Linear flame welding machine and welding method thereof

A flame and welding machine technology, applied in the field of linear flame welding machine and its welding, can solve the problems of affecting work efficiency, waste of manpower and material resources, backward production methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

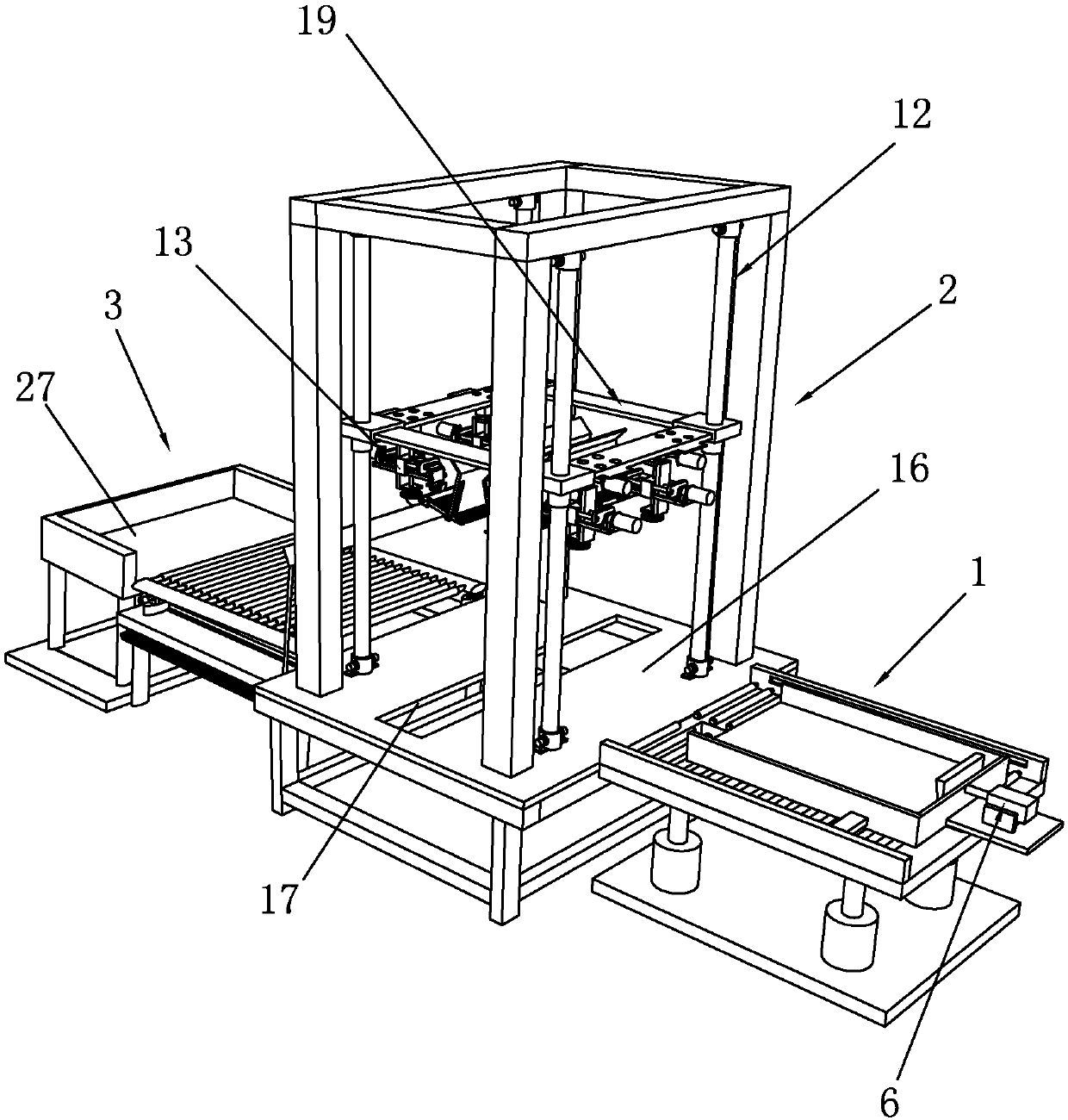

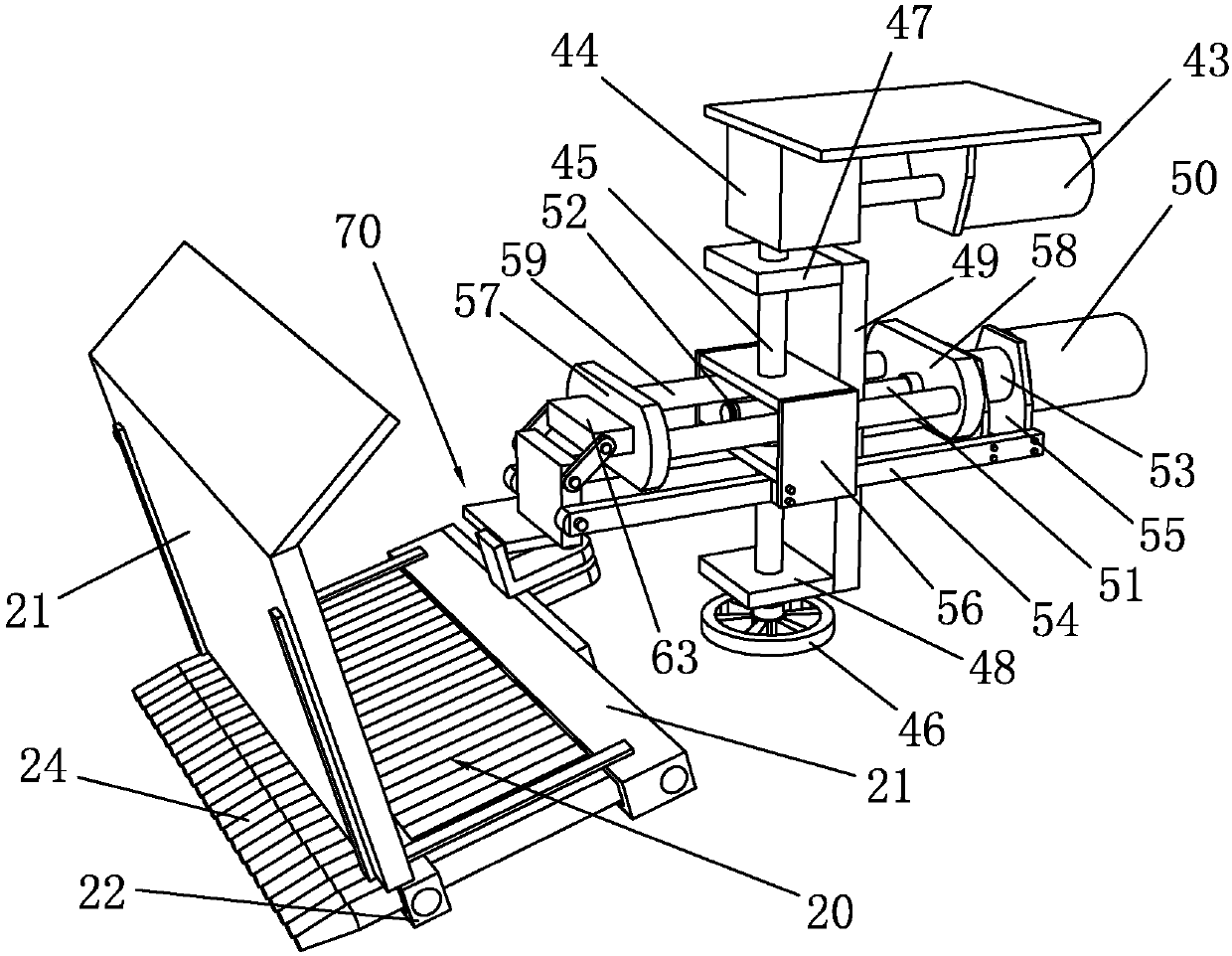

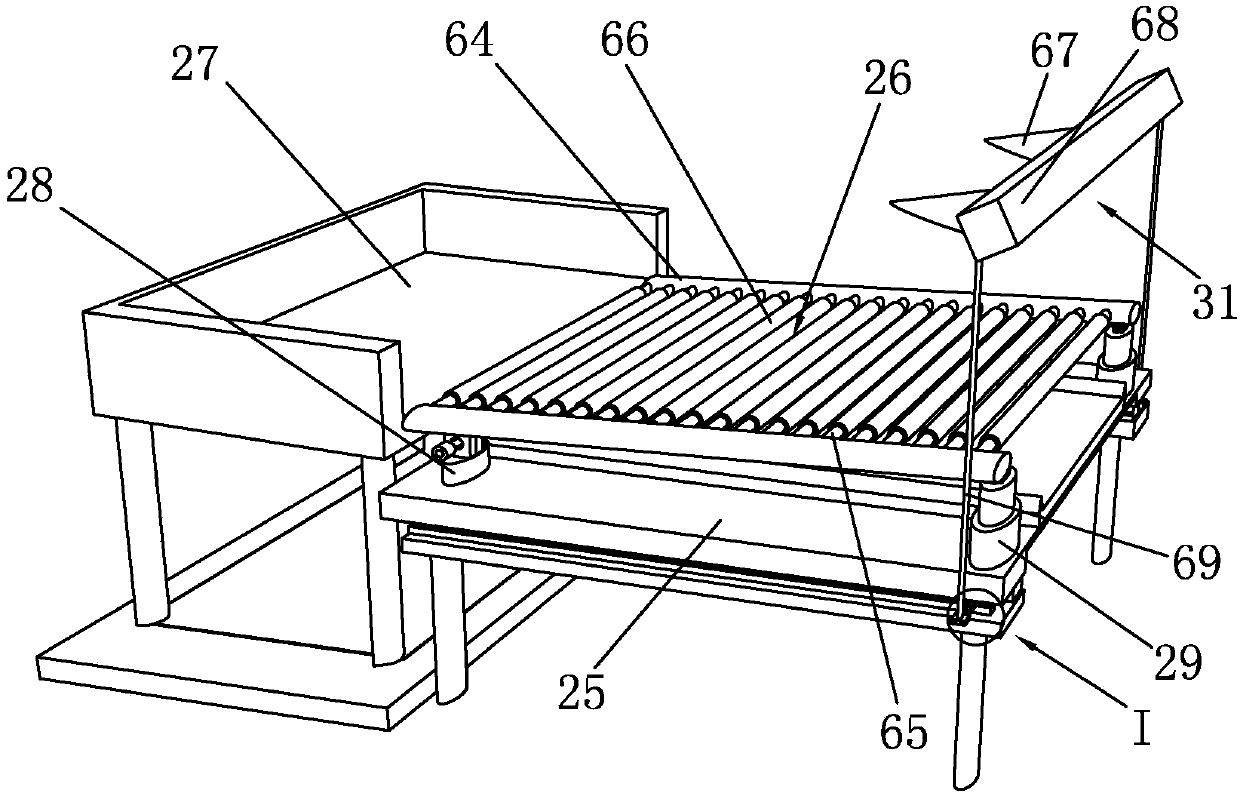

[0045] Such as Figure 1 to Figure 8 As shown, it is a linear flame welding machine of the present invention, comprising a feeding mechanism 1, a welding mechanism 2 and a blanking mechanism 3, the feeding mechanism 1, the welding mechanism 2 and the blanking mechanism 3 are sequentially arranged from right to left, and the feeding mechanism The mechanism 1 includes a feeding table 4, a feeding table 5 and a pushing device 6. The top surface of the feeding table 4 is provided with a front and rear relative guide roller assembly 7, and the center of the feeding table 4 is provided with a transverse chute 8, The four corners of the bottom surface of the feeding platform 4 are provided with lifting adjustment columns 9, the bottom surface of the feeding platform 4 is provided with a moving cylinder 10, and the bottom of the feeding platform 5 is provided with a connecting slider 11, and the connecting slider 11 passes through the horizontal direction. The chute 8 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com