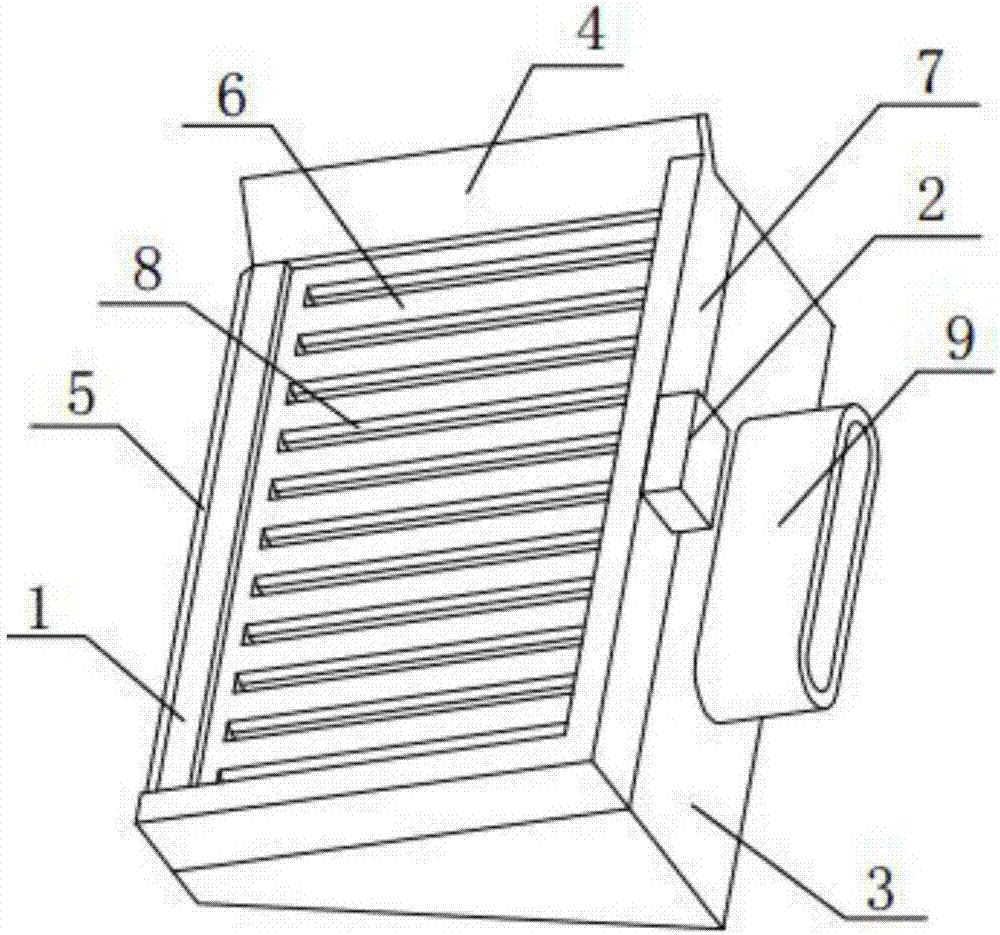

Fluidized bed dry-method sorting device

A sorting device and fluidized bed technology, applied in chemical instruments and methods, solid separation, wind shaker, etc., can solve the problems that the wind hole is difficult to distribute the wind force evenly on the bed surface, and the gangue blockage of the wind hole is achieved. The effect of uniform wind pressure, avoiding blockage of wind holes, and uniform and reasonable distribution of wind force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

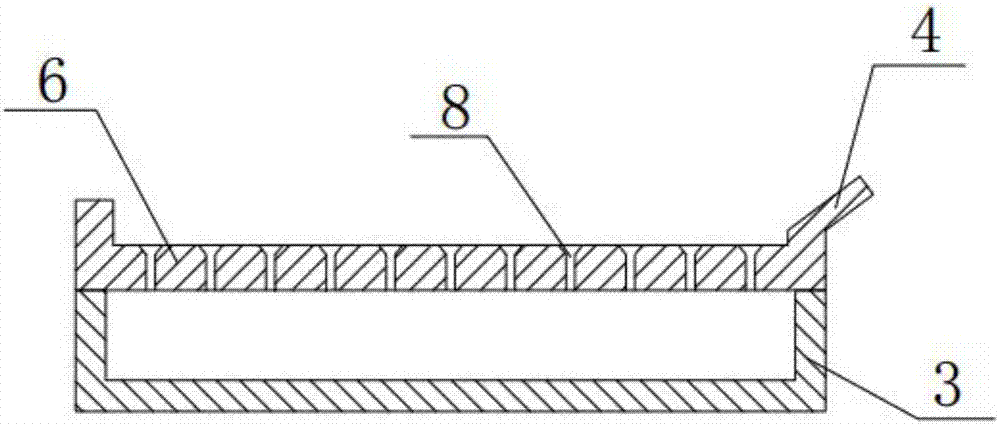

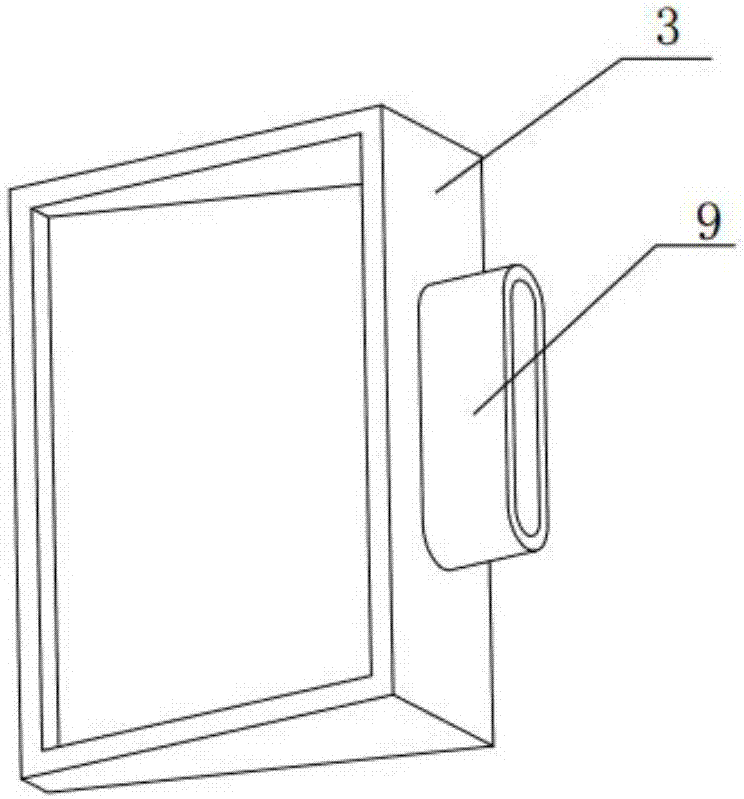

[0029] The embodiment of the present application provides a fluidized bed dry separation device, which solves or partially solves the problem that the air holes of the dry separation bed in the prior art are easily blocked by gangue, and the shape of the air holes is difficult to make the wind force uniform For technical problems distributed on the bed surface, a fluidized bed dry separation device consisting of a sorting bed, vibrating parts, an air chamber and an air inlet pipe is installed. The sorting bed includes: The bed plate is provided with several air holes; the cross section of the air hole is trumpet-shaped, and the trumpet-shaped air hole can avoid the blockage of the air hole; the vibrating parts are set to make the bed plate produce segregation to screen the mineral powder; by setting the cross-section of the trapezoidal air chamber structure , and the air duct of the air inlet pipe parallel to the bed board is set, so that the wind input from the air inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com