Particle processing device of printer

A processing device and particulate matter technology, which is applied in manufacturing auxiliary devices, processing data acquisition/processing, additional manufacturing, etc., can solve the problems of non-processing ABS ultrafine particles, direct emission of particles, etc., achieve high reliability and improve exhaust quality , good feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

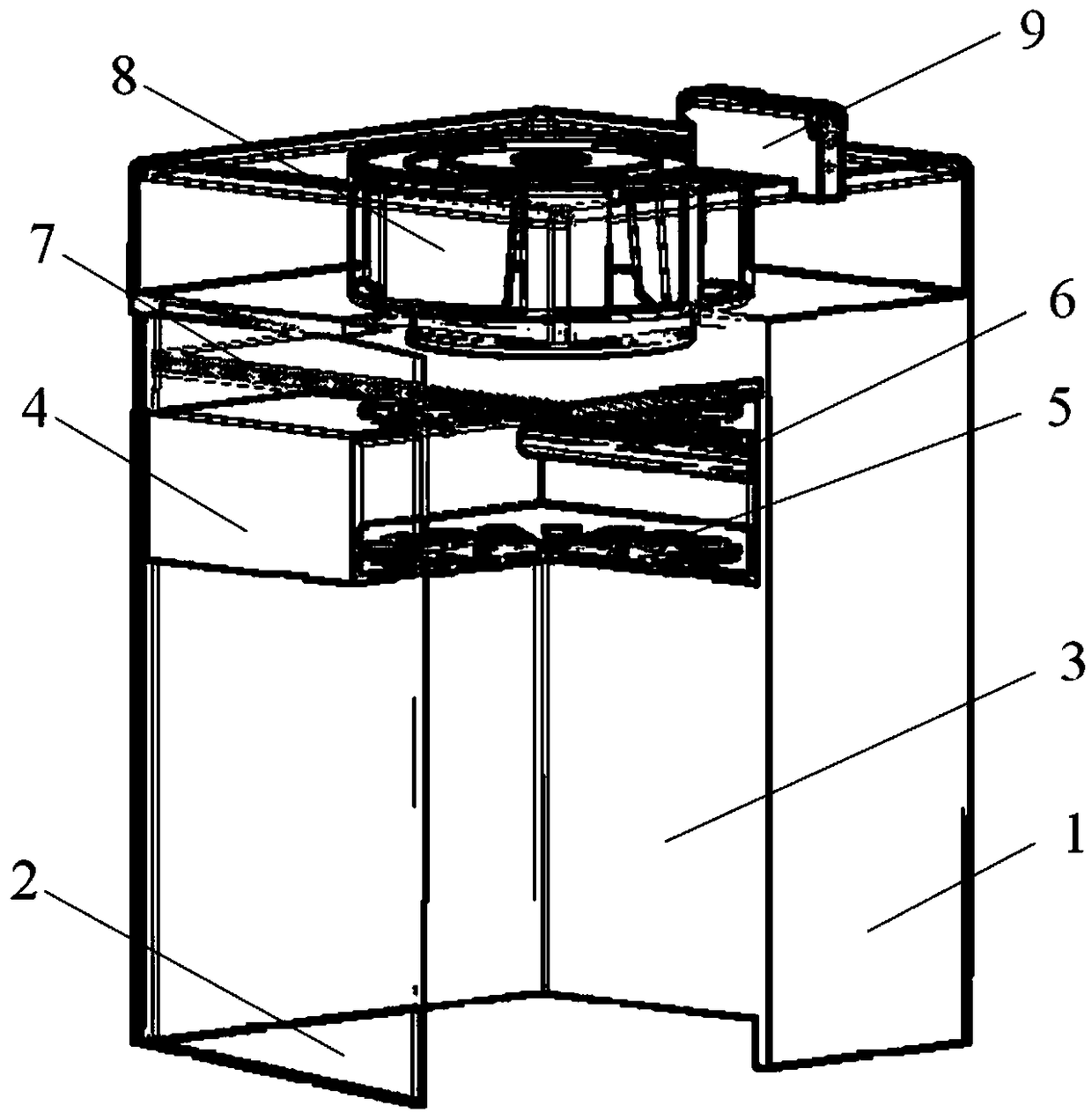

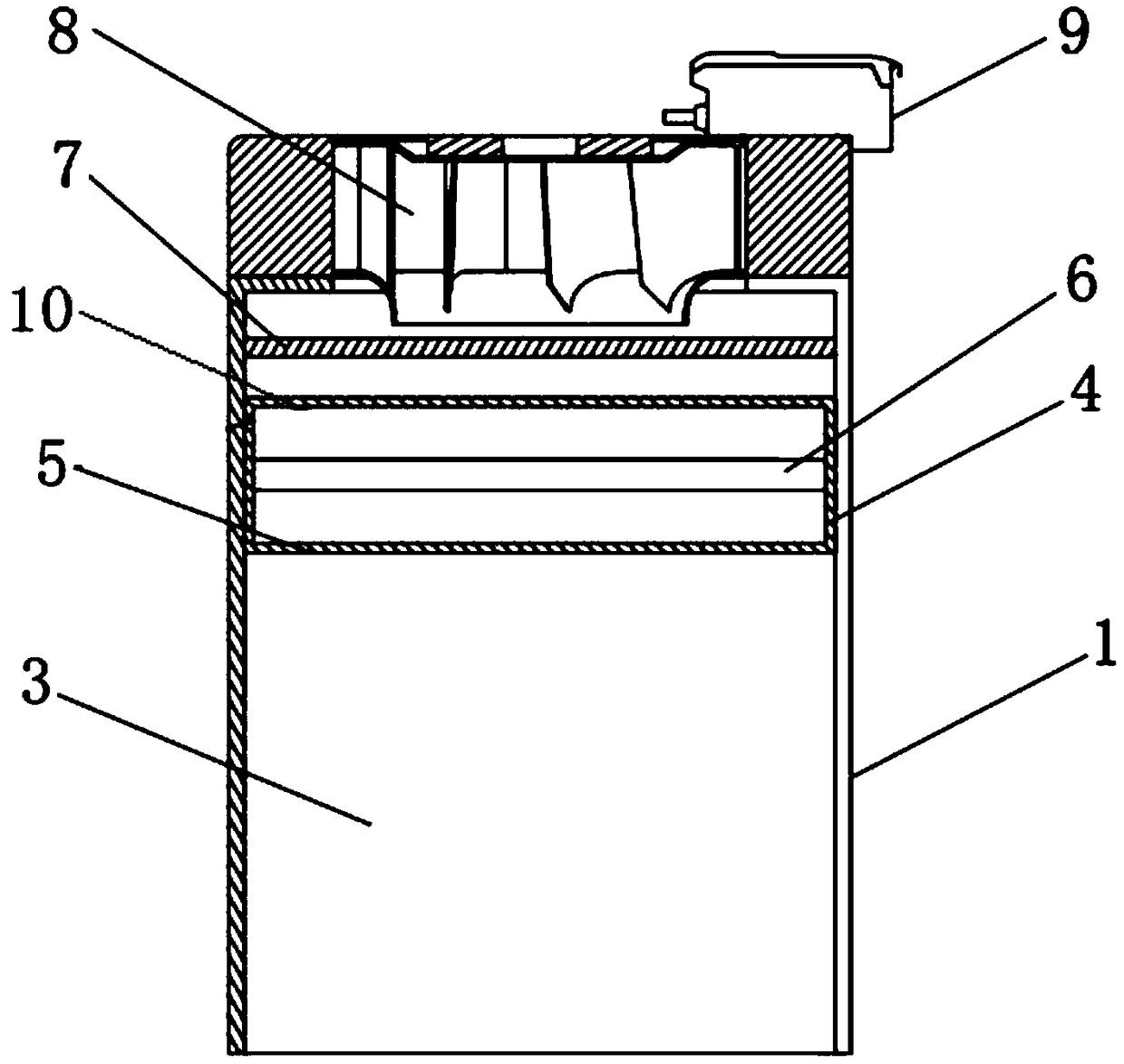

[0021] Such as figure 1 with figure 2 A printer particle treatment device shown mainly includes a closed casing 1, an ultraviolet degradation box built in the casing 1, a centrifugal fan 8 and an emission detection structure 9, and the inner lower part of the casing 1 is a printing studio 3, for installing a 3D printer; the ultraviolet degradation box is located above the printing studio 3, and the entrance of the ultraviolet degradation box is communicated with the printing studio 3; the outlet of the ultraviolet degradation box is communicated with the entrance of the centrifugal fan 8, The centrifugal fan 8 is arranged at the inner upper part of the housing 1 ; the discharge detection structure 9 is arranged at the outlet of the centrifugal fan 8 .

[0022] Preferably, the ultraviolet d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com