Threshing and pneumatic separating discharging device of screen with pneumatic balancing function and for pneumatic separating

A divider and screen technology, applied in application, tobacco, food science and other directions, to achieve the effect of balanced suction and good screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

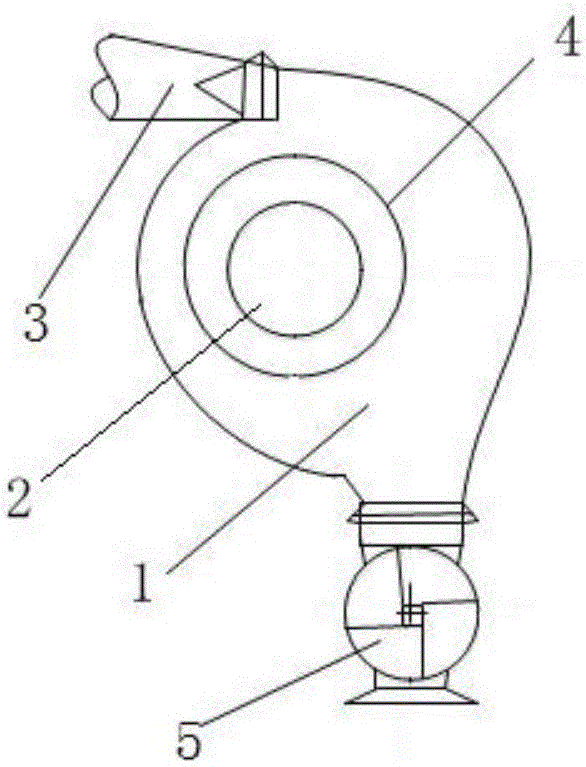

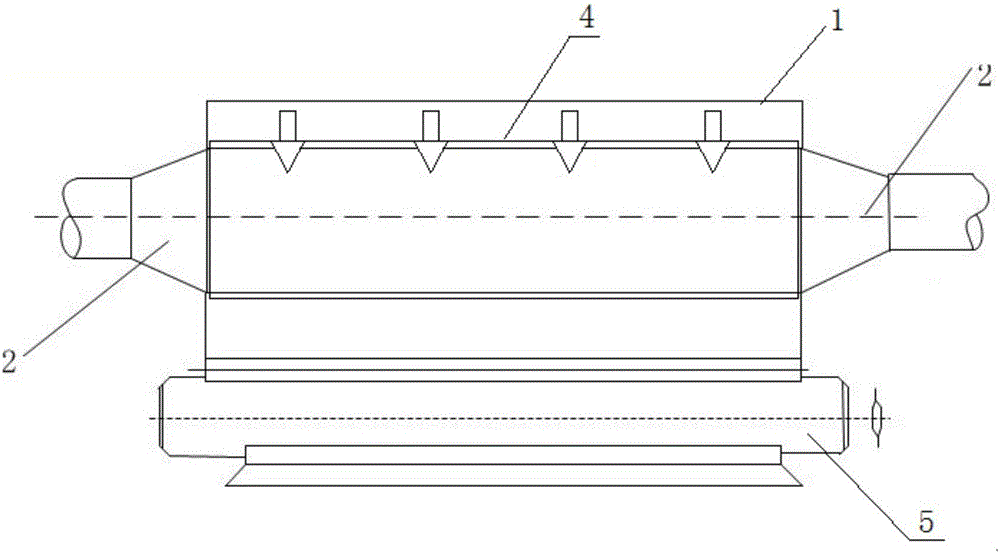

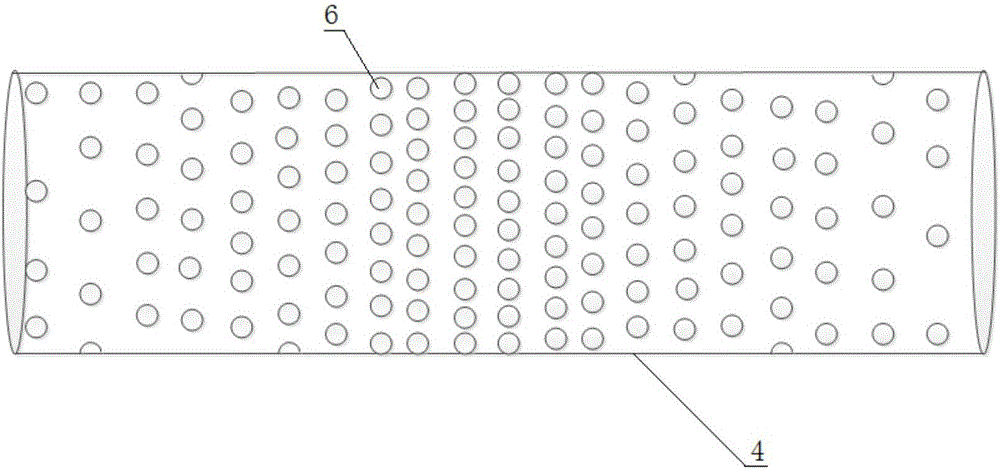

[0018] Example: such as figure 1 , figure 2 Shown: a leaf blowing and air-separating feeder with a wind-balanced air-separating screen, including a feeder body 1, which runs through an exhaust tube 2 placed horizontally in the feeder body 1, and is connected to the feeder The feeding flat tube 3 at the upper end of the device body 1, the screen 4 wraps the exhaust cylinder 2 and places it in the material distributor body 1, and the star-shaped discharge roller 5 is arranged at the lower bottom of the material distributor body 1, and the sieve A number of mesh holes 6 are distributed on the net 4, and the number of the mesh holes 6 gradually decreases from the middle of the screen mesh 4 to both ends. The exhaust cylinder 2 is connected to the air network system through the dust removal pipe. When the two fans of the air network system force suction, the exhaust pipe forms a negative pressure through the dust removal pipe, such as Figure 4 As shown, due to the suction effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com