Shell breaking equipment capable of reducing surface damage of walnut kernels

A technology of surface damage and shell breaking equipment, which is applied in the direction of shelling, cleaning method using gas flow, filter and sieve, etc. It can solve the problems of incomplete shell breaking of walnuts, easy damage to walnut kernels, and difficult shell breaking, etc., and achieve shell toughness Reduce, improve the effect of breaking the shell, and help the effect of breaking the shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

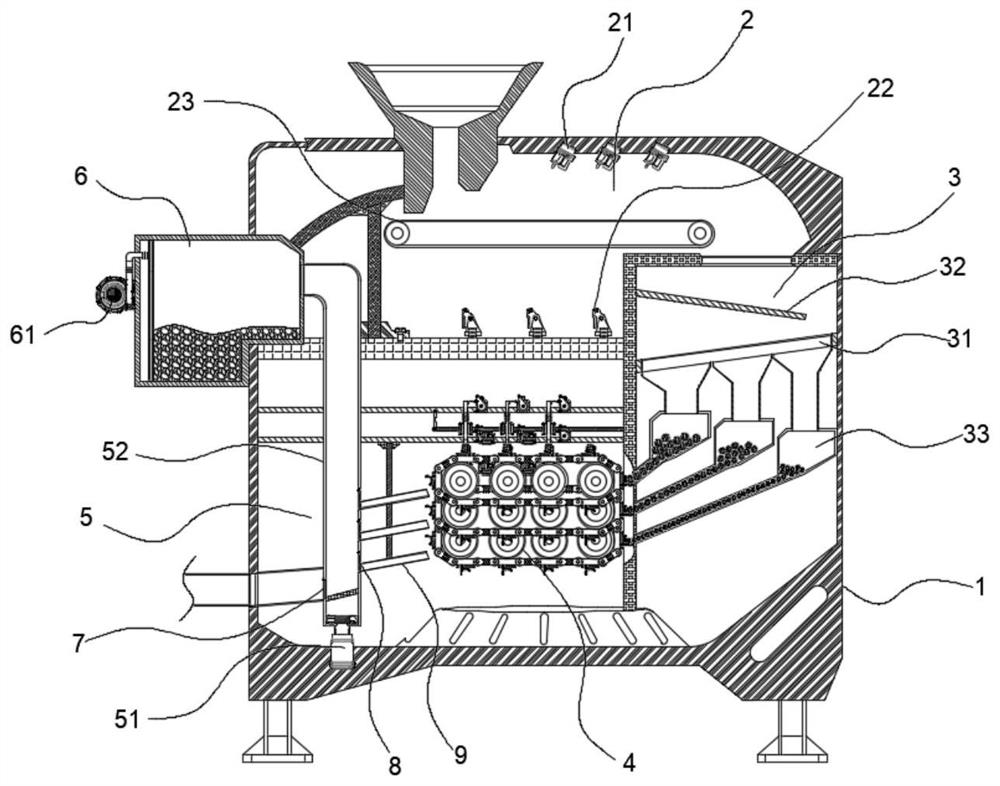

[0044] see figure 1 , in an embodiment of the present invention, a walnut shell breaking device that can reduce damage to the surface of walnut kernels includes a casing 1, an air-drying assembly 2, a grading assembly 3, a shell breaking assembly 4, and a shell kernel separation device 5, wherein the machine A feed hopper is installed on the top of the shell 1 for introducing walnuts to be shelled into the device, and an air-drying assembly 2 is arranged at the upper end inside the casing 1 for drying the walnuts to be shelled, so that the dried walnuts Enter the classification component 3;

[0045] The grading assembly 3 is arranged at the right end inside the casing 1, and forms a grading chamber with the right inner wall of the casing 1, and is used for size grading walnuts;

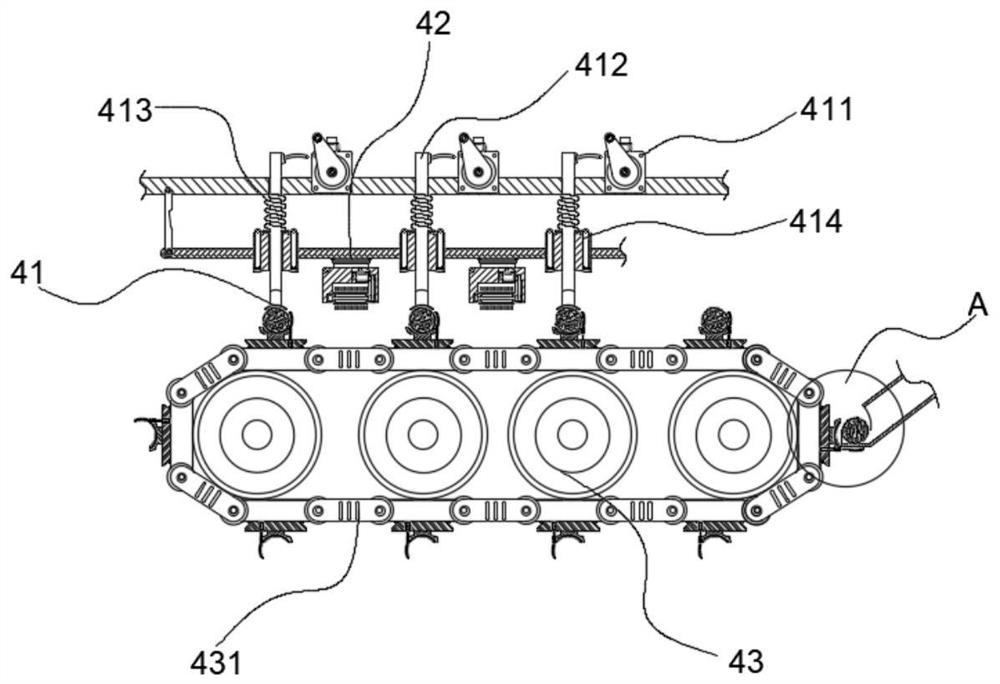

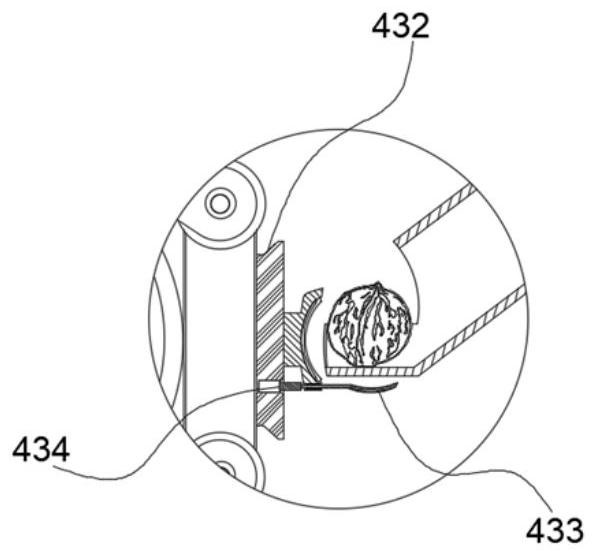

[0046] Described casing 1 interior is equipped with a plurality of cracking shell components 4, and communicates with grading component 3 respectively, is used for walnut cracking shell;

[0047] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com