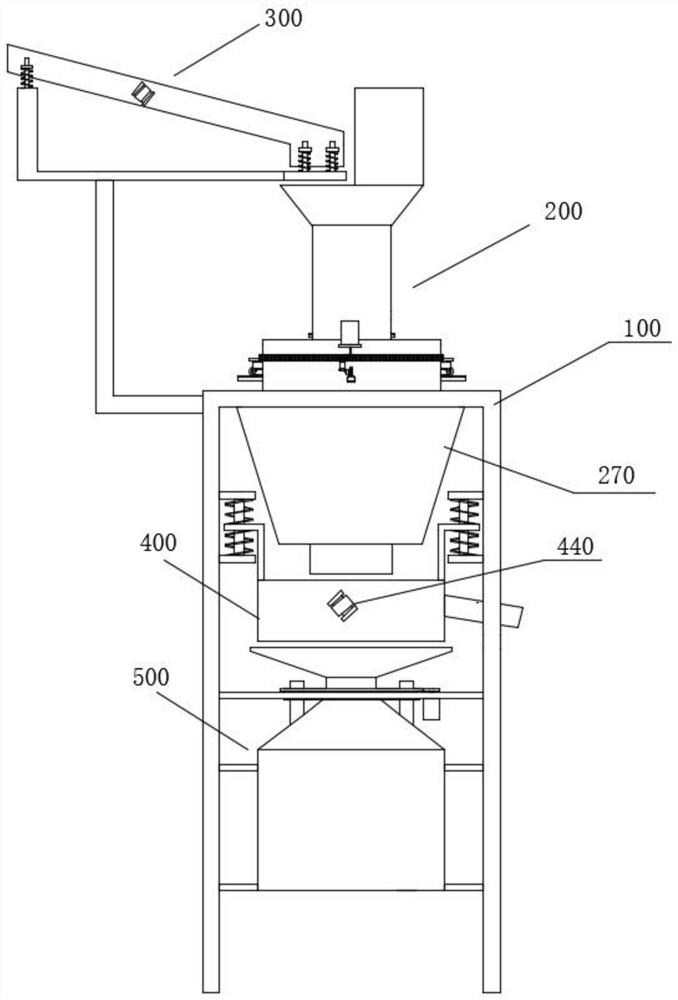

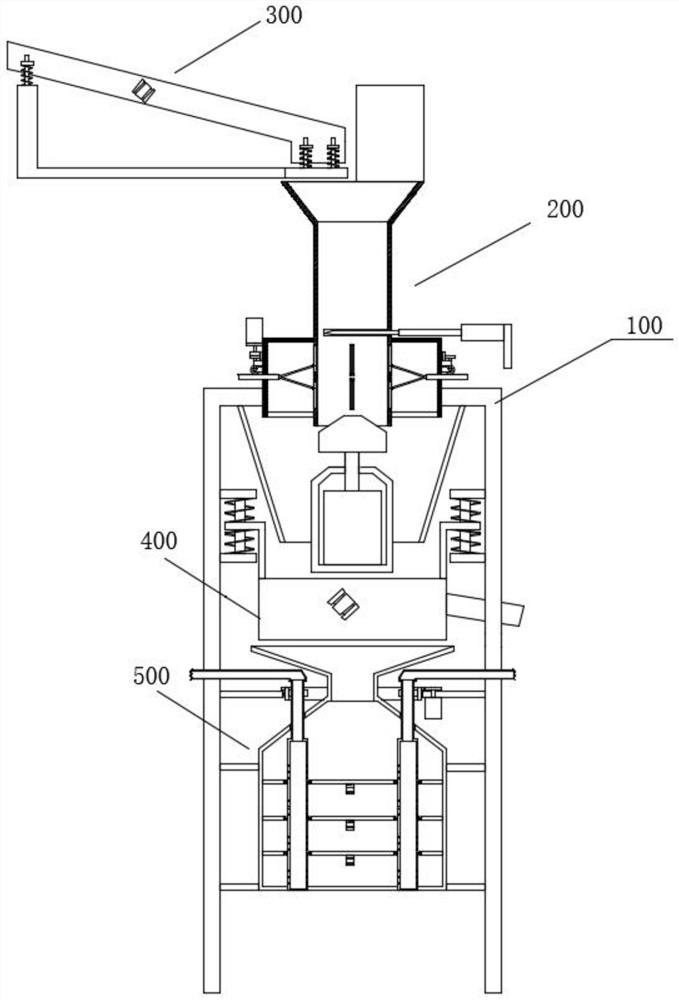

Walnut shelling equipment and shelling method thereof

A walnut and equipment technology, which is applied to walnut shelling equipment and the field of shelling, can solve the problems of large broken degree of walnut kernels, and achieve the effect of improving quality and reducing the amount of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

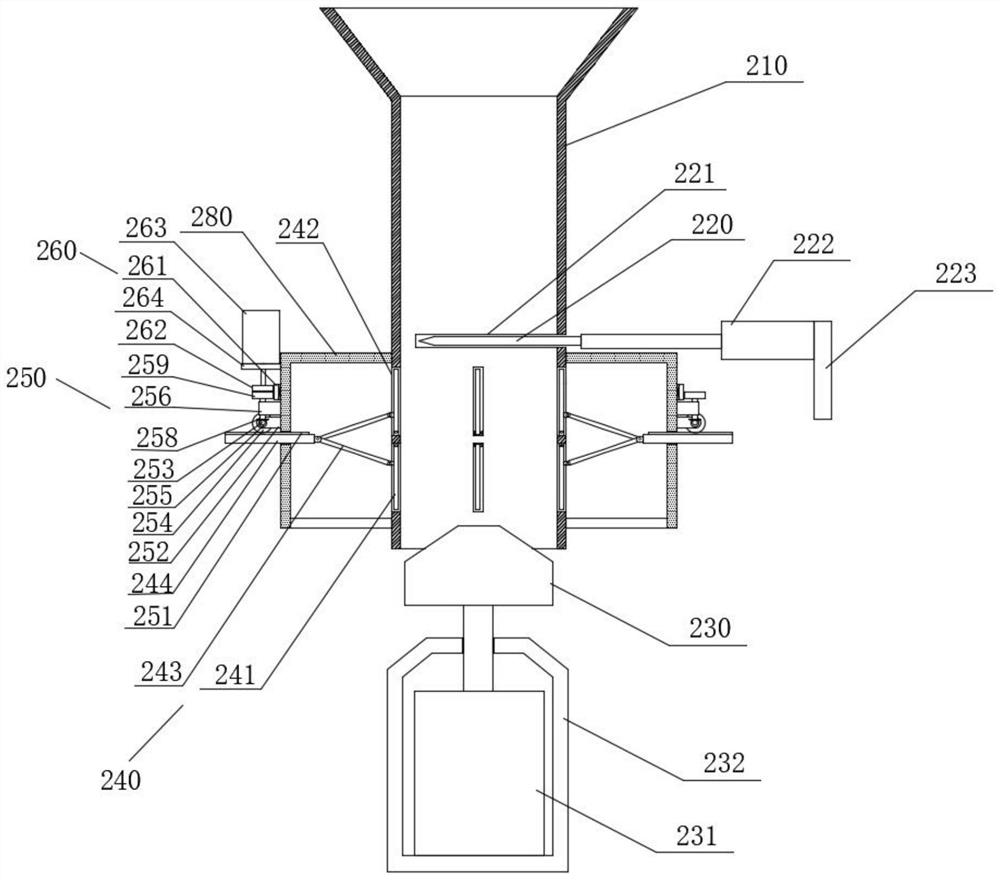

[0107] As an optimization scheme of Embodiment 1,

[0108] The transmission structure 250 includes

[0109] The rack 251 is arranged on the push rod 244, and the rack 251 slides through the positioning cover 280;

[0110] The first positioning plate 252 and the second positioning plate 256 are respectively arranged on the positioning cover 280;

[0111] The first rotating shaft 253 is rotatably arranged on the first positioning plate 252, one end is connected with the first gear 254, and the other end is connected with the first bevel gear 255;

[0112] The second rotating shaft 257 is rotatably arranged on the second positioning plate 256, one end is connected with the second gear 259, and the other end is connected with the second bevel gear 258; wherein, the first gear 254 meshes with the rack 251, the first The bevel gear 255 meshes with a second bevel gear 258 .

[0113]This embodiment is implemented in this way, the rotation of the second gear 259 in the transmission ...

Embodiment 3

[0120] As an optimization scheme of Embodiment 1,

[0121] The first screening structure 400 includes

[0122] The screening cover 410 is located directly below the positioning box 232;

[0123] The first screen 420 is arranged on the inner wall of the screening sleeve 410;

[0124] The first discharge plate 430 is arranged on the screening sleeve 410 and is used to discharge the oversize on the first screen 420;

[0125] The second vibrator 440 is arranged on the outer wall of the screening cover 410;

[0126] Support plates 450, several, are arranged on the screening sleeve 410;

[0127] Several sliding rods 460 slide through the support plate 450, and the two ends of the sliding rods 460 are respectively connected with two second supporting plates 470, and the second supporting plates 470 are arranged on the frame 100;

[0128] A plurality of second springs 480 are respectively provided on two ends of the sliding rod 460 passing through the support plate 450 , and the s...

Embodiment 4

[0131] As an optimization scheme of Embodiment 1,

[0132] The second screening structure 500 includes

[0133] The screening bucket 510 is arranged on the frame 100 and is located directly below the screening sleeve 410, and is used to receive the undersieve of the first screen 420;

[0134] The second sieves 520, several, arranged vertically, are arranged in the screening bucket 510;

[0135] The second discharge plate 530, several, is arranged on the sidewall of screening bucket 510, is used for discharging the oversize on the second screen cloth 520 of corresponding position;

[0136] The third vibrator 521, several, is separately arranged at the lower end of the second screen 520;

[0137] Several through holes 540 are arranged on the second screen 520 and pass through the second screen 520, and the positions of the through holes 540 on the second screen 520 are the same;

[0138] There are several dust collection buckets 550, which vertically pass through the through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com