Anti-interference high-voltage metalized polypropylene film capacitor

A polypropylene film, metallization technology, applied in the field of capacitors, can solve the problems of high viscosity, poor compatibility of polypropylene film, single function, etc., to achieve the effect of enhanced stability, stable performance and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

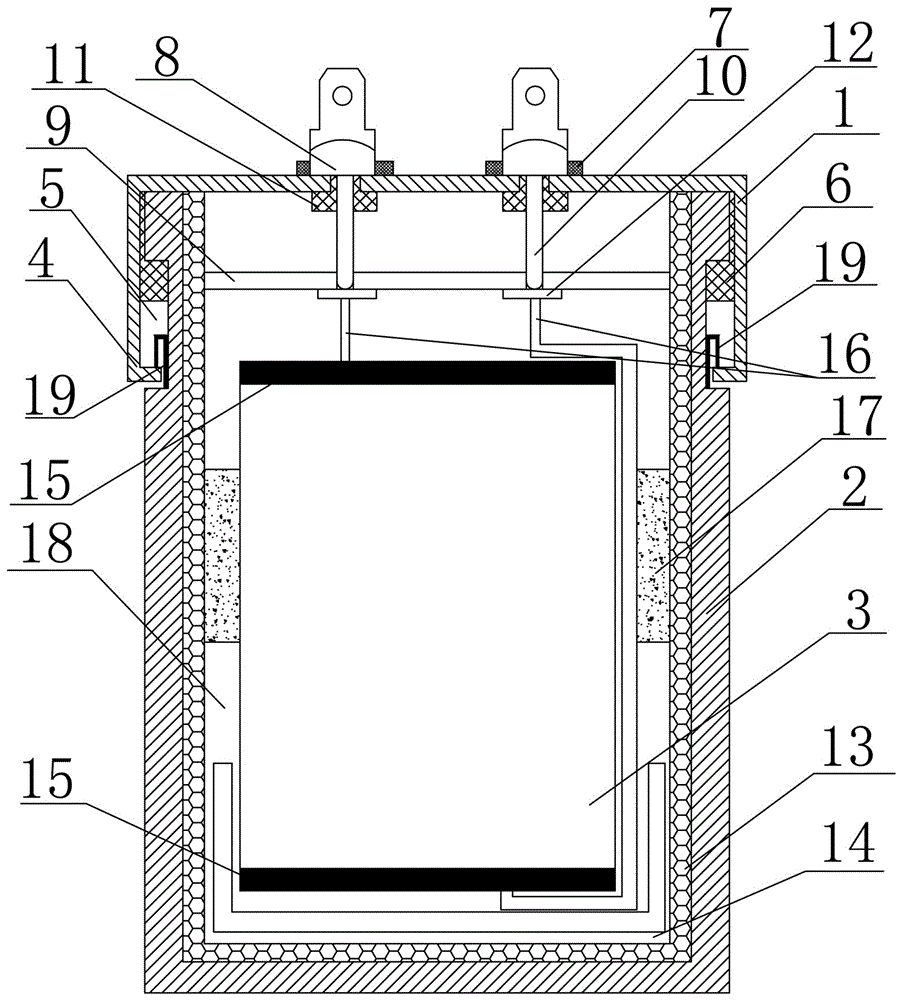

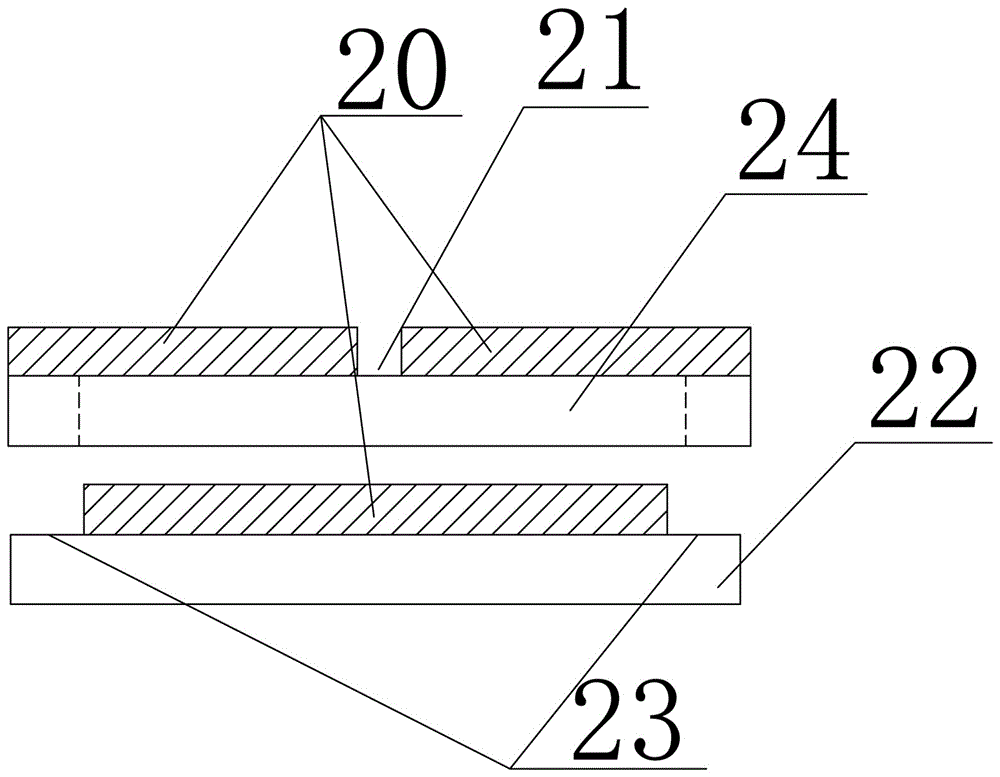

[0028] Such as figure 1 and figure 2 As shown, an anti-interference high-voltage metallized polypropylene film capacitor includes a cover plate 1, a shell 2 and a core body 3. The inner wall of the opening of the cover plate 1 is provided with an annular protrusion 4, and the upper part of the shell 2 is provided with an annular groove 5, and the annular protrusion 4 is arranged in the annular groove 5 and can move longitudinally in the annular groove 5. An elastic sealing ring 6 is arranged between the lower inner wall of the cover plate 1 and the upper outer wall of the casing 2 to ensure that when the annular protrusion 4 is in the annular groove 5 The interior of the capacitor is in a sealed state when moving longitudinally; the elastic rubber ring 19 is fixedly connected between the annular protrusion 4 and the bottom of the annular groove 5, which can further ensure that the interior of the capacitor is in a completely sealed state; two insulating bases 7 are symmetrica...

Embodiment 2

[0034] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0035] The insulating heat transfer oil is prepared from the following raw materials in parts by weight: 52 parts of castor oil, 28 parts of olive oil, 12 parts of diaryl ethane, modified nano-TiO 2 1.1 part, 0.8 part of antioxidant, 0.25 part of bis((3,4-epoxycyclohexyl) methyl) adipate, 0.25 part of polyisobutylene bis-succinimide ashless dispersant, metal deactivator T1201 is 0.25 servings.

[0036] Among them, modified nano-TiO 2 The preparation method comprises the following steps: the nano-TiO 2 Dissolve in deionized water and ultrasonically disperse for 25 minutes, in which nano-TiO 2 The weight ratio with deionized water is 1:2.5, use nitric acid solution to adjust the pH of the solution to 5.5, add a modifier, the modifier is a mixture of oleic acid and sodium laurate in a weight ratio of 1:1, the modifier with nano TiO 2 The weight ratio of the solution is 1.2:10; then ultrasonicall...

Embodiment 3

[0039] Embodiment 3 is basically the same as Embodiment 1, the difference is:

[0040] The insulating heat-conducting oil is prepared from the following raw materials in parts by weight: 54 parts of castor oil, 25 parts of olive oil, 10 parts of diaryl ethane, modified nano-TiO 2 1.2 parts, 0.9 parts of antioxidant, 0.3 parts of bis((3,4-epoxycyclohexyl) methyl) adipate, 0.2 parts of dispersant polyisobutenyl succinimide, 0.2 parts of metal deactivator T551 share.

[0041] Among them, modified nano-TiO 2 The preparation method comprises the following steps: the nano-TiO 2 Dissolve in deionized water and ultrasonically disperse for 20min, in which nano-TiO 2 The weight ratio with deionized water is 1:3, use sulfuric acid solution to adjust the pH of the solution to 6.0, add a modifier, the modifier is a mixture of oleic acid and sodium laurate in a weight ratio of 1:1, the modifier with nano TiO 2 The weight ratio is 1.5:10; then ultrasonically disperse at 50-60°C for 70 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com