Auger type steel shot feeding circulator, and metal surface treating apparatus by using the same

A circulator and auger-type technology, applied in the direction of abrasive feeding devices, metal processing equipment, abrasives, etc., can solve the problems of easy damage, short working life, high failure rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

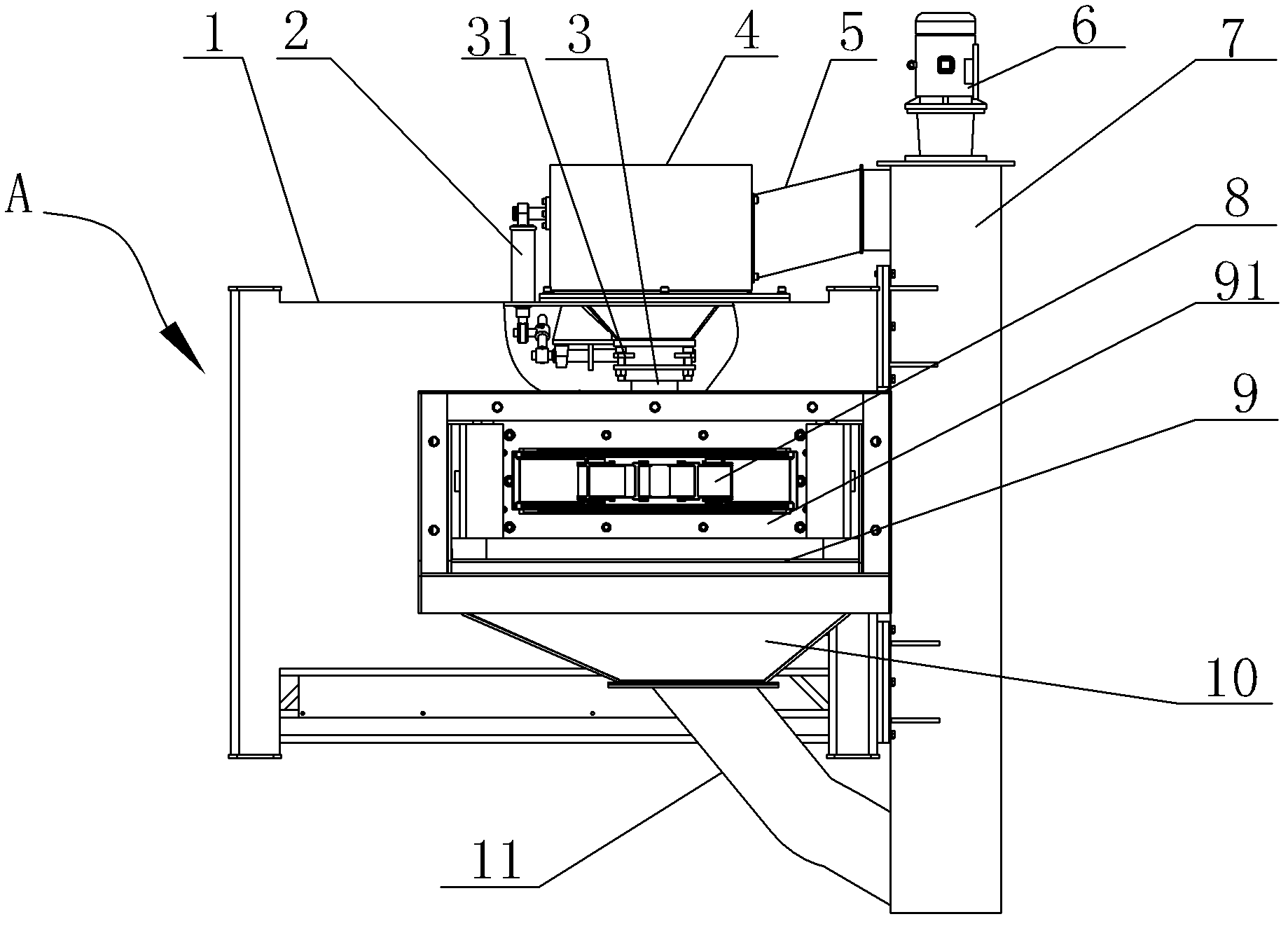

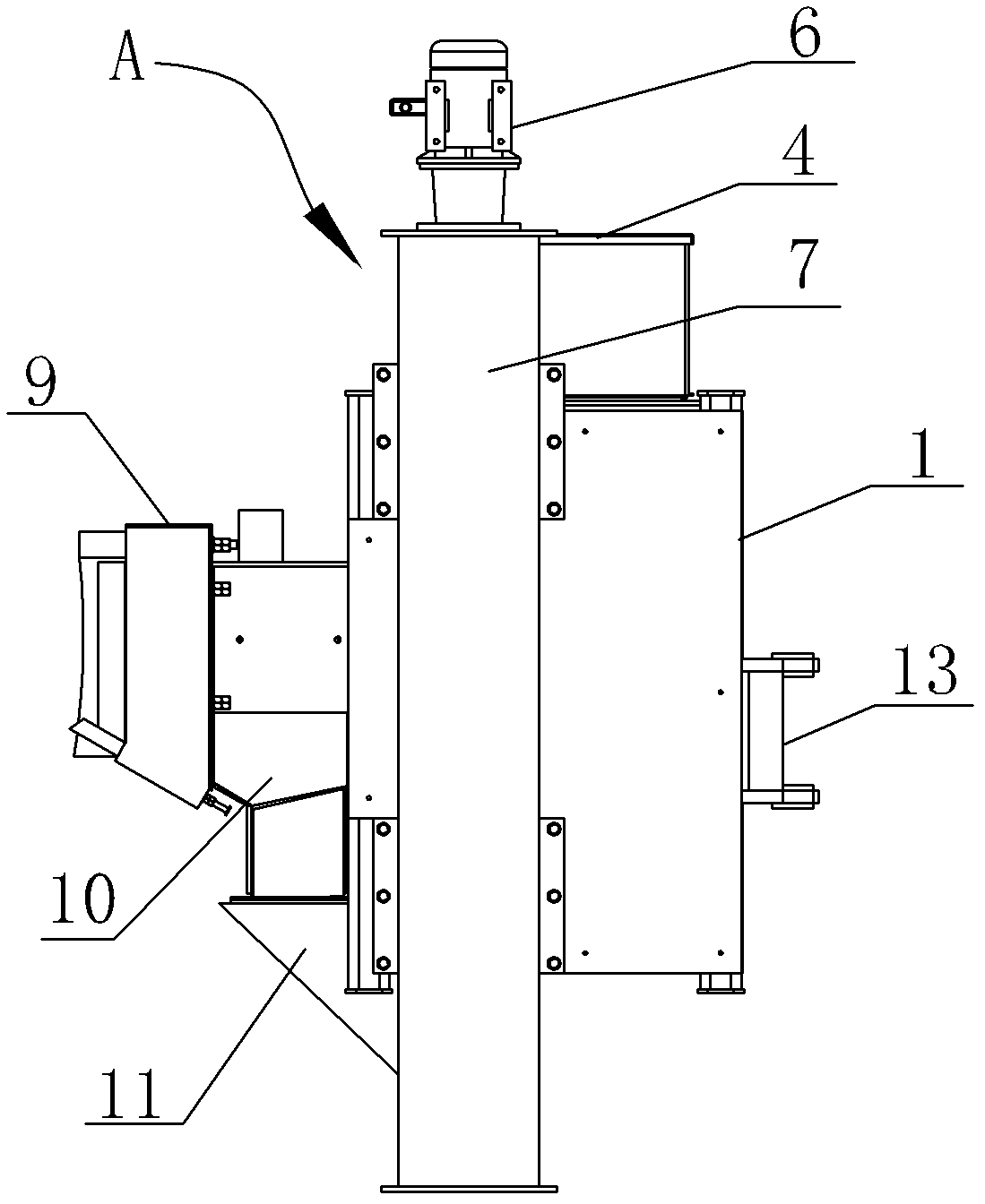

[0021] Figure 1 ~ Figure 2 Shown is an auger-type steel shot feeding circulator A, comprising a box body 1, the interior of the box body 1 is provided with a shot blasting device installation space, and the front wall of the box body corresponding to the shot blasting device 8 is provided with a shot blasting window 91 and Stretch out the sealing shield 9 of casing, be provided with feed hopper 4 at casing top, above-mentioned feed hopper 4 is connected with the feed inlet of shot blasting device 8 by the feed pipe 3 that is provided with flow control valve 31; The lower part of the cover 9 is provided with a return hopper 10, which is characterized in that an auger 7 is vertically arranged on the outer side of the box body 1, and the feed port at the bottom of the auger 7 communicates with the above-mentioned return hopper 10 through a return pipe 11, and the outlet of the auger top is The feed port communicates with the above-mentioned supply hopper 4 through the feed pipe ...

Embodiment 2

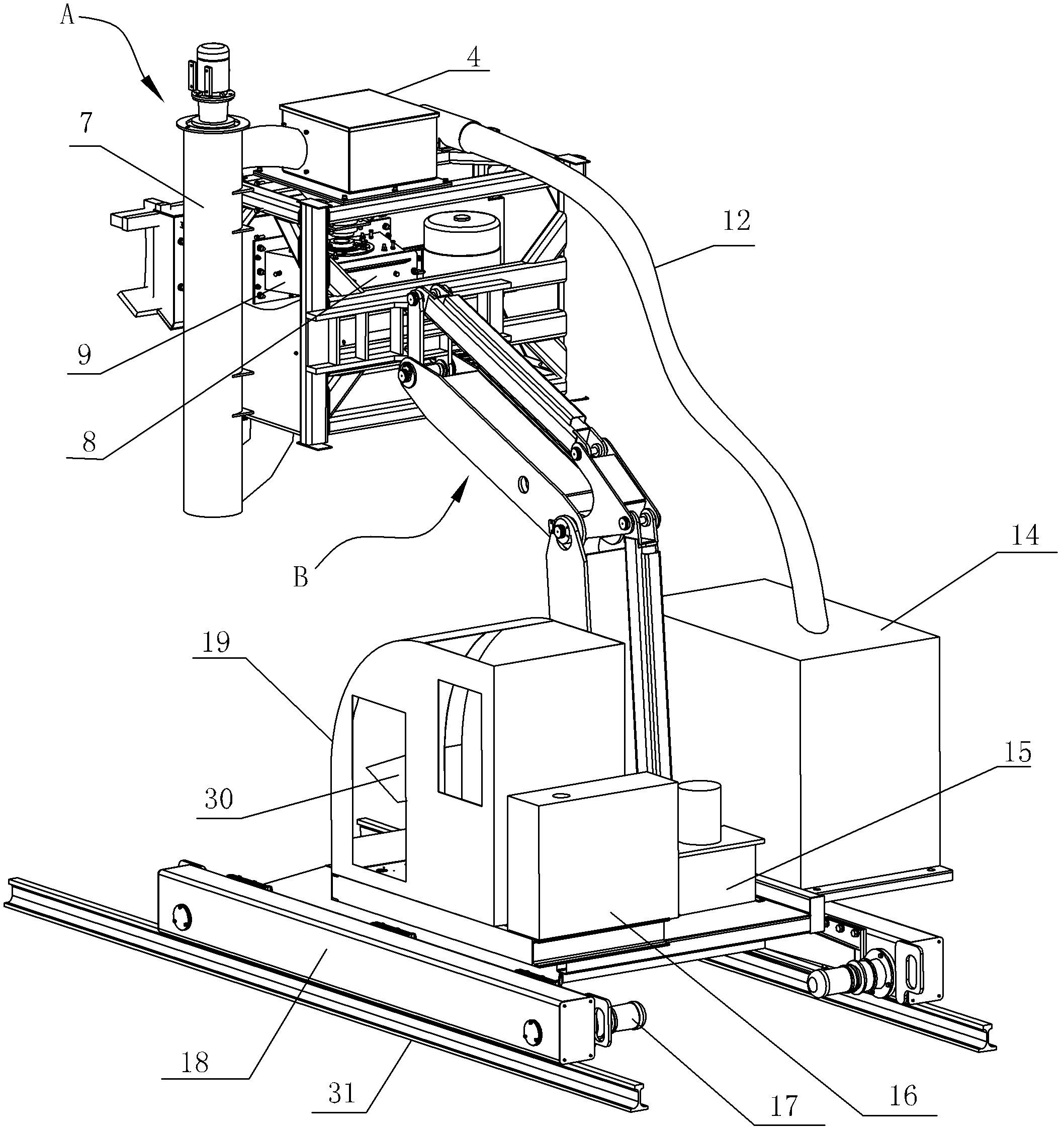

[0024] Figure 3 ~ Figure 5 It shows a metal surface treatment machine, including a walking base 18, an operating room 19, a control box 16, a hydraulic station 15, a dust collector 14, a shot blaster 8, a mobile support arm B for controlling the position of the shot blaster, and steel shot feed Circulator, the above-mentioned shot blasting device 8 is installed in the steel shot feeding circulator, and the above-mentioned operation room 19, control box 16, hydraulic station 15, dust collector 14 and mobile support arm B are arranged on the walking base 18, in this embodiment , the mobile support arm B adopts a double four-link type two-dimensional mobile support arm that can move up and down, forward and backward. The operating room 19 is electrically connected with the dust remover 14, the steel shot feeding circulator, the shot blasting device 8 and the walking base 18 through the control box 16, and is hydraulically connected with the mobile support arm B through the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com