Patents

Literature

409 results about "Velocity Rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

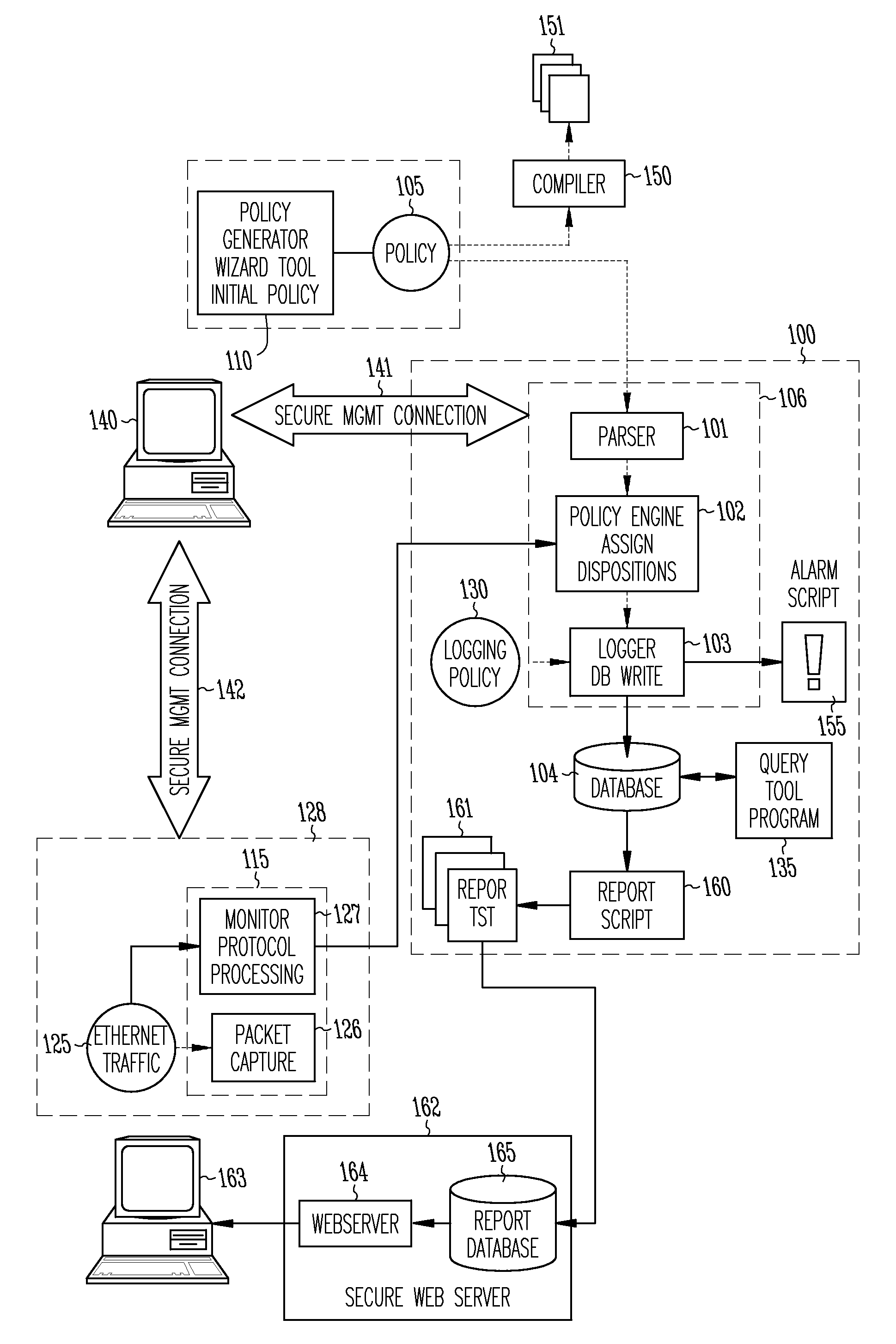

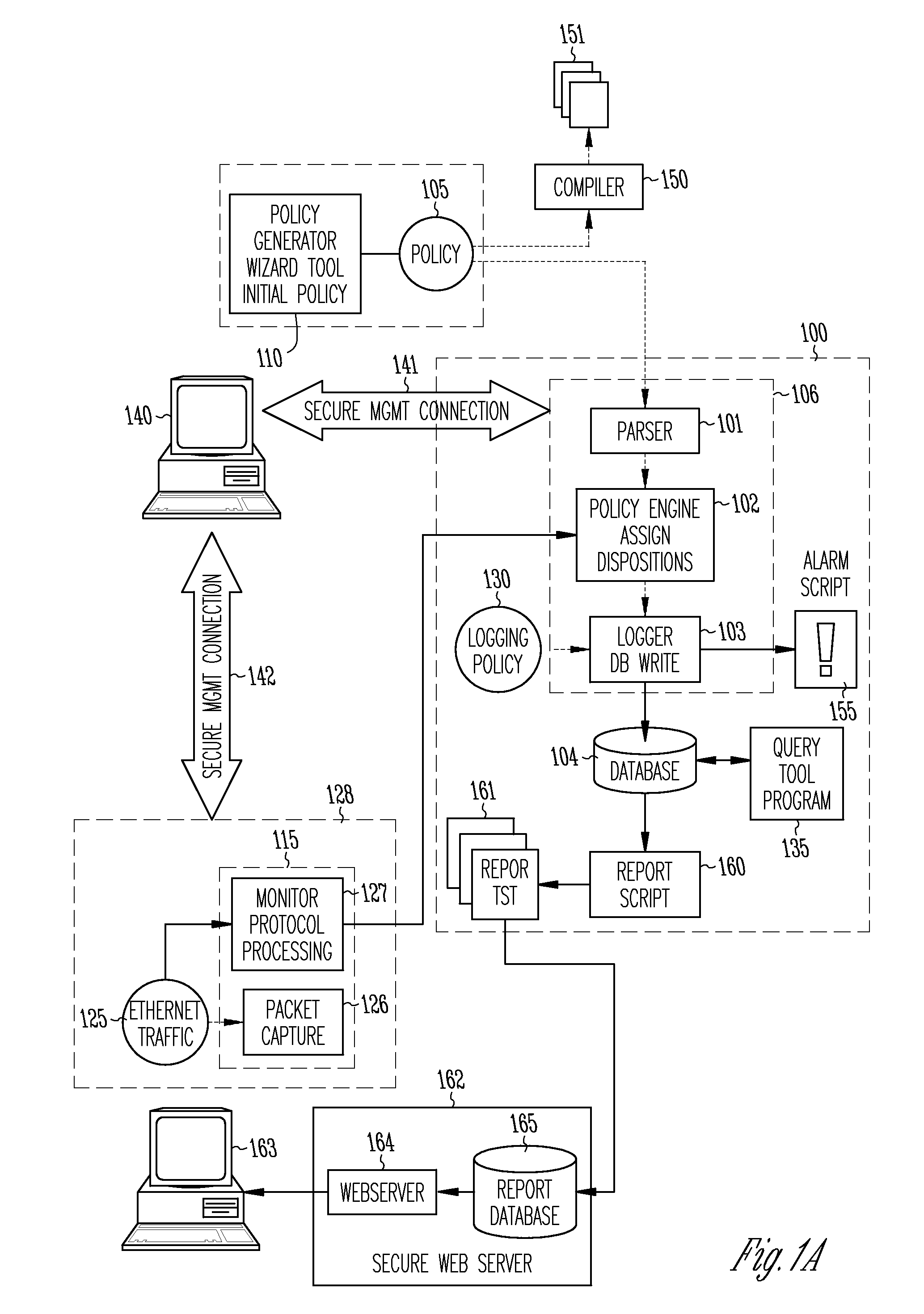

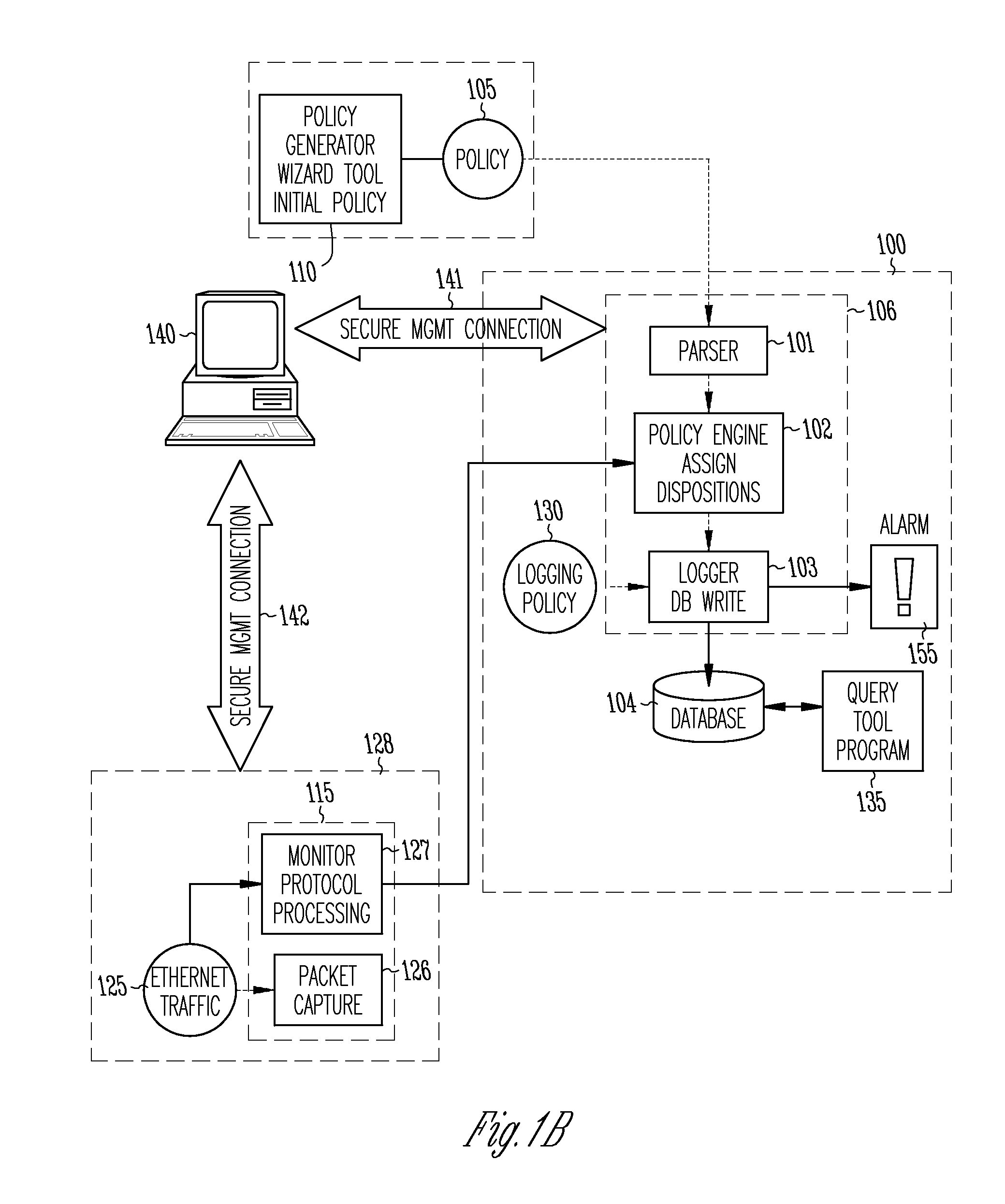

Method and apparatus for rate limiting

A method and apparatus for a network monitor internals mechanism, which serves to translate packet data into multiple concurrent streams of encoded network event data, to contribute to enterprise management, reporting, and global mechanisms for aggregating monitors at a centralized aggregation point, and to facilitate rate limiting techniques because such monitors are not in control (i.e. cannot back pressure flow) is provided.

Owner:MCAFEE LLC

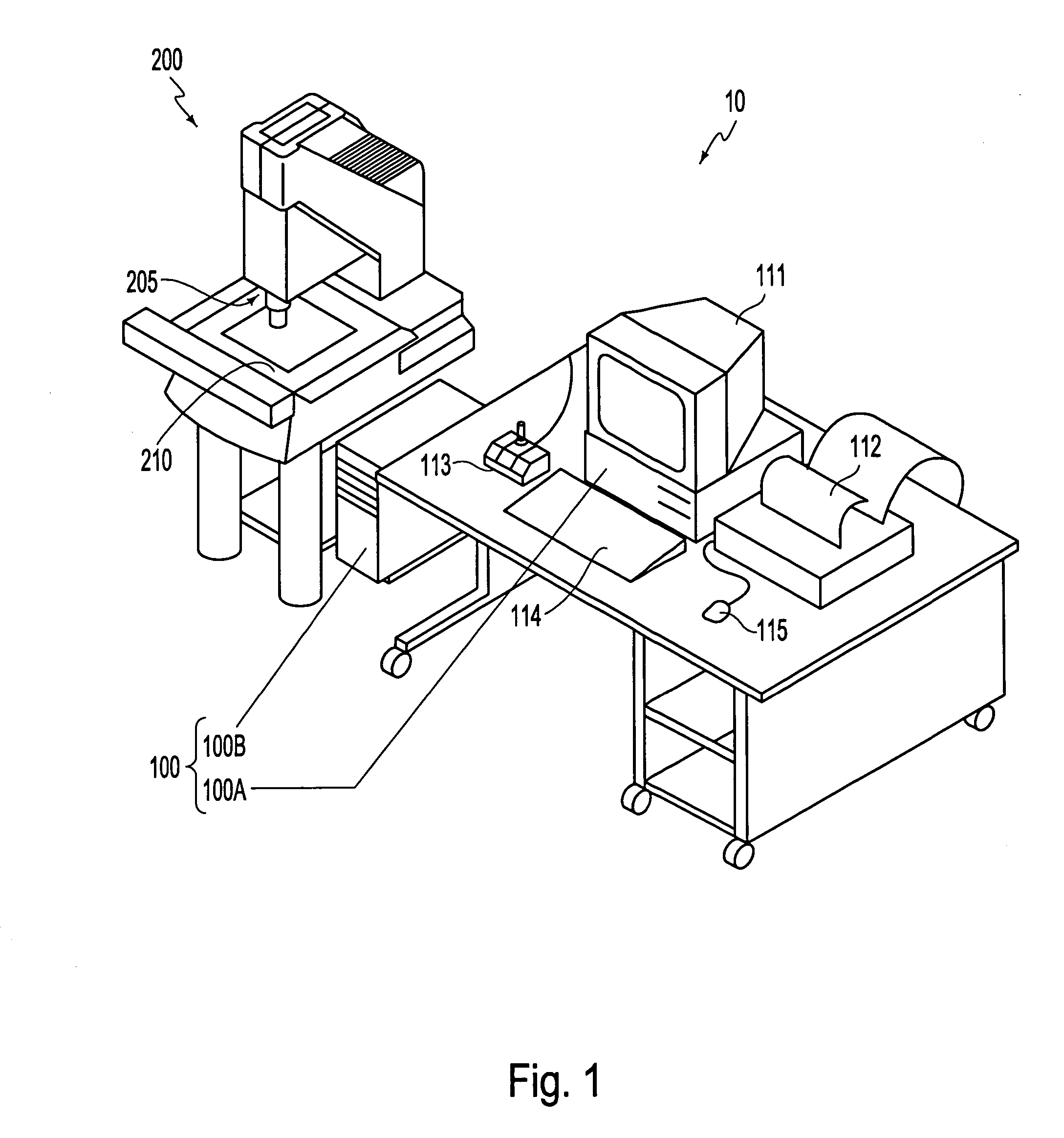

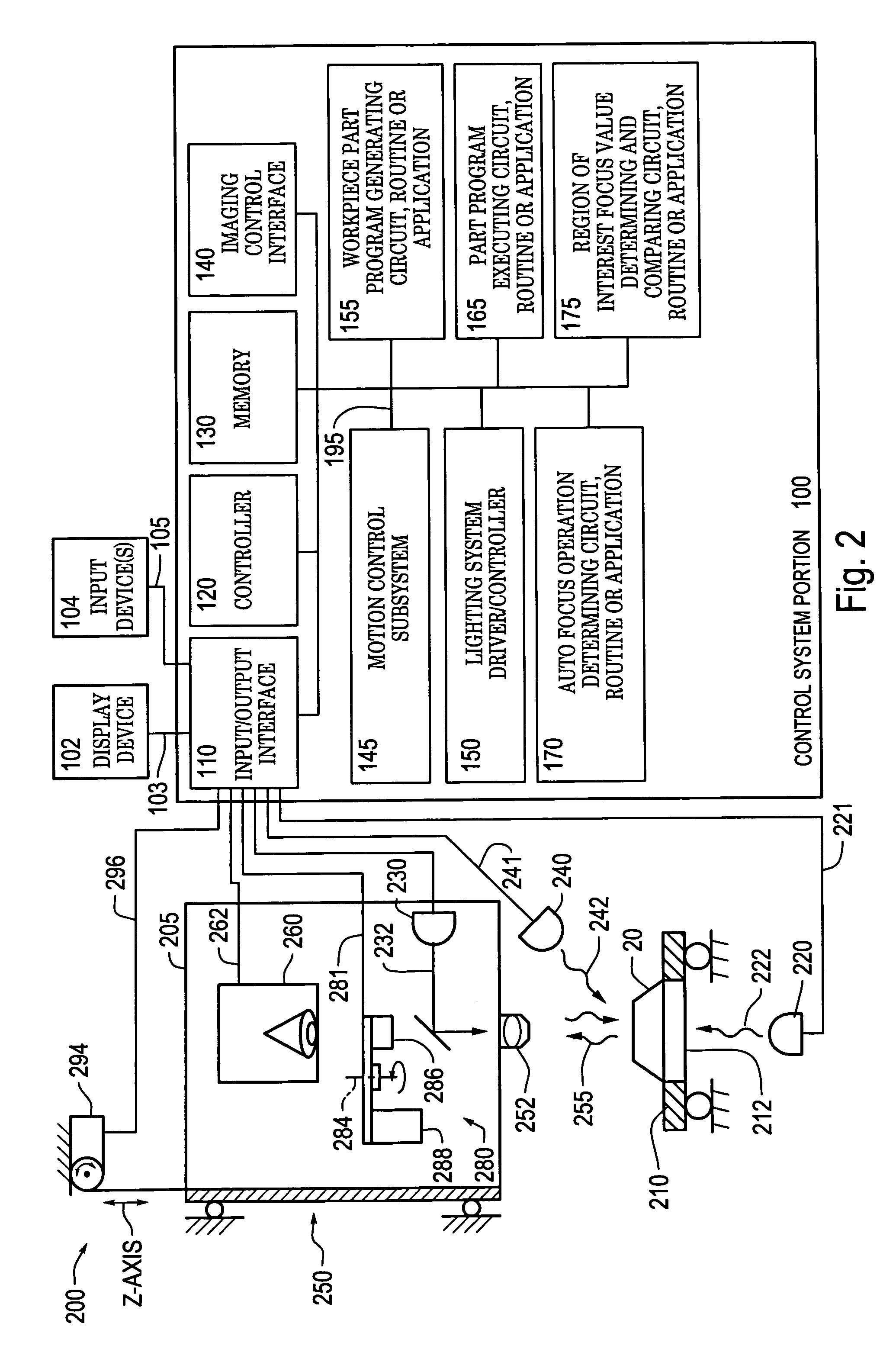

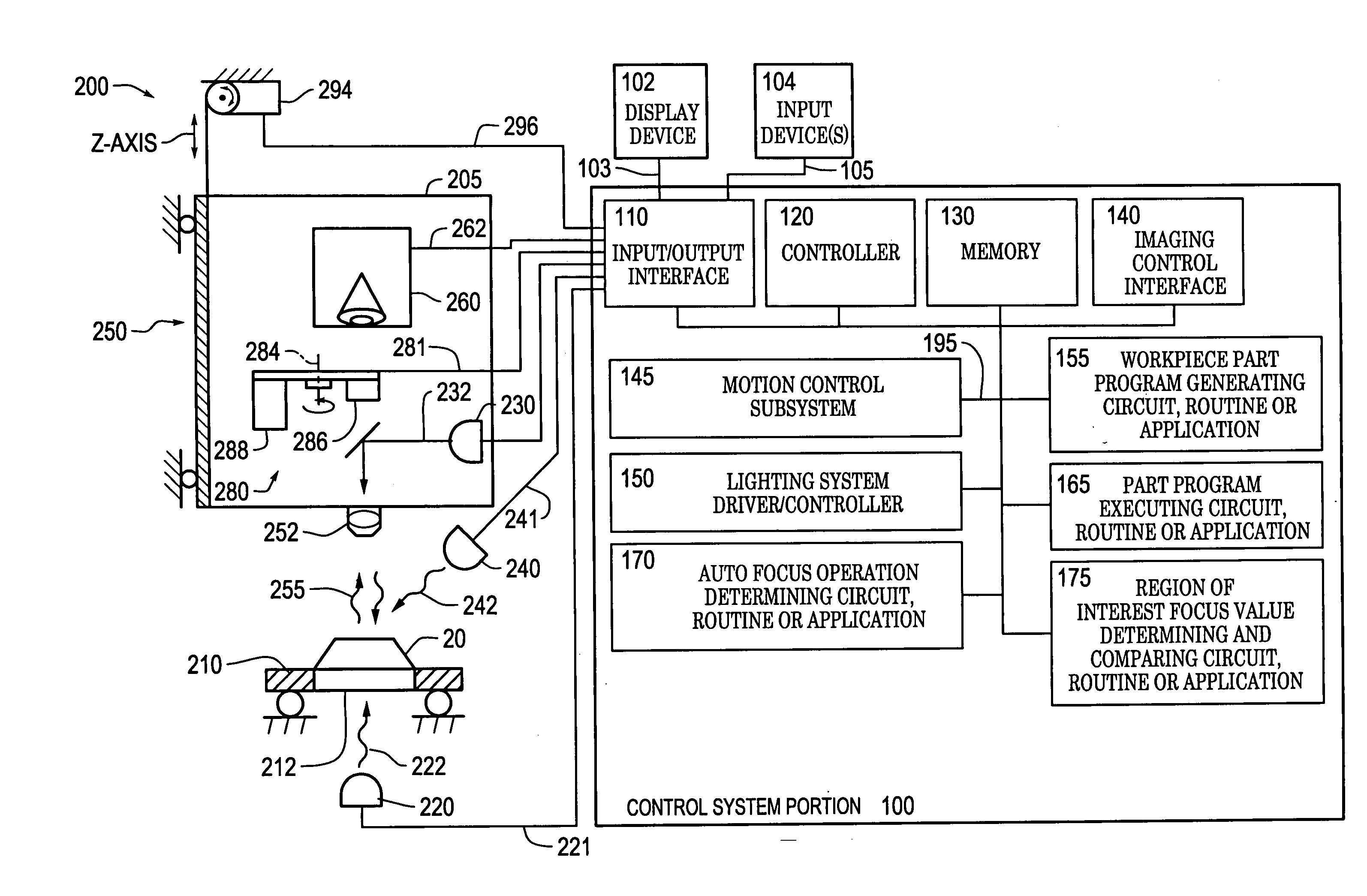

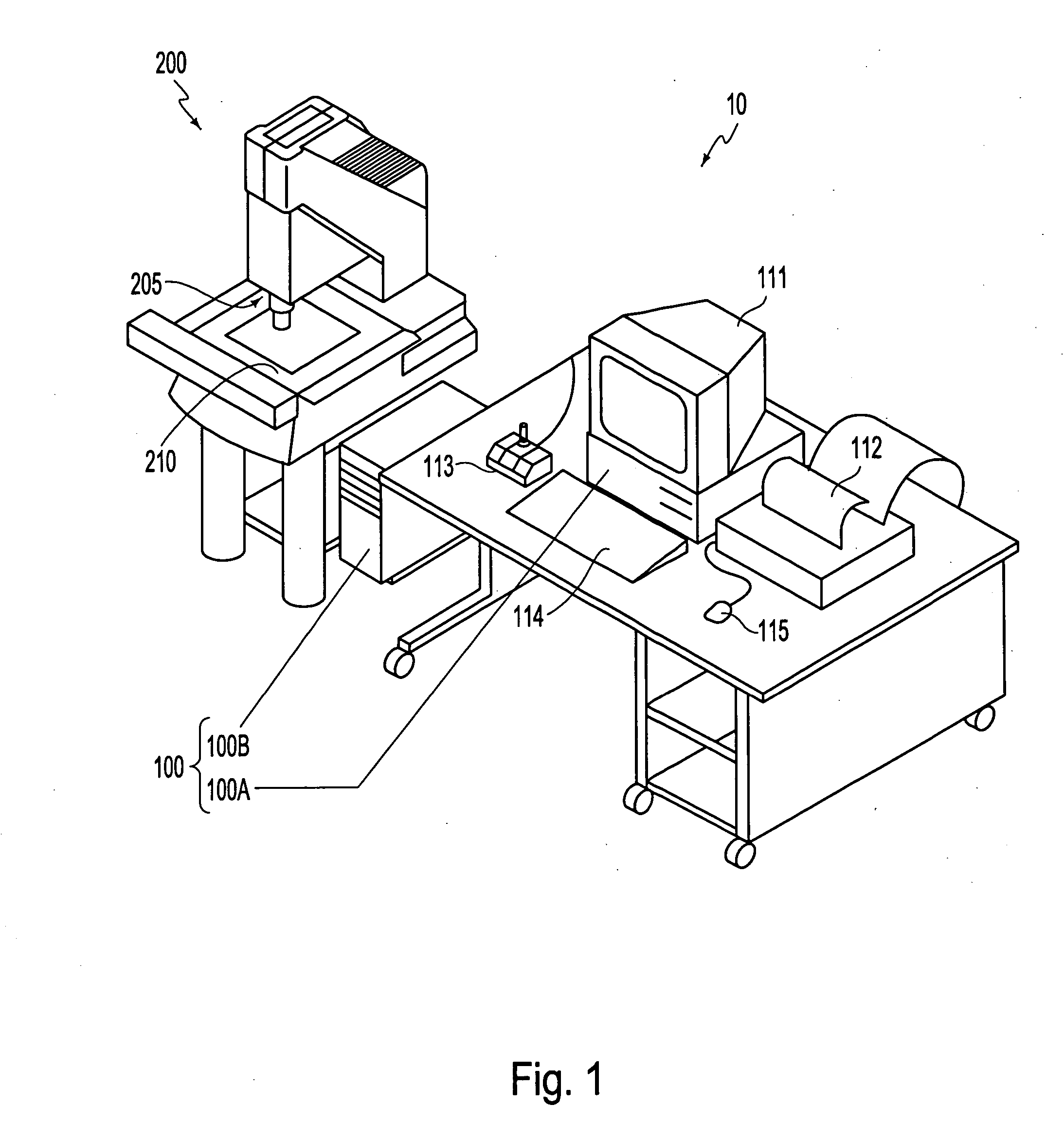

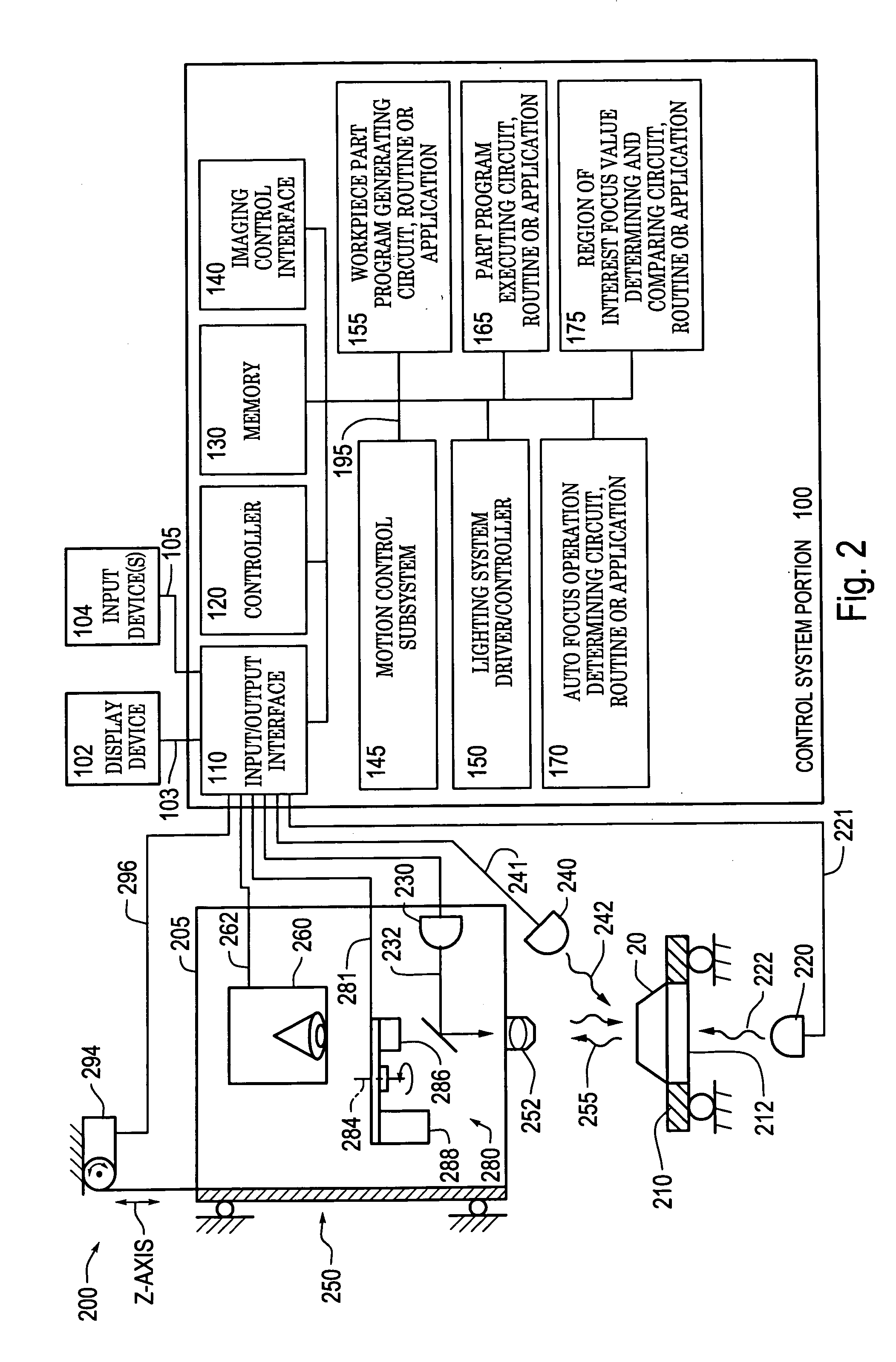

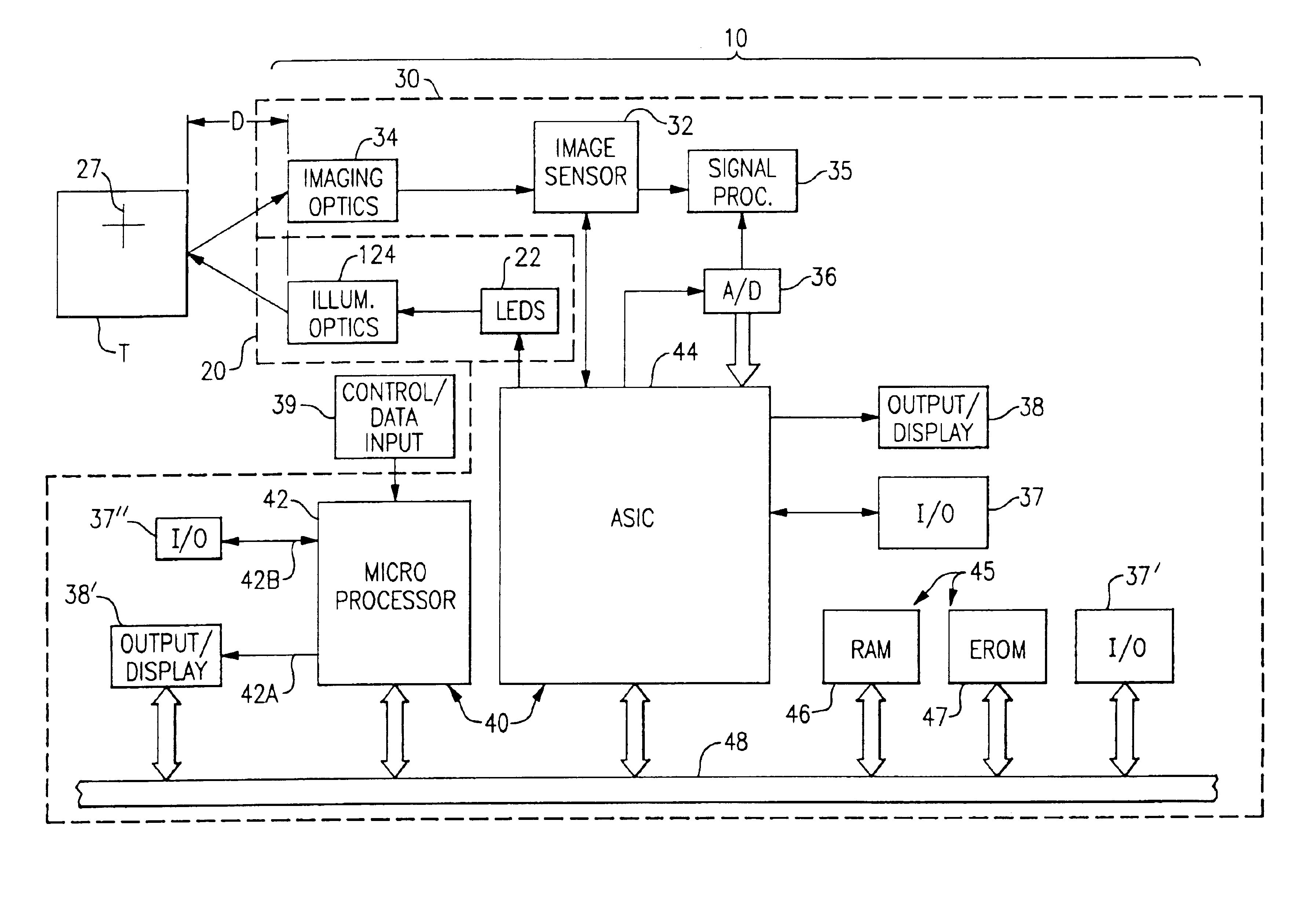

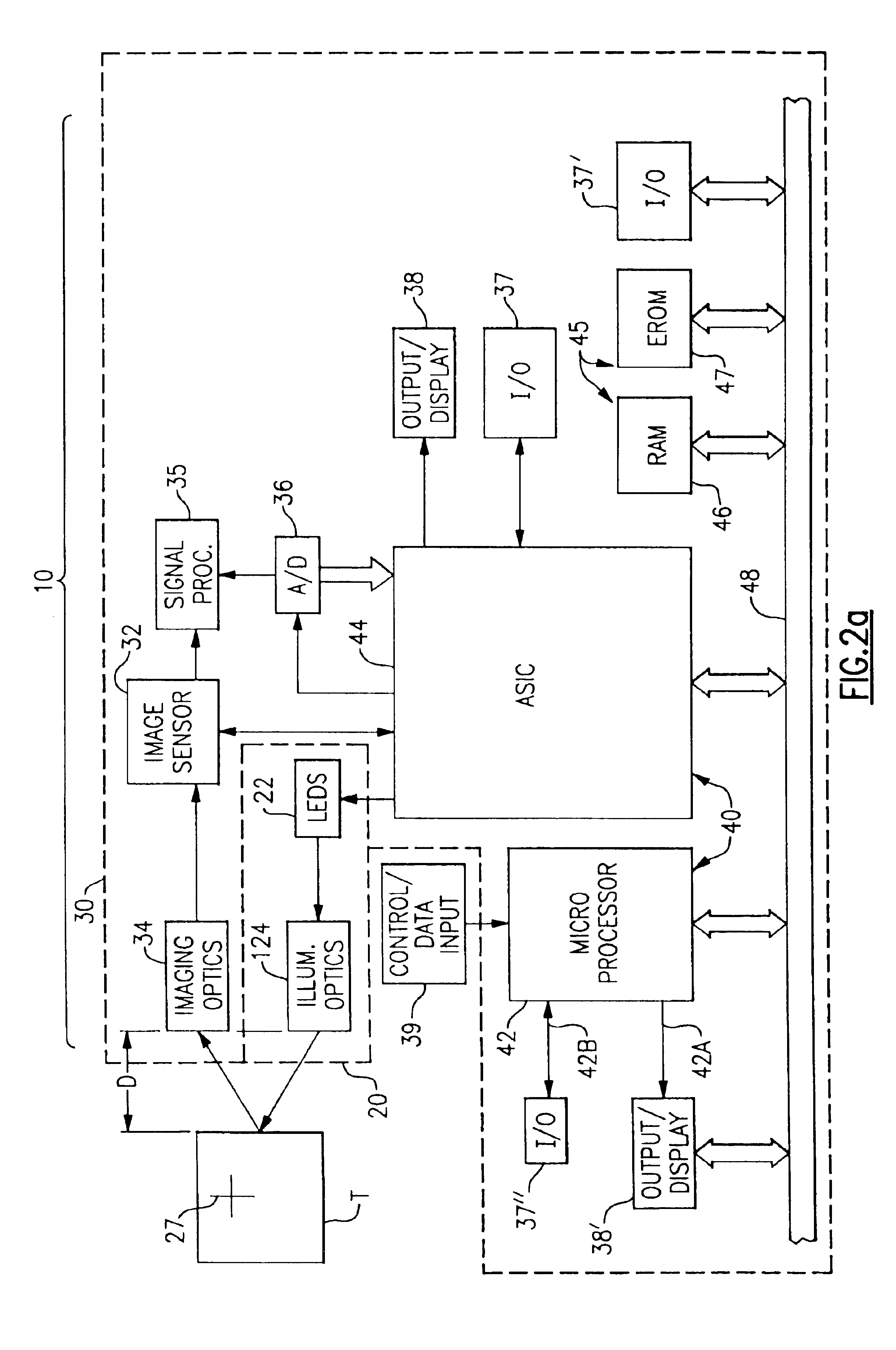

Systems and methods for rapidly automatically focusing a machine vision inspection system

ActiveUS7030351B2Increase speedAccurate autofocusTelevision system detailsSolid-state devicesMachine visionMetrology

Owner:MITUTOYO CORP

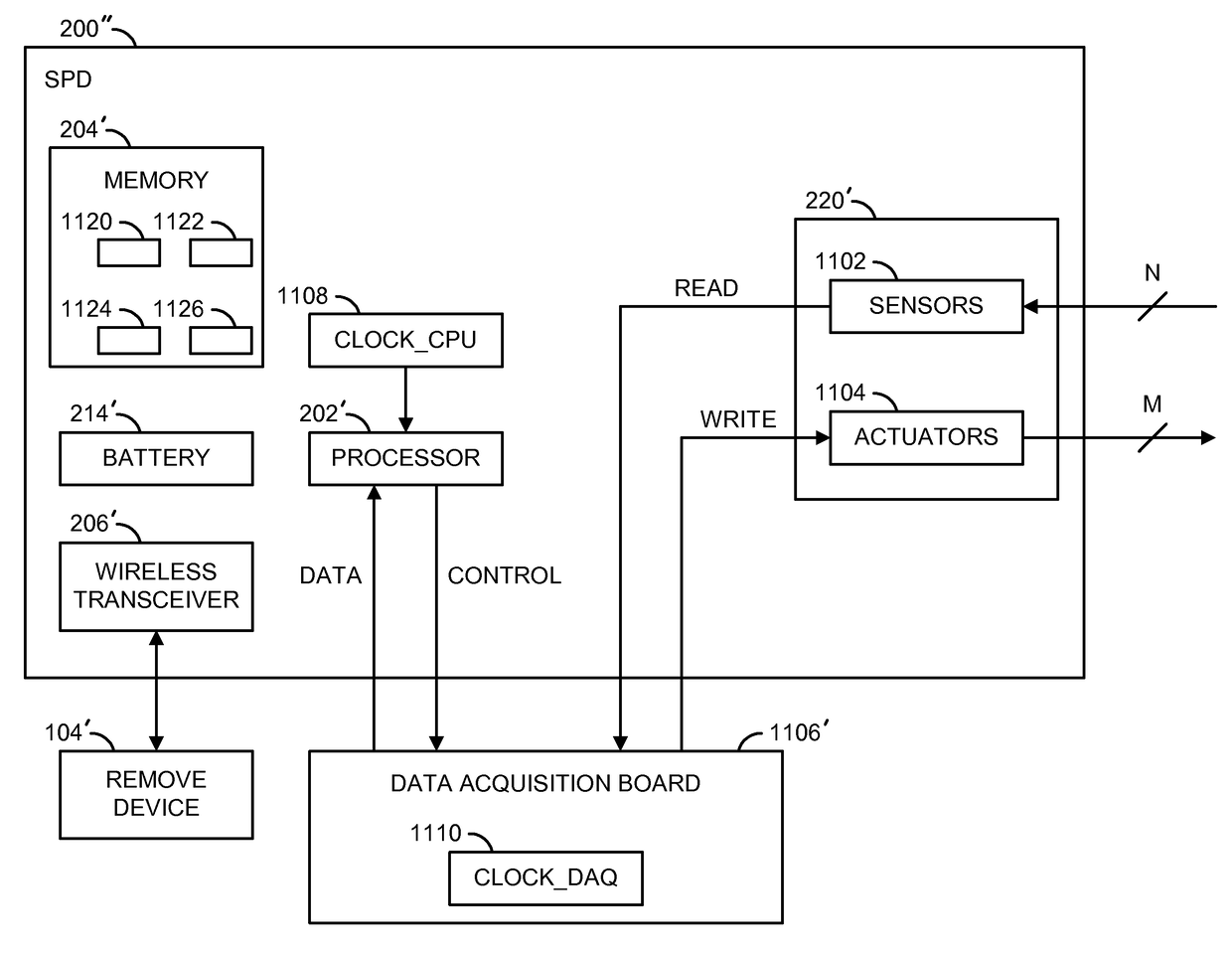

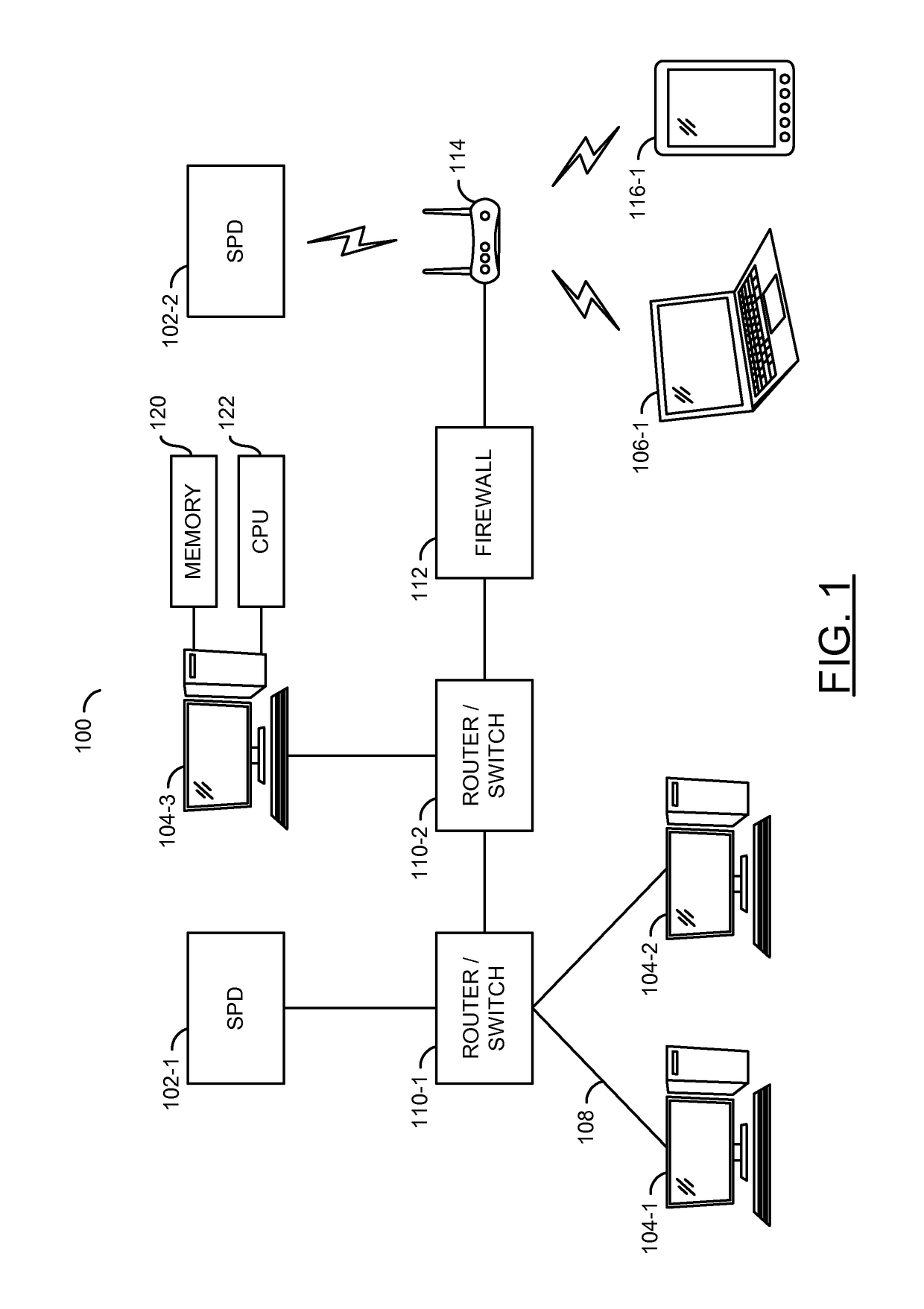

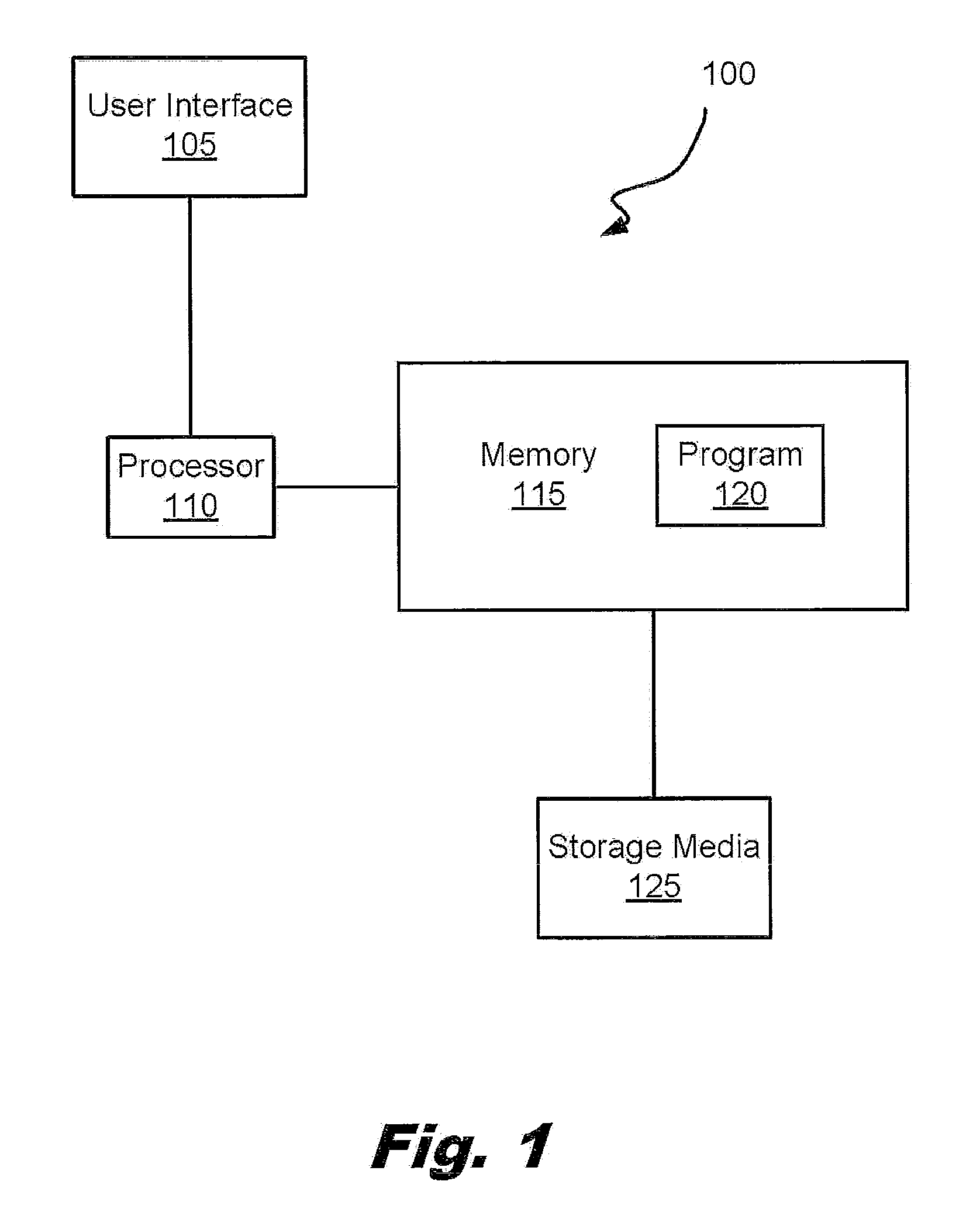

Power management for a self-powered device scheduling a dynamic process

ActiveUS9874923B1Input/output to record carriersPower supply for data processingElectric forceClock rate

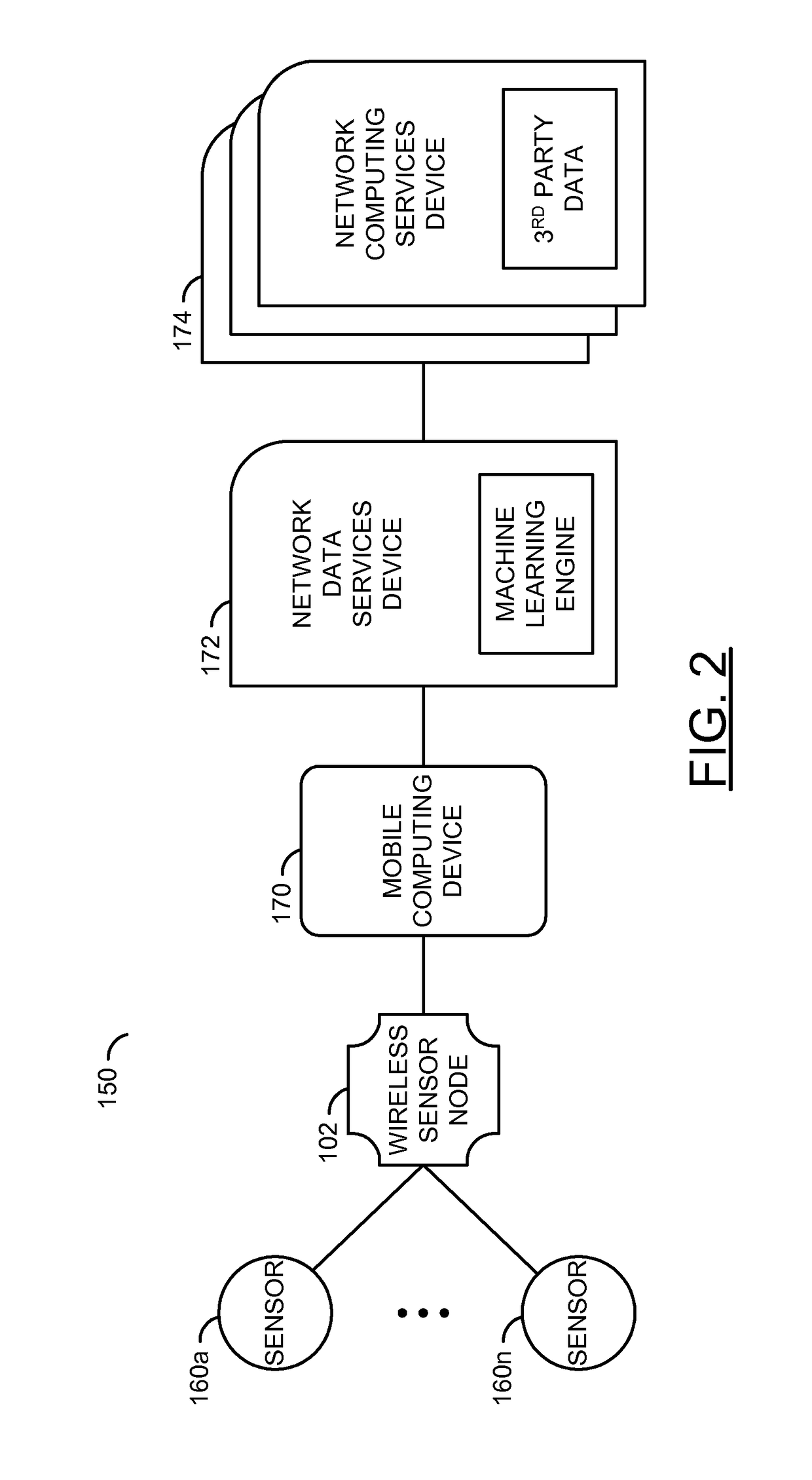

A device comprising a battery, a memory, a data acquisition circuit and a processor. The sensors may sample a current state of a dynamic process. The data acquisition circuit may have a first clock rate based on a sampling rate of the dynamic process. The data acquisition circuit may read sensor information from the sensors. The processor may have a second clock rate. The processor may process the sensor information and generate a monitoring signal based on at least one of the sensor information, a model of the dynamic process and a desired state of the dynamic process. The processor may schedule procedures for the device and determine computation times for the procedures based on context information. The second clock rate is faster than the first clock rate. The procedures are scheduled based on the sampling rate, the computation times for the procedures and opportunities to enter a standby mode to conserve power.

Owner:INVENT LY LLC

Method for measuring diffusivities of compounds using microchips

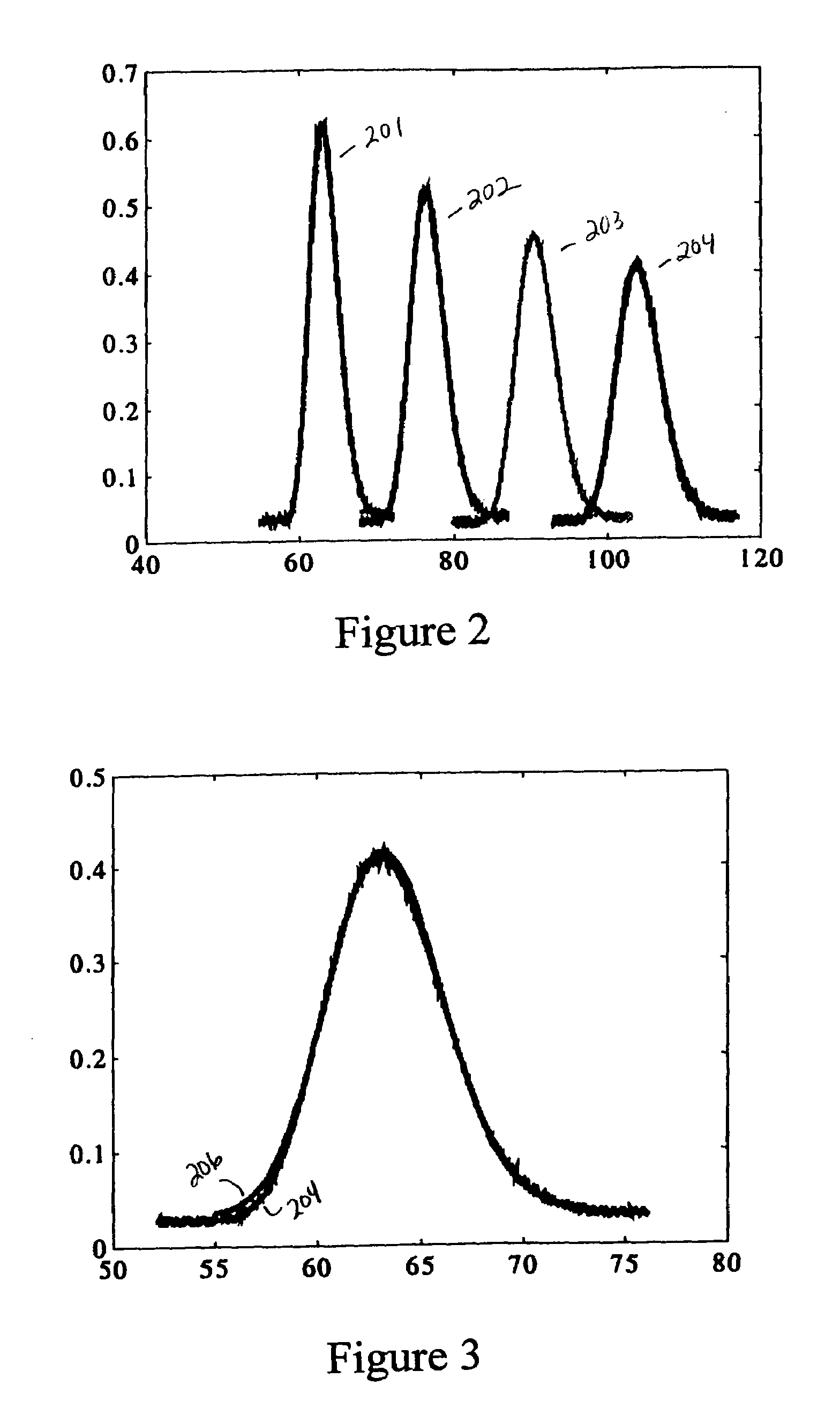

ActiveUS7039527B2High peakReduce concentrationMaterial analysis by electric/magnetic meansLaboratory glasswaresChemistryMolecular diffusion

Owner:CAPLIPER LIFE SCI INC

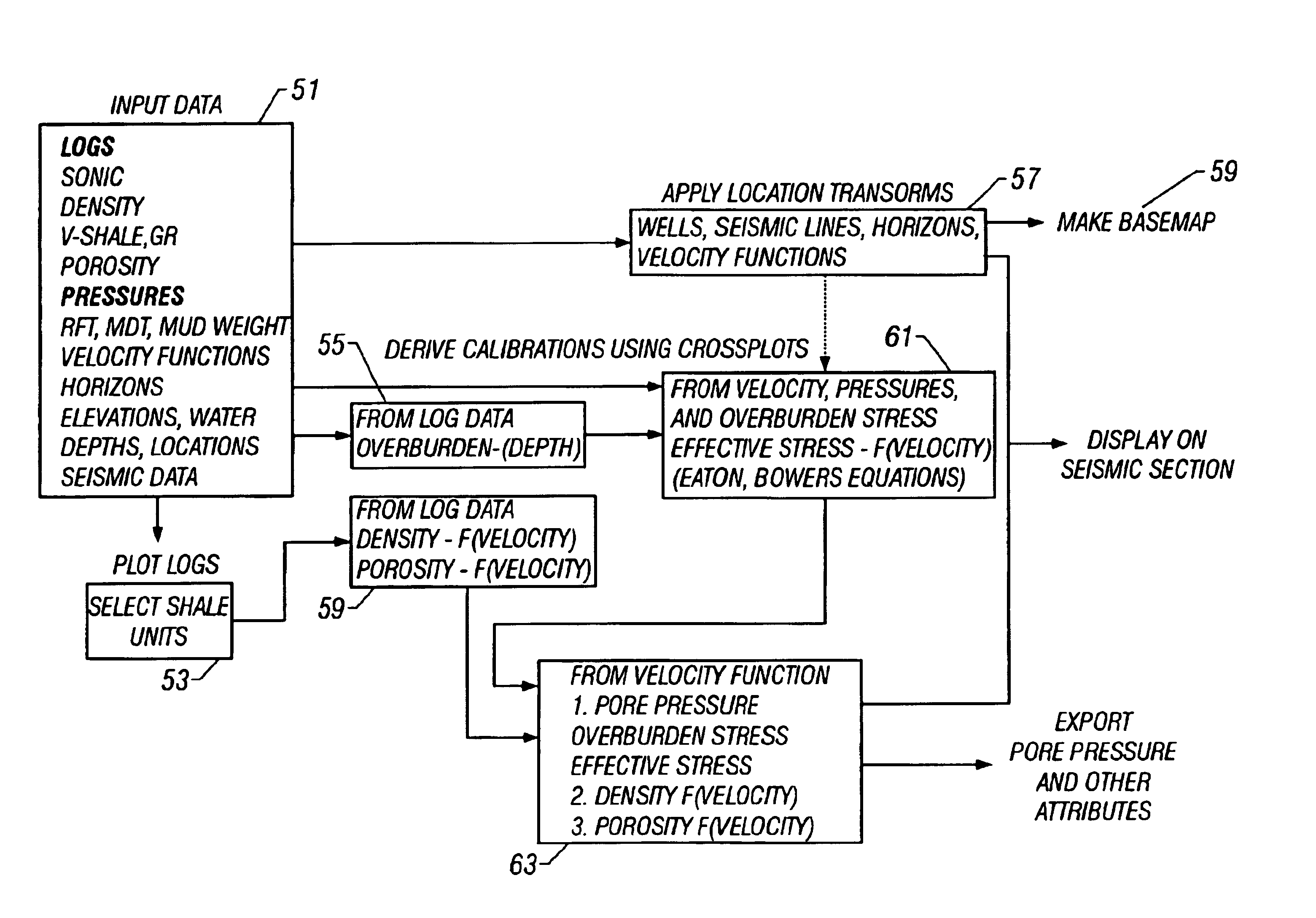

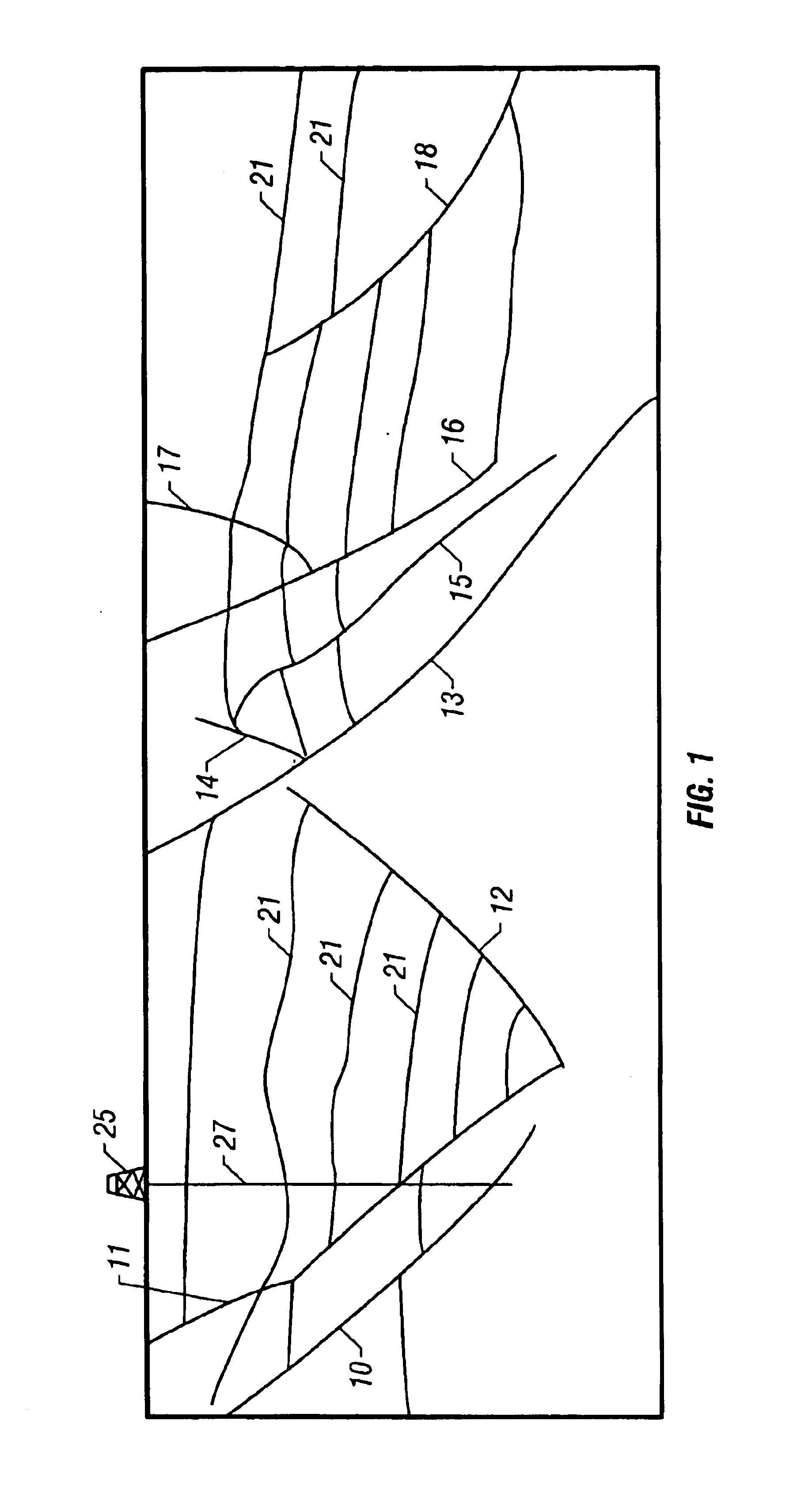

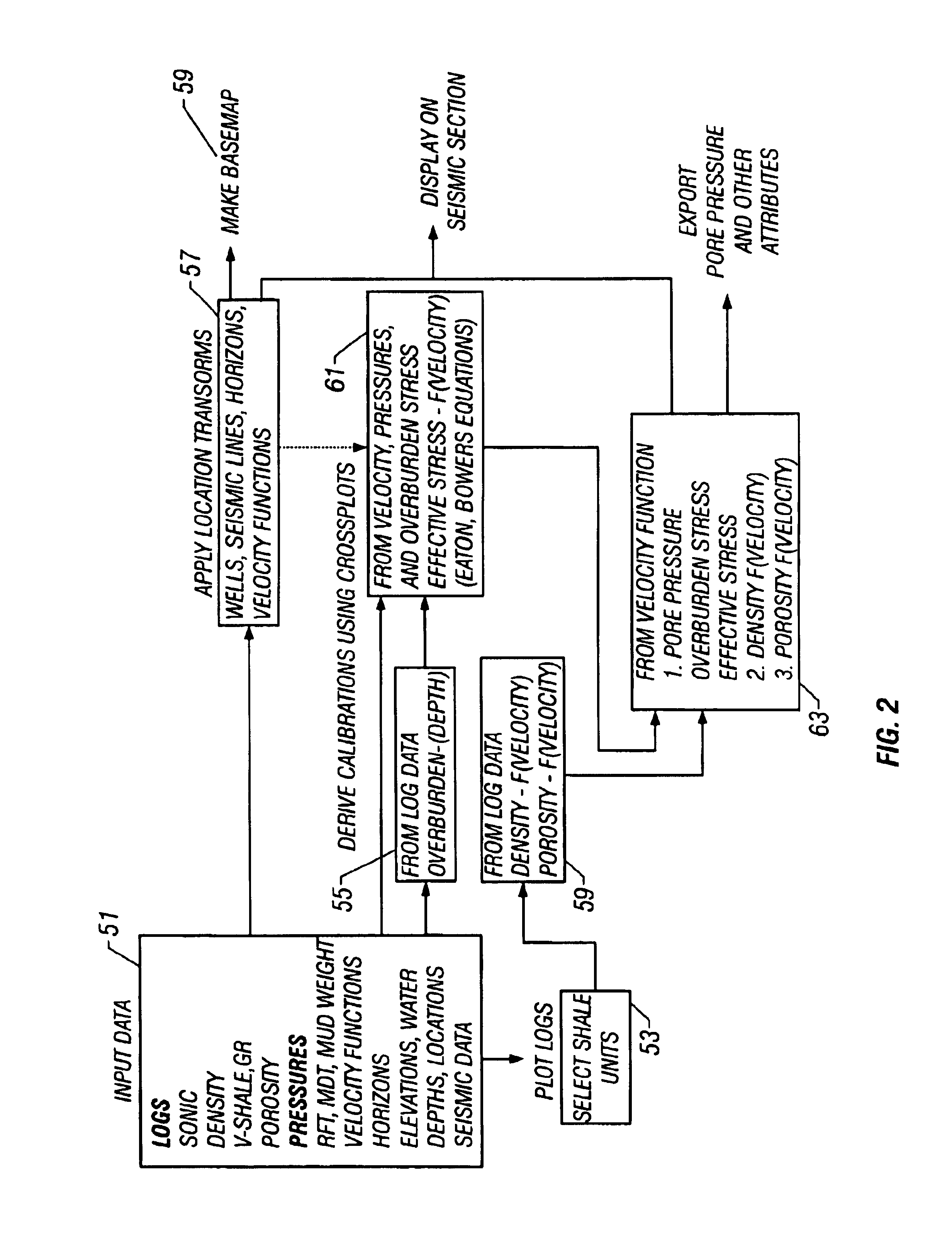

Method and process for prediction of subsurface fluid and rock pressures in the earth

A method of determination of fluid pressures in a subsurface region of the earth uses seismic velocities and calibrations relating the seismic velocities to the effective stress on the subsurface sediments. The seismic velocities may be keyed to defined seismic horizons and may be obtained from many methods, including velocity spectra, post-stack inversion, pre-stack inversion, VSP or tomography. Overburden stresses may be obtained from density logs, relations between density and velocity, or from inversion of potential fields data. The seismic data may be P-P, P-S, or S-S data. The calibrations may be predetermined or may be derived from well information including well logs and well pressure measurements. The calibrations may also include the effect of unloading. The determined pressures may be used in the analysis of fluid flow in reservoirs, basin and prospect modeling and in fault integrity analysis.

Owner:CONOCOPHILLIPS CO

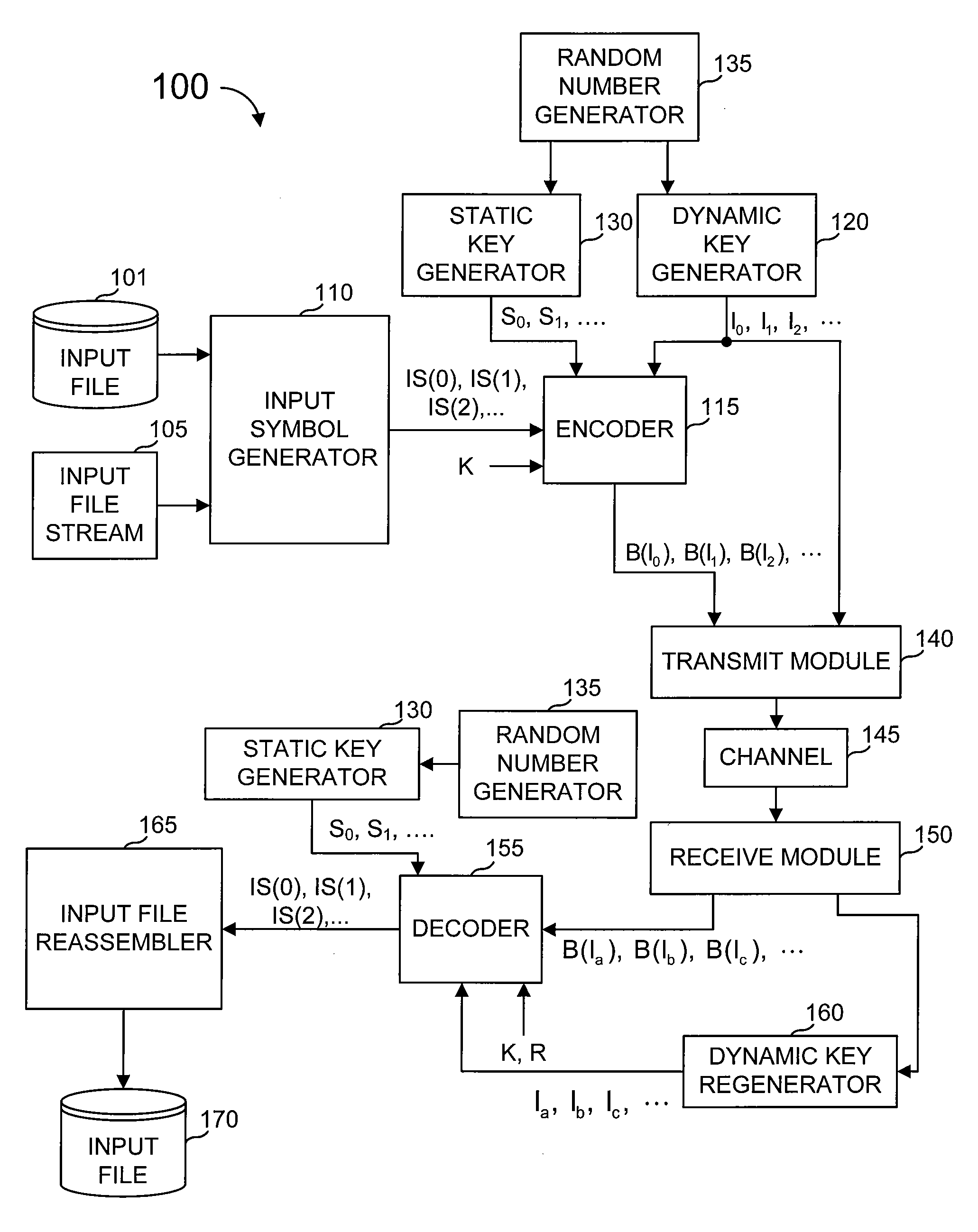

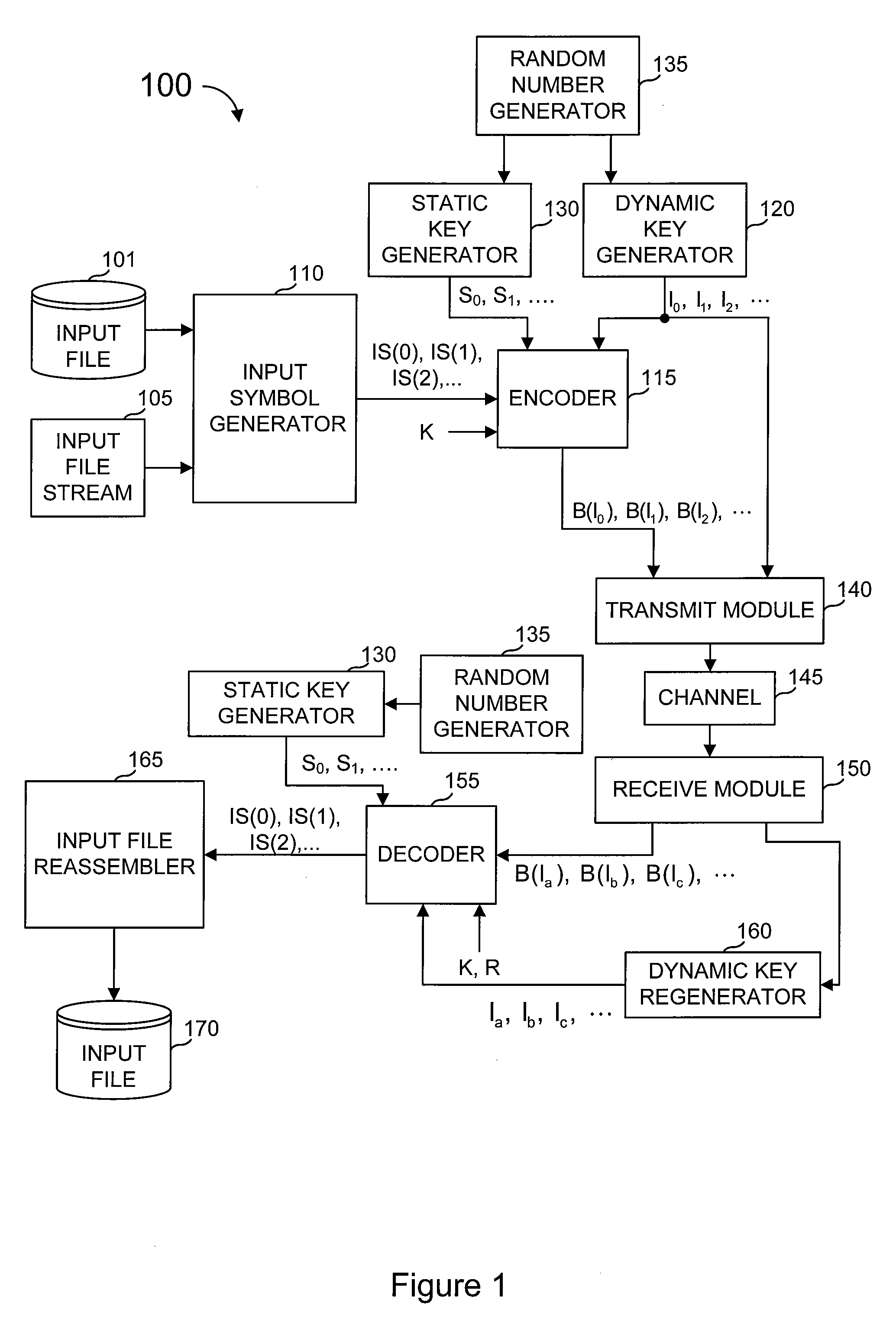

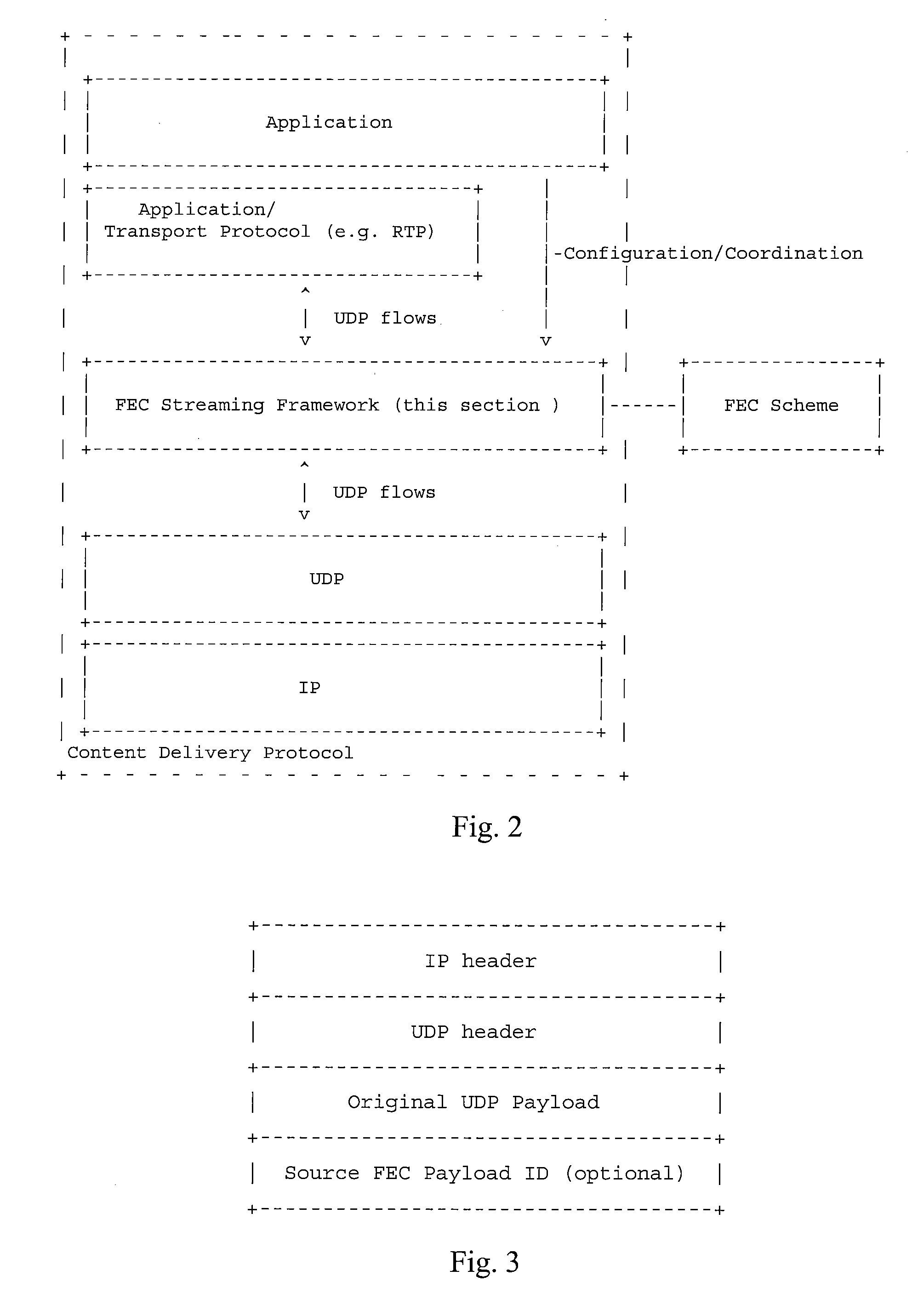

Streaming and buffering using variable FEC overhead and protection periods

InactiveUS20070204196A1Data rate variesError prevention/detection by using return channelCode conversionStreaming dataForward error correction

Data is streamed from a transmitter to a receiver, wherein streaming is transferring data with an assumption that the receiver will begin using the data before it is all transmitted and received and the streamed data includes forward error correction (“FEC”) and the rates of data consumption can vary. The transmitter has an input rate and a transmit rate and the two rates can be different and can change. At the receiver, there is a reception rate (at which the receiver receives data) and a consumption rate (at which the receiver uses up data for its output). The transmitter transmits using a transmit rate higher than the consumption rate and the extra bandwidth is usable for FEC protection and buffering. In some embodiments, the excess rate varies over a transmission period.

Owner:QUALCOMM INC

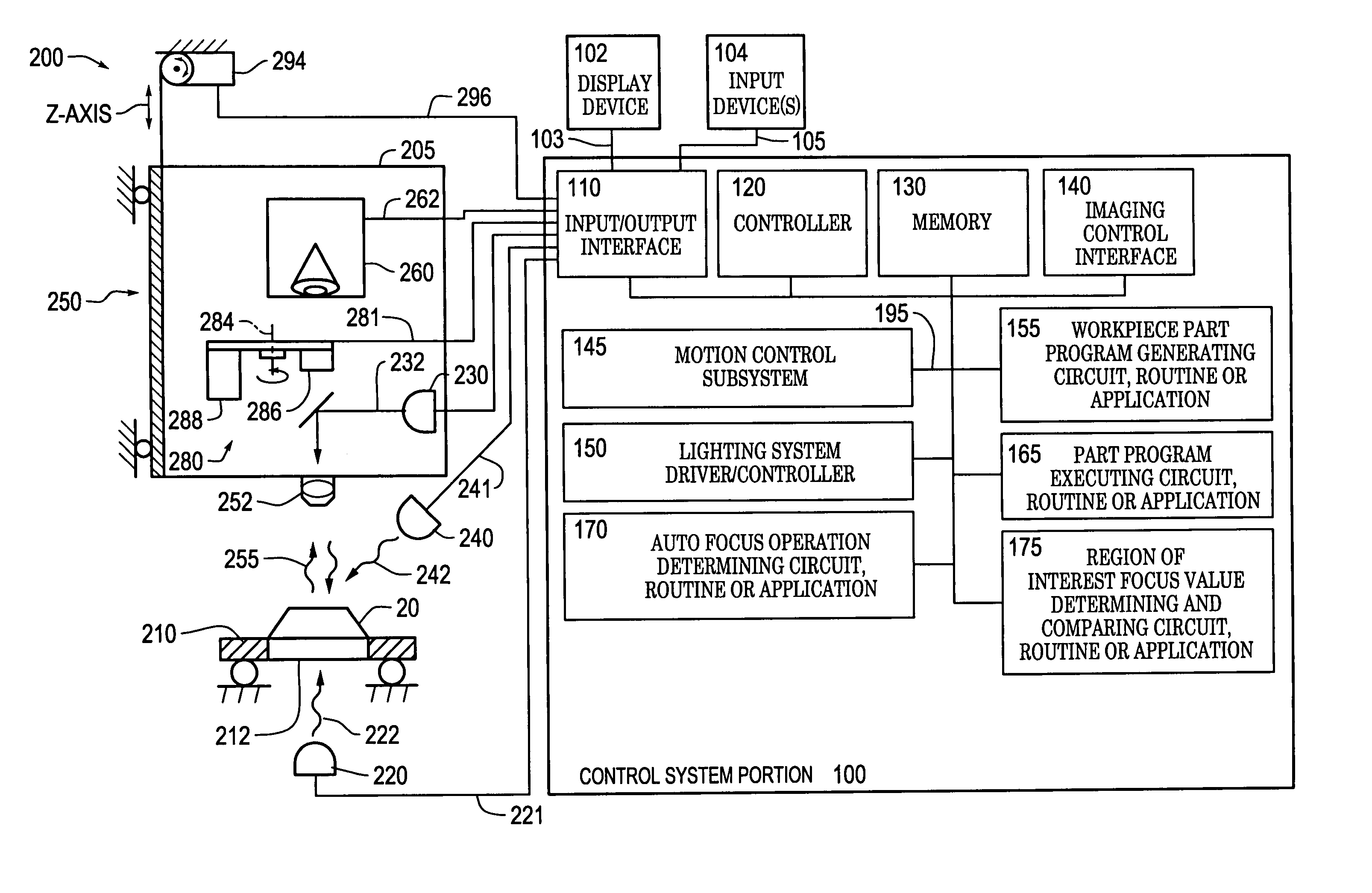

Systems and methods for rapidly automatically focusing a machine vision inspection system

ActiveUS20050109959A1Increase speedAccurate autofocusTelevision system detailsSolid-state devicesMachine visionMetrology

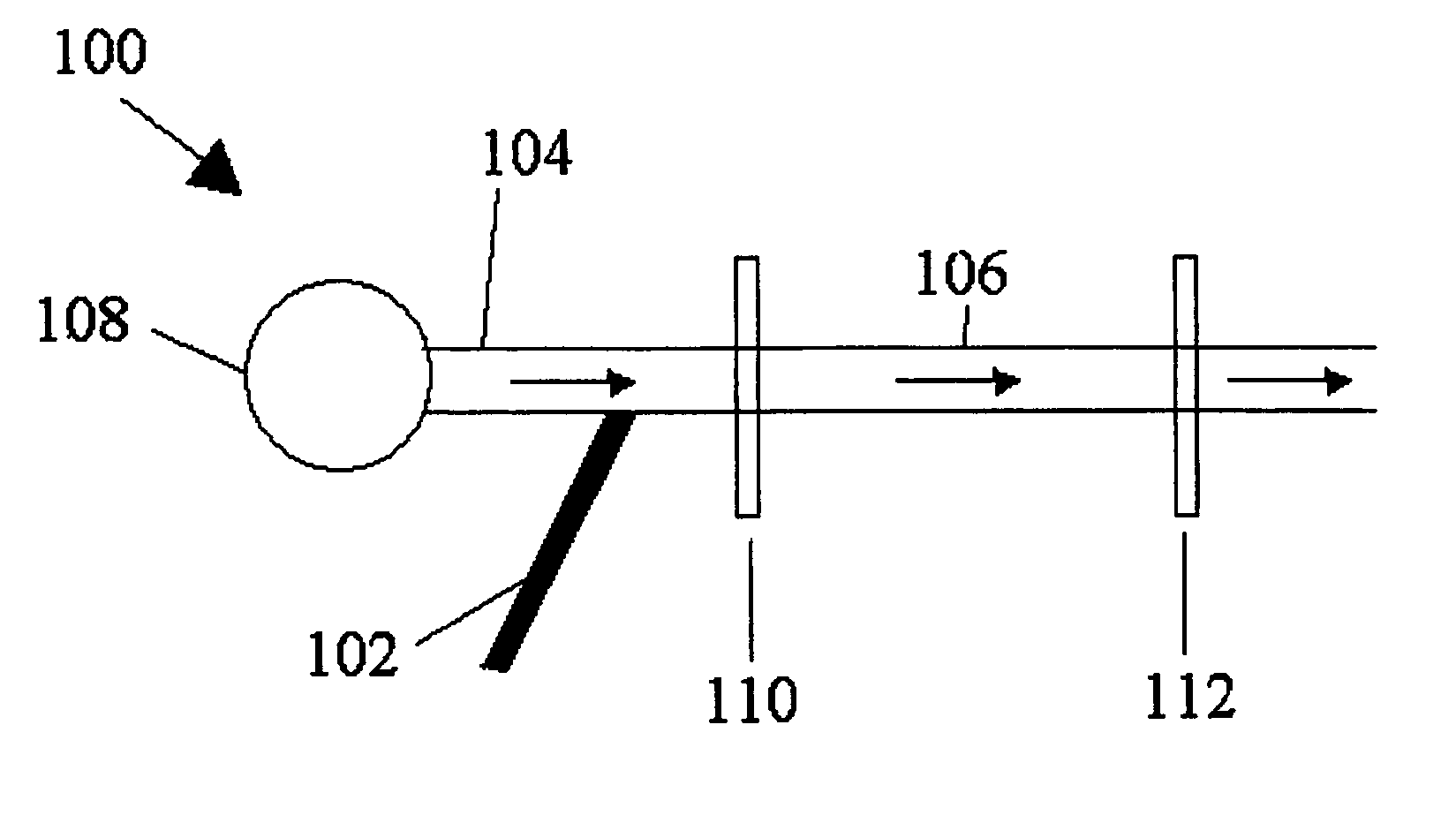

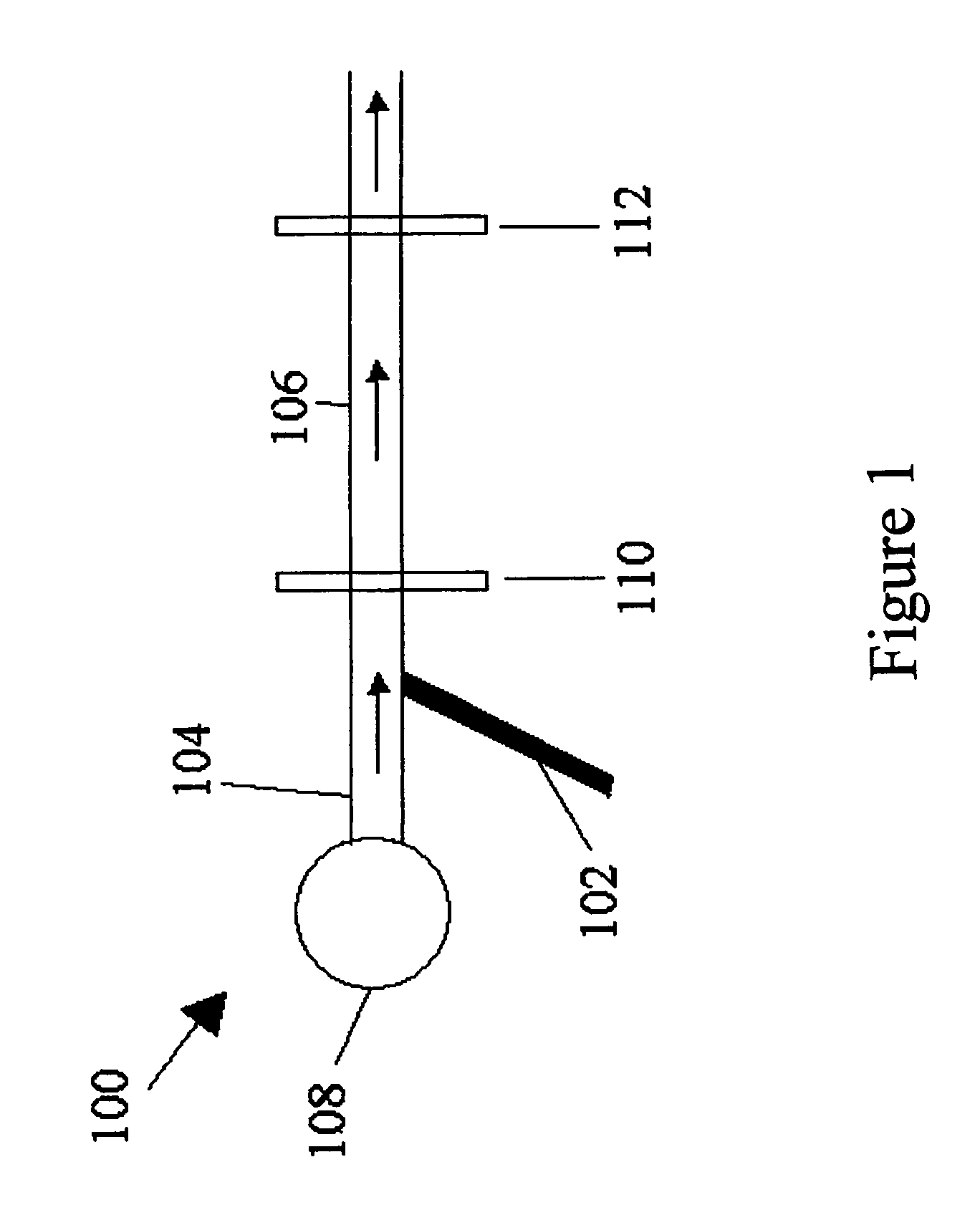

Auto focus systems and methods for a machine vision metrology and inspection system provide high speed and high precision auto focusing, while using relatively low-cost and flexible hardware. One aspect of various embodiments of the invention is that the portion of an image frame that is output by a camera is minimized for auto focus images, based on a reduced readout pixel set determined in conjunction with a desired region of interest. The reduced readout pixel set allows a maximized image acquisition rate, which in turn allows faster motion between auto focus image acquisition positions to achieve a desired auto focus precision at a corresponding auto focus execution speed that is approximately optimized in relation to a particular region of interest. In various embodiments, strobe illumination is used to further improve auto focus speed and accuracy. A method is provided for adapting and programming the various associated auto focus control parameters.

Owner:MITUTOYO CORP

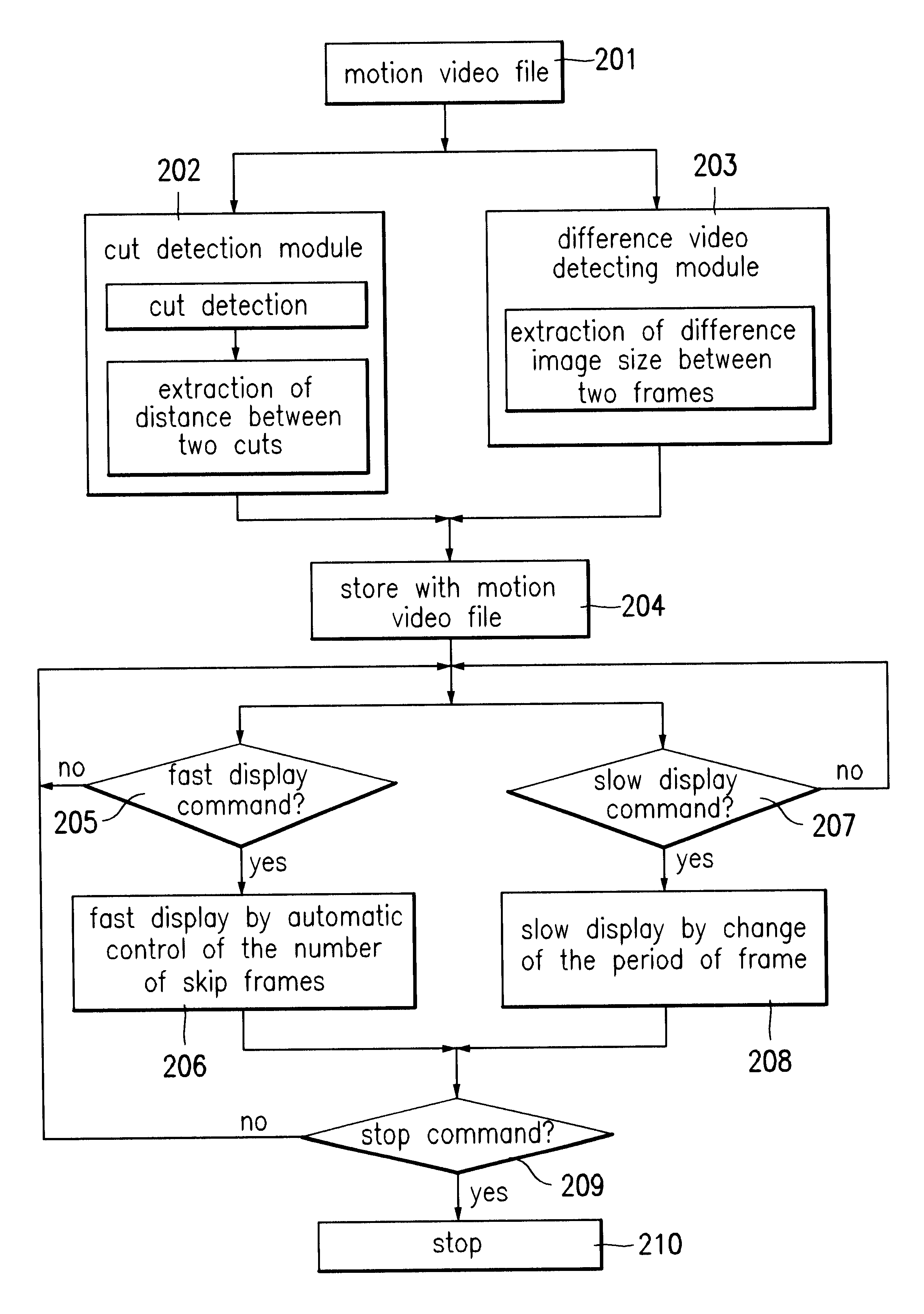

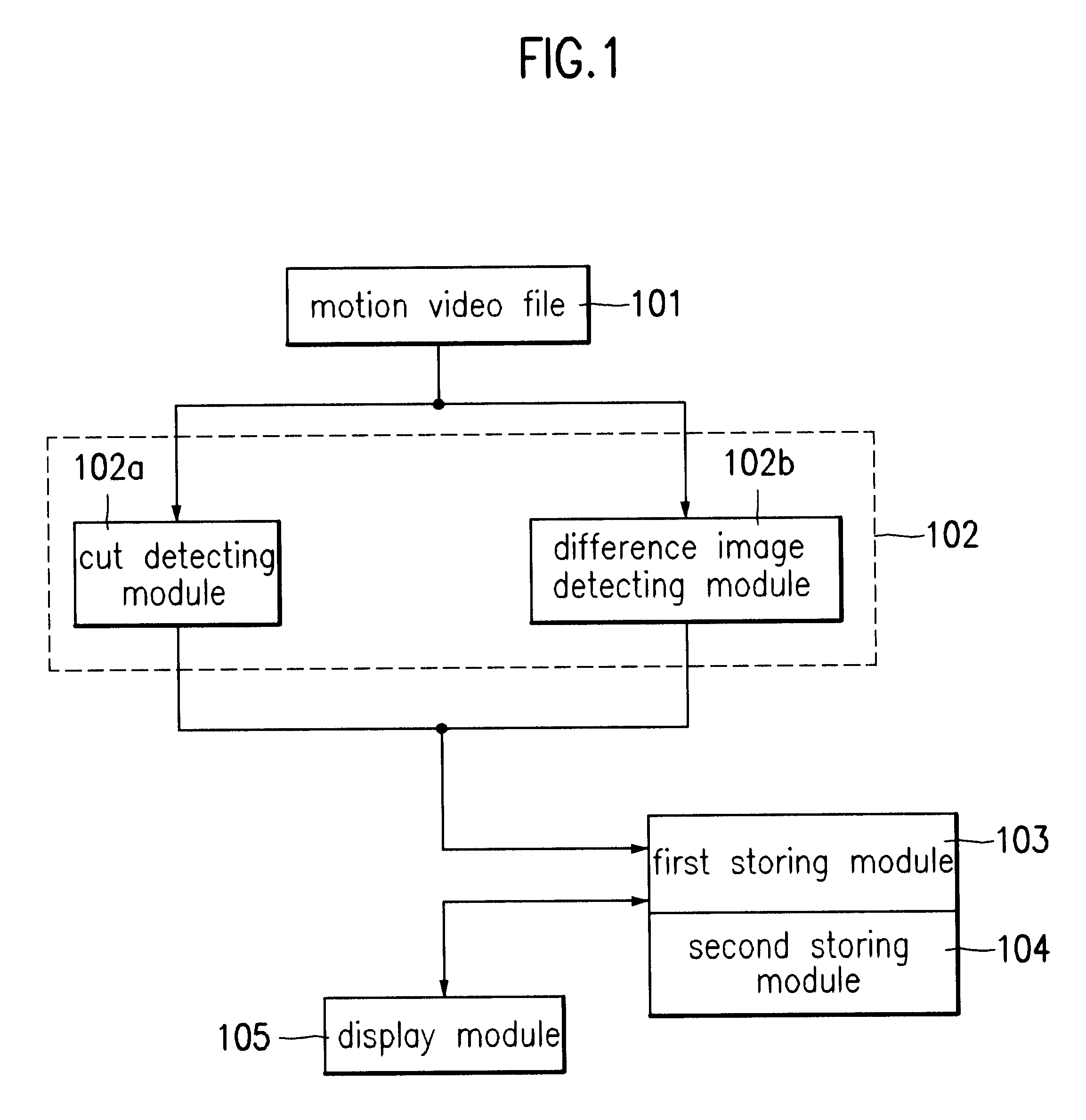

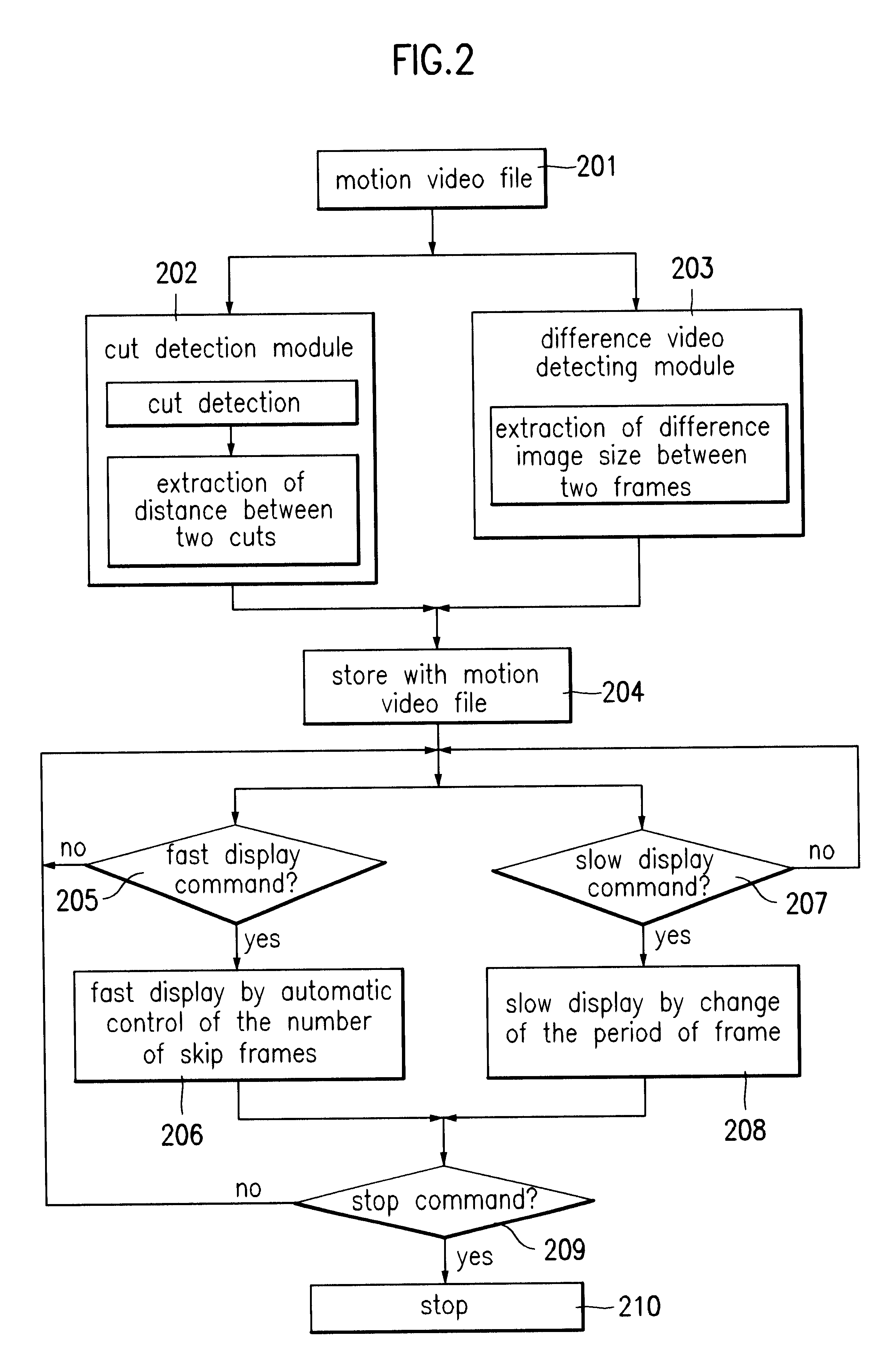

Adaptive display speed automatic control device of motional video and method therefor

InactiveUS6611653B1Television system detailsPulse modulation television signal transmissionAutomatic controlSelf adaptive

An automatic control device and method for an adaptive display speed of a motion video is disclosed. The present invention is capable of adaptively controlling acceleration and speed change of a motion video according to the variation rate of the motion video within the interval of fast forward or slow motion modes.

Owner:LG ELECTRONICS INC

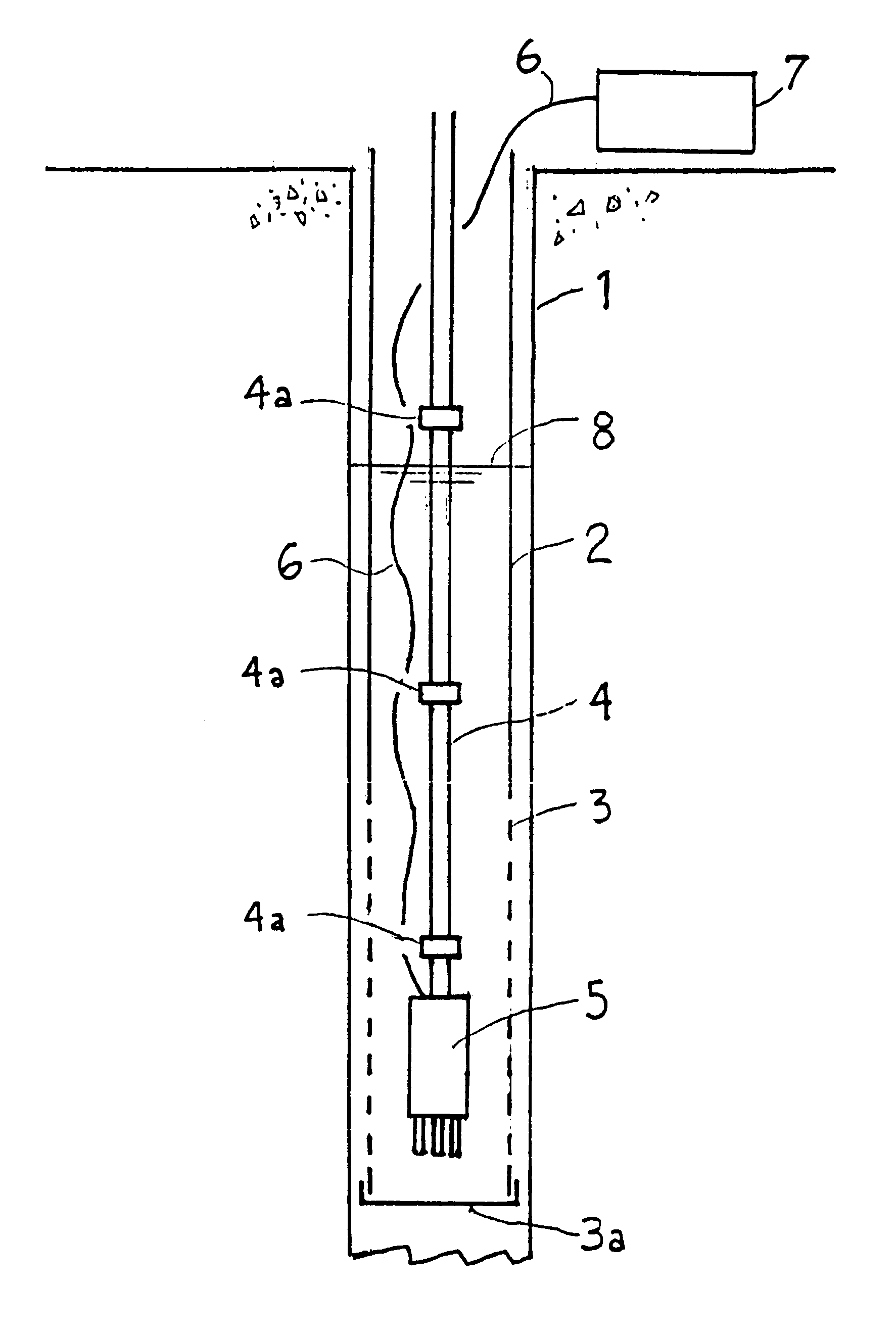

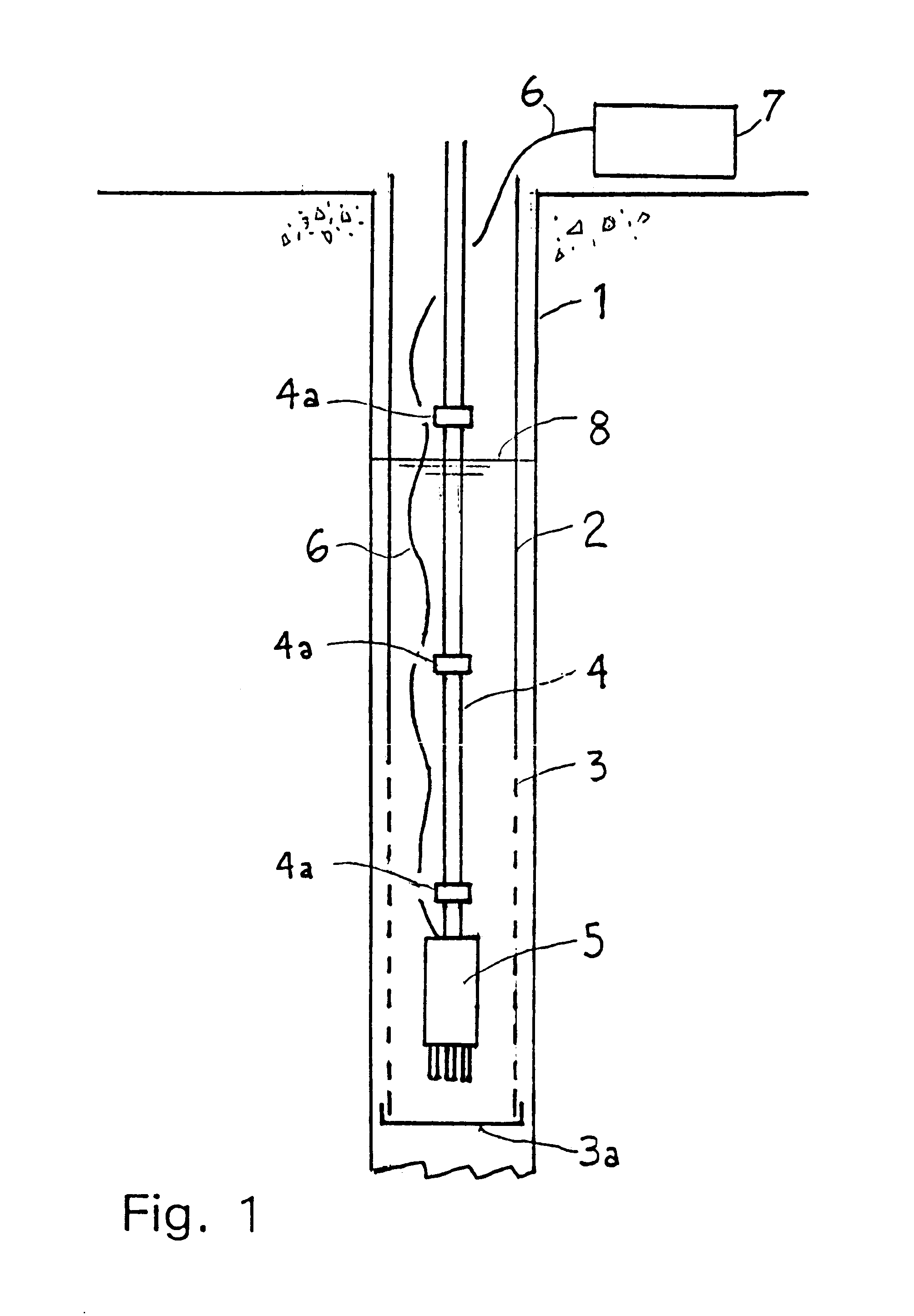

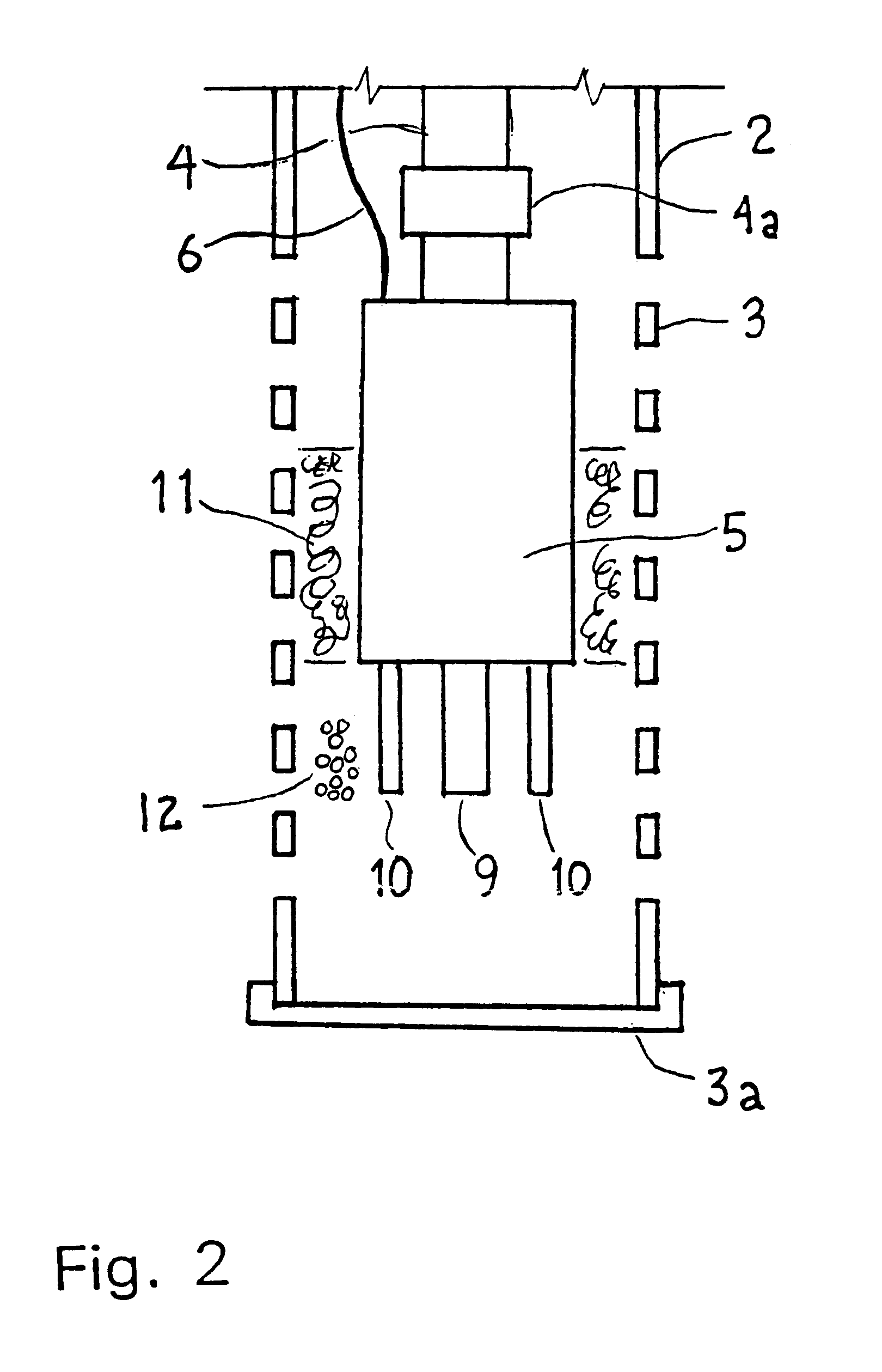

Groundwater flow measuring system

A probe for monitoring groundwater flow seepage velocity and direction has an electrical heater and a plurality of temperature sensors located equidistant from the heater. The probe with the heater and temperature sensors is lowered into a monitoring well and positioned so as to be immersed in the groundwater. Energy is sent to the heater, and the temperature response at the temperature sensors is measured and recorded. From the measured response to temperature, the groundwater flow velocity and direction are computed and recorded. The temperature sensors may be resistance temperature detectors, thermocouples, or any other state-of-the-art temperature sensing device.

Owner:U S ARMY CORPS OF ENGINEERS AS REPRESENTED BY THE SEC OF THE AMRY

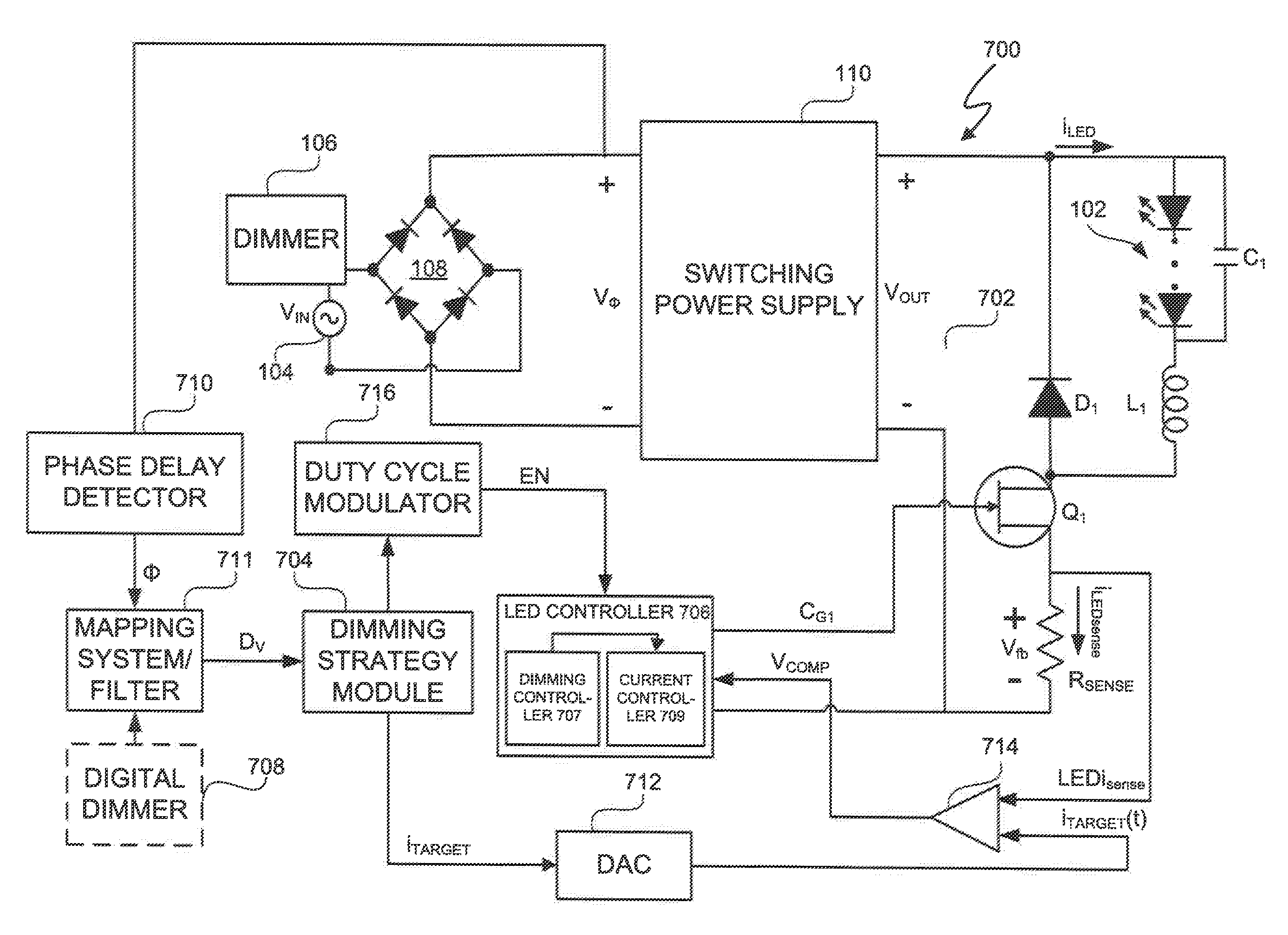

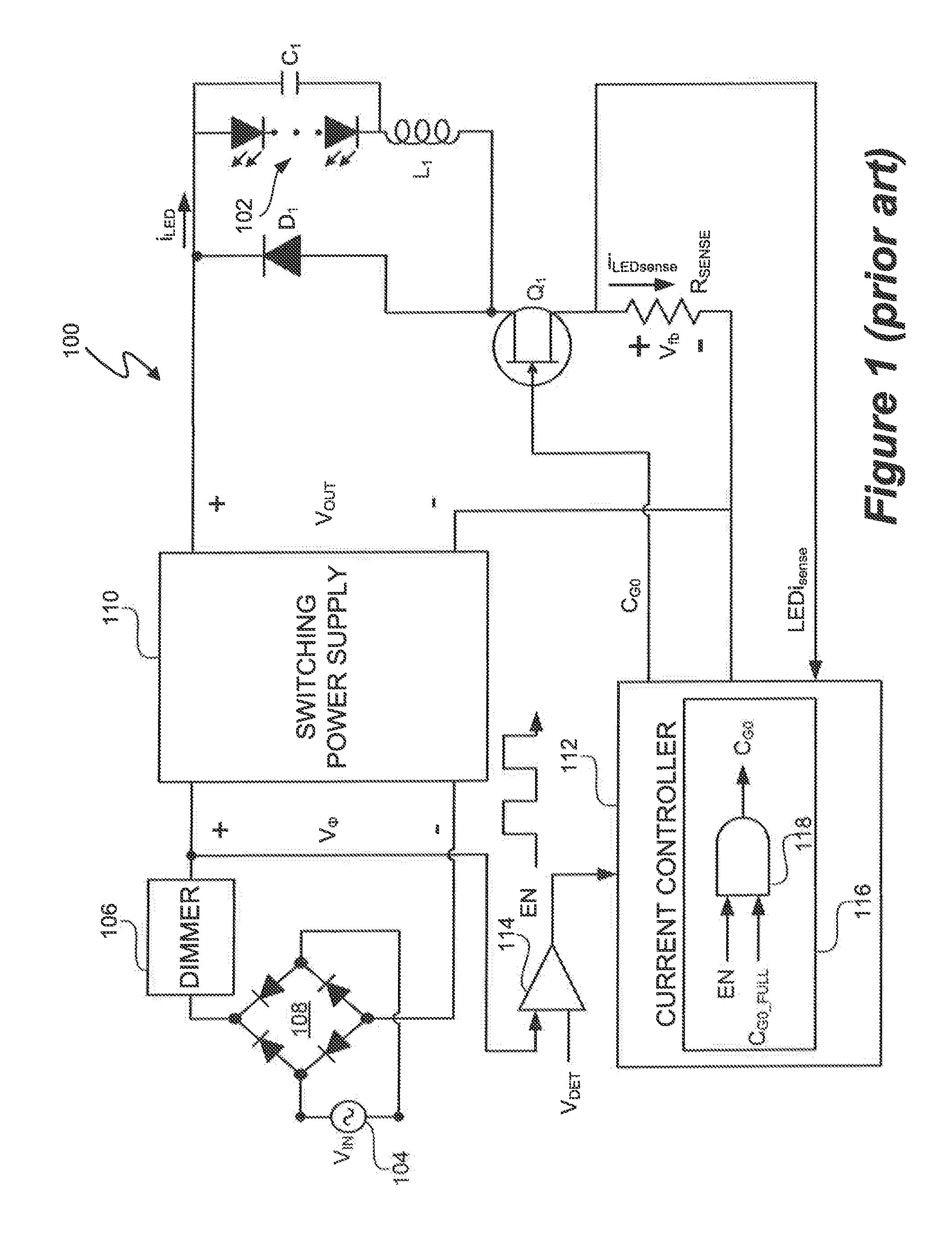

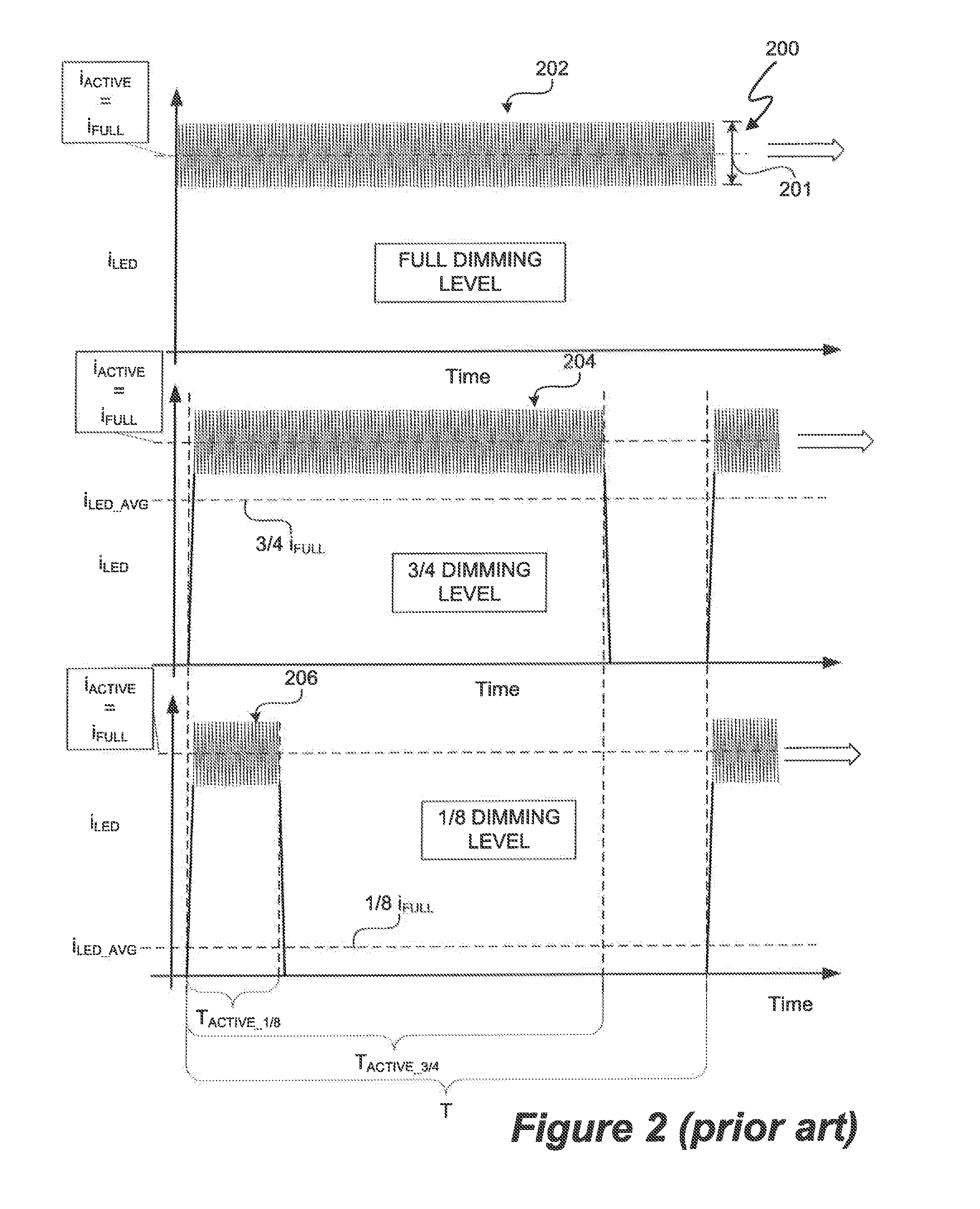

LED Lighting System with Accurate Current Control

A light emitting diode (LED) lighting system and method are disclosed. The LED lighting system and method include an LED controller to accurately control a current in an LED system. The LED controller includes components to calculate, based on the current and an active time period of an LED current time period, an actual charge amount delivered to the LED system wherein the LED current time period is duty cycle modulated at a rate of greater than fifty (50) Hz and to utilize the actual charge amount to modify and provide a desired target charge amount to be delivered during a future active time period of the LED current time period. The LED system and method further involve components to compare the actual charge amount to a desired charge amount for the active time period and compensate for a difference between the actual charge amount and the desired charge amount during the future active time period.

Owner:SIGNIFY HLDG BV

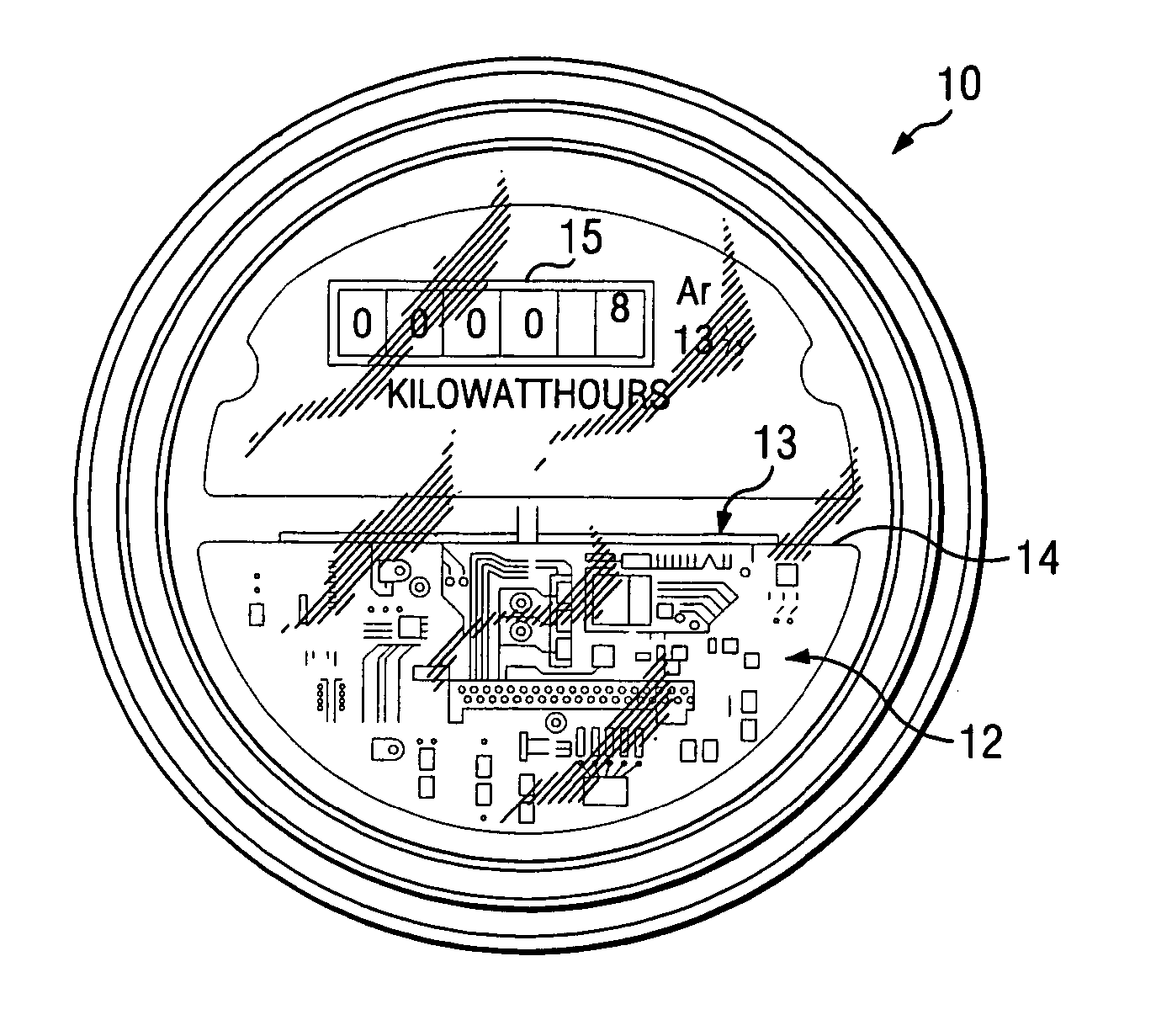

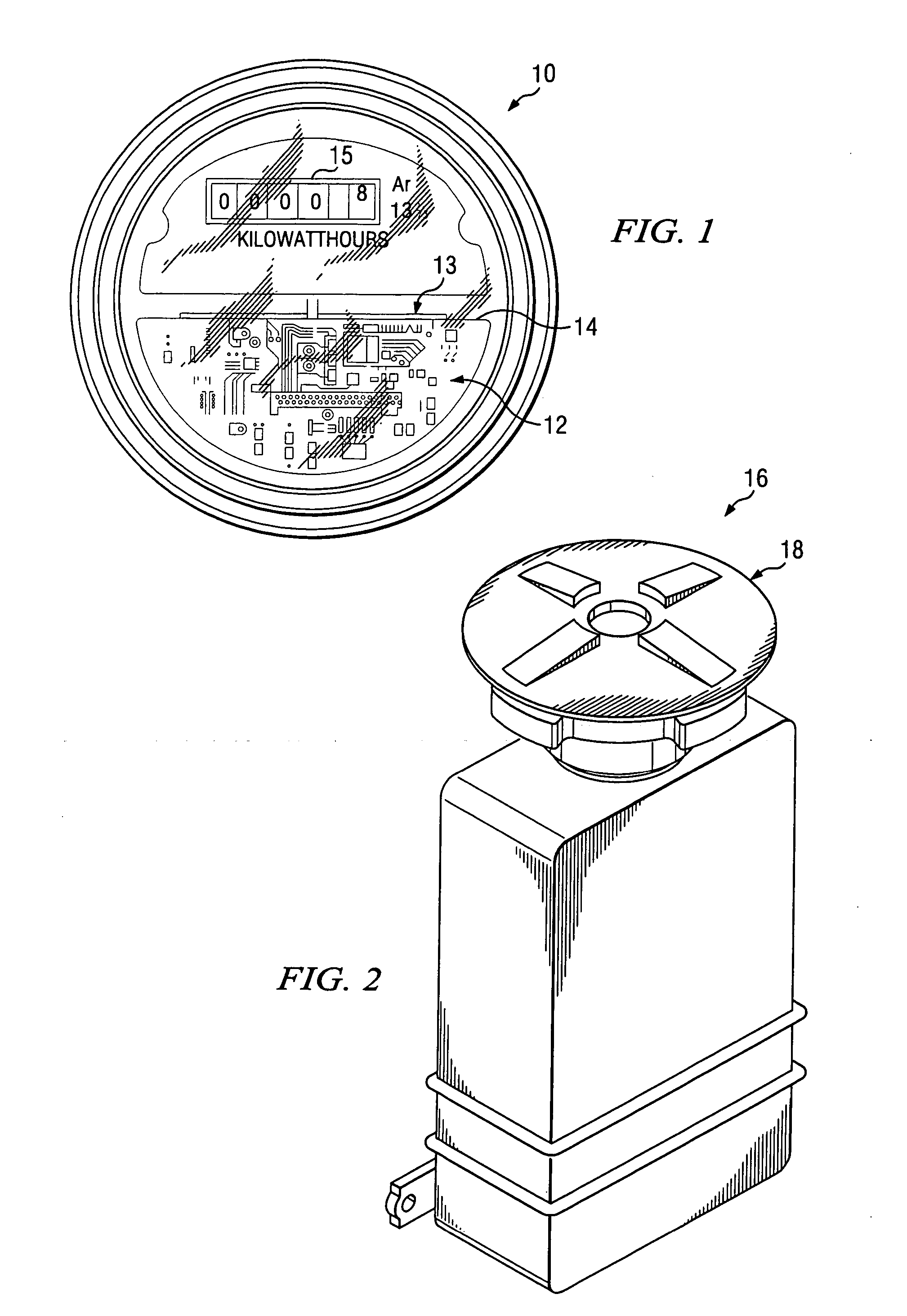

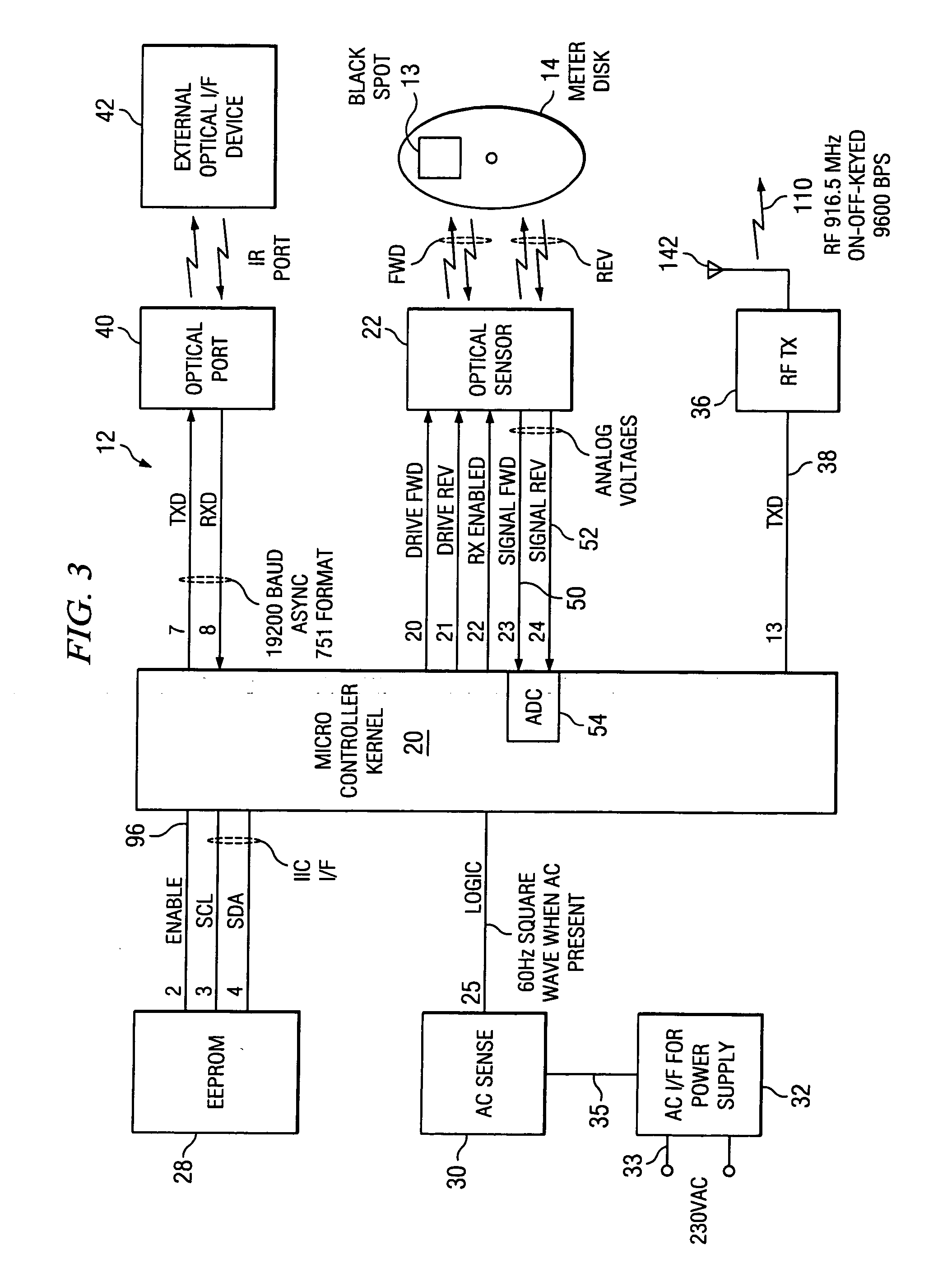

Automated meter reader having peak product delivery rate generator

InactiveUS20060028355A1Electric signal transmission systemsTariff metering apparatusTime informationPeak value

A AMR device adapted to couple to utility meters and detect an peak rate of product delivery and responsively generate a signal indicative of the peak rate of product delivery. This information is transmitted to a remote location, such as to a utility or to a municipality. This peak rate of delivery is time-stamped and can be determined each clock cycle to generate real-time information. Moreover, previous peak rate delivery information can also be stored for transmission, and associated with a time of delivery. This information is useful to help understand the maximum flow rates a particular metering device is subject to for equipment selection, as well as applications in the area of conservation enforcement.

Owner:PINE TREE HLDG

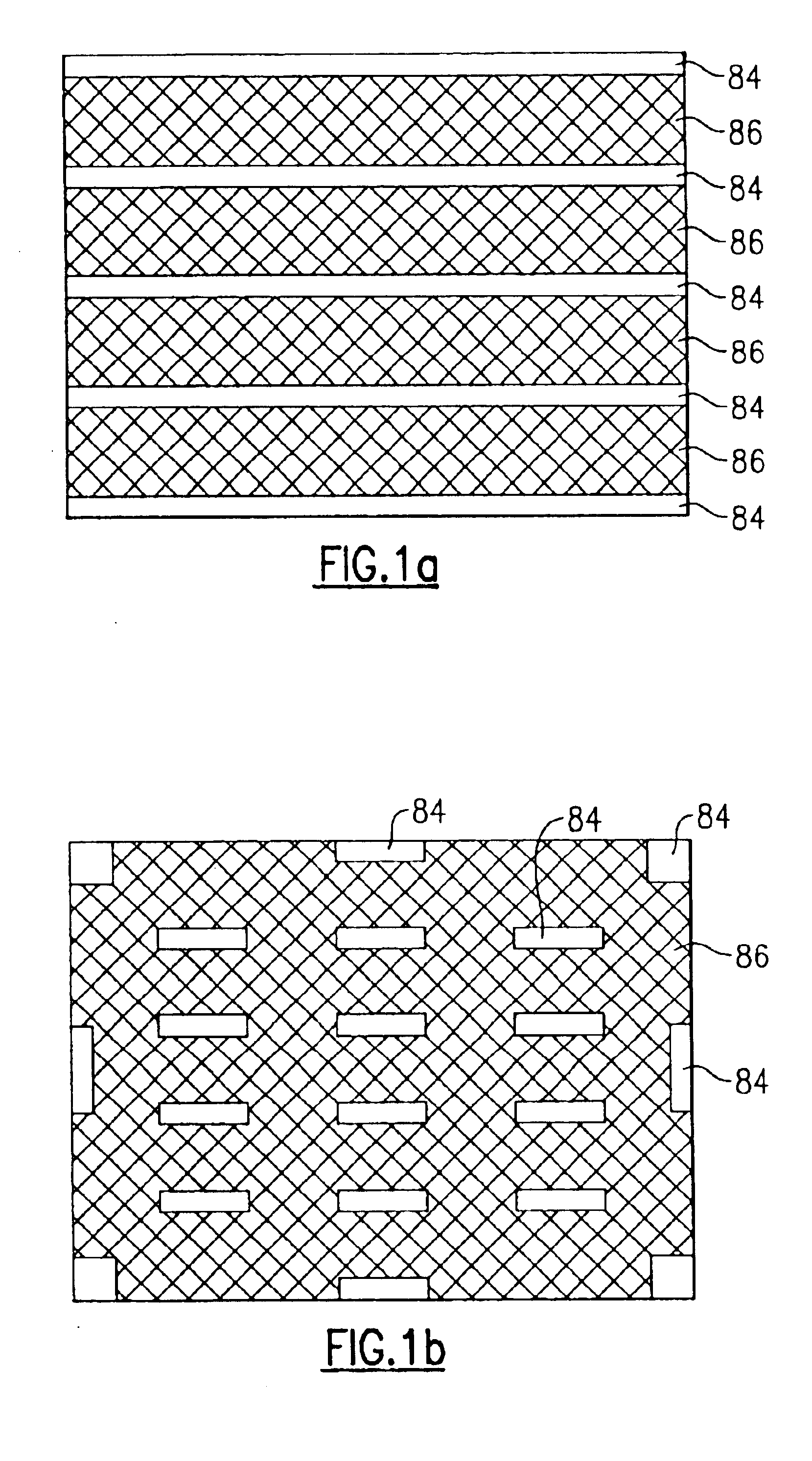

Optical reader having reduced parameter determination delay

InactiveUS7268924B2Reduce delaysHigh resolutionColour-separation/tonal-correctionSensing by electromagnetic radiationSensor arrayImage resolution

In the present invention, an optical reader image sensor is adapted to clock out image data from an image sensor according to “low resolution” mode of operation in order to reduce a parameter determination delay of the reader. In a low resolution mode, some pixels of the readers image sensor array are clock out at normal clock out speed sufficient to develop electrical signals accurately reflecting the intensity of light at the respective pixel positions, while other pixels of the array are either not clocked out or are clocked out at a higher clock out rate which may be insufficient to allow development of electrical signals that accurately represent light incident on the image sensor's sensor array but which nevertheless, results in a reduction of the overall frame clock out rate of the frame of image data. An optical reader according to the invention operates in a low resolution frame clock out mode to capture a low resolution parameter determining frame of image data at high speed, reads pixel data from the parameter determination frame to determine an operation parameter based on actual illumination conditions, then utilizes the operation parameter in operating an optical reader.

Owner:WELCH ALLYN DATA COLLECTION

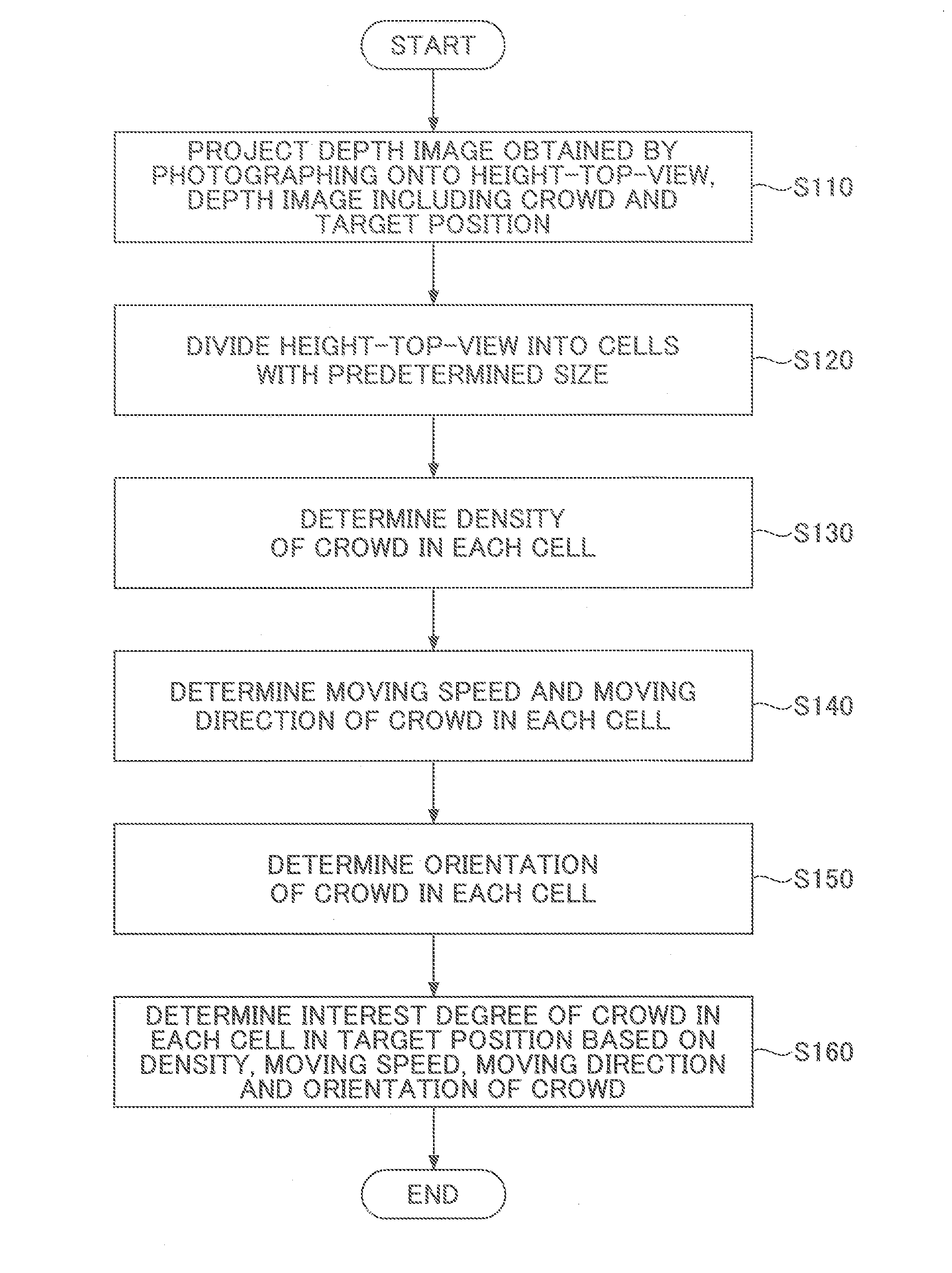

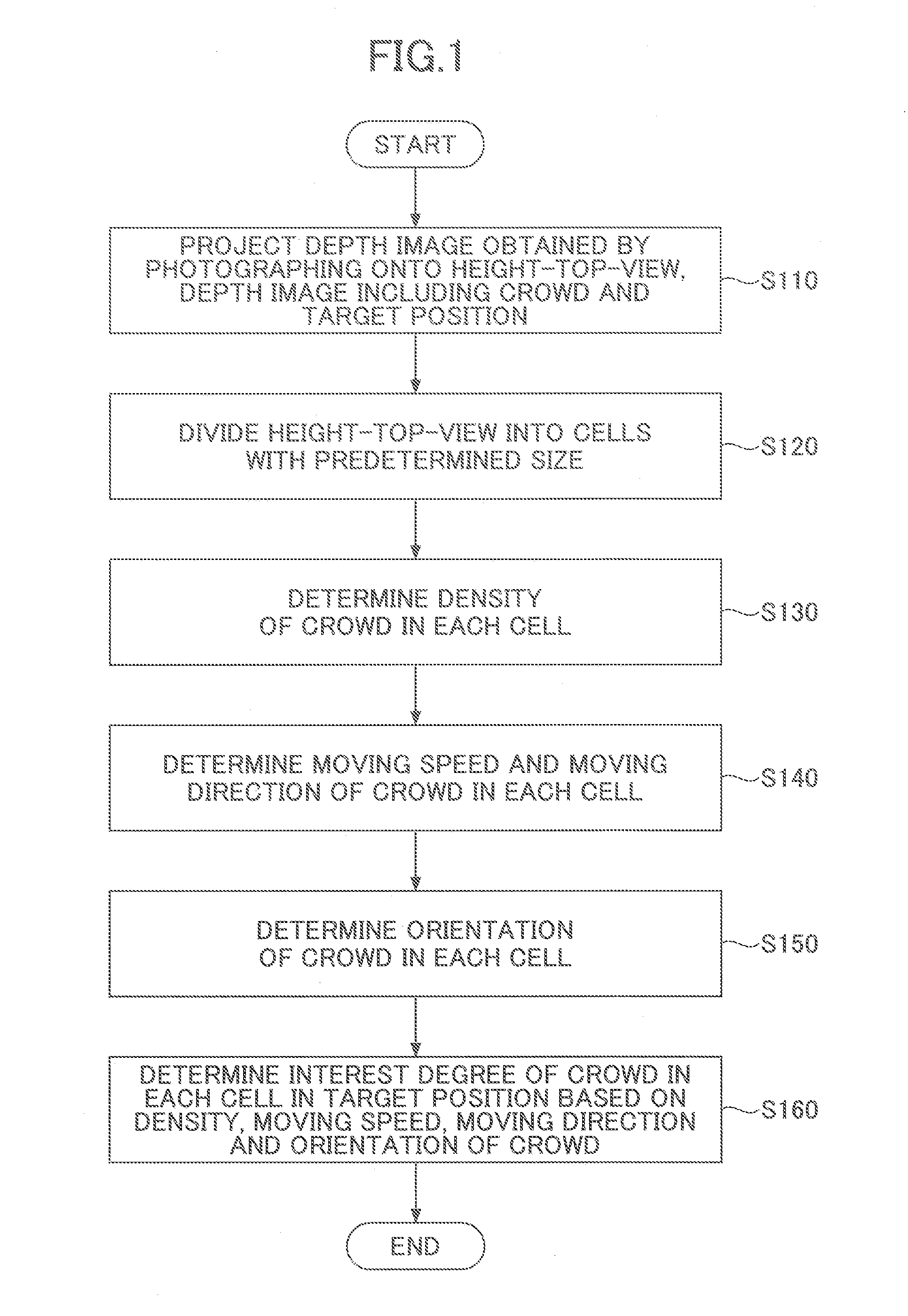

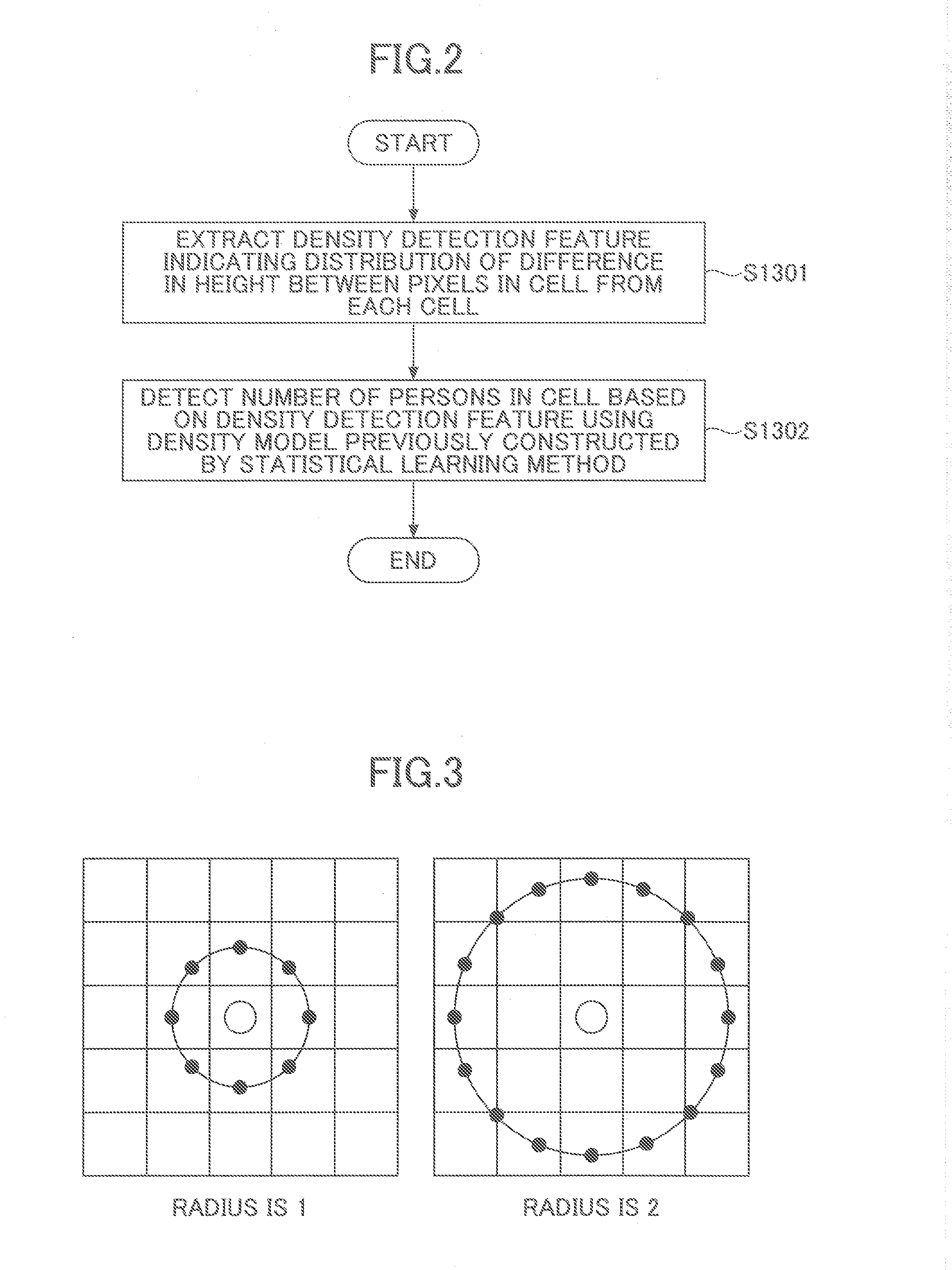

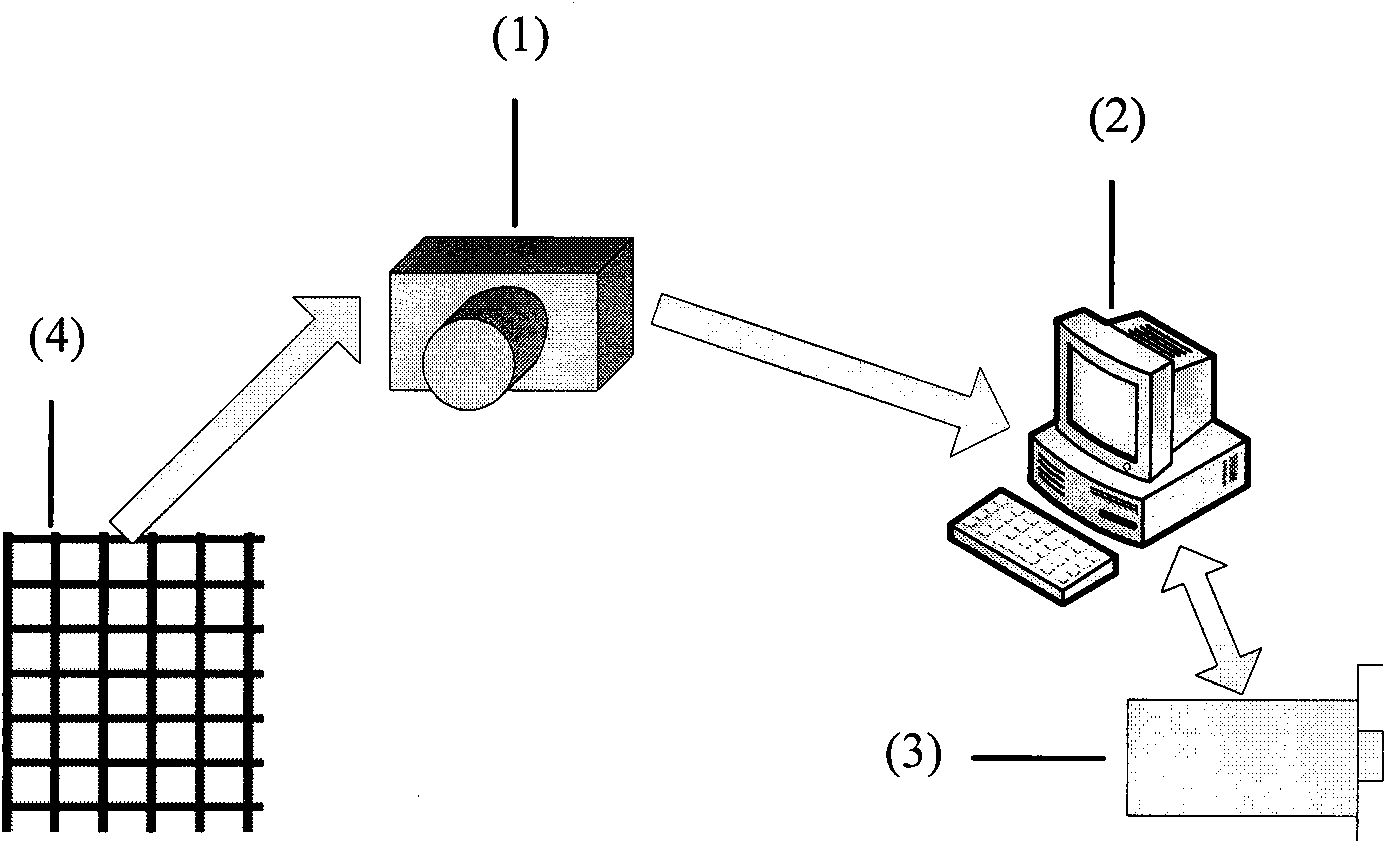

Method for detecting crowd density, and method and apparatus for detecting interest degree of crowd in target position

ActiveUS20160133025A1Optimize detection resultsMore accurateImage enhancementImage analysisComputer graphics (images)Density based

A method and an apparatus for detecting an interest degree of a crowd in a target position are disclosed. The interest degree detection method includes projecting a depth image obtained by photographing onto a height-top-view, the depth image including the crowd and the target position; dividing the height-top-view into cells; determining density of the crowd in each cell; determining a moving speed and a moving direction of the crowd in each cell; determining orientation of the crowd in each cell; and determining, based on the density, the moving speed, the moving direction and the orientation of the crowd, the interest degree of the crowd in each cell in the target position. According to this method, the interest degree of the crowd in the target position can be detected accurately, even at a crowded place where it is difficult to detect and track a single person.

Owner:RICOH KK

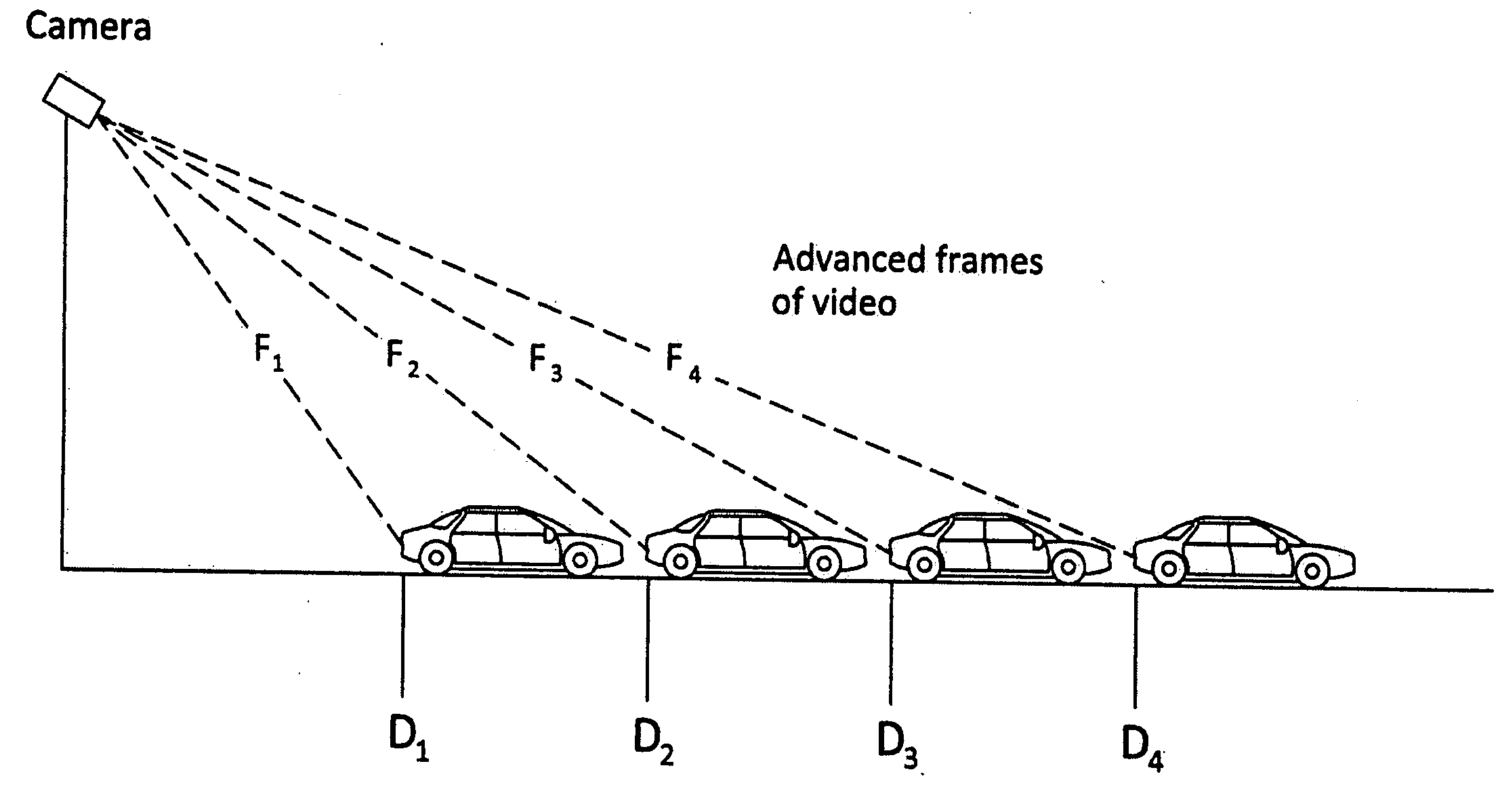

Multiple object speed tracking system

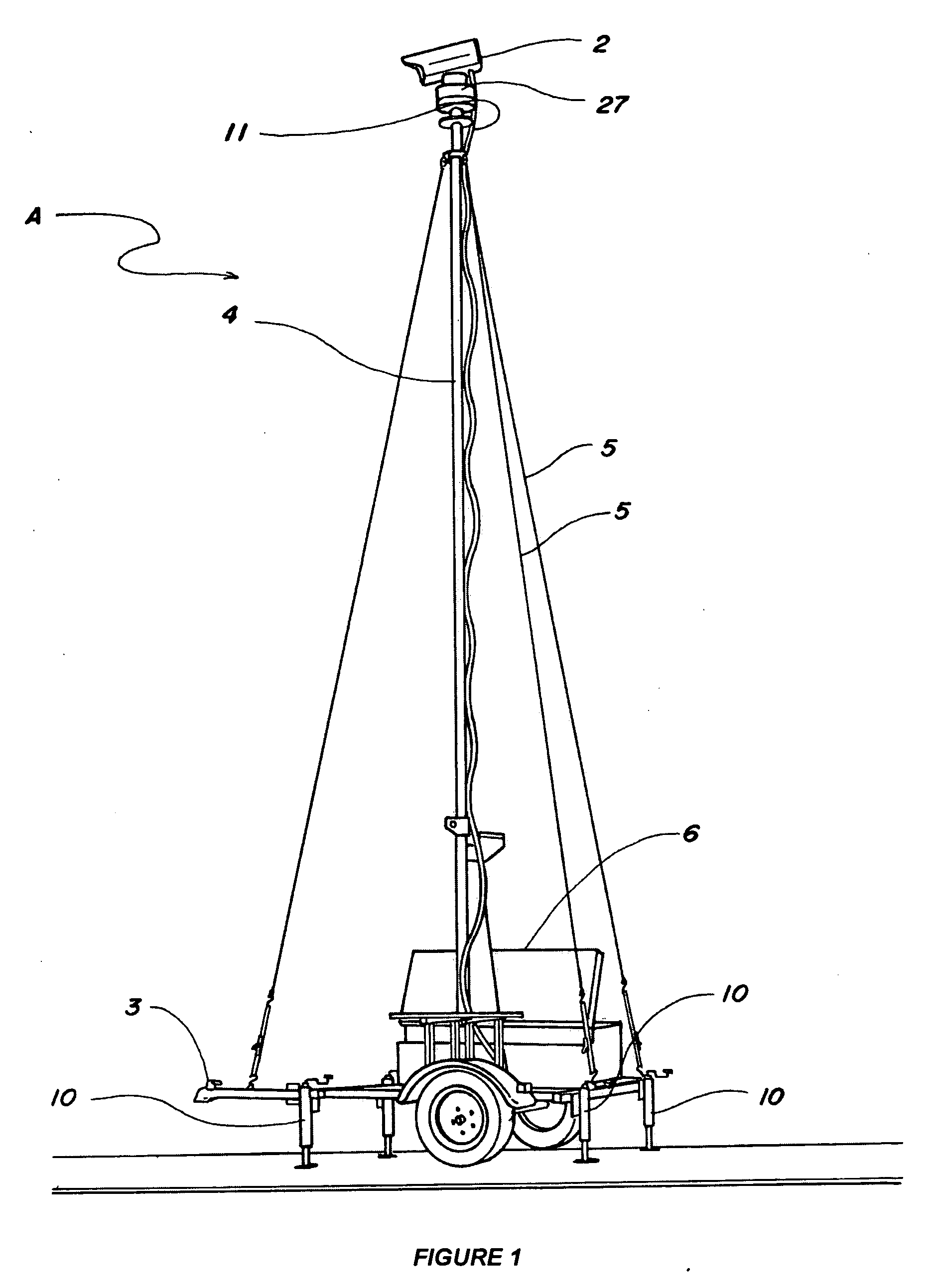

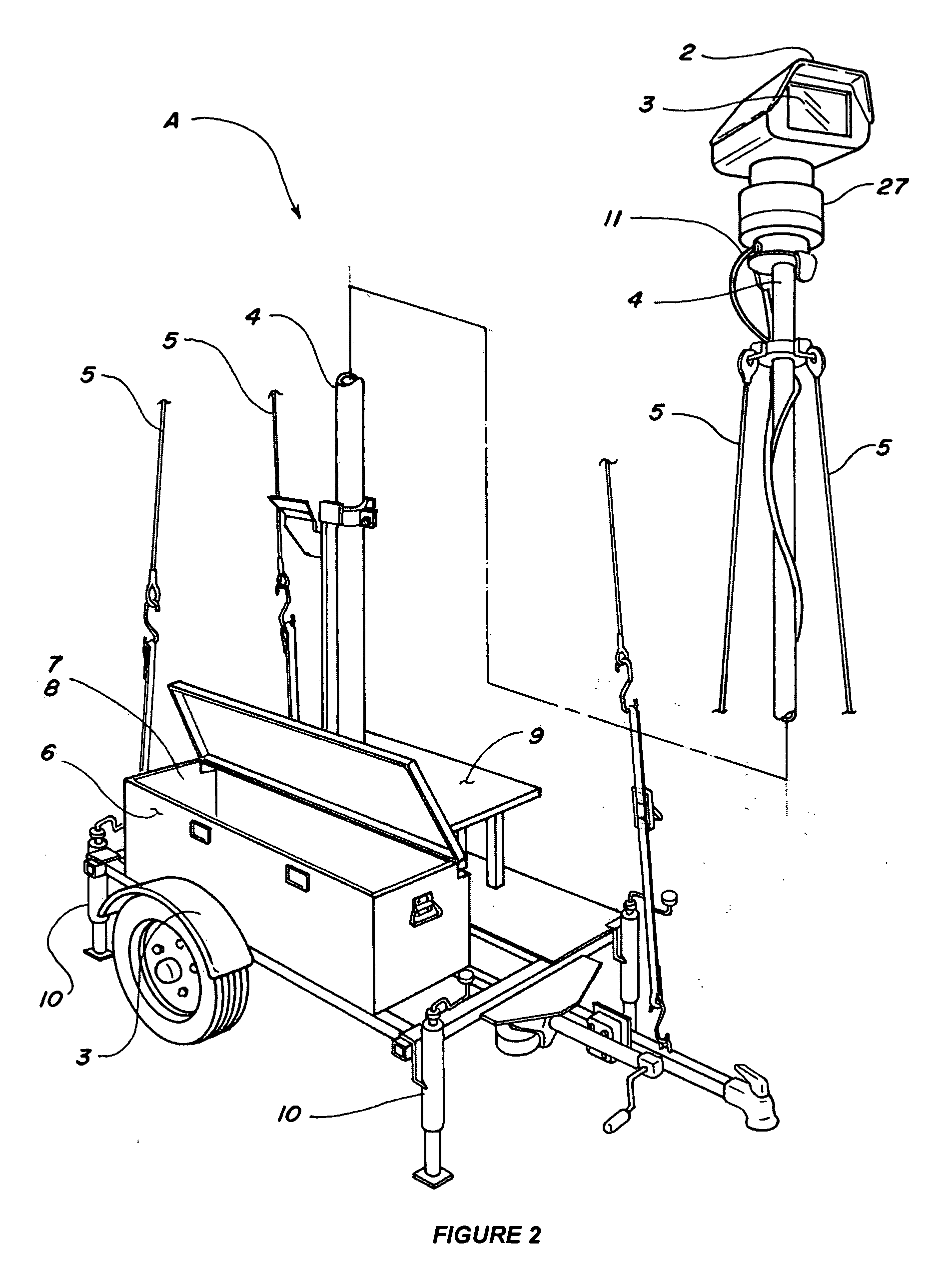

ActiveUS20100172543A1Accurately determineImage enhancementImage analysisTracking systemVelocity Rate

A multiple object speed tracking system that can provide data related to the rate of travel of each object in a set of multiple objects as each object is traveling either toward or away from a predetermined point.

Owner:AMERICAN TRAFFIC SOLUTIONS

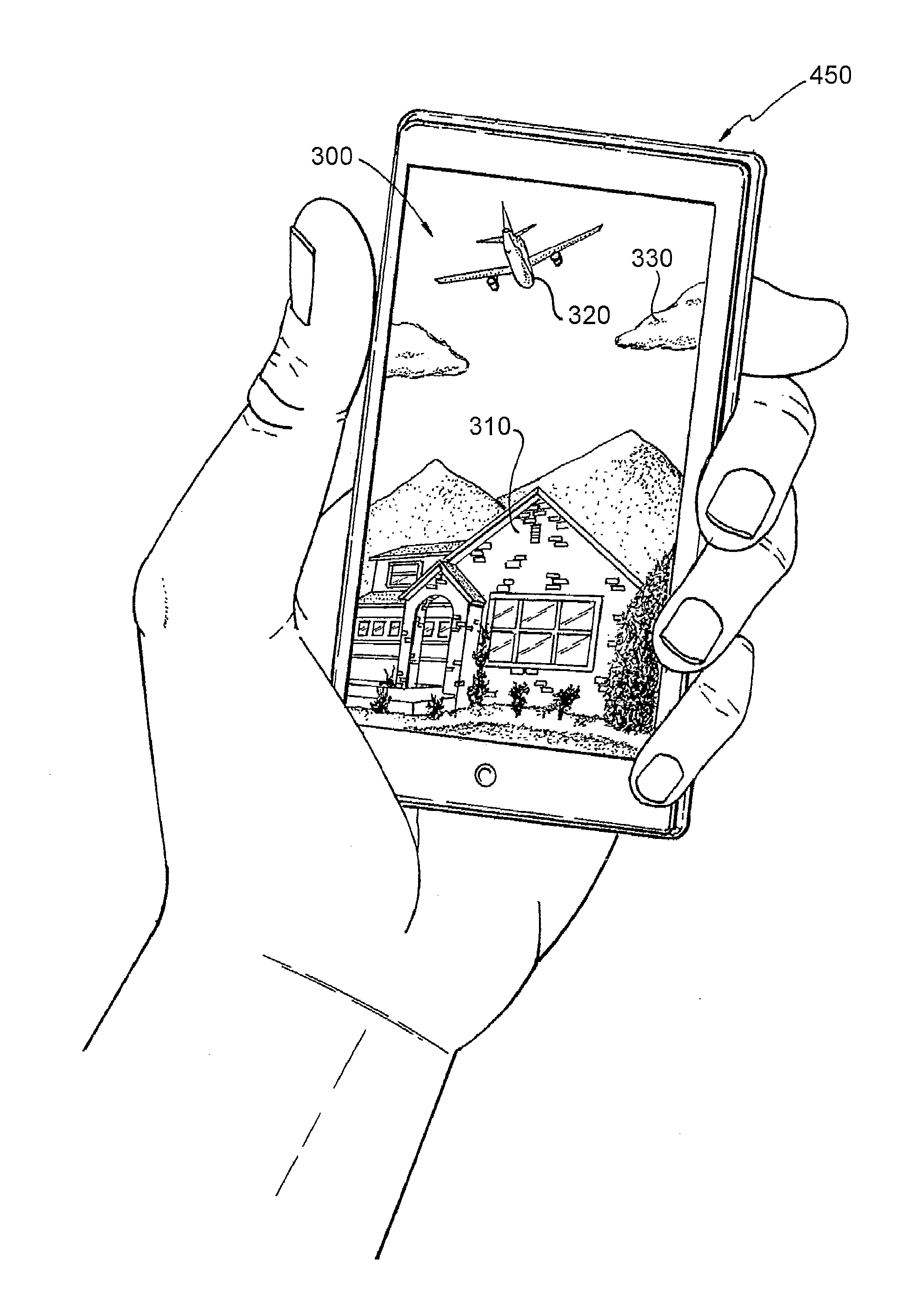

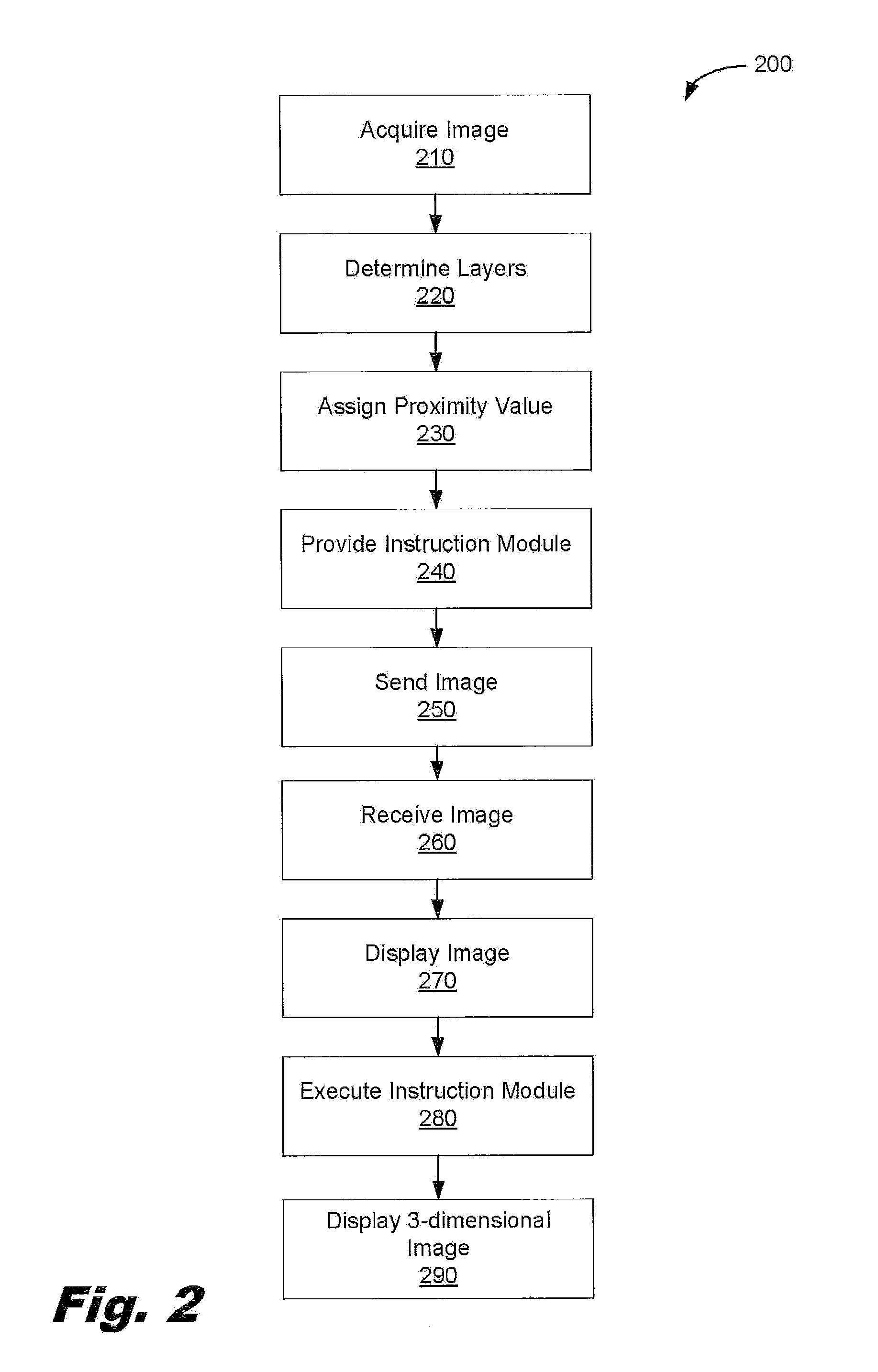

System and method for the creation of 3-dimensional images

The invention relates to a method and system for generating a 3-dimensional image on a 2-dimensional display of a device. The method includes the steps of receiving an image in image processor means and using the image processor means to determine at least two pixels layers in the image. A proximity value is then assigned to each pixel layer wherein the proximity value is indicative of a depth perception of the pixel layer relative to a user of a device having a display screen. An instruction module is then coupled to the image operative to cause each pixel layer to move along an axis of orientation on the 2-dimensional display of the device and at a velocity rate dependent upon the proximity value assigned to the pixel layer.

Owner:BMUSE GRP

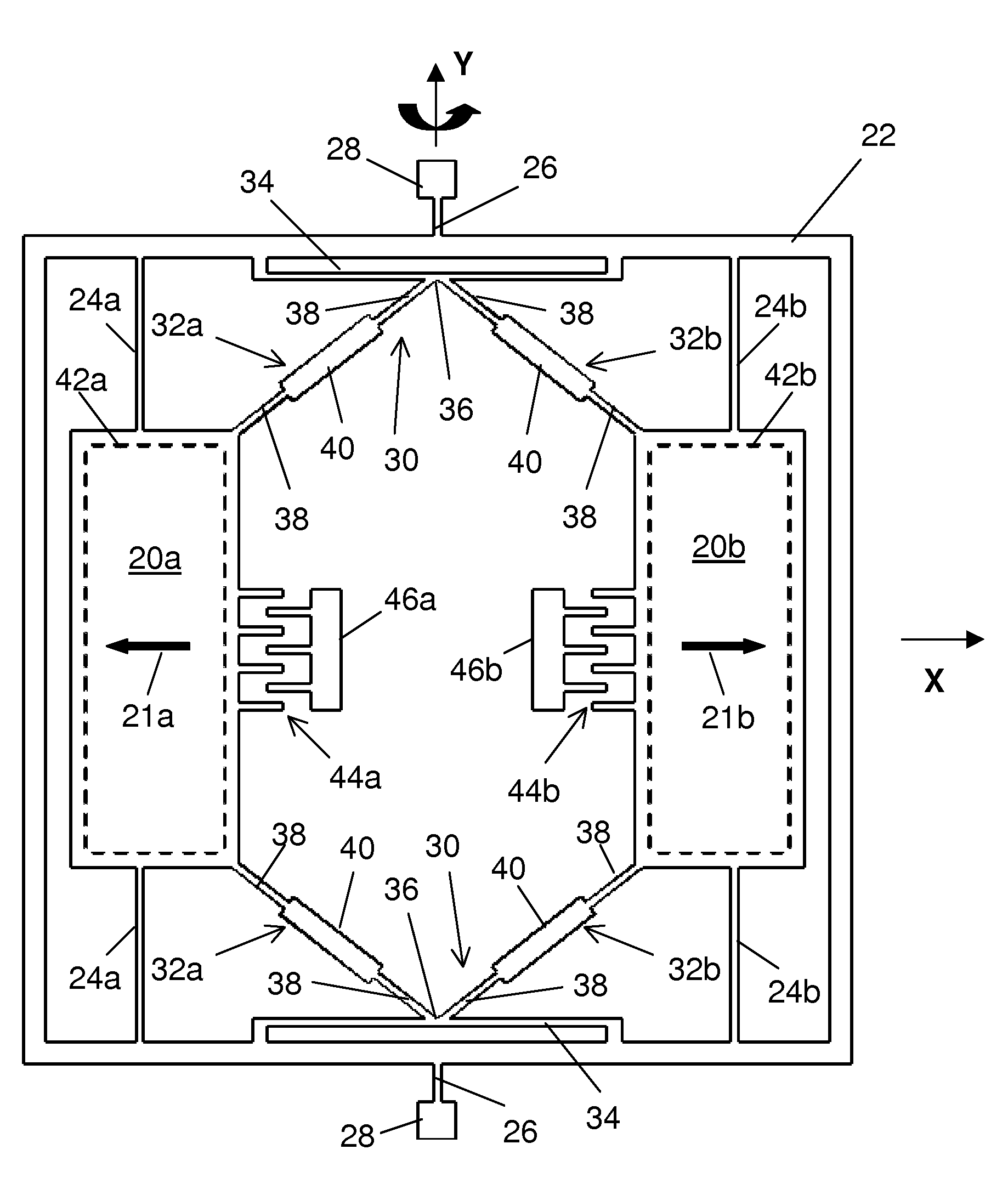

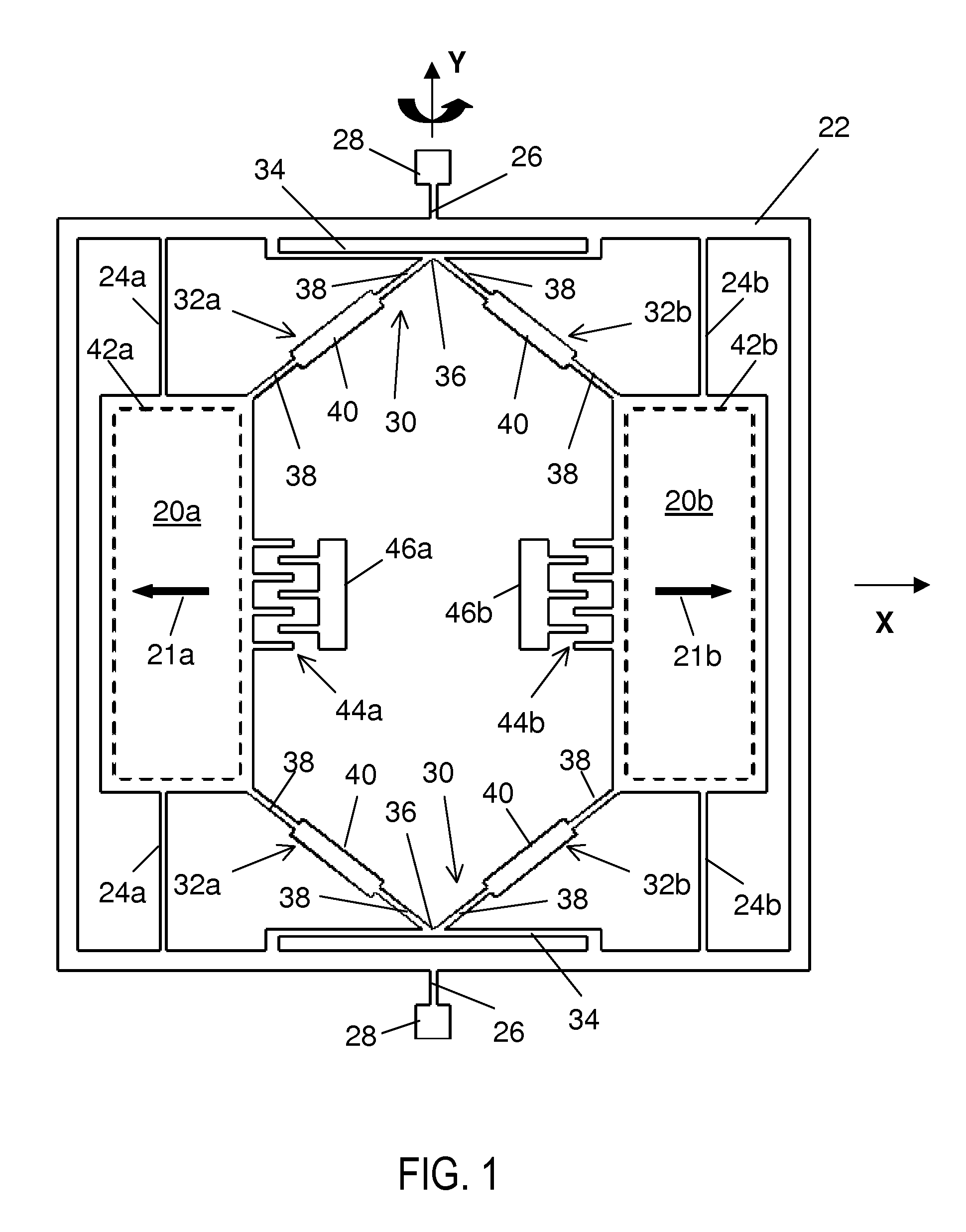

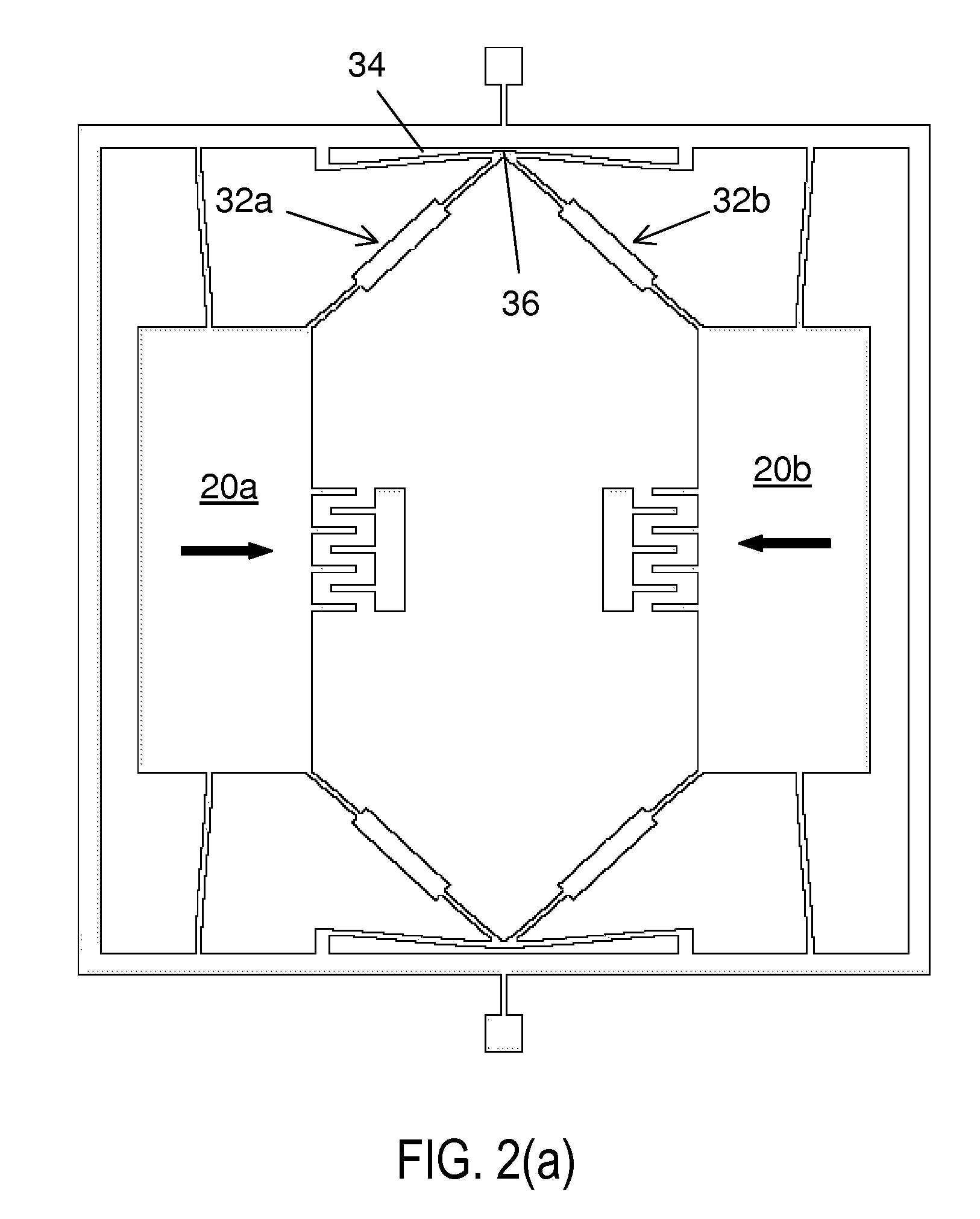

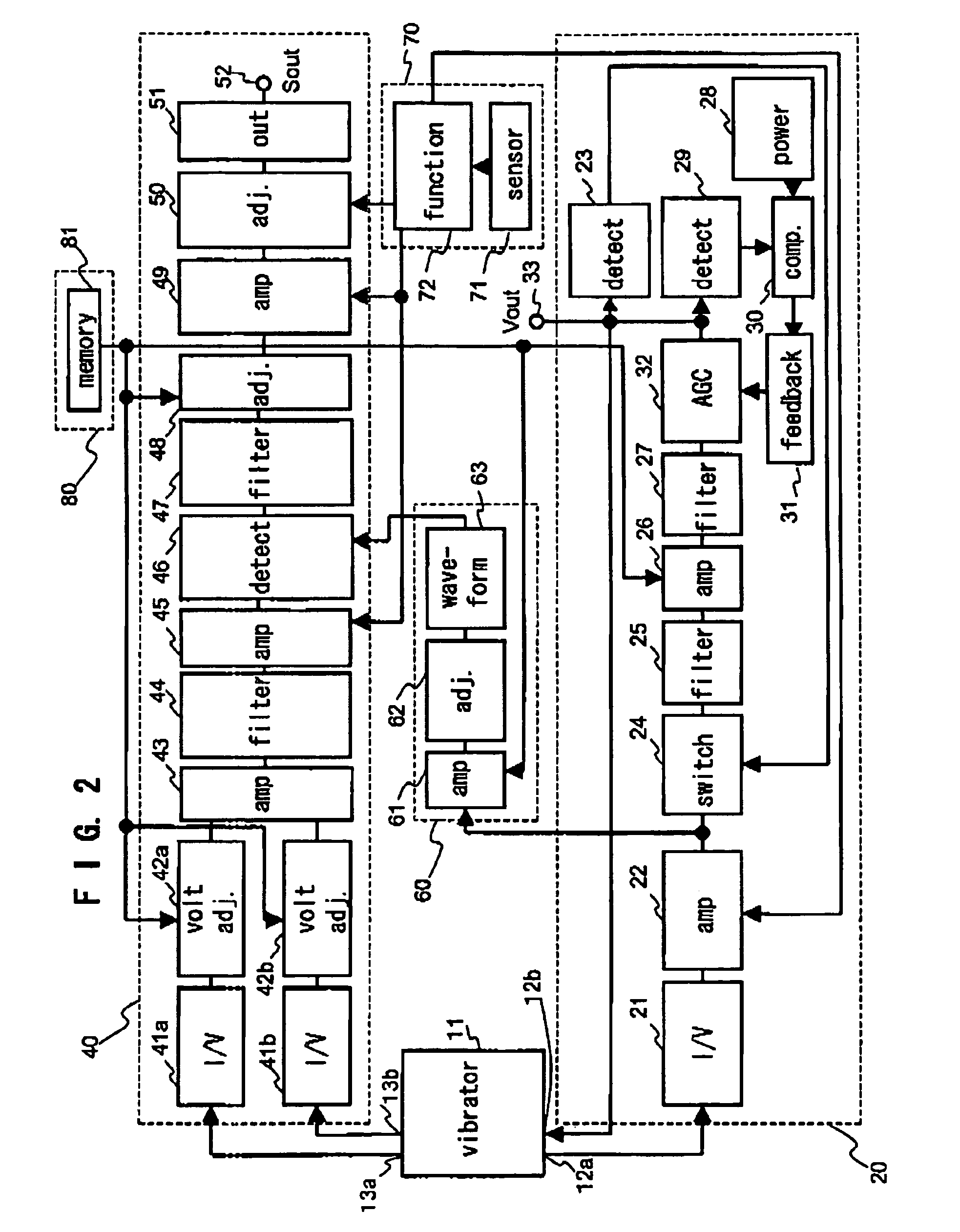

Angular rate sensor with suppressed linear acceleration response

ActiveUS8453504B1Angular velocity stabilityAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular rate sensorRotation velocity

An angular rate sensor having two generally planar proof masses, a drive axis in the plane of the masses, and an input axis perpendicular to the drive axis. The masses are suspended from a sensing frame and constrained for anti-phase movement along the drive axis in drive-mode. The sensing frame is mounted for torsional movement in sense-mode about the input axis in response to Coriolis forces produced by rotation of the masses about the input axis, with sensors responsive to the torsional movement of the sensing frame and the masses about the input axis for monitoring rate of rotation.

Owner:MEMSLINK TECH CO LTD

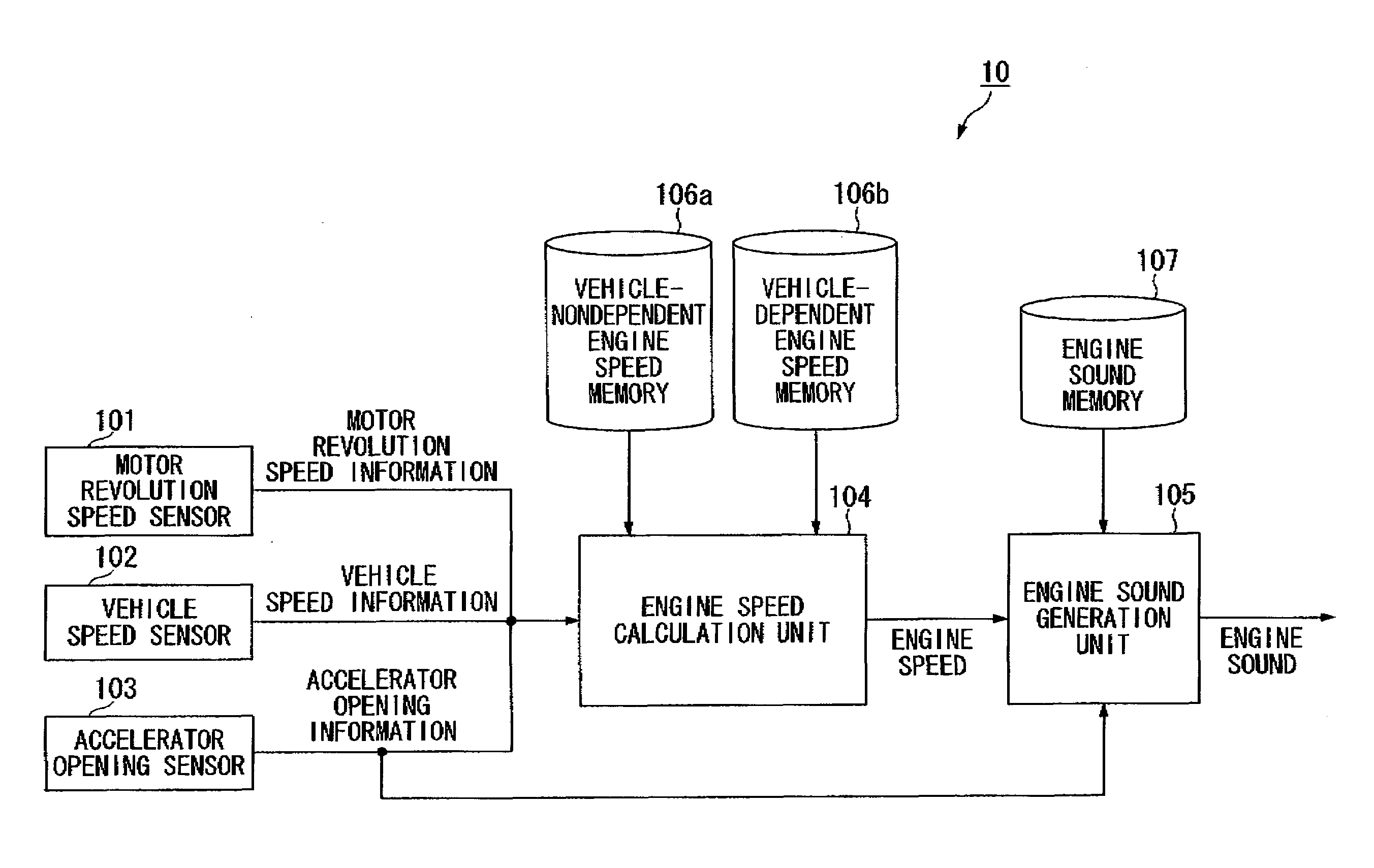

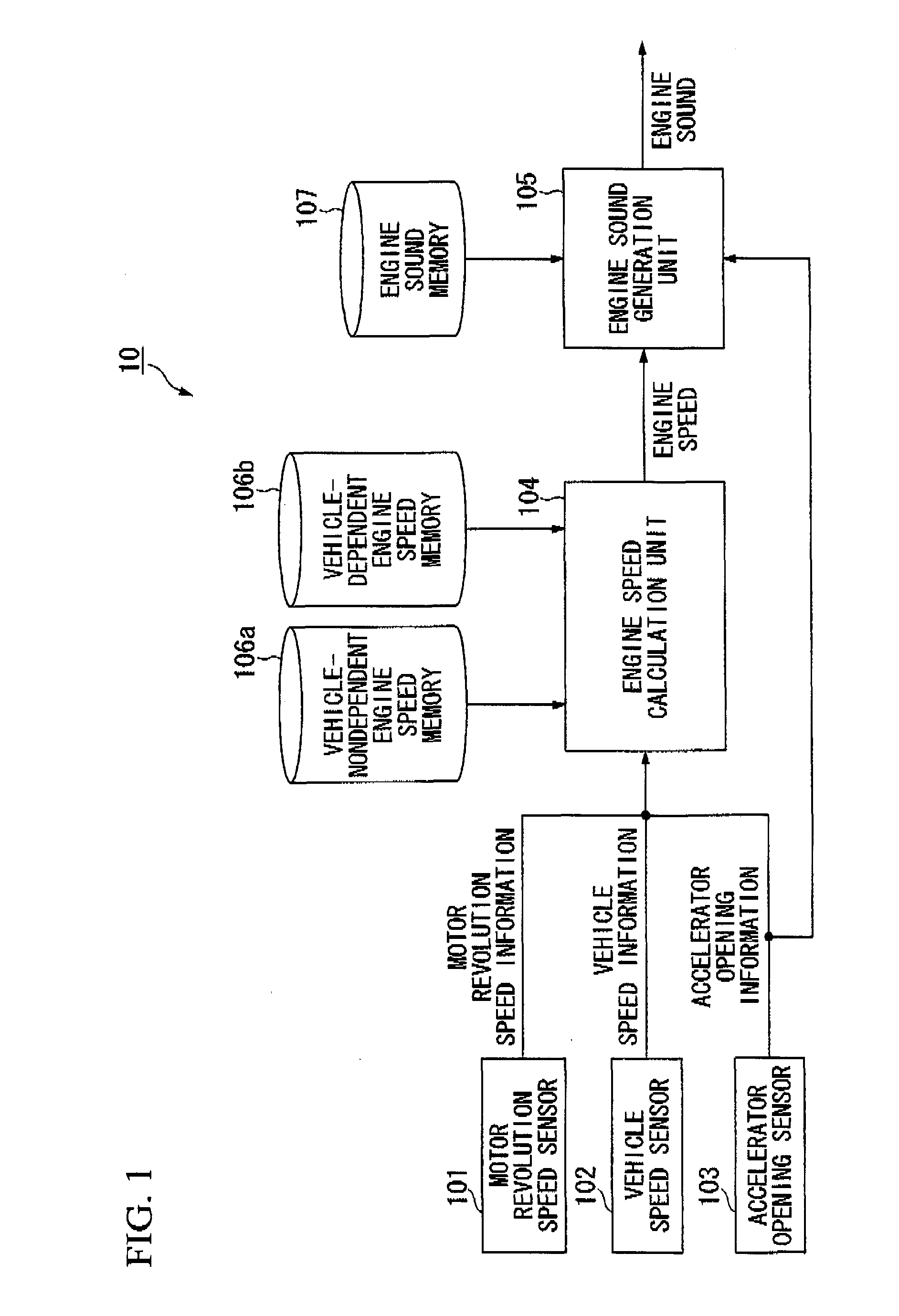

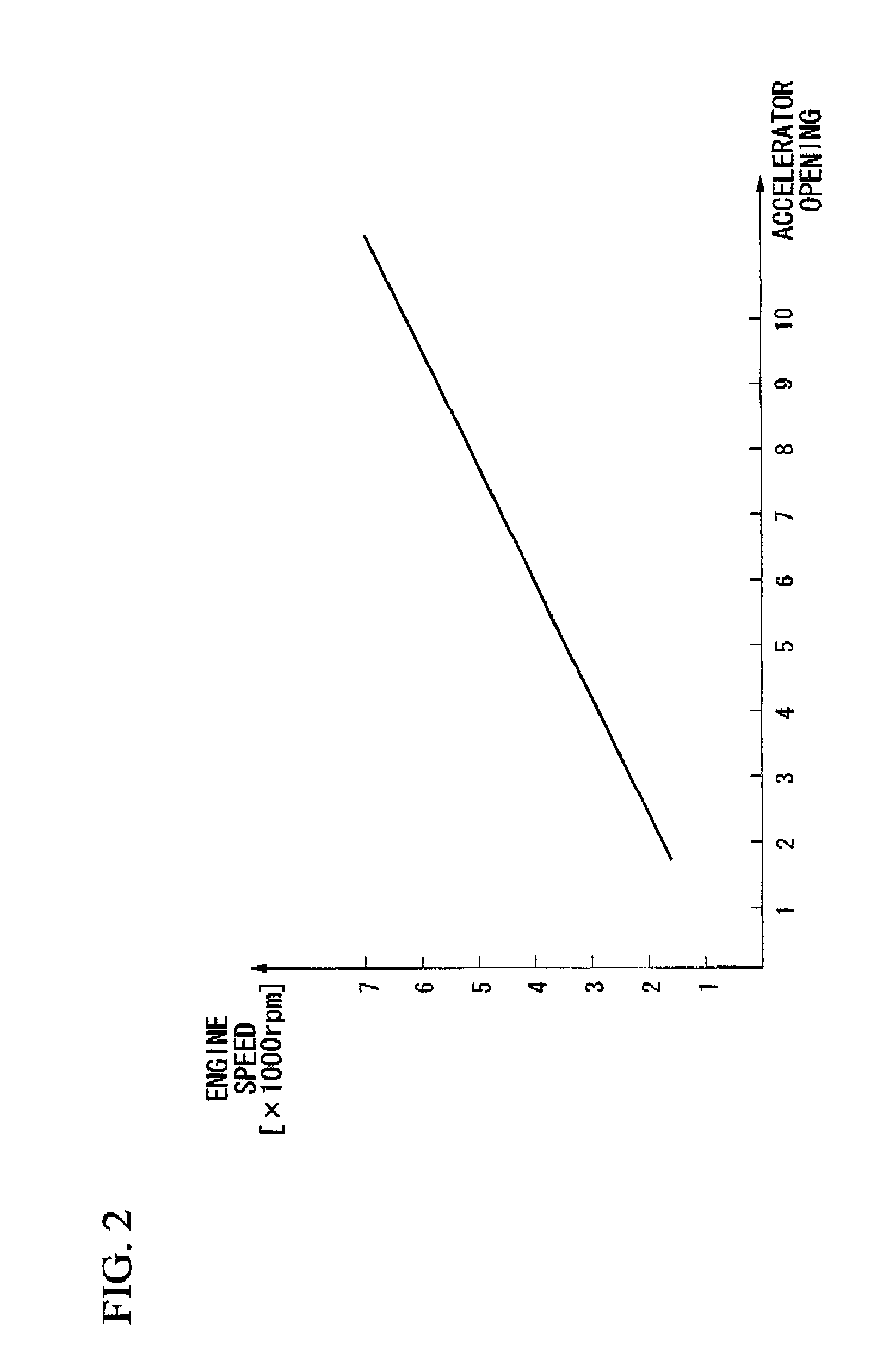

Engine speed calculation device and engine sound generation device

InactiveUS20100166210A1Accurate calculationGain controlOptical signallingSound generationEngineering

An engine sound generation device adapted to an electric vehicle includes an engine speed calculation unit which calculates the virtual engine speed based on the motor revolution speed, vehicle speed, and acceleration opening. The engine speed calculation unit calculates the virtual engine speed with reference to the vehicle-dependent engine speed memory on the condition that the virtual engine speed is deemed proportional to the vehicle speed. In addition, the engine speed calculation unit calculates the virtual engine speed with reference to the vehicle-nondependent engine speed memory on the condition that the virtual engine speed is not deemed proportional to the vehicle speed, thus generating the common engine sound matching the behavior of an engine in a prescribed event such as the startup of the electric vehicle and the semi-engagement of a clutch.

Owner:YAMAHA CORP

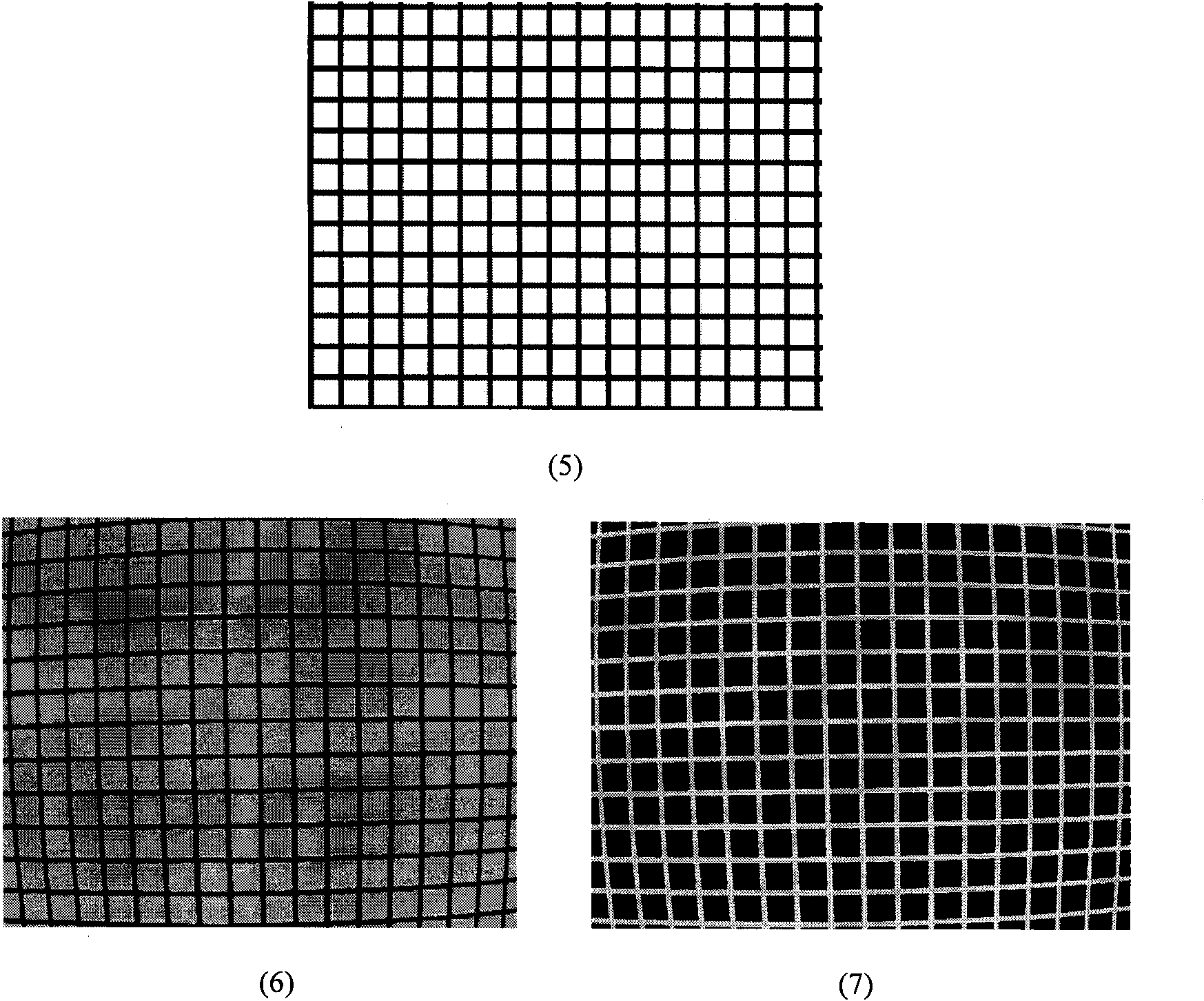

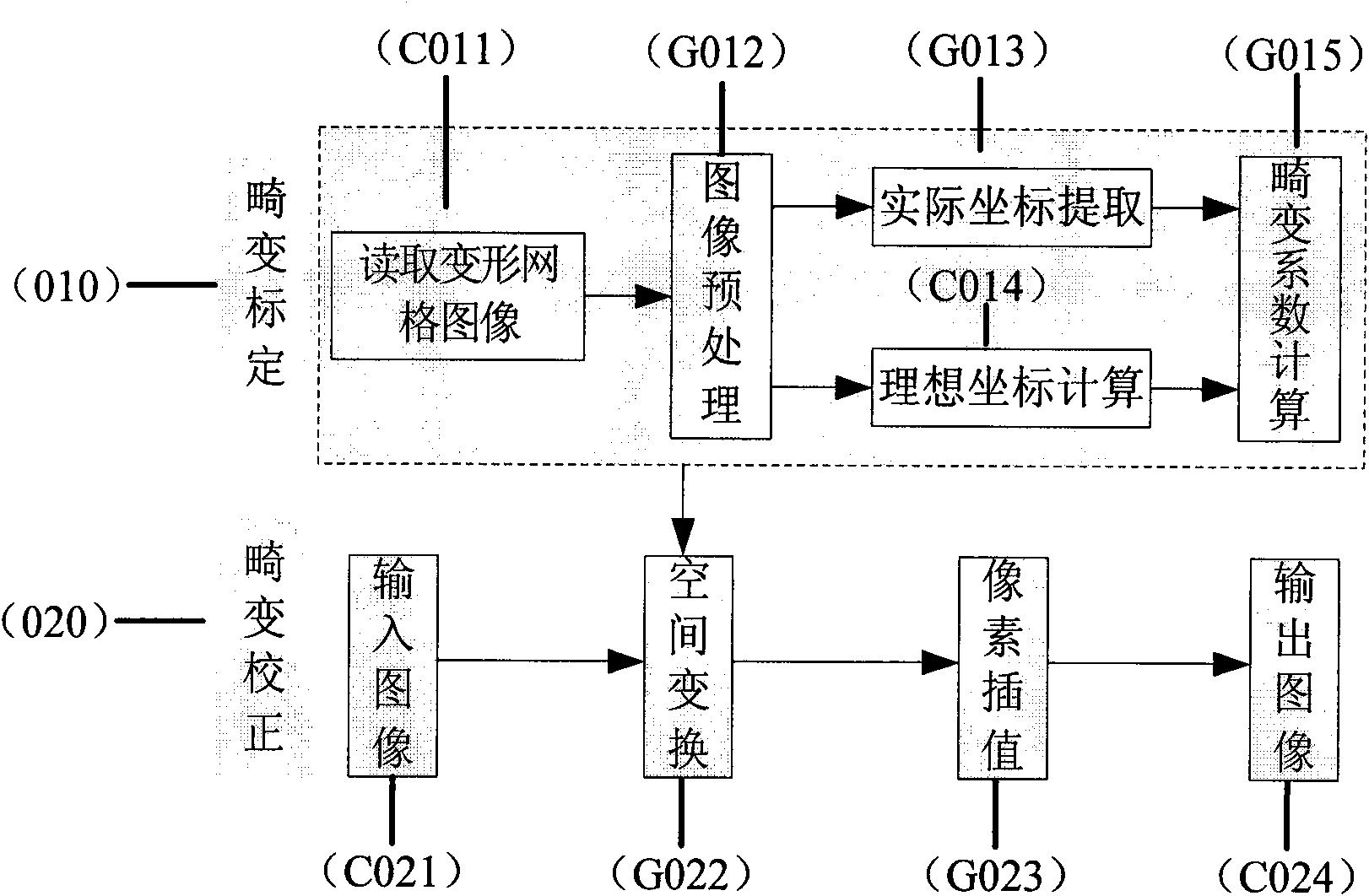

Method for correcting distortion in real time based on GPU camera and video camera

InactiveCN101572828AReduce the cost of optical design processingSolving optical distortion problemsImage analysisTelevision systemsCamera lensTime distortion

The invention discloses a method for correcting distortion in real time based on a GPU camera and video camera. The method adopts digital image processing technology to calculate a system of nonlinear equations consisting of two radial distortion coefficients, two centrifugal distortion coefficients and two thin prism distortion coefficients by a least square method in a correction algorithm based on a planar grid model so as to obtain a space transformation equation, and carries out synchronous spatial alternation on pixel spots of an image shot by an imaging system so as to obtain an image after distortion correction. The method solves the problem of optical distortion, and improves the correction precision to sub-pixel grade; through adopting the GPU technology with parallel processing capability, the processing velocity is improved by over 40 times, realizing real-time distortion correction (over 30 frame / second) of an 1920*1080 high-definition image, and reducing the processing cost for lens optical design by 20 to 70 percent.

Owner:CHANGCHUN UNIV OF SCI & TECH

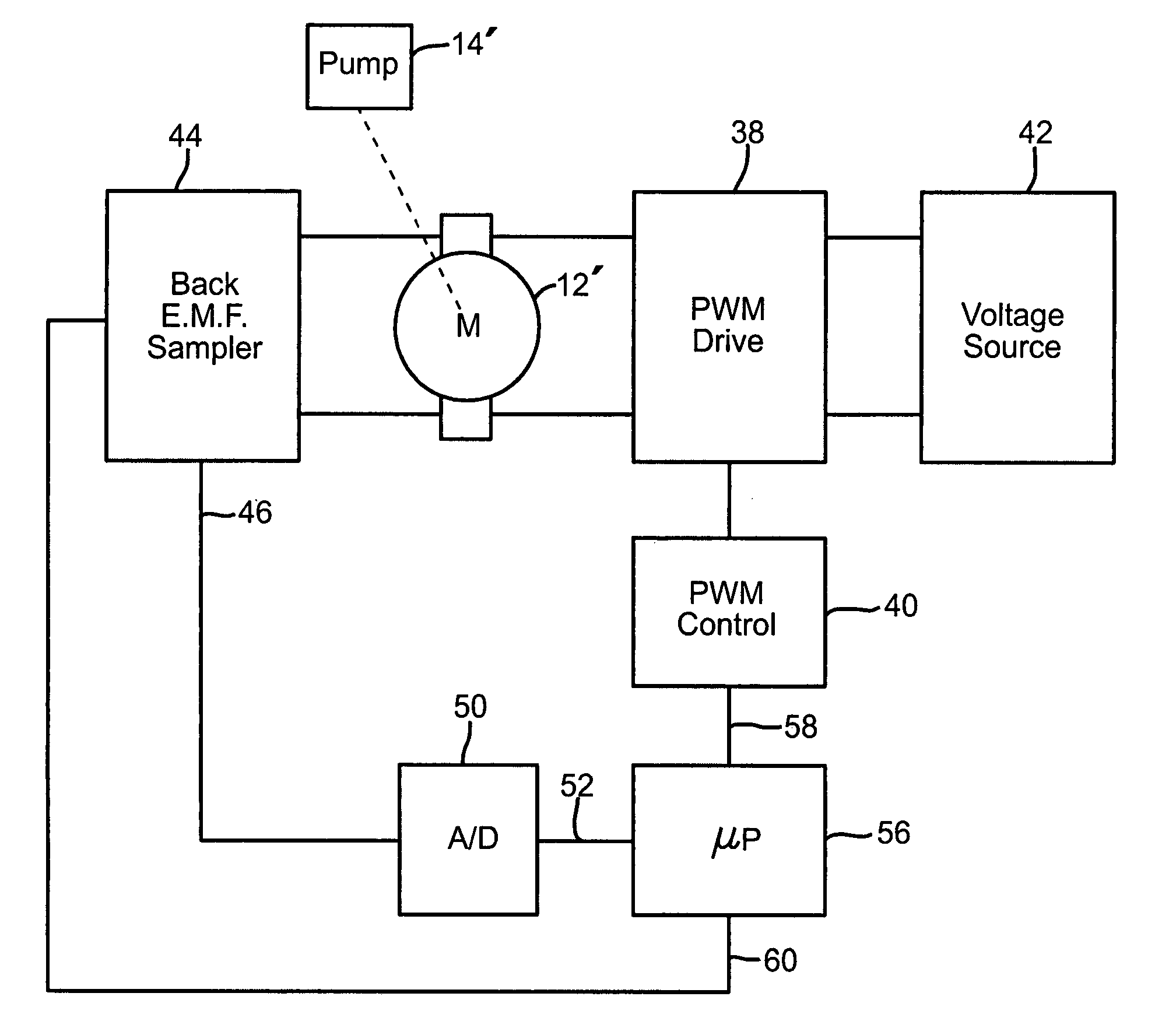

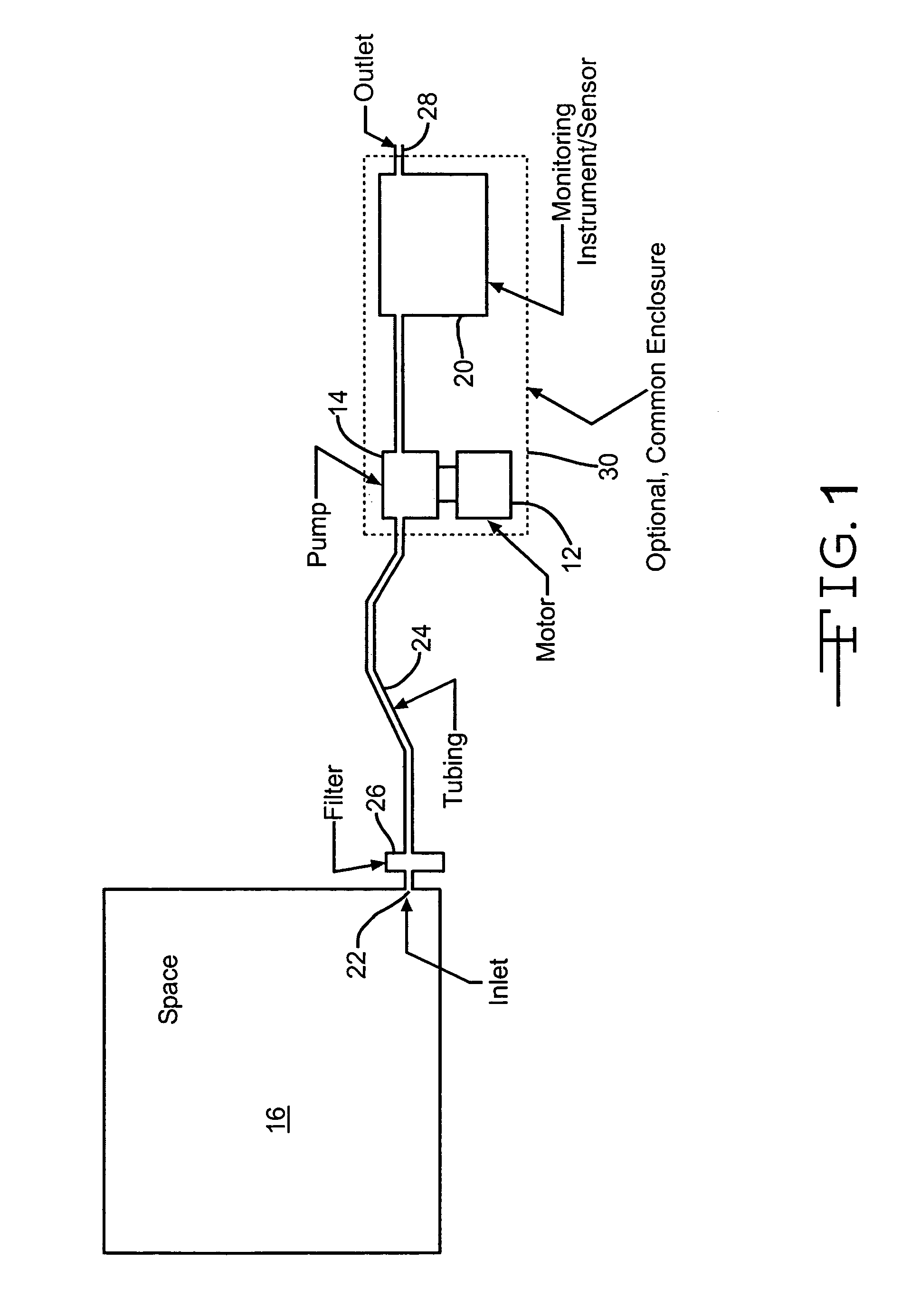

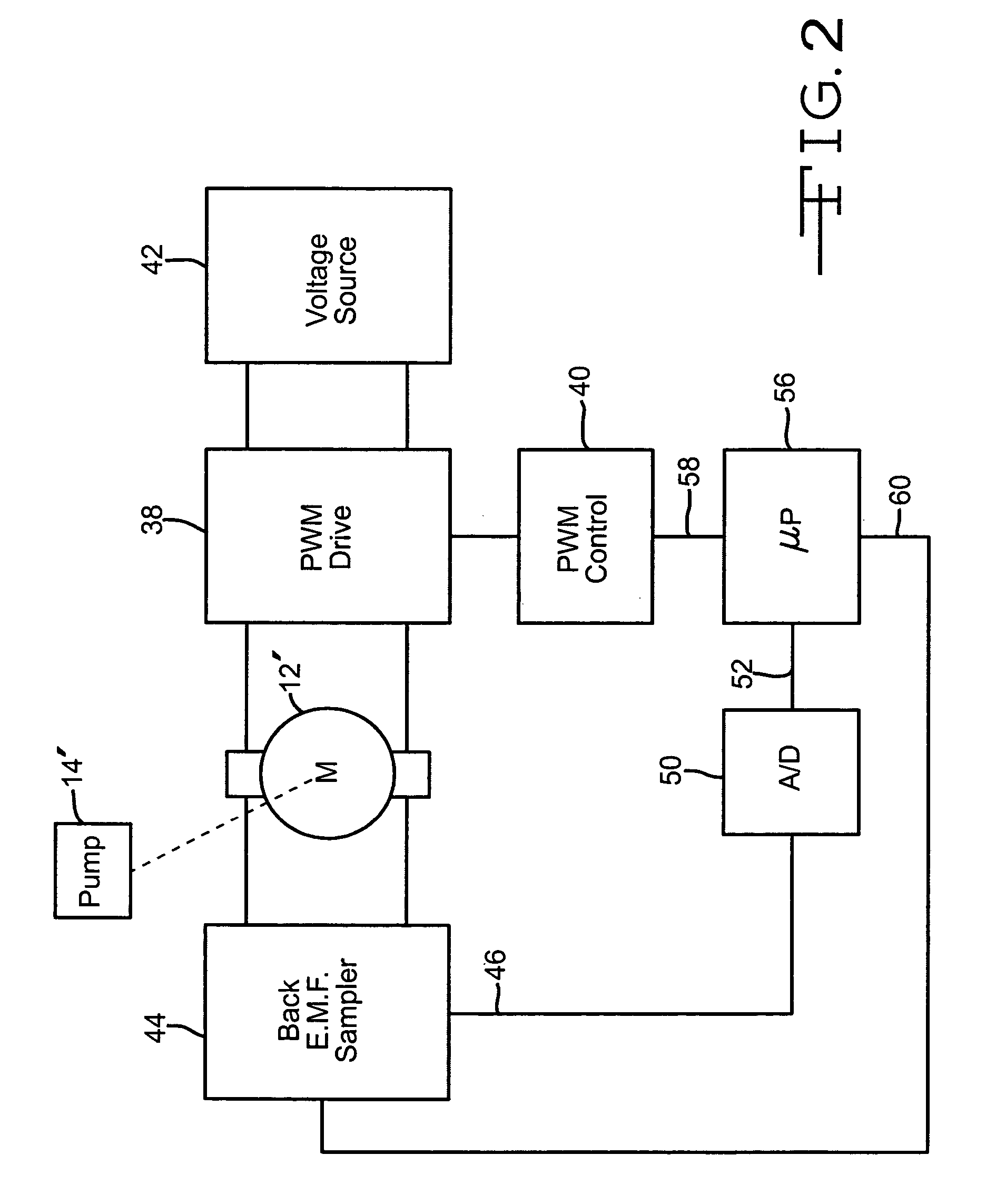

Speed and fluid flow controller

InactiveUS6981402B2Reduced sampling rate requirementsEasy to useFlow controlProgramme controlMotor speedVoltage source

A system and method for measuring fluid flow rate in a system where fluid is pumped, such as a gas monitoring instrument where gas is pumped from a space such as a room or enclosure through a conduit to a sensor. The flow of gas through a pump is determined by measuring motor back-e.m.f. which is proportional to motor speed. In a system where motor speed is regulated by pulse width modulation of the motor drive voltage, the back-e.m.f. is sampled during intervals between the drive pulses applied to the motor, and in a further aspect the sampling is done at selected, spaced-apart or infrequent intervals such as once for every ten or once for every hundred motor drive pulses. Advantageously, in an instrument that uses a microprocessor and analog-to-digital converter to measure gas-concentration, the same microprocessor and converter can provide the PWM control of the pump, in response to the back-e.m.f. generated by the pump motor between the drive pulses. The microprocessor compares the output of the analog-to-digital converter, corresponding to the back-e.m.f., which in turn corresponds to the pump motor speed, to a set-point value, representative of the desired pump motor speed. The processor then adjusts the PWM to control the pump motor to achieve and maintain the desired speed. As a result, in a gas monitor, the gas-flow rate may be maintained close to a desired gas flow rate regardless of the voltage supplied by the battery or other voltage source, regardless of the degree to which the gas is filtered, and under a wide range of operating conditions.

Owner:TELEDYNE DETCON INC

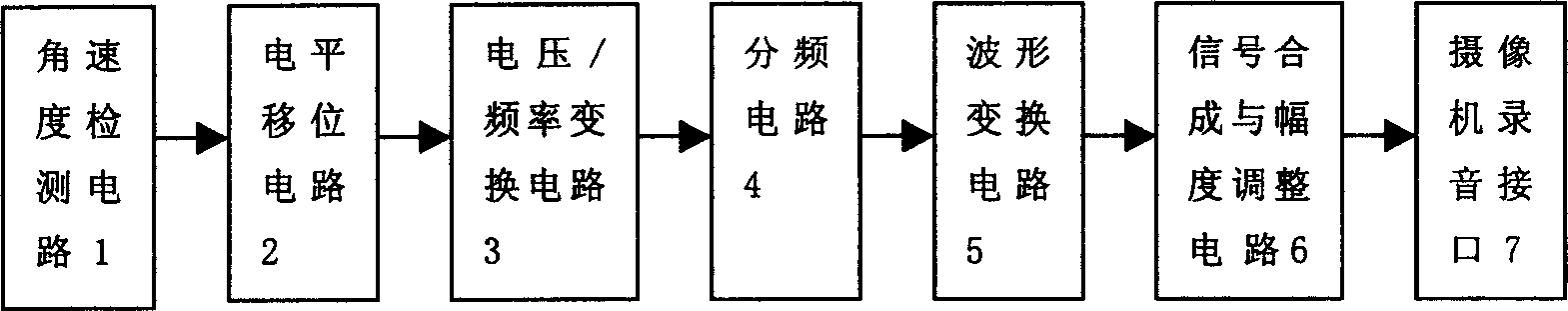

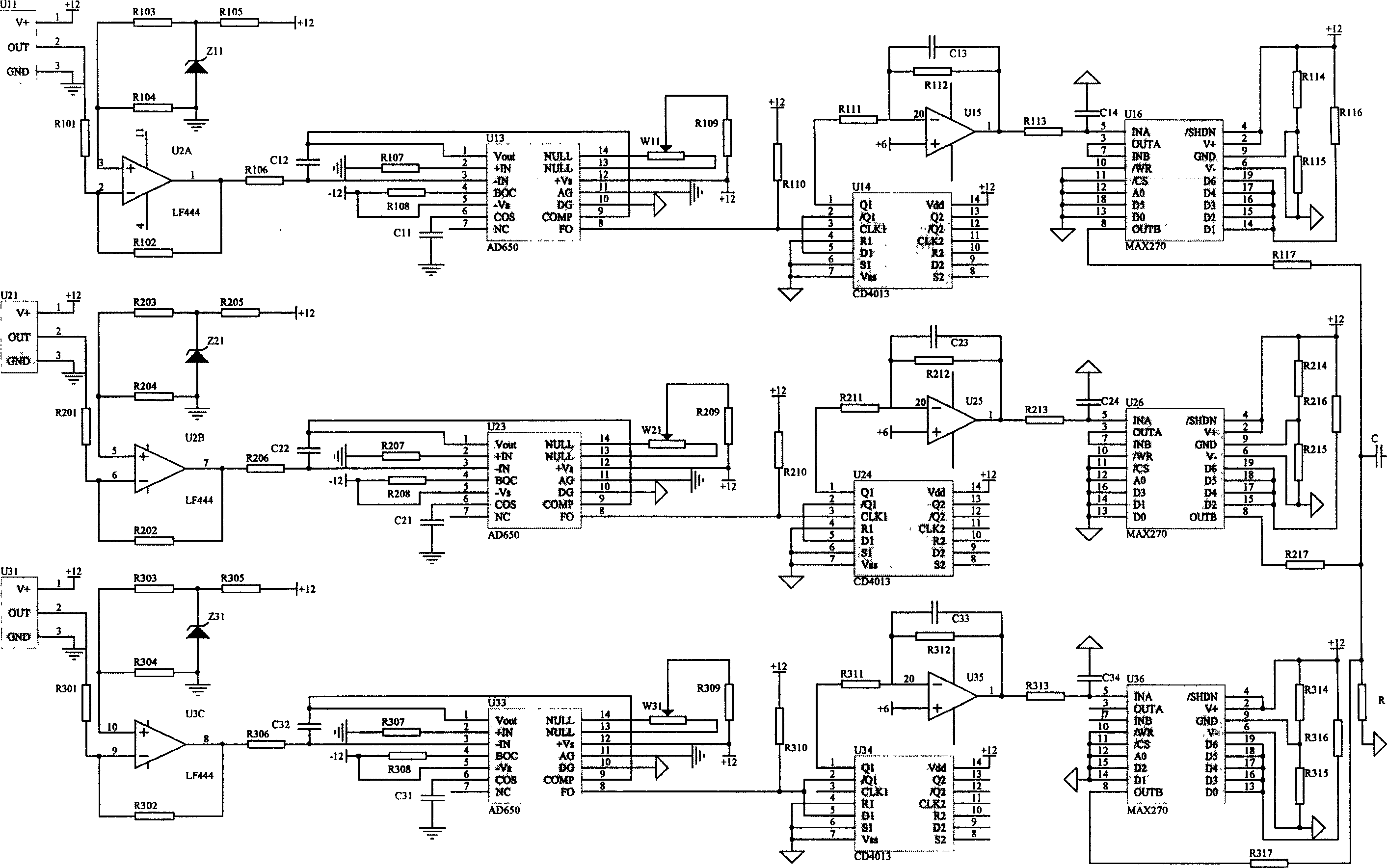

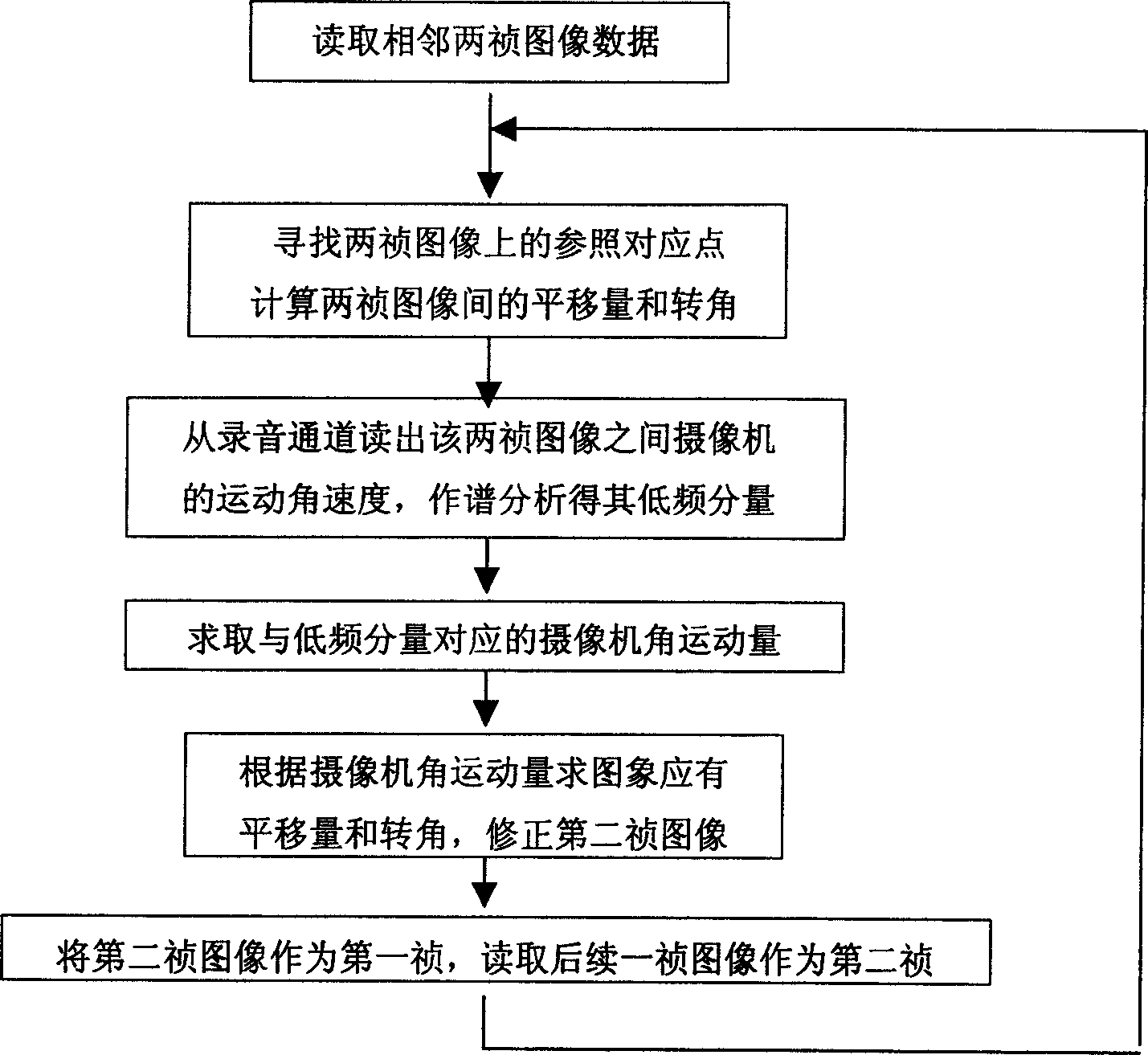

Method of image stability improvement for video camera and assistor thereof

InactiveCN1571475AImprove clarityReduce difficultyTelevision system detailsImage enhancementSignal processing circuitsAngular velocity

The invention relates to an auto-stability method for camera image and the auxiliary device used in hand held state or motion state. It uses angular velocity sensor to check the angular velocity of the camera rotating round the three space axes in real-time and records synchronistical with image signal. The variance of the attitude angle between two pictures would be gained by integral in afterward process software, and the attitude angle variance related to slow-varying low frequency element in motion angular velocity is reserved, meanwhile the attitude angle variance related to dithering angle element would be eliminated. Then, the image dithering would be eliminated by translation and rotation the image. The device is made up of three same circuits. And every process circuit is connected by angular velocity checking circuit which is belonged to signal collection circuit, power lever shifting circuit which is belonged to signal process circuit, voltage / frequency transformation circuit, frequency division circuit, wave transformation circuit, signal compound and extent regulation circuit in series. The output signal is sent to the interface of camera.

Owner:SOUTHEAST UNIV

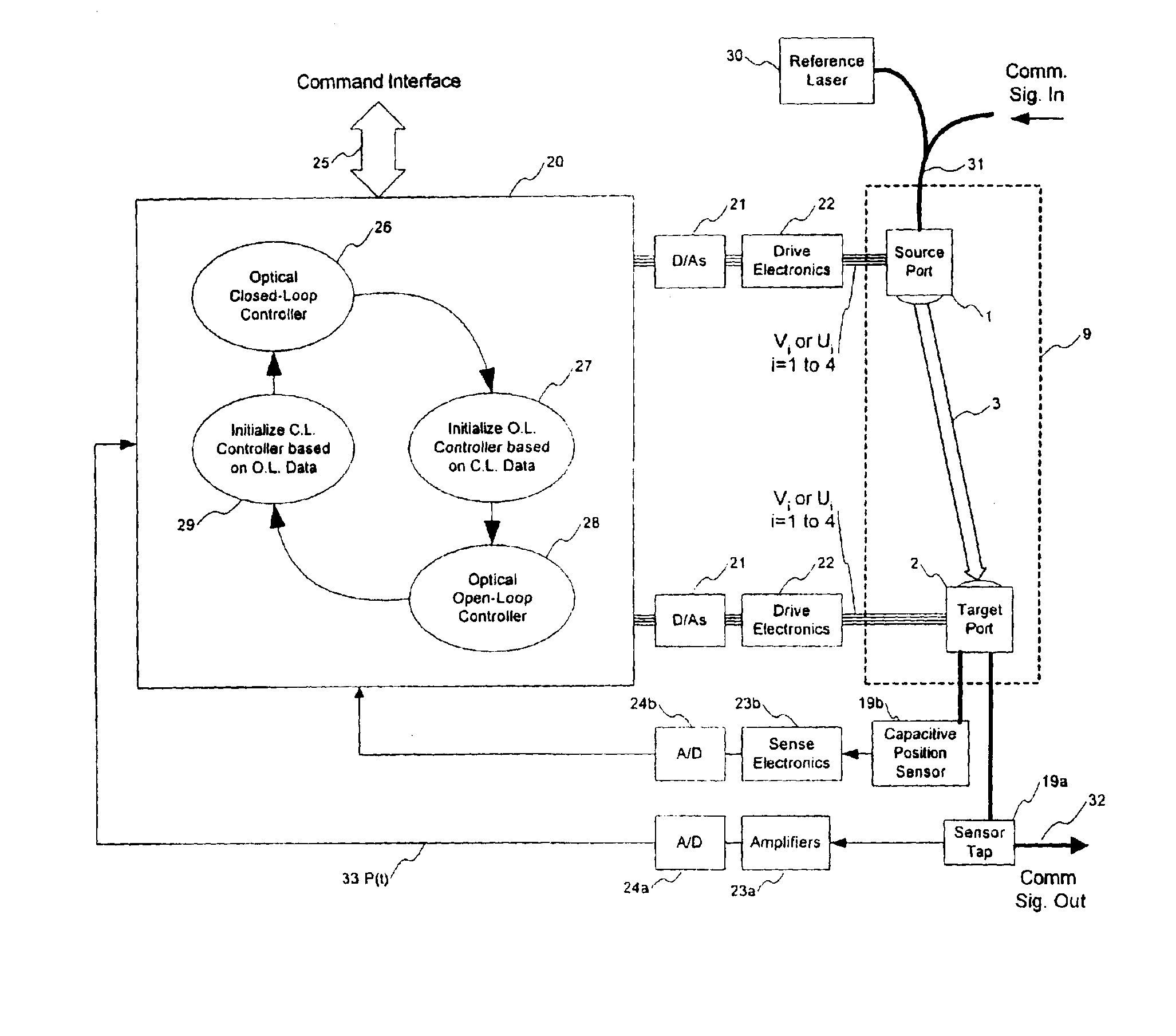

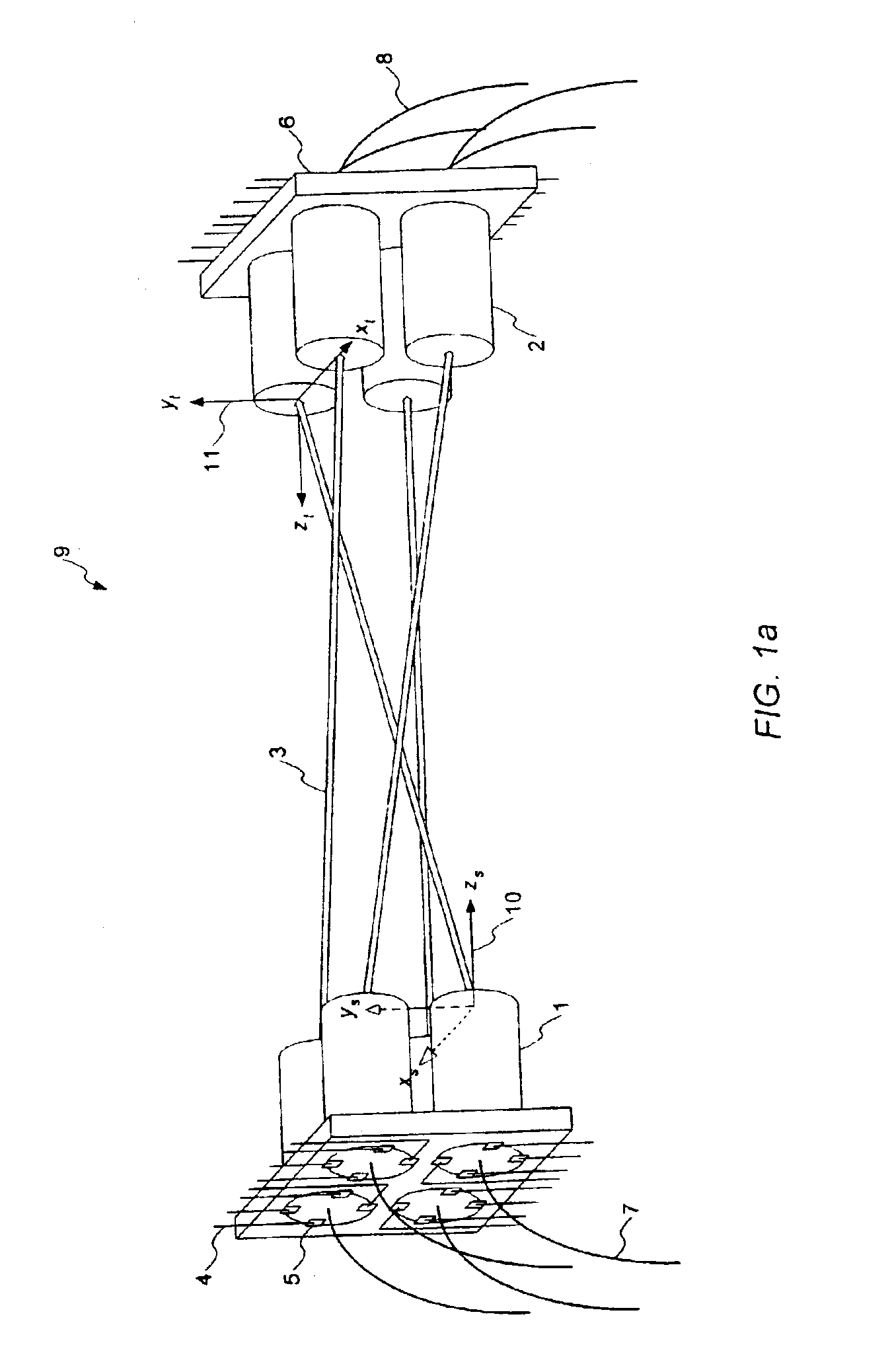

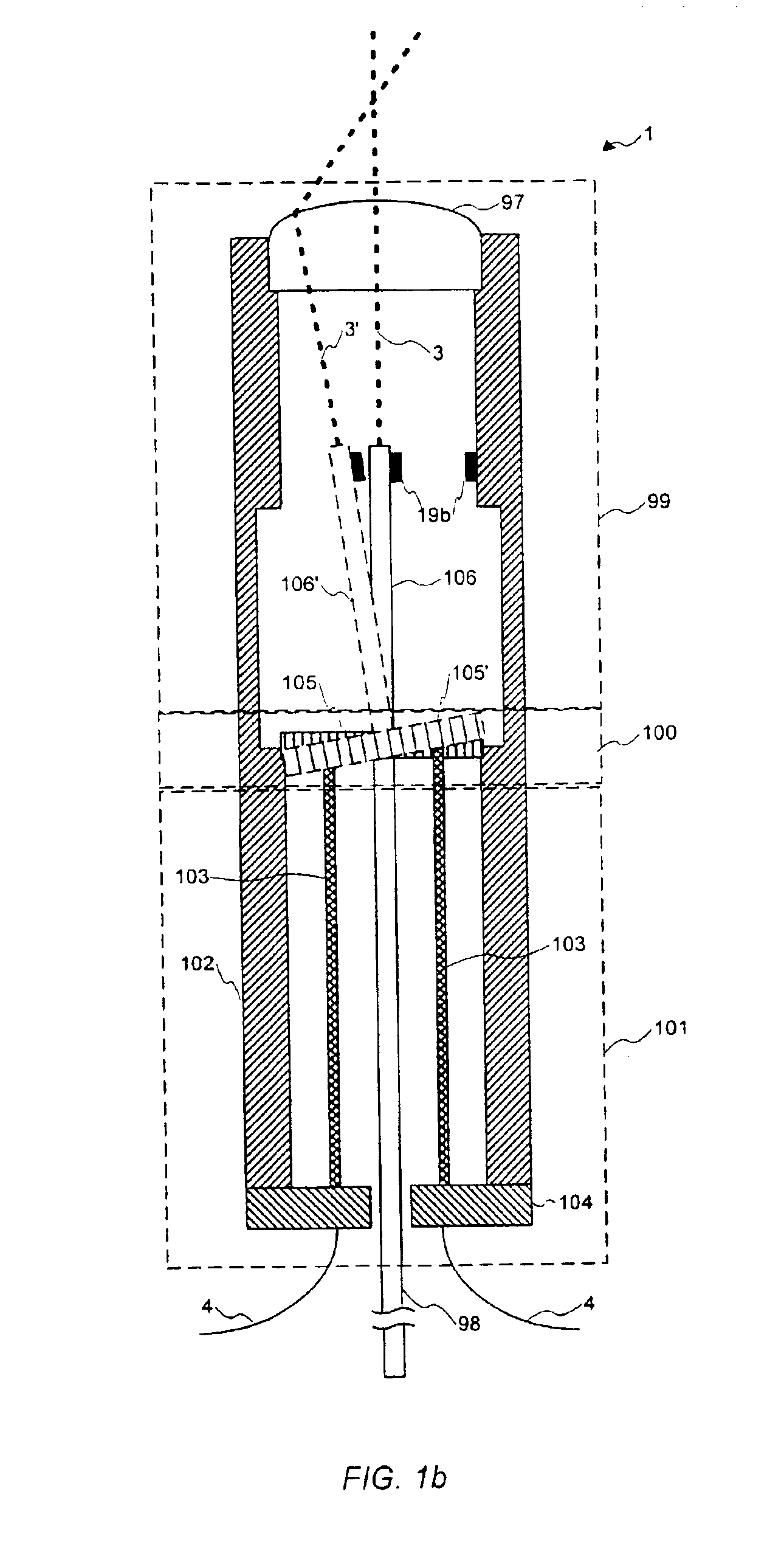

Multiple-axis control system for an optical switch

ActiveUS6975785B2Move fastRapidly tiltMultiplex system selection arrangementsCoupling light guidesFir systemLoop control

A free space optical switch that uses both an open loop control mode and a closed loop control mode. The open loop control mode is used to transition to a state where at least some light is sensed at a destination port. A closed loop control mode is then used, whereby a series of controlled dither signals are adjusted for system dynamics. Modifying the dither signals in this matter allows moving actuators at a rate that is much closer to the natural frequency of the underlying system, and hence speeds up the system convergence process. Variable modulation amplitudes may be employed on the dither signals to maximize convergence speed. In particular, changes in the dither signal can be made in accordance with the change in amplitude as a function of a gradient along a parabola that models the optical system response. According to still further aspects, the dither signals may be compensated for a desired and selectable attenuation level of output optical power.

Owner:POLATIS PHOTONICS INC

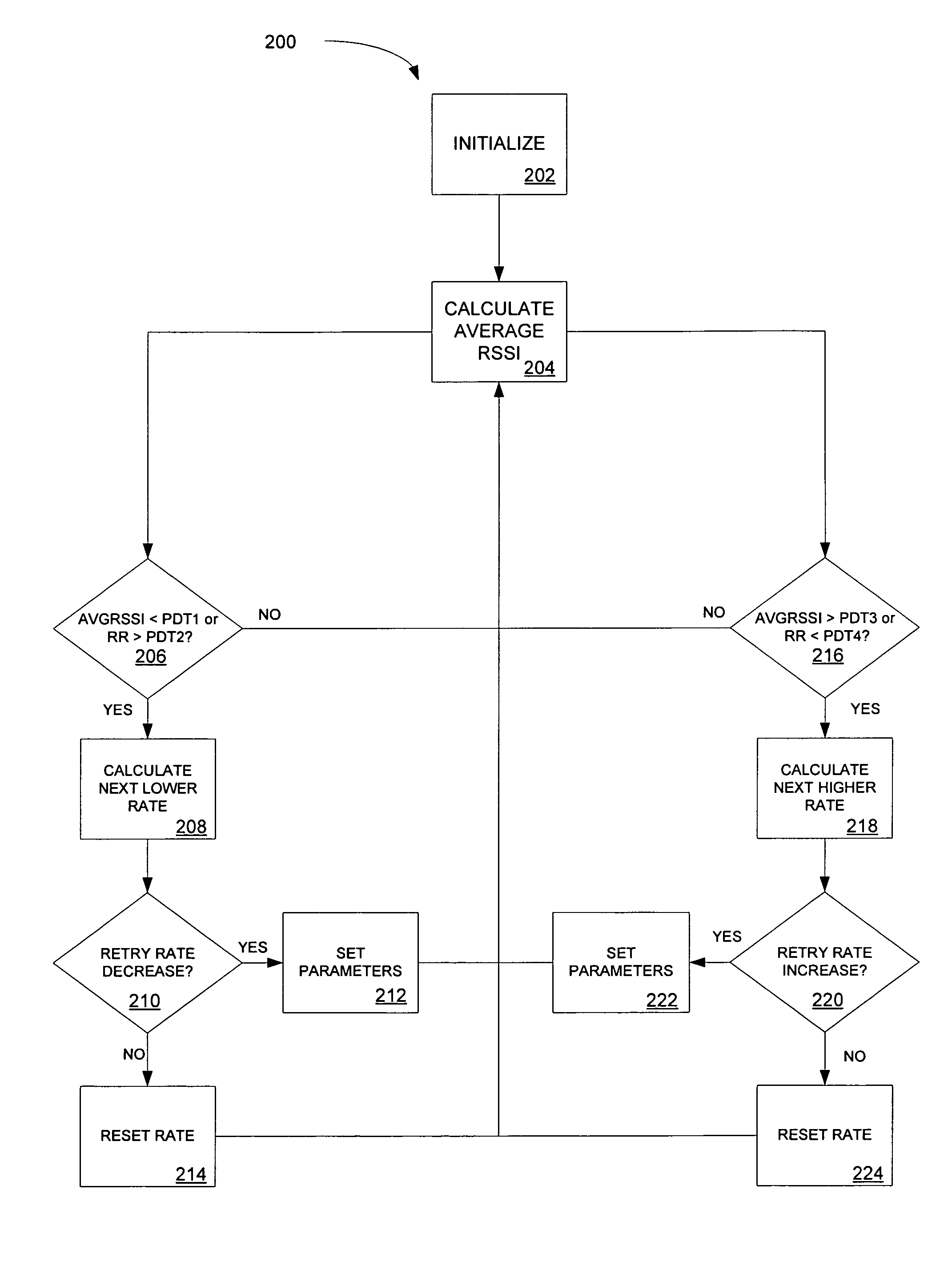

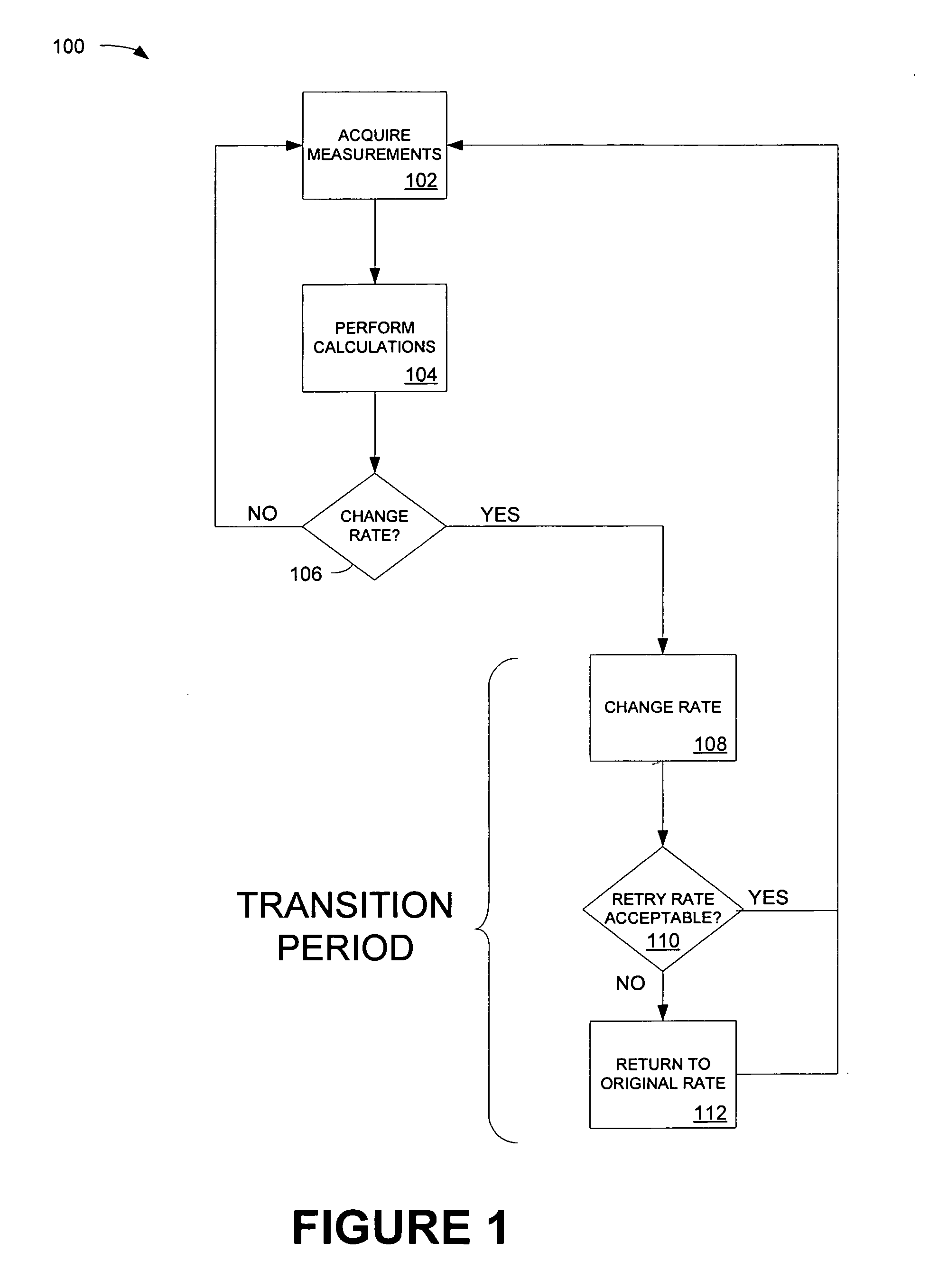

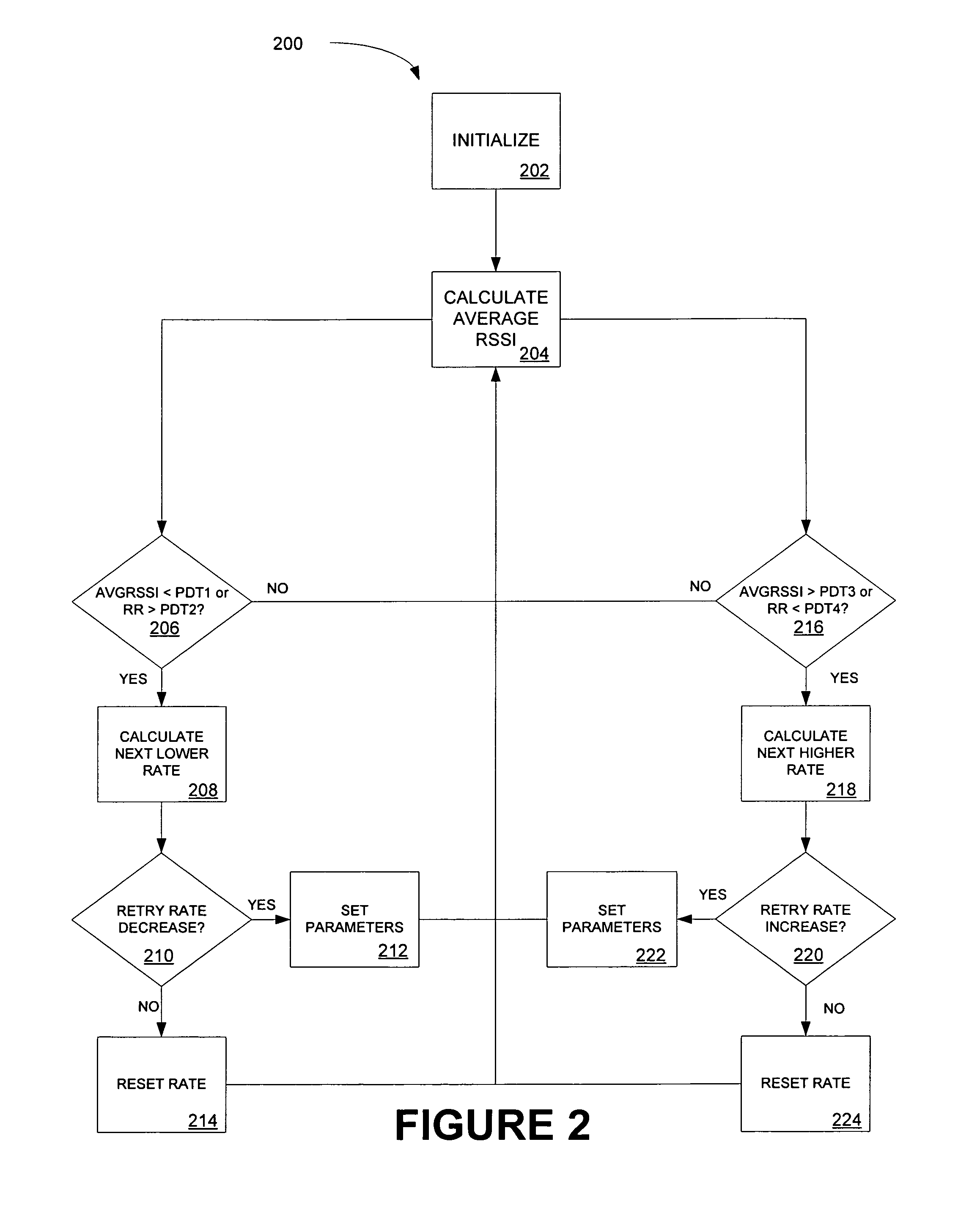

System and method for rate shifting for wireless VoIP

ActiveUS20070189225A1Low rate of false shiftingLow false rateError prevention/detection by using return channelFrequency-division multiplex detailsTelecommunicationsInternet traffic

A method of rate shifting specially suited for the voice traffic, which differentiates poor channel conditions from a heavily loaded channel of a WLAN and adapts to the network traffic condition and channel condition promptly with low rate of false shifting. Determining when to rate shift is based on a combination of the received signal strength indication and the retry rate.

Owner:CISCO TECH INC

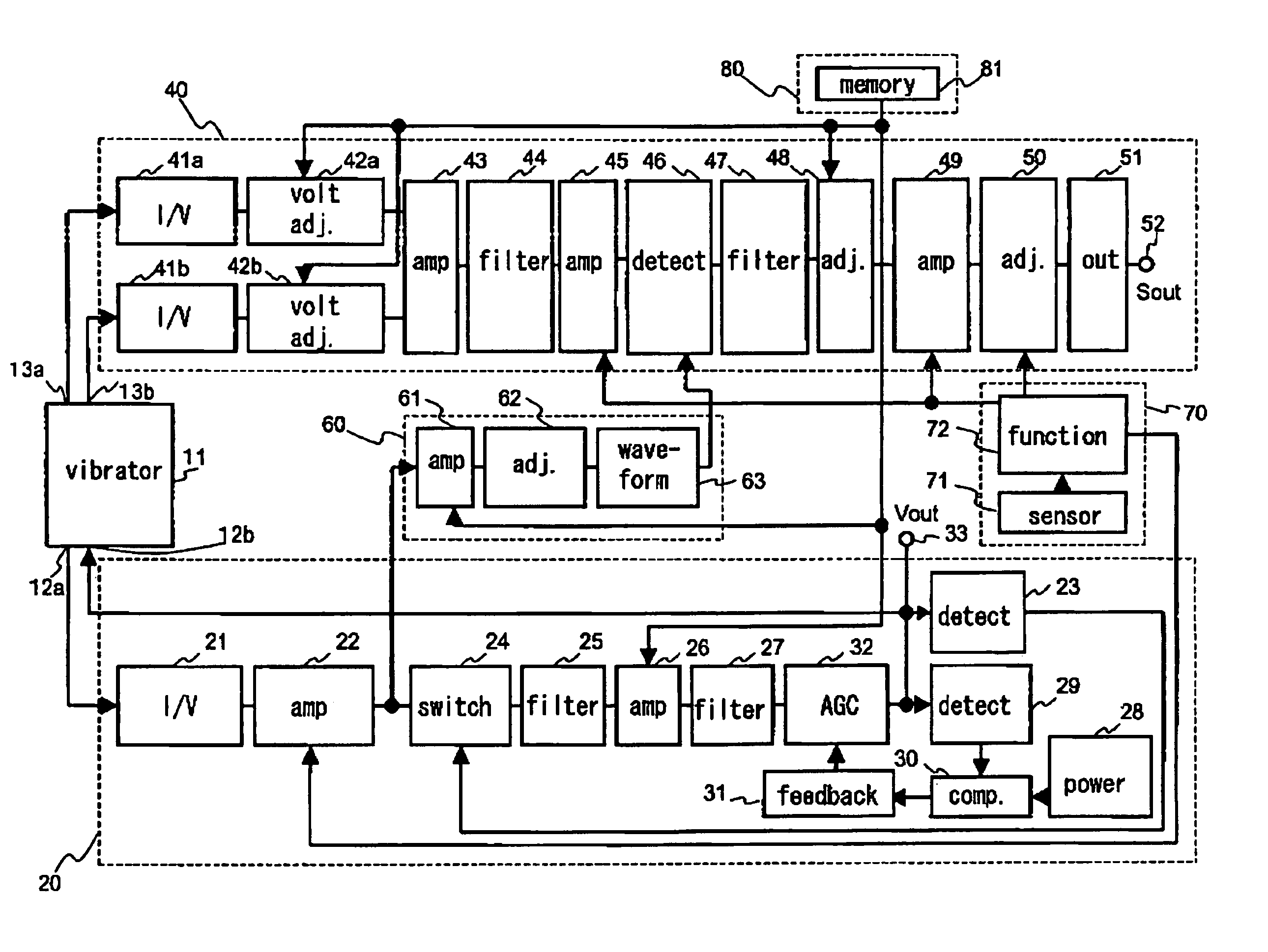

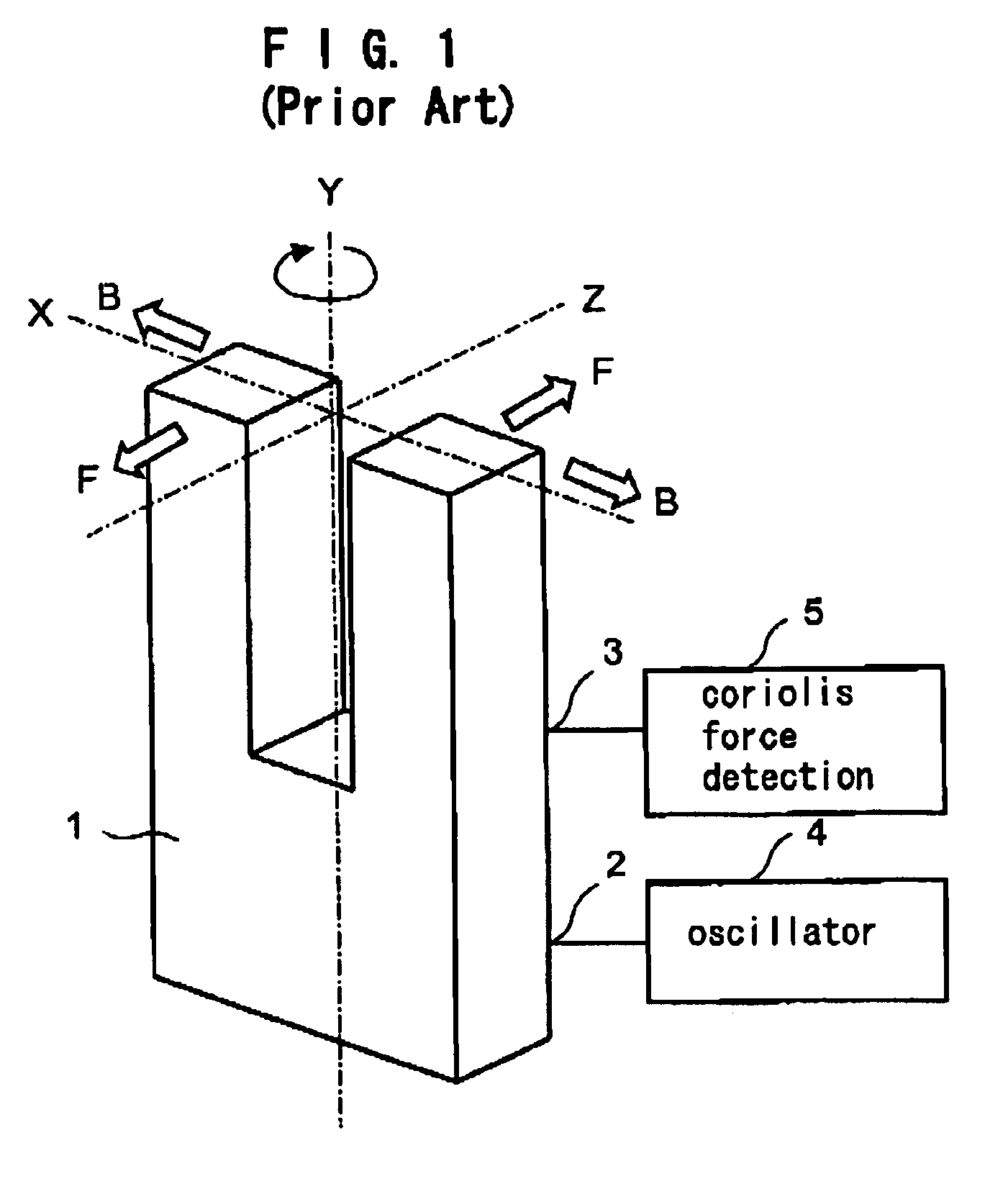

Angular velocity sensor

InactiveUS7069783B2Stable and precise angular velocityFacilitates temperature compensationAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsPiezoelectric actuatorsAngular velocity

Owner:GYTRONIX

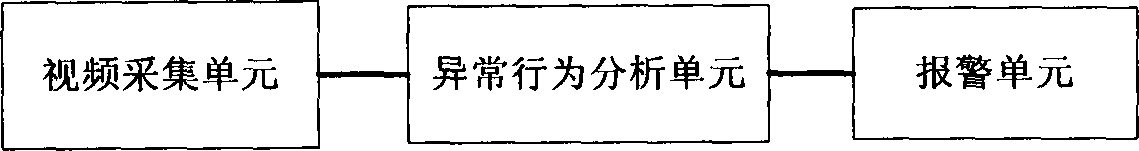

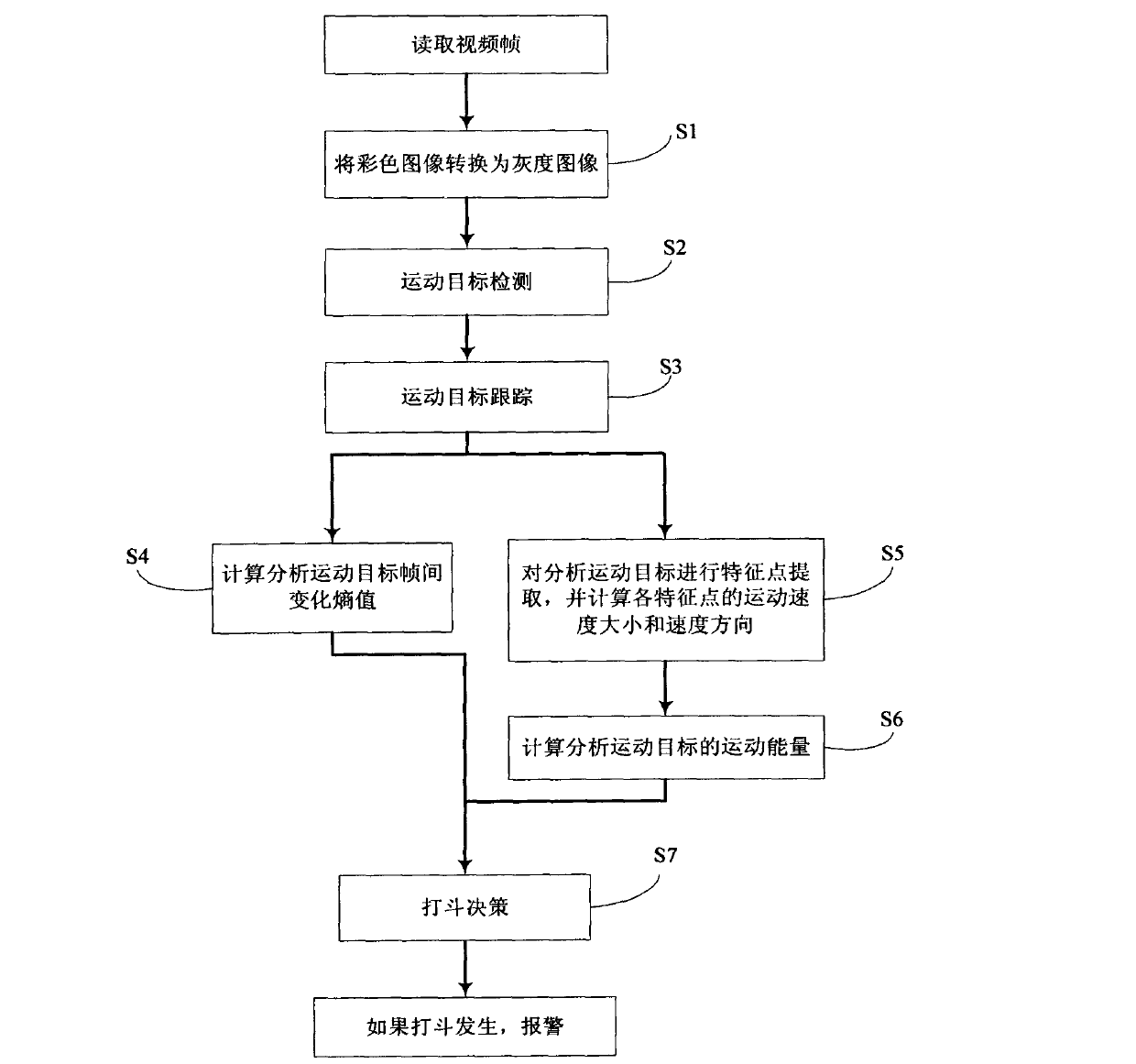

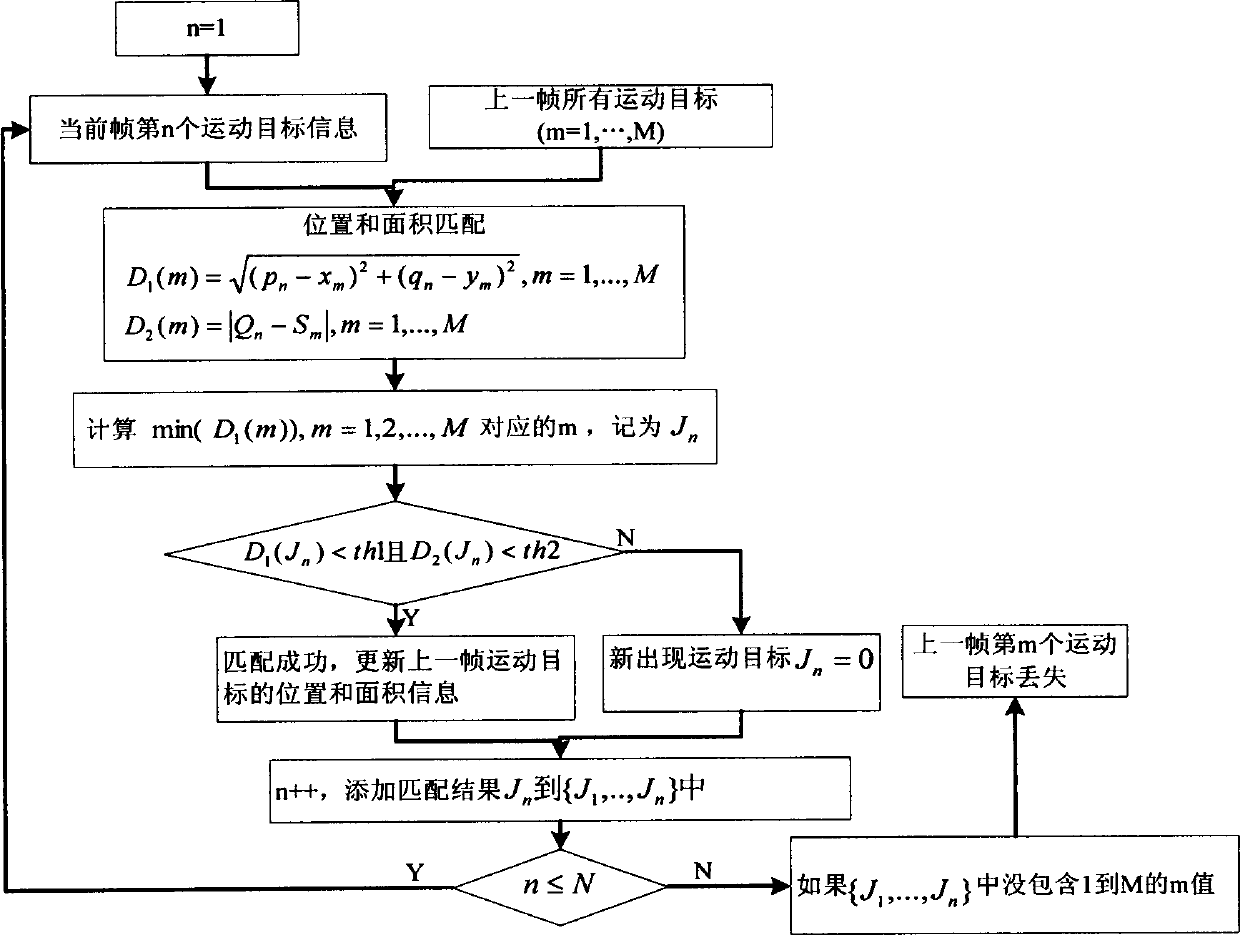

Method for detecting abnormal behavior during video monitoring

ActiveCN102629384ANo false alarms will occurImprove the success rate of alarmImage analysisClosed circuit television systemsVideo monitoringPattern recognition

The invention discloses a method for detecting an abnormal behavior during video monitoring. By using the current detection method, there is one single consideration factor and misinformation is easy to be generated. By using the method of the invention, the above problem can be solved. The method comprises the following steps: a. reading a video image frame and converting a video image into a grayscale image; b. detecting a motion object in the grayscale image; c. tracking the motion object, determining and analyzing the motion object; d. calculating and analyzing an interframe variation entropy value of the motion object and simultaneously carrying out motion object characteristic point extraction, calculating a motion speed and a direction of the each characteristic point and calculating motion energy of the motion object; e. according to the interframe variation entropy value of the motion object and the motion energy, carrying out a fighting decision, giving an alarm if there is a fight.

Owner:CHENGDU JIAYITONG INFORMATION TECH CO LTD

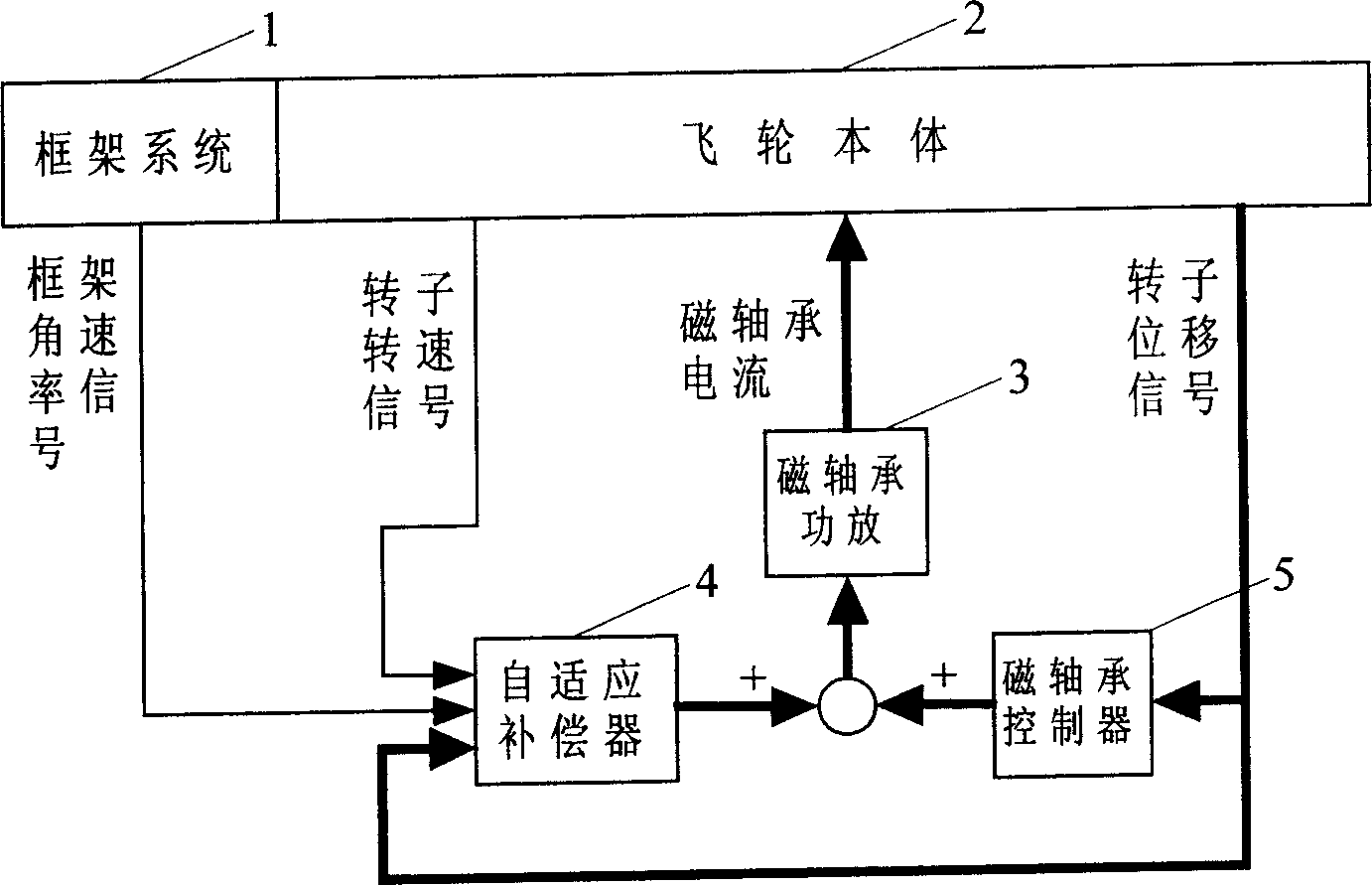

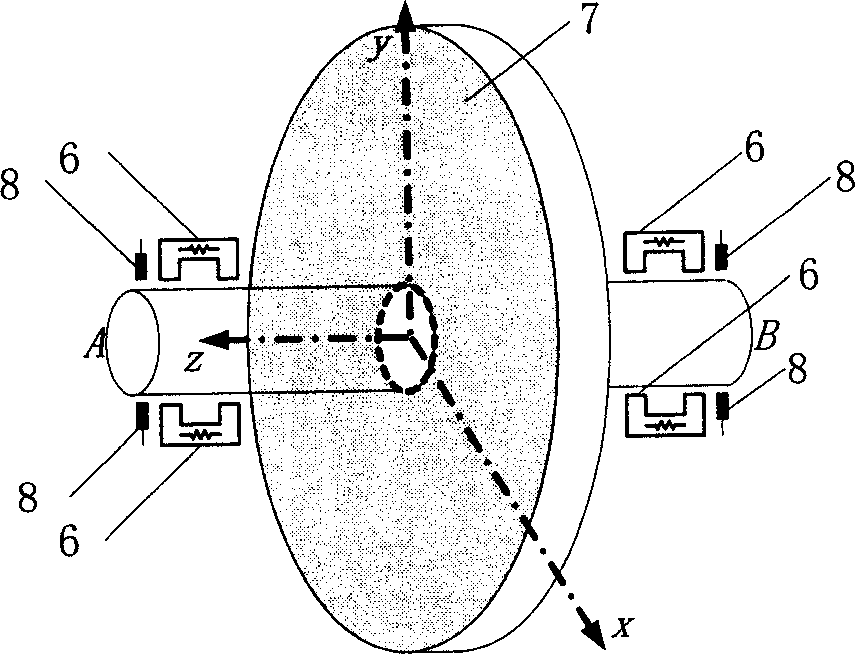

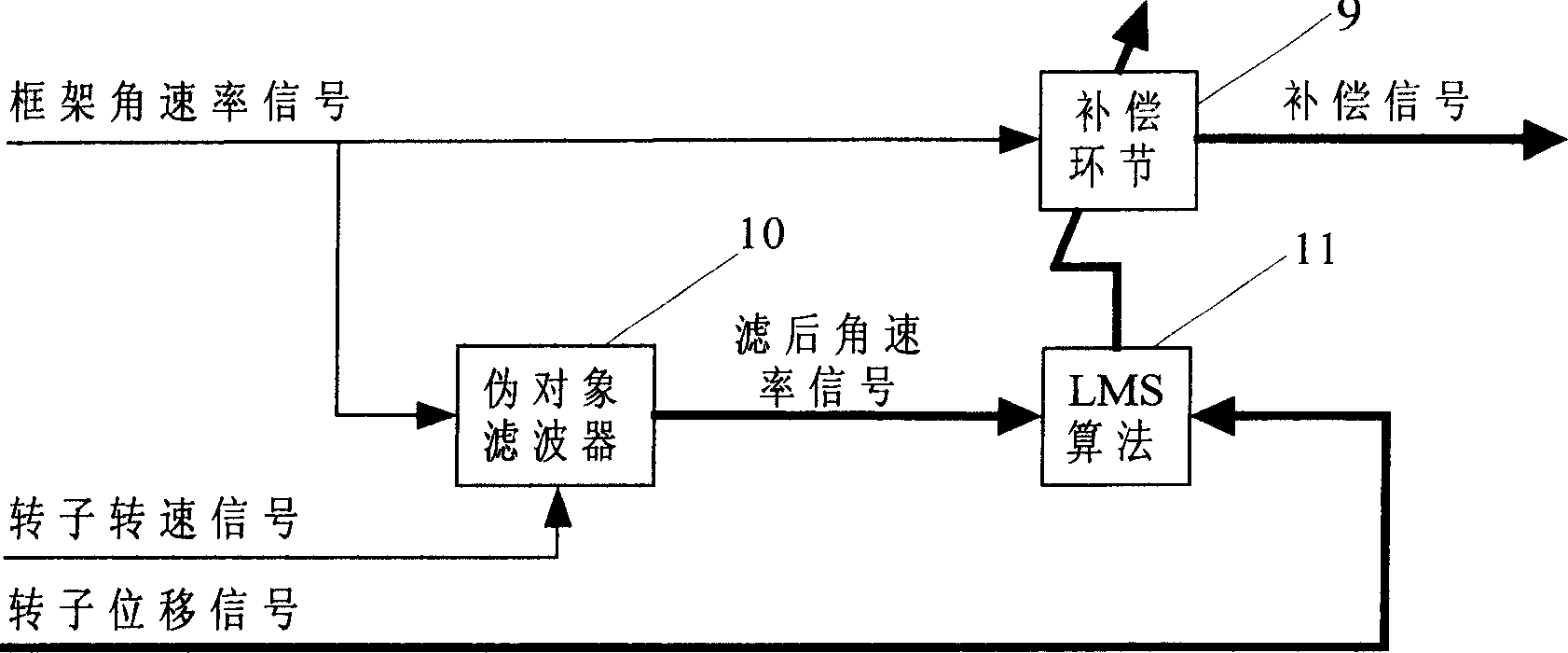

Magnetic bearing control system of accurately compensating magnetic suspension control torque gyroscope support rigidity

InactiveCN1710800AAvoid the risk of increased displacementDoes not intensifyMagnetic holding devicesMagnetic bearingGyroscope

The disclosed control system includes flywheel body, power amplifier for magnetic bearing, controller for magnetic bearing and adaptive compensator. Through collecting signals including angular rate of frame, speed of rotor, and displacement of rotor, the adaptive compensator carries out adaptive compensation calculation. Sum of calculated compensation quantity and the output of controller for magnetic bearing is connected to the power amplifier for magnetic bearing in order to eliminate disturbing moment on rotor of magnetic suspension caused by moving frame. The invention lowers displacement of rotor caused by rotation of frame, raises response speed and precision of angular rate of frame, and improves response speed and precision of moment output of magnetic suspension control moment.

Owner:BEIHANG UNIV

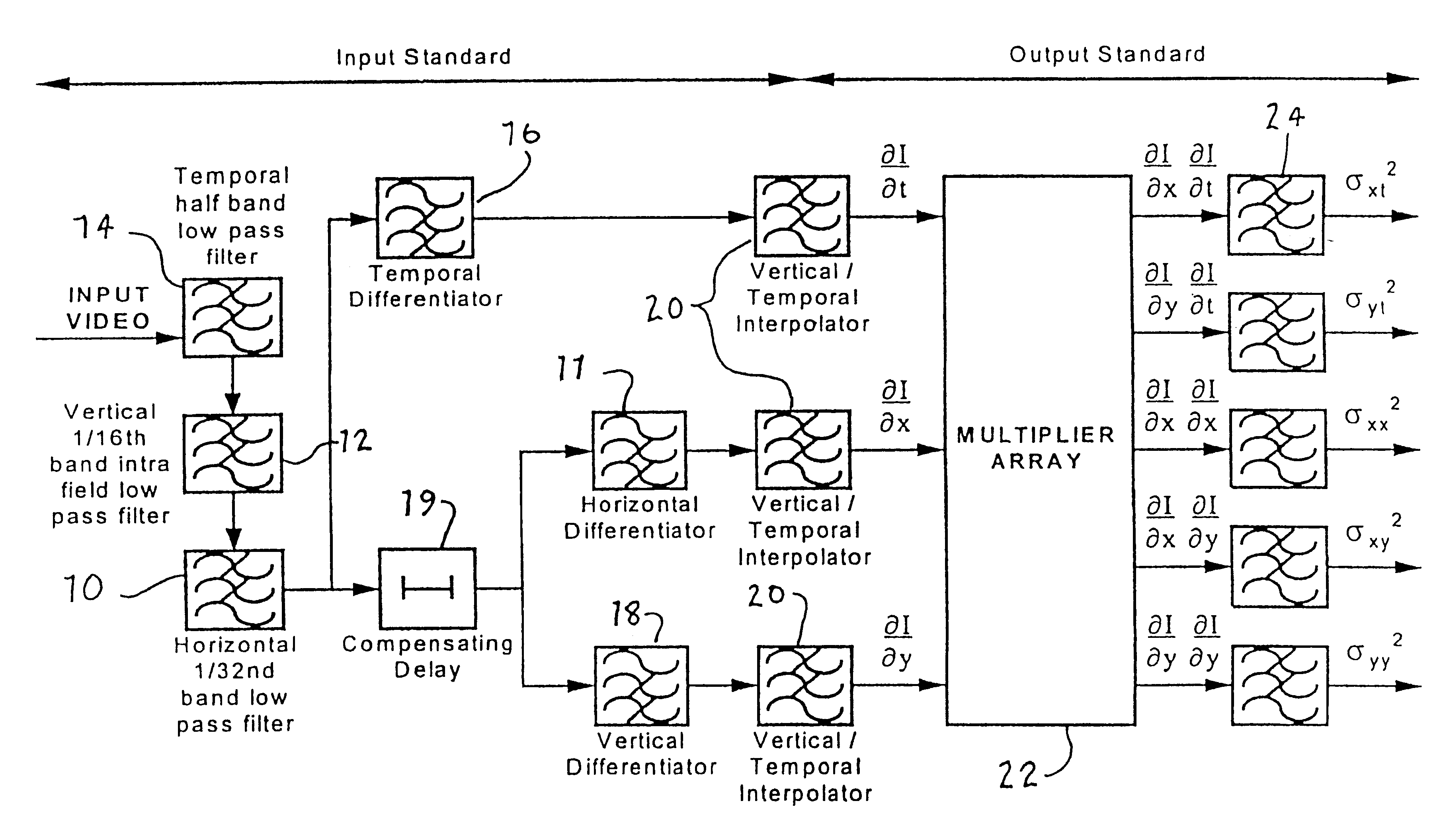

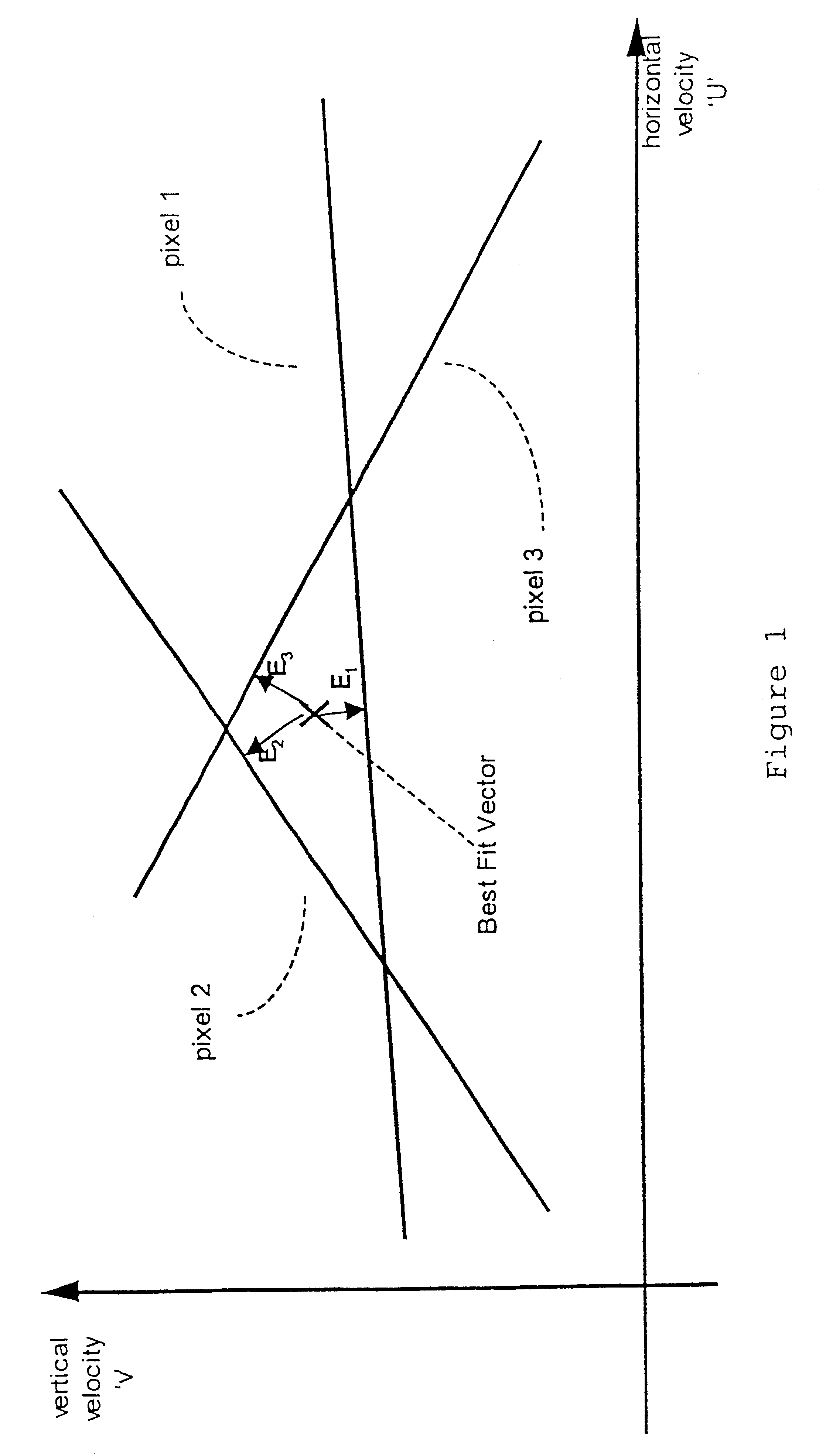

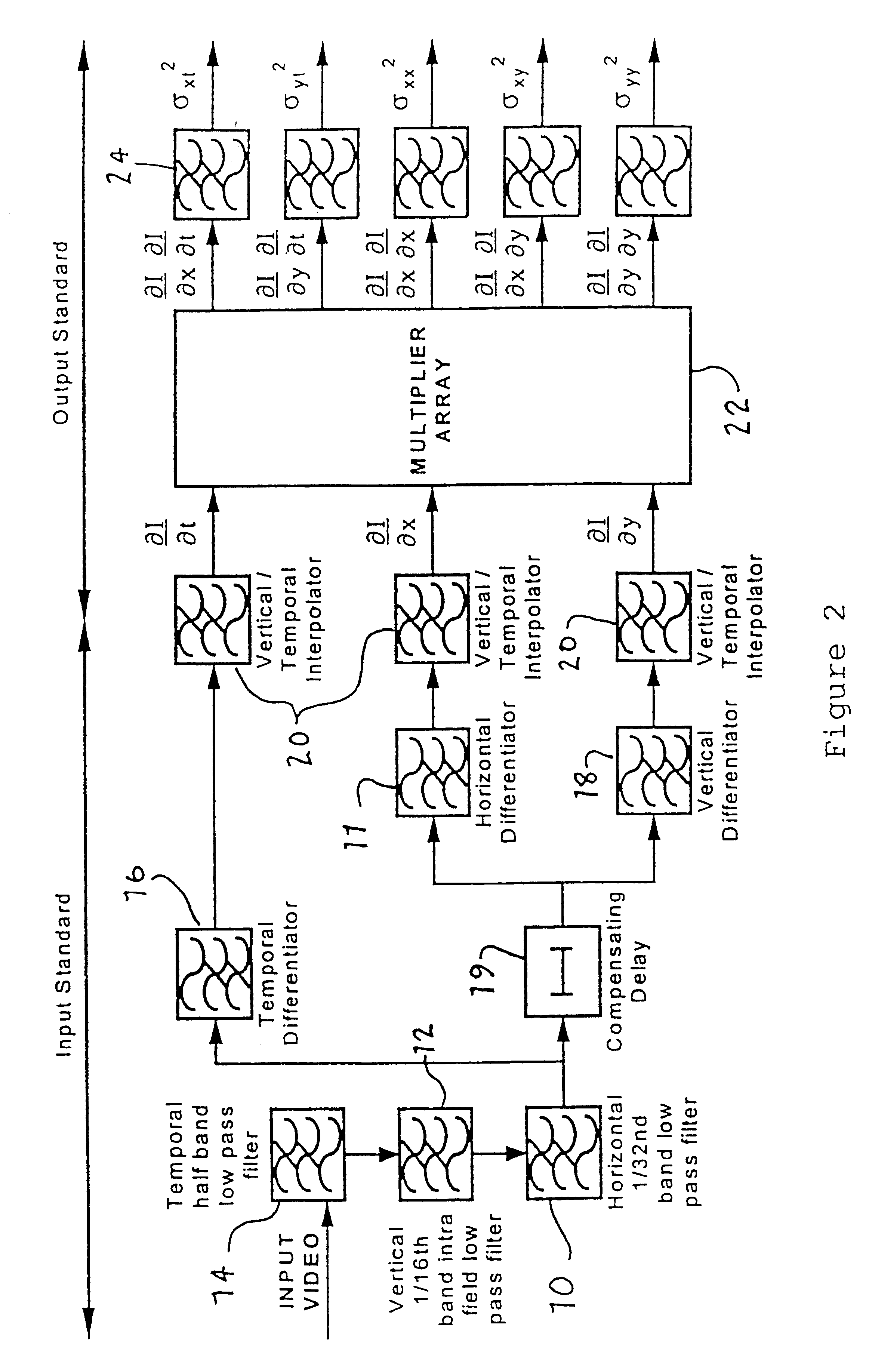

Motion vector field error estimation

InactiveUS6442202B1Less accurateSimple technologyTelevision system detailsImage analysisObservational errorMotion vector

A technique is disclosed for estimating the measurement error in motion vectors used for example in a motion compensated video signal process. For each motion vector corresponding to a region of an image a plurality of temporal and spatial image gradients are calculated corresponding to that region. From the constraint equations of the image gradients a plurality of error values can be calculated for each motion vector and a parameter generated describing the size of the distribution of motion vector measurement errors. Subsequent processing of the video signals using the motion vectors can then be adapted, for example by graceful fallback in motion compensated interpolation, depending on the accuracy of each motion vector. The "confidence' in the accuracy of each motion vector can be described by a parameter calculated in relation to the size of the error distribution and the motion vector speed.

Owner:HB COMM UK LTD

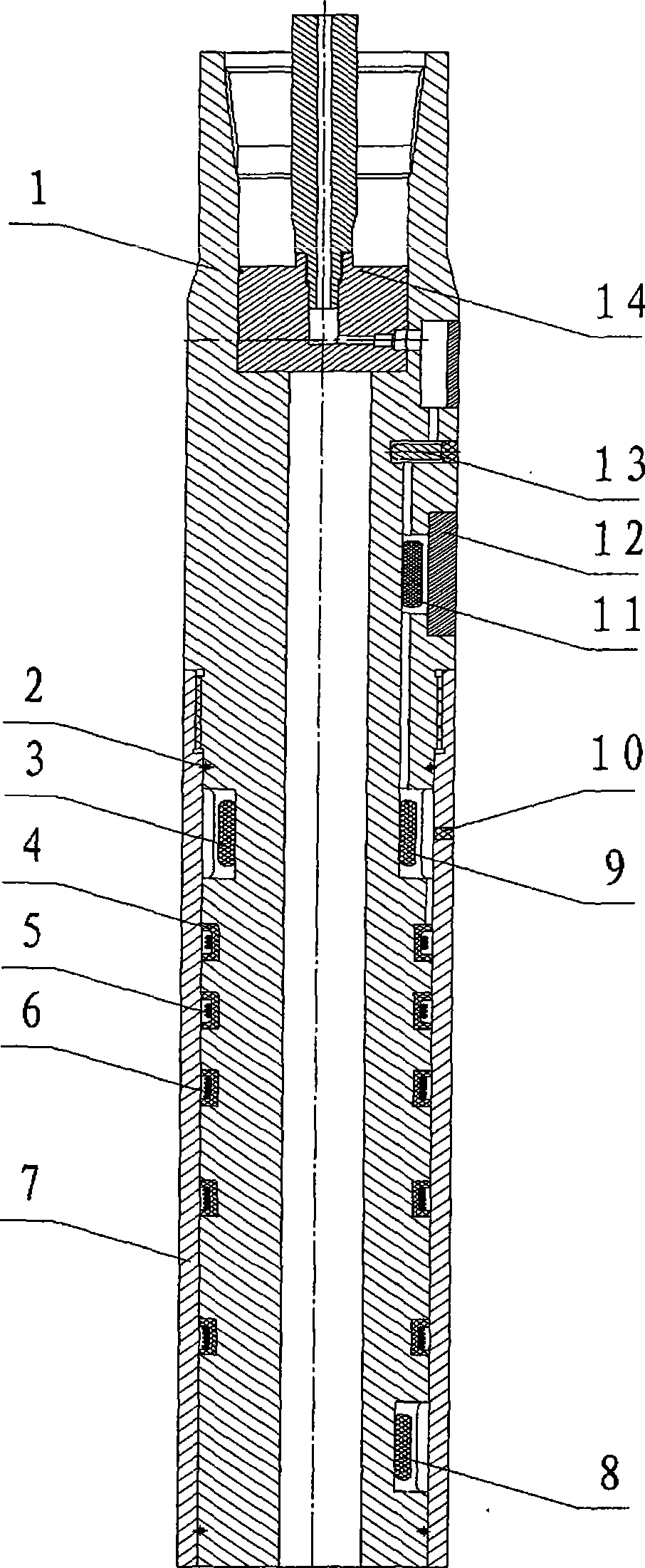

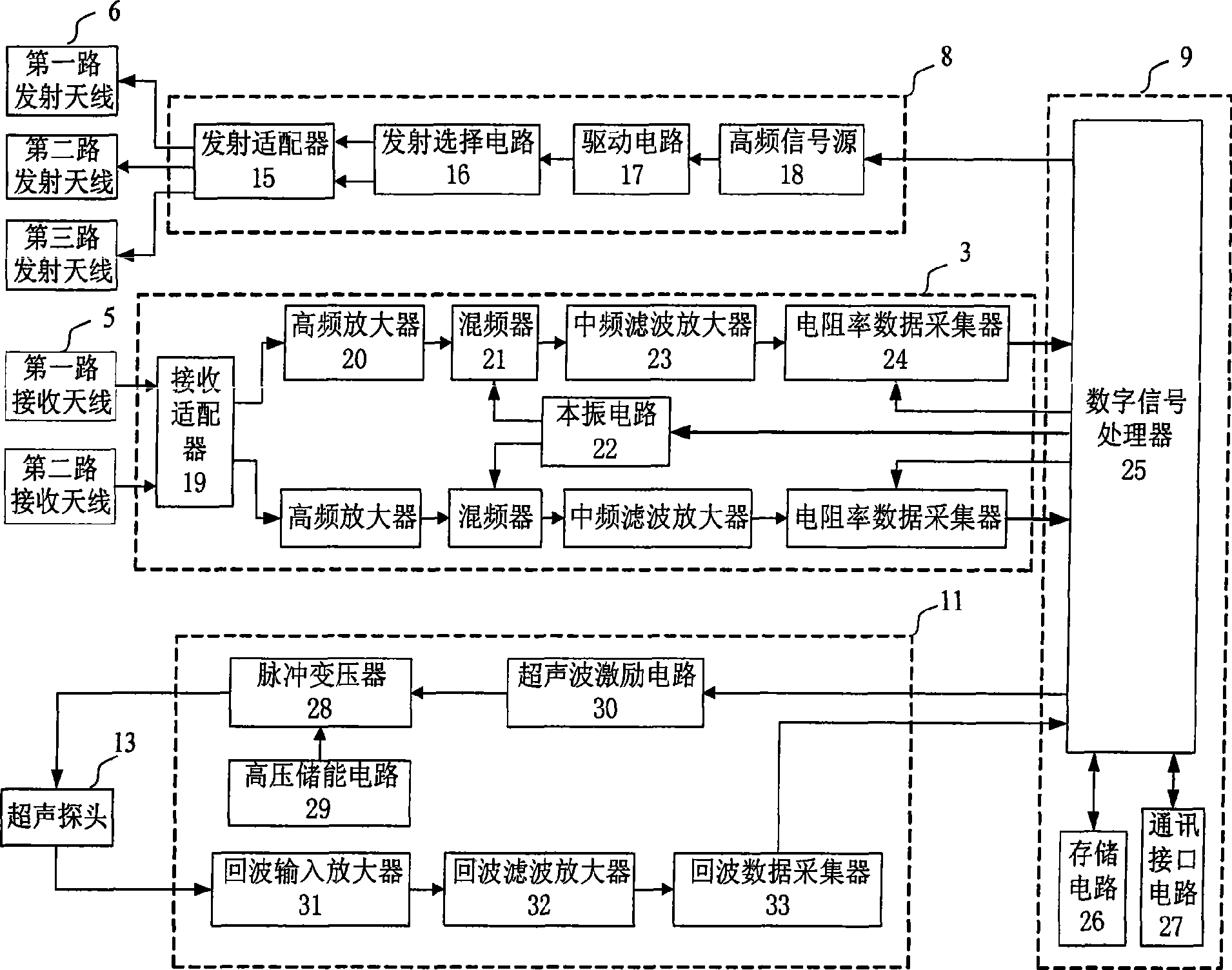

While-drilling borehole compensation electromagnetic wave resistivity survey apparatus

ActiveCN101482013AReal-time compensation functionShorten the lengthElectric/magnetic detection for well-loggingBorehole/well accessoriesSonificationNon symmetric

A borehole compensation electromagnetic wave resistivity measuring device while drilling uses a transmitting antenna which is at one side of a receiving antenna and has a non-symmetric coil system with different spacing, and sleeves the non-symmetric coil system and a measuring circuit on a drilling collar for obtaining a strata resistivity measurement value with a plurality of detecting depths; moreover, an ultrasonic probe and the measuring circuit are installed on the drilling collar for measuring the diameter of a borehole, and compensating and modifying the strata resistivity measurement value according to the relationship among the resistivity measurement value and the diameter of the borehole and the electrical conductivity of slurry, thereby achieving accurate measurement of the strata resistivity. Therefore, not only the length of the measuring device is shortened, the manufacturing cost is reduced, and the occurrence for the bending of the instrument and the clamping of the drill in a highly-deviated well or a branch well with small curvature radius is avoided, but also the real-time borehole compensation function is achieved, and the drilling speed is not affected; the invention is good for adjusting the well trajectory in time in a highly-deviated well or a horizontal well and controlling the drilling tool to pass through the best position in a reservoir according to the geological information.

Owner:SINOPEC SSC +3

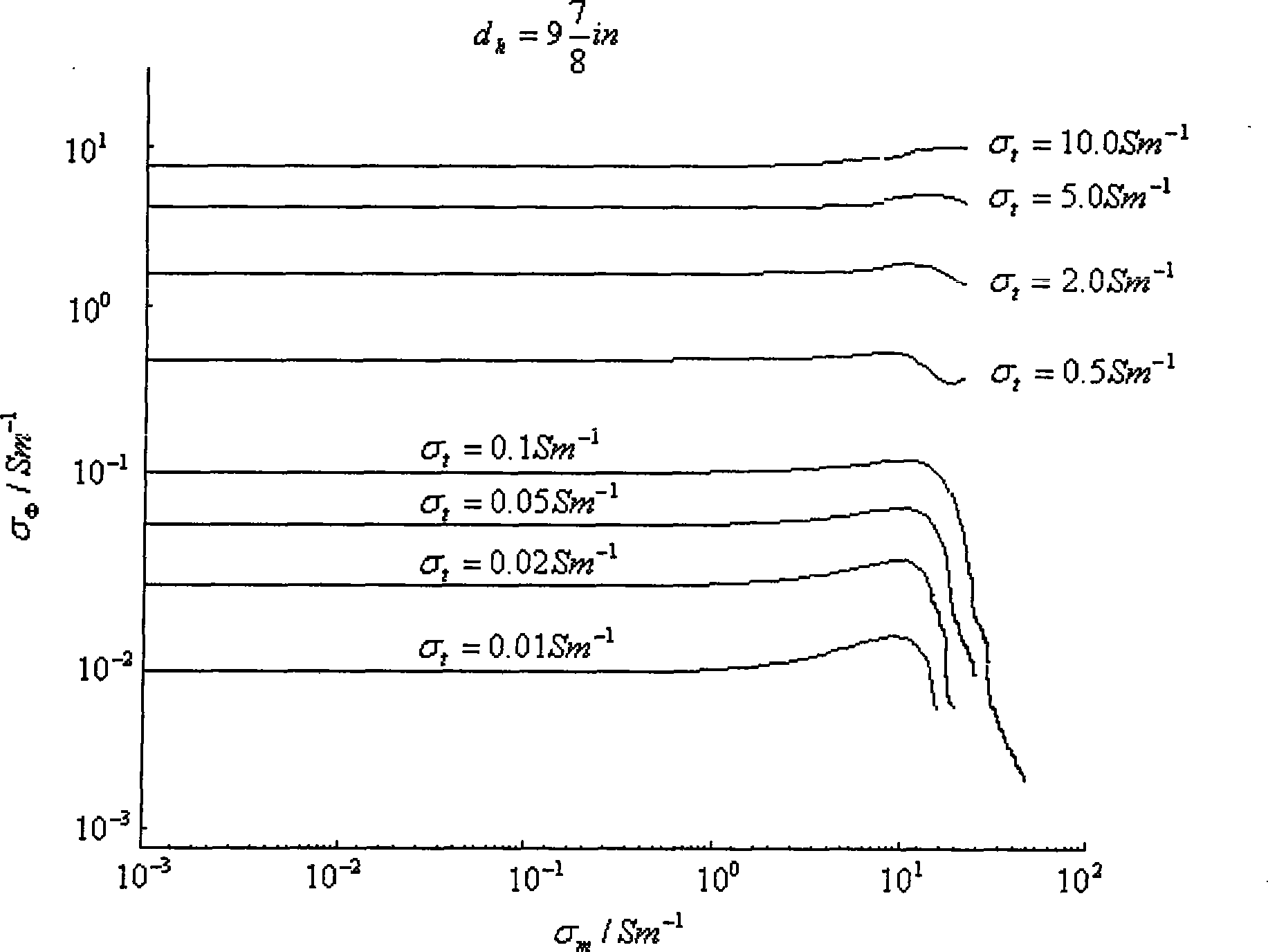

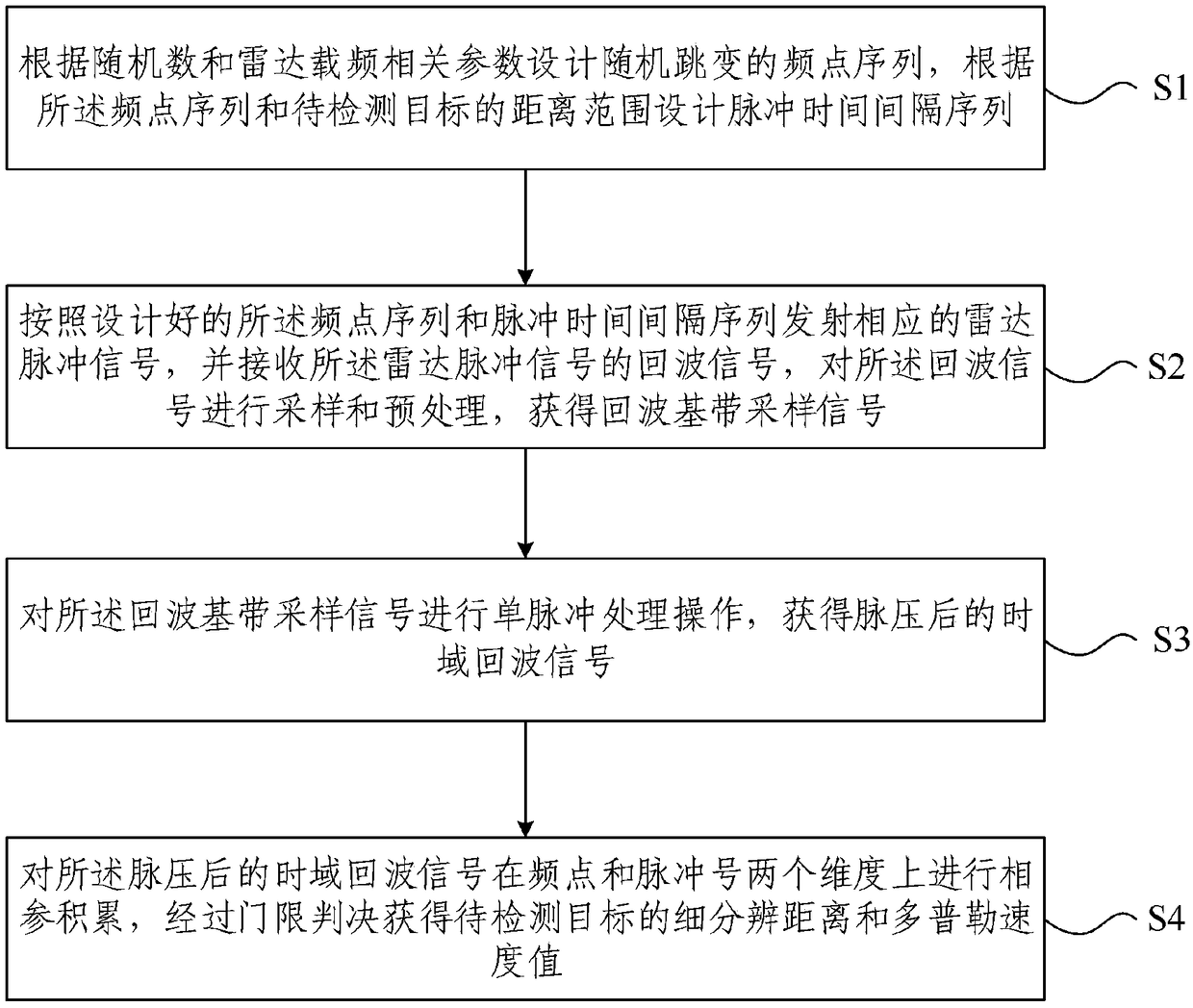

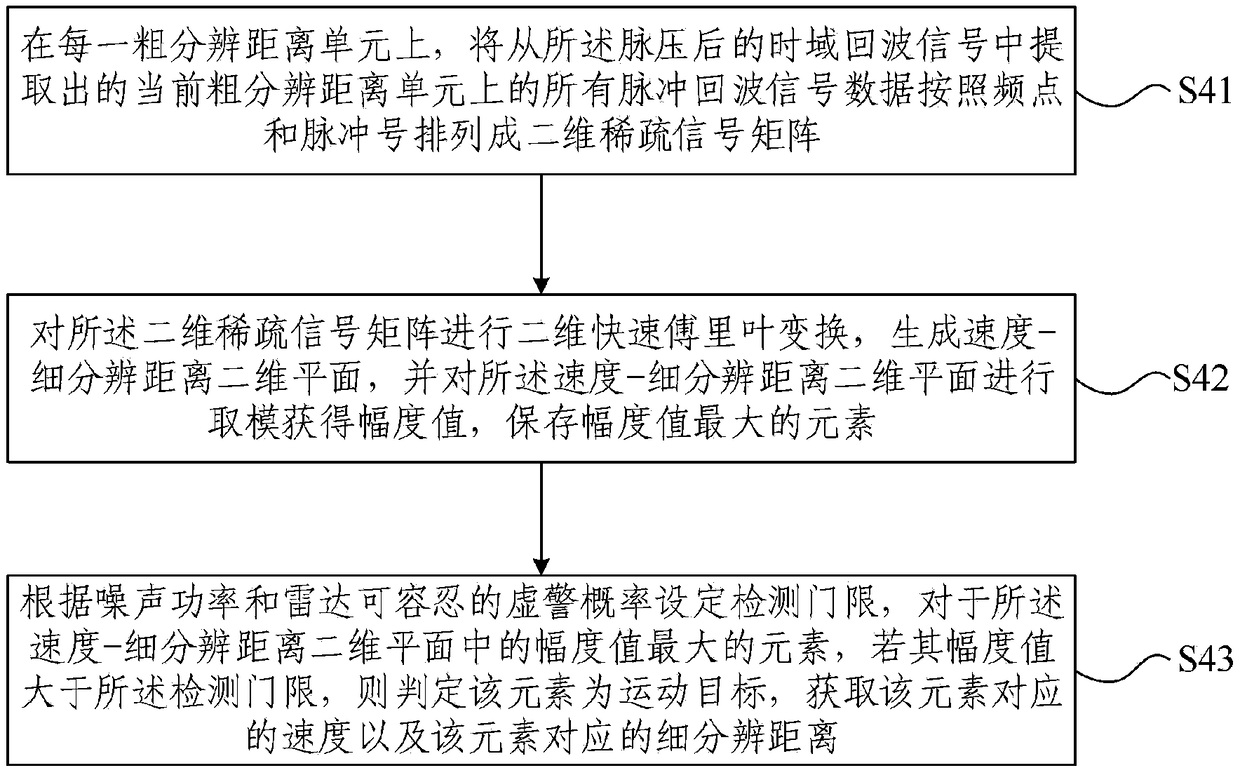

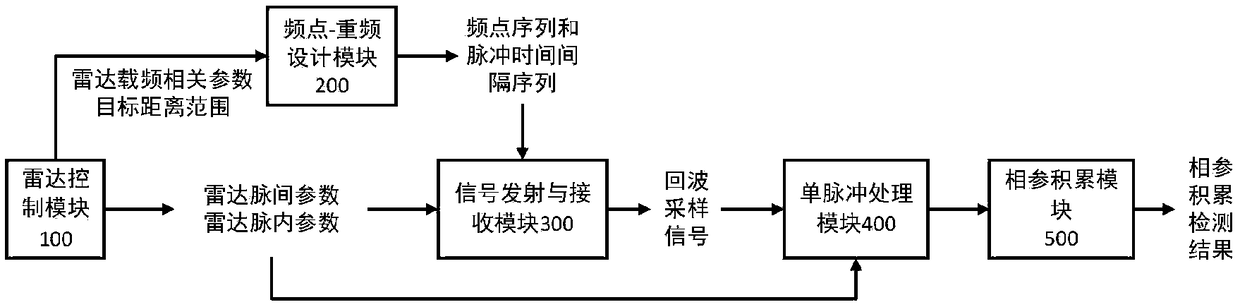

Signal processing method and device for frequency-agile radar based on variable repetition frequency technology

ActiveCN109143179AReal-time processingReduce processingWave based measurement systemsBasebandEcho signal

The invention provides a signal processing method and device for frequency-agile radar based on a variable repetition frequency technology. The method includes the following steps: designing a frequency point sequence of random hopping according to a random number and the carrier frequency related parameters of radar, and designing a pulse time interval sequence according to the frequency point sequence and the distance range of a target to be detected; emitting a radar pulse signal according to the designed frequency point sequence and the designed pulse time interval sequence, receiving an echo signal of the radar pulse signal, and sampling and preprocessing the echo signal to obtain a baseband echo sampling signal; processing the baseband echo sampling signal by a single pulse to obtaina time-domain echo signal after pulse compression; and coherently accumulating the time-domain echo signal after pulse compression in the two dimensions of frequency point and pulse number, and obtaining the fine resolution distance and Doppler velocity values of the target to be detected through threshold decision. Accurate detection of the distance and velocity of a moving target by coherent frequency-agile radar is realized, and the amount of computation for the processing of coherent frequency-agile signals can be reduced.

Owner:TSINGHUA UNIV

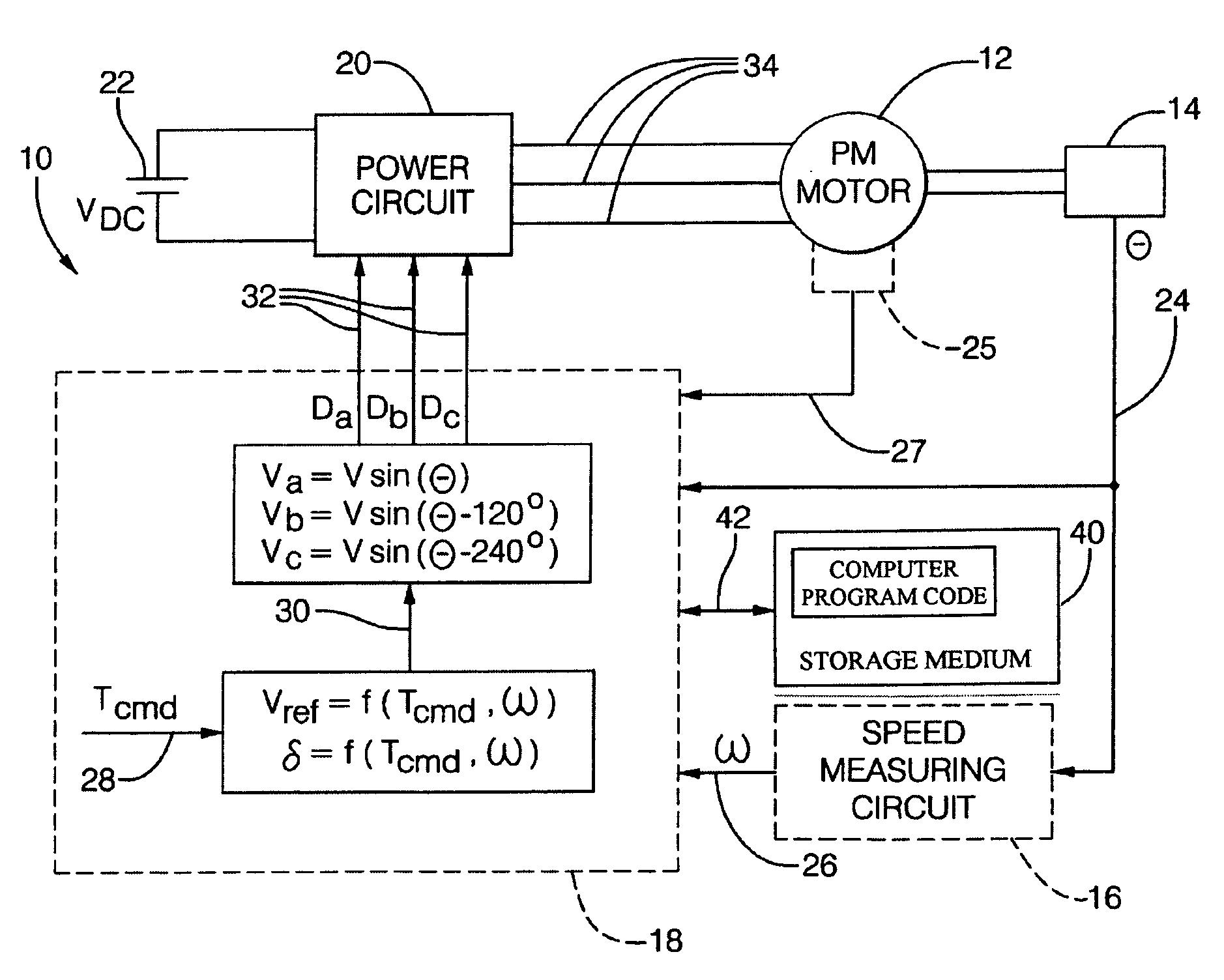

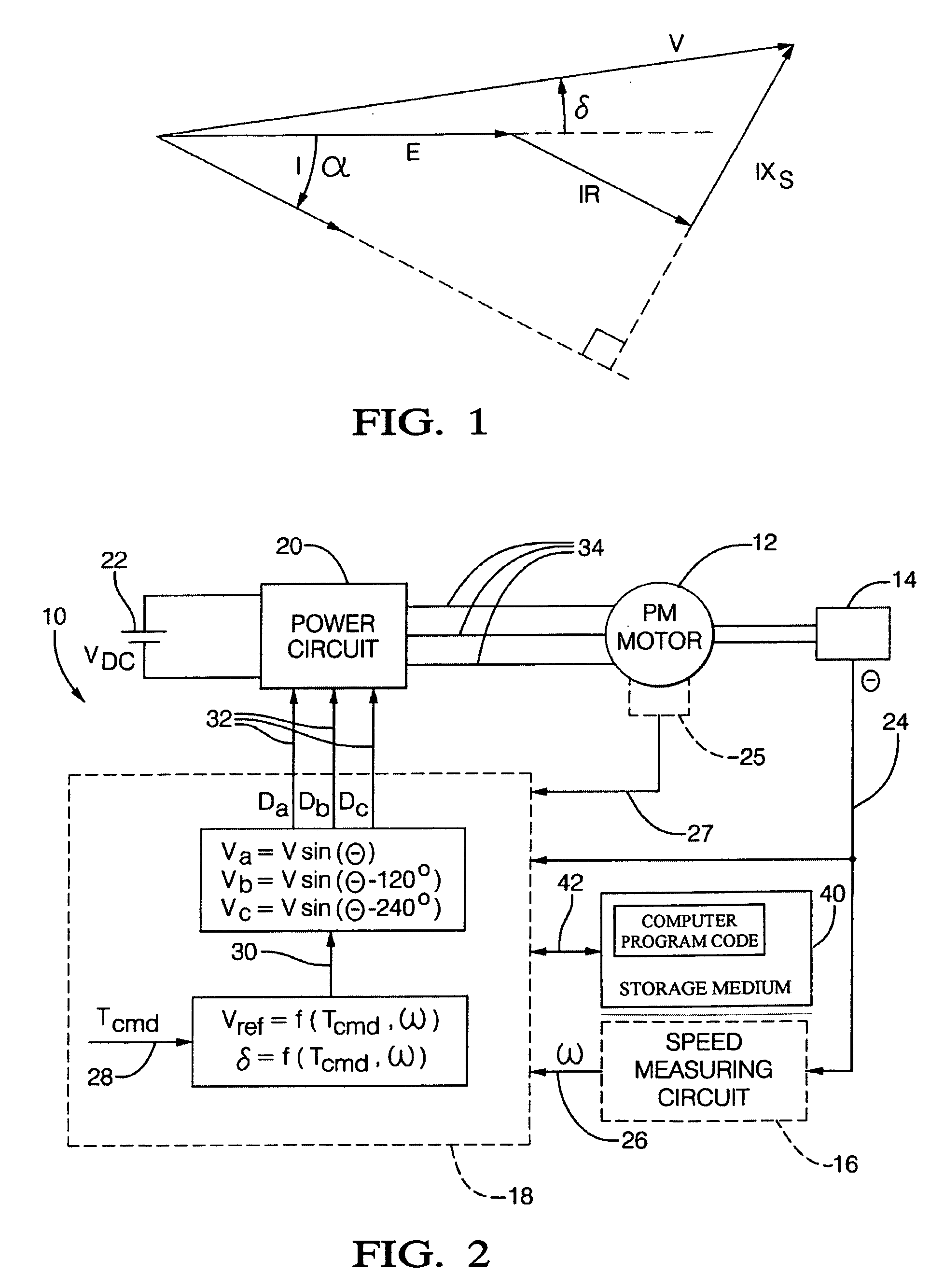

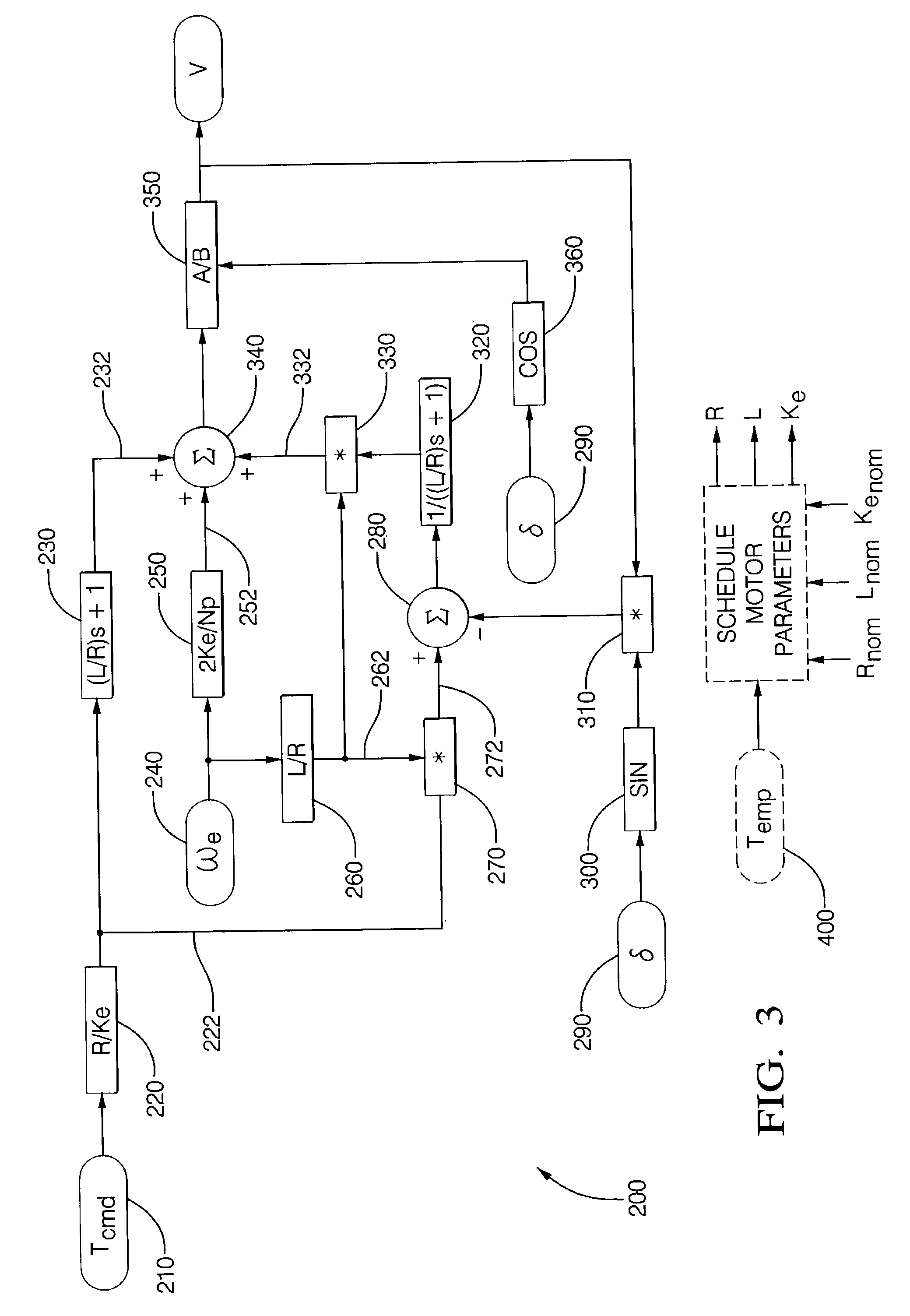

Transient compensation voltage estimation for feedforward sinusoidal brushless motor control

InactiveUS7157878B2Single-phase induction motor startersAC motor controlBrushless motorsTransient state

A method for controlling a voltage mode controlled electric machine comprising: receiving a torque value representative of a desired torque; obtaining a speed value indicative of a rotational velocity of the electric machine; acquiring a phase advance value indicative of a desired phase advance angle; generating a voltage command responsive to the torque value, the position value; the generating is responsive to the torque value, the speed value, and the phase advance value.

Owner:STEERING SOLUTIONS IP HLDG +1

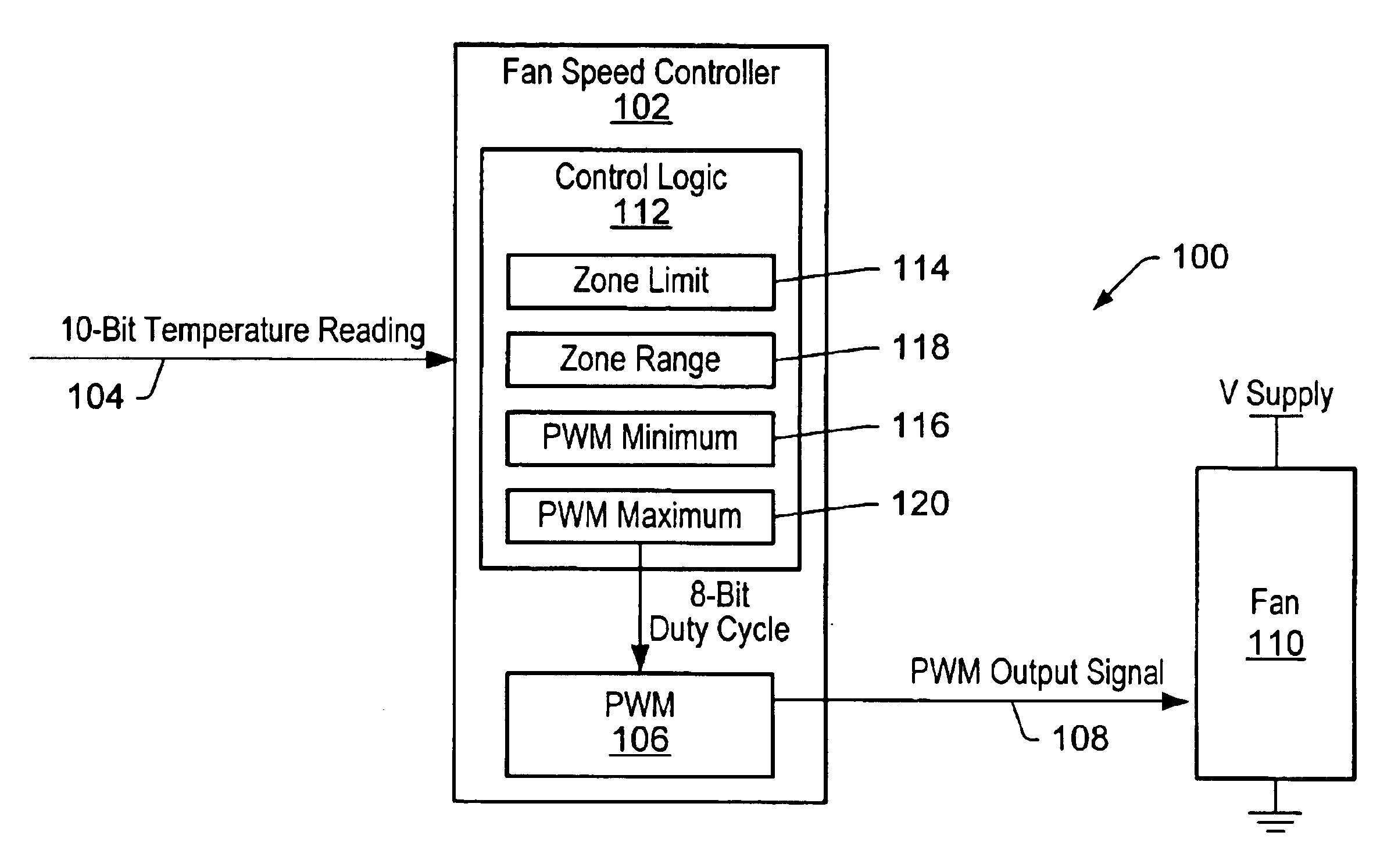

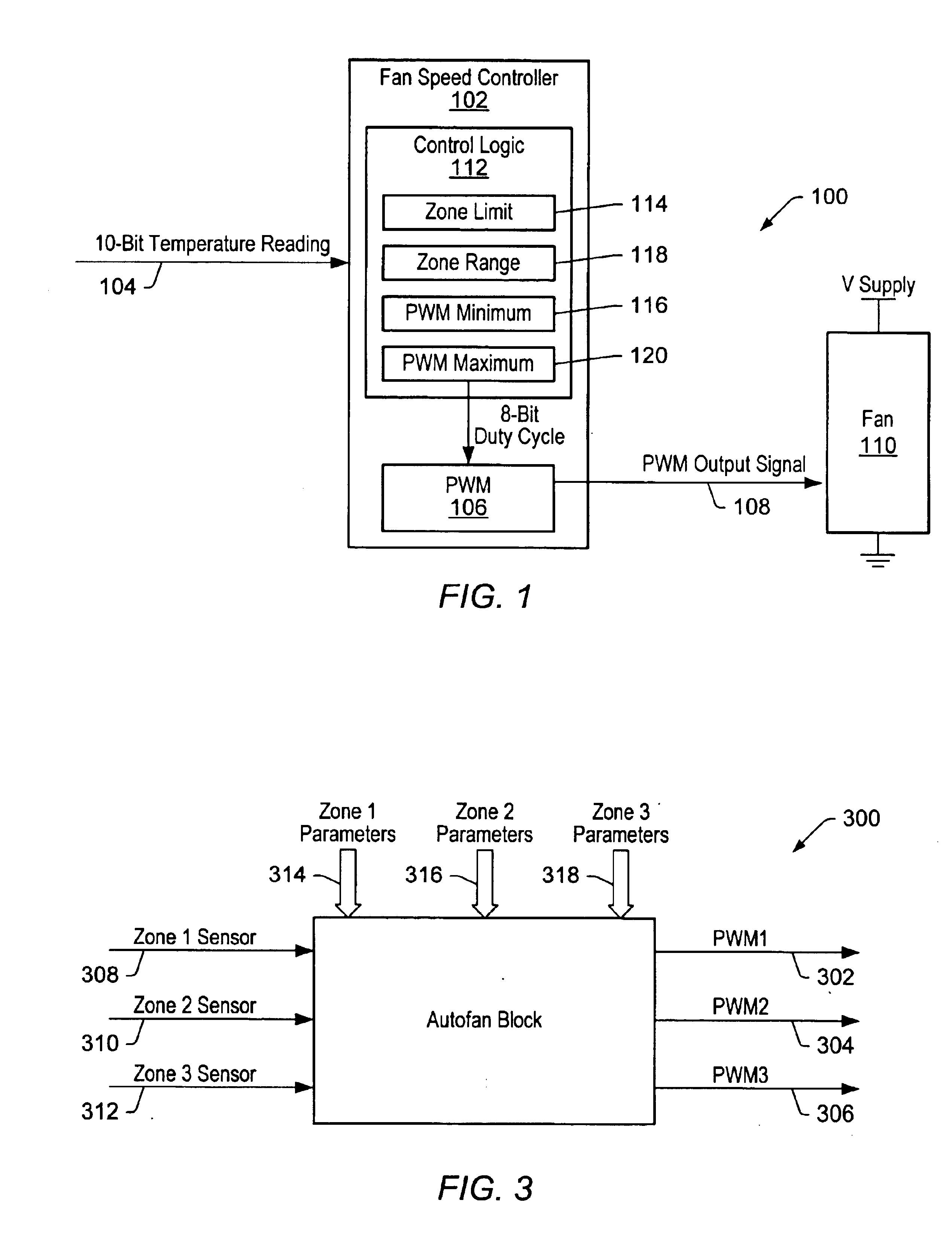

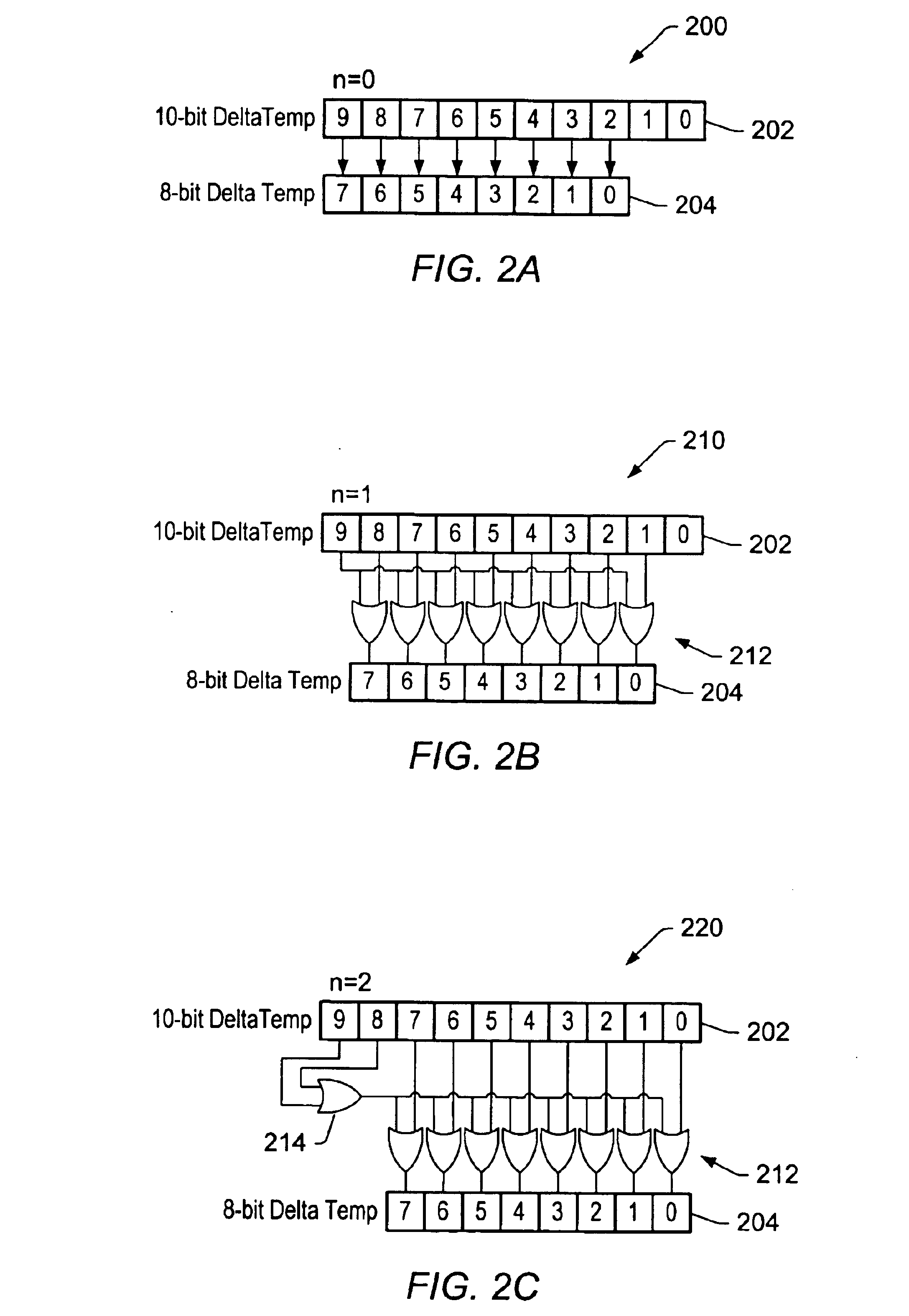

Fan control system with improved temperature resolution

ActiveUS6874327B1High resolutionAvoid duplicationDC motor speed/torque controlLighting and heating apparatusTemporal resolutionControl system

A system and method for increasing resolution of pulse width modulated (PWM) signal duty cycle calculations in a fan speed control system operating to control rotational speed of at least one fan. The method may comprise obtaining a temperature reading from a first temperature sensor in the fan speed control system during a first time period. The temperature reading has resolution of a first number of bits. A portion of the first number of bits is selected for calculating a PWM signal duty cycle with the resolution of the first number of bits in the temperature reading using only the portion of the first number of bits and zone parameters associated with the first temperature sensor. The PWM signal duty cycle may then be converted into a PWM signal that may be provided to the at least one fan.

Owner:MICROCHIP TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com