Patents

Literature

37results about How to "Guaranteed gas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

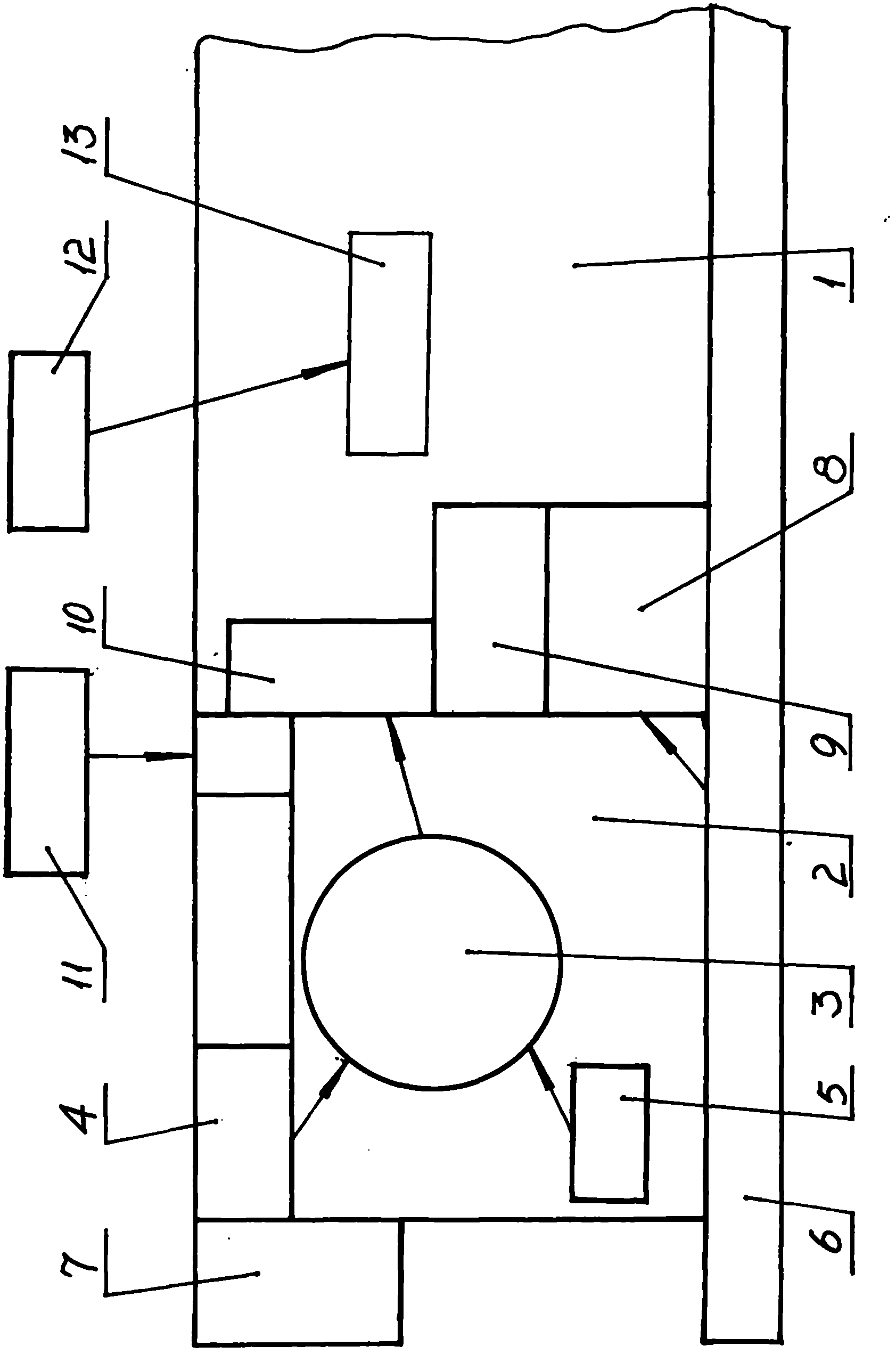

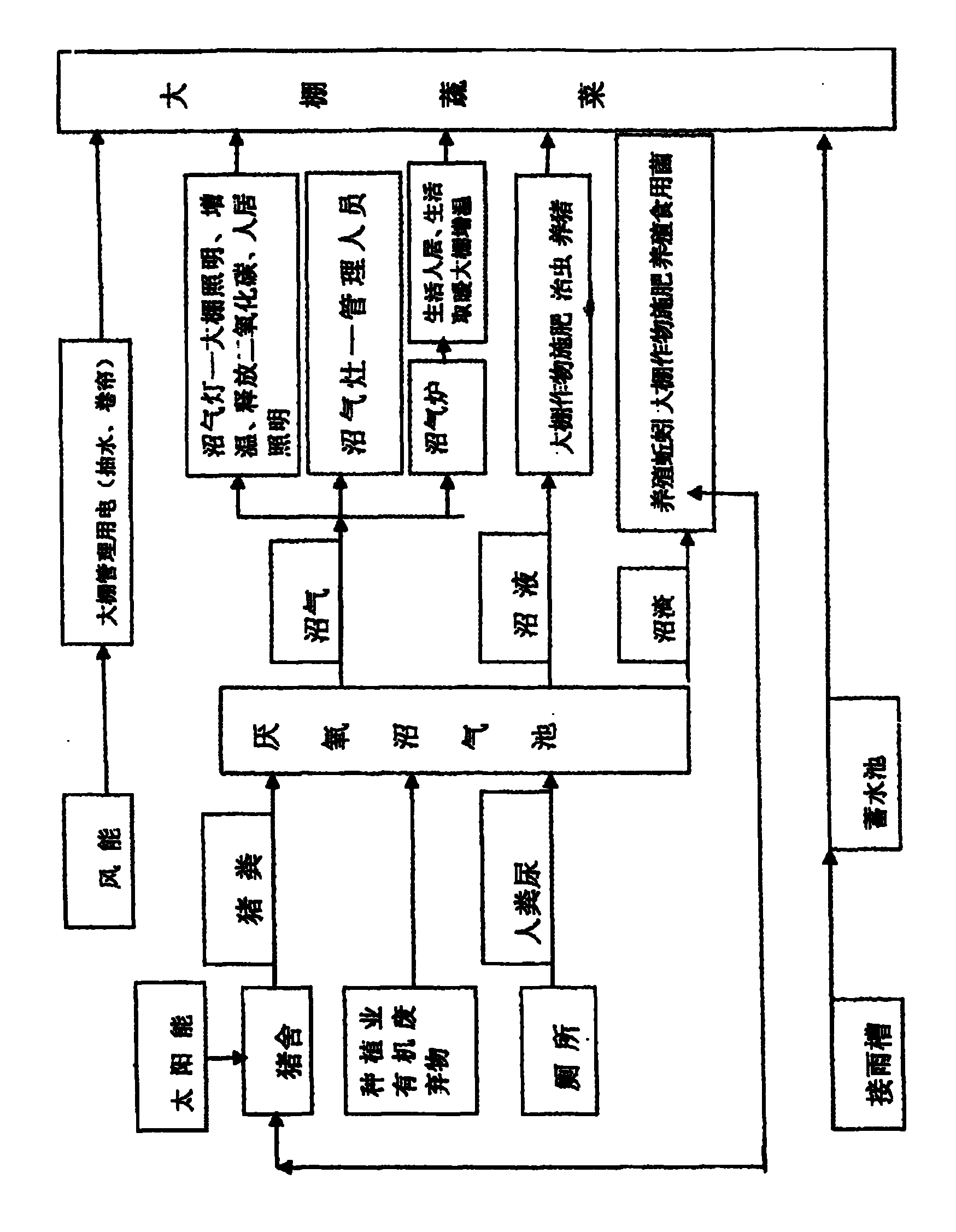

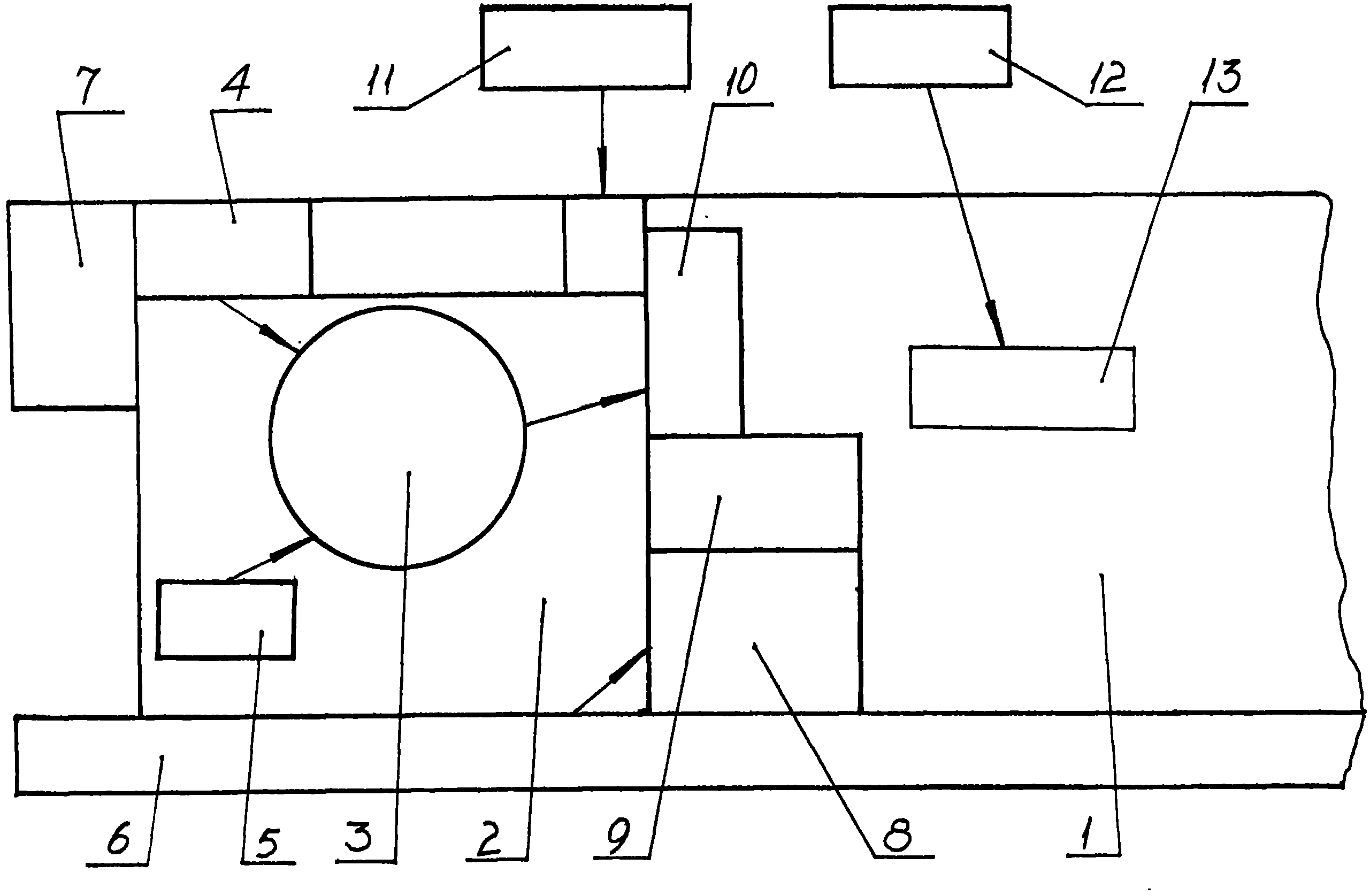

Design method of energy ecological greenhouse

InactiveCN102140856ASpeed up the slaughterImprove qualityRoof covering using slabs/sheetsRoof covering using tiles/slatesWind drivenWater storage tank

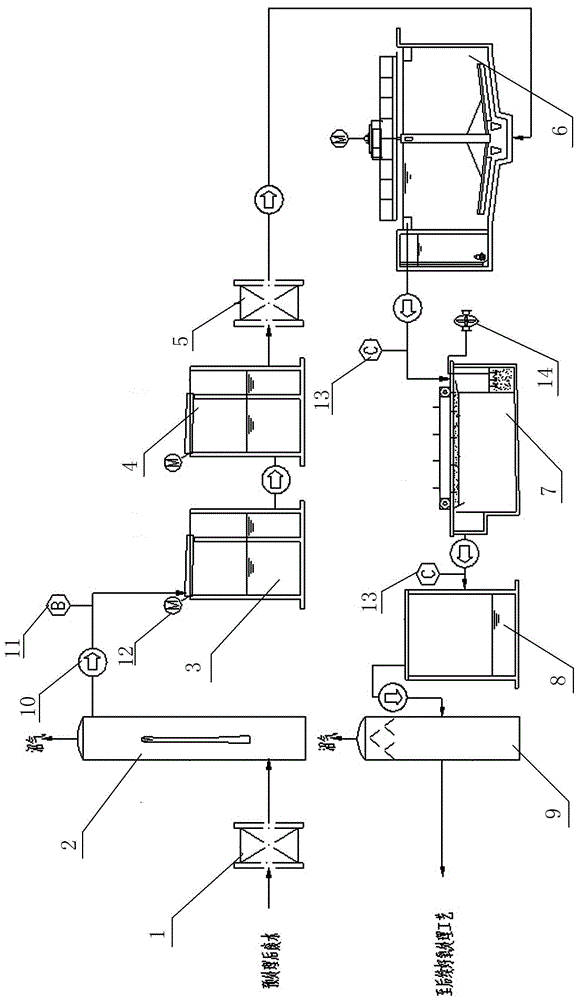

The invention discloses a design method of an energy ecological greenhouse, and belongs to the technical field of ecological resource utilization. The design method comprises the following steps: arranging a greenhouse, a swine house, a toilet and a methane tank, wherein the special points are as follows: the methane tank is arranged underground at one side of the greenhouse, the swine house is arranged above the methane tank, a guardrail is arranged at the periphery of the swine house, the inside of the swine house is equipped with a feed inlet communicated with the methane tank, and the joint between the vegetable greenhouse and the guardrail of the swine house is equipped with a water storage tank, an earthworm tank and a feed discharge room communicated with the methane tank, which are sequentially arranged from front to back; and arranging a living and working room and the toilet outside the guardrail of the swine house, and arranging a solar water heater and a wind driven generator above the greenhouse. Compared with the prior art, the designed energy ecological greenhouse is provided with an energy ecosystem which integrates planting and cultivation functions, has complete biologic chain structure and realizes the positive cycle energy and substance flows, thus achieving the purpose of harmonious regulation and control of people, plants, microbes and animals, and forming perfect combination.

Owner:中国农业大学烟台研究院

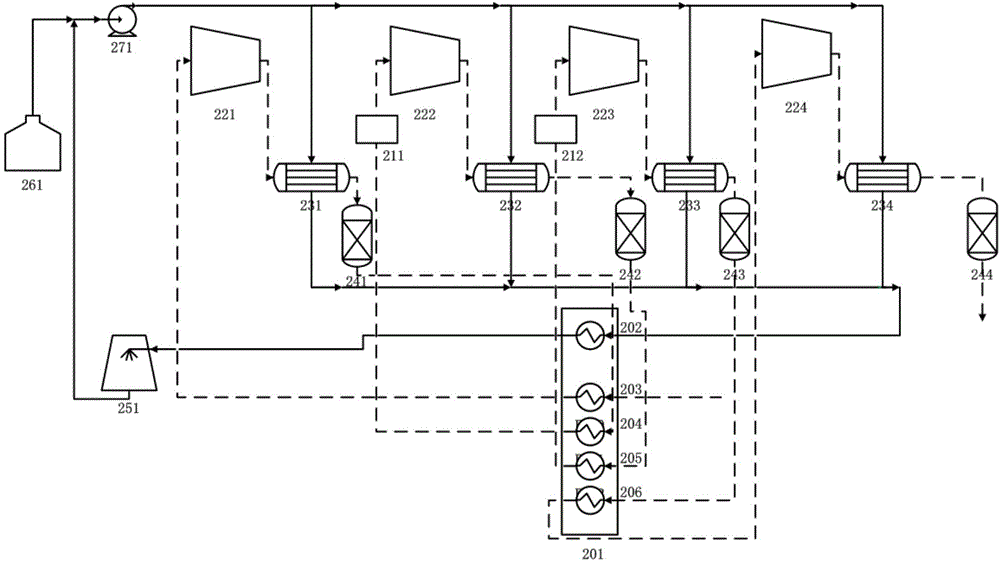

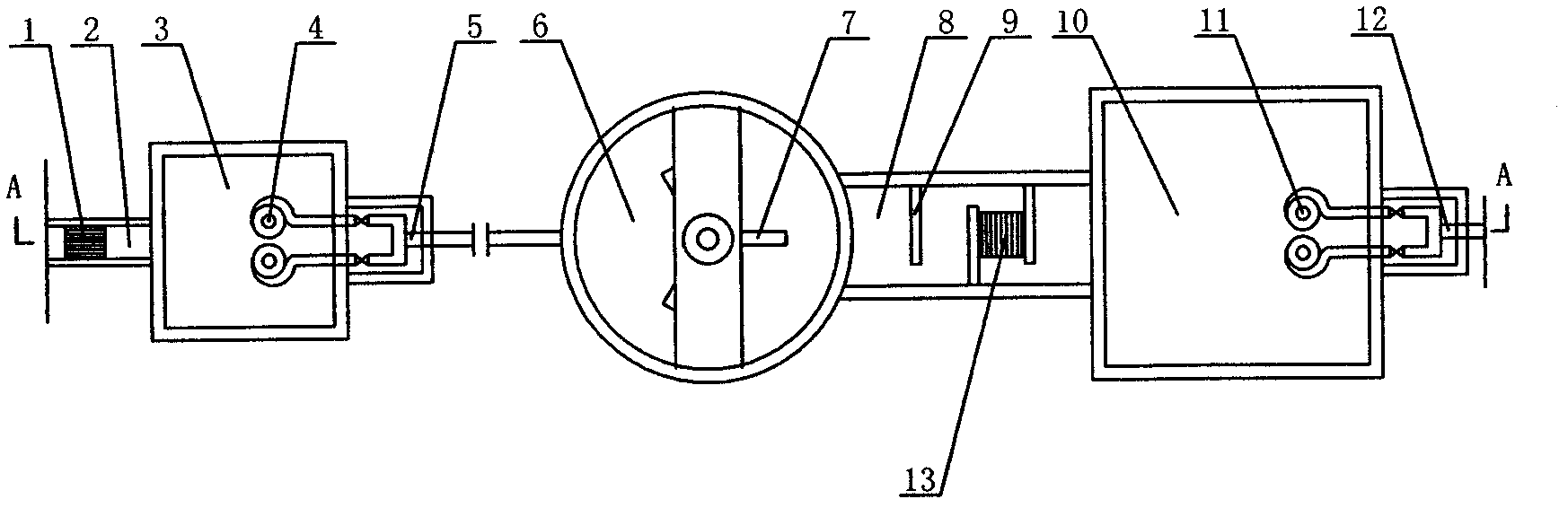

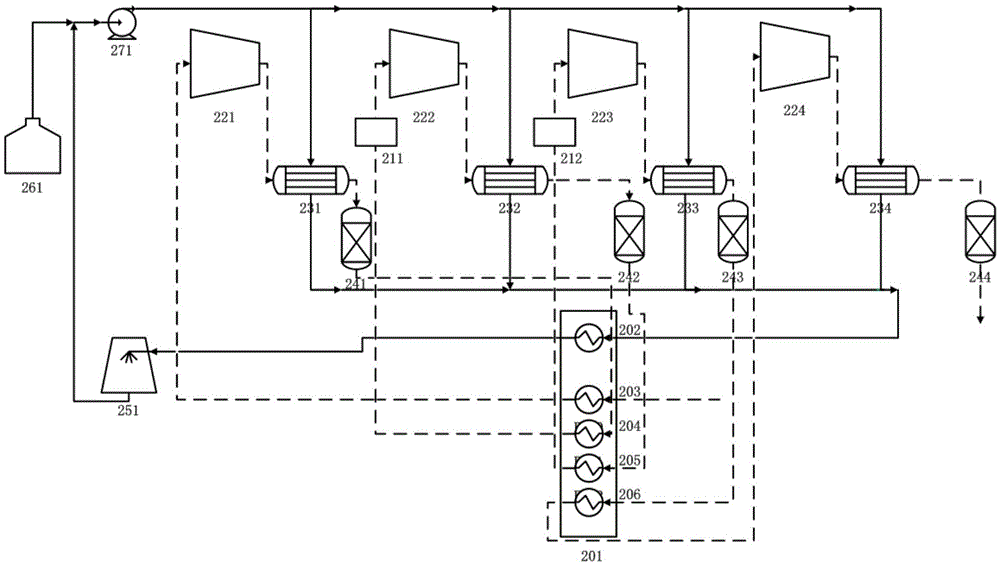

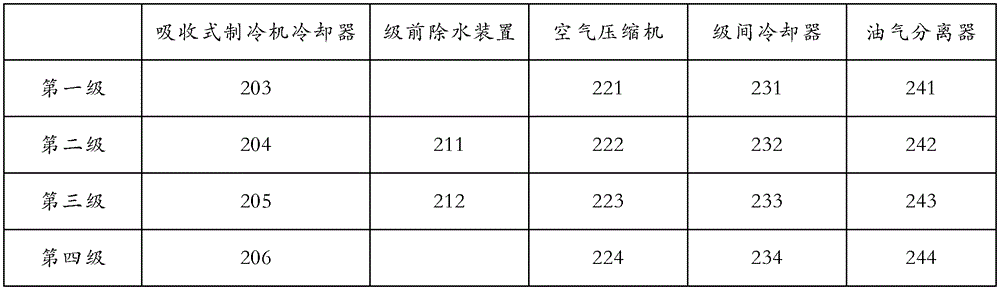

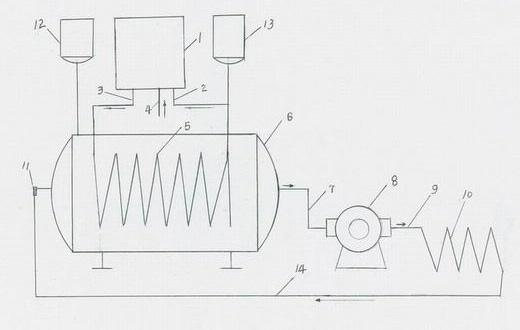

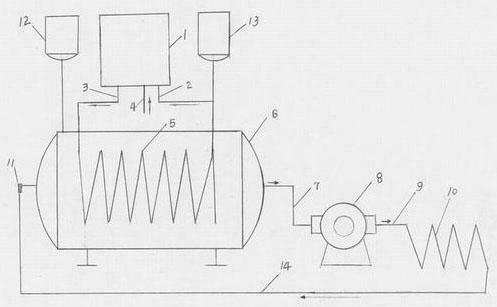

Air compression method and system with self-precooling function

ActiveCN104100494AReduce moisture contentImprove operating conditionsPositive displacement pump componentsPositive-displacement liquid enginesProduction rateAir compression

The invention discloses an air compression method and system with a self-precooling function. According to the method, air is compressed by multi-stage compression and interstage cooling, a cooling medium is used for recycling interstage compression heat and exergy, the recycled heat is used as a heat source, and cooling capacity is generated by an absorption refrigeration method and is used for precooling to-be-compressed air before each stage. The system mainly comprises three parts, i.e., a compressor unit gas circuit subsystem, a compressor unit water route subsystem and an absorption refrigeration machine subsystem. The air compression method and system are particularly suitable for being used in summer or high temperature environment; when the air is compressed by the air compression method and system, the gas production rate of the compressed air can be ensured, the moisture content of the compressed air is reduced, the pressure ratio of a compressor in each stage is increased, and power consumption in the compression process of each stage is obviously reduced; besides, the interstage compression heat and exergy of all the stages are fully utilized, and the energy usage ratio of the system is further improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

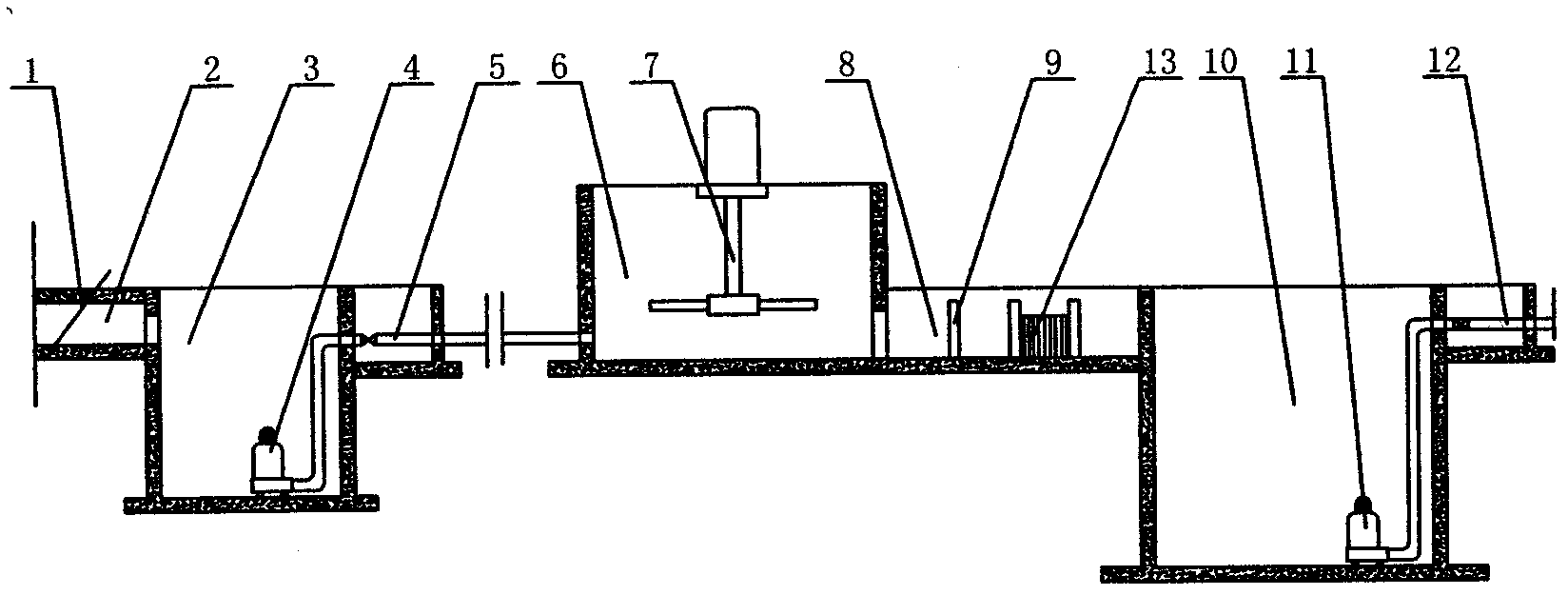

Two-stage anaerobic treatment system for cassava alcohol wastewater

ActiveCN103172215AReduce outputImprove processing efficiencyMultistage water/sewage treatmentAlcoholProcess engineering

The invention discloses a two-stage anaerobic treatment system for cassava alcohol wastewater. The system comprises a primary heat exchanger, a high temperature anaerobic fermentation tank, a primary drum screen, a secondary drum screen, a secondary heat exchanger, a sedimentation pool, an air floatation pool, an adjustment pool and a medium temperature UASB reactor. Wastewater goes by the primary heat exchanger for cooling, enters the high temperature anaerobic fermentation tank for high temperature anaerobic fermentation, goes by the two-stage drum screen, the secondary heat exchanger, the sedimentation pool and the air floatation pool for removing suspending matters and partial COD, and enters the UASB reactor for medium temperature anaerobic fermentation. The system has the following advantages: biogas generated in the two-stage fermentation is collected and used, and wastewater enters a subsequent aerobic segment for continuous treatment; and the whole treatment process flow is concise, the management is convenient, the energy consumption of the production and the operation is low, the treatment efficiency is high, and sludge has a less output and is easy to dispose.

Owner:SHANGHAI SAFBON WATER SERVICE CO LTD

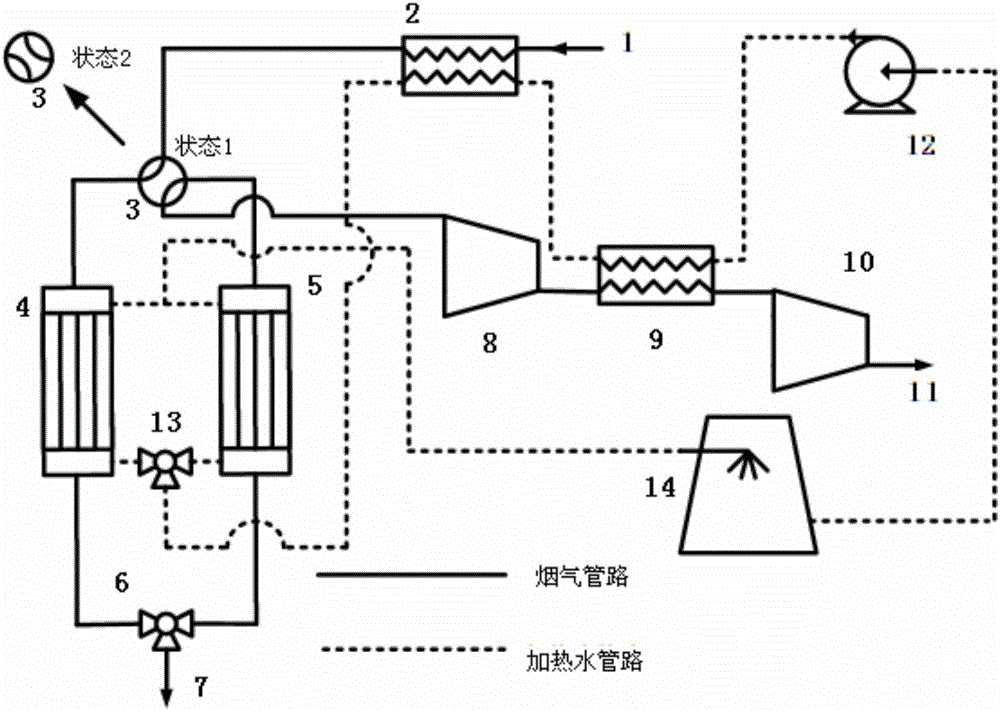

Carbon dioxide capturing compression system using flue gas and multistage compressing waste heat

InactiveCN106582201AReduce energy consumptionEnsuring the ability to save energy and reduce emissionsGas treatmentLighting and heating apparatusCooling towerDevice form

The invention discloses a carbon dioxide capturing compression system using flue gas and multistage compressing waste heat. The system comprises a flue gas pipeline and a heating water pipeline. The flue gas pipeline comprises a first heat exchanger and a second heat exchanger, a four-way reversing valve, a first temperature swing adsorption tower unit and a second temperature swing adsorption tower unit, a first three-way valve and a first compressor and a second compressor. The heating water pipeline comprises a water pump, a second three-way valve and a cooling tower. A multistage compressing cooling device formed by multistage of alternately connected heat exchangers and compressors can be connected between the outlet of the second compressor and the outlet of the flue gas pipeline, and the outlet of the last stage compressor is the outlet of the flue gas pipeline; and a water pump is connected in series to the low-temperature sides of all the heat exchangers. According to the system disclosed by the invention, by virtue of multistage compression and intermediate cooling, the compressing energy consumption before carbon dioxide is reduced; by combining the intermediate cooling and flue gas waste heat utilization of the compressor with temperature swing adsorption carbon capturing, the capacity of energy conservation and emission reduction of a coal-fired power plant is ensured; the two groups of temperature swing adsorption towers same in quantity ensure the industrial operating persistence so as to maintain the gas generating capacity of the system.

Owner:TIANJIN UNIV

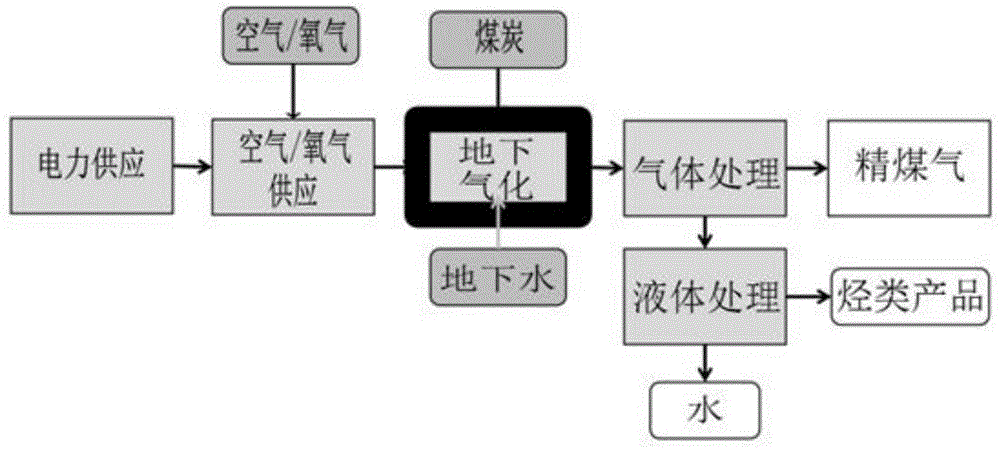

Method for generating coal gas underground through air fracture and micro negative pressure

ActiveCN104153750AGuaranteed gasification efficiencyGuaranteed gas productionFluid removalEnergy developmentProcess engineering

The invention provides a method for generating coal gas underground through air fracture and micro negative pressure, and belongs to the field of energy development. The method comprises the following steps that air inlet wells and a plurality of gas outlet wells are drilled, then a gasification tunnel is formed along drilled holes in the bottom of a coal seam to enable the air inlet wells and the gas outlet wells to be communicated, and therefore a gasification furnace is formed integrally; the coal seam is fractured through multi-level air pressure raising, igniter is added in an oxidation section between two adjacent wells, the igniter enables partial coal underground to burn, and generated mixed gas is exhausted to a ground well mouth through the gas outlet wells to obtain gas mixture of CO, H2 and CH4; in the burning process, micro negative pressure is formed in the gas outlets of the gas outlet wells and three working sections. The air fracture technology enables fractured coal to be loose, even and convenient to burn, environment pollution is not likely to happen, and gasification efficiency and gas output are guaranteed; the micro negative pressure prevents the generated gas from diffusing and escaping to other directions, and underground water pollution also can be avoided. The method can achieve the purposes of high coal recovery efficiency, low cost, environment friendliness and energy conservation.

Owner:CATECH TECH

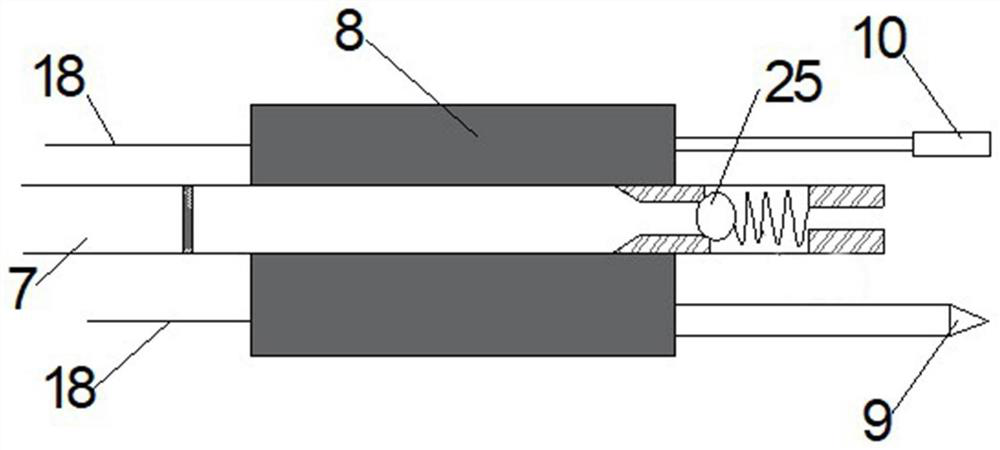

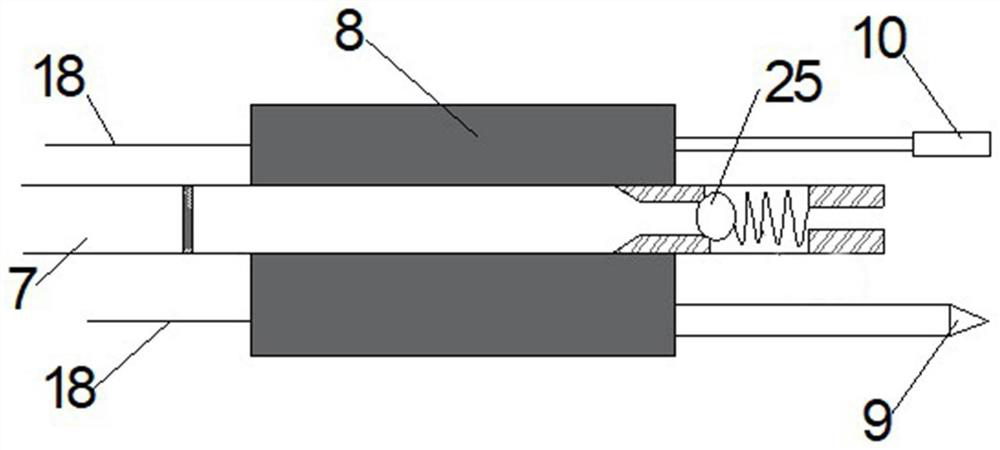

Refracturing method and system

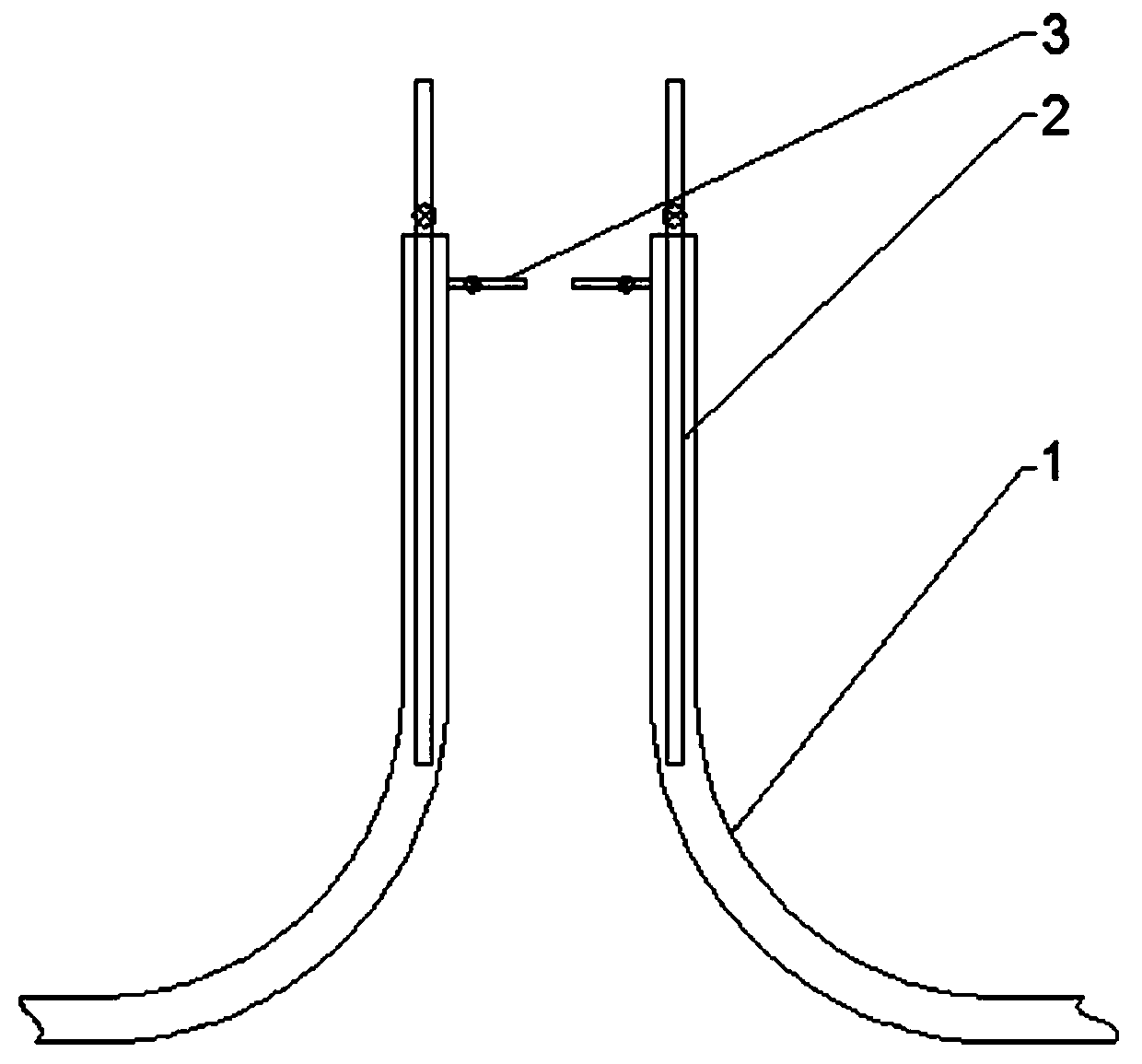

ActiveCN107387049AImprove quality goodGuaranteed gas production and recoveryFluid removalCoalFracture process

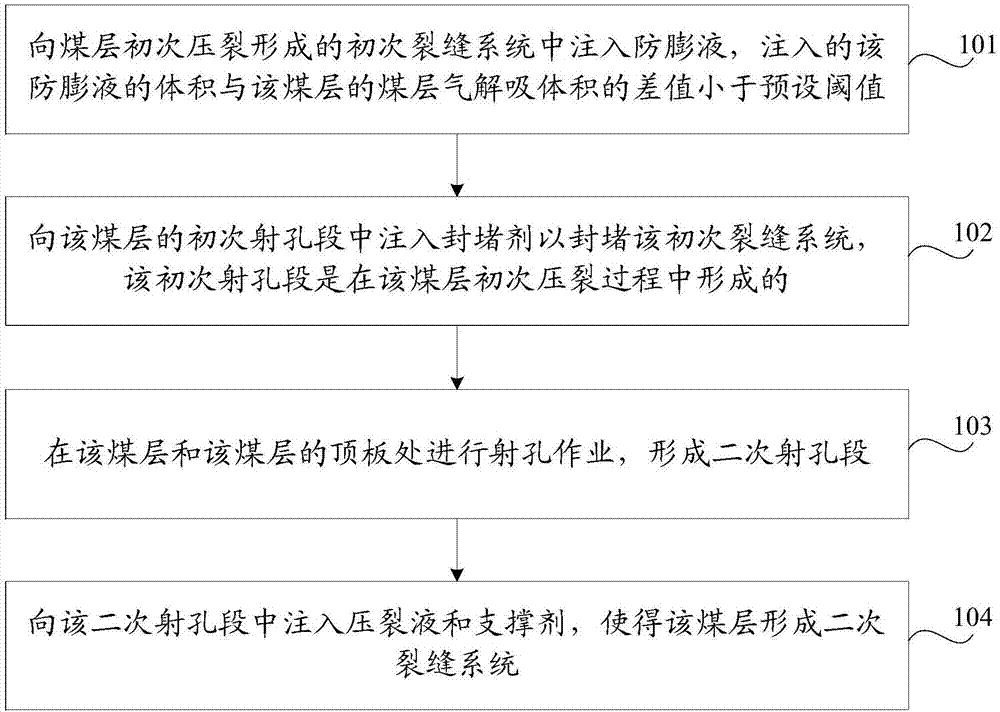

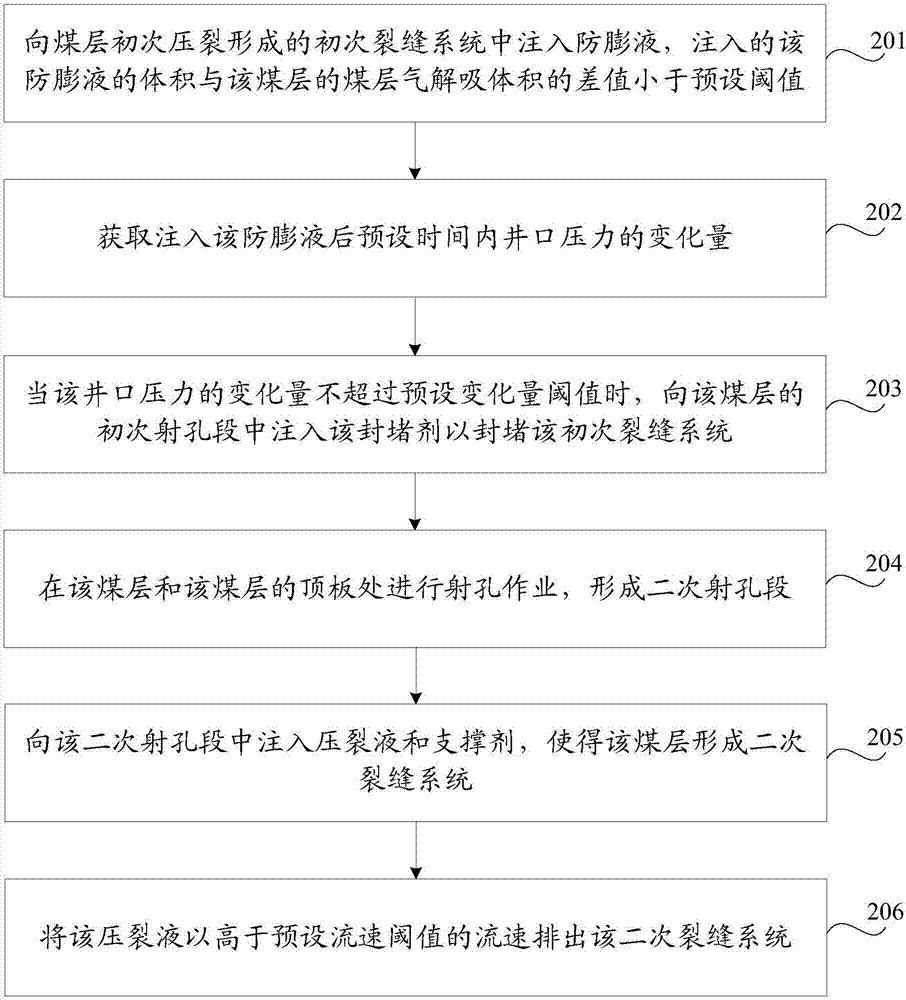

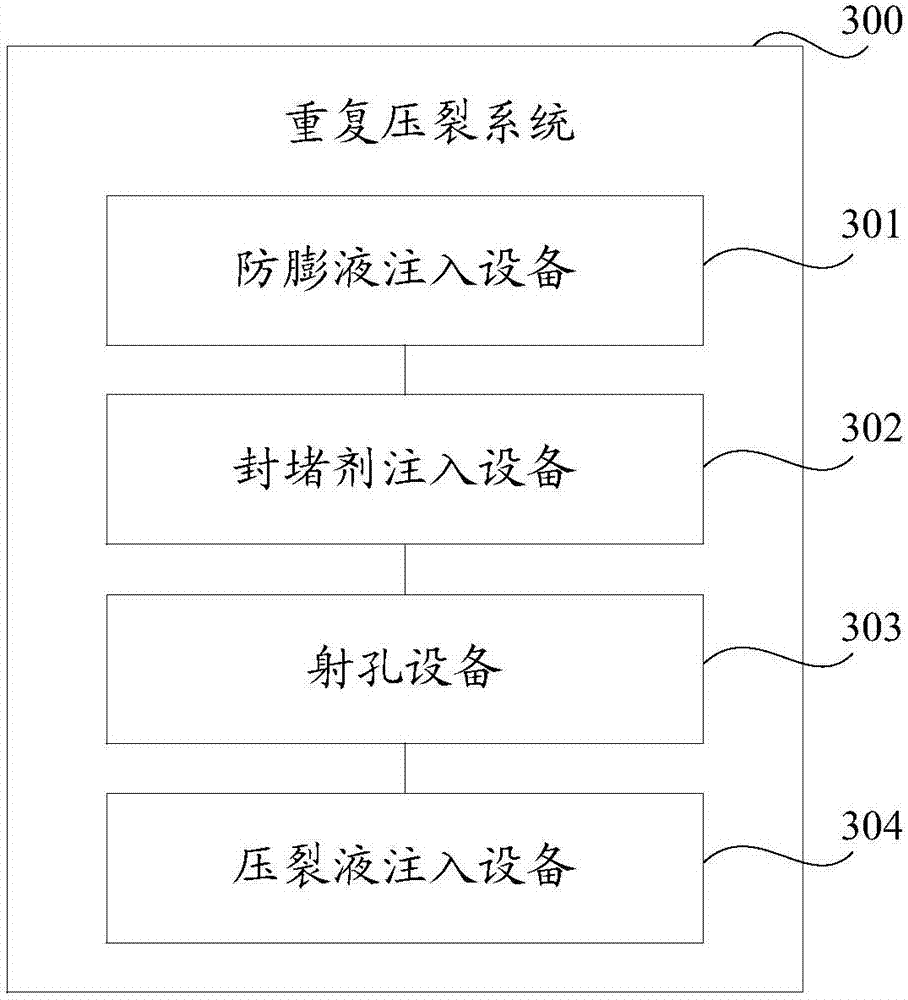

The invention discloses a refracturing method and system, and belongs to the field of coal bed gas mining. The refracturing method and system are used for conducting refracturing on a coal bed. The refracturing method comprises the following steps that anti-swelling liquid is injected into a primary fracture system formed by primary fracturing of the coal bed; plugging agents are injected into a primary perforated interval of the coal bed so as to plug the primary fracture system, and the primary perforated interval is formed in the primary fracturing process of the coal bed; perforated operation is conducted on the coal bed and a roof of the coal bed, and a secondary perforated interval is formed; and fracturing liquid and propping agents are injected into the secondary perforated interval, and a secondary fracture system is formed in the coal bed. According to the refracturing method and system, by injecting the anti-swelling liquid into the primary fracture system formed through the primary fracturing of the coal bed and injecting the plugging agents into the primary perforated interval of the coal bed so as to plug the primary fracture system, the fracture systems formed through refracturing are easier to extend and expand to areas without fractures, and accordingly the gas production and the recovery ratio of the coal bed are guaranteed.

Owner:PETROCHINA CO LTD +1

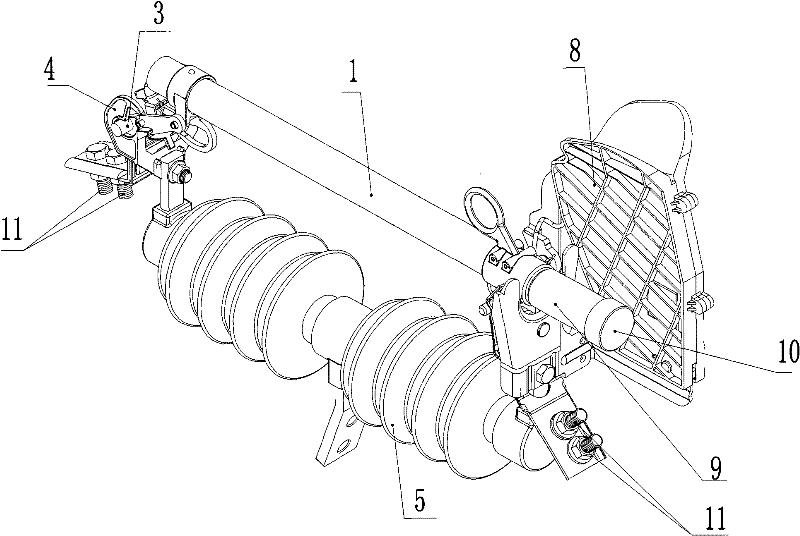

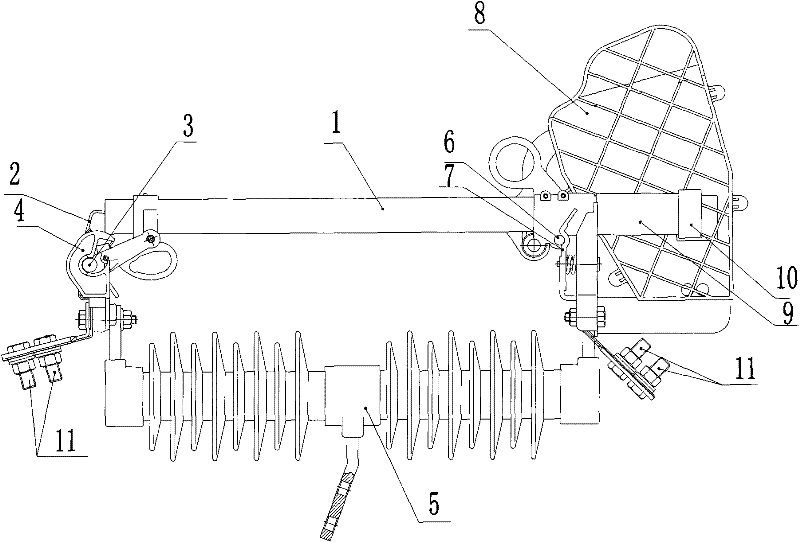

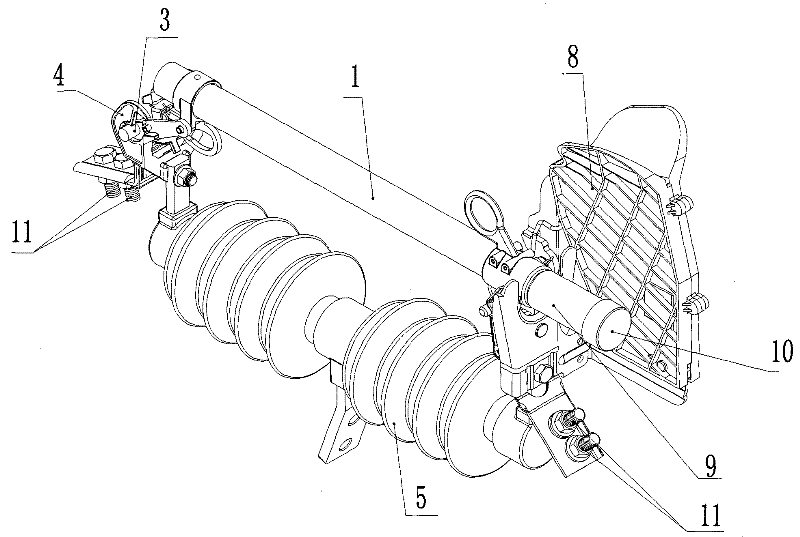

High-voltage-dropout-type fuse cutout

InactiveCN102347179AExtended service lifeHigh strengthProtective switch operating/release mechanismsEngineeringGuide tube

The invention discloses a high-voltage-dropout-type fuse cutout comprising a fuse tube, a fuse wire, a fixed contact, a fixed contact support, a pillar insulator, a moving contact, a moving contact support and an arcing shield, wherein the fixed contact is arranged on the fuse tube; the fixed contact support is arranged at one end of the pillar insulator; the moving contact is arranged at the other end of the pillar insulator; the moving contact support is arranged on the fuse tube; the moving contact is also provided with the arcing shield; the fuse wire is used for tensioning the moving contact on the moving contact support; the fixed contact support and the moving contact are provided with a wire connecting bolt respectively; and the moving contact support end of the fuse tube is also provided with a flow guide tube, and one end of the flow guide tube is provided with a cover. Because the flow guide tube and the cover used for covering the end of the flow guide tube are arranged at one side of the arcing shield of the fuse tube in the scheme, the damages to the arcing shield caused by arcs can be reduced, thus the arcing shield can be repeatedly used.

Owner:SUZHOUSNLIAN HIGH TENSION CONDENSER

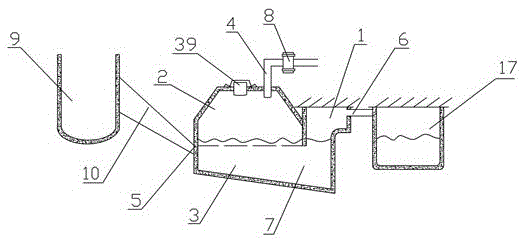

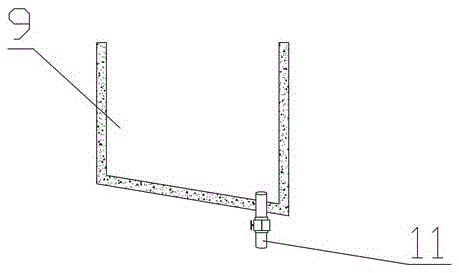

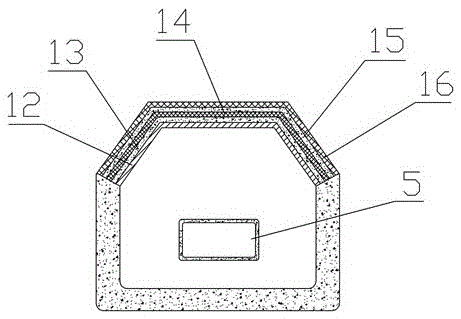

Methane tank with novel structure

InactiveCN104073431AGuaranteed stabilitySatisfy the requirements of gas stabilityBiological substance pretreatmentsGas production bioreactorsEngineeringFermentation

The invention discloses a methane tank with a novel structure, which comprises a main tank and a water pressure chamber, wherein the main tank comprises a methane storage room and a fermentation tank, a methane guide pipe is arranged at the top of the methane storage chamber, an excrement inlet is formed in one side of the main tank, and the other side of the main tank is communicated with the water pressure room; an overflow opening is formed in the water pressure chamber, and the excrement inlet is formed in the sidewall of the fermentation tank; an excrement outlet is formed between the fermentation tank and the water pressure chamber, and the excrement outlet is located in the other sidewall of the fermentation tank; the upper edge of the excrement inlet and the top end of the excrement outlet are on the same horizontal line; the bottom of the fermentation tank downwards inclines to the water pressure chamber from the sidewall, where the excrement inlet is located in, and extends to the sidewall where the overflow opening of the water pressure chamber is located in; an excrement dreg drainage channel with a concave semi-spherical cross section is arranged at the bottom of the fermentation tank; the whole methane storage chamber takes the shape of a trapezoid wider in upper part and narrow in lower part, the upper edge of the excrement inlet is arranged at the bottom end of the sidewall of the methane storage chamber, the methane guide pipe is located at the top of the trapezoid and provided with a safety valve. The invention aims to provide the methane tank with the novel structure, which is constant in pressure, convenient for discharging dreg, low in probability of incrustation and high in methane output.

Owner:何跃超

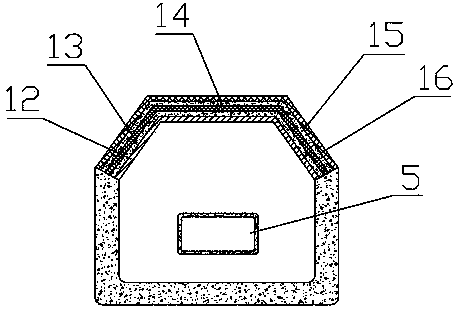

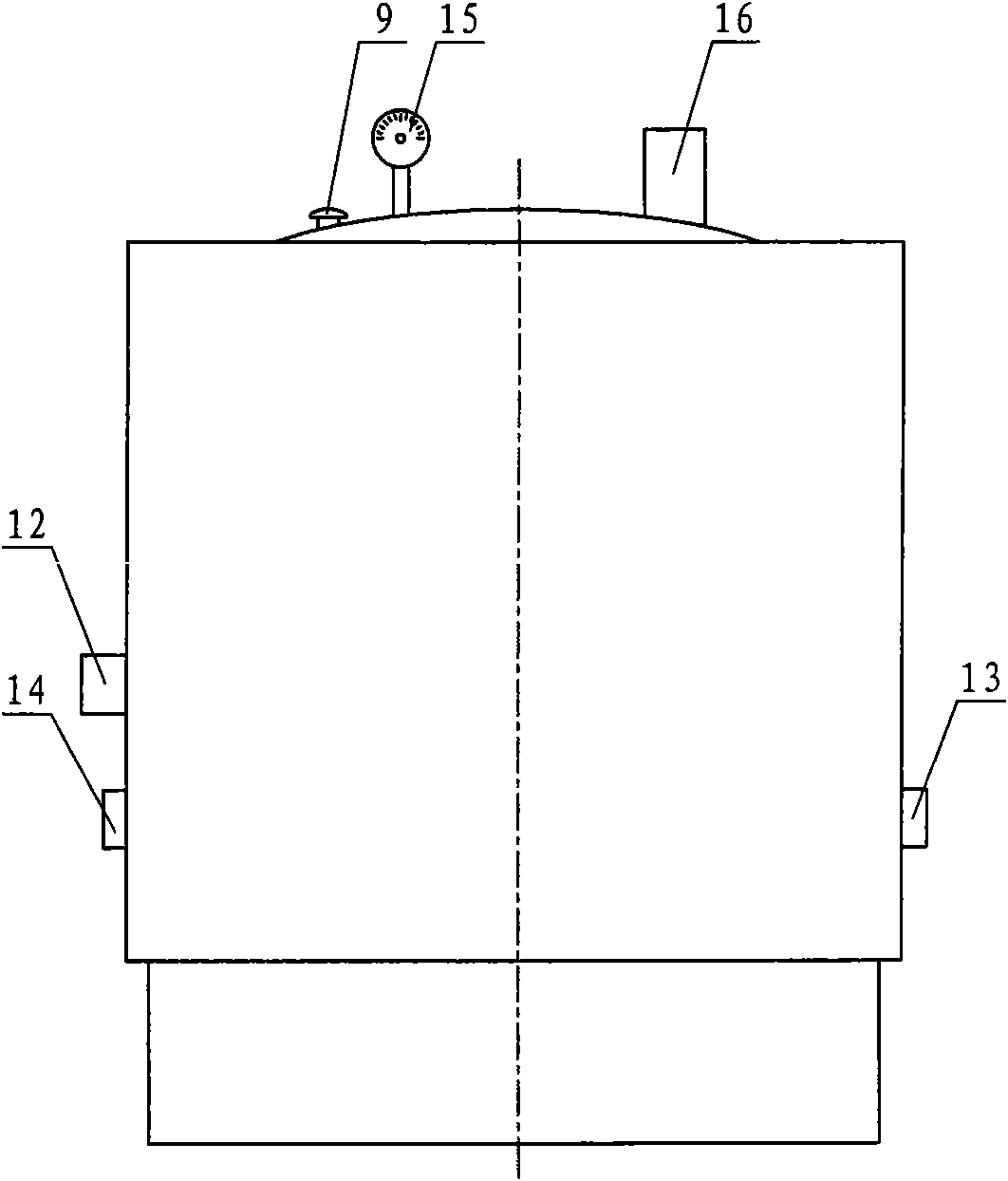

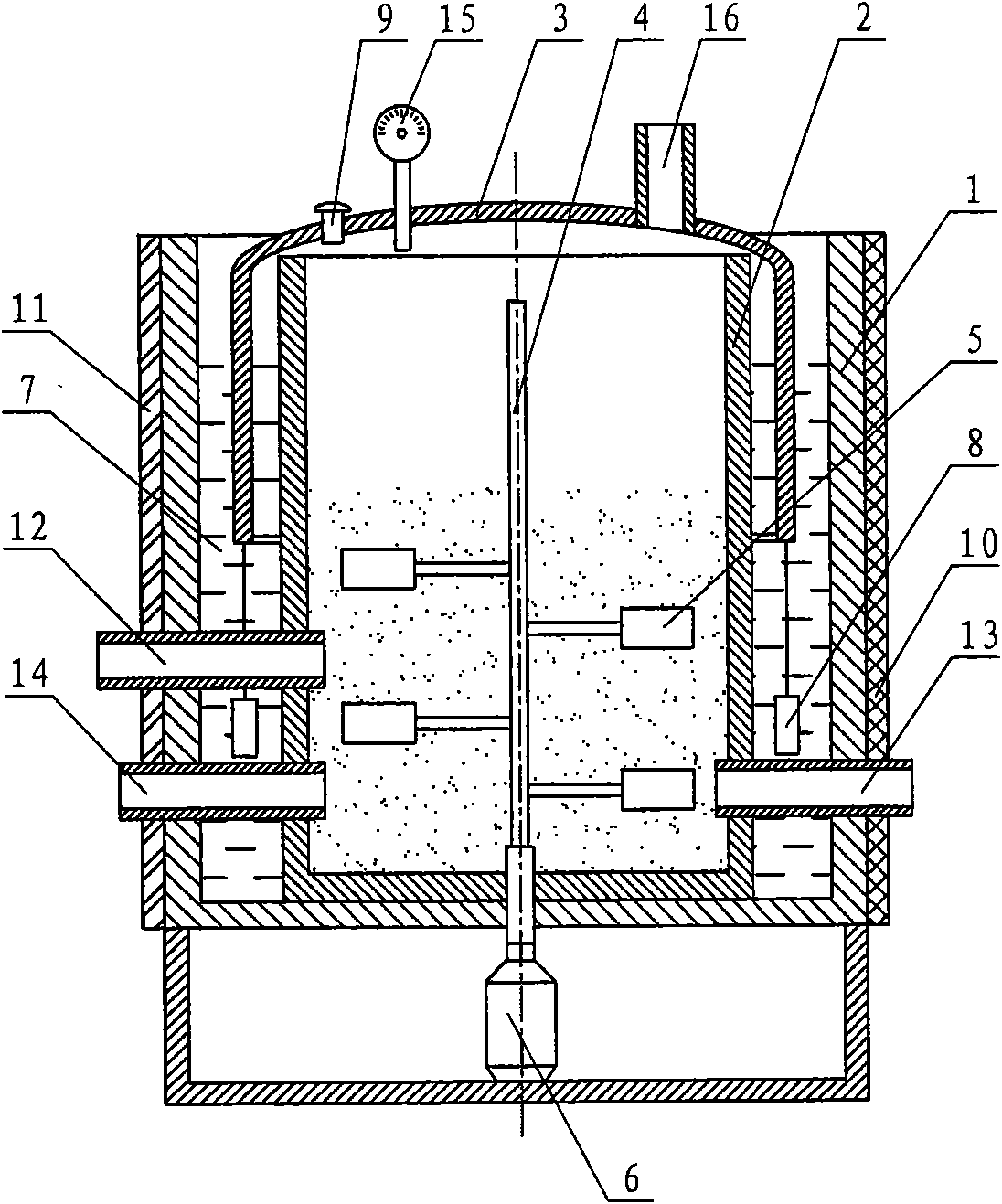

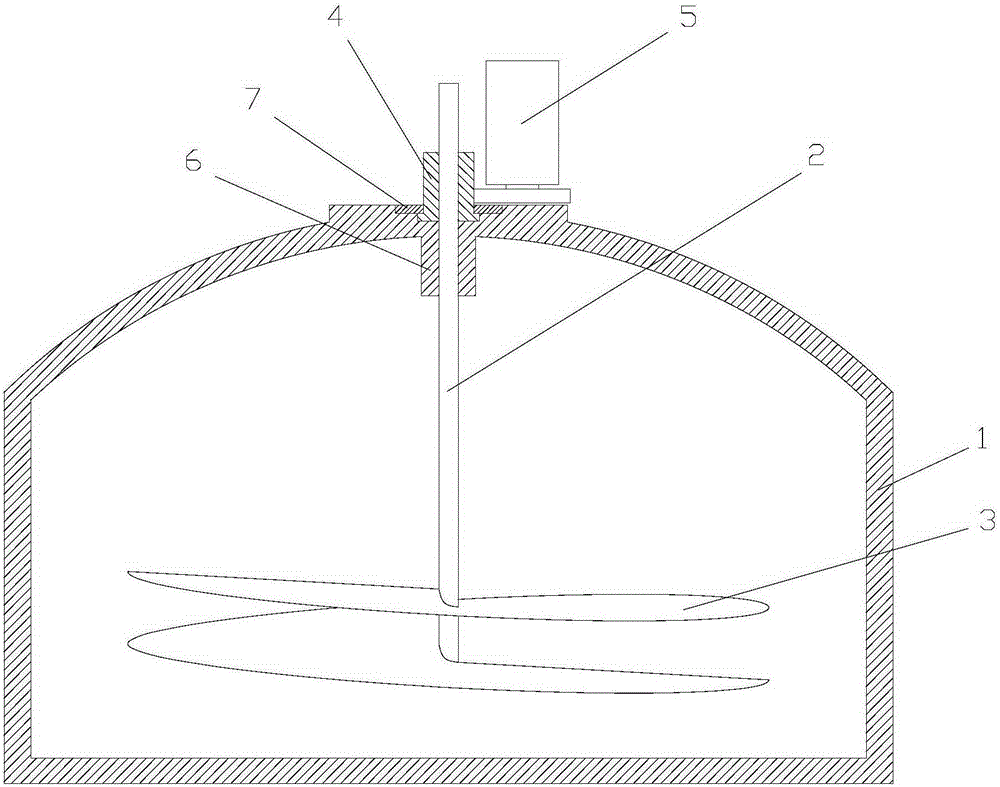

Large-sized biogas fermentation device integrating fermentation and gas storage

InactiveCN101575561ACompact structureSmall footprintBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringFermentation

The invention relates to a large-sized biogas fermentation device integrating fermentation and gas storage, comprising a feed port, a liquid outlet port and a dreg discharge port. The large-sized biogas fermentation device integrating fermentation and gas storage is characterized by comprising a casing, a gas generation chamber installed in the casing and a gas storage floating cover sleeved outside the gas generation chamber, wherein a water layer is arranged between the casing and the gas generation chamber; the gas generation chamber is internally provided with a biogas stirring device; and the bottom part of the gas storage floating cover is provided with balancing weights. The invention has the following advantages of compact structure, small occupied space, and convenient operation, management and maintenance due to the integration of fermentation and gas storage, safe and reliable use, ensuring of gas generation amount in winter, improvement of gas generation amount due to complete fermentation of raw materials and large-scale industrial production for facilitating the popularization of biogas.

Owner:TIANJIN DESHENGYUAN ENVIRONMENT ENG

Briquette for gas producer produced by high volatile bituminous coals and method

InactiveCN101805650AIncrease cold strengthNo reduction in fixed carbon contentSolid fuelsBulk chemical productionFixed bedAnthracite

The invention relates to a briquette for a gas producer produced by high volatile bituminous coals and a method. The briquette can meet the requirements of the two-stage fixed bed gas producer for coal quality. The briquette is characterized in that: aiming at the characteristics of high bituminous coal forming elasticity, anthracite coal with the weight 10-20% of that of the bituminous coal is added by weight percentage and is taken as a carbon skeleton, thereby improving the cold strength of the briquette formed by the bituminous coals; modified clay with the weight 4-6% of that of the bituminous coal is added by weight percentage and is taken as a thermal intensifier, and simultaneously a sodium humate binder with the weight 4-6% of that of the bituminous coal is formed by cold pressing, thereby not only improving the cold strength of the briquette, but also not reducing the fixed carbon content of the briquette so as to ensure the heating value and gas production quantity of the briquette; and a small amount of modified clay is added to improve the thermal strength and thermal stability of the briquette, and can be used as a catalyst in the gasification process simultaneously,thereby improving the gasification activity of the briquette.

Owner:河南中美铝业有限公司

Shale gas production promoting method based on combination of blasting fracturing and hydraulic fracturing

ActiveCN113338889APrevent unmineableGuaranteed gas productionSurveyFluid removalMining engineeringHorizontal wells

The invention discloses a shale gas production promoting method based on combination of blasting fracturing and hydraulic fracturing. The method comprises the following steps that firstly, a blasting fracturing horizontal well is punched, then a perforation fracture is formed in the blasting fracturing horizontal well, a first blasting hole packer is installed, a hole sealing section is formed, and if the value required by explosion is reached in the hole sealing section within a set time, blasting gas is triggered to conduct primary impact fracturing on the perforation fracture; if the value required by explosion is not reached, blasting gas is supplemented into the hole sealing section, then one-time blasting fracturing is completed, next, the above process is repeated, a blasting fracturing fracture network is formed around the blasting fracturing horizontal well through retreating blasting fracturing, and hole sealing is conducted; and finally, a hydraulic fracturing horizontal well is punched below the blasting fracturing horizontal well, a hydraulic fracturing fracture area is formed around the hydraulic fracturing horizontal well by adopting a retreating hydraulic fracturing method, wherein the fracture area can be in communication with the blasting fracturing fracture network, and at the moment, shale gas extraction work is conducted on a shale reservoir through the hydraulic fracturing horizontal well.

Owner:CHINA UNIV OF MINING & TECH

Method for processing high-purity low-dew point hydrogen-nitrogen mixture gas

InactiveCN101402447AStable supplyGuaranteed gas productionHydrogen productionProcess efficiency improvementComing outMoisture

The invention relates to a method for processing hydrogen-nitrogen mixed gas with high purity and low dew point. The hydrogen-nitrogen mixed gas processed by the method has stable yield and low dew point. The method is characterized in that liquid ammonia is sent to an evaporator through a filter; after gaseous ammonia comes out from the evaporator, the pressure of the gaseous ammonia is controlled at 0.05 Mpa through an adjusting valve; heat of pyrolysis gas is absorbed through a rotor flowmeter and a heat exchanger, is preheated and enters a cracking furnace; ammonia gas is heated to a temperature between 800 and 850 DEG C and is decomposed into the hydrogen-nitrogen mixed gas under the action of nickel as a catalyst; the hydrogen-nitrogen mixed gas is cooled through the heat exchanger and a water cooler and enters a purification system; an adsorption tower of the purification system is provided with two sets of towers in parallel connection; each set of the towers is formed by two stages of the adsorption towers in serial connection; the mixed gas passes through a primary adsorption tower and a secondary adsorption tower; and moisture and residual ammonia are removed through molecular sieves in the adsorption towers.

Owner:程坚明

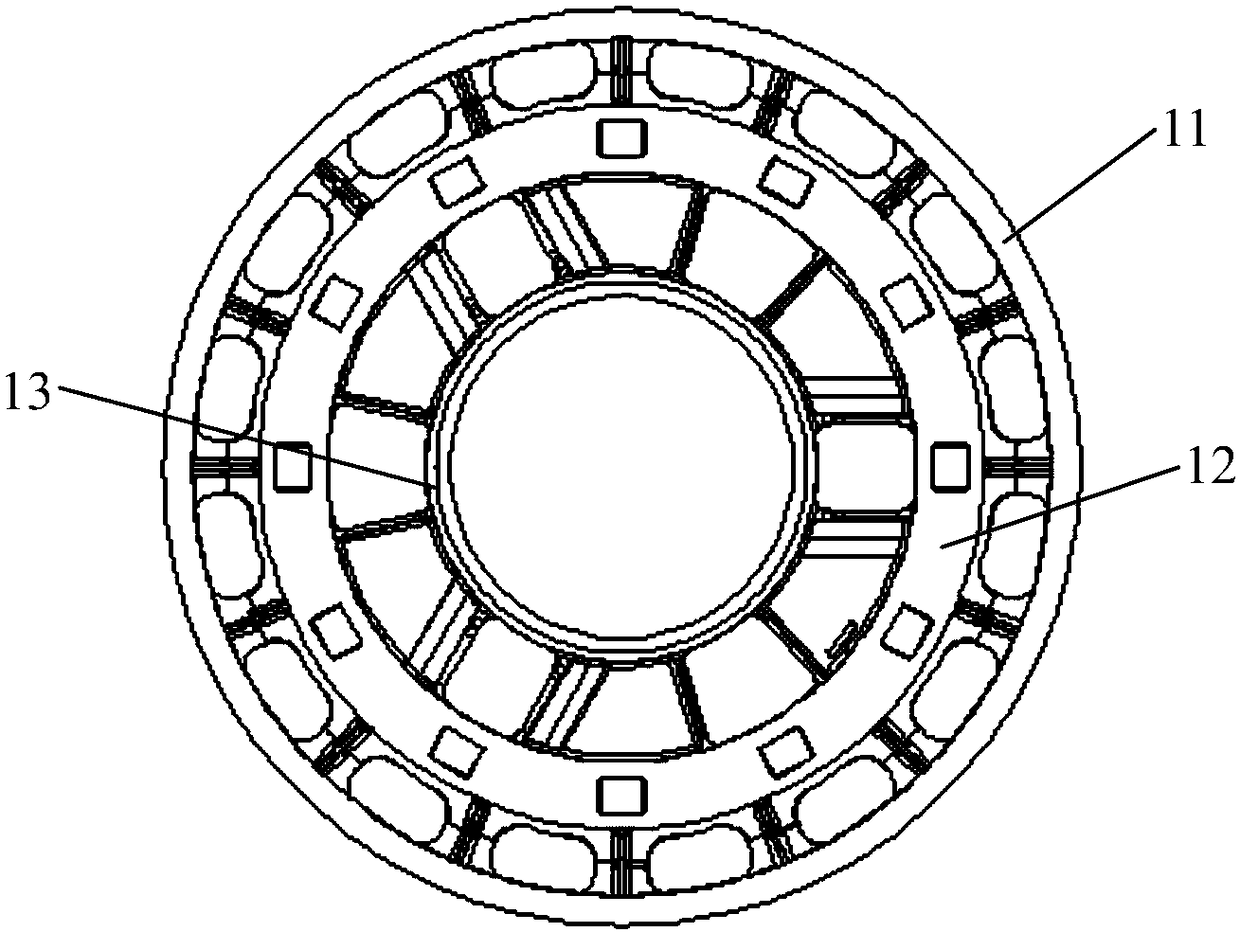

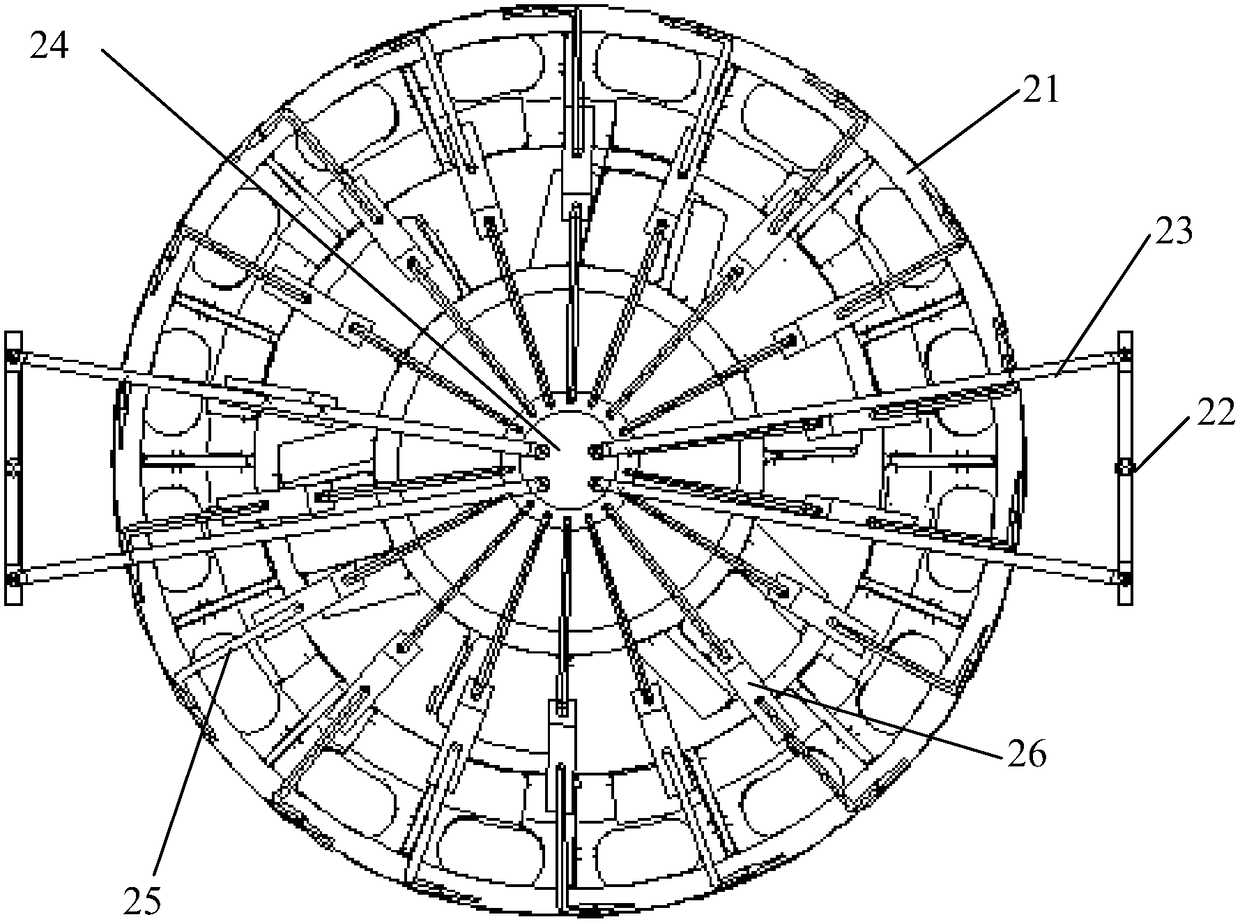

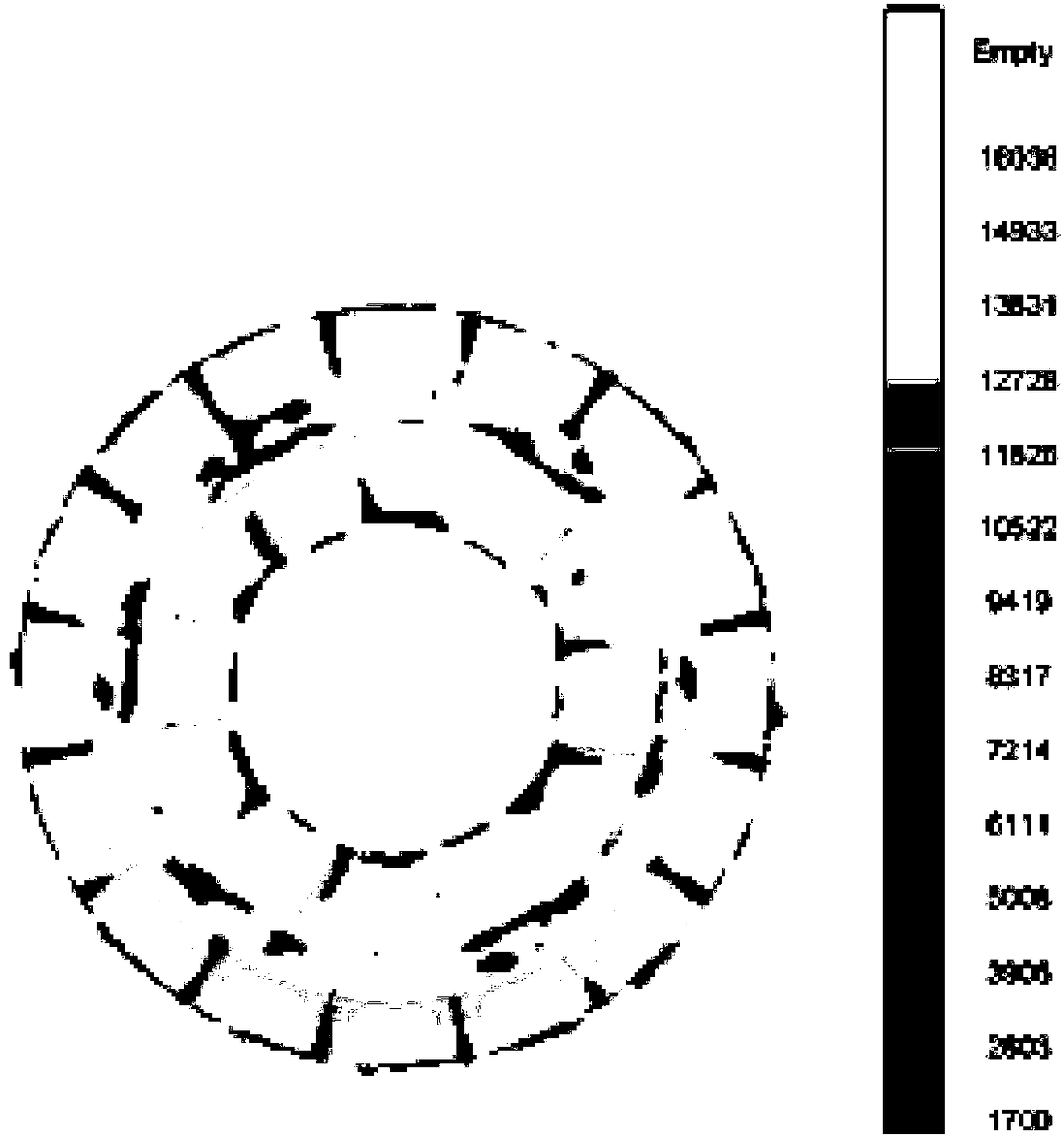

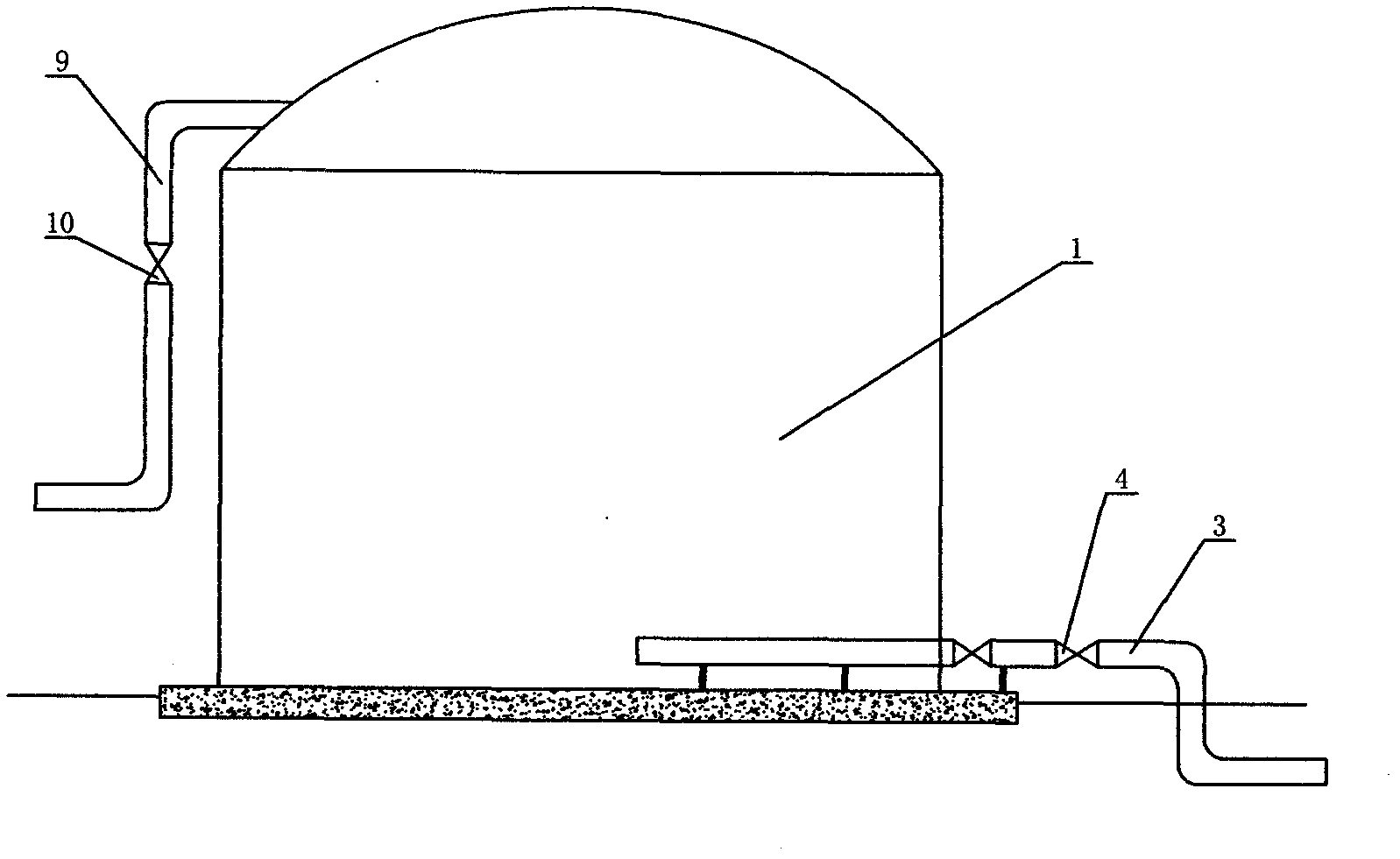

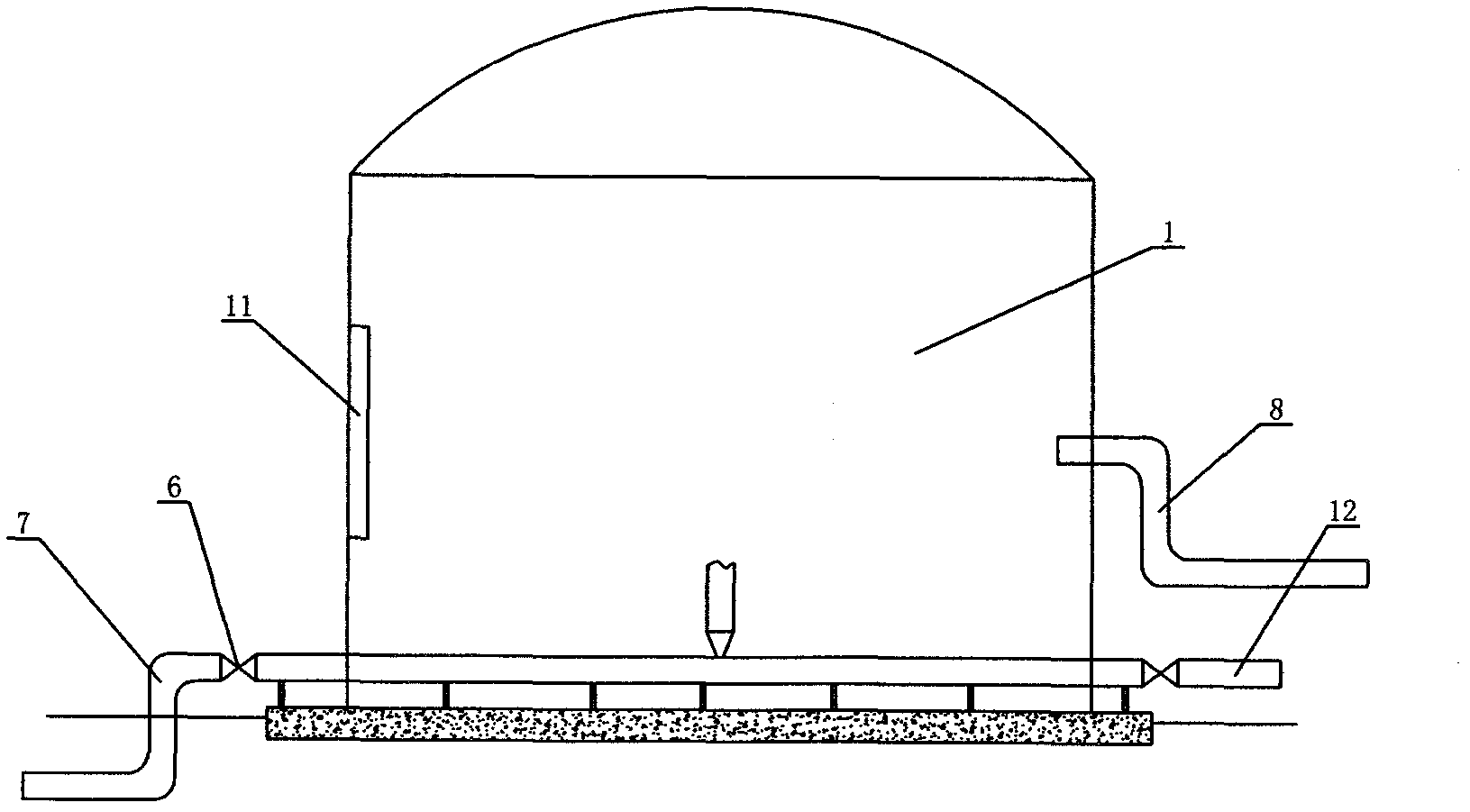

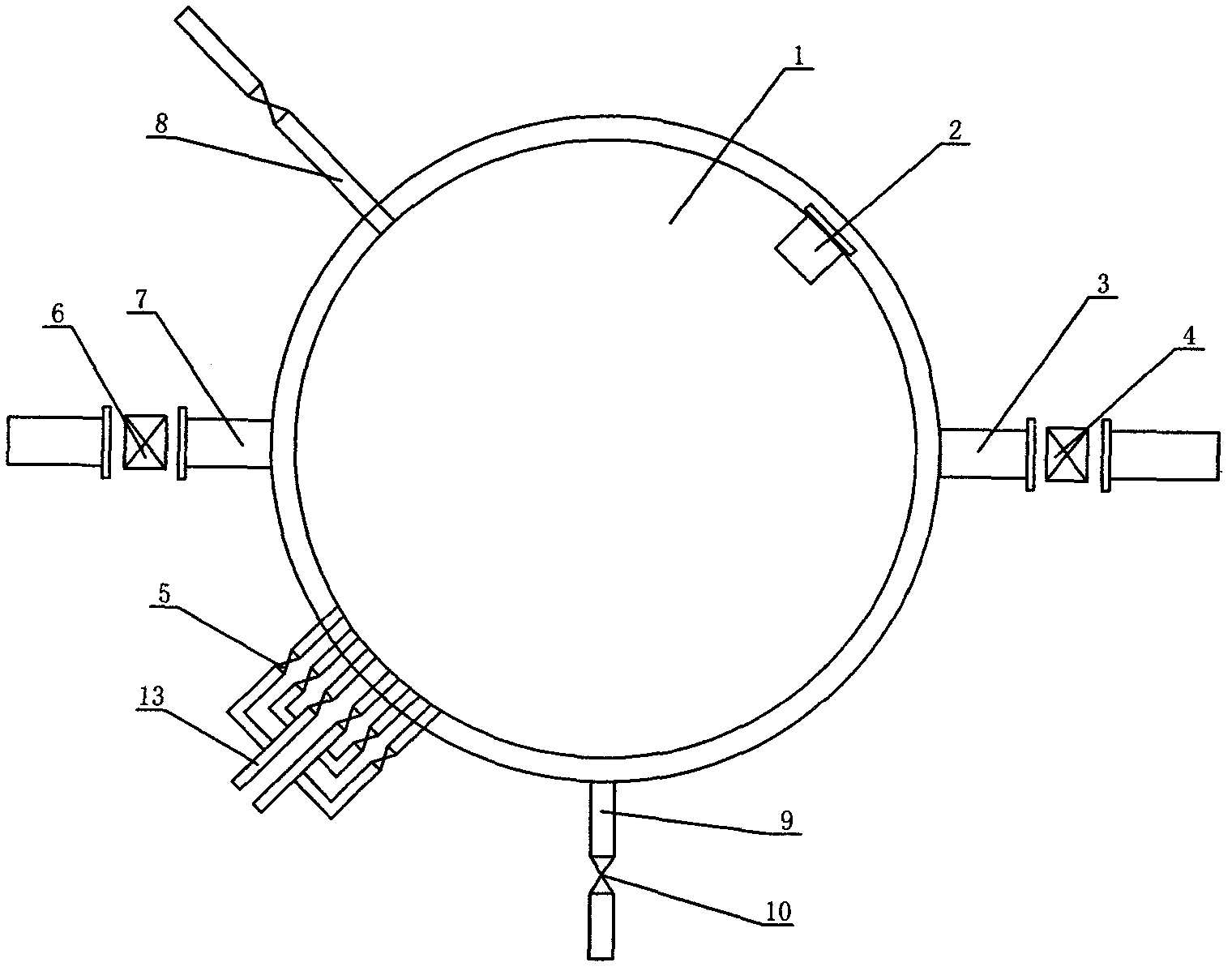

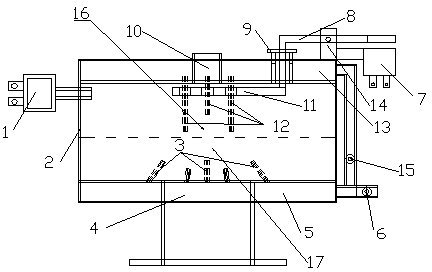

Casting mold and casting method for large-size disc type complicated-structure part

The invention discloses a casting mold for a large-size disc type complicated-structure part. The casting mold comprises a casting mold body; the casting mold body is provided with a disc-like part cavity, a plurality of riser cavities, a plurality of air outlets and a grouting system; the grouting system comprises at least two iron inlets, at least two liquid iron main flow channels, a central flow dividing chamber, a plurality of liquid iron branch flow channels and a plurality of filters; the liquid iron main flow channels and the liquid iron branch flow channels are arranged at the bottomof the casting mold body; and the central flow dividing chamber is arranged at the central position of the bottom of the casting mold body. The grouting system is reasonably distributed, so the grouting time can be greatly shortened, and stable iron feeding is guaranteed. The riser cavities and the air outlets are arranged in a targeted manner in order to guarantee the air generation quantity of the cavities and shrinkage compensation of the riser. The invention also discloses a casting method, and the casting method adopts the casting mold which is combined with graphite chill iron and mold weight, thereby effectively solving the casting problems such as shrinkage, loosening, slag inclusion, cold shut and deformation which are easily generated in a casting process.

Owner:JIANGSU JIXIN WIND ENERGY TECH

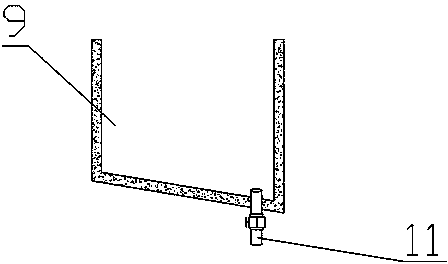

Fermentation tank for biogas engineering

InactiveCN103045464AGuaranteed fermentation temperatureGuaranteed outputGas production bioreactorsWaste based fuelCold seasonBiogas production

The invention relates to a fermentation tank for biogas engineering, which comprises a tank body. The tank body is provided with a feed pipe, a discharge pipe and an air outlet pipe, wherein the feed pipe and the discharge pipe are arranged on the both corresponding bottom sides of the tank body, the tank body is connected with a storage pool through the feed pipe and connected with a biogas residue treatment plant through the discharge pipe, the air outlet pipe which communicates the tank body and the biogas purification plant is arranged at the top of the tank body, the tank body is provided with a heating pipe which connects the tank body and the heating boiler, and a thermometer is arranged on the tank body. According to the invention, the thermometer is arranged inside the fermentation tank for monitoring the internal temperature of the fermentation tank, and meanwhile the fermentation tank is provided with the heating pipe which communicates the fermentation tank and the heating boiler for heating the fermentation tank in cold season, so as to ensure the fermentation temperature in fermentation tank and the biogas production.

Owner:段国有

Shale gas reservoir multi-branch well detonation pressure reinforced extraction method

The invention discloses a shale gas reservoir multi-branch well detonation pressure reinforced extraction method. The shale gas reservoir multi-branch well detonation pressure reinforced extraction method comprises the following steps that firstly, a vertical well and a horizontal well are dug to extend into a shale reservoir, and a plurality of fishbone-shaped branch wells are laterally drilled at different positions of the horizontal well through a jet drill bit; then blasting materials are placed in the fishbone-shaped branch wells, and blasting hole packers are installed to form hole sealing sections; the explosive is ignited and detonated through an ignition head, and impact fracturing is carried out on shale around the fishbone-shaped branch wells by high-temperature and high-pressure gas and detonation impact waves generated by explosion, so that explosive cracks are generated around the fishbone-shaped branch wells; finally, hydraulic fracturing is adopted to enable fracturing fluid to enter the branch wells, crack expansion fracturing is carried out on the fire blast cracks around the branch wells to enable the adjacent fire blast cracks to communicate with one another, and finally a crack network is formed around each branch well; and after completion, the shale gas in the shale reservoir enters each branch well from the fracture network and reaches the horizontal well after being desorbed, and finally the shale gas extraction work is carried out on the shale reservoir through the vertical well and the horizontal well.

Owner:CHINA UNIV OF MINING & TECH

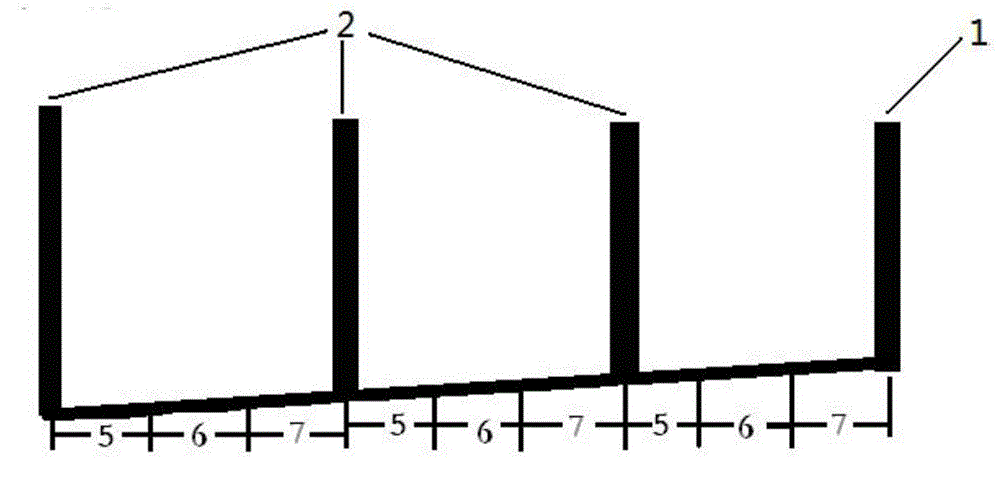

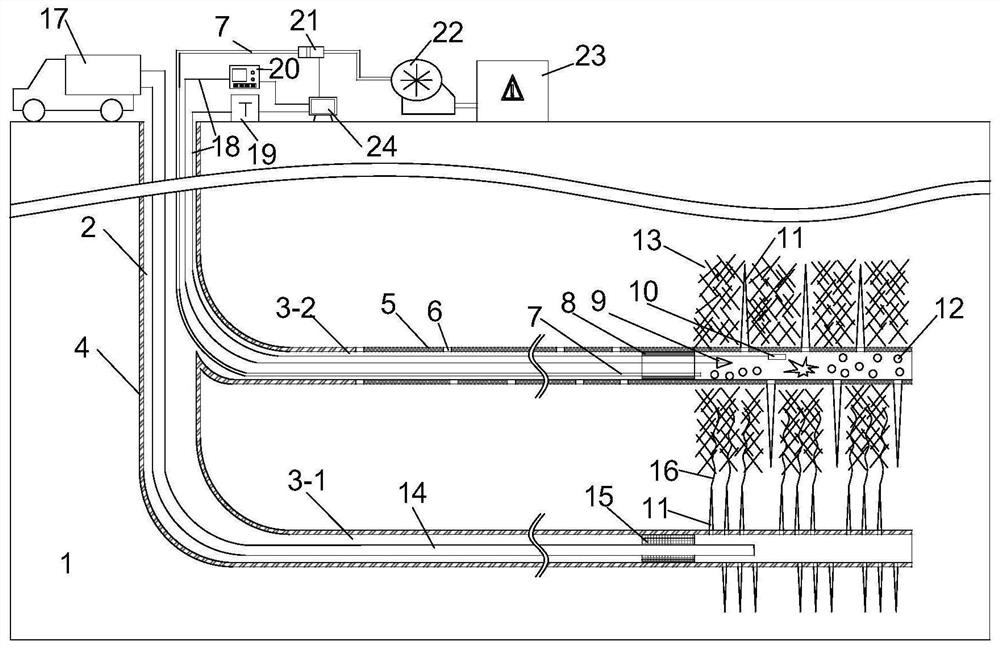

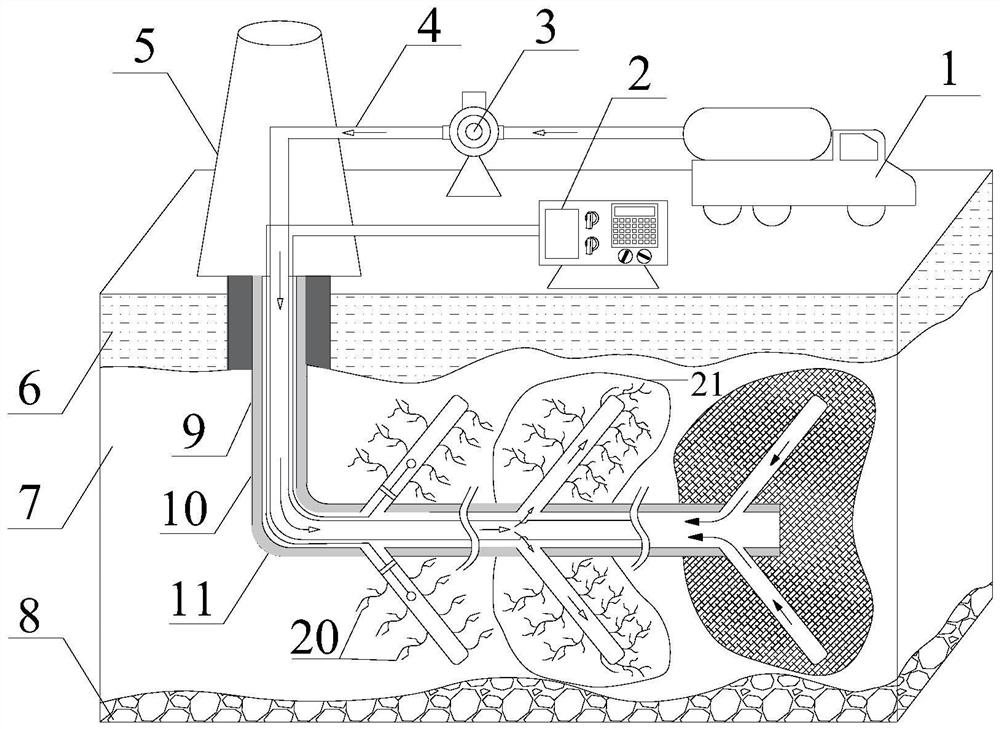

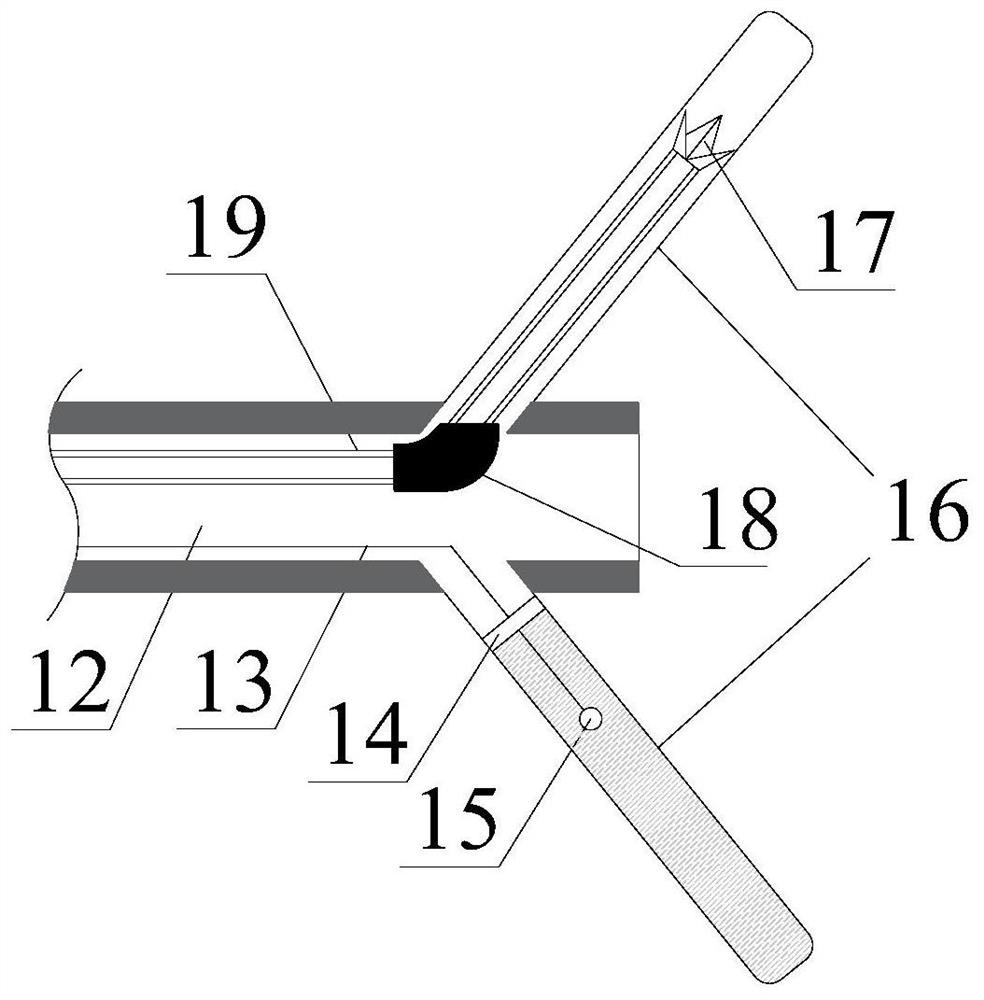

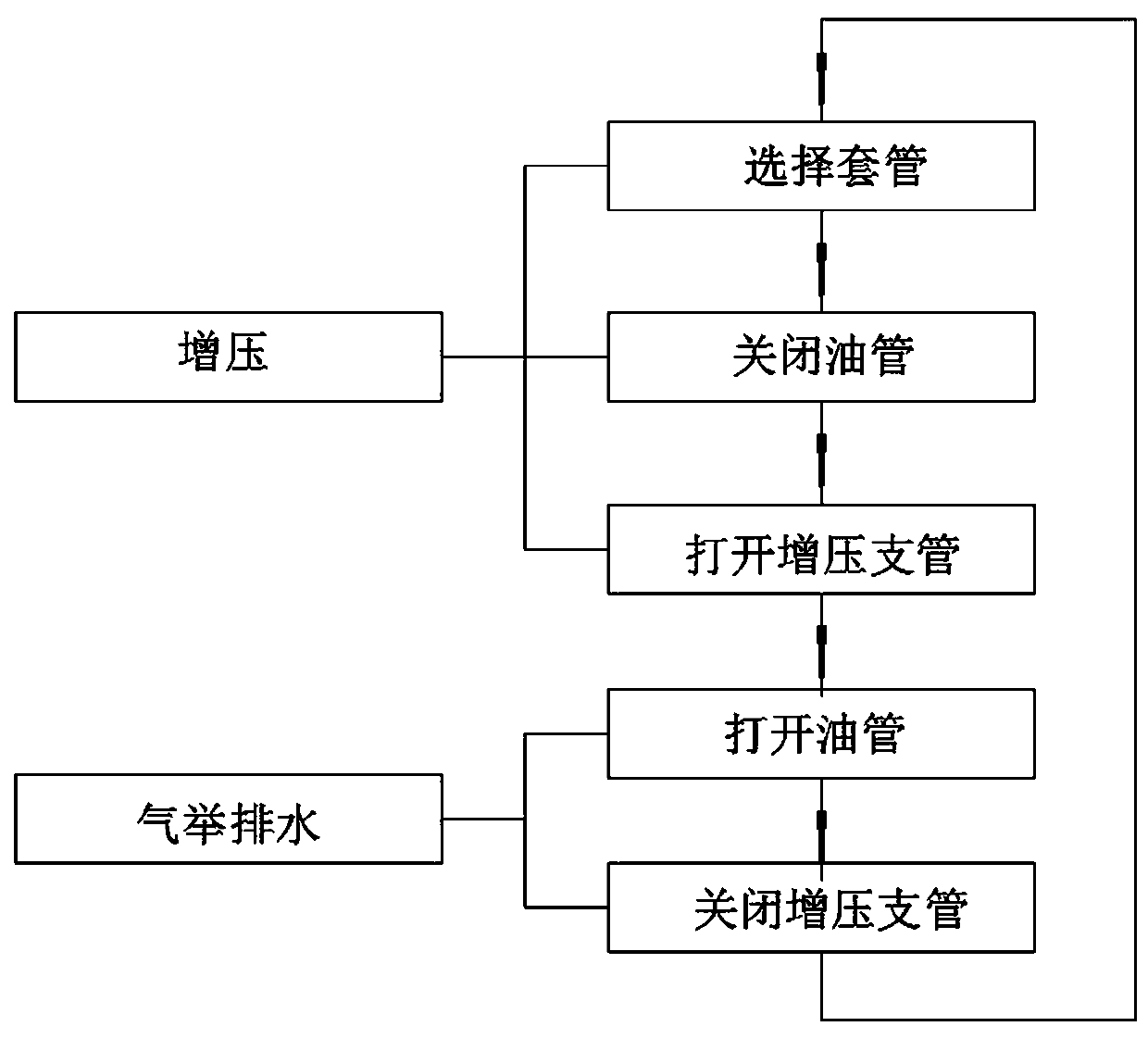

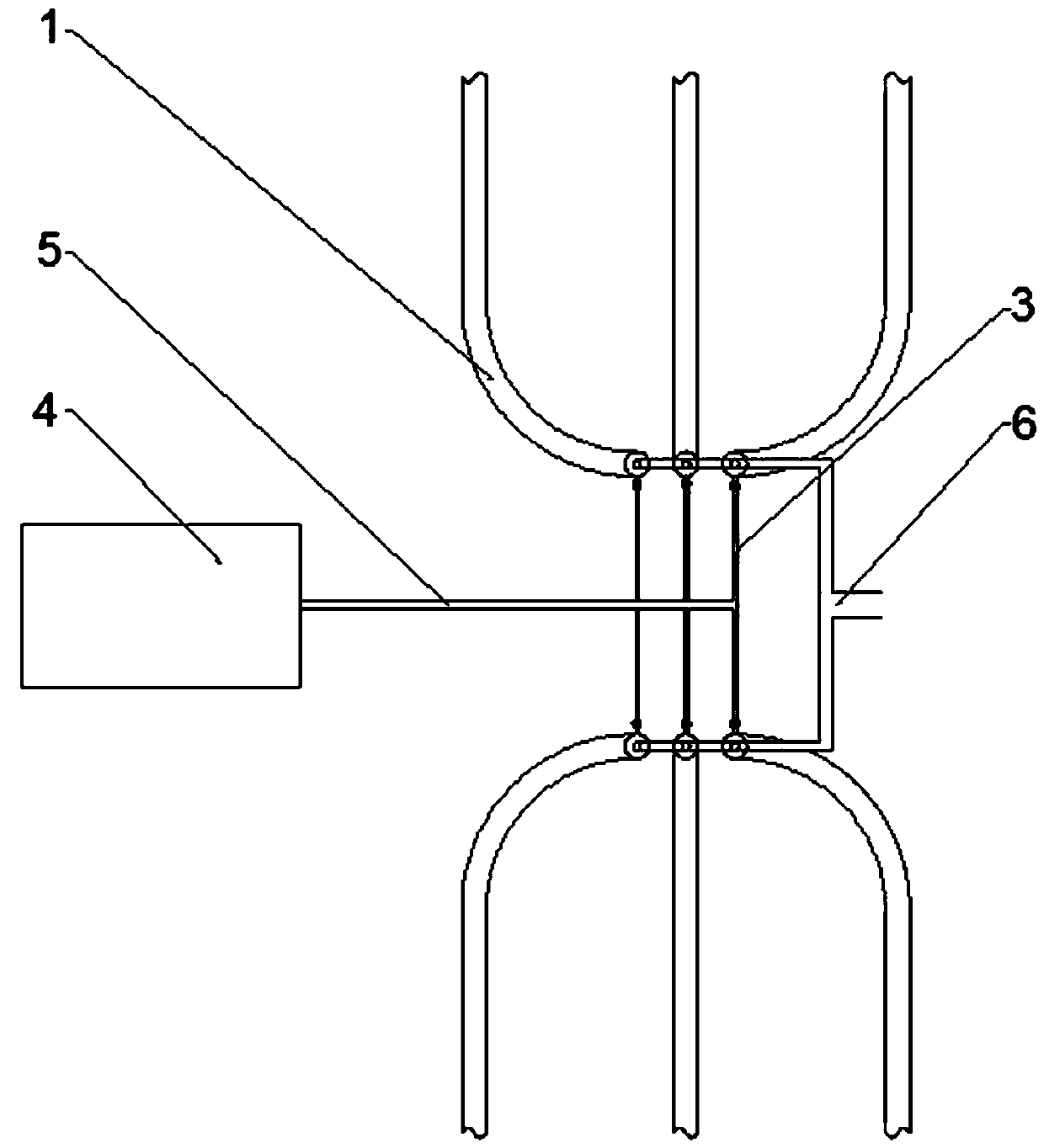

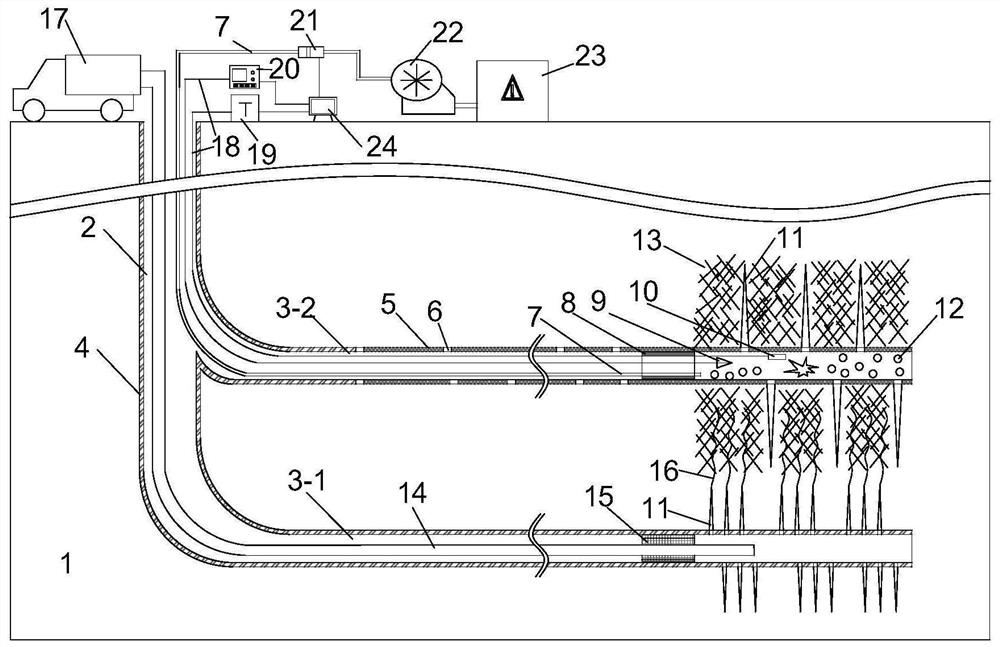

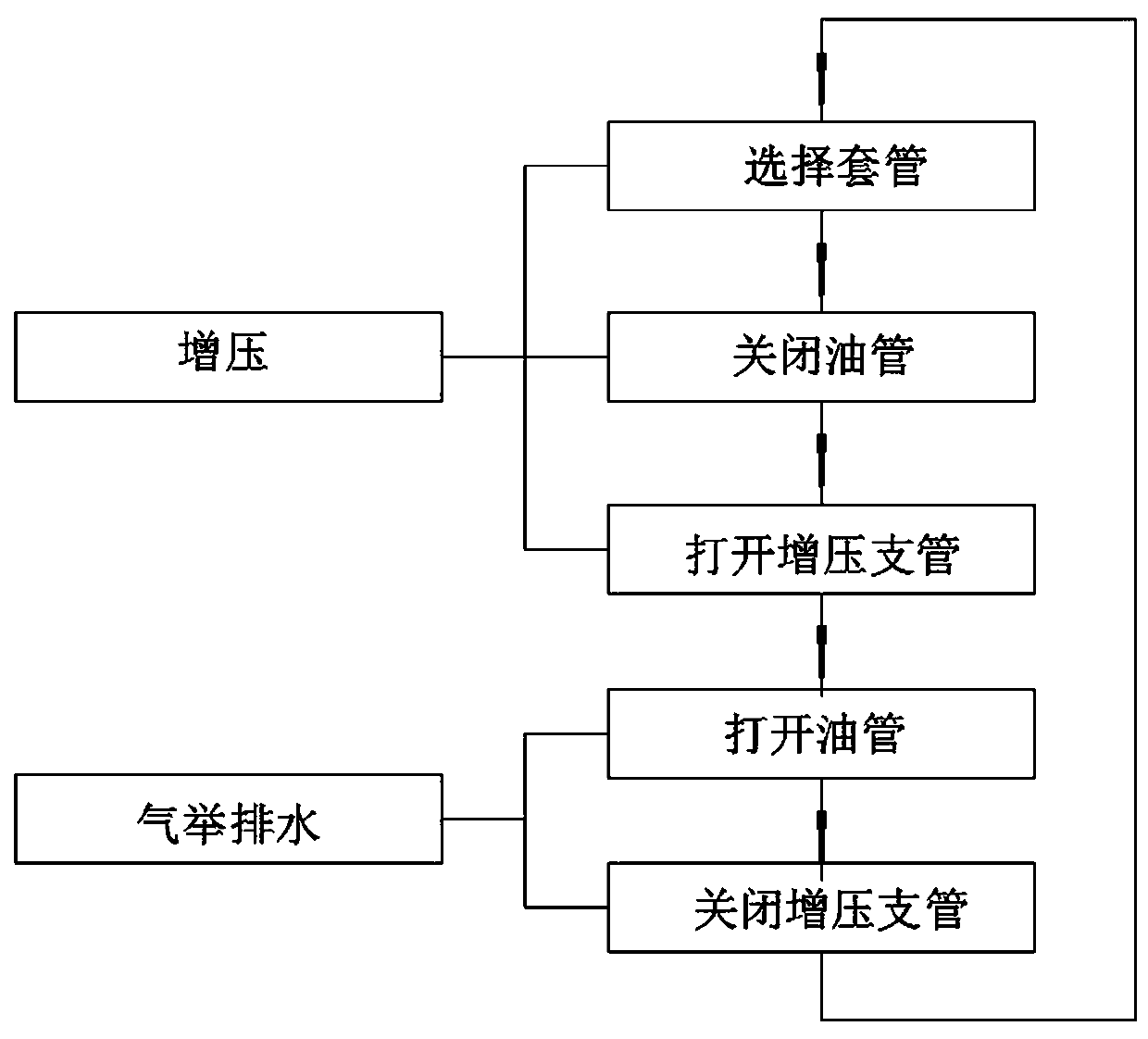

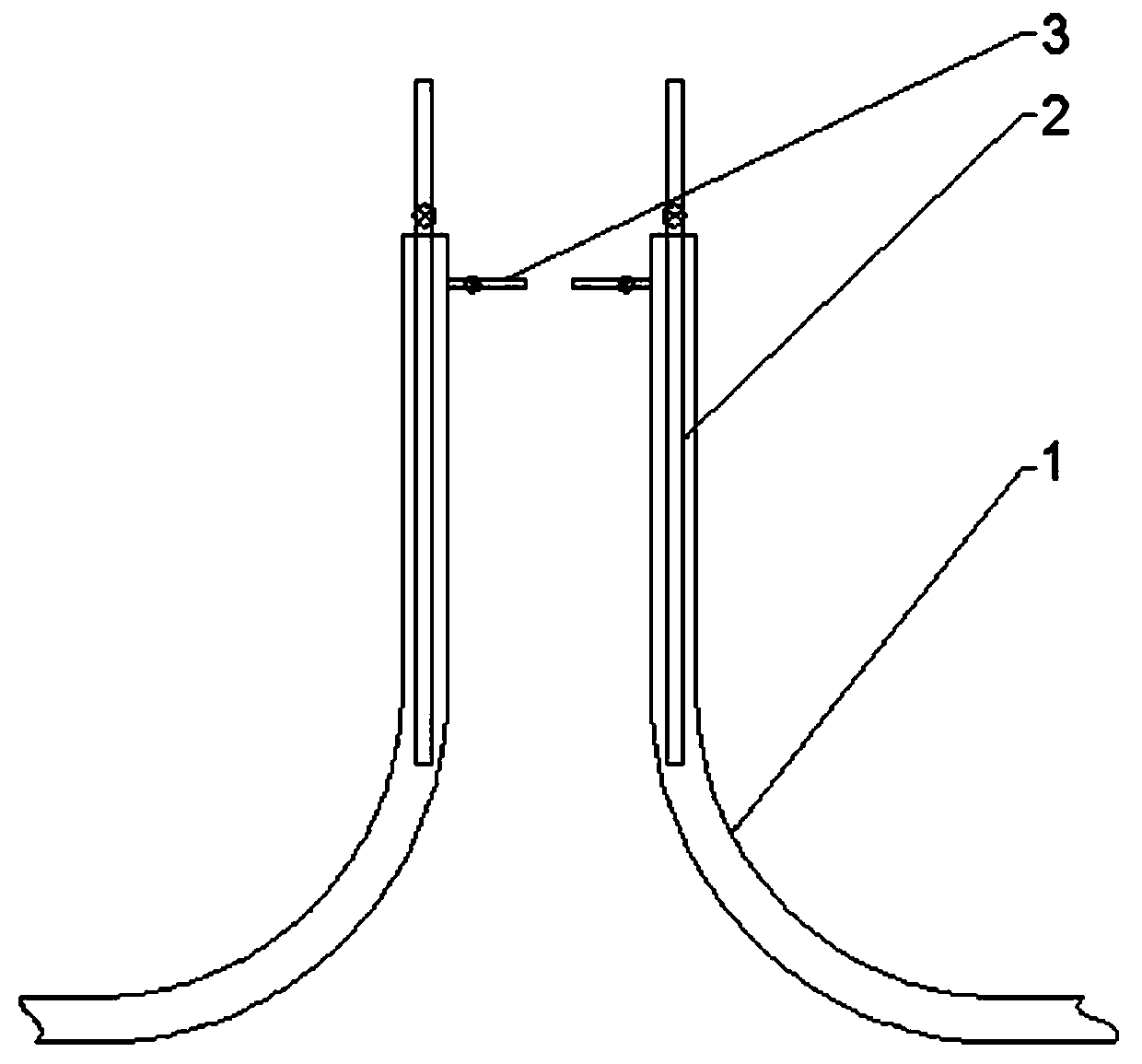

Unconventional gas reservoir horizontal well gas lift water draining gas production device and method

The invention relates to an unconventional gas reservoir horizontal well gas lift water draining gas production device. The device comprises multiple casings (1), multiple oil pipes (2), a compressor(4), a pressurizing main pipe (5), multiple pressurizing branch pipes (3) and a control main unit. One oil pipe (2) and one pressurizing branch pipe (3) are inserted in each casing (1), an annulus isformed between each oil pipe (2) and the inner wall of the corresponding casing (1), the pressurizing branch pipes (3) are connected with the compressor (4) through the pressurizing main pipe (5), a pressure sensor is mounted in each annulus, electromagnetic valves are mounted on each oil pipe (2) and each pressurizing branch pipe (3), the signal output ends of the pressure sensors are electrically connected with the control main unit, and the signal output end of the control main unit is electrically connected with multiple electromagnetic valves. The control main unit is used for carrying out circular pressurizing on the casings (1), the gas production rate of multiple gas wells on one platform can be ensured, the production cost is reduced, production efficiency can be improved, and meanwhile, progressive decreasing of formation pressure can be relieved.

Owner:中国石油天然气股份有限公司西南油气田分公司工程技术研究院

A spiral flow stirring type biological fermentation device

InactiveCN106801006AStir wellGuaranteed gas productionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringScrew thread

A spiral flow stirring type biological fermentation device is disclosed. The device includes a biogas digester main body, a stirring body and a drive assembly. The stirring body includes a lifting bar and a spiral plate. The lifting bar is vertically disposed at the center of the biogas main body. The spiral plate is fixed to the lower end of the lifting bar. The drive assembly includes a screw thread insert and a motor. The screw thread insert sleeves the lifting bar and is rotatably connected to the biogas digester main body around the axis of itself in a unidirection manner. The screw thread insert and the lifting bar are connected through screws to form a lead screw nut pair. The lifting bar is slidingly connected to the biogas digester main body around the axis of itself in a unidirection manner. The device achieves uniform and full stirring of a material liquid through up-down floating of the spiral plate, facilitates hull breaking and ensures the gas yield of the biogas digester.

Owner:开县元中养殖场

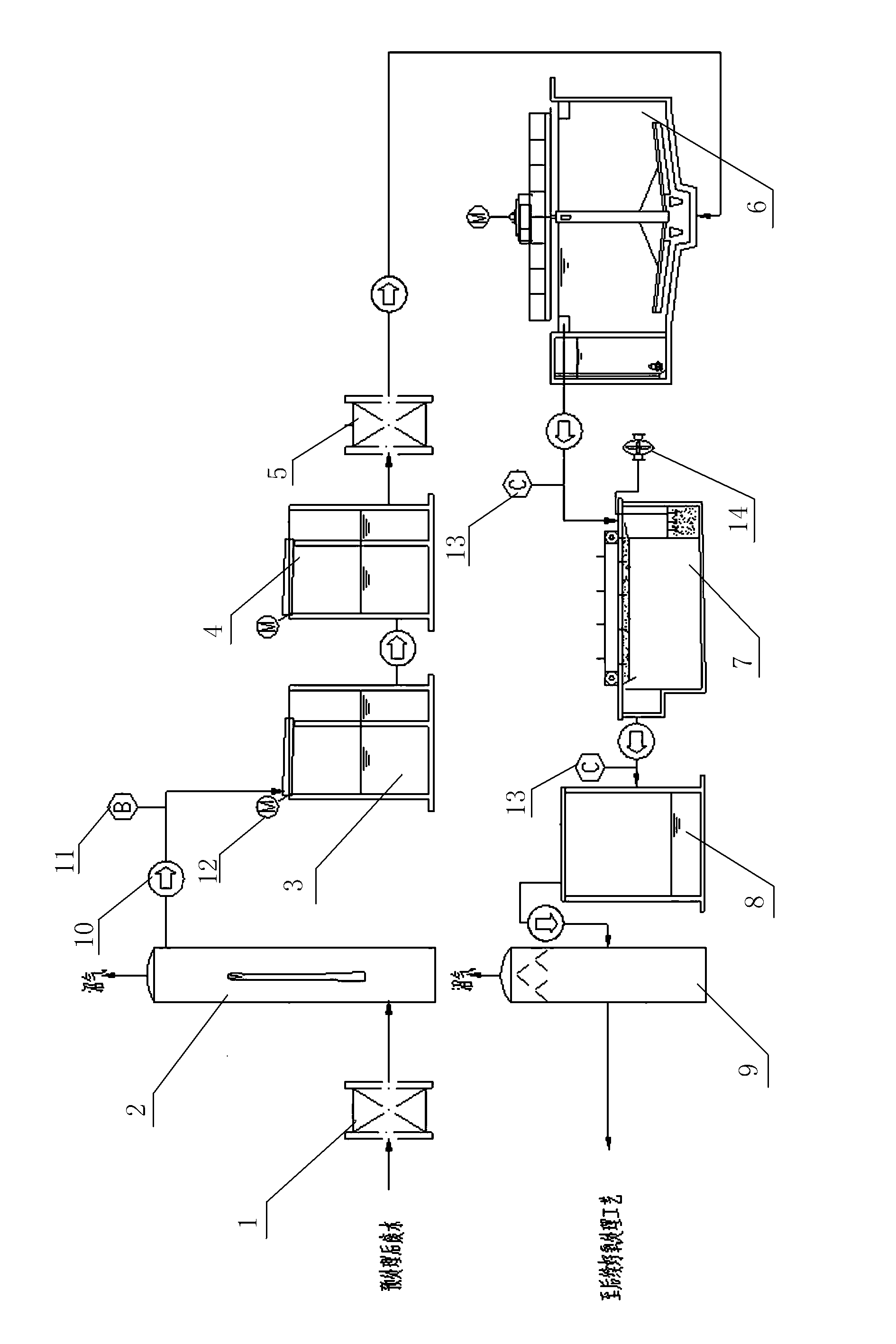

Biogas raw material pretreatment device

InactiveCN103071335AChange flow directionTo achieve the purpose of removing sedimentFiltration circuitsSludgeSewage

The invention relates to a biogas raw material pretreatment device comprising a sewage collection tank, a blending tank, and an adjustment tank. The sewage collection tank communicates with a sewage channel, and is connected with the blending tank through a sewage pipe. A stirrer is arranged on the blending tank. A secondary delivery pump is arranged on the bottom of the adjustment tank. The outlet of the secondary delivery pump communicates with a material pipe. The adjustment tank communicates with a biogas fermentation tank through the material pipe. The blending tank and the adjustment tank are communicated through a sand precipitation channel. Separation plates are arranged in the sand precipitation channel, and are staggered on the side wall of the sand precipitation channel. First grills are directly provided on two separation plates close to the adjustment tank. According to the invention, the sand precipitation channel is arranged between the blending tank and the adjustment tank, and the separation plates are staggered in the sand precipitation tank, such that sewage flow direction is changed, and sand is precipitated in the sand precipitation channel. Therefore, a purpose for removing sand and sludge is achieved.

Owner:QINYANG FUMIN NEW ENERGY DEV

High-density and low-shrinkage rubber and plastic thermal insulation material and preparation method thereof

InactiveCN112940367AEvenly dispersedSmall shrinkageTubular articlesThermal insulationPlastic materials

The invention discloses a high-density and low-shrinkage rubber and plastic thermal insulation material and a preparation method thereof, and relates to the technical field of thermal insulation materials. The thermal insulation material includes 18 to 24 parts of rubber, 18 to 24 parts of a foaming agent, 68 to 82 parts of a smoke abatement flame retardant, 8 to 12 parts of carbon black, 13 to 17 parts of polyvinyl chloride resin, 1.3 to 1.7 parts of stearic acid, 1.3 to 1.7 parts of a dispersant, 1.3 to 1.7 parts of a calcium-zinc stabilizer, 28 to 32 parts of chlorinated paraffin oil, 5 to 8 parts of ointment, 14 to 17 parts of argil, 6 to 8 parts of silicon dioxide, 3.1 to 4.5 parts of an accelerant and 5 to 10 parts of glass fiber powder. By adding the glass fiber powder, the glass fibers can be arranged along the flowing direction in the processing process, so that the shrinkage of the rubber and plastic material is effectively reduced; besides, the argil, as a filler, can improve the mechanical properties of the rubber, improve the processability of the material, play a reinforcing role, reduce the supporting strength of the material to bubble walls, and reduce the problem of spouting or collapse.

Owner:亚罗斯建材(江苏)有限公司

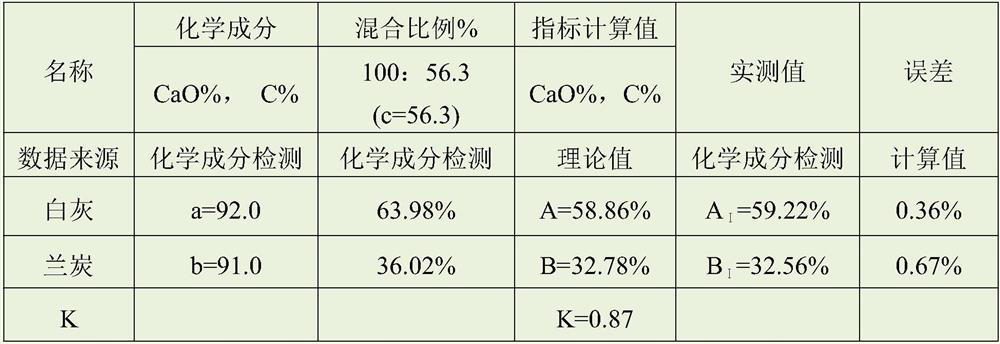

A kind of method of calcium carbide quality control

ActiveCN112010309BQuality improvementImprove stabilityCalcium carbidePhysical chemistryQuality control

The present invention relates to the calcium carbide field, in particular to a method for calcium carbide quality control. First, calculate the theoretical content and saturation coefficient of CaO and C in the mixed material: set the CaO content of lime in the mixed material as a, and the C content of the carbon material as b , the theoretical content of CaO is A, and the theoretical content of C is B. Use the rate value method to control the material ratio, set K as the saturation coefficient, and determine the K value; secondly, determine the detection value A of the CaO content in the actual mixed material Ⅰ and saturation coefficient K Ⅰ , and sampling, analysis, record the detection value of CaO A Ⅰ and the detection value of C B Ⅰ , and calculate K Ⅰ value, and then count the day A Ⅰ or K Ⅰ pass rate; finally, set A Ⅱ or K Ⅱ is the control index value, A Ⅱ =A±1% or K Ⅱ =K±0.02, when A Ⅰ in A Ⅱ range or K Ⅰ in K Ⅱ qualified within the range. By adopting the calcium carbide quality control method of the present invention, the problem in the prior art that the accuracy of furnace material proportioning is low during calcium carbide processing and resulting in low calcium carbide quality is effectively solved.

Owner:SHAANXI BEIYUAN CHEM GROUP

A shale gas production stimulation method based on the combination of explosive fracturing and hydraulic fracturing

ActiveCN113338889BPrevent unmineableGuaranteed gas productionSurveyFluid removalThermodynamicsCombustion

The invention discloses a method for promoting production of shale gas based on the combination of explosive fracturing and hydraulic fracturing. First, a horizontal well for explosive fracturing is drilled, and then a perforation fracture is formed in the horizontal well for explosive fracturing and installed. The first detonation sealing device forms a sealing section. If the required value for explosion is reached in the sealing section within the set time, the detonation gas will be triggered to perform impact fracturing on the perforation fracture; if the required value for explosion is not reached, value, supplement the detonation gas in the sealing section, then complete detonation fracturing once, and then repeat the above process to form detonation fracturing fracture network around the detonation fracturing horizontal well and seal Finally, a hydraulic fracturing horizontal well is drilled under the explosion fracturing horizontal well, and the method of retreating hydraulic fracturing is adopted to form a hydraulic fracturing fracture area around the hydraulic fracturing horizontal well, and the fracture area can be in contact with the combustion chamber. The shale gas is extracted from the shale reservoir through hydraulic fracturing horizontal wells.

Owner:CHINA UNIV OF MINING & TECH

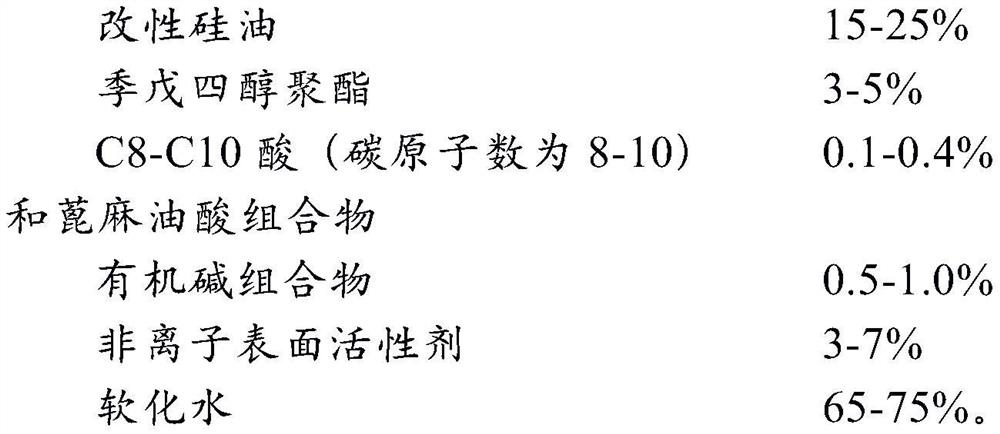

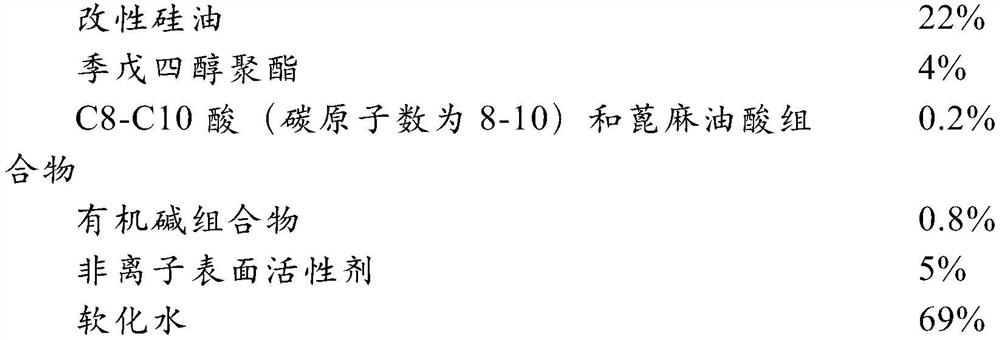

Die-casting release agent for aluminum alloy structural parts

ActiveCN113134566AMeet stability requirementsEasy to handleFoundry mouldsFoundry coresPolyesterOrganic acid

The invention discloses a die-casting release agent for an aluminum alloy structural part. According to the formula, specially-made pentaerythritol polyester is used for replacing a wax component, the demolding performance is guaranteed, meanwhile, the gas forming amount is effectively reduced, and the porosity is effectively reduced. Meanwhile, the components of the release agent and the characteristics of an application process are fully considered, the pH difference between a release agent diluent and a process waste liquid is utilized, the stability requirement of the diluent is met, meanwhile, the waste liquid treatability is improved, meanwhile, due to the combination of the organic acid and the organic amine, when the release agent waste liquid is treated, the combination can form a synergistic effect with a waste liquid treatment agent PAC, and the separation degree of the waste liquid is improved.

Owner:QUAKER CHEM CHINA

A kind of biological treatment process of cassava alcohol wastewater

InactiveCN105174601BHigh yieldRealize emission reductionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentDistillationFixed bed

Owner:SOUTH CHINA UNIV OF TECH

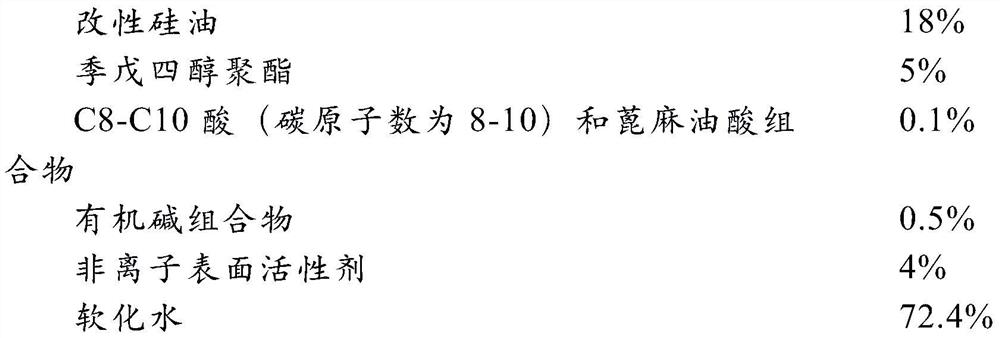

A gas recovery device and method for horizontal wells in unconventional gas reservoirs by gas lift and drainage

ActiveCN110984918BGuaranteed gas productionReduce consumptionFluid removalSolenoid valveHorizontal wells

The invention relates to an unconventional gas reservoir horizontal well gas lift drainage gas recovery device, which comprises multiple casings (1), multiple oil pipes (2), compressors (4), booster main pipes (5), multiple booster tubes Compression branch pipe (3) and control main engine; an oil pipe (2) and booster branch pipe (3) are inserted into each casing (1), and a ring is formed between the oil pipe (2) and the inner wall of the casing (1) empty, the multiple booster branch pipes (3) are connected to the compressor (4) through the booster main pipe (5), a pressure sensor is set in each annular space, and each oil pipe (2) is connected to the booster The branch pipes (3) are all provided with electromagnetic valves, the signal output end of the pressure sensor is electrically connected to the control host, and the signal output end of the control host is electrically connected to a plurality of electromagnetic valves. The control host of the present invention performs cyclic pressurization on each casing (1) to ensure the gas production of multiple gas wells on one platform, reduce production costs and improve production efficiency, and at the same time ease the gradual decrease of formation pressure.

Owner:中国石油天然气股份有限公司西南油气田分公司工程技术研究院

A compressed air method and system with self-precooling function

ActiveCN104100494BImprove cooling effectTake advantage ofPositive displacement pump componentsPositive-displacement liquid enginesProduction rateAir compression

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Briquette for gas producer produced by high volatile bituminous coals and method

InactiveCN101805650BIncrease cold strengthNo reduction in fixed carbon contentSolid fuelsBulk chemical productionFixed bedAnthracite

The invention relates to a briquette for a gas producer produced by high volatile bituminous coals and a method. The briquette can meet the requirements of the two-stage fixed bed gas producer for coal quality. The briquette is characterized in that: aiming at the characteristics of high bituminous coal forming elasticity, anthracite coal with the weight 10-20% of that of the bituminous coal is added by weight percentage and is taken as a carbon skeleton, thereby improving the cold strength of the briquette formed by the bituminous coals; modified clay with the weight 4-6% of that of the bituminous coal is added by weight percentage and is taken as a thermal intensifier, and simultaneously a sodium humate binder with the weight 4-6% of that of the bituminous coal is formed by cold pressing, thereby not only improving the cold strength of the briquette, but also not reducing the fixed carbon content of the briquette so as to ensure the heating value and gas production quantity of the briquette; and a small amount of modified clay is added to improve the thermal strength and thermal stability of the briquette, and can be used as a catalyst in the gasification process simultaneously,thereby improving the gasification activity of the briquette.

Owner:河南中美铝业有限公司

Bidirectional air intake device of biomass gasifier

ActiveCN103131475BUniform temperatureReduce air intakeCombustible gas productionCombustionEngineering

The invention discloses a bidirectional air intake device of a biomass gasifier. The bidirectional air intake device comprises a ventilation door (6), upper air passages (13) and lower air passages (5), wherein the upper air passages (13) are annularly distributed at the periphery of an outlet passage of a fuel gas outlet (10); the lower air passages (5) are annularly distributed at the periphery of an inlet passage of a feed inlet (4); the upper air passages (13) face downwards to be communicated with upper air ducts (12); the lower air passages (5) face upwards to be communicated with lower air ducts (3); the upper air ducts (12) and the lower air passages (5) are located at upper and lower positions inside a hearth (2); a plurality of upper air ducts (12) are vertically and annularly and cylindrically distributed at the periphery of the fuel gas outlet (10); a plurality of lower air ducts (3) are slantwise and annularly distributed at the periphery of the feed inlet (4) in a circular truncated cone shape; and air outlets of the upper air ducts (12) and the lower air ducts (3) are respectively formed at a duct orifice. Uniform wind field, wind pressure and combustion of the bidirectional air intake device can be realized by distributing the upper air ducts and the lower air ducts in upper and lower layers, thereby favorably controlling the temperature of the hearth between 600 DEG C and 650 DEG C.

Owner:孙吉章

A two-stage anaerobic treatment system for cassava alcohol wastewater

ActiveCN103172215BReduce outputImprove processing efficiencyMultistage water/sewage treatmentSuspended matterFermentation

The invention discloses a two-stage anaerobic treatment system for cassava alcohol wastewater, comprising a primary heat exchanger, a high-temperature anaerobic fermentation tank, a primary drum screen, a secondary drum screen, a secondary heat exchanger, a sedimentation tank, and an air flotation tank , regulating pool, medium temperature UASB reactor. The waste water enters the high-temperature anaerobic fermentation tank for high-temperature anaerobic fermentation after being cooled by the primary heat exchanger, and then enters the UASB for medium-temperature anaerobic fermentation after passing through two-stage drum sieves, secondary heat exchangers, and sedimentation air flotation to remove suspended solids and part of COD fermentation. The advantages of the system are: the biogas generated by the two-stage anaerobic process is collected and utilized, and the wastewater enters the subsequent aerobic stage for further treatment; the entire treatment process is simple, easy to manage, low energy consumption in production and operation, high in treatment efficiency, less in sludge output and easy to dispose of .

Owner:SHANGHAI SAFBON WATER SERVICE CO LTD

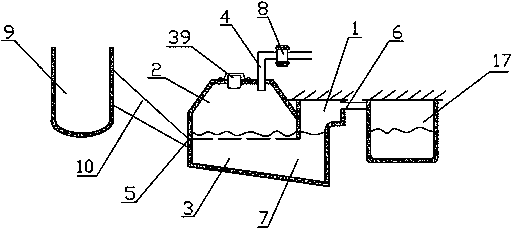

Device for heating methane tank

InactiveCN102533532AGuaranteed gas productionSimple structureBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateEngineering

The invention discloses a device for heating a methane tank. The device for heating the methane tank comprises a methane wall hanging stove; a hot water outlet pipe of the methane wall hanging stove is provided with a heat exchange coil pipe; the heat exchange coil pipe is arranged in a heating water tank; a water return pipe of the heat exchange coil pipe is connected to a cold water inlet pipe of a water replenishing hopper of the wall hanging furnace; one side of the heating water tank is provided with a hot water pump; a water pipe is communicated between the water inlet of the hot water pump and the water outlet of the heating water tank; a water outlet pipe of the hot water pump is connected with a heater in the tank; a water return pipe of the heater in the tank is connected to the other side of the heating water tank through a sensor; and a water replenishing hopper of the water tank is arranged above the heating water tank. The device for heating the methane tank has a simple structure, and can be used safely and reliably, and effectively guarantee the year-round gas production rate of the methane tank.

Owner:新乡市方舟暖通设备工程有限公司

A new type of biogas digester

InactiveCN104073431BImprove sealingImprove insulation effectBiological substance pretreatmentsGas production bioreactorsEngineeringFermentation

The invention discloses a methane tank with a novel structure, which comprises a main tank and a water pressure chamber, wherein the main tank comprises a methane storage room and a fermentation tank, a methane guide pipe is arranged at the top of the methane storage chamber, an excrement inlet is formed in one side of the main tank, and the other side of the main tank is communicated with the water pressure room; an overflow opening is formed in the water pressure chamber, and the excrement inlet is formed in the sidewall of the fermentation tank; an excrement outlet is formed between the fermentation tank and the water pressure chamber, and the excrement outlet is located in the other sidewall of the fermentation tank; the upper edge of the excrement inlet and the top end of the excrement outlet are on the same horizontal line; the bottom of the fermentation tank downwards inclines to the water pressure chamber from the sidewall, where the excrement inlet is located in, and extends to the sidewall where the overflow opening of the water pressure chamber is located in; an excrement dreg drainage channel with a concave semi-spherical cross section is arranged at the bottom of the fermentation tank; the whole methane storage chamber takes the shape of a trapezoid wider in upper part and narrow in lower part, the upper edge of the excrement inlet is arranged at the bottom end of the sidewall of the methane storage chamber, the methane guide pipe is located at the top of the trapezoid and provided with a safety valve. The invention aims to provide the methane tank with the novel structure, which is constant in pressure, convenient for discharging dreg, low in probability of incrustation and high in methane output.

Owner:何跃超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com