Anti-explosion touch screen

A touch screen, resistive touch screen technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problems of monitoring and human-computer interaction devices that cannot be applied, lack, lack of equipment, etc., to increase safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

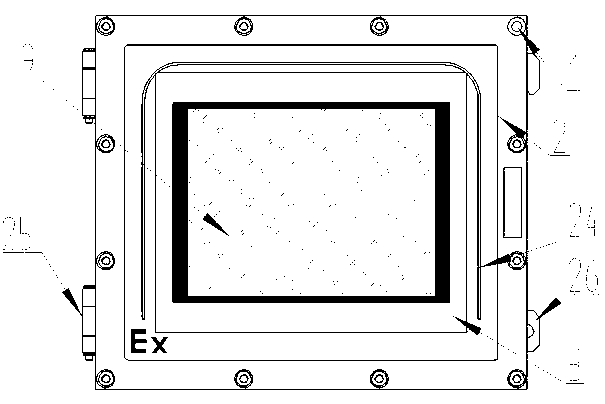

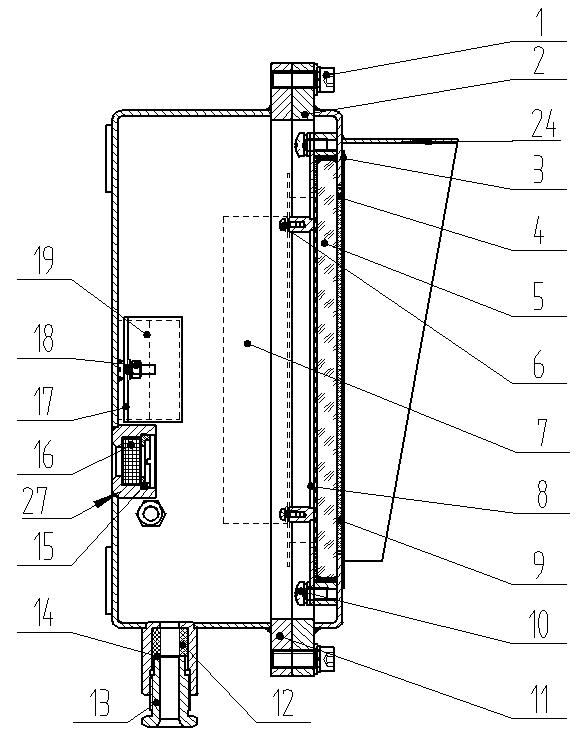

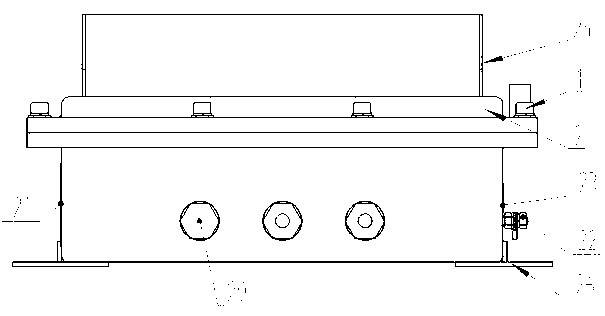

[0014] Below with reference to accompanying drawing, the present invention will be further described:

[0015] See attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 : explosion-proof touch screen, it is characterized in that, comprises box body [11], box cover [2], resistive touch screen [4], touch screen control board [7], window glass [5]; Wherein, box body [11] and box cover [2] Fasten together to form a closed space. There is a hole larger than the resistive touch screen on the case cover, and a fixing column is welded on the case cover, which cooperates with the screw to fix the window pressure plate, and at the same time, the window rubber pad and the window glass It is pressed tightly on the box cover, and there is an epoxy resin glue seal between the window glass and the fixing column, and the resistive touch screen is glued on the window glass. It is characterized in that it also includes a PVC film covering the outer surface of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com