Laminating and horizontally-spreading type hatching method for swan geese

A flat-spreading, swan technology, applied in the field of aquaculture, can solve problems such as not meeting market needs, and achieve the effects of good ventilation, tidy shelling, and easy breaking of seedlings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0018] A method for hatching of gray swans in a stacked flat style, comprising the following method steps,

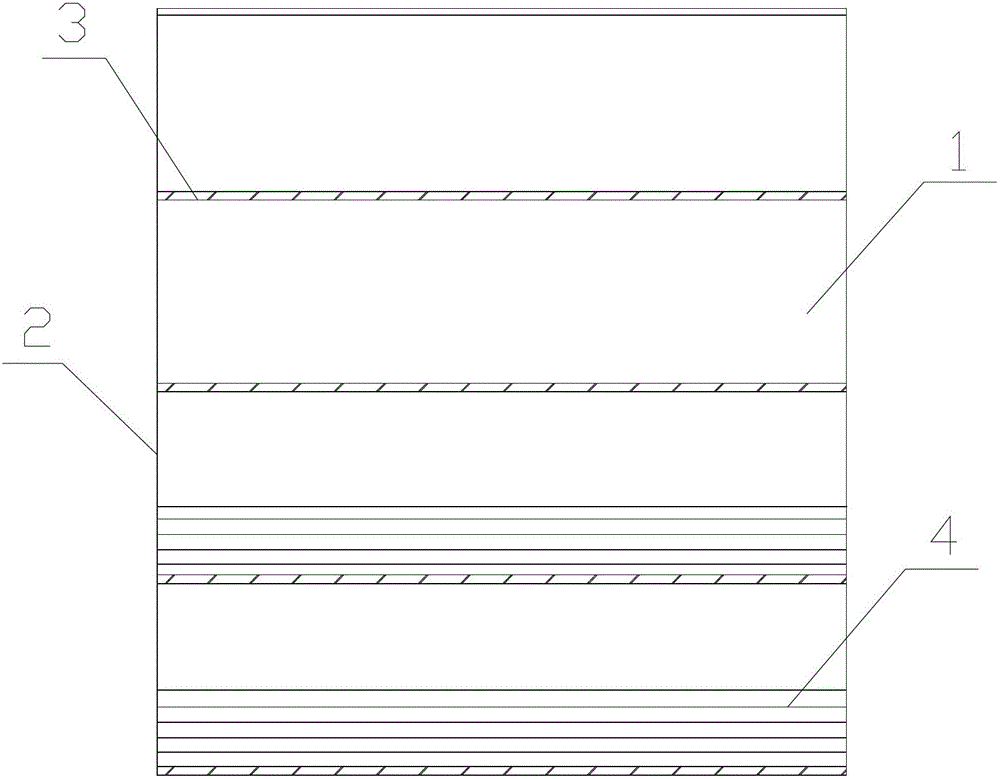

[0019] ①. Such as figure 1 As shown, first use 4cm*6cm square tube 2 to weld or screw to make a frame 1 with a height of 1.8m, a width of 2m, and a length of 4m. The frame 1 is welded into 4 layers, and then each layer is tiled with wooden boards 3, paved with cattail mats on the wooden boards 3, and the edges of the two layers below the frame 1 are welded 20 cm up with small square tubes 4 to form guardrails to make a flat spreading frame ;

[0020] ②. Use artificial heating to raise the indoor temperature to 28-32°C, then move the hatching eggs fertilized for 18-20 days from the incubator to the flat rack, and place two layers of hatc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com