A spiral flow stirring type biological fermentation device

A biological fermentation and spiral flow technology, applied in the field of biogas digesters, can solve the problems of low gas production, difficult to break, low utilization rate of fermentation raw materials, etc., and achieve the effect of improving the stirring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

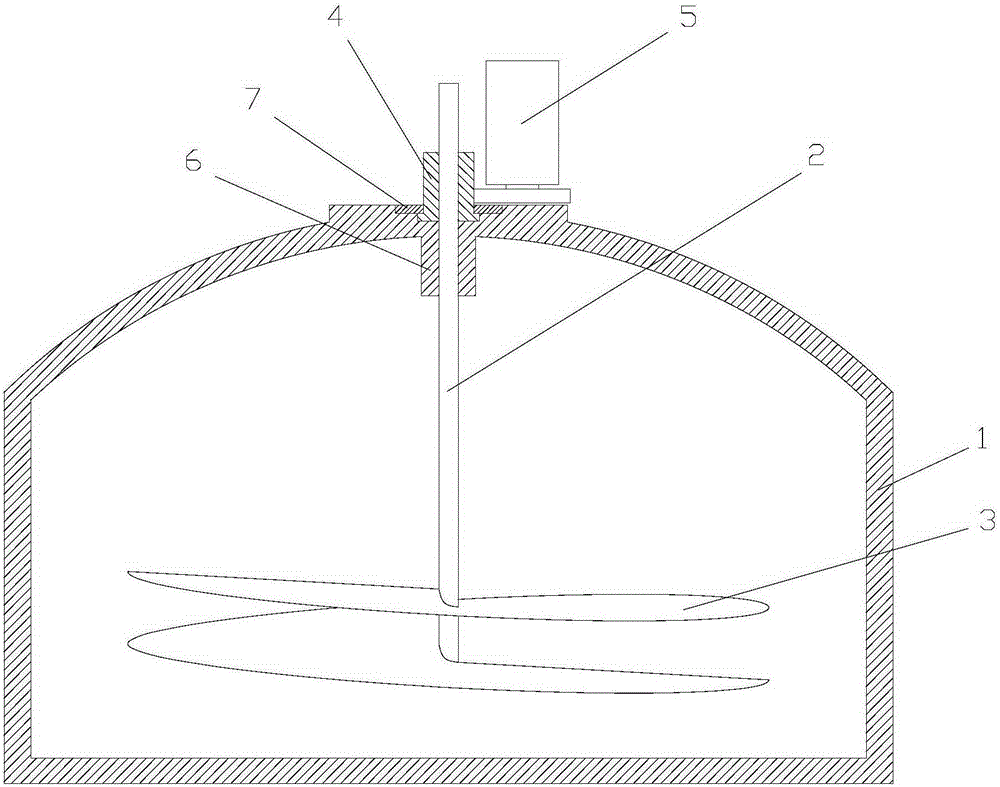

[0014] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the spiral flow stirring bio-fermentation device of this embodiment includes a biogas digester body 1, a stirring body and a drive assembly;

[0015] The stirring body includes a lifting rod 2 and a spiral plate 3; the lifting rod 2 is vertically arranged at the center of the digester body 1; the spiral plate 3 is fixed at the lower end of the lifting rod 2; figure 1 As shown, the spiral plate 3 has a spiral structure around the lifting rod 2, so that the surface of the spiral plate 3 forms a slope, which is conducive to the spiral flow of the material liquid;

[0016] The drive assembly includes a screw sleeve 4 and a motor 5; the screw sleeve 4 is set on the outside of the lifting rod 2 and is connected to the biogas digester body 1 in a single degree of freedom around its own axis; the screw sleeve 4 and the lifting rod 2 pass through The threaded connection forms a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com