Patents

Literature

39results about How to "Easy to break the shell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

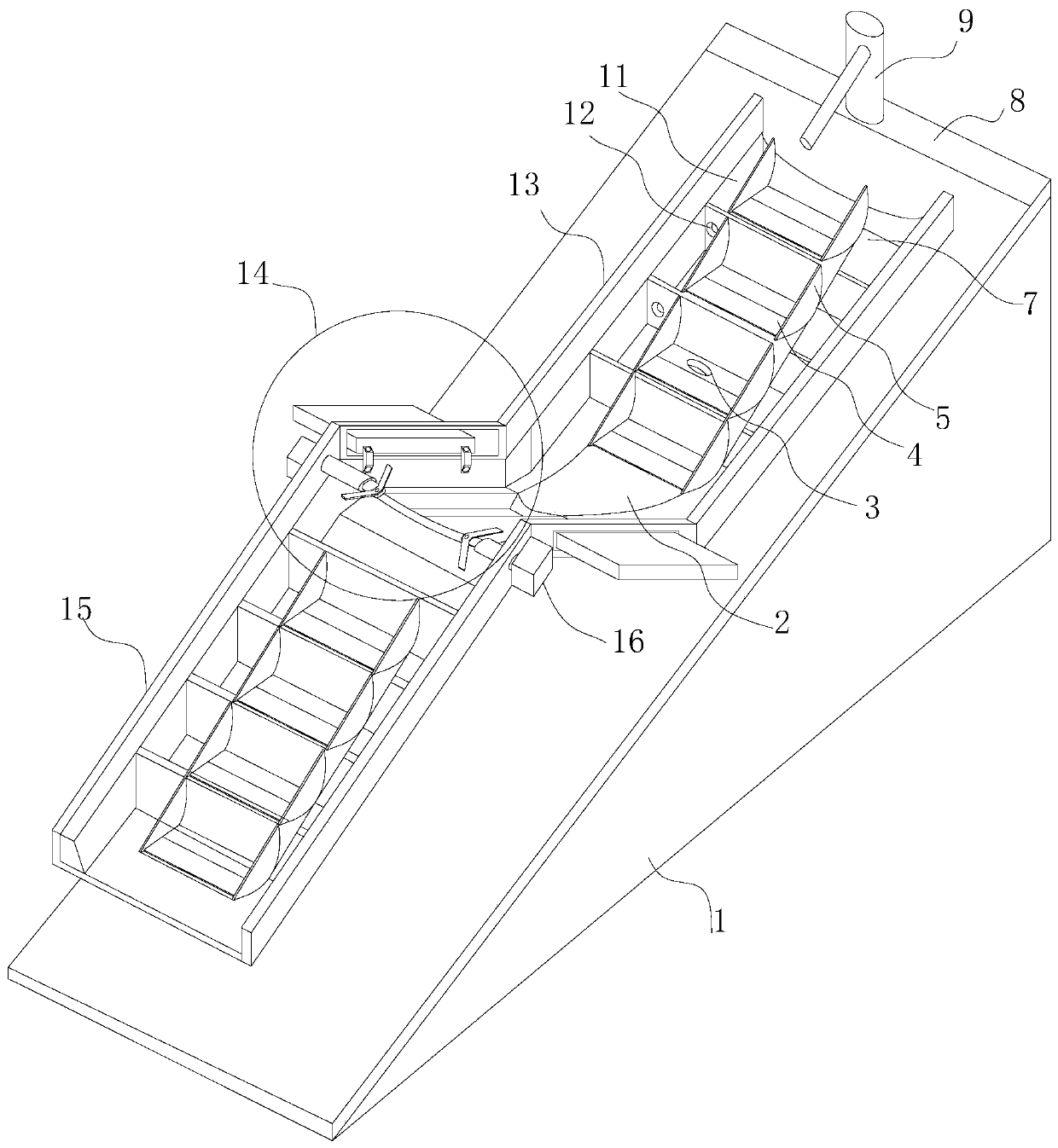

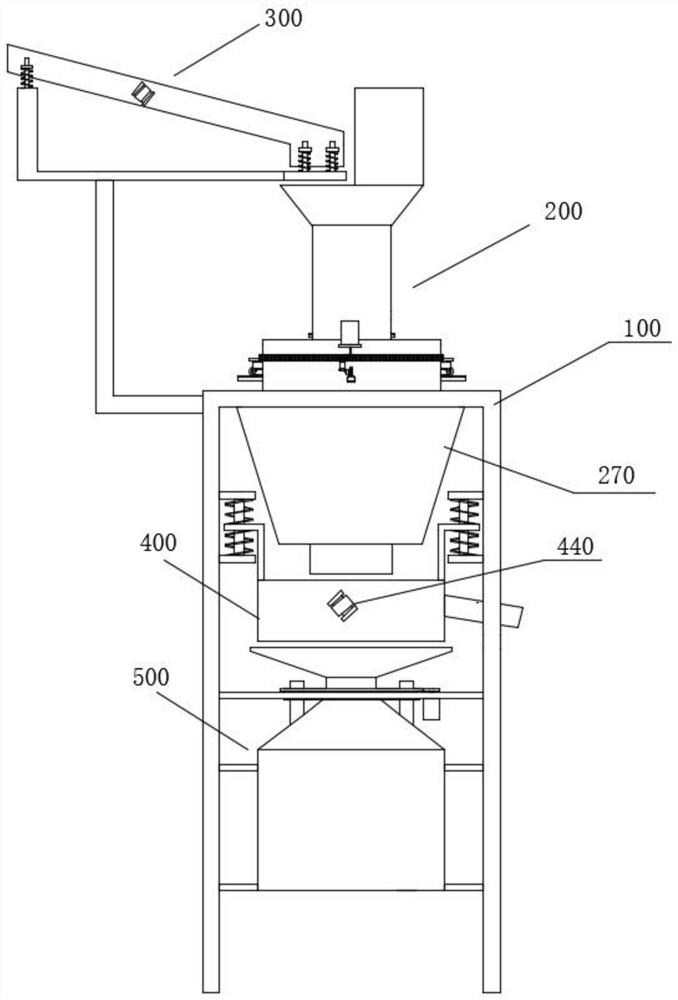

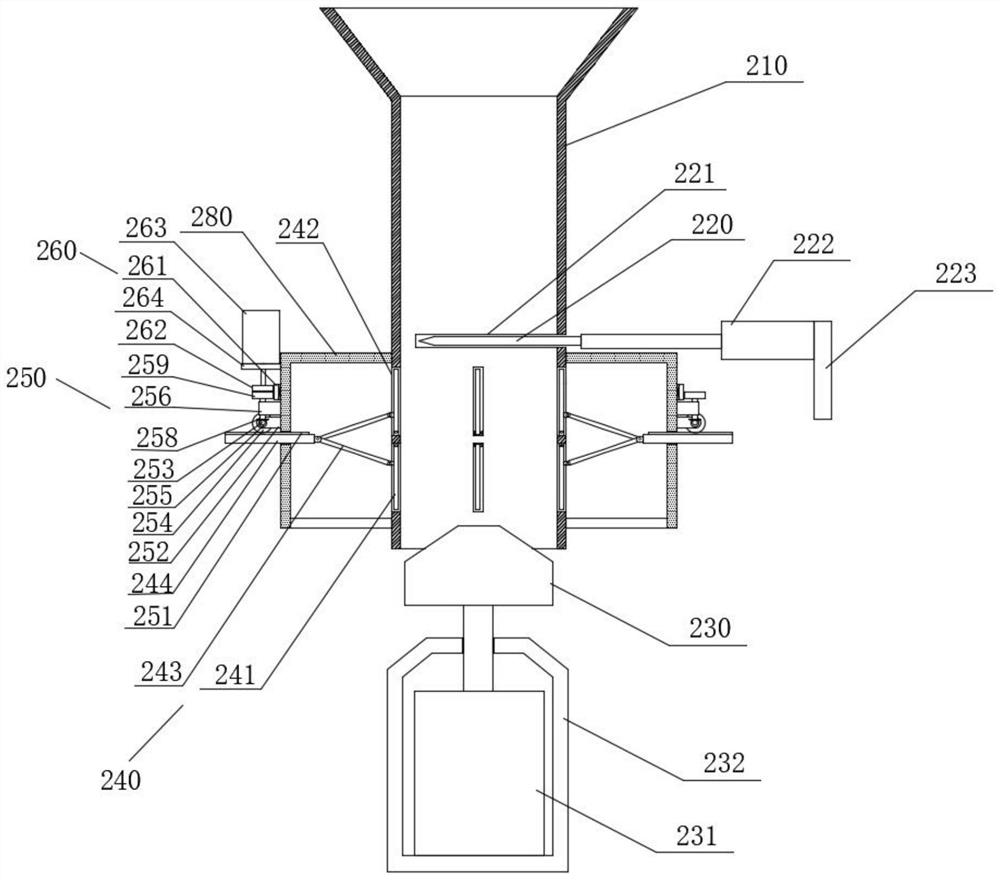

Auger-delivery walnut feeding grading device and shell-kernel separating system

PendingCN111729847AExquisite structureHigh classification accuracySievingGas current separationStructural engineeringMechanical engineering

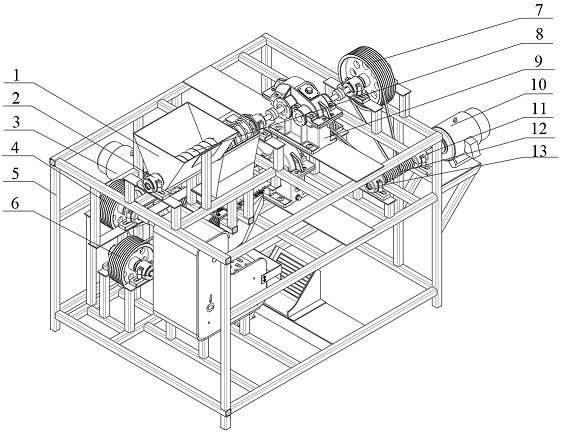

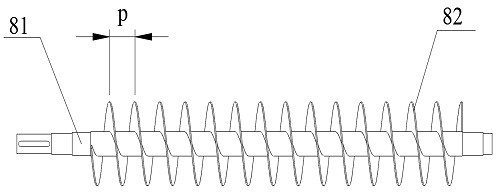

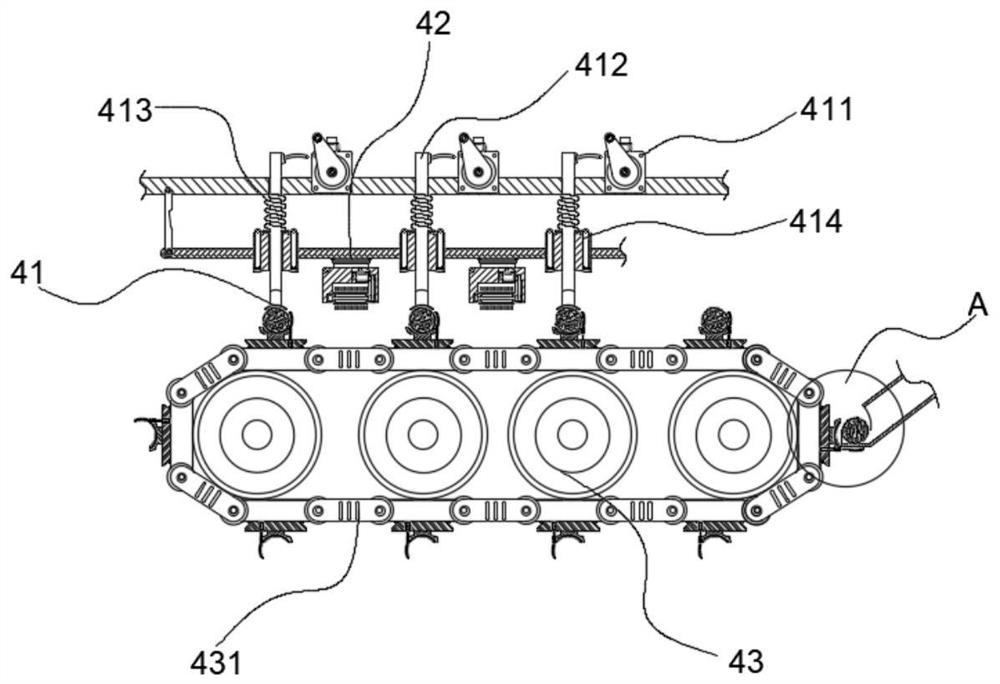

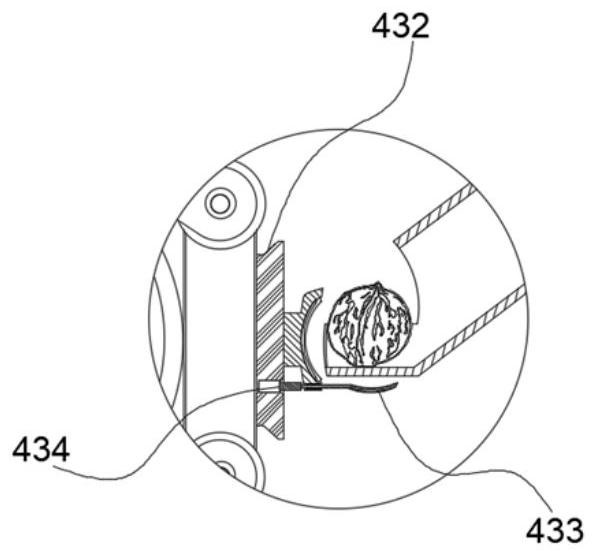

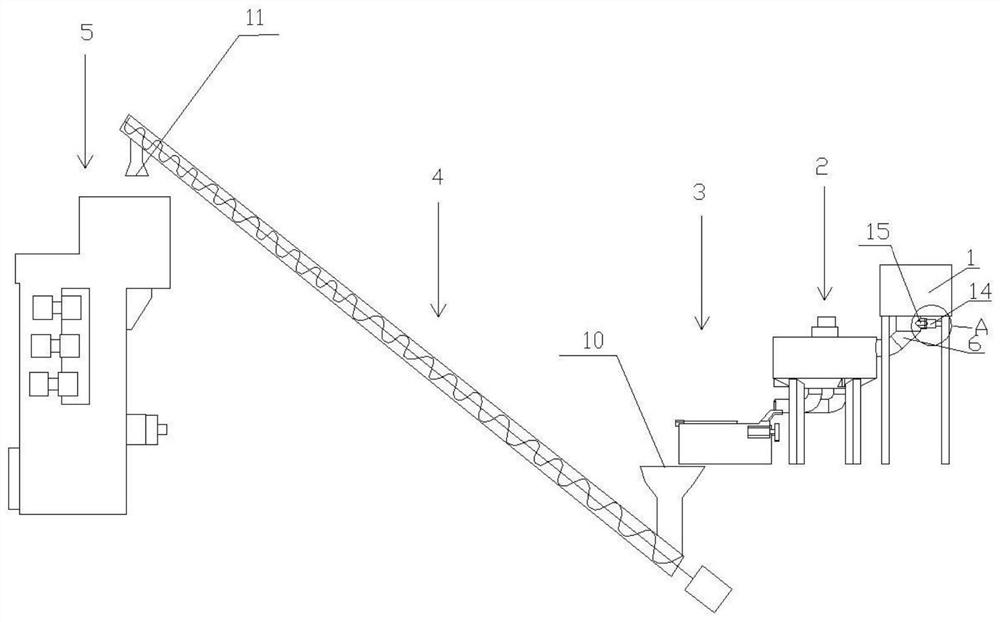

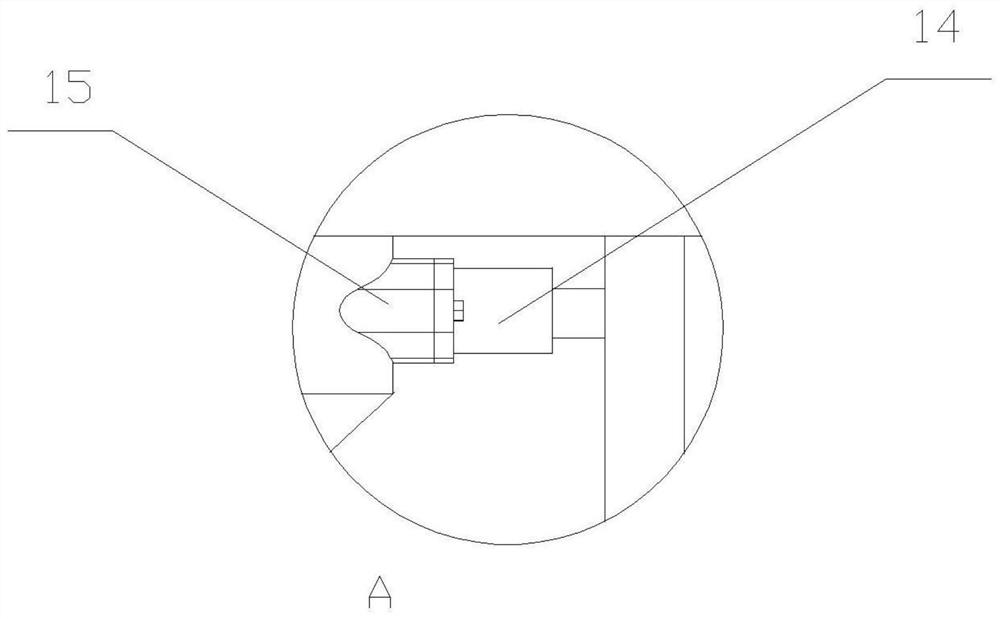

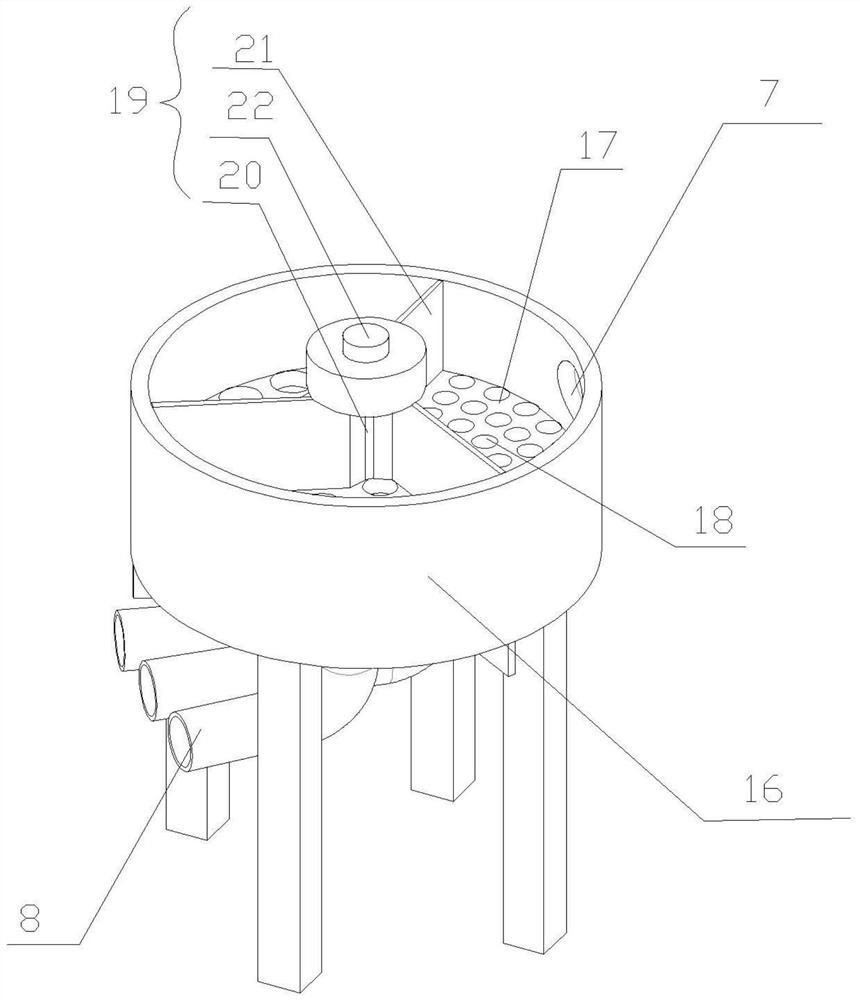

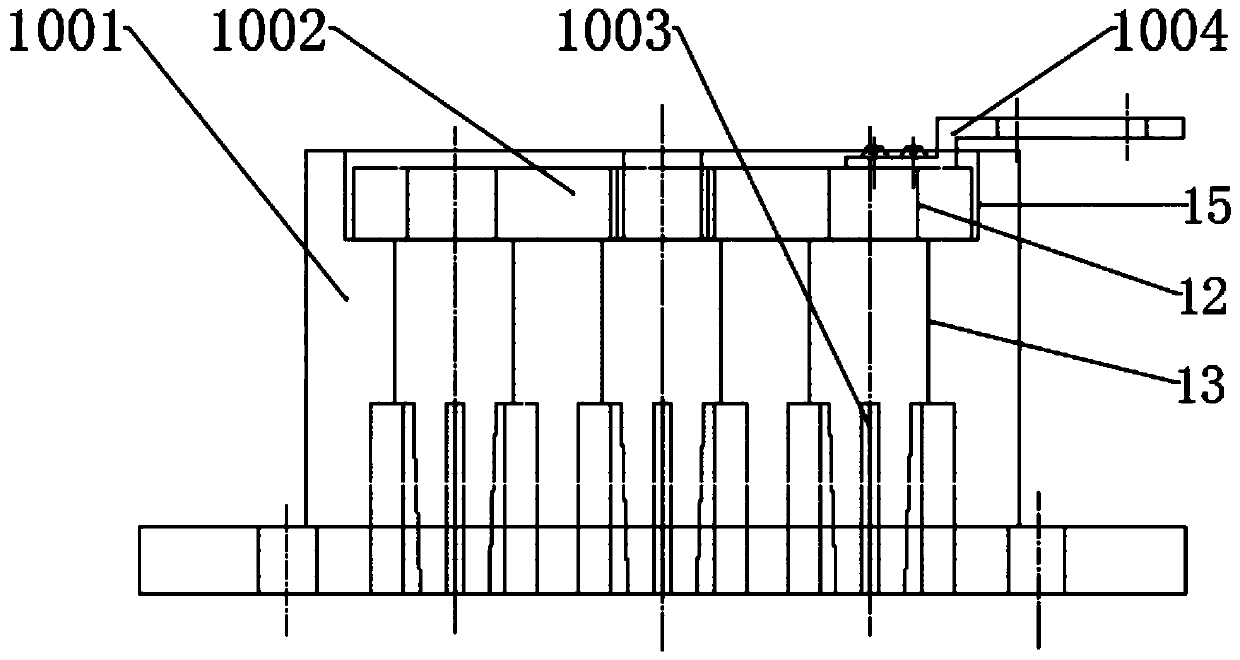

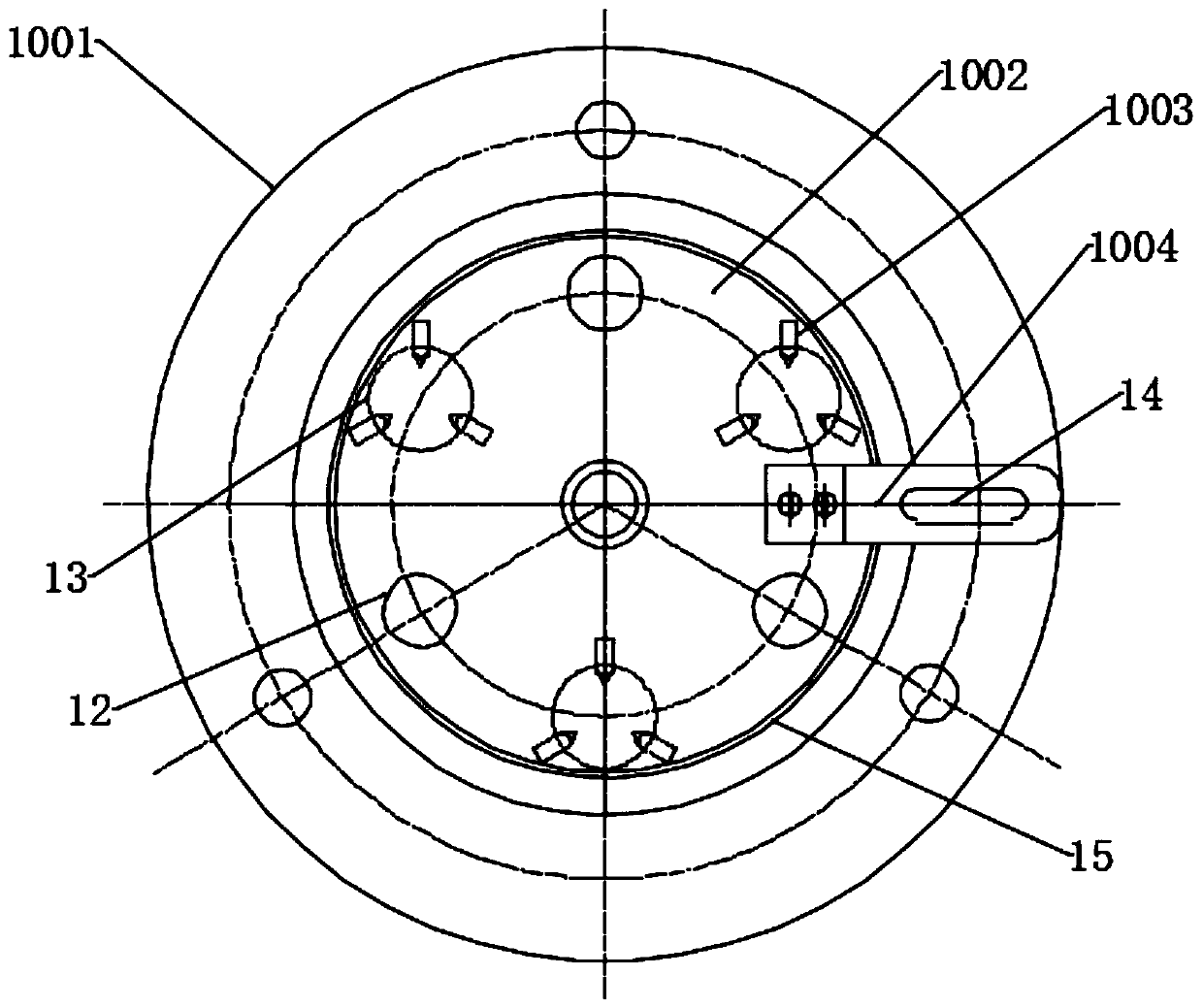

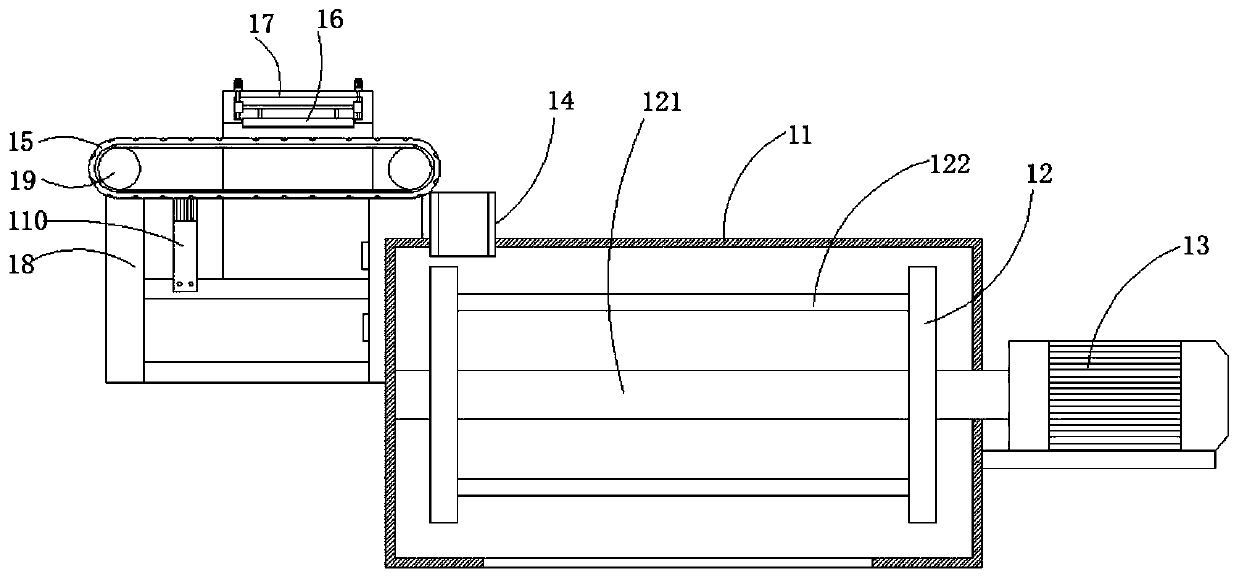

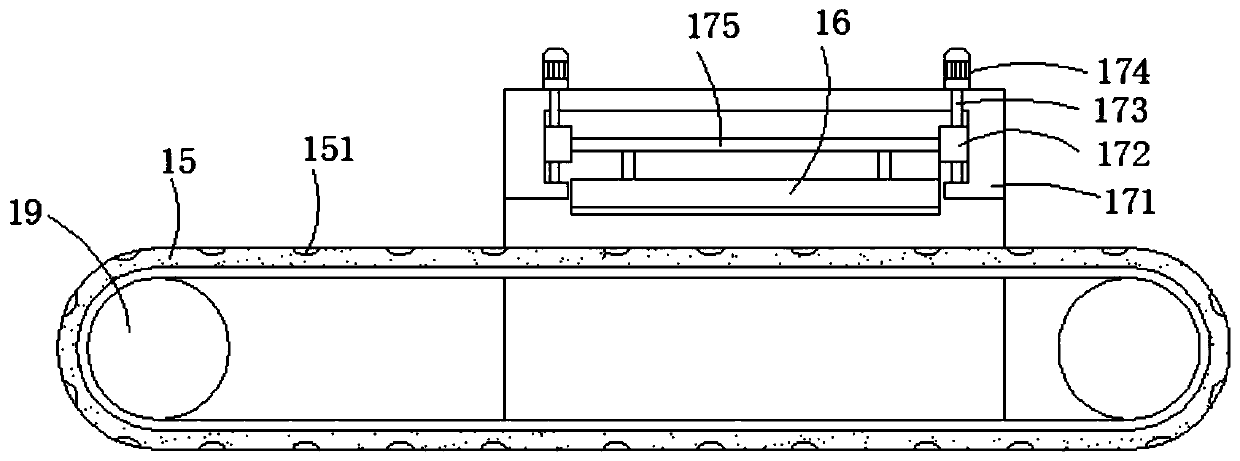

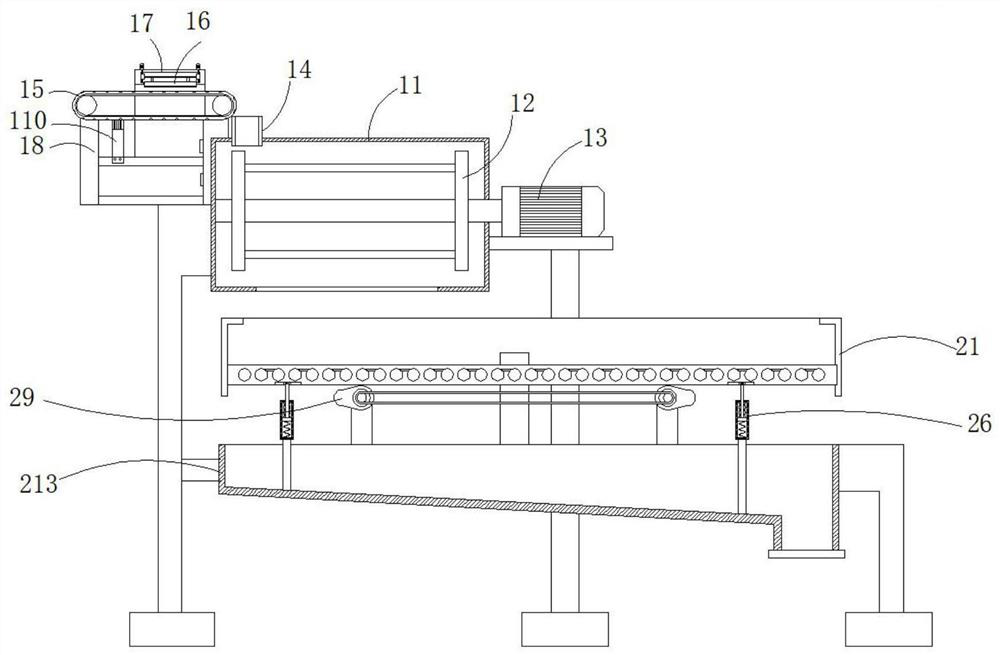

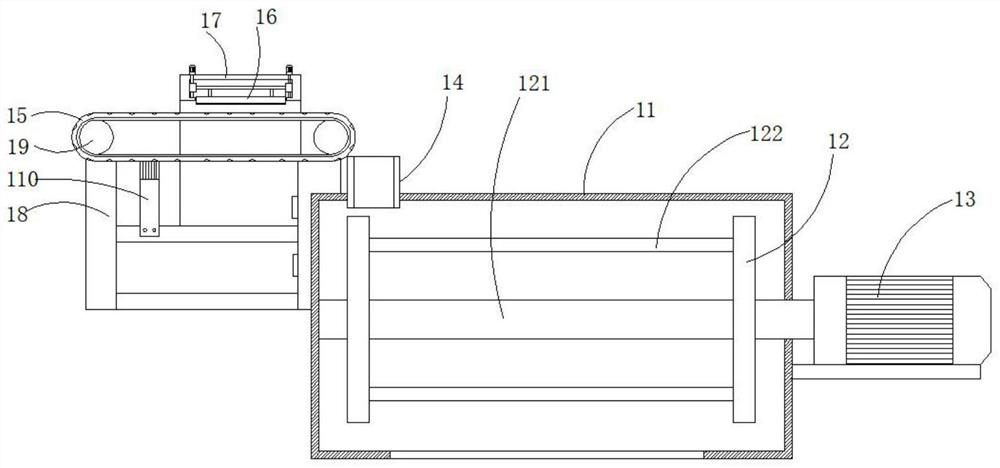

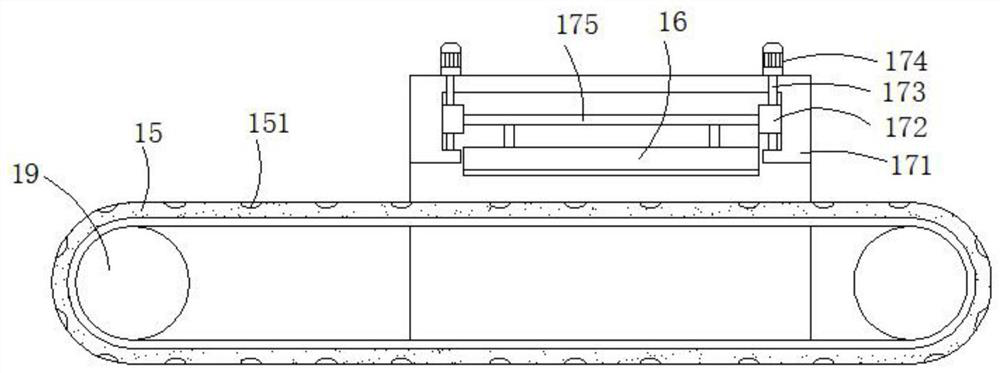

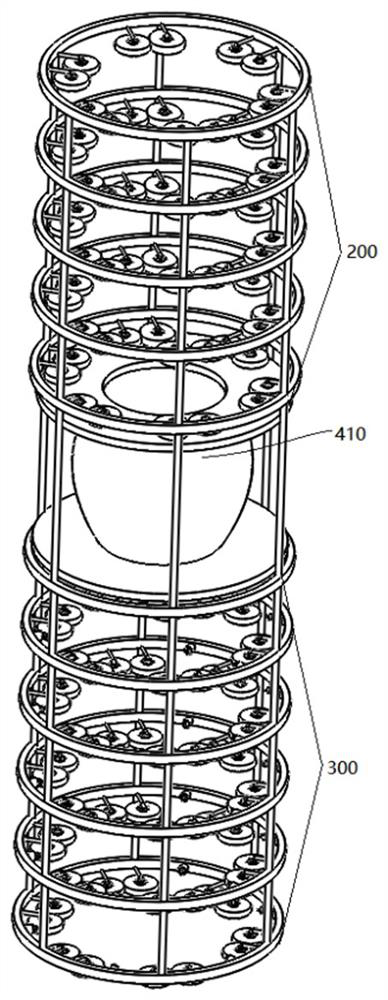

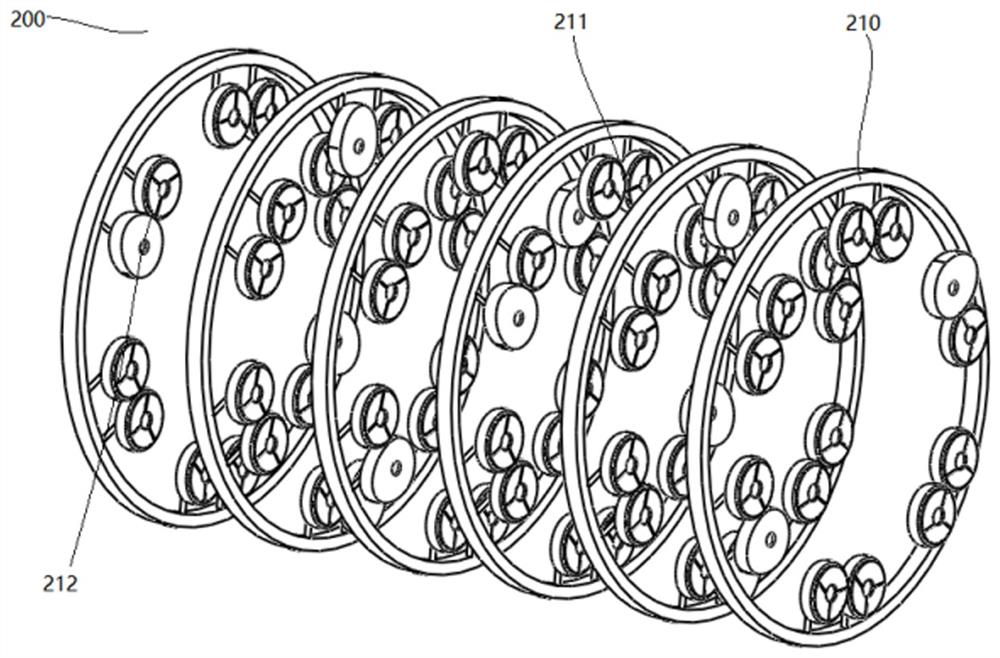

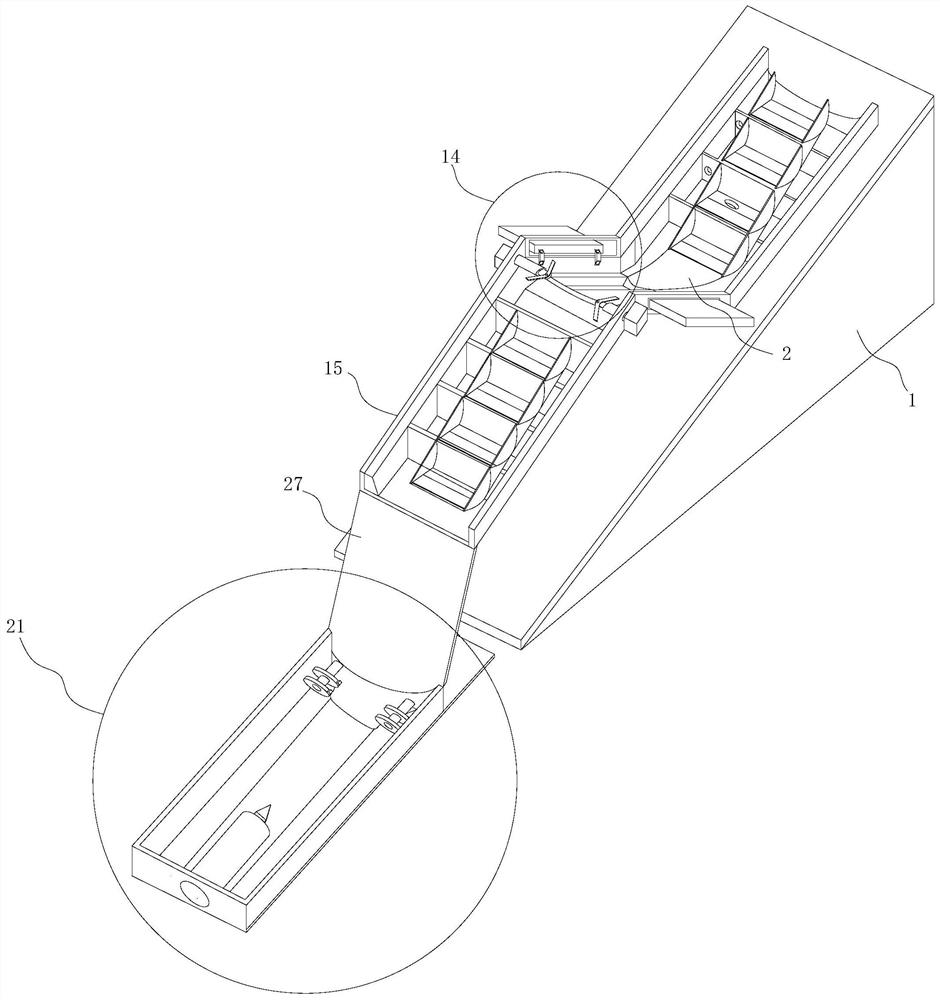

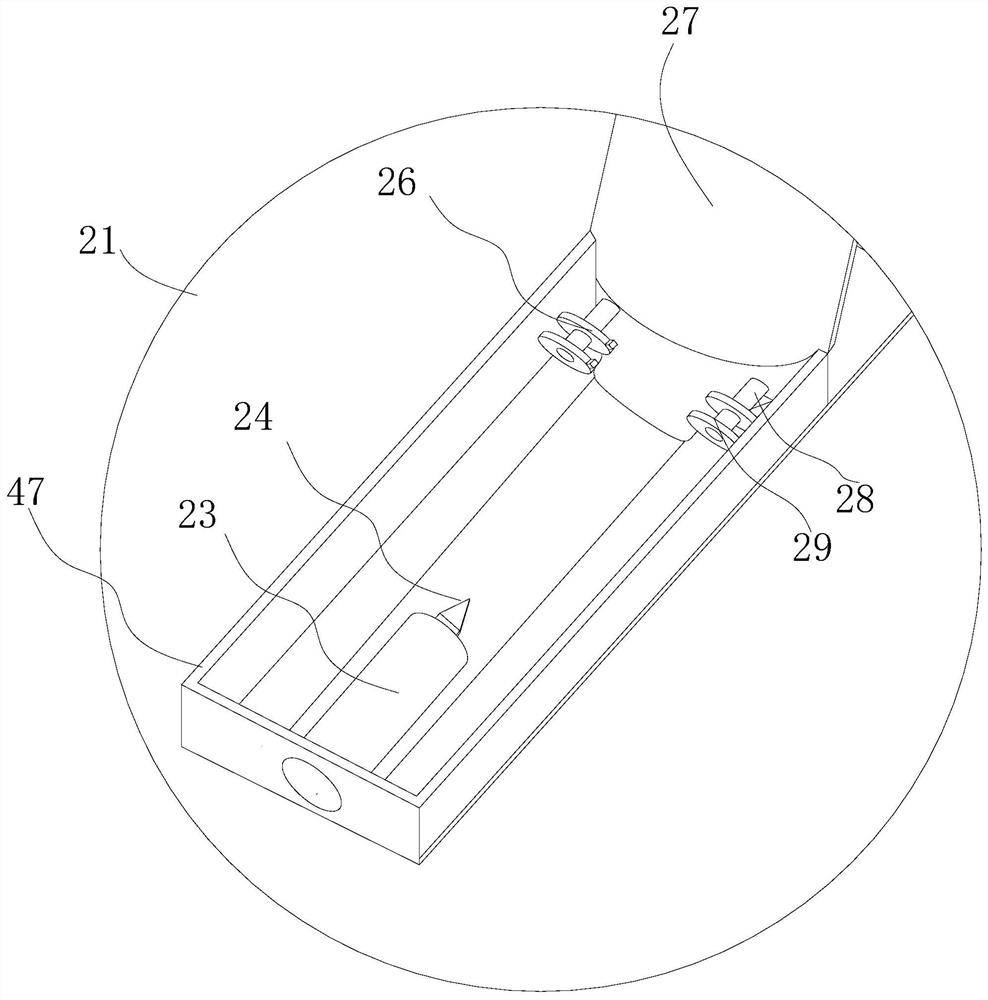

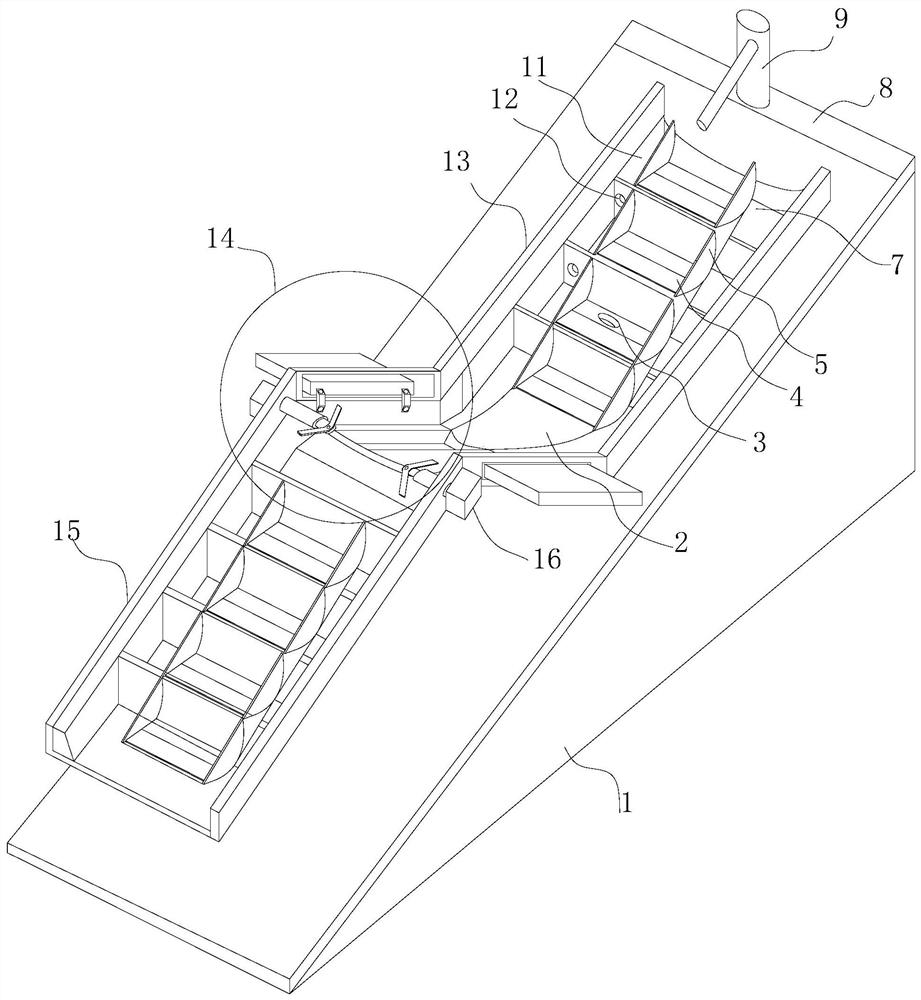

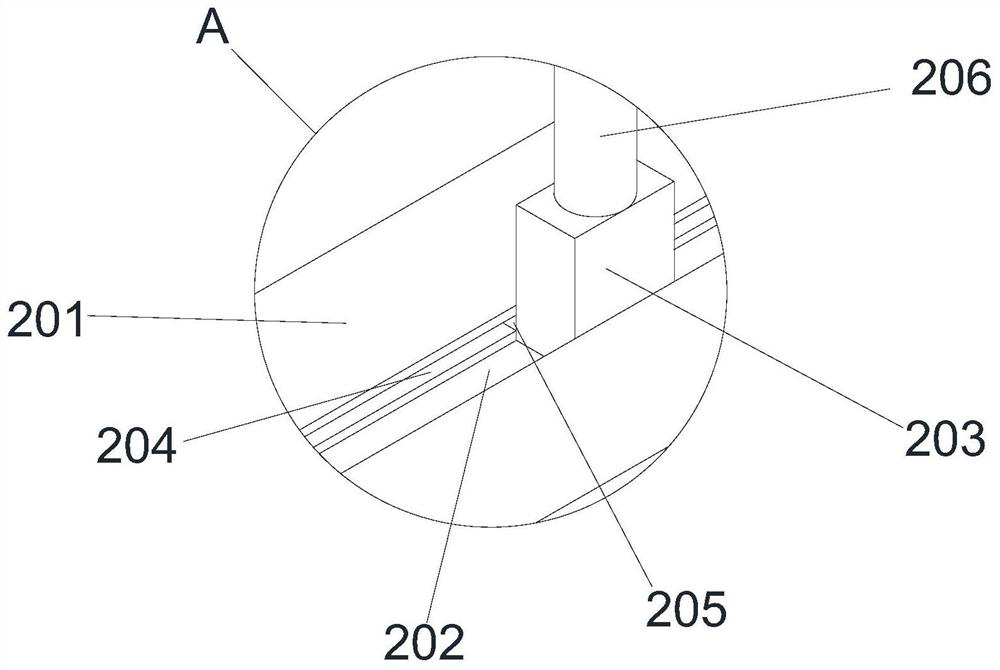

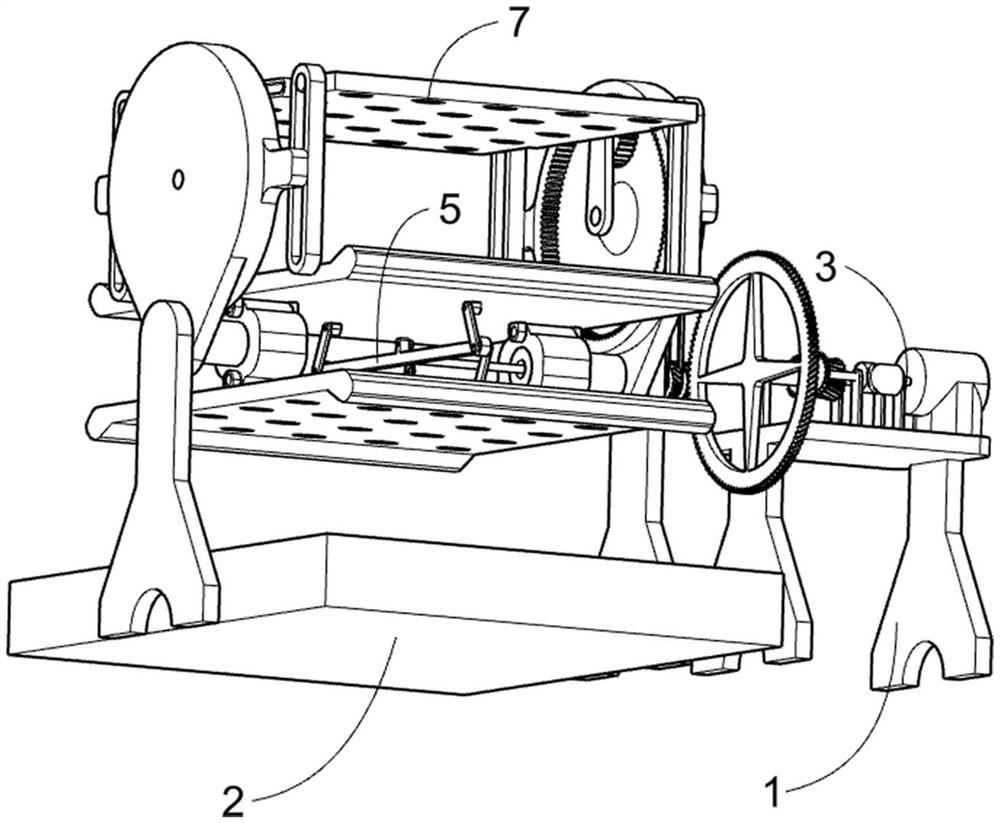

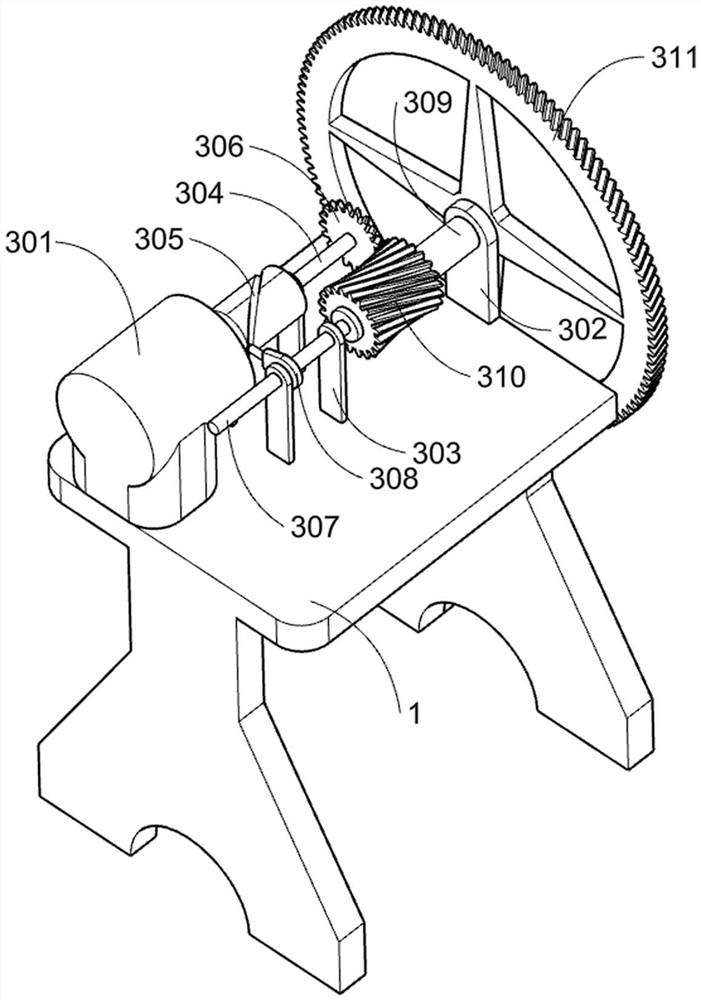

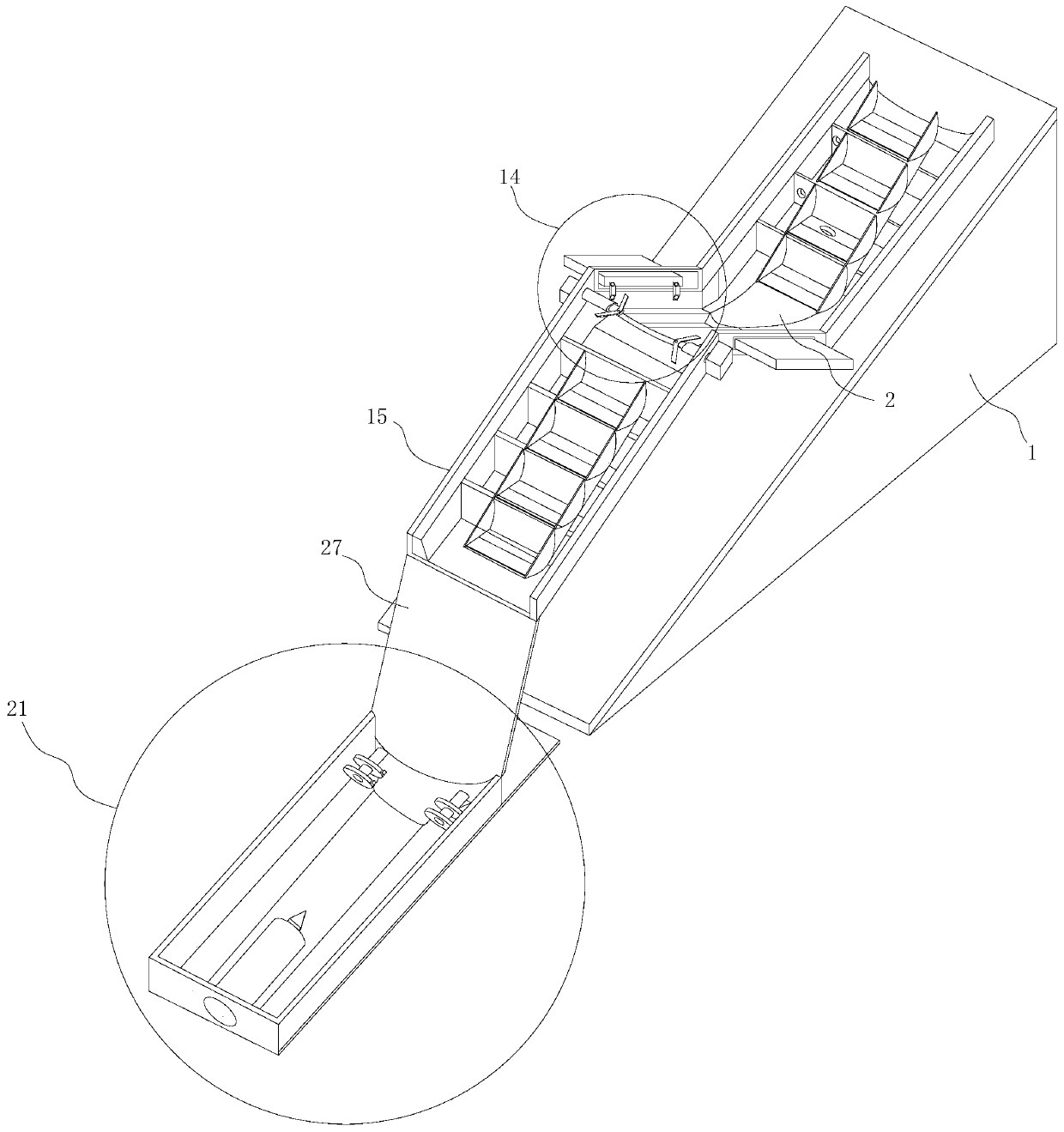

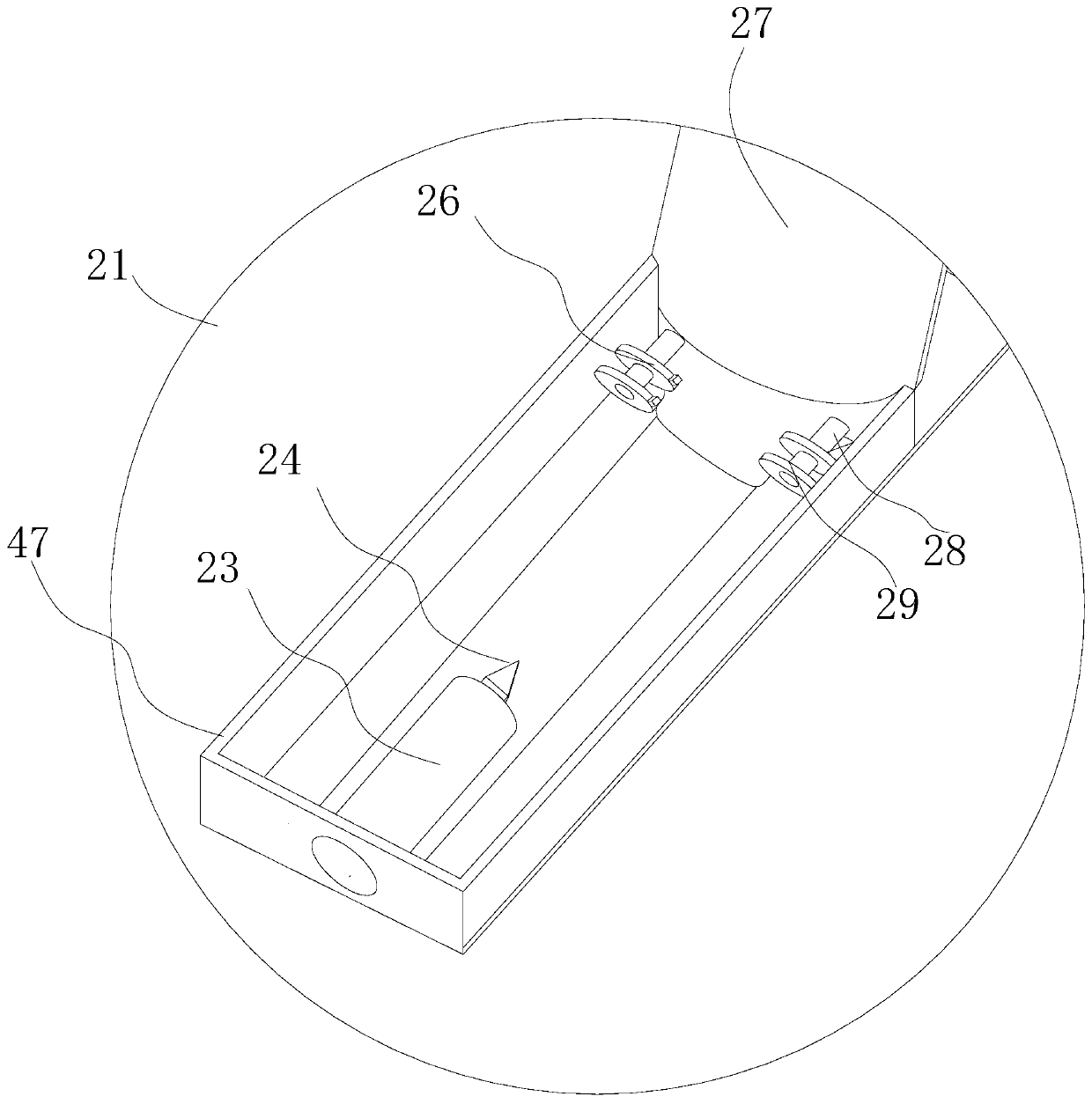

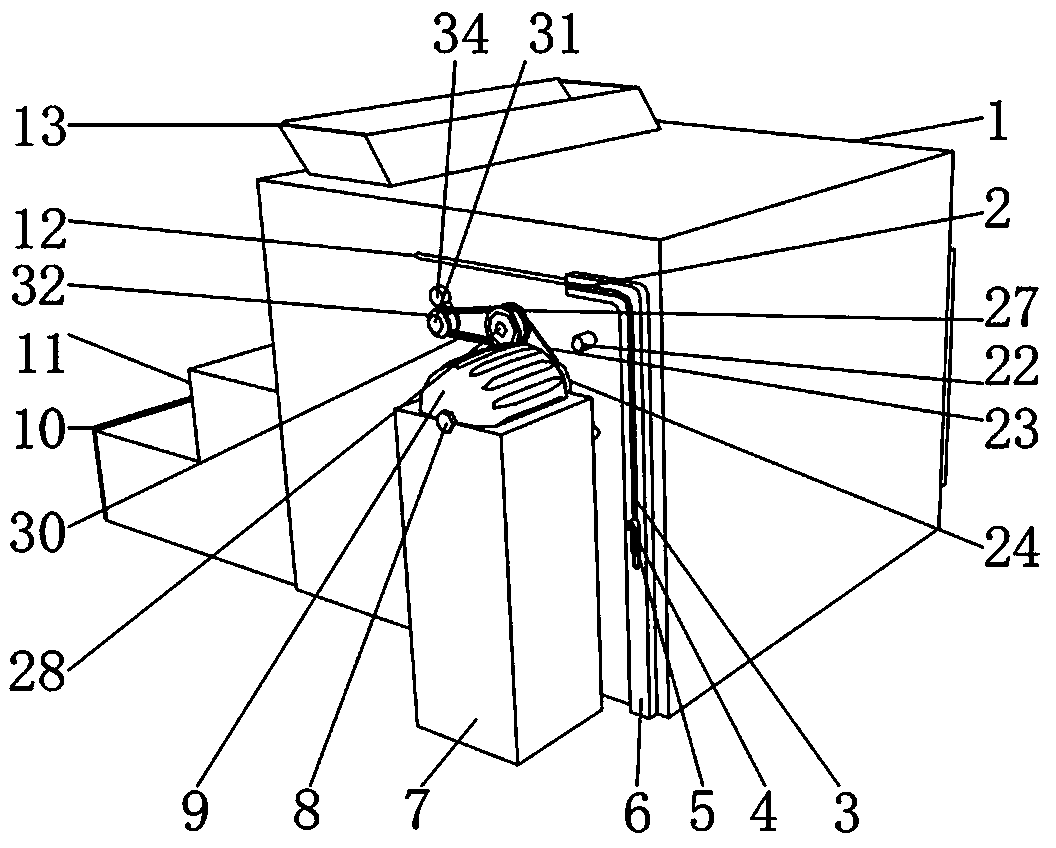

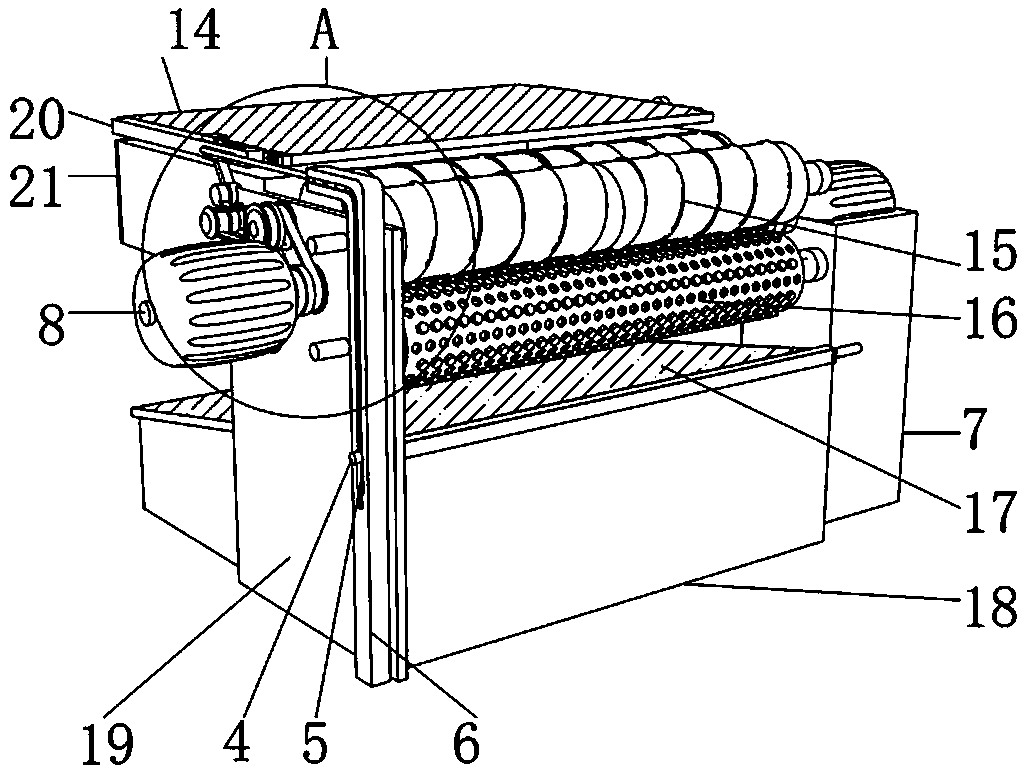

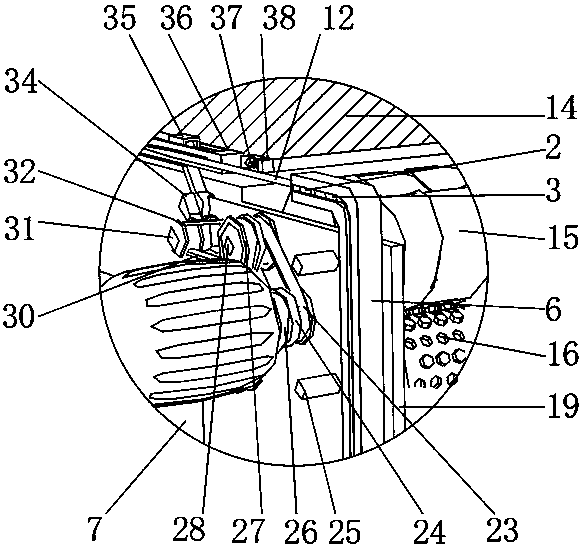

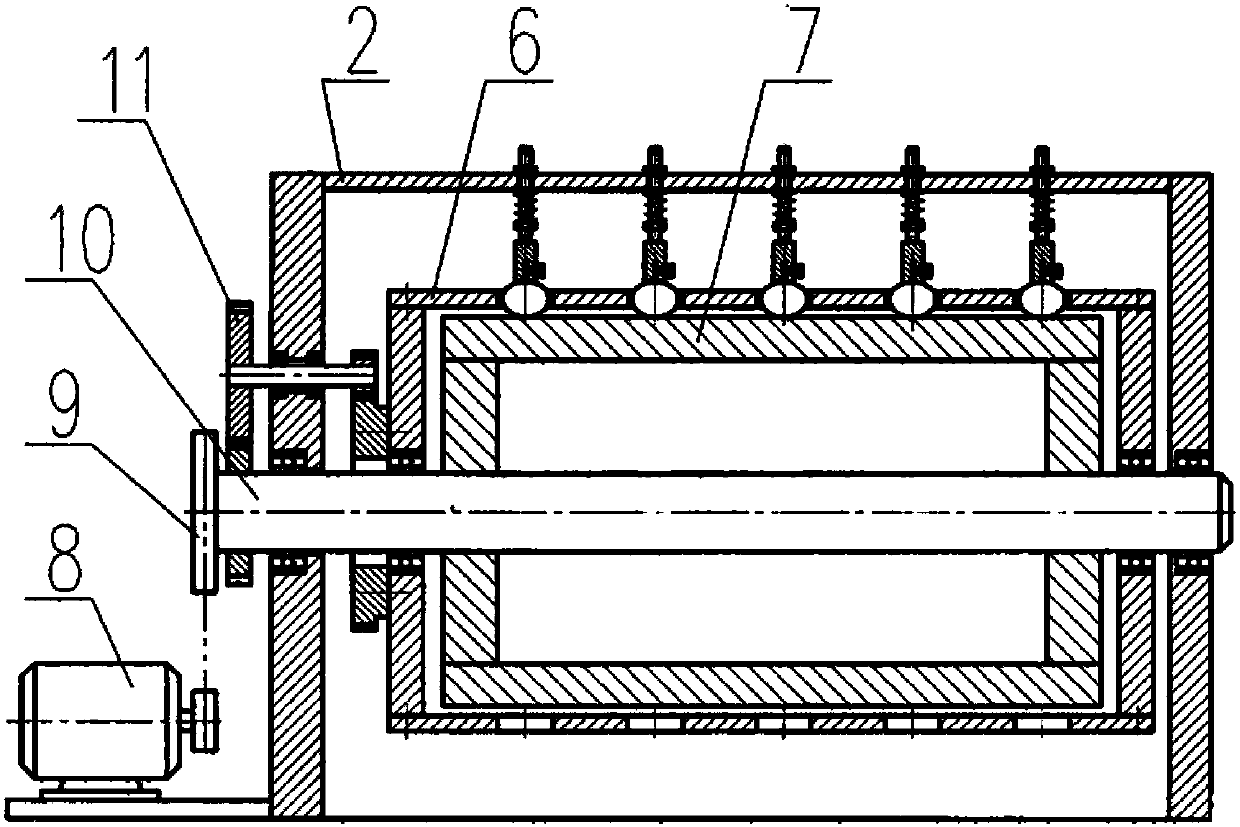

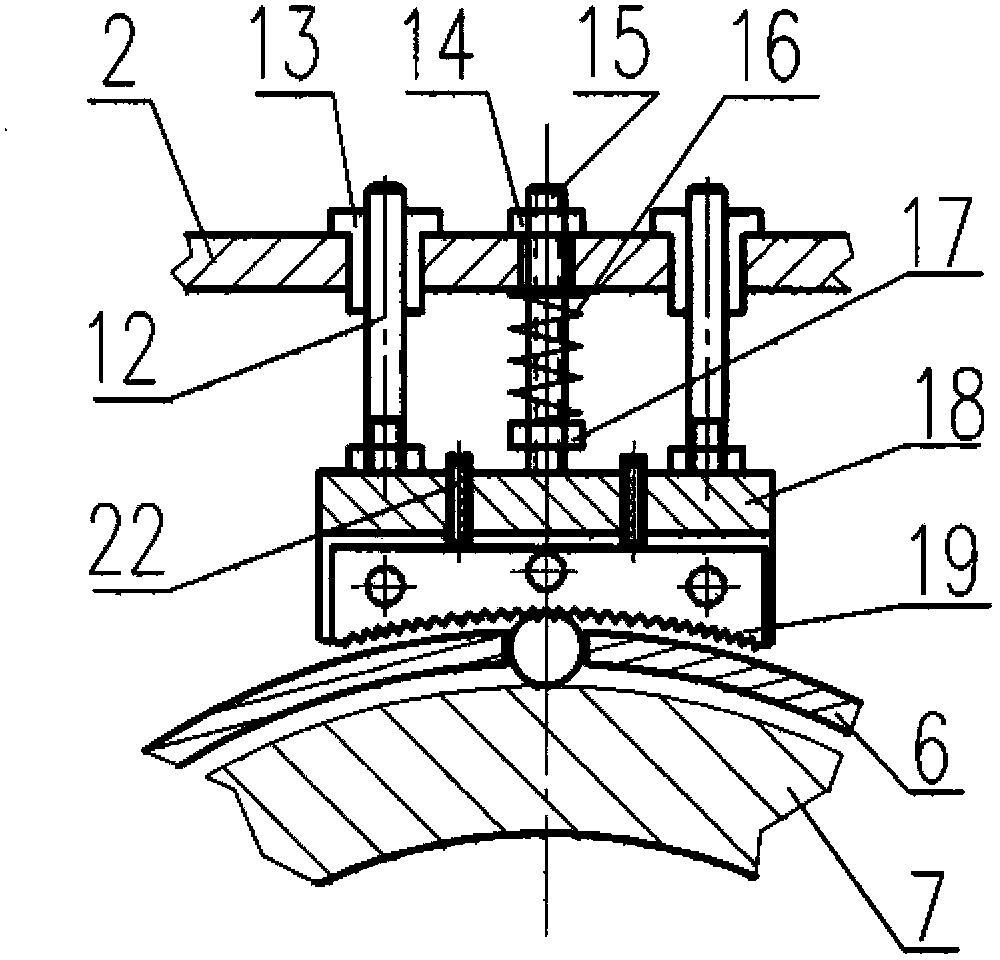

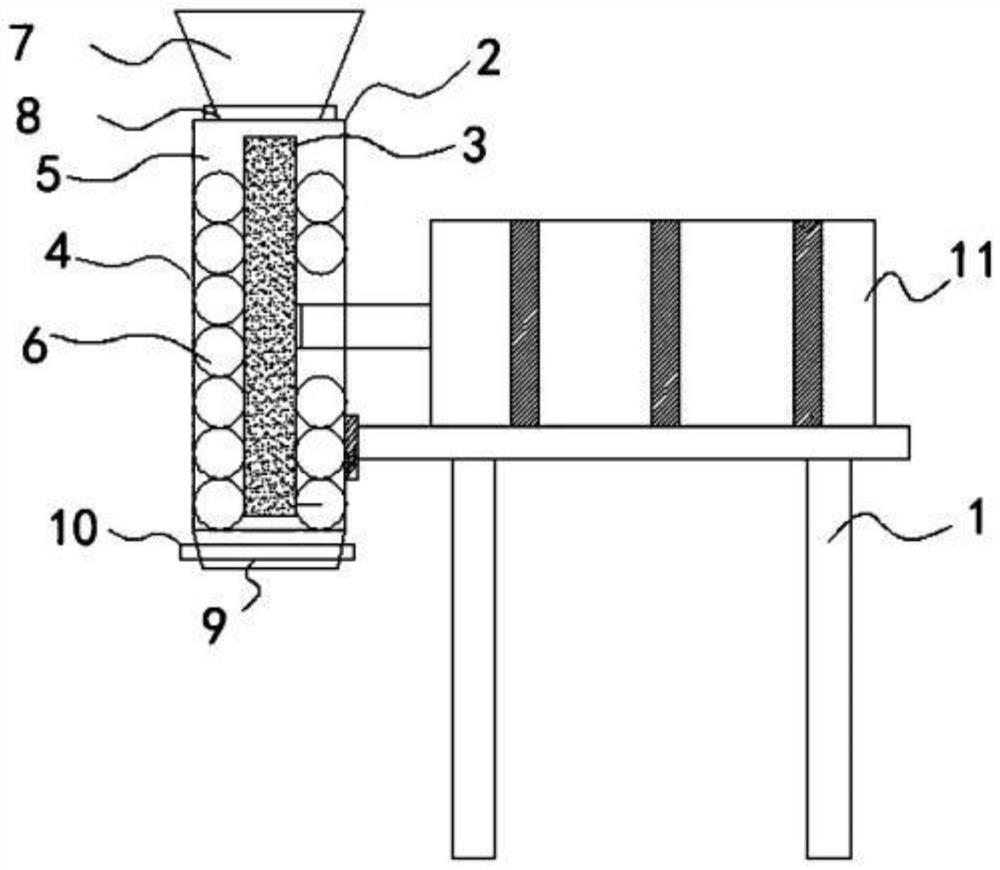

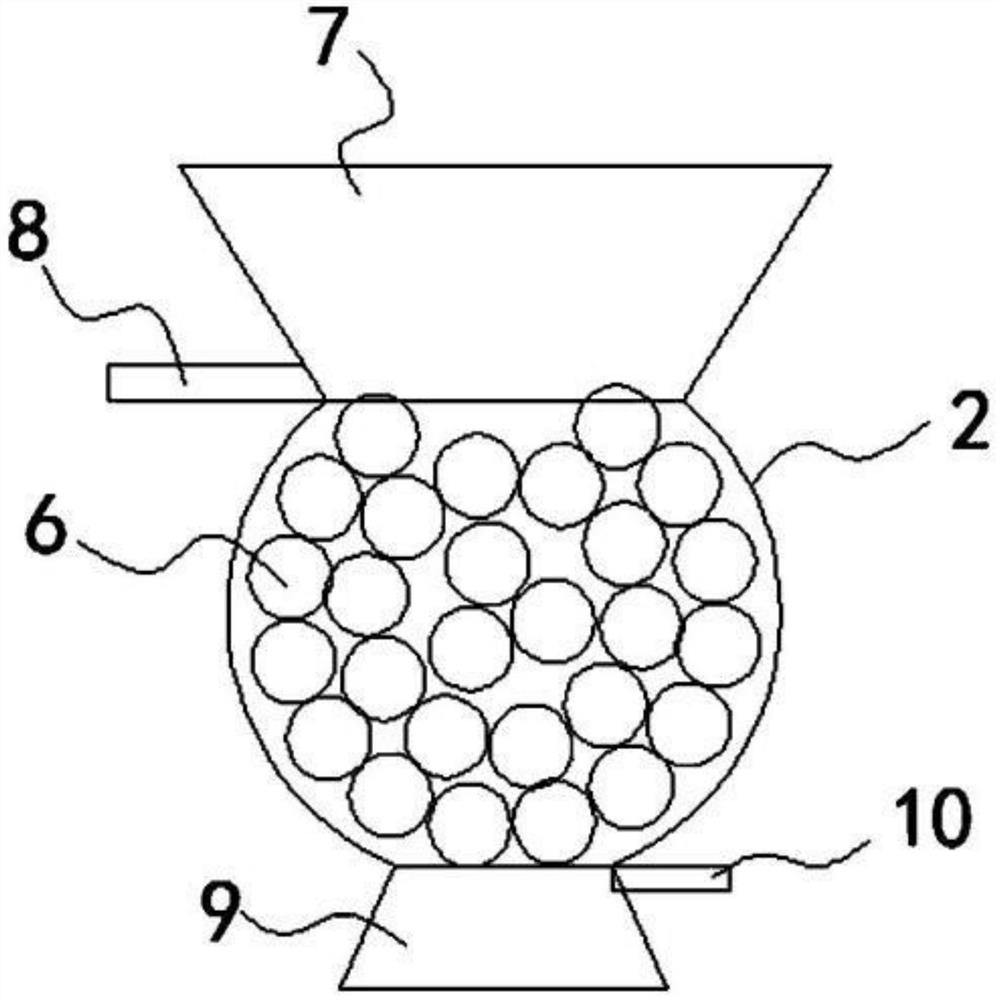

The invention discloses an auger-delivery walnut feeding grading device and shell-kernel separating system. A walnut auger delivery device, a circular grid grading device and a three-grade shell-kernel separating system are included. An auger delivery mechanism is arranged at the bottom of a V-shaped feeding hopper and penetrates through the V-shaped feeding hopper and the circular grid grading device; the posture of walnuts is adjusted by the auger delivery mechanism when the walnuts are delivered, thereby facilitating accurate grading of the circular grid grading device; after the walnuts are graded, the circular grid grading device also adjusts the walnut posture to prepare for shell breaking; and each grade of shell-kernel separating device of the three-grade shell-kernel separating system correspondingly separates walnut shells and kernels with varying degrees of sizes. According to the auger-delivery walnut feeding grading device and shell-kernel separating system, grading of thewalnuts with different sizes can be realized, the grading structure is simple, a walnut shell breaking device is cooperatively arranged on the shell-kernel separating system; and the three-stage shell-kernel separating devices correspondingly separate the walnut shells and kernels with different sizes, and the separating effect is good.

Owner:SOUTHWEST UNIVERSITY

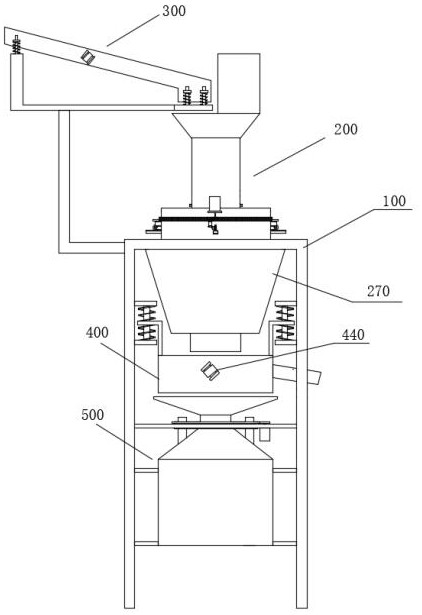

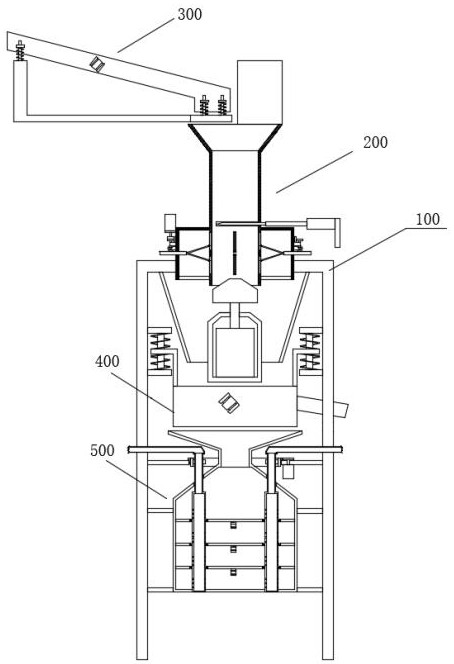

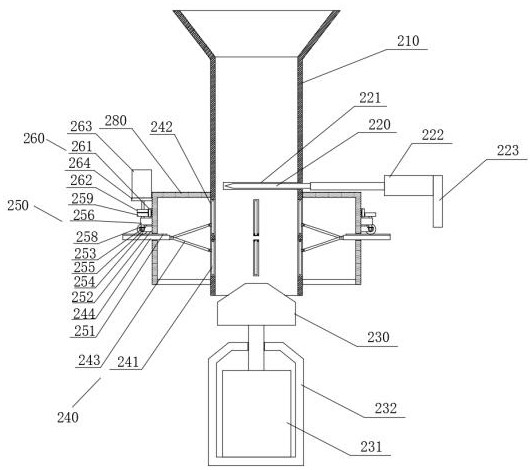

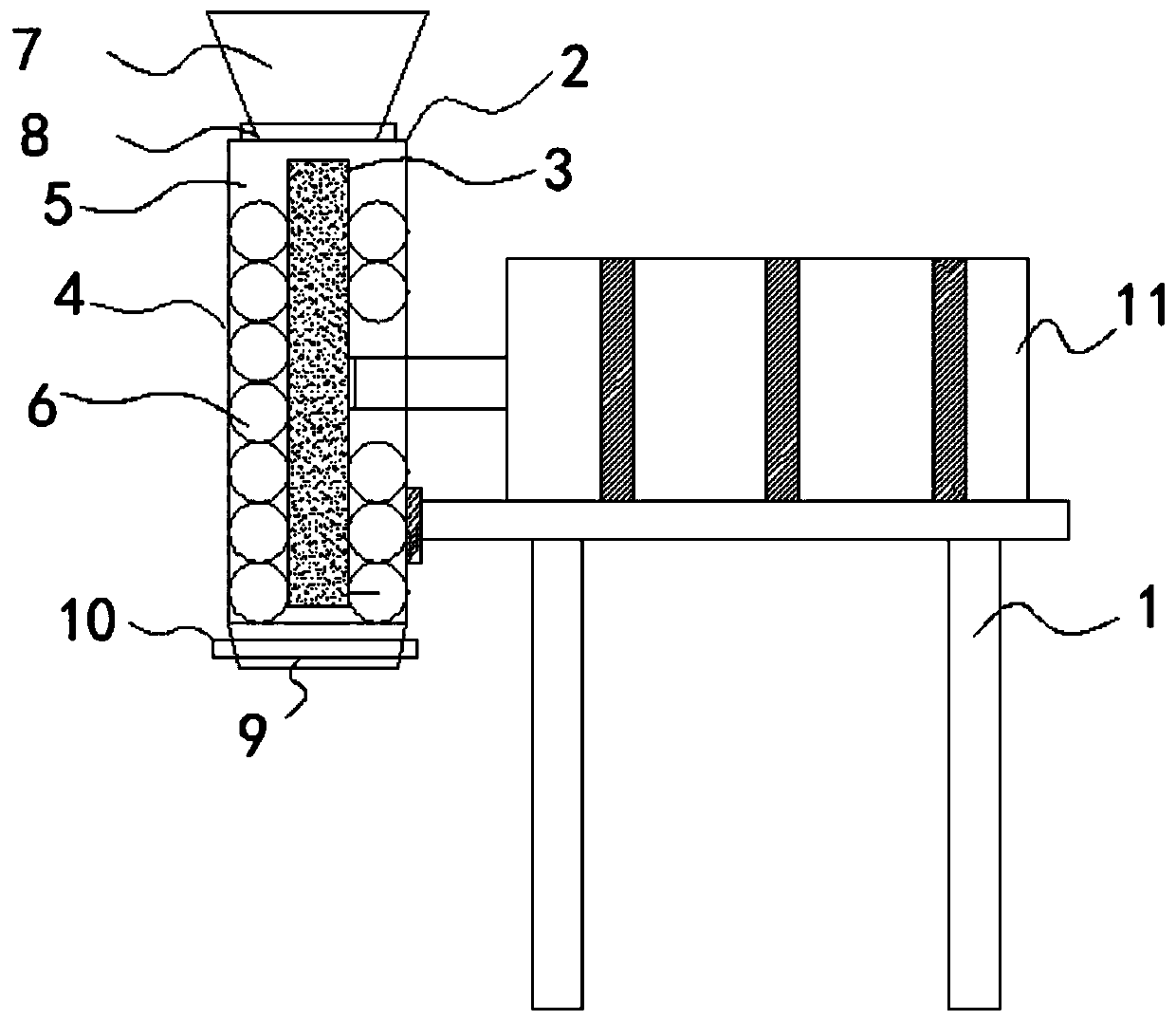

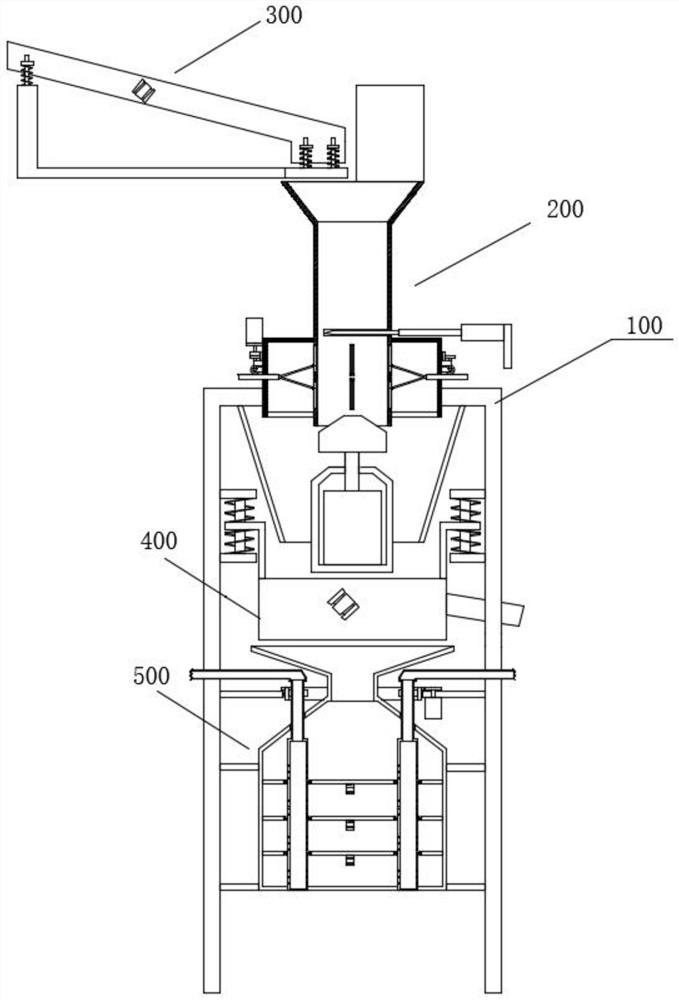

Shell breaking equipment capable of reducing surface damage of walnut kernels

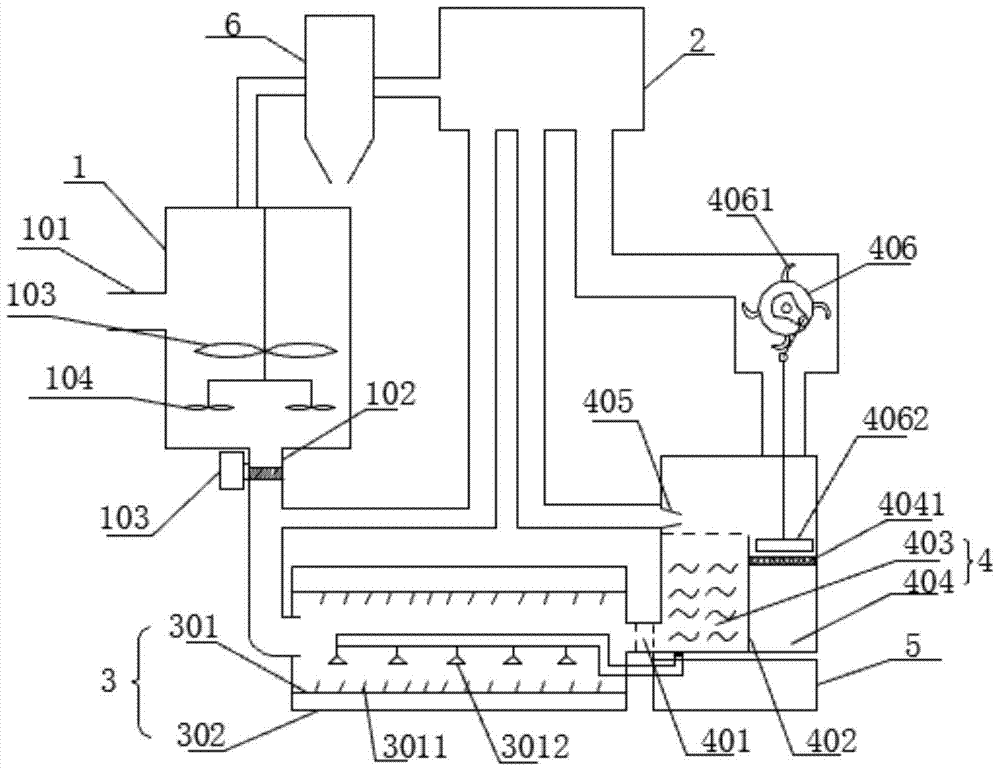

ActiveCN111990663AFully dryReduced shell toughnessSievingGas current separationWalnut NutEngineering

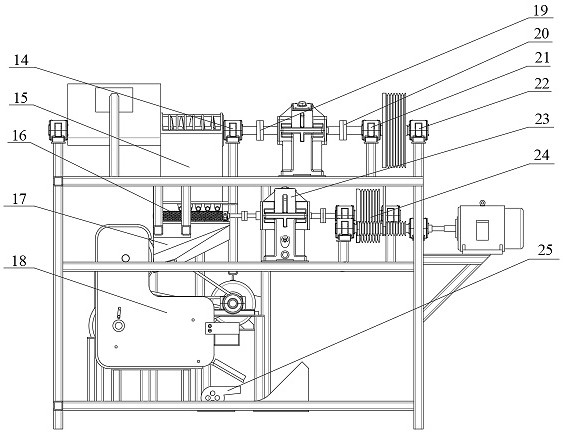

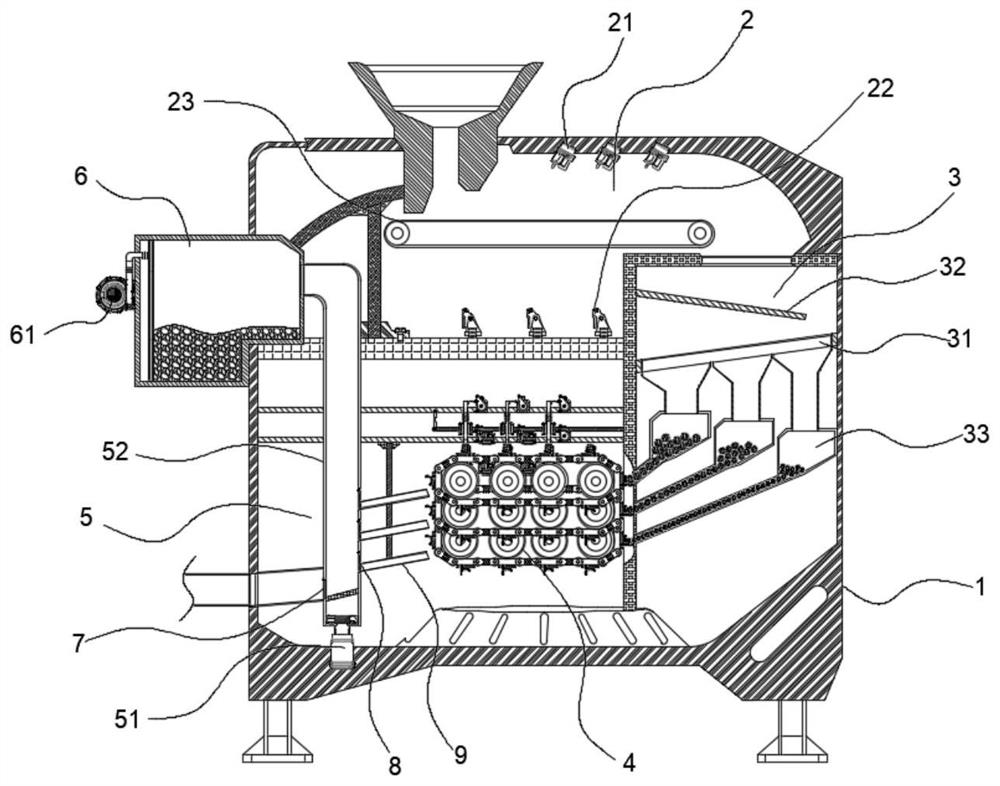

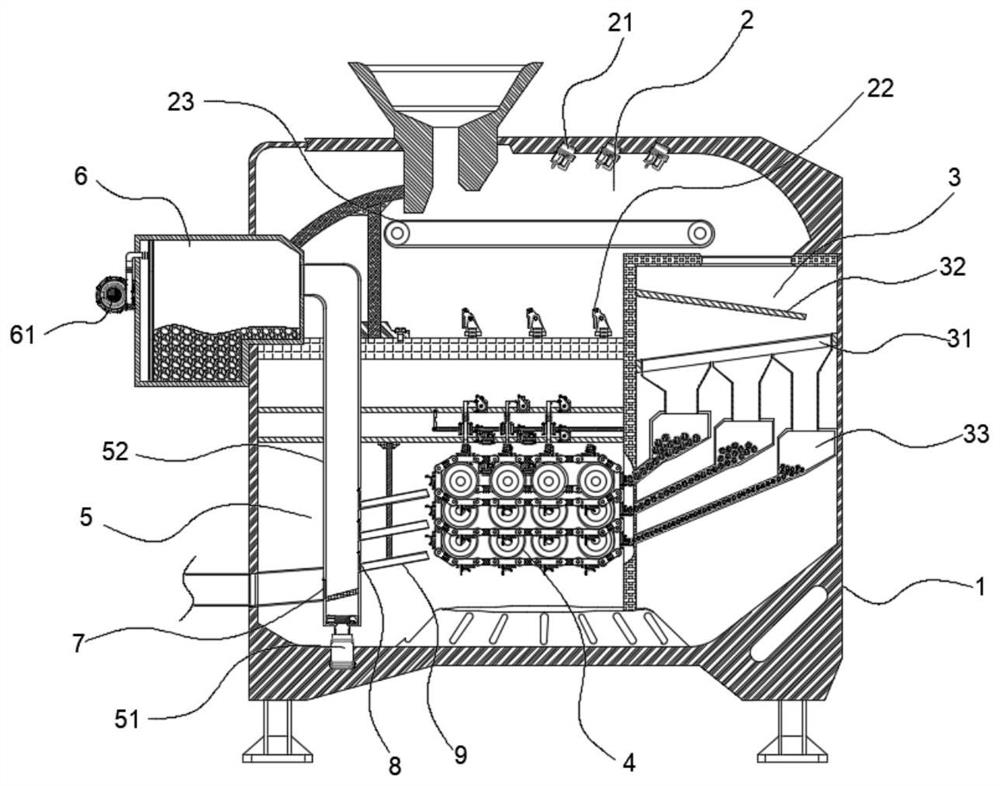

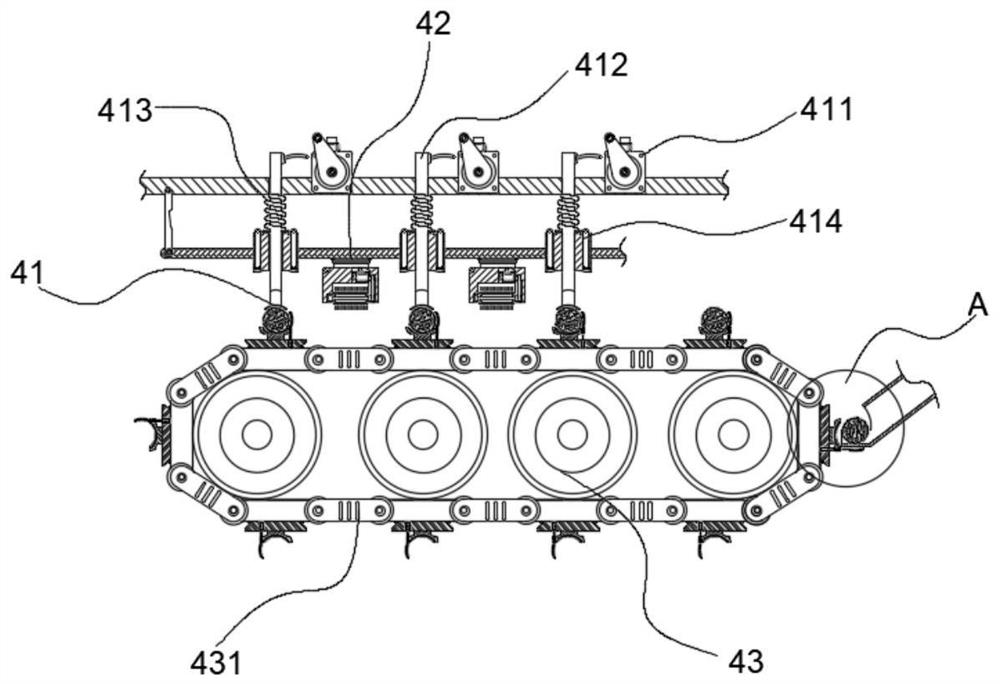

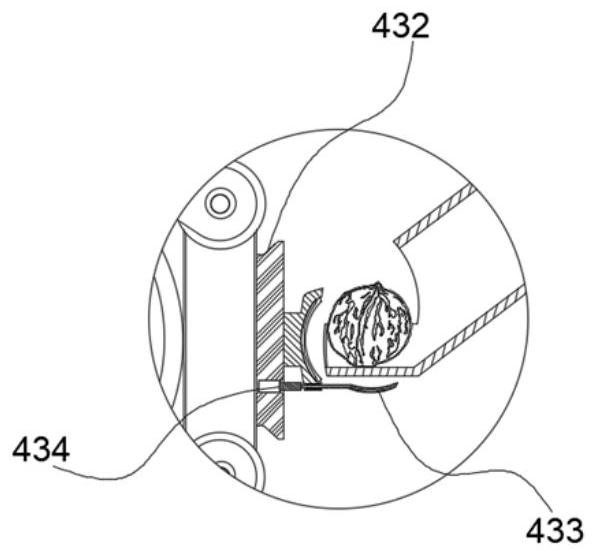

The invention discloses shell breaking equipment capable of reducing surface damage of walnut kernels. The shell breaking equipment comprises a machine shell, an air drying assembly, a grading assembly, shell breaking assemblies and a shell-kernel separating device, wherein a feeding hopper is mounted at the top end of the machine shell and is used for introducing walnuts to be subjected to shellbreaking into the equipment. The shell breaking equipment is characterized in that the air drying assembly is arranged at the upper end of the interior of the machine shell and is used for drying thewalnuts to be subjected to shell breaking, so that the dried walnuts enter the grading assembly; the grading assembly is arranged at the right end of the interior of the machine shell, and a grading chamber is formed by the grading assembly and the inner wall of the right side of the machine shell and is used for grading the walnuts according to the size; the multiple shell breaking assemblies aremounted in the machine shell, respectively communicate with the grading assembly and are used for breaking the shells of the walnuts; and the shell-kernel separating device is further arranged on theleft side of the interior of the machine shell and is used for separating the shells and the kernels of the walnuts subjected to shell breaking, so that the relatively complete walnut kernels are collected.

Owner:TARIM UNIV

Nut shell crusher

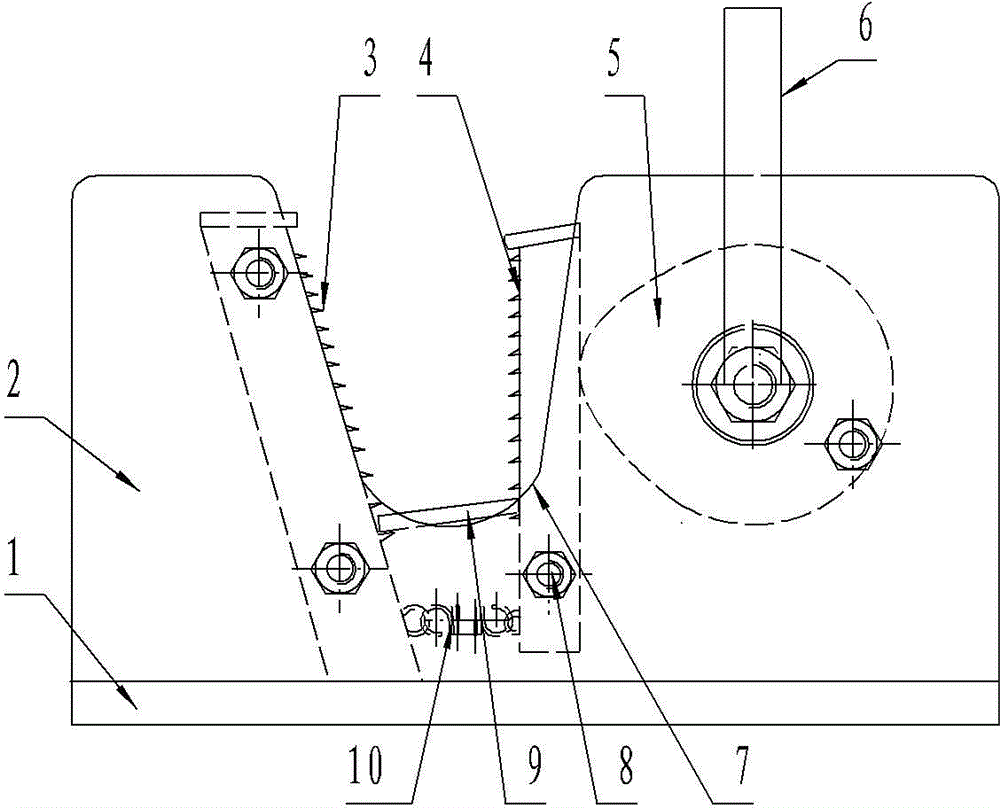

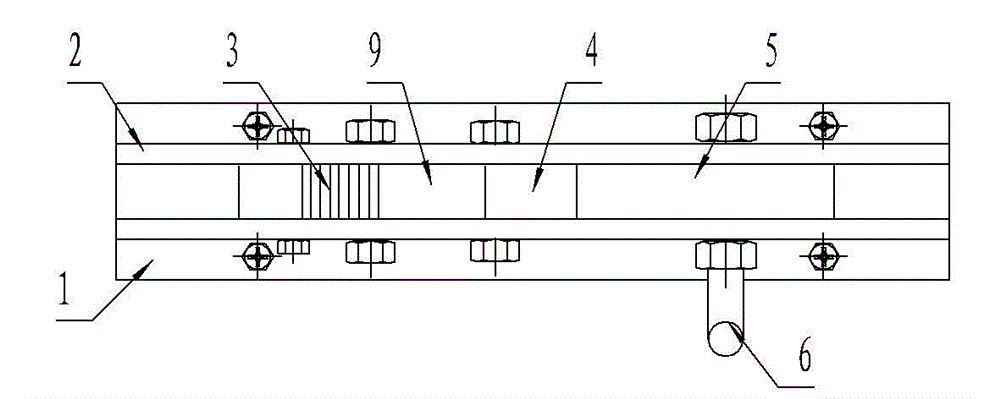

The invention discloses a nut shell crusher. The nut shell crusher comprises two clamping plates vertically mounted on a base, wherein the two clamping plates are correspondingly provided with grooves for clamping nuts, two toothed spina plates are arranged on two sides of the grooves between the two clamping plates, two toothed surfaces of the two spina plates are oppositely arranged, one spina plate is hinged to the clamping plates and connected with the other spina plate through a spring under a hinge position, an eccentric wheel is arranged at the position behind one of the spina plates between the clamping plates, and the eccentric wheel is connected with a handle. Compared with the prior art, the nut shell crusher disclosed by the invention can solve the problems of high difficulty and low efficiency during crushing macadimia nuts.

Owner:CENXI XINFENG AGRI COMPREHENSIVE DEV CO LTD

Automatic walnut sheller and shelling process

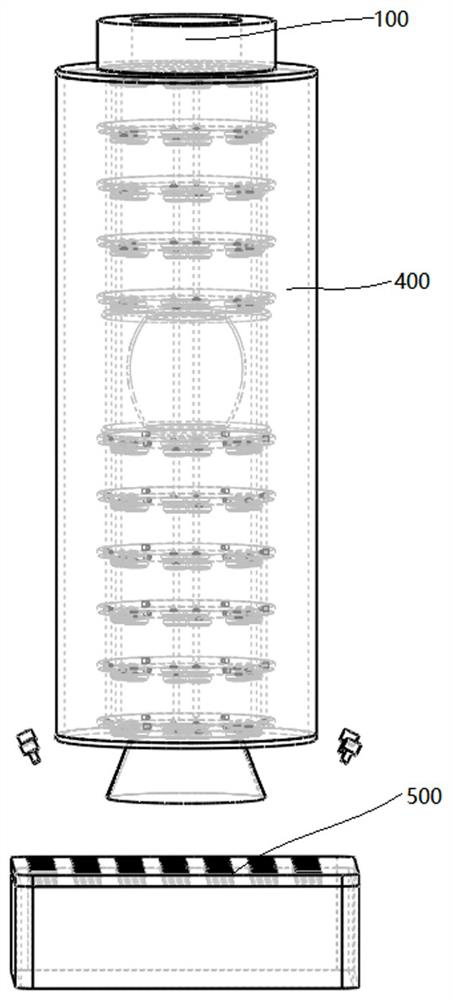

The invention discloses an automatic walnut sheller and a shelling process. The sheller comprises a storage barrel, a walnut sorting mechanism, a walnut peel grinding mechanism, a conveying mechanism and an extrusion shell breaking mechanism which are sequentially arranged in the walnut advancing direction. A first discharging pipe is arranged on the material storage barrel, a sorting feeding port and a plurality of second discharging pipes are arranged on the walnut sorting mechanism, a plurality of feeding areas and a plurality of peel grinding discharging ports are arranged on the walnut peel grinding mechanism, and a conveying feeding port and a conveying discharging port are formed in the conveying mechanism. The extrusion shell breaking mechanism is provided with a shell breaking feeding port and a collecting box, the first discharging pipe is communicated with a sorting feeding port of the walnut sorting mechanism, the second discharging pipes are arranged above a corresponding feeding area, the peel grinding discharging port is arranged above a conveying feeding port of the conveying mechanism, and a conveying discharging port of the conveying mechanism is arranged above the shell breaking feeding port. After the shell of a walnut is broken by the sheller, the integrity of the walnut kernel is high.

Owner:HEBEI YANGYUAN ZHIHUI BEVERAGE

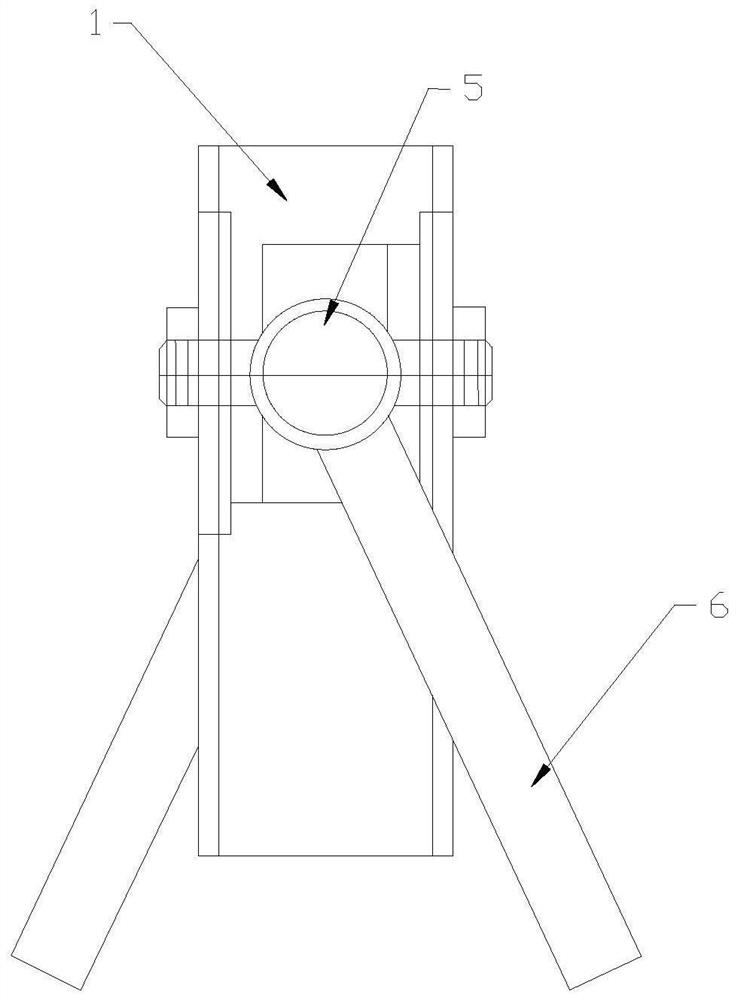

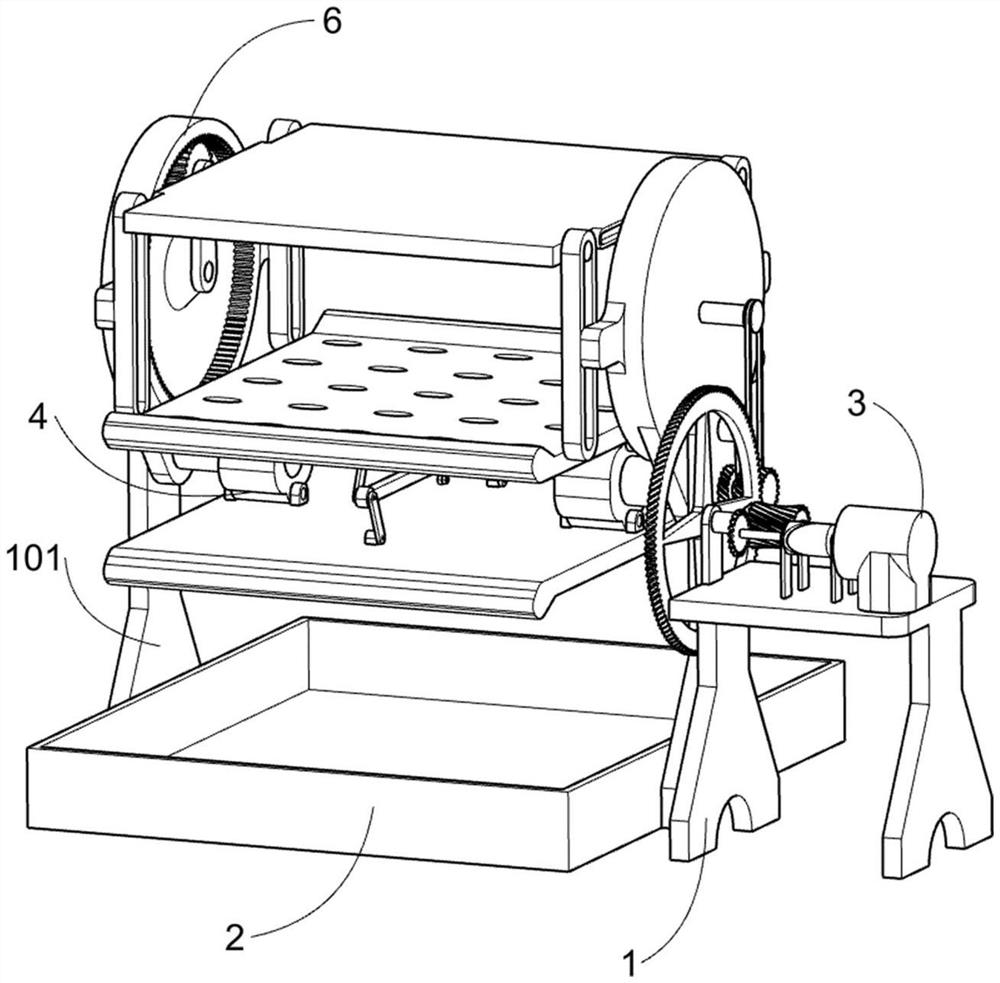

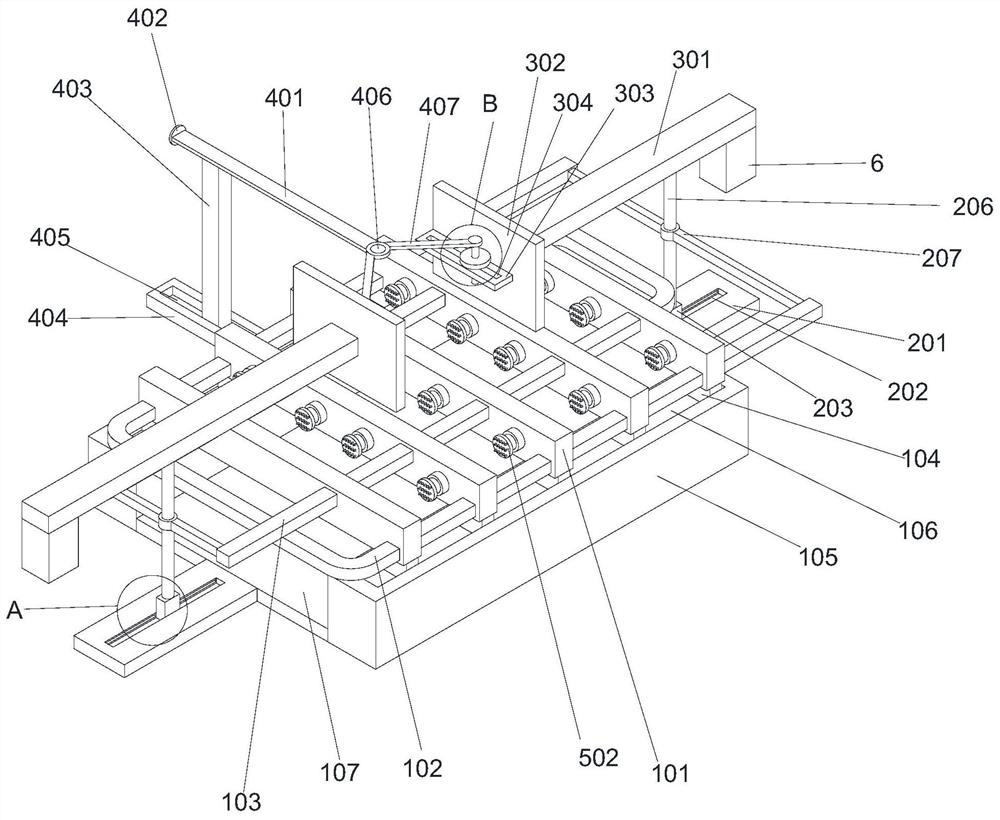

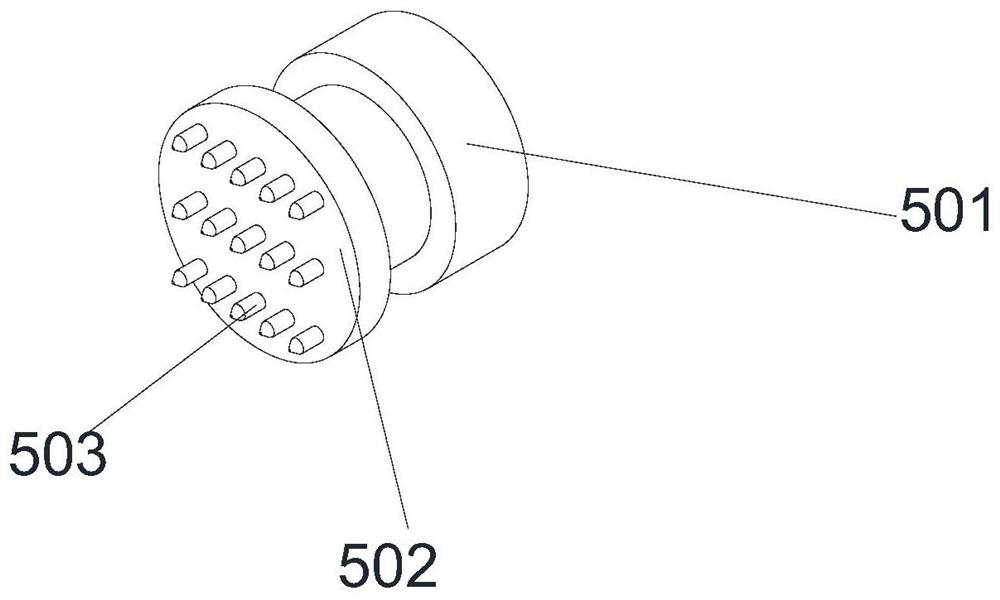

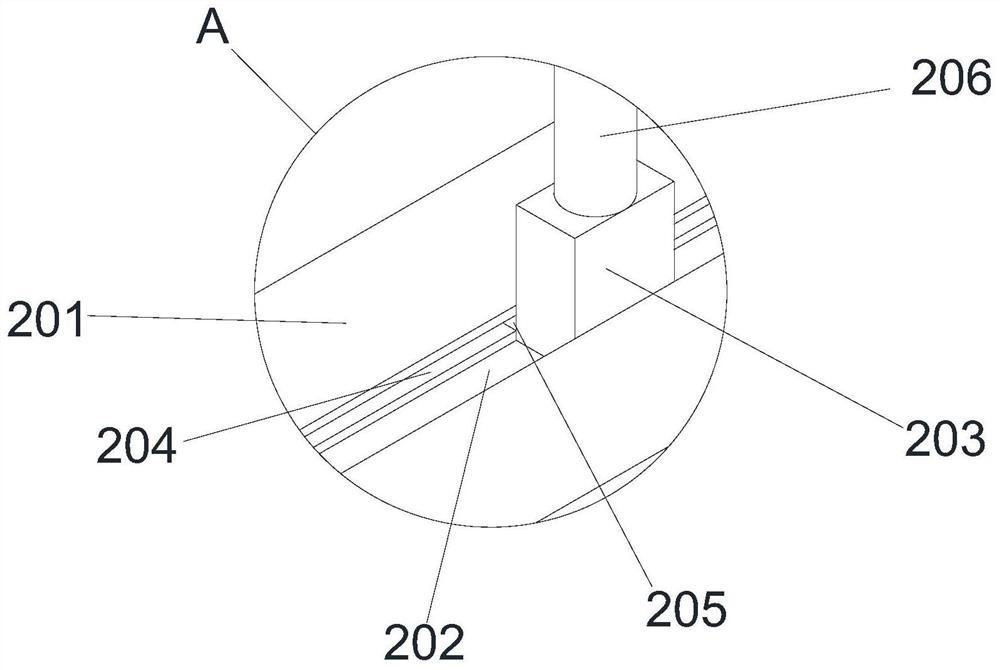

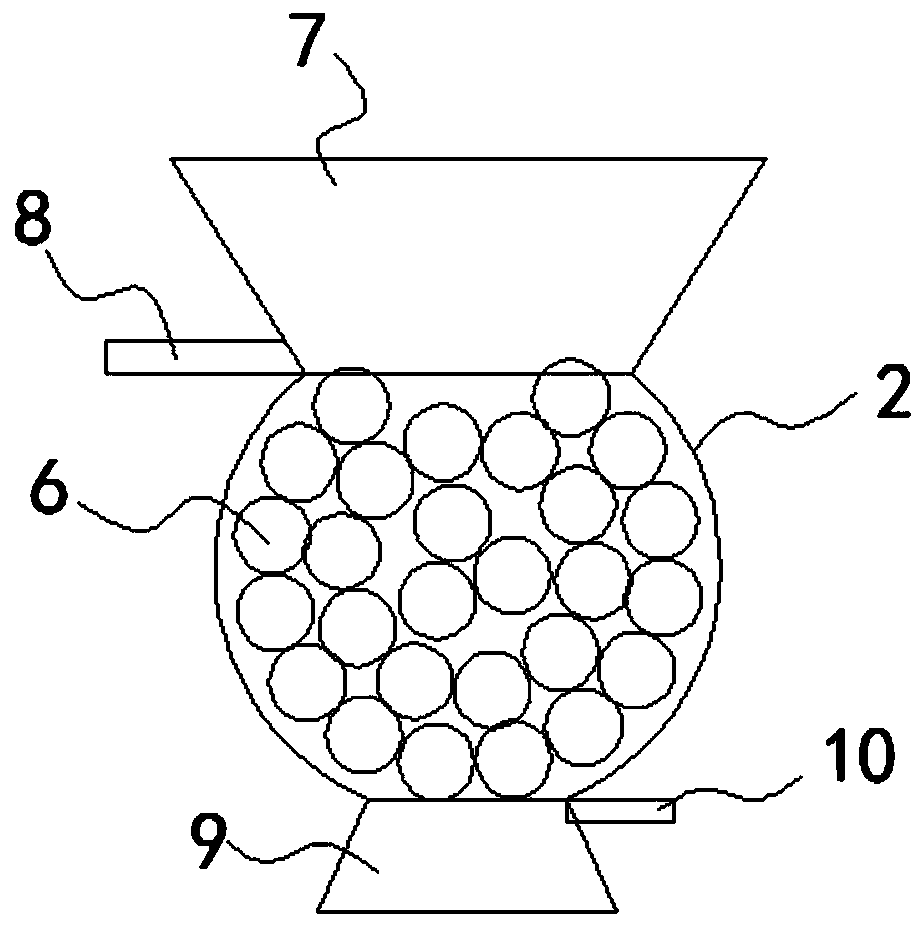

Drive plate-type gorgon fruit extruding and shell-breaking device

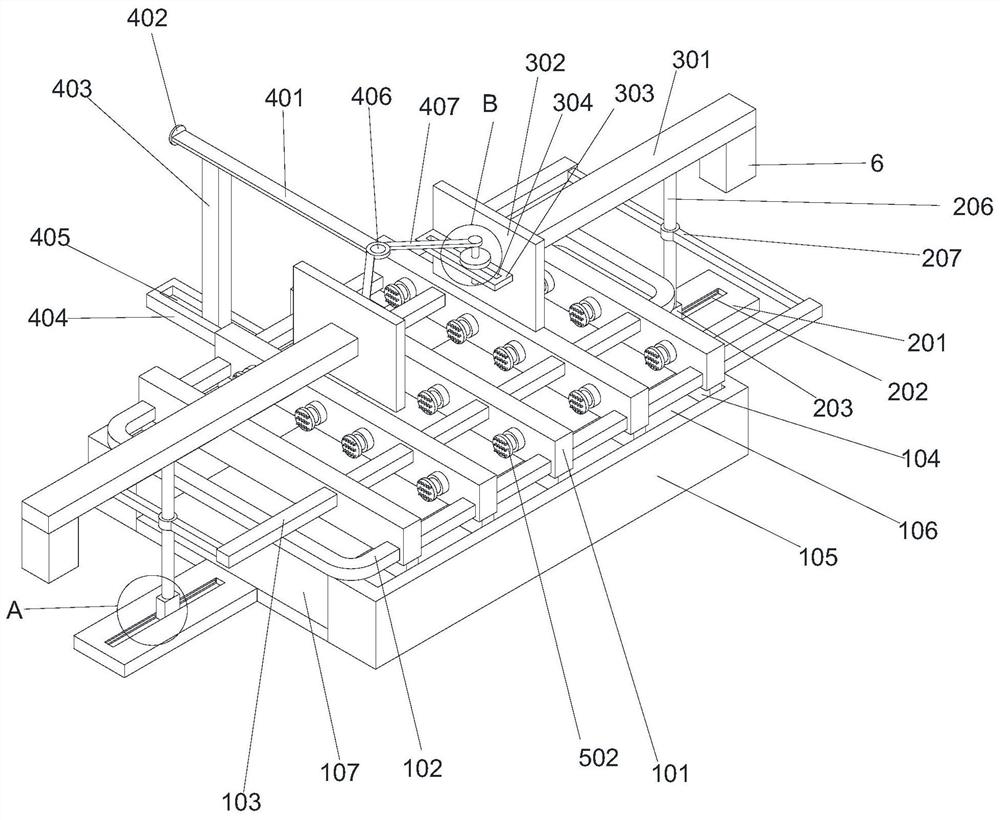

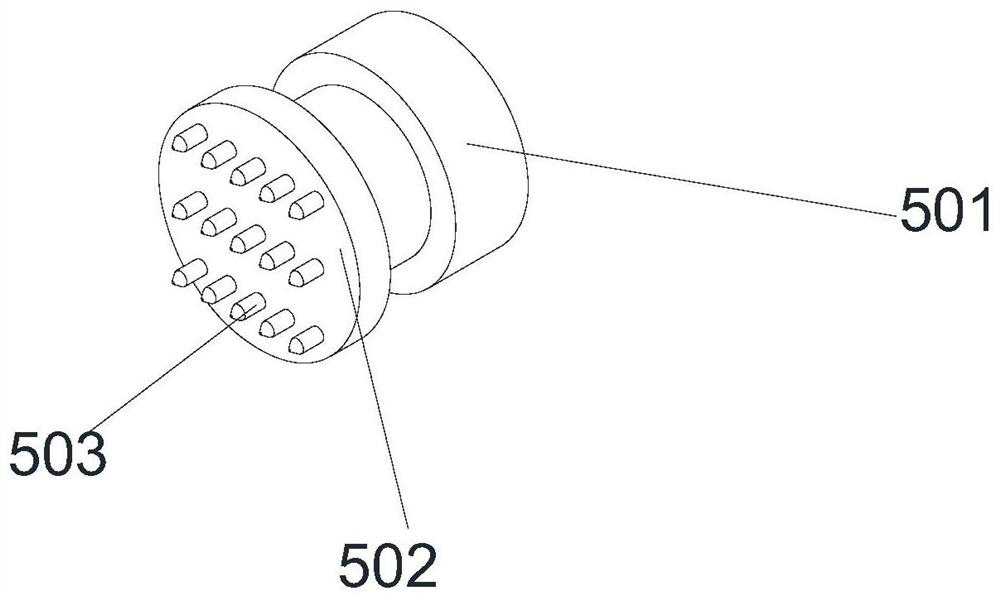

ActiveCN111011880AGuaranteed smoothImprove the efficiency of breaking upHuskingHullingEngineeringMechanical engineering

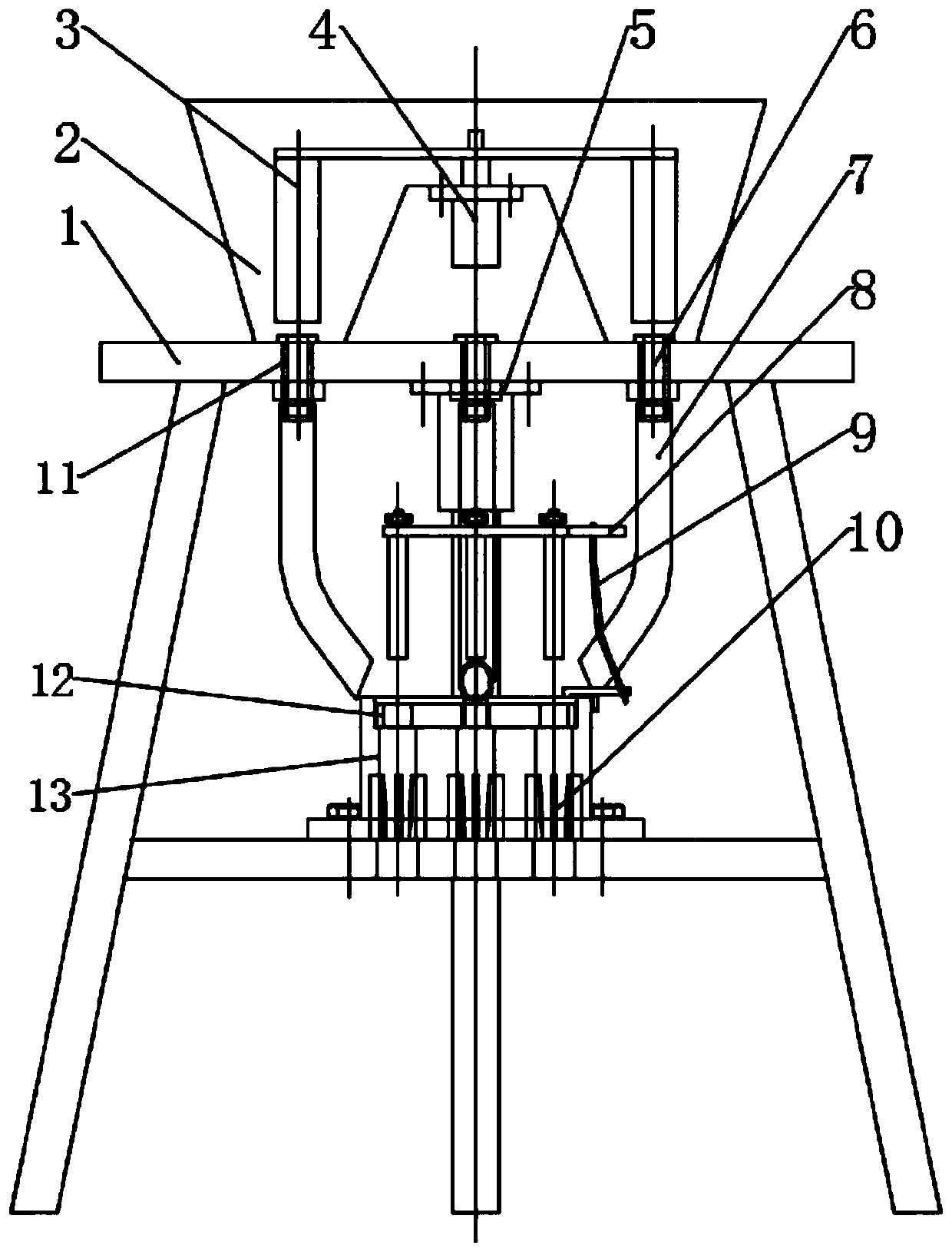

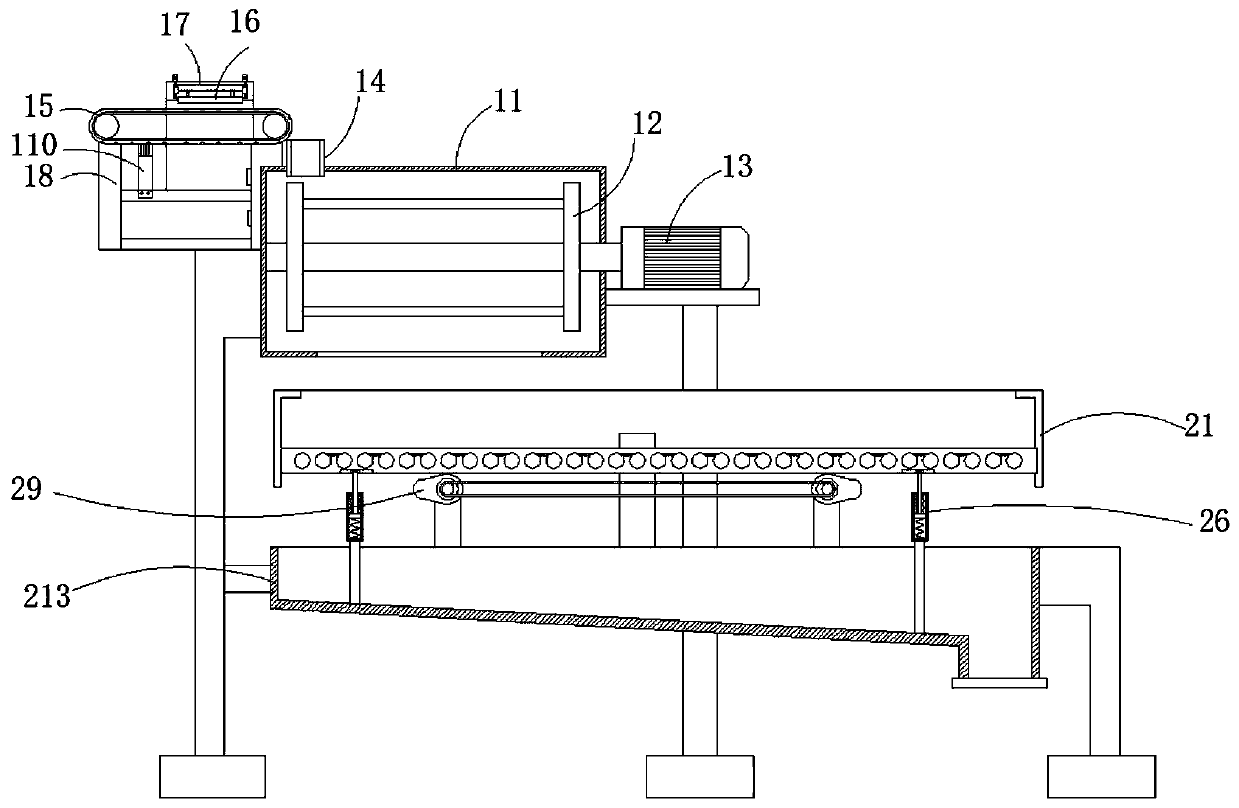

The invention provides a drive plate-type gorgon fruit extruding and shell-breaking device, which comprises a base, a feeding mechanism is arranged on the base, the bottom of the feeding mechanism isfixedly connected to a platform at the upper end of the base, a plurality of first through holes are formed in the platform at the upper end of the base, a seed extractor is arranged in the pluralityof first through holes, the seed extractor is communicated with a seed extracting pipe, the seed extracting pipe is communicated with a shell breaker, an extruder is arranged above the shell breaker,the upper end of the extruder is fixedly connected with an electric cylinder, and the electric cylinder is fixedly connected to the bottom surface of the platform at the upper end of the base; the shell breaker comprises a mounting table, a driving plate, a rotating plate and a plurality of shell-breaking knives, the extruder comprises a plurality of extrusion rods, a mounting plate and a supporting plate, the extrusion rods are fixedly connected to the mounting plate, the supporting plate is fixedly connected to the right side face of the mounting plate, and the extrusion rods and the shell breaking knives are arranged in an up-down corresponding mode; and a driving lever is connected between the supporting plate and the rotating plate. The gorgon fruit extruding and shell-breaking deviceis used for solving the problems that manual husking efficiency is low, the amount of labor used is large, an existing gorgon fruit seed husking machine is low in husking efficiency and not high in husking quality, and the gorgon fruit seed crushing and damage rate is high.

Owner:CHUZHOU UNIV

Goose egg incubation method

InactiveCN106852296AEasy to break the shellImprove hatchabilityTesting eggsAnimal husbandryObserved SurvivalEgg incubation

The invention discloses a goose egg incubation method. The method includes the following steps of 1, making earlier-stage preparation, wherein an incubation room needs to be cleaned and disinfected before being used, and an incubator is comprehensively inspected before incubation starts; 2, feeding breeding eggs into the incubator, wherein the breeding eggs are preheated before being incubated, the breeding eggs are placed in the incubation room for 4-6 h, the temperature is controlled to be 22-25 DEG C, and incubation starts after 4:00 p.m.; 3, candling the eggs, wherein the eggs are candled for the first time after being incubated for one week, infertile eggs and addle eggs are removed, the eggs are candled once every 10 days afterwards, and the eggs are candled three times in total; 4, cooling the eggs and spraying water, wherein after the eggs are incubated for 17-19 days, a box cover is opened to cool the eggs once every day, 25 days later, the eggs are cooled 3-4 times every day, and meanwhile after the eggs are incubated for 19 days, it is needed to spray water to the breeding eggs 1-3 times every day; 5, conducting hatching, wherein bamboo baskets are prepared in advance, grass is laid in the bamboo baskets, and goslings are collected once every 3-4 h. By means of the method, the incubation efficiency can be improved, and the survival rate is high.

Owner:刘同明

Laminating and horizontally-spreading type hatching method for swan geese

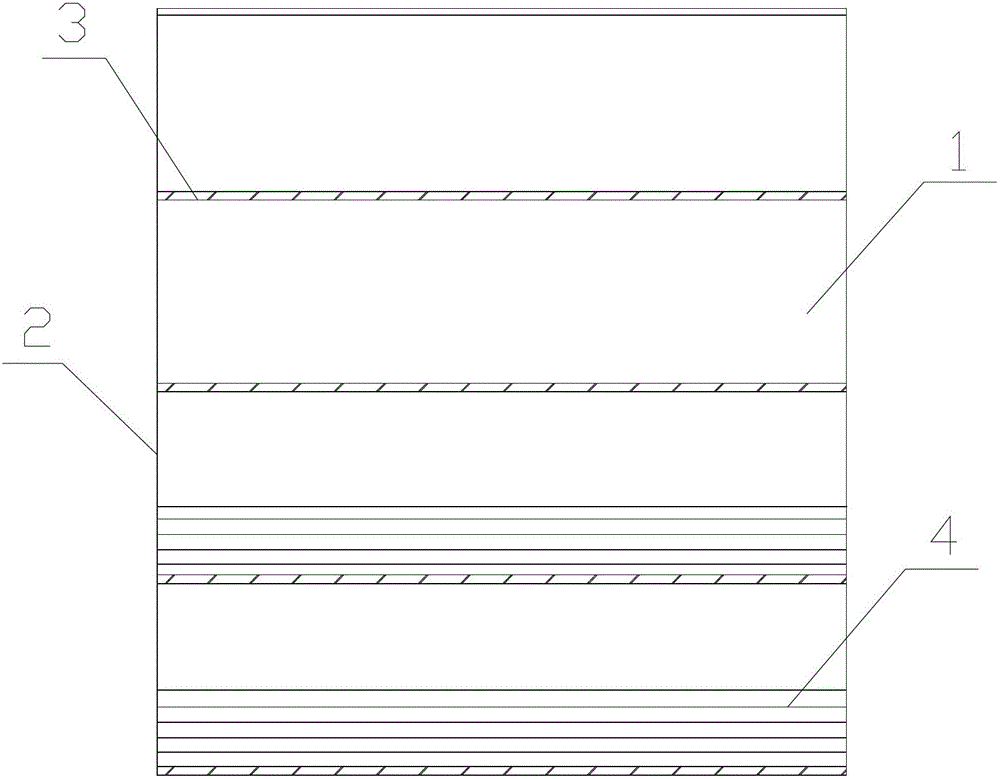

The invention discloses a laminating and horizontally-spreading type hatching method for swan geese, and relates to the technical field of cultivation. Firstly, square pipes of 4 cm * 6 cm are welded or punched through screws, so that a framework with the height of 1.8 m, the width of 2 m and the length of 4 m is formed; secondly, square pipes of 4 cm * 6 cm are used for encircling the framework from top to bottom at intervals of 50 cm, the framework is welded into four layers, then each layer of the frame is tiled with a wooden plate, each wooden plate is tiled with a rush straw mat, small square pipes are welded all around in positions which are 20 cm higher than edges of two layers below the framework, so that guardrails are formed; manual heating is adopted, so that the indoor temperature is raised to 28-32 DEG C, hatching eggs fertilized for 18-20 days are transferred onto a horizontally-spreading frame from an incubator, two layers of hatching eggs are placed along the peripheries of two layers above the horizontally-spreading frame, a layer of eggs is placed in the middle, and then the hatching eggs are covered with floss silk quilts or common quilts; cold boiled water spraying and egg airing are performed, particularly, the water is sprayed six times every day, and the hatching eggs are transferred to the lower two layers of the horizontally-spreading frame after the water is prayed continuously for 5-6 days; and the eggs are observed for 1-2 days, water spraying and egg airing is stopped when shells are pecked, the room temperature is maintained to be in a range from 35 DEG C to 38 DEG C, and the swan geese are waited to be hatched naturally. The method effectively improves the hatchability and saves energy, and compared with the original hatchability, the hatchability is improved to about 90%.

Owner:固镇县淮鸿灰天鹅养殖专业合作社

Camellia oleifera shell breaking and separating equipment

ActiveCN111202251AHigh breaking efficiencyGood applicabilitySievingScreeningKnife bladesCamellia oleifera

The invention discloses camellia oleifera shell breaking and separating equipment. The camellia oleifera shell breaking and separating equipment comprises a shell breaking part and a shell separatingpart, wherein the shell separating part is located at the downstream of the shell breaking part; and the discharging end of the shell separating part corresponds with the feeding end of the shell breaking part. According to the camellia oleifera shell breaking and separating equipment disclosed by the invention, a scratching assembly is arranged at a feeding opening of a shell breaking cavity, andis used for scratching crusts of camellia oleifera fruits, subsequent shell breaking of the camellia oleifera fruits is facilitated, and the shell breaking efficiency is high; the height of a knife blade for scratching can be regulated, and the knife blade can be used for scratching the shells of the camellia oleifera fruits of different diameters, so that the applicability is good; and in the shell separating part, separating rollers on a separating bottom disk relatively rotate to pull the shells towards the lower part of the separating bottom disk, so that the separation of fruits from theshells is realized, the structure is simple, and the function is practical; and the separating bottom disk can swing in a left and right manner, and is used for redistributing the positions of the fruits and the shells on the separating bottom disk to prevent the fruits from staying at the bottom of a material tank, and continuous separation of the shells from the shells is facilitated.

Owner:湖南省海华农业综合开发有限公司

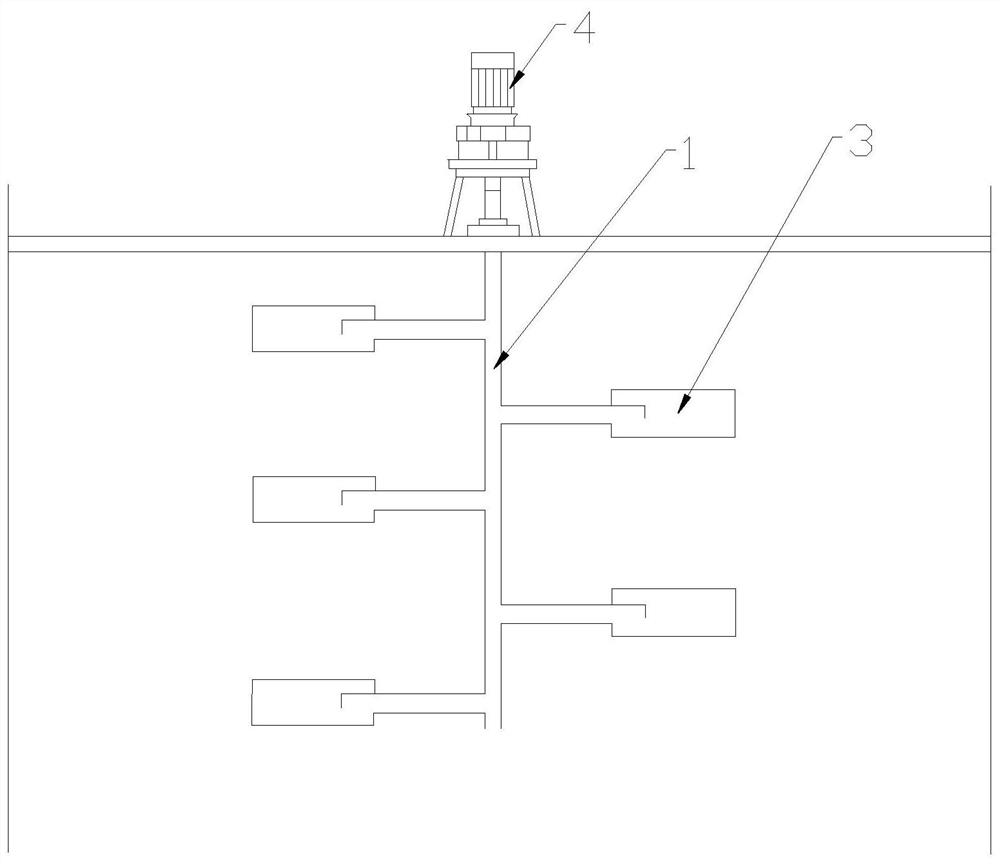

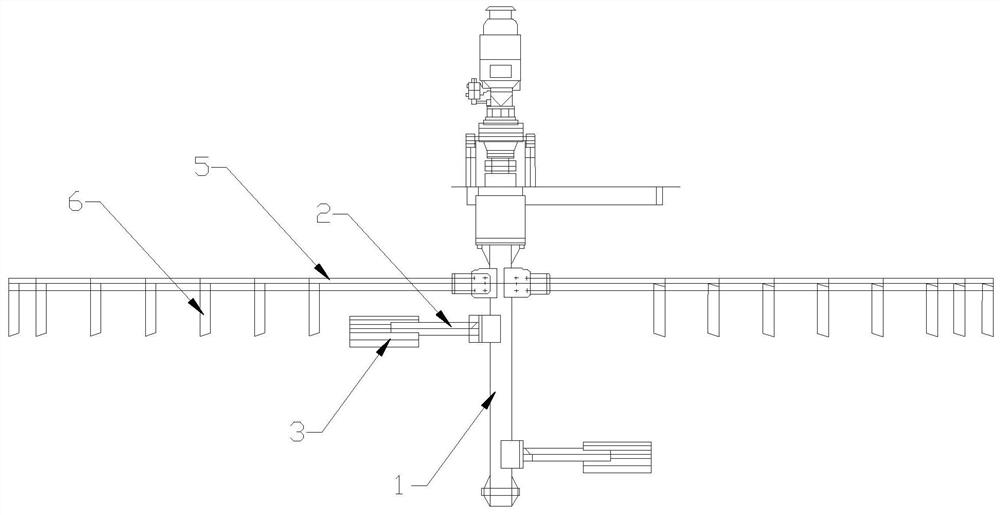

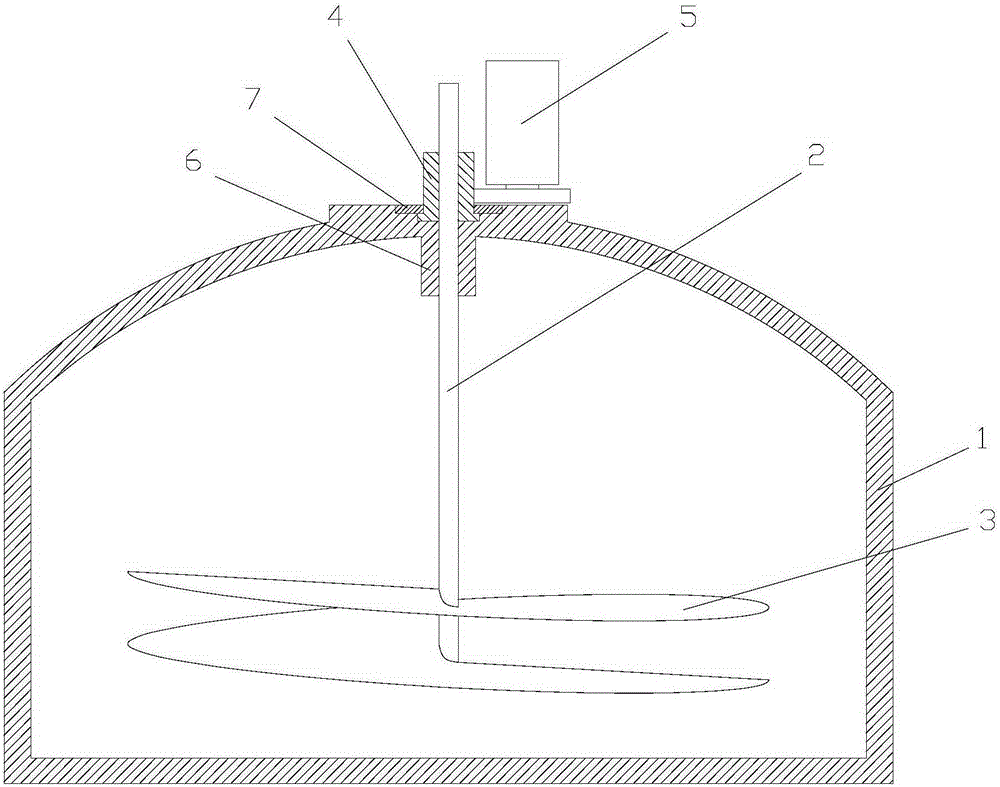

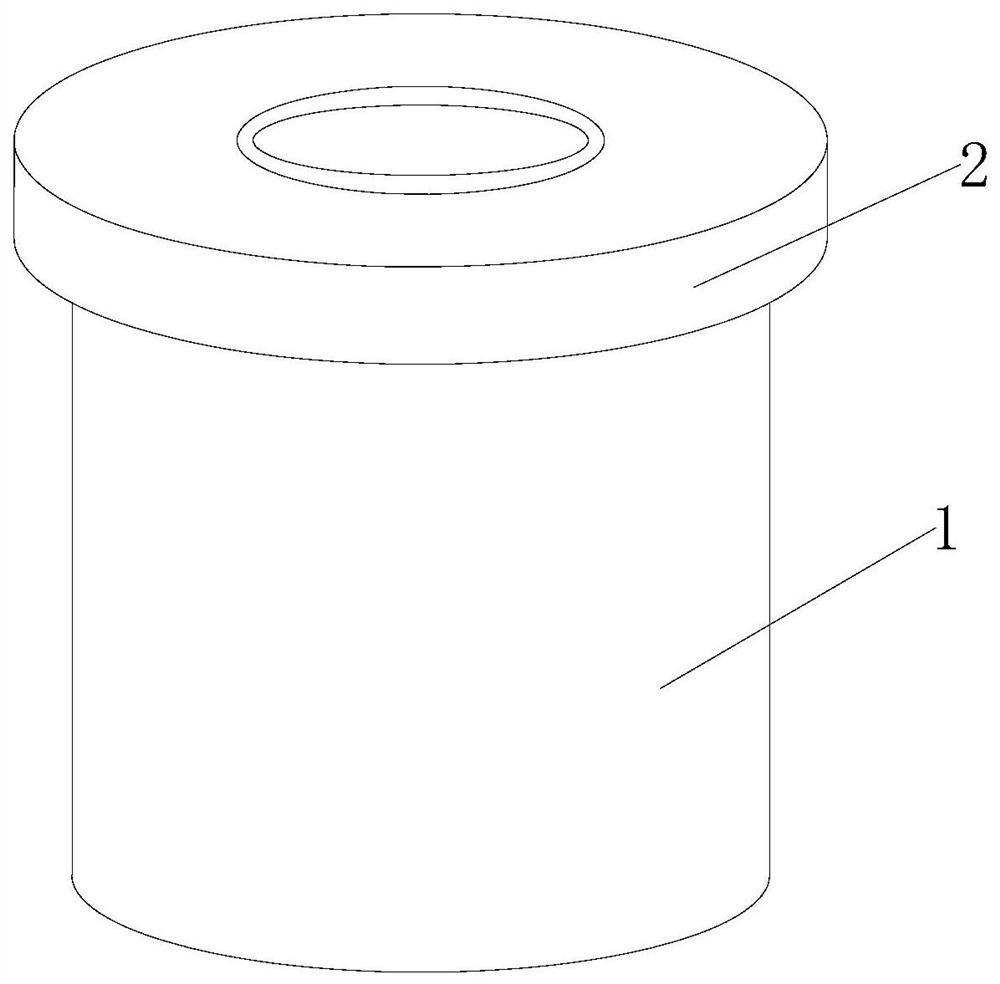

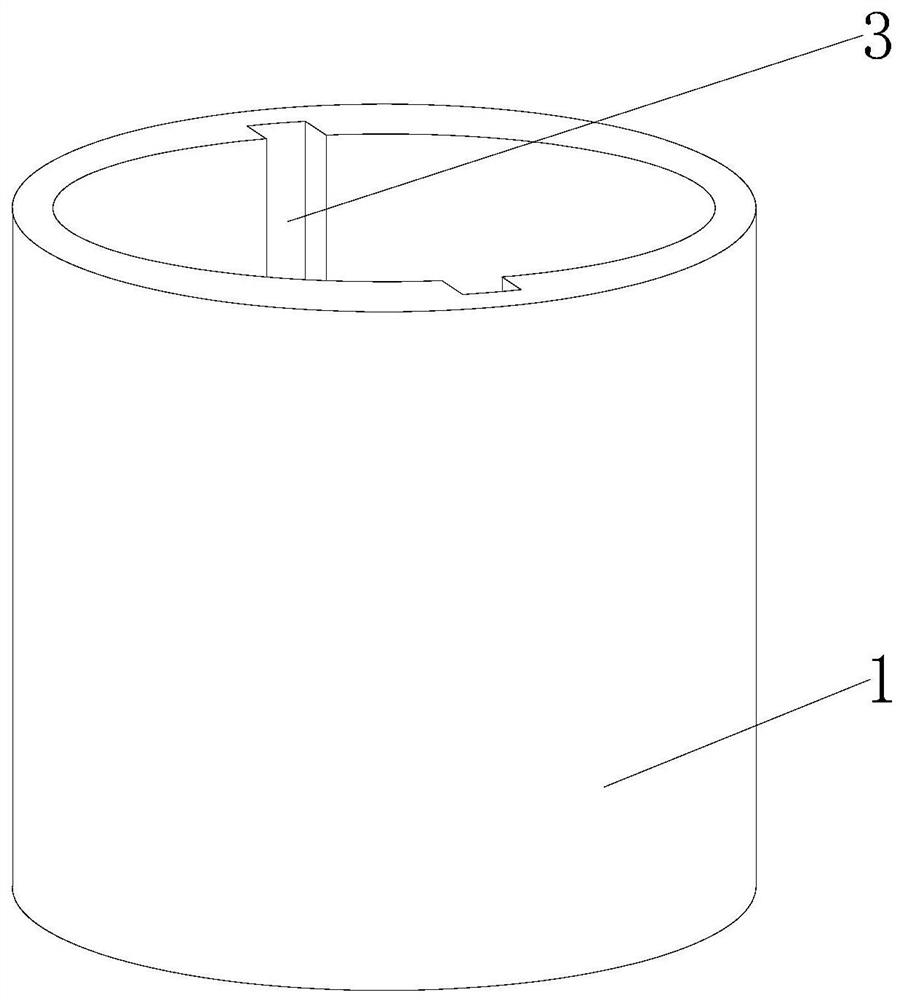

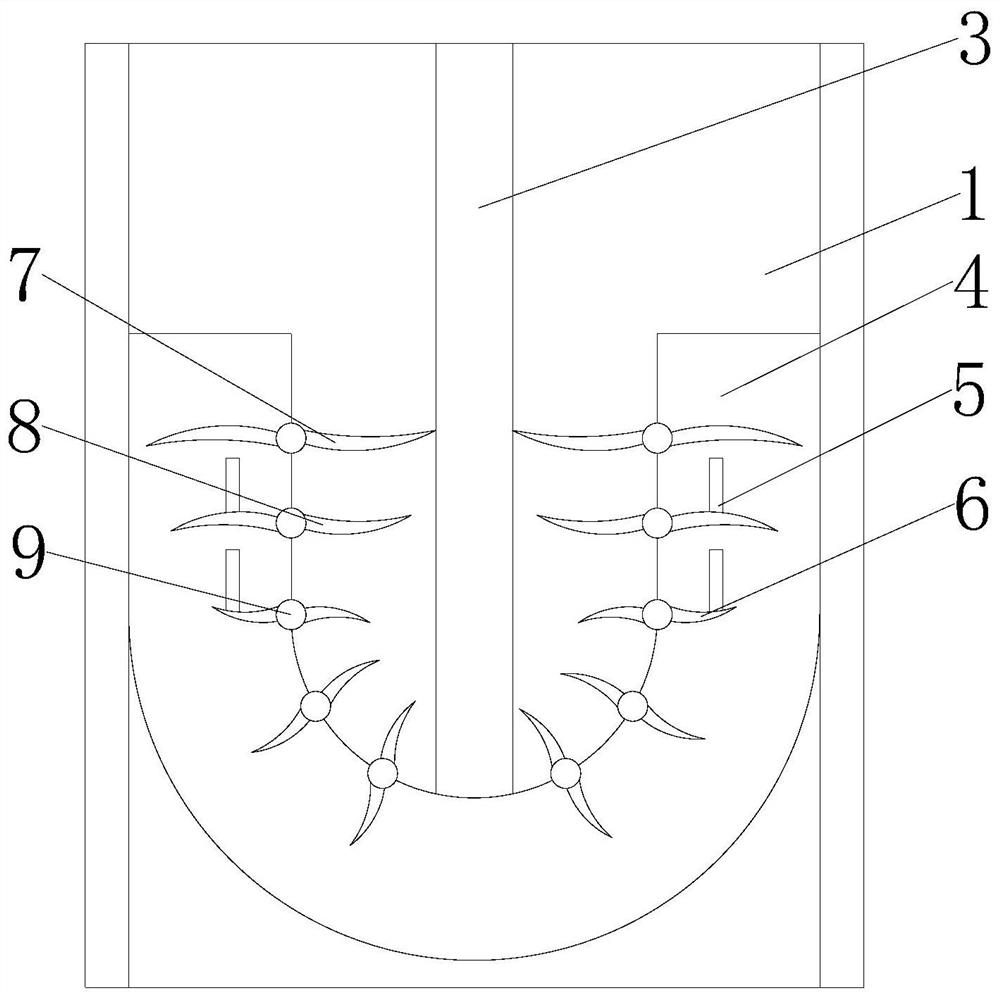

Marginal effect disturbance elimination system of large straw biogas project

PendingCN113337376AFully exploit the potential of gas productionSmooth feedingBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismStraw

The invention relates to the technical field of biogas engineering facilities, and provides a marginal effect disturbance elimination system for a large straw biogas engineering in order to solve a series of technical problems that materials in an existing fermentation tank float to form crusts and hinder gas production, the marginal effect disturbance elimination system is provided with a transverse compensator, and the transverse compensator is installed on a stirring shaft; the transverse compensator is used for breaking shells of floating biogas residues; the transverse compensator comprises a stirring arm and stirring teeth, the stirring arm is mounted on the stirring shaft, and the stirring teeth are mounted on the stirring arm. Through the transverse compensator, upper-layer scum can be stirred and hulled, the problems of scum and crusting in a straw biogas project are solved, stirring is more uniform, homogenization is achieved, fermentation materials and microorganisms make full contact, the maximum temperature difference between the upper portion, the middle portion and the lower portion does not exceed 2 DEG C, fermentation is promoted, the gas production potential of the materials is fully exerted, and the production efficiency is improved. Meanwhile, due to reduction of crusts and scum, material feeding is smoother, and the problem that the tank capacity is reduced is solved.

Owner:深圳市德润生物质投资有限公司 +1

Shell breaking device for pecans

The invention belongs to the technical field of dried fruit processing, and particularly relates to a shell breaking device for pecans. The shell breaking device comprises a shell breaking base body, a material storage box is fixedly installed at the top end of the shell breaking base body, and a material taking window is formed in the surface of the lower half portion of the shell breaking base body. A conical dredging frame is fixedly mounted on the surface of the inner wall of the material storage box. An arc-shaped dredging plate is driven to rotate at a constant speed under the driving of a motor I, and the pecans located between a material storage box and the conical dredging frame are dredged by utilizing t aherc-shaped structure design of the arc-shaped dredging plate while the arc-shaped dredging plate rotates, so that the pecans can enter the material guide pipe through the discharging opening in sequence; the pecans are adjusted to be in a vertical state when passing through the arc-shaped guide pipe according to the vertical falling movement tendency of the pecans, the pecans enter the pecan shell breaking clamp, and due to the fact that the arc-shaped limiting block penetrates through the pecan shell breaking clamp, the pecan shell breaking clamp stops moving downwards when the bottom ends of the pecans make contact with the arc-shaped limiting block.

Owner:山东正禾园食品有限公司

A spiral flow stirring type biological fermentation device

InactiveCN106801006AStir wellGuaranteed gas productionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringScrew thread

A spiral flow stirring type biological fermentation device is disclosed. The device includes a biogas digester main body, a stirring body and a drive assembly. The stirring body includes a lifting bar and a spiral plate. The lifting bar is vertically disposed at the center of the biogas main body. The spiral plate is fixed to the lower end of the lifting bar. The drive assembly includes a screw thread insert and a motor. The screw thread insert sleeves the lifting bar and is rotatably connected to the biogas digester main body around the axis of itself in a unidirection manner. The screw thread insert and the lifting bar are connected through screws to form a lead screw nut pair. The lifting bar is slidingly connected to the biogas digester main body around the axis of itself in a unidirection manner. The device achieves uniform and full stirring of a material liquid through up-down floating of the spiral plate, facilitates hull breaking and ensures the gas yield of the biogas digester.

Owner:开县元中养殖场

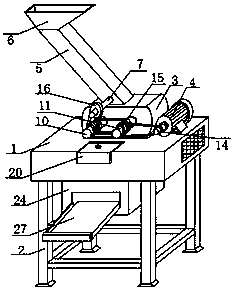

Camellia seed shell breaking device with washing function

The present invention discloses a camellia seed shell breaking device with a washing function. The camellia seed shell breaking device comprises a workbench, supporting legs are welded at four cornersof a lower end of the workbench, a shell breaking box is fixedly arranged at a middle position of an upper end surface of the workbench, a first motor is placed at one horizontal side of the shell breaking box, a material channel is obliquely arranged at an upper end of the shell breaking box, a material feeding hopper is fixedly connected with an upper end of the material channel, a first rotating rod is rotatably arranged at a bottom part of the material channel, a rotating roller sleeves the first rotating rod, material spreading shovels are symmetrically welded on the rotating roller, a second rotating rod and a third rotating rod are rotatably horizontally respectively arranged in the shell breaking box, and a conical shell breaking roller sleeves on the second rotating rod. In the camellia seed shell breaking device with the washing function, a washing sliding way is designed, water washing by a water supply box is cooperated to reach effects of washing and rinsing materials, awashing problem is solved while shell breaking is conducted, and the camellia seed shell breaking device saves time and labor, is suitable for different working conditions, and brings a better use prospect.

Owner:安徽德昌苗木有限公司

Camellia oleifera shell breaking and separation equipment

ActiveCN111202251BEasy to break the shellThe broken shell of the broken shell separation equipment is convenientSievingScreeningCamellia oleiferaHusk

Owner:湖南省海华农业综合开发有限公司

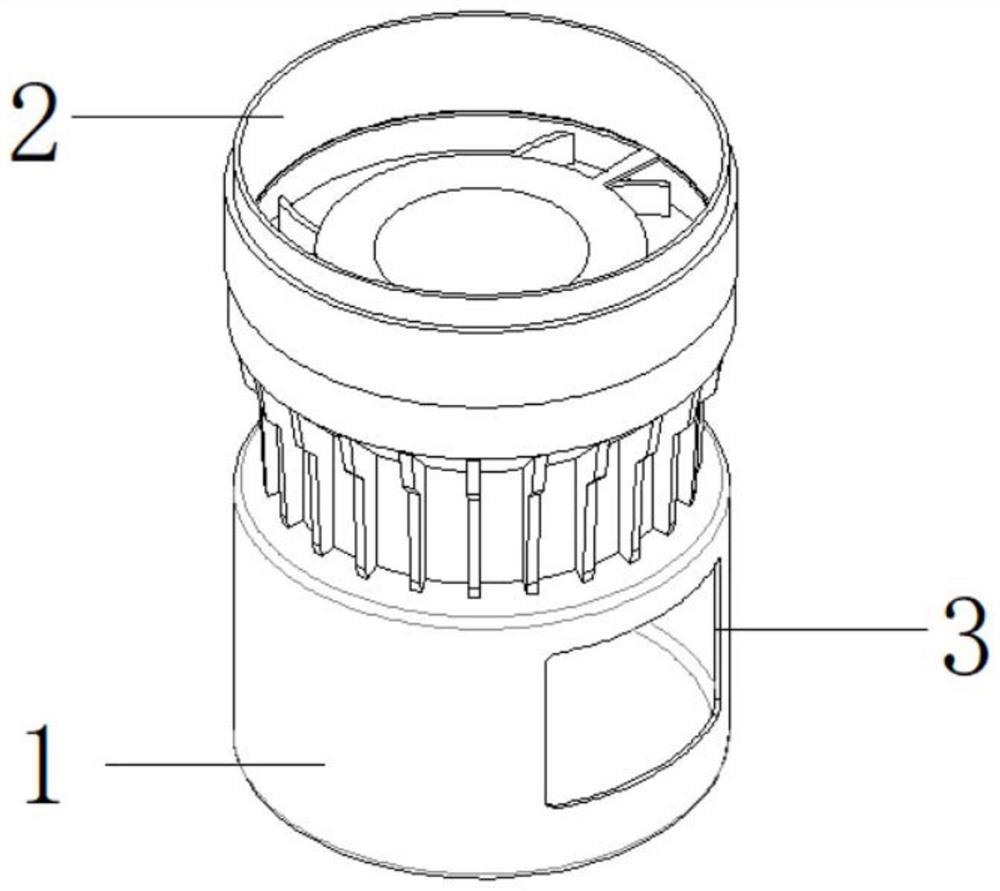

Automatic raw chestnut taking machine and using process thereof

ActiveCN112335898ASimple processReduce labor costsMeasurement devicesHuskingControl valvesIndustrial engineering

The invention discloses an automatic raw chestnut taking machine, which includes: raw chestnuts sequentially pass through a feed opening, a burr stripping and cutting device, a chestnut stripping device and a raw chestnut collecting screen from top to bottom; the raw chestnuts are input one by one from the feed opening; the burr stripping and cutting device is formed by connecting a plurality of sub stripping and cutting pipelines, and each sub stripping and cutting pipeline is formed by circumferentially surrounding a plurality of rotating roller sets and a plurality of extrusion roller sets;the chestnut stripping device is formed by connecting a plurality of sub chestnut stripping pipelines, each sub chestnut stripping pipeline is formed by circumferentially distributing a plurality ofshelling roller sets at equal angles, and the burr stripping and cutting device is communicated with the chestnut stripping device through a control valve; the rotating speeds of the rollers in the sub stripping and cutting pipeline are sequentially increased in the direction from the feeding opening to the control valve; the diameter of the control valve is smaller than that of a channel of the burr stripping and cutting device, and a laser diameter detection sensor and a weight detection sensor are arranged in the control valve. A set of automatic processing equipment with a flow path is used for taking chestnuts, and the shelling and chestnut taking procedures are greatly simplified through the working procedures of one-by-one feeding, burr stripping and cutting, extrusion shelling, shelling and chestnut taking and the like.

Owner:湖北弘福食品有限公司

A continuous walnut shell breaking equipment

The invention relates to the technical field of walnut shell breaking, and discloses a continuous walnut shell breaking device. The invention solves the problem that when the walnut is broken, the broken surface of the walnut tends to be irregular, and it is in multiple groups of broken shapes, which is inconvenient to take the walnut kernel, and the walnut kernel itself is easily picked out by external force. The present invention can push the extruding panel by cooperating with the upper pushing component, and the walnut can be extruded, and the walnut placing box is placed vertically, and is connected to the rotating brakes connected above the left and right sides of the lower inclined platform. Drive the driving rod to rotate, and the concave blocking block connected above the outer wall of the driving rod can block the walnut, which is convenient for the rotary brake to block the walnut extrusion process and the discharge after extrusion. If the concave blocking block blocks the walnut, the walnut will be separated from the horizontal clamping walnut panel, and the clamping process will not achieve continuous clamping.

Owner:阿克苏金易农业机械科技有限公司

Pneumatic conveying peanut device

The invention discloses a device for pneumatically conveying peanuts, which comprises: a collection chamber, which is provided with a feed inlet and a discharge outlet, the discharge outlet is arranged at the bottom of the collection chamber, and the top of the collection chamber It communicates with the inlet of the exhaust fan through a pipeline; the impurity removal bin communicates with the collection chamber, and the impurity removal bin includes: a drum, one end of which is connected to the discharge port through a material transfer pipe, and the exhaust fan The outlet of the outlet is connected to the material transfer pipe through the first pipeline, and the wall of the drum is provided with a lifter that moves the peanuts to the other end of the drum, and a water mist nozzle is provided in the drum, and the The cylinder wall of the drum is evenly covered with through holes; and the outer cylinder has an inner space for accommodating the drum, and the outer cylinder is provided with a sewage hole; wherein, the space in the collection chamber is lower than the feeding port There are several rotors inside. The invention has the advantages of simple structure, rich functions, resource saving and the like.

Owner:海宁经开产业园区开发建设有限公司

A device for cracking walnut shells

ActiveCN112741515BEasy to collectIncrease local pressureKitchen equipmentHuskingWalnut NutStructural engineering

The invention discloses a walnut shell breaking device, which relates to the technical field of food processing equipment. The walnut shell cracking device includes a splint, the left and right sides of the splint, the front and rear ends of the splint are slidably connected with a stay wire 1, the left and right sides of the splint are slidably connected with a stay wire 2, the stay wire 2 is located above the stay wire 1, and the lower surface of the splint is fixed. Slider 1 is connected, a support plate is arranged under slider 1, a chute 1 is opened on the upper surface of the support plate, the lower surface of slider 1 slidably connects with the inner wall of chute 1, and the lower end of the opposite side of the support plate is fixedly connected with Bottom plate, the left side of the plywood is provided with a top plate, the left and right ends of the bottom plate are provided with support rods, and the top of the plywood is provided with a vertical plate, which solves the problem that most of the existing walnut shell breaking methods are people holding a hammer to break the walnuts, Opened walnuts will splash around, resulting in waste of walnut kernels and inconvenient cleaning, and only one walnut can be processed at a time, which is time-consuming and labor-intensive.

Owner:宁波鑫象不锈钢制品有限公司

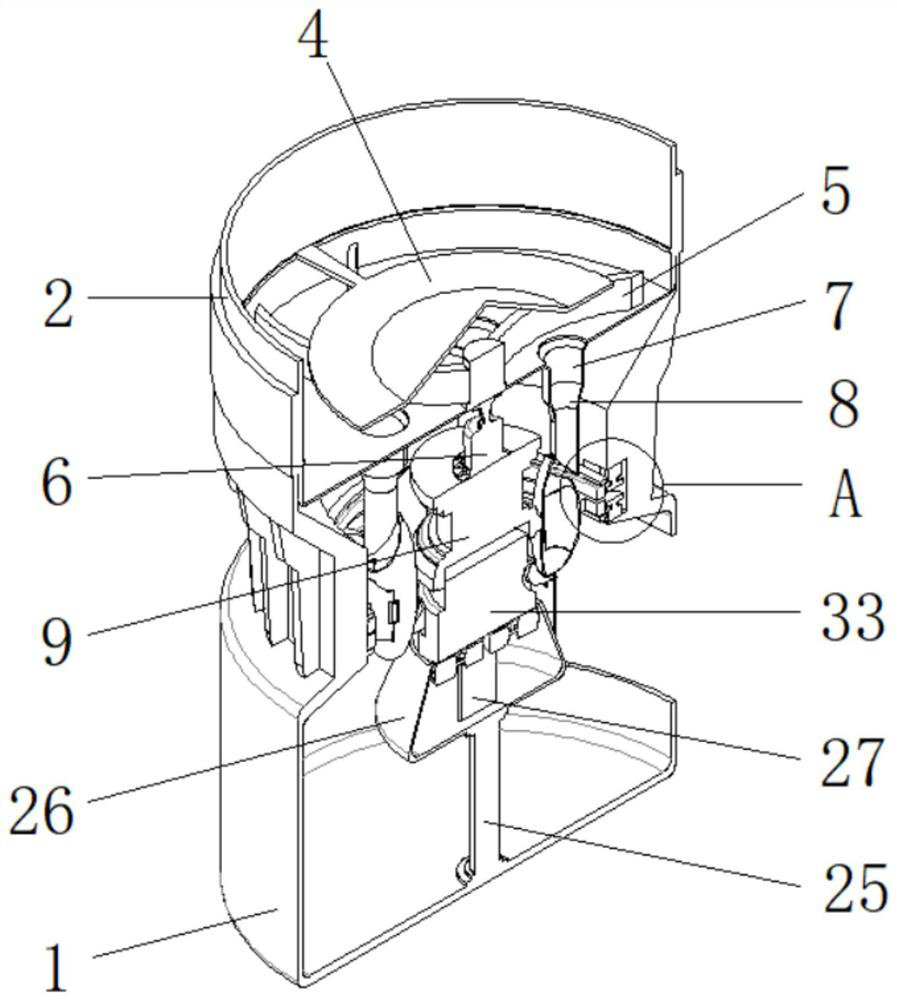

A cracking device capable of reducing surface damage of walnut kernels

ActiveCN111990663BFully dryReduced shell toughnessSievingGas current separationWalnut NutEngineering

The invention discloses a device for cracking walnut kernels that can reduce surface damage, which includes a casing, an air-drying component, a grading component, a cracking component and a shell kernel separation device, wherein a feeding hopper is installed on the top of the casing, It is used to introduce the walnuts to be cracked into the equipment, and it is characterized in that: the upper end of the inside of the casing is provided with an air-drying component, which is used to dry the walnuts to be cracked, so that the dried walnuts enter the grading component; the grading component It is installed at the right end inside the casing, and forms a grading chamber with the right inner wall of the casing, which is used for grading walnuts; multiple shell breaking components are installed inside the casing, and are respectively connected with the grading components, It is used to crack the shell of walnuts; the left side of the inside of the casing is also equipped with a shell and kernel separation device, which separates the shells and kernels of the broken walnuts so as to collect relatively complete walnut kernels.

Owner:TARIM UNIV

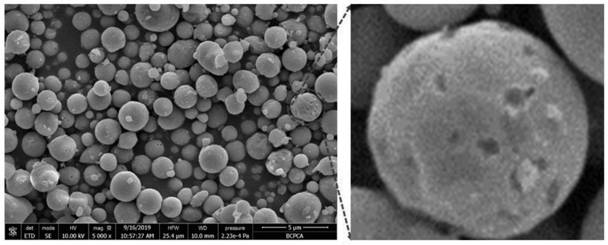

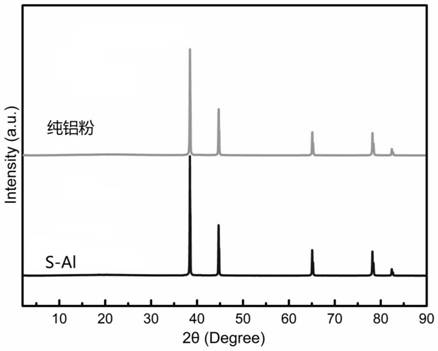

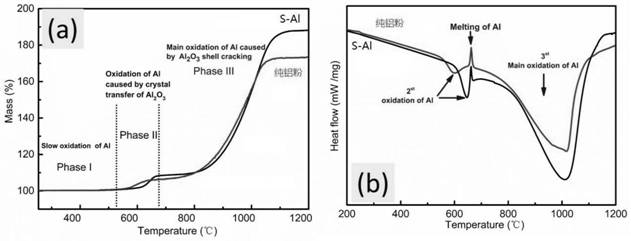

High-thermal-oxidation-activity aluminum powder with surface nanostructure and preparation method thereof

InactiveCN111790905AHigh thermal oxidation activity of surface nanostructureHigh thermal oxidation activityTransportation and packagingMetal-working apparatusAluminium powderNanostructure

The invention discloses high-thermal-oxidation-activity aluminum powder with a surface nanostructure and a preparation method thereof, and belongs to the technical field of preparation of energetic materials. The high-thermal-oxidation-activity aluminum powder does not contain additives, an original spherical structure is kept, and nanoscale pits and holes are formed in the surface of the aluminumpowder. According to a wet chemical method, a micron aluminum powder aqueous suspension is mixed with a low-concentration acid aqueous solution, and stirring and mixing are carried out at room temperature, so that ions in an aluminum oxide shell layer on the surface of the micron aluminum powder react with ions in the low-concentration acid aqueous solution to cause nanoscale corrosion defects onthe aluminum oxide shell layer, and the micron aluminum powder particles with the surface nanostructure are obtained. The aluminum powder prepared by the method has the characteristics of simple preparation method, cheap and easily available used raw materials and high thermal oxidation activity.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A shell breaking device for pistachio processing

The invention relates to the technical field of pistachio processing and shell breaking, in particular to a shell breaking device for pistachio nut processing. There is a chassis, the two sides of the chassis are respectively fixed with the second frame, the power mechanism is fixedly installed on the top surface of the first frame, and the upper part of the second frame is rotatably connected with a pressing plate rotating mechanism. Through the pistachio extrusion mechanism, the second platen is in contact with the first platen, and the elliptical shell on the second platen squeezes the pistachios in the first clamping groove, which effectively squeezes the pistachios to break the shell, and can squeeze a large number of pistachios. Shell breaking is faster than manual shell breaking, and the processing output is improved to a greater extent.

Owner:三明市尚谷食品生产有限公司

Continuous walnut shell breaking equipment

The invention relates to the technical field of walnut shell breaking, and discloses continuous walnut shell breaking equipment. The equipment solves the problem that broken surfaces of walnuts are easy to be irregular and are in multiple groups of broken shapes when the shell of the walnuts are broken, taking-out of the walnut kernel is inconvenient, and the overall separation of the walnut kernel is easy to appear when the walnut kernel is picked out by using an external force. According to the equipment, pushing assemblies can push squeezing panels, so that the walnuts can be squeezed, thewalnuts are vertically placed in walnut placing boxes, rotary brakes connected to the upper left and right sides of a lower inclined platform drive driving rods to rotate, a concave-shape blocking block connected to the upper side of an outer wall of each driving rod can block the walnuts, so as to help the rotary brakes to block the walnuts during the squeezing process and discharge the walnuts after squeezing, if the concave-shape blocking blocks are not used to block the walnuts in the equipment, the walnuts can be separated from a horizontal walnut clamping panel, and the continuous clamping cannot be achieved during a clamping process.

Owner:阿克苏金易农业机械科技有限公司

A kind of walnut shelling equipment and shelling method thereof

ActiveCN112754029BEasy to break the shellReduce destructive powerSievingScreeningWalnut NutEngineering

Owner:TARIM UNIV

Shell-breaking device for peanut production and planting

PendingCN110972600AImprove the efficiency of breaking upEfficient distinctionSievingSeed and root treatmentAgricultural scienceDrive wheel

The present invention relates to the technical field of peanut shell breaking and also discloses a shell-breaking device for peanut production and planting. The shell-breaking device for the peanut production and planting comprises a shell body and a pedal, a fixed block is fixed on one side of an outer wall of the shell body through a bolt, a water tank is arranged on a bottom part of an inner wall of the shell body, a motor is fixed on an upper surface of the fixed block through a bolt, a fixed plate is welded at a bottom part of the inner wall of the shell body, a plurality of connectors are arranged in one side of an outer wall of the fixed plate, besides, a driven wheel is welded on inner walls of the connectors, second rotating shafts, third rotating shafts and a fourth rotating shaft are connected to the inner wall of the driven wheel in a transmission manner, and besides, the number of the second rotating shafts and the third rotating shafts are two. After peanuts are put intoa material feeding pipe, the peanuts are primarily screened, so that a first screen net shakes left and right, the peanuts which are not suitable for planting can fall into a second storage box through the first screen net, the good and bad peanuts are efficiently distinguished, manpower and time are saved, peanut shell-breaking efficiency is improved, one end of a second screen net can shake up and down, and efficiency of peanut seeds falling into a first storage box is improved.

Owner:罗源县金源竹业有限公司

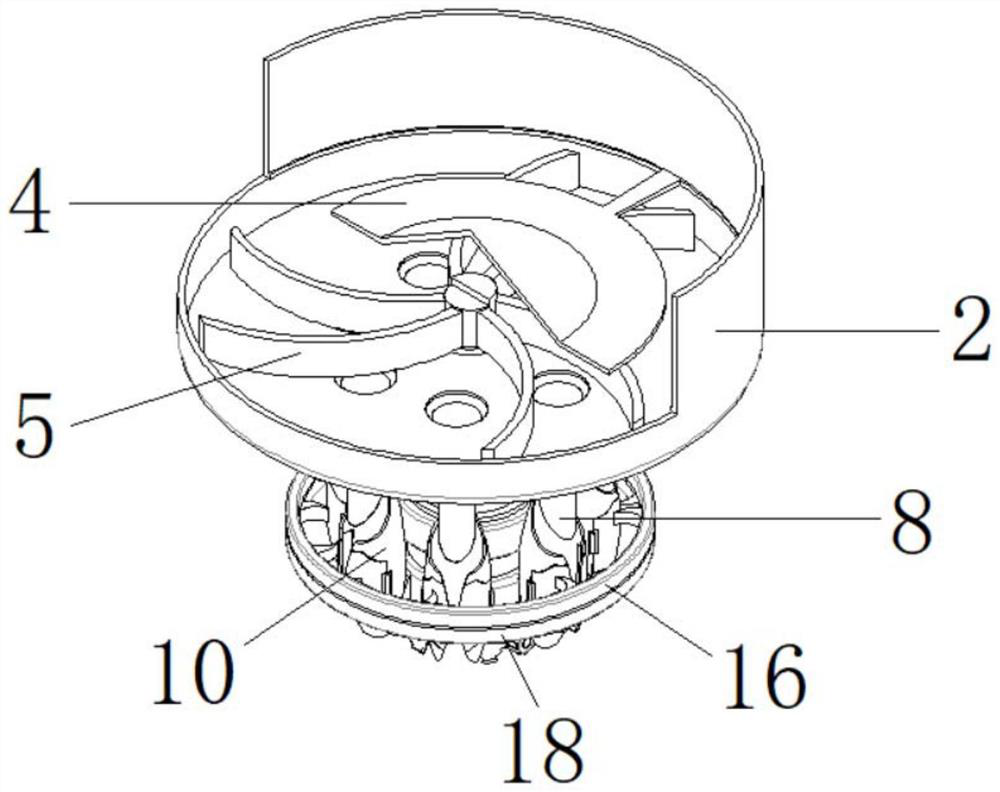

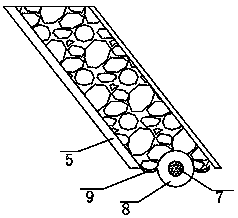

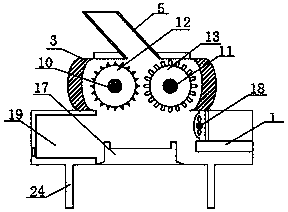

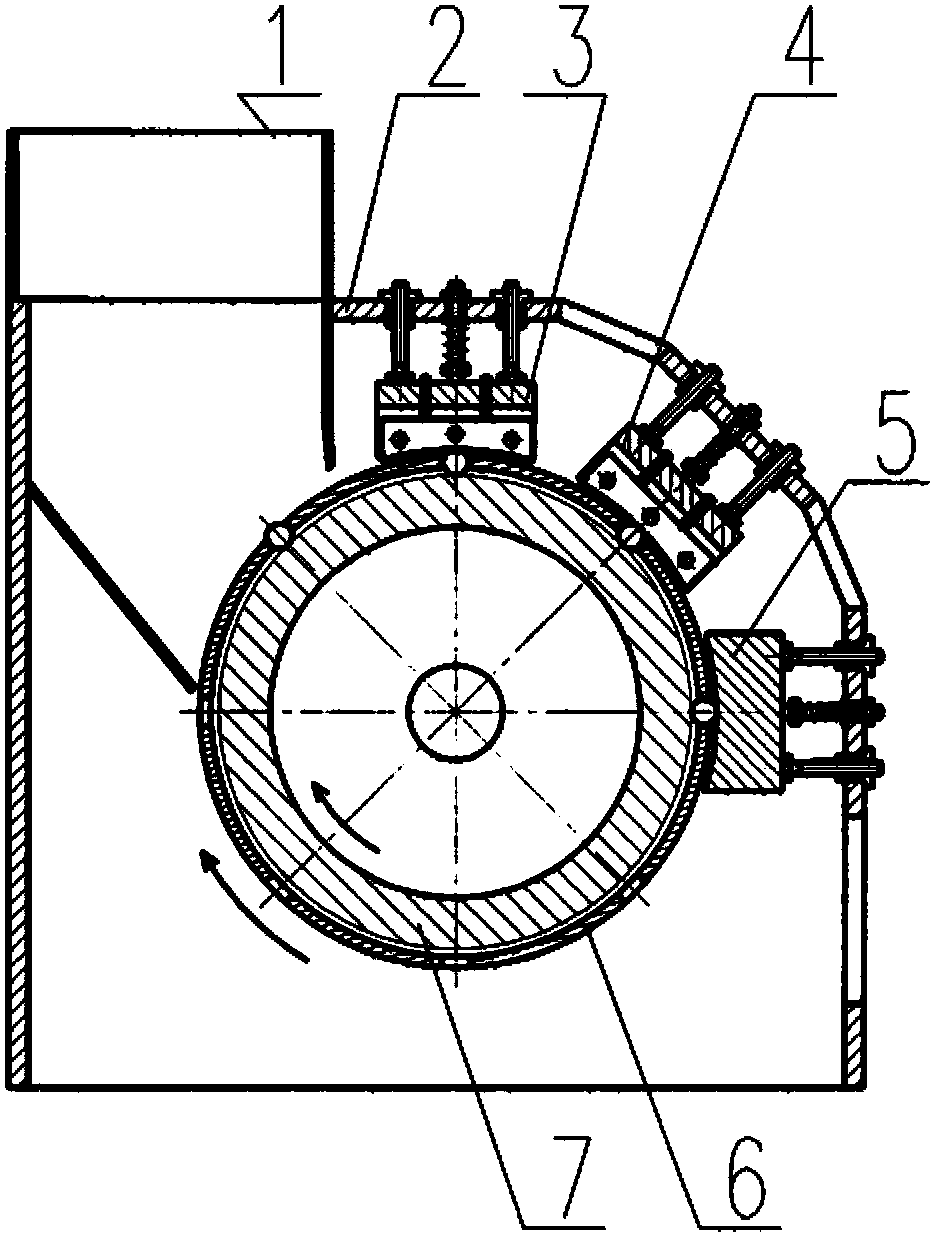

Multichannel star-shaped lotus seed hulling machine

The invention discloses a multichannel seed hulling machine, relating to the field of lotus seed processing. The hulling machine comprises a hopper, a machine body, a main shaft, a drive roller, a motor and a transmission device; and the hulling machine mainly consists of a multichannel feeding roller, an arc surface hull rolling pricking device, an arc surface rolling cutting device, an arc surface rolling hull separating device and a reduction gear system. The drive roller is coaxially fixed on the main shaft, and the multichannel feeding roller is coaxially installed outside the drive roller and is supported on the main shaft through a bearing; and a plurality of groups of positioning delivery holes are formed on the feeding roller so as to form a plurality of lotus seed delivery channels, the hopper is distributed on one side of the upper half part of the feeding roller, and the arc surface hull rolling pricking device, the arc surface rolling cutting device and the arc surface rolling hull separating device are sequentially distributed on each delivery channel. The hulling machine has the advantages of small hull breaking force, less broken lotus, high hulling efficiency, large yield, stable performance and simple structure.

Owner:湖南省粮油产品质量监测中心

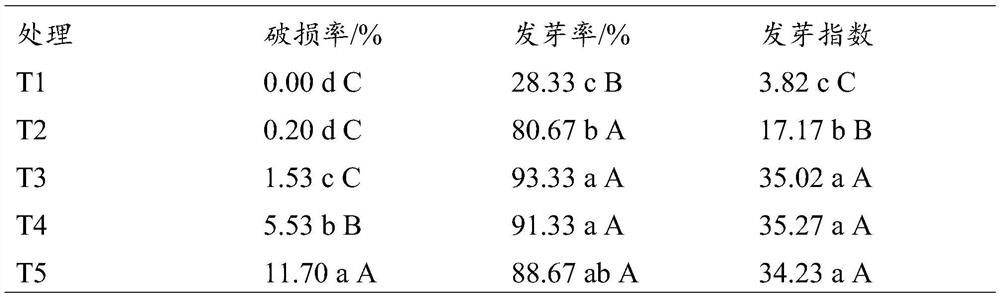

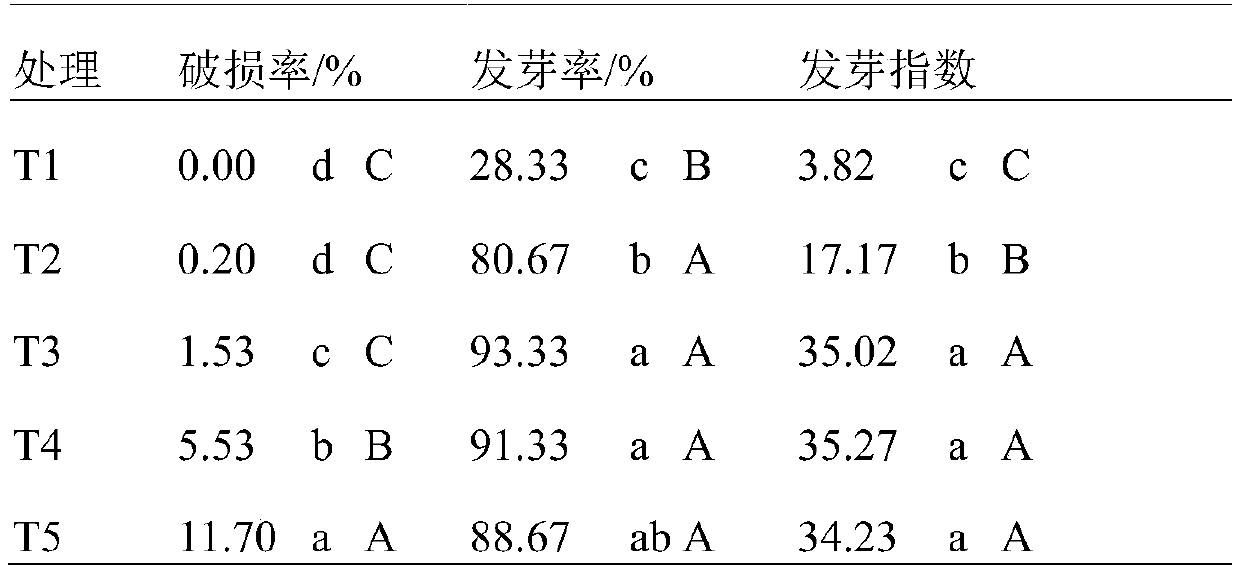

Grinding machine, application thereof and method for breaking dormancy of flemingia philippinensis seeds

InactiveCN114026990AAvoid uneven frictionEasy to break the shellGerminating apparatusSeed dormancyBench grinder

The invention discloses a grinding machine, application thereof and a method for breaking dormancy of flemingia philippinensis seeds. The method for breaking dormancy of flemingia philippinensis seeds comprises the following steps that firstly, the flemingia philippinensis seeds are subjected to winnowing and screen mesh screening and then aired till the water content of the seeds is 8% or below; 2, a grinding machine is used for conducting friction on the surfaces of the dried seeds for 60 seconds at the rotating speed of 2840 r / min, and broken seeds are obtained; and 3, seed coat ash is removed from the broken seeds, the broken seeds aresoaked in water for 6 hours, the broken seeds are soaked in a liquid fertilizer prepared from a humic acid fertilizer and water in a mass ratio of 1: 2 for 1 hour, and finally accelerating germination or sowing is conducted in an environment of 30 DEG C, so that the seeds can germinate after 2 days. According to the method, the technical problems that in the prior art, flemingia philippinensis seeds do not germinate or the germination rate is extremely low, and seedlings emerge irregularly are solved through initial treatment of the seeds and skin breaking treatment of the grinding machine, and the method can be widely applied to large-scale planting of flemingia philippinensis and has good market prospects.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

Reciprocating vibration type walnut shell breaking device

The invention provides a reciprocating vibration type walnut shell breaking device which comprises a shell breaking device body and a fixing plate, the fixing plate is arranged at the top end of the shell breaking device body, sliding grooves are formed in the front side and the rear side of the interior of the shell breaking device body, a fixing rack is fixedly connected to the interior of the shell breaking device body, and first blades are arranged on the lower portion of the inner side of the fixing rack. According to the walnut shell breaking device, fixing frames are in a C shape, when a walnut is subjected to shell breaking, the corner angle in the middle of the walnut is located in a gap between the two fixing frames, a pressing plate is pressed downwards, gas in a gas cylinder moves into a gas bag through a gas guide pipe, and the side, away from the gas bag, of a clamping plate is tightly tangent to the outer side of the walnut; and the walnut shell breaking device can conveniently fix walnuts of different sizes during shell breaking of the walnuts, and is capable of preventing the walnuts from shifting, so that shell breaking of the walnuts is more convenient.

Owner:伊瓦特机器人设备制造有限公司

Walnut shell breaking device

ActiveCN112741515AEasy to collectIncrease local pressureKitchen equipmentHuskingWalnut NutStructural engineering

The invention discloses a walnut shell breaking device, and relates to the technical field of food processing equipment. The walnut shell breaking device comprises clamping plates, a first pull wire is slidably connected to the front and rear ends of the left and right side faces of the clamping plates in a penetrating mode, a second pull wire is slidably connected to the left and right side faces of the clamping plates in a penetrating mode and located above the first pull wire, first sliding blocks are fixedly connected to the lower surfaces of the clamping plates, and supporting plates are arranged under the first sliding blocks, first sliding grooves are formed in the upper surfaces of the supporting plates, the lower surfaces of the first sliding blocks are slidably connected to the inner walls of the first sliding grooves, a bottom plate is fixedly connected to the lower ends of the opposite side faces of the supporting plates, top plates are arranged on the left side faces of the clamping plates, and supporting rods are arranged at the left end and the right end of the bottom plate, and vertical plates are disposed above the clamping plates. The walnut shell breaking device solves the problems that according to an existing walnut shell breaking mode, people hold a hammer to break walnuts open, the broken walnuts splash everywhere, so that walnut kernels are wasted, cleaning is not convenient, only one walnut can be processed each time, and time and labor are wasted.

Owner:宁波鑫象不锈钢制品有限公司

Method for breaking dormancy of moghania philippinensis seeds

InactiveCN110121977AGood market prospectAvoid uneven frictionGerminating apparatusWater contentHumic acid

The invention discloses a method for breaking dormancy of moghania philippinensis seeds. The method comprises the following steps: step one, winnowing and screening moghania philippinensis seeds witha screen, and airing the moghania philippinensis seeds until the water content of the seeds is 8% or below; step two, carrying out friction on the surfaces of the dried seeds for 60 seconds by using agrinding machine at the rotating speed of 2840 r / min to obtain peeled seeds; step three, removing seed coat ash from the peeled seeds, soaking the peeled seeds for 6 hours by using water, and then soaking the peeled seeds for 1 hour in a liquid fertilizer prepared from a humic acid fertilizer and water according to the mass ratio of 1: 2, and finally accelerating germination or seeding in an environment at the temperature of 30 DEG C, wherein the germination can be implemented two days later. The technical problems of no germination or extremely low germination rate of moghania philippinensisseeds and irregular seedling emergence in the prior art are solved through primary treatment of seeds and peeling treatment through the grinding machine, and the method can be widely used for large-scale planting of moghania philippinensis, and has good market prospect.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com