Shell-breaking device for peanut production and planting

A shell breaking device and peanut technology are applied in the fields of application, seed and rhizome treatment, solid separation, etc., which can solve the problems that peanuts cannot be broken efficiently and cannot be quickly screened for good and bad peanut seeds, saving manpower and time, and easy to break. Shell, the effect of speeding up work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

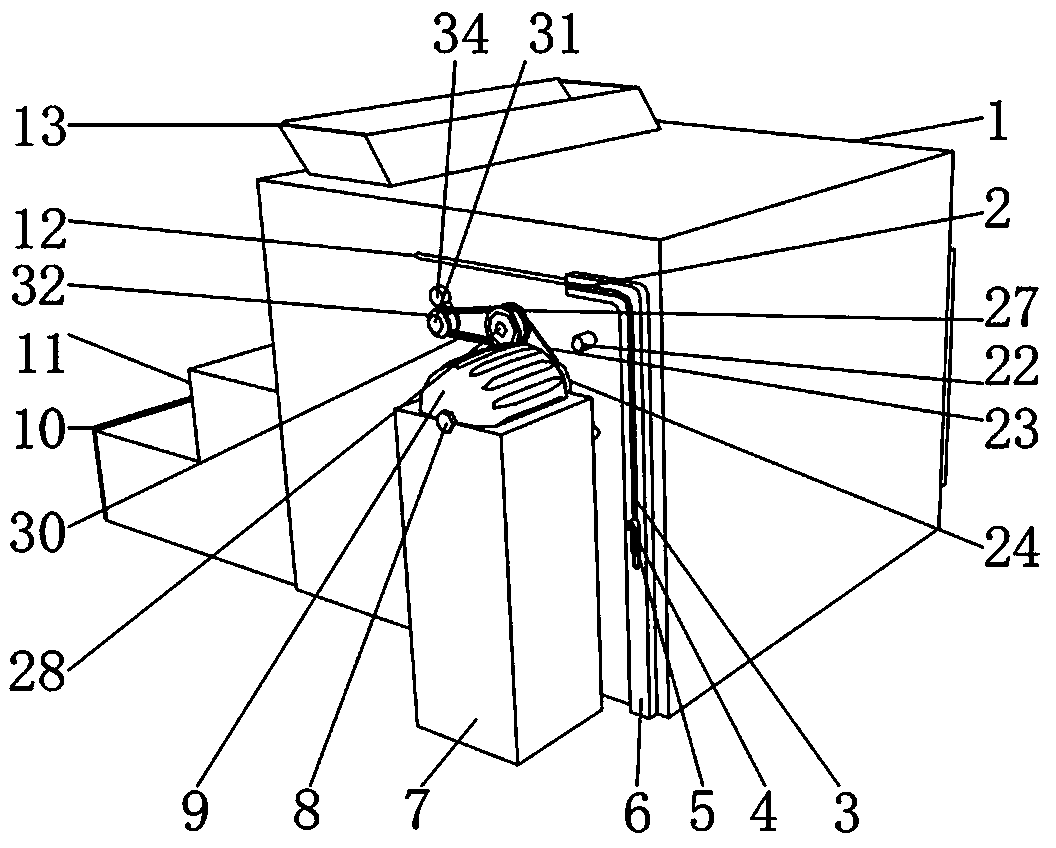

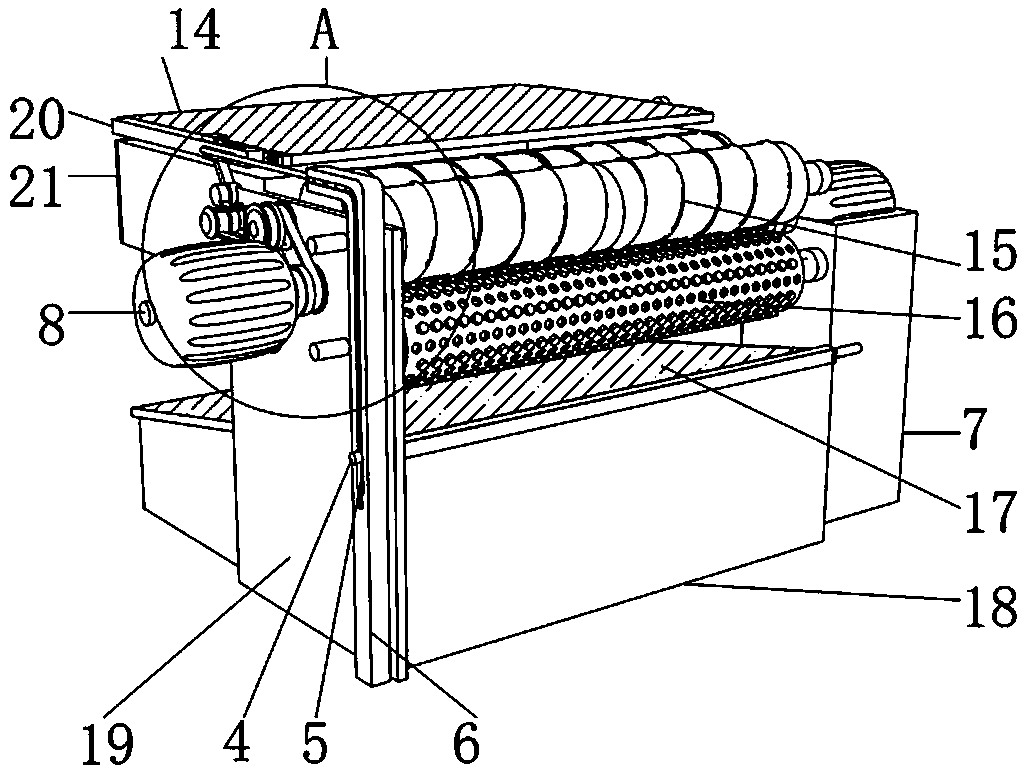

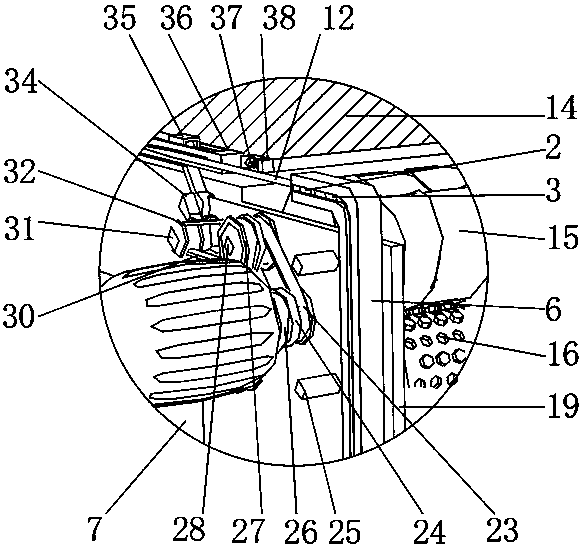

[0029] refer to Figure 1-4 , a shell breaking device for peanut production and planting, comprising a housing 1 and a pedal 11, a fixing block 7 is fixed on one side of the outer wall of the housing 1 by bolts, a water tank 18 is arranged at the bottom of the inner wall of the housing 1, and the upper surface of the fixing block 7 is fixed by bolts The motor 9 is fixed, and the bottom of the inner wall of the housing 1 is welded with a fixed plate 19. There are a plurality of connecting ports on one side of the outer wall of the fixed plate 19, and a driven wheel is welded on the inner wall of the connecting port. Three rotating shafts 25 and the fourth rotating shaft 31, and the quantity of the second rotating shaft 28 and the third rotating shaft 25 is two, the second rotating shaft 28 outer wall side is fixed with the cutting roller 15 by bolts, the third rotating shaft 25 outer wall one side The concave-convex rolling roller 16 and the fourth runner 22 are fixed by bolts,...

Embodiment 2

[0033] refer to Figure 5 , a shell breaking device for peanut production and planting. Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a housing 1 is included, and a protective plate 33 is fixed on one side of the outer wall of the housing 1 by bolts. The setting of 33 can prevent the noise from affecting the staff when the machine is running, and also enhances the safety of the operator, and there is an installation opening on one side of the outer wall of the housing 1, and the inner wall of the installation opening is fixed with the same maintenance door 29 by bolts. The setting of the maintenance door 29 can facilitate the repair and maintenance of the equipment by the operator, increasing its service life.

[0034] The working principle of this embodiment: when in use, when the operator is operating the machine, the protective plate 33 on one side of the outer wall of the housing 1 reduces the noise generated during the oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com