is provided with a transverse slide rail 603, and the transverse slide rail 603 is provided with a pair of mechanical arms 604, and the mechanical arm 604 is connected with a mechanical clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com