Steel wire rail transportation mechanical equipment system for mountain land

A technology of rail transportation and mechanical equipment, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of reducing fruit picking and transportation efficiency, consuming a lot of human energy, and difficulty in transporting fruits out of the mountains and forests, so as to improve the use of Effects of range and flexibility of use, increased device stability, improved smoothness of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

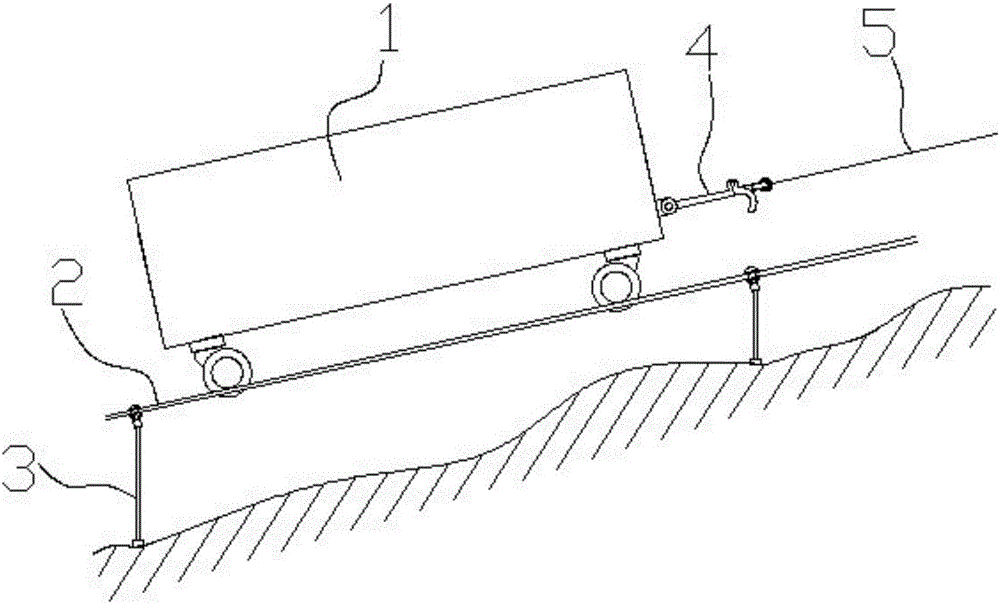

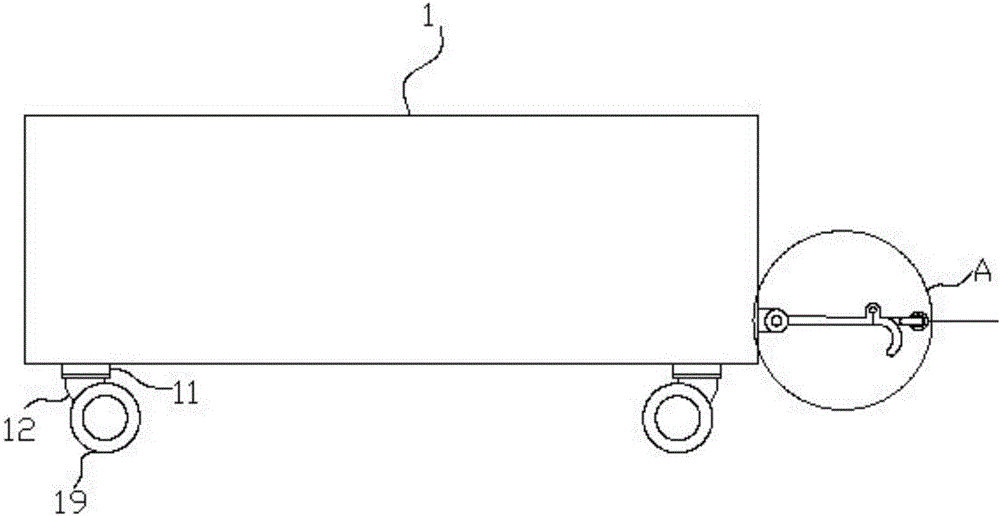

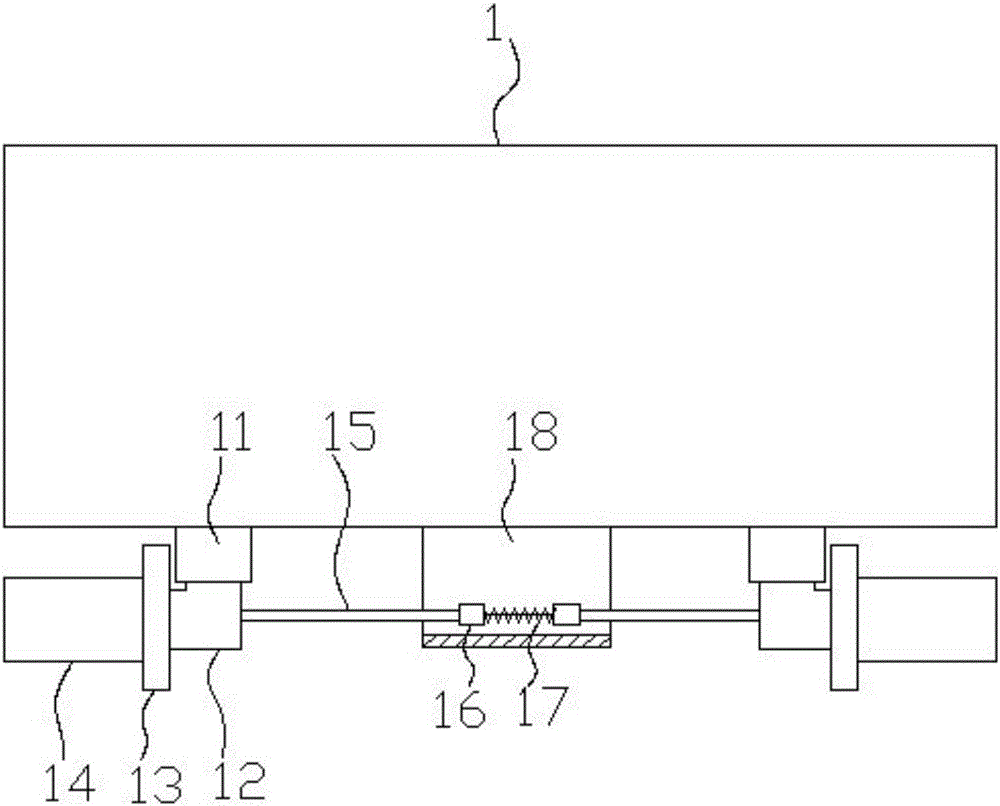

[0036] Such as Figure 1-Figure 13 Shown, the specific structure of the present invention is: a kind of mountain steel wire track transportation mechanical equipment system, it comprises two pairs of running mechanism 19 before and after the bottom of the compartment 1 and its bottom, and described running mechanism 19 walks on two steel cable tracks that are arranged in parallel 2; the cable track 2 is installed on the mountain through the track fixing device 3 according to the terrain; the two ends of the cable track 2 are respectively fixed on the top and the foot of the mountain and tightened; Conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com