Multichannel star-shaped lotus seed hulling machine

A multi-channel, shelling machine technology, applied in the direction of shelling, pod removal, food science, etc., can solve the problems of unstable shelling, unreliable circumcision, complex structure, etc., to improve shelling stability and drive load The effect of stability and simple structure of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

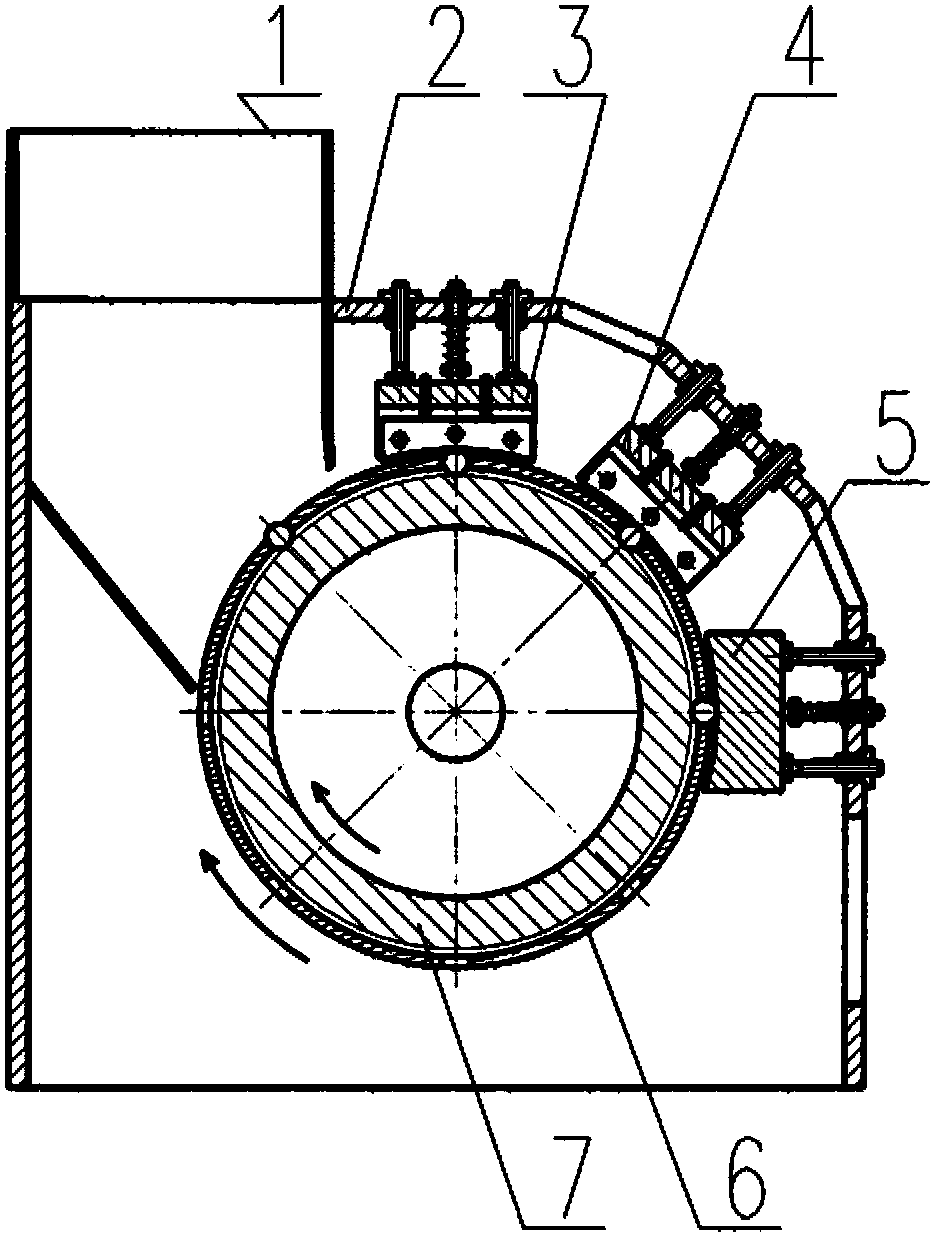

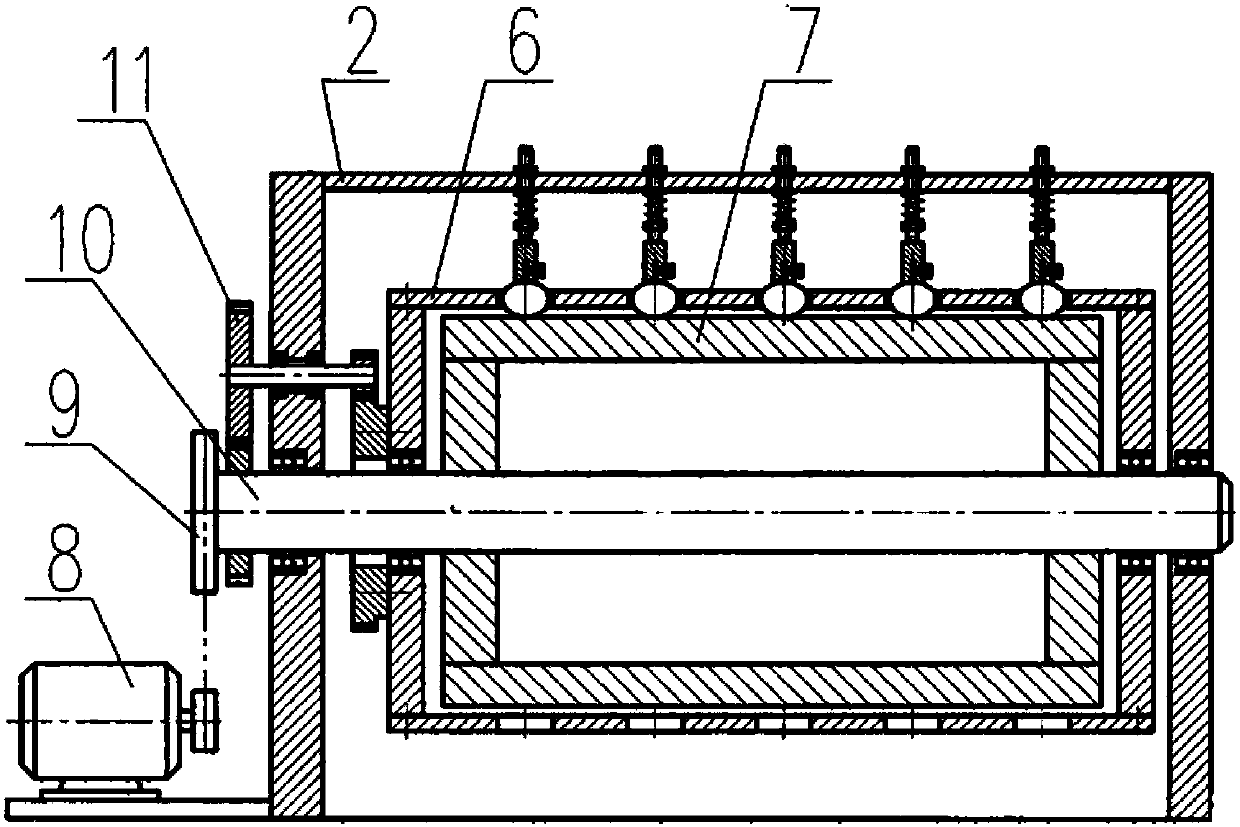

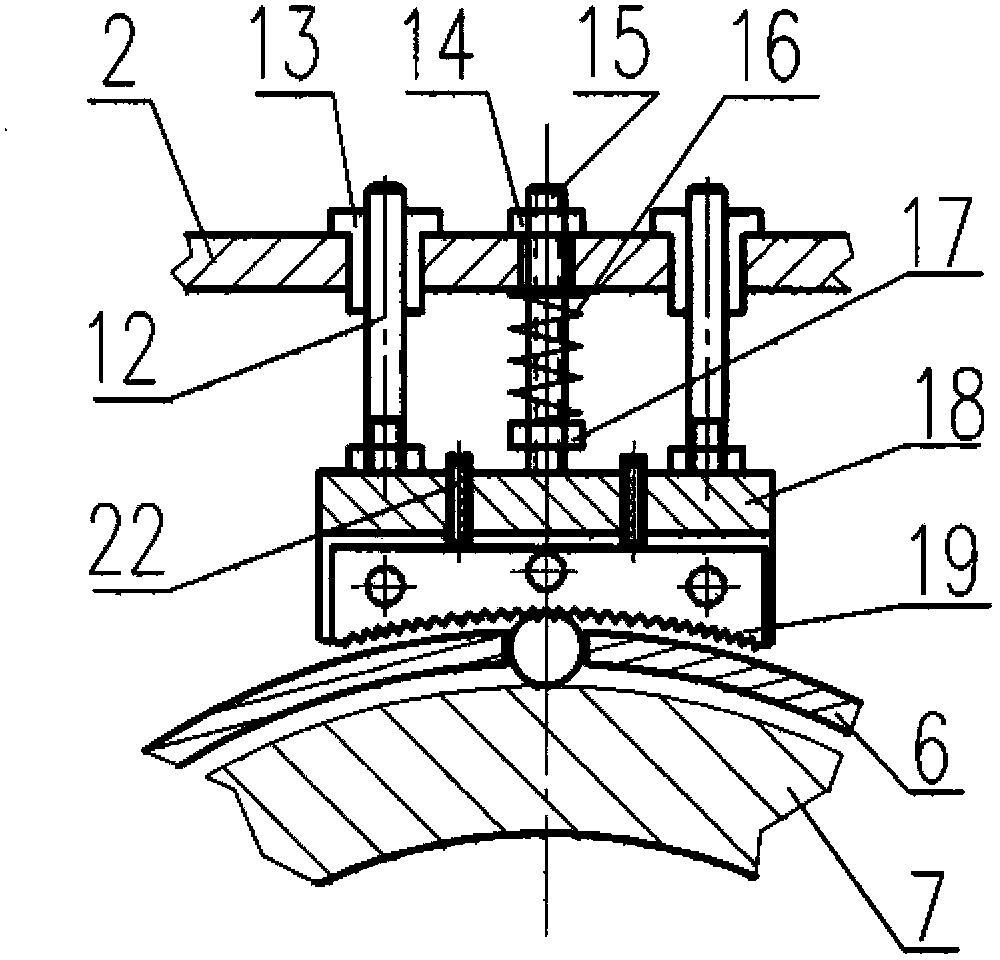

[0028] like Figure 1 to Figure 6 As shown, the present invention adopts the following technical solutions: it includes a hopper 1, a body 2, a main shaft 10, a driving roller 7, a motor 8, and a transmission device 9, and is characterized in that it also includes a multi-channel feeding roller 6, an arc-shaped surface rolling piercer Shell device 3 , arc surface rolling and cutting device 4 , arc surface rolling shell splitting device 5 , reduction gear system 11 . The motor 8 is arranged outside the body 2, the drive roller 7 is concentrically fixed on the main shaft 10, the two ends of the main shaft 10 are supported on the two side plates of the body 2 through bearings, and the support plates at both ends of the multi-channel feeding roller 6 are installed on the main shaft 10 through bearings Above, a gear is concentrically fixed on the support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com