High-thermal-oxidation-activity aluminum powder with surface nanostructure and preparation method thereof

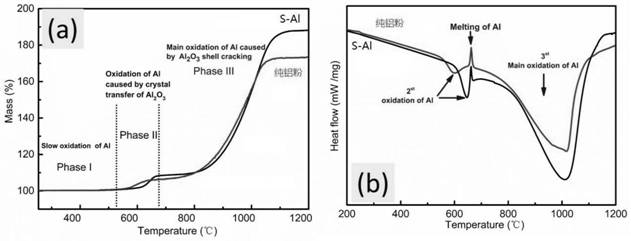

A nanostructured, oxidatively active technology that can be used in metal processing equipment, transportation and packaging to solve problems such as hindering complete oxidation, high process energy consumption, and increased specific surface area of aluminum particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

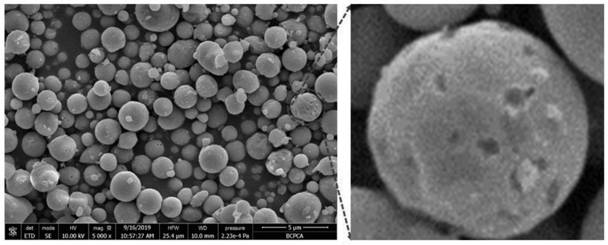

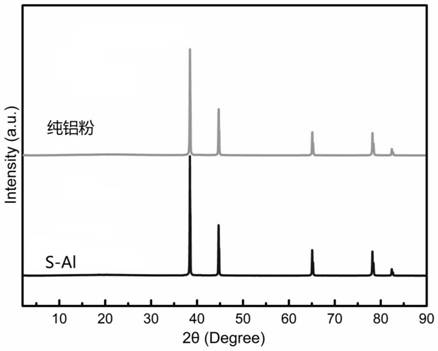

Embodiment 1

[0020] Add 2.5g of spherical aluminum powder and 0.185g of ammonium fluoride to 50ml of purified water to prepare aluminum powder aqueous suspension and ammonium fluoride aqueous solution respectively. After the preparation is completed, add the ammonium fluoride aqueous solution to the aluminum powder suspension under magnetic stirring at a speed of 600r / min, and react for 5 minutes; quickly centrifuge and filter to collect the solid filtrate; wash the solid filtrate with ethanol; The solid filtrate was dried under vacuum conditions at 60° C. for 12 hours, and spherical aluminum powder with high thermal oxidation activity with surface nanostructures was finally obtained.

Embodiment 2

[0022] Add 2.5g of flake aluminum powder and 0.185g of ammonium fluoride to 50ml of purified water to prepare aluminum powder aqueous suspension and ammonium fluoride aqueous solution respectively. After the preparation is completed, add the ammonium fluoride aqueous solution to the aluminum powder suspension under magnetic stirring at a speed of 600r / min, and react for 5 minutes; quickly centrifuge and filter to collect the solid filtrate; wash the solid filtrate with ethanol; The solid filtrate was dried under vacuum conditions at 60° C. for 12 hours to finally obtain flake aluminum powder with surface nanostructure and high thermal oxidation activity.

Embodiment 3

[0024] Add 2.5g of spherical aluminum powder and 0.5g of ammonium fluoride to 50ml of purified water to prepare aluminum powder aqueous suspension and ammonium fluoride aqueous solution respectively. After the preparation is completed, add the ammonium fluoride aqueous solution to the aluminum powder suspension under magnetic stirring at a speed of 600r / min, and react for 3 minutes; quickly centrifuge and filter to collect the solid filtrate; wash the solid filtrate with ethanol; The solid filtrate was dried under vacuum conditions at 60° C. for 12 hours, and spherical aluminum powder with high thermal oxidation activity with surface nanostructures was finally obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com