Five-shaft image measurement device used for measuring film hole shape and position parameters

An image measurement and air film hole technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems that the accuracy and repeatability of air film hole measurement results cannot meet the needs of engineering, and achieve high positioning accuracy and high efficiency. , Universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

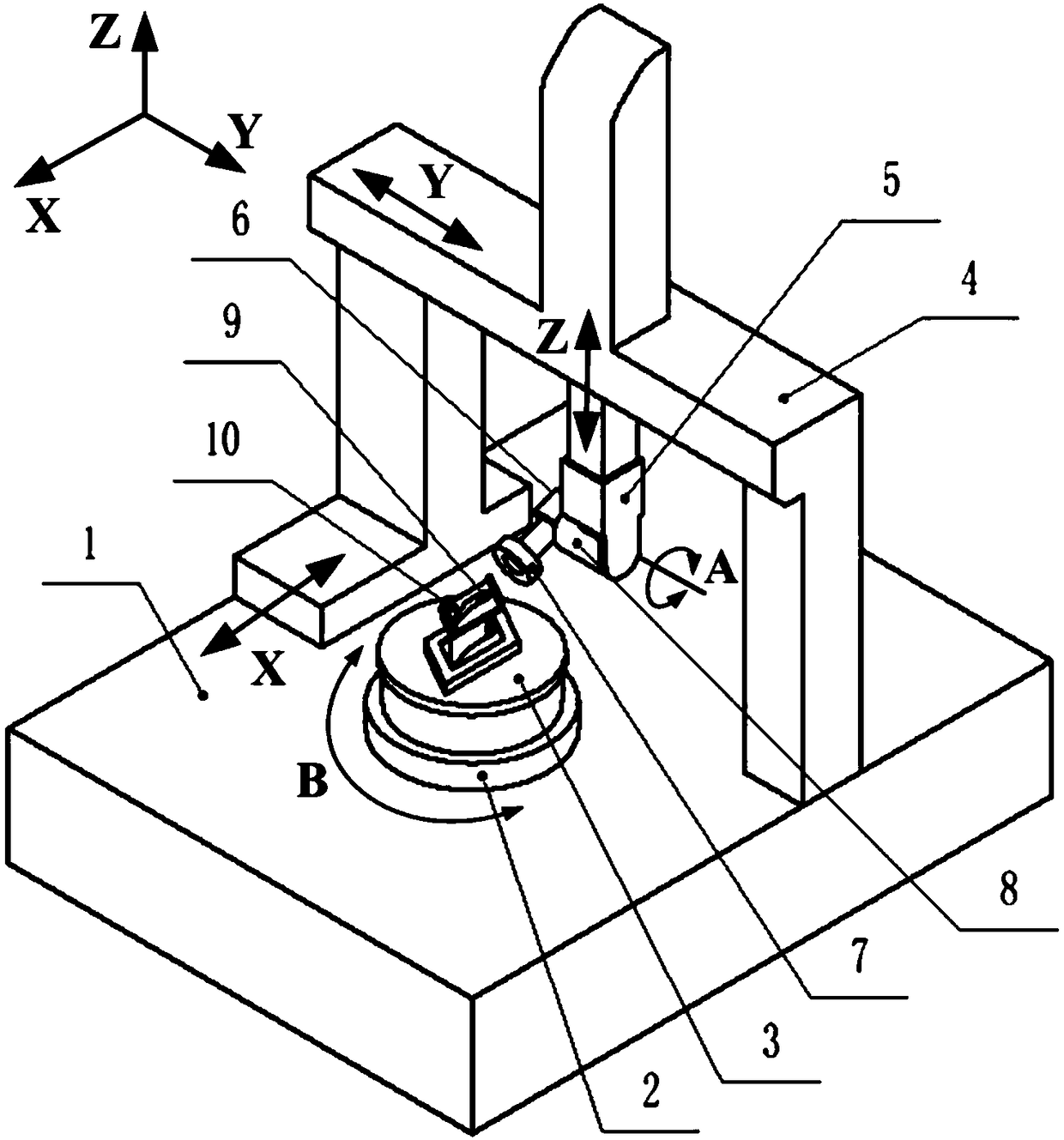

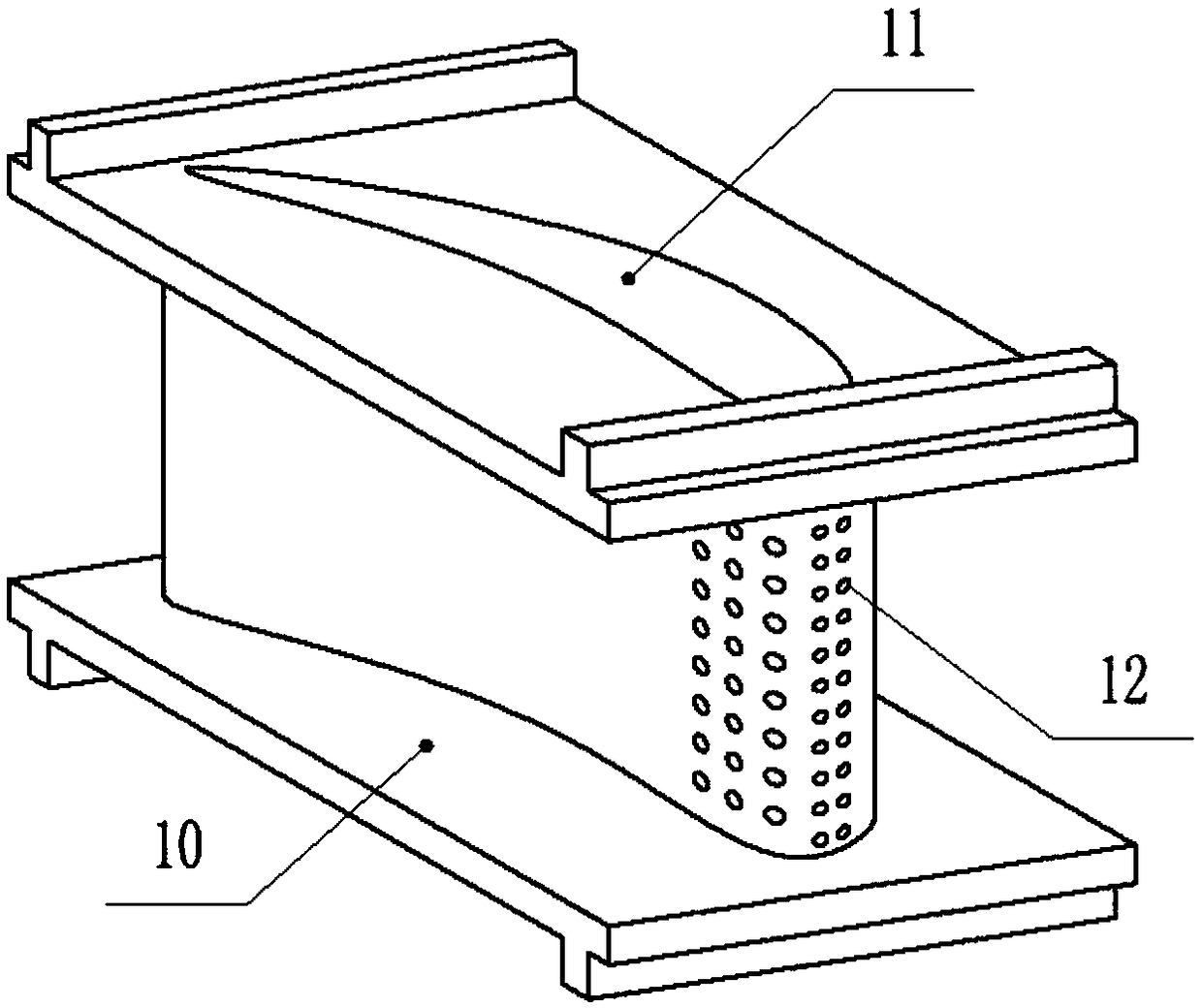

[0024] See attached Figure 1~4 As shown, this five-axis image measuring device for measuring the shape and position parameters of air film holes is based on the principle of machine vision measurement, and is aimed at the multiple air film hole features 12 distributed on the airfoil profile surface of the hollow turbine blade 10 of the aero-engine. , adopt the lighting method combining backlighting and forward lighting, and use the image acquisition device 6 to collect the digital image of the measured air film hole feature 12, and then obtain the aperture size of each air film hole feature 12 through subsequent image processing , axis space angle and hole center coordinates and other shape parameters. The device has five motion axes, including three linear axes X, Y, and Z and two rotary axes A, B, and can realize five-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com