Small steel shot feeding circulator and numerical control metal surface treating machine using the same

A circulator and steel shot technology, applied in abrasive feeding devices, metal processing equipment, abrasives, etc., can solve the problems of complex structure and control, inability to transport the whole machine, difficult to change the working position, etc., and achieve production and transportation costs. The effect of lowering, simplification of structure and control, and improved maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

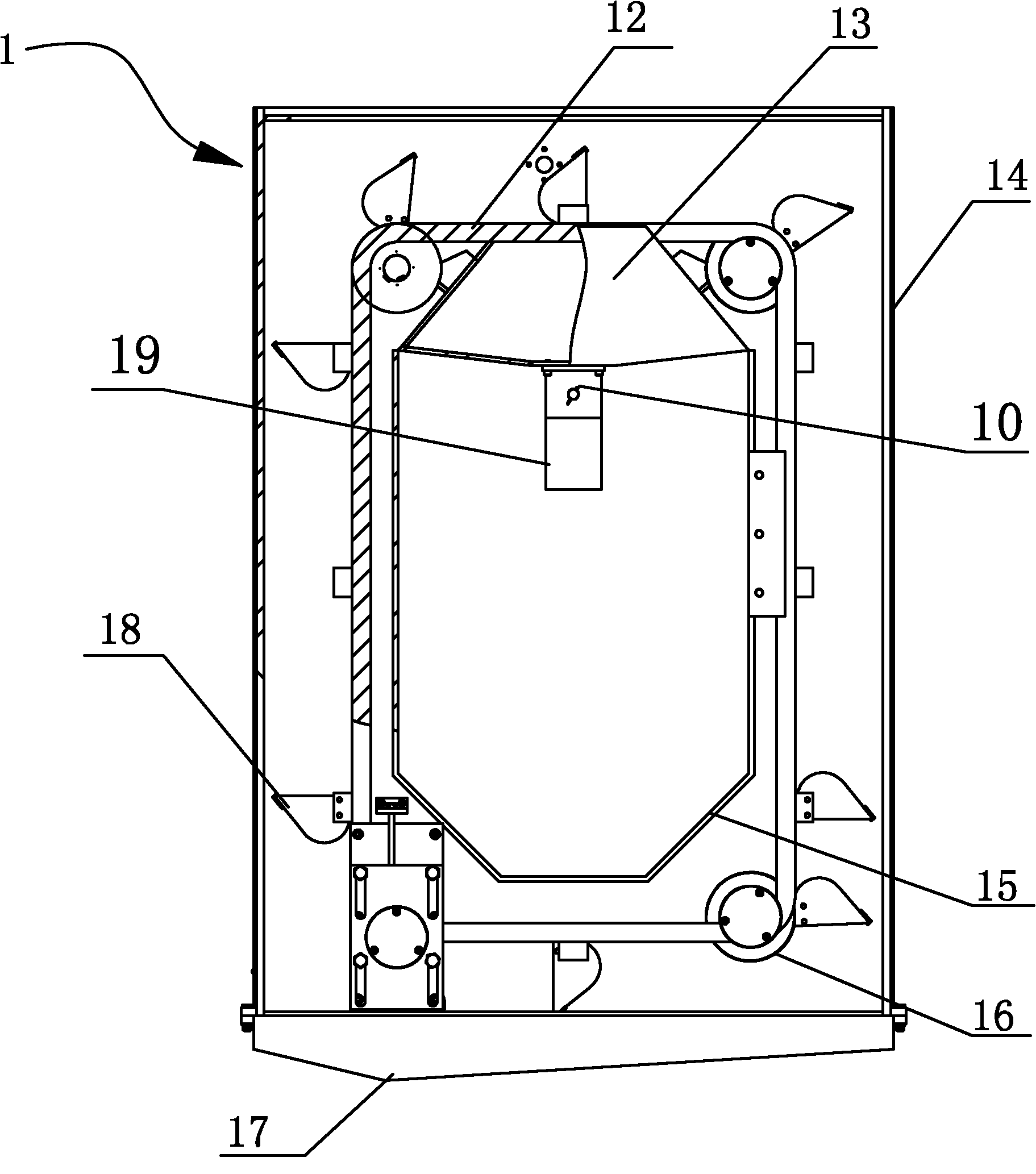

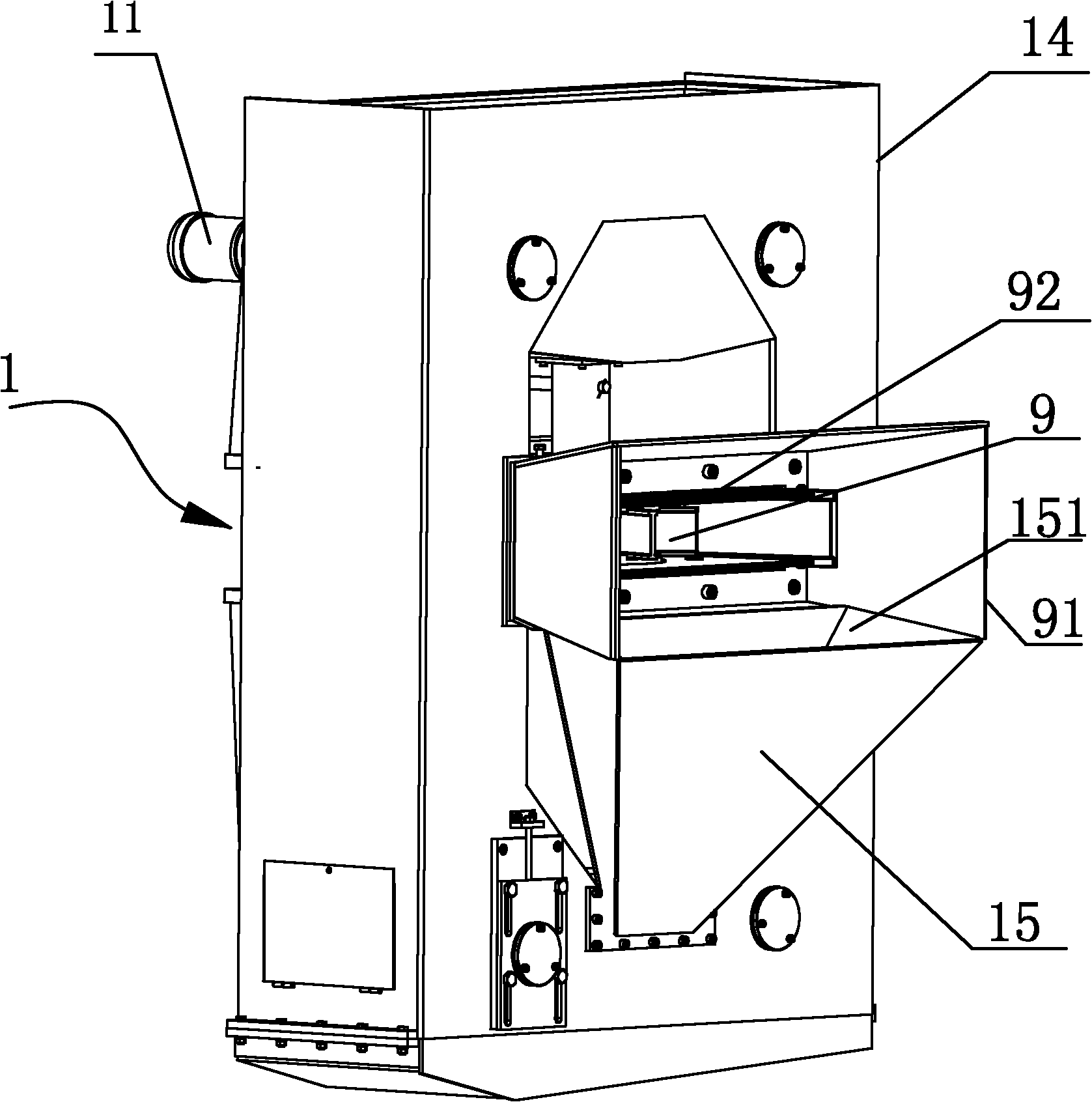

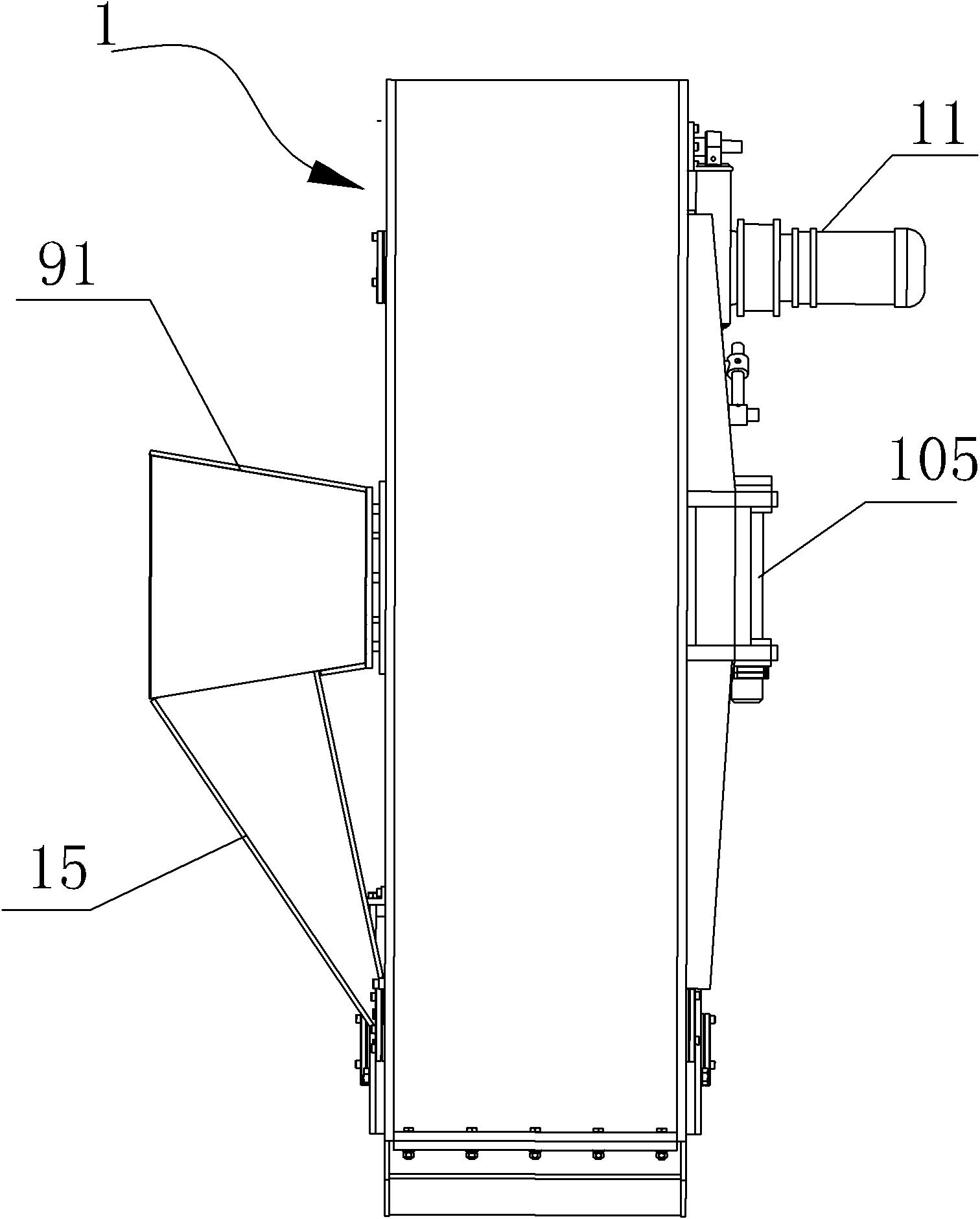

[0023] Figure 1 ~ Figure 4 Show a kind of small-sized steel shot feeding circulator and the overall structure after it is packed into the shot blasting device, the small-sized steel shot feeding circulator includes a feeding motor 11 for feeding the shot blasting device 9, and the feeding The double-layer sprocket 16 driven by the motor 11, the double-chain 12 meshed on the double-layer sprocket 16, and a plurality of feeding hoppers 18 connected between the double-chain are characterized in that a box 14 is provided, and the middle part of the box is shot blasting. The installation space of the device 9, the front wall of the box corresponding to the shot blasting device 9 is provided with a shot blasting window 92 and a sealing shield 91 extending out of the box, the above-mentioned feeding motor 11, multiple groups of double-layer sprockets 16, double chains 12 And a plurality of feeding hoppers 18 are arranged in the casing 14 around the blasting device 9; a feeding hoppe...

Embodiment 2

[0025] Figure 5 ~ Figure 7It shows a numerically controlled metal surface treatment machine, including a walking base 5, an operating room 7, a control box 6, a hydraulic station 4, a dust collector 3, a shot blaster 9, a mobile support arm for controlling the position of the shot blaster, and a feeding motor , the double-layer sprocket driven by the feeding motor, the double chain meshed with the double-layer sprocket and the steel shot feeding circulation system of multiple feeding hoppers connected between the double chains, the above-mentioned operation room 7, control box 6, hydraulic pressure The station 4, the dust collector 3 and the mobile support arm are set on the walking base 5; the operation panel 71 of the above-mentioned operation room 7 is electrically connected to the dust collector 3, the steel shot feeding cycle system, the shot blasting machine 9 and the walking base 5 through the control box 6. Connected, and hydraulically connected with the mobile suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com